#How to Get IATF Certification

Explore tagged Tumblr posts

Text

1 note

·

View note

Text

IATF 16949 Certification:7 Reasons Your Business Can’t Ignore It

Gathering techniques must be of the highest standard in the rapidly evolving vehicle sector. In response to this demand, the International Automotive Task Force (IATF) developed the IATF 16949 standard, a widely accepted framework for quality control designed specifically for the automotive industry. By putting an emphasis on defect avoidance and minimal supply chain waste, IATF 16949 Certification in the United Arab Emirates serves as an assurance that the company has complied with the requirements to generate continuous improvement.

We will examine the requirements, value, and implementation factors that IATF 16949 Certification offers to firms as we go into the specifics of this certification in this post.

What is the International Automotive Task Force?

An organization of manufacturers within the National Automotive Industry Association is called the International Automotive Task Force (IATF). IATF seeks to produce better quality products globally by concentrating on customer-specific requirements. The IATF's main goals are:

Creating an International Quality System specifications for the materials needed for each stage of production, such as painting, heating, plating, etc.

Supplying suitable guidelines and regulations to guarantee consistency across the globe and bolstering the IATF registration program.

IATF 16949 is a technical specification and quality management standard that the IATF established to promote continuous improvement in the automobile industry's supply chain and manufacturing.

Key Benefits of Obtaining IATF 16949 Certification in UAE

Organizations in the automotive sector receive significant assistance from IATF 16949 in the United Arab Emirates. It is a legal requirement that automobile businesses worldwide must adhere to. However, it offers a great deal of benefits in exchange. The following advantages come with the IATF 16949 Certification:

Credibility- Acquiring IATF 16949:2016 is evidence of the company's dedication to improving its quality management system and shows customers that they can rely on the company to provide them with flawless products.

International Reach- The international standard IATF 16949 will expand the company's global reach.

Customer Satisfaction- A significant benefit of obtaining the IATF 16949 accreditation is improving customer satisfaction. Customers feel that the product's certification is reliable, which increases consumer happiness..

The integrity of the Production- In UAE, IATF 16949:2016 encourages process integration to boost process efficiency and save costs through reliable supply chains and resources.

Efficient Decision Making- IATF provides the required data and papers about operational and production procedures, which greatly assists the authorities of UAE enterprises in making informed and effective decisions.

Employee Engagement- Employee productivity has a beneficial relationship with an improved quality management system, which supports an organization's long-term performance and success.

Continuous Improvement: Businesses operating in the automobile industry can benefit greatly from continuous improvement. The continuous improvement culture in certified organizations is established under IATF 16949.

Several benefits, including business-enhanced customer satisfaction, increased efficiency, wider market potential, and improved reputation, might result from achieving IATF 16949 in the United Arab Emirates. It can support businesses in succeeding in the fast-paced, highly regulated car sector.

Who is ISO 16949 Applicable to?

In 2016, the automotive industry-focused technical specification ISO/TS 16949 was replaced by IATF 16949. It can be used by businesses that design, develop, manufacture, install, and repair automotive products. This includes companies that provide the automotive industry as well as those who manufacture car systems, parts, and components. The standard aims to ensure the quality and safety of automotive goods and to promote continuous improvement throughout the automotive supply chain.

These seven Quality Management Principles are characterized as adhering to:

Relationship management

Customer focus

Evidence-based decision-making

Improvement

Process approach

Engagement of people

Leadership

How to Get IATF 16949 Certification in UAE?

Achieving IATF 16949 certification in the UAE involves several key steps:

Understand the Standard: Acquire sufficient knowledge about the IATF 16949 requirements, which integrate ISO 9001 principles with specific automotive industry criteria focused on process improvement, defect prevention, and waste reduction.

Gap Analysis: Conduct a gap analysis to compare your current quality management system (QMS) with IATF 16949 requirements. Identify areas needing improvement.

Develop an Implementation Plan: Create a detailed plan to address gaps, including timelines, responsibilities, and resources needed. Engage top management for support and allocate necessary resources.

Training: Train employees on IATF 16949 standards and their roles in the QMS. Consider external training for key staff.

Implement Changes: Revise processes and documentation to align with IATF 16949. Ensure effective implementation across all departments.

Internal Audit: Conduct internal audits to ensure compliance. Address any non-conformities identified.

Select a Certification Body: Choose an accredited certification body familiar with the UAE market. Schedule a certification audit.

Certification Audit: The certification body will perform a thorough audit. If successful, you will receive IATF 16949 certification.

Continuous Improvement: Maintain compliance through regular audits, continuous improvement, and staying updated with industry changes.

By following these steps, your organization can achieve and maintain IATF 16949 certification, enhancing quality and competitiveness in the automotive industry.

Challenges in Implementing IATF 16949:

Extensive Requirements:

IATF 16949 necessitates detailed documentation of processes, procedures, and policies. Organizations often struggle with the volume and complexity of documentation required to meet the standard.

Consistency and Accuracy:

Maintaining consistent and accurate documentation across multiple departments and locations can be challenging. Ensuring that all documentation aligns with the standard's requirements requires high attention to detail.

Continuous Improvement:

IATF 16949 emphasizes continuous improvement. Ensuring that employees are continuously developing their skills and knowledge can be a sustained challenge.

Identifying Risks:

IATF 16949 places a strong emphasis on risk management. Organizations need to identify potential risks in their processes and supply chains, which can be a detailed and intricate task.

ISO 9001 Relevance to IATF 16949 Certification

The 16949:2016 edition was released by IATF in October 2016, superseding ISO/TS 16949 as the standard for improving quality management required systems in the automotive sector. The 16949:2016 has been coordinated with the 9001:2015, the ISO's acknowledged quality management standard.

The foundation of IATF 16949:2016 is ISO 9001 Certification, which includes all ISO 9001 specifications. Along with the customer-specific strategy of IATF 16949, IATF has used the structure of ISO 9001 to focus on customer satisfaction within the organization.

Conclusion

In conclusion, it can be said that for businesses in the automobile sector aiming to create and preserve a robust quality management system, certification is essential. In a highly competitive and dynamic business, certification guarantees adherence to global standards while also promoting a culture of continual improvement. This leads to long-term progress.

Automakers are positioning themselves as leaders in quality and advancement as they adopt IATF 16949 standards, setting themselves up for long-term growth and consumer satisfaction.

#IATF 16949 Certification#International Automotive Task Force#How Can I get IATF Certification in UAE?

0 notes

Text

Driving Success: Path to IATF 16949 Process in the Automotive Industry

For any business to develop and flourish, improvement as well as compliance in progress is vital. Taking into account that the business market of the auto business is turning out to be increasingly more customer-driven and evolving quickly. Revisioning the nature of the items and administrations is one of the key advances that can lead you to practical development and achievement.

You can accomplish exceptional quality improvement by carrying out standards, for example, International Automotive Task Force (IATF 16949.)

Why Should A Company Obtain IATF 16949 Certification?

Assuming your business is associated with the auto business, it is basic to make it IATF 16949 ensured. The IATF 16949 certificate is the fundamental prerequisite for achieving the wanted outcome in the auto business. Also, the advantages that go along will give you an edge over your rivals.

Investigate these relevant motivations behind why you should choose the IATF 16949.

It will further develop your brand name and reliability

Quick Track Development

Upgrade Organizational critical thinking skills

It will enable and propel your employees.

IATF 16949 accreditation will guarantee ceaseless improvement

Acquiring validity as a provider in the auto area

How Can I get IATF Certification in UAE?

Get Certified in 7 Stages:

1. Learn

You should get in-depth training on IATF 16949 so you comprehend what you want to do in your organization to meet the necessities of the standard.

IATF 16949 Qualification and Necessities

What Norms do I want?

What are the Requirements?

Obtain the standard that you want for certification

IATF 16949:2016

IATF 16949 Guidelines Fifth Version

2. Perform Gap Analysis

Conduct out a Gap Analysis to figure out where you want to change your current QMS.

Gap Analysis Choices

Gap Analysis by a Specialist

Gap Analysis Agenda

3. Plan

Make a Venture Plan

Start with a Free Fast Beginning Unit

Decide your Scope

4. Instruct Your Organization

Your staff should be all prepared to work with the IATF 16949 Quality System.

Online Worker IATF 16949 Training

PowerPoint Show and Training Materials

Introduction to IATF 16949 PPT

IATF 16949 Worker Bulletins

5. Plan and Record

Plan and record your IATF 16949 Quality Manual and Strategies. The greatest part of the task is taking a look at your ongoing cycles, and upgrading them to address every one of the requirements under the norm. Whenever you have altered or created cycles to fulfill the guideline, you should control those cycles. Recording the cycles as Quality Management strategies is important for this control.

6. Use and Work on Your QMS

When your system is created and reported, workers will follow the methods, collect records, and make upgrades to the system. For roughly 3 months or more, your association will run the QMS, and collect records.

7. Audit the QMS Implementation/Performance

Use and work on your QMS: Is it working? You will lead internal audits to perceive how your system is functioning and to further develop it. This sets you up for a review by a registrar. International Automotive Task Force requires a process-based review to control the linkage between the cycles.

IATF 16949 Internal Examiner Preparing Materials

IATF 16949 Internal Audit Agenda

7. Accomplish Enrollment

Utilize our IATF 16949 Across Management Documentation and Training Package and execute your system yourself. It incorporates what you really want to set aside time and cash and find success.

To accomplish enlistment, you should choose a registrar who will play out a registration audit.

What Are The Requirements of IATF 16949?

IATF 16949 standard contains general and documentation requirements that empower organizations to make a powerful and significant arrangement for their business.

Recognize the cycles of the association and connection of these processes.

Decide functional controls to guarantee processes are viable.

Control any reevaluated processes that influence item conformity.

Guarantee the accessibility of satisfactory resources and data.

Screen, measure, and examine processes.

Perform important activities to accomplish targeted goals.

Conclusion

All in all, obtaining the International Automotive Task Force certificate isn't simply a checkbox for auto organizations; it's an essential obligation to excellence and constant improvement. By embracing the norms illustrated in the certification process, organizations can improve their brand name, speed up development, engage employees, and guarantee supported progress in a competitive and challenging market.

The 7-step process gives a guide to associations to explore the certification venture really, from beginning learning and gap analysis to execution and continuous improvement. Eventually, the IATF 16949 certificate fills in as a demonstration of an organization's commitment to quality, consumer loyalty, and development, situating them as pioneers in the powerful scene of the auto business.

0 notes

Text

IATF 16949 Certification Explained: 5 Steps to Adherence and Implementation

IATF 16949 is a standard that basically consolidates all the existing automotive quality management standards all over the world. It was formulated by the International Automotive Task Force (IATF) and the International Organization for Standardization (ISO). The IATF 16949 Certification standard seeks to create a quality management system that will help in continuous improvement, it gives importance to zero defect culture and the process of reducing variation and waste in the automotive supply chain.

Certification of IATF 16949 is built on the ISO 9001 standard with these requirements plus some more that are specific to the automotive industry. It targets any corporation that is engaged in the design, development, manufacture, installation, or servicing of automobile components.

Identifying the requirements

The initial step in the accomplishment of IATF 16949 certification is to perfectly understand what it implies. This encompasses: Examining the Standard: Get your hands on ISO 9001:2015 standard requirements and the official IATF 16949 standard document. Read definitions, terms, requirements, and information, etc. Gap Analysis: Assess your current QMS thoroughly to ensure it meets the requirements of IATF 16949 through a detailed gap analysis which will enable the understanding of which areas need a complete transformation or overhaul. Education and Training: Train key staff to ensure they understand the importance and implications of the standard. Consider using established trainers for more detailed training sessions.

Key Steps for A Successful IATF 16949 Implementation

It’s hard to imagine having to implement a Quality Management System (QMS) and get it certified to IATF 16949:2016. If you’re not sure where to start, we’ll give you a high-level overview of the 12 steps you need in this successful implementation. You can make sure you don't miss anything by following these procedures, which will also help you get ready for your certification audit.

Identify the requirements for the QMS: Equally important is to identify each of the requirements within your quality management that need to be taken care of. Of course, it also refers to needs such as legislative and regulatory standards for the benchmark, as well as cultural needs to be met by your business.

Define the Scope: The areas of your business that your QMS extends to, or should extend to, is called the scope of the QMS. Since the entire organization can be included in the scope, this is usually not necessary because you don’t wish to specify parts of your business that aren’t affected by your quality management.

Define your procedure and protocols: To deliver the essential consistency and quality, your organization may require additional processes or procedures, therefore you'll need to specify those as well as any processes that are mandated by IATF 16949:2016. Define all of your business processes and pay attention to how they interact within your company; here is where issues usually surface.

Put these guidelines and practices into action: It is now necessary for you to implement all of these policies and procedures. Some of these are probably already in place; they simply need to be updated to meet the new needs. The others will have to be developed from beginning to end.

Conclusion

The process of becoming certified to IATF 16949 Certification is complex and calls for careful preparation, thorough execution, and a continuous dedication to quality. Your company can successfully adhere to and implement the IATF 16949 standard, improving its reputation and competitiveness in the automotive industry, by following these five steps which have been discussed above.

#IATF 16949 Certification#International Automotive Task Force#How Can I get IATF Certification in UAE?

0 notes

Text

Top 10 Electronics Manufacturing Companies in India – Verified Partners on FindingMFG

India’s electronics manufacturing industry has experienced rapid growth in recent years, driven by a mix of global demand, government support, and technological advancement. As OEMs look for cost-effective and reliable manufacturing partners, Electronics Manufacturing Companies in India have become an essential part of the global supply chain.

In this blog, we highlight the top 10 electronics manufacturing companies in India and explain how FindingMFG simplifies the process of connecting with the best EMS (Electronics Manufacturing Services) providers in the country.

Why India is Emerging as a Global Electronics Manufacturing Hub

India’s electronics manufacturing market is poised to surpass USD 300 billion in value, making it one of the most important destinations for electronic product development and assembly.

Key factors contributing to this growth include:

Competitive production costs

A large, skilled engineering workforce

Production-linked incentive (PLI) schemes from the Indian government

Expanding domestic and export markets

High-quality standards and ISO certifications

This ecosystem supports a wide range of applications, from consumer electronics and automotive components to medical devices and industrial systems.

Top 10 Electronics Manufacturing Companies in India

Here is a list of the top 10 EMS providers in India that offer world-class electronics manufacturing services:

1. Dixon Technologies

One of the largest contract manufacturers in India, Dixon provides electronics manufacturing for leading brands across TVs, mobile phones, appliances, and lighting products.

2. Sahasra Electronics

Specializing in PCB manufacturing and assembly, Sahasra serves telecom, automotive, defense, and consumer electronics sectors.

3. Centum Electronics

Known for its advanced microelectronics and embedded system solutions, Centum caters primarily to aerospace, defense, and automotive sectors.

4. SFO Technologies (NeST Group)

SFO offers end-to-end solutions in electronics design, manufacturing, and system integration for medical, communication, and industrial automation industries.

5. Elin Electronics

Elin provides EMS services for small appliances, LED lighting, fans, and medical electronics. They are known for reliability and large-scale production capacity.

6. VVDN Technologies

VVDN offers product engineering and EMS for high-growth sectors like 5G, networking, cloud, and IoT devices.

7. Amber Enterprises

Amber is a leading manufacturer of air conditioners and large appliances. It provides complete product assembly for major OEM brands.

8. Kaynes Technology

Offering design, prototyping, PCB assembly, and system integration, Kaynes is one of the most respected EMS providers in the industrial and automotive space.

9. Rabyte Electronics

Rabyte combines EMS capabilities with strong component distribution and supports a broad range of electronic applications.

10. Jabil India

A subsidiary of global EMS provider Jabil, the Indian division supports electronics manufacturing with a strong focus on quality and scalability.

How FindingMFG Helps You Connect with the Best EMS Companies

While the companies listed above are leaders in the industry, there are hundreds of mid-sized, specialized, and high-performing electronics manufacturing companies across India. FindingMFG is a digital sourcing platform designed to help you discover and connect with the most suitable partner based on your project needs.

What You Get on FindingMFG:

Access to verified electronics manufacturers

Real-time quotes from multiple suppliers

A secure platform for project tracking and file exchange

Suppliers with ISO, IATF, and RoHS certifications

Transparent communication and full project visibility

Services Offered by Electronics Manufacturers on FindingMFG

Whether you are a startup developing a prototype or a global OEM scaling up production, FindingMFG provides access to companies offering:

PCB assembly (SMT and through-hole)

Prototyping and small-batch production

Box build and final product assembly

Cable and wire harness manufacturing

Functional testing and quality control

Industries Served by EMS Providers in India

Electronics manufacturing companies in India serve a wide range of industries through the FindingMFG platform:

Automotive electronics

Industrial control systems

Consumer electronics

Telecommunication hardware

Medical and diagnostic devices

Defense and aerospace technology

Each supplier is selected based on technical capability, industry certifications, and past performance to ensure you receive only the highest quality manufacturing solutions.

Why OEMs Trust FindingMFG for Electronics Manufacturing in India

FindingMFG has helped hundreds of global buyers streamline their sourcing process and reduce the time and cost of vendor selection. With a reliable digital interface and pre-vetted suppliers, it becomes easy to manage everything from RFQs to production tracking in one place.

Key benefits include:

Faster turnaround on quotes

Access to niche and large-scale EMS companies

End-to-end supply chain support

Protection for your IP and design files

Project-specific recommendations from industry experts

Conclusion: Partner with the Best Electronics Manufacturing Company in India

Electronics manufacturing company in India is more accessible than ever through FindingMFG. Whether you are developing a new product, expanding to new markets, or looking to improve your supply chain, this platform connects you to India’s top EMS companies.

Explore a wide range of options, get instant quotes, and manage your entire project from concept to production — all in one place

0 notes

Text

Join our exclusive free webinar tailored for quality professionals and manufacturers! Get expert insights on the IATF 16949 clauses list and how each clause applies in real-world automotive scenarios. Perfect for auditors, consultants, and compliance teams preparing for 2025 standards.

✅ Explore clause-wise interpretations ✅ Learn best practices for implementation ✅ Live Q&A with IATF experts

📅 Reserve your spot now and stay ahead in your certification journey!

0 notes

Text

Why Texas Is a Top Destination for Quality Vehicle Engines?

The engine of your vehicle is the heart that keeps it beating, and when it comes to quality engine production, you’ll find that Texas holds the keys to revealing peak performance. As you search for a reliable engine that meets your specific needs, you’re likely to find yourself drawn to the Lone Star State. But what sets Texas apart from other destinations? Is it the state’s rich history of engine building, the cutting-edge manufacturing facilities, or something else entirely? Let’s take a closer look at what makes Texas a top choice for vehicle engines.

Unparalleled Expertise in Engine Building

How do top-tier engine builders consistently produce high-performance, reliable vehicle engines? It starts with unparalleled expertise in engine building. In Texas, you’ll find skilled professionals with extensive knowledge of various engine models, including the Ford used engine and the popular used Coyote engine for sale. These experts have spent years honing their craft, studying engine dynamics, and mastering the art of precision engineering.

When you choose an engine builder in Texas, you’re getting more than just a replacement engine. You’re getting a custom-built powerhouse that’s tailored to your specific needs. These builders take pride in their work, carefully selecting and refurbishing components to guarantee maximum performance and reliability. Whether you’re looking for a high-performance engine or a reliable workhorse, Texas engine builders have the expertise to deliver.

Their attention to detail and commitment to quality are what set them apart from the competition. By combining technical knowledge with hands-on experience, these engine builders create engines that are not only powerful but also durable and long-lasting.

State-of-the-Art Manufacturing Facilities

Within Texas’ thriving engine-building industry, state-of-the-art manufacturing facilities play a pivotal role in the production of high-performance, reliable vehicle engines. As you explore the manufacturing landscape in Texas, you’ll notice that many facilities are equipped with cutting-edge technologies, including advanced machining tools, robotics, and automation systems. These technologies enable manufacturers to optimize production processes, reduce waste, and improve overall efficiency.

You’ll also find that many Texas-based facilities have implemented Industry 4.0 solutions, such as IoT sensors and AI-powered quality control systems. These solutions enable real-time monitoring and data analysis, allowing manufacturers to identify potential issues before they become major problems. Additionally, many facilities have achieved certifications such as ISO 9001 and IATF 16949, demonstrating their commitment to quality and continuous improvement.

The state-of-the-art manufacturing facilities in Texas are also designed with flexibility and scalability in mind. Many facilities have modular layouts, allowing manufacturers to quickly adapt to changing demand or new technologies. This flexibility enables manufacturers to respond rapidly to market trends and stay ahead of the competition.

Competitive Pricing and Incentives

Texas’ competitive pricing and incentives are a significant draw for companies looking to establish or expand their engine-building operations in the state. As you explore the Lone Star State’s offerings, you’ll discover that the cost of establishing and maintaining a manufacturing facility is lower compared to other states. This is largely due to the state’s favorable business climate, which features lower taxes, minimal regulations, and a highly competitive labor market.

When it comes to incentives, Texas offers a range of programs designed to support businesses in the automotive sector. These include the Texas Enterprise Fund, which provides financial incentives to companies that create jobs and invest in the state. Additionally, the state’s Skills Development Fund offers training and development programs for employees, helping to guarantee that your workforce has the skills needed to succeed in the industry.

Diverse Range of Engine Services

As you establish or expand your engine-building operations in Texas, you’ll find an extensive range of engine services at your disposal. From cylinder head machining and crankshaft grinding to engine block boring and honing, you can access the specific services you need to maintain, repair, or rebuild your engines. Many Texas-based engine shops also offer advanced services, including 3D engine scanning, CNC machining, and engine performance testing. Additionally, you can leverage the state’s strong network of suppliers and manufacturers to source high-quality engine components, such as pistons, rings, and bearings. This thorough range of services allows you to streamline your operations, reduce lead times, and increase overall efficiency. Moreover, many Texas-based engine shops have invested in the latest technology and equipment, ensuring that your engines receive the highest level of care and precision. By taking advantage of these diverse engine services, you can improve your engine-building capabilities and stay competitive in the market.

Conclusion

As you rev up your engine, imagine the precision and expertise that went into crafting it. Texas, the hub of high-performance engine production, is where your vehicle’s heartbeat comes to life. With world-class facilities, skilled technicians, and state-of-the-art technology, the Lone Star State delivers durable, custom-built engines that purr like a well-oiled machine. The result: a driving experience that’s as smooth as the Texas plains and as powerful as a Texan’s pride.

Blue Prism Automotive

3419 Westminster Ave #1037 Dallas, TX 75205, United States

Tel: (469) 546-3400

Map Location: https://maps.app.goo.gl/jbiCKBuRBLYKKjhP7

0 notes

Text

IATF 16949 Certification

What is the IATF 16949 Standard?

The International Automotive Task Force (IATF) 16949 standard is an ISO standard that specifies the requirements for a quality management system (QMS) for the automotive industry. IATF 16949 certification is a process by which organizations can demonstrate that they have met these requirements. It demonstrates that they have implemented a QMS that meets the highest standards for quality and reliability.

Importance

The importance of the IATF 16949 certification for quality management in the automotive industry is significant. The certification provides a framework for organizations to improve the quality of their products and processes. It also helps to ensure that the automotive industry meets customer requirements and international standards. Additionally, the certification can help organizations to improve efficiency, reduce costs, and increase profits.

Benefits

It demonstrates your organization’s commitment to quality and continuous improvement.

It helps you improve your performance by identifying and addressing gaps in your quality management system.

It assures customers that your products and services meet the highest quality standards.

It enhances your organization’s image and reputation in the marketplace.

It helps you win new business and retain existing customers.

It makes it easier to achieve and maintain compliance with other quality management system standards.

It enables you to benchmark your performance against the best-in-class organizations.

Which Organizations Can Apply?

Any organization that is involved in the design, development, production, assembly, and/or servicing of automotive-related products can apply for iatf 16949 certification. This includes organizations in the automotive supply chain such as component manufacturers, parts suppliers, systems integrators, and service providers.

How to Get IATF 16949 Certified?

The first step is to become familiar with the IATF 16949 standard and make sure that your organization meets the requirements. Once you are confident that you can meet the standard, you can apply for certification. The certification process involves completing an application, submitting documentation, and undergoing an assessment by a certification body. If your organization is successful, you will be awarded IATF 16949 certification.

Conclusion

The IATF 16949 certification is an important achievement for quality management in the automotive industry. It demonstrates that your organization has met the highest standards for quality and reliability. The benefits of certification include improved performance, customer satisfaction, image and reputation, and competitiveness. Any organization involved in the automotive industry can apply for certification, and the process is overseen by a certification z

iatf16949 consultant in morocco

0 notes

Text

ISO Consultant

Take your Business to Global level...!!

ISO CERTIFICATION

ISO is an independent, International Standards Organization that develops International Standards to ensure the organizations across the world deliver products/services that are safe, reliable and of good quality. If you’re an entrepreneur looking to expand your business with government tenders or large corporations, your business needs an “ISO Certification”. We are partner with ISO and Product certification organizations across the globe to broaden their market to reach & help the customer accredited their business transformation.

About Us

ISO Consultant is One Stop Solution for your ISO and Product Certification managed by Highly Qualified Specialized team with ISO Consultant & Auditors, CS – Company Secretaries. Our process is Consultation, Implementation, Audit & We issue Accredited Certification, provided genuinely and legally. 100% success rate, Government Tender approved, Worldwide accepted, 24/7, Guaranteed Certification. 100% success rate. Best Price Guaranteed, Fast & Hazel free process. 27+ Global Presence, Trusted Clients. We have our in house team IRCA Certified Lead Auditors. www.isoconsultant.co.in

Who can take ISO Certificate?

Any company, irrespective of the size can go for ISO Certification. You can go for ISO certification even if your organization is run by just 1 staff, Start-ups ,Small , Medium & Large Size Company, Proprietorship to incorporate businesses for Retail, Trading, IT Industry, Financial institutions, International Companies, Educational Institutional , NGO , Societies, Trusts, E-commerce business approach follow the way of formal business efficiency etc….

Benefits of ISO Certificate

Brand Image | Increase Revenue & Efficiency | Go Globally reorganization standards | Better Quality Internal Management | Customer Satisfaction | Tender Eligibility | Improve Efficiency | Employee Satisfaction | Less Wastage | Better Quality Products & Services

Competitive Price

Our prices are very competitive in the market, we provide a premium services with cost effective, affordable, and reliable and 100 % guaranteed ISO & Product Certification.

Qualified Team

Our team of Highly Qualified professionals with all our consultants are certified lead auditors & industry experts to guide you with the updated information on the ISO & Product Certification.

5 Best Reasons to utilize an ISO Consultant:

Benefits of using a good ISO Consultant:

· ISO Consultants bring you a ‘fresh eyes’ approach to your processes. They can bring insights to how ‘best-practice’ can be used, as well as highlighting if legal minimums are being missed

· ISO Consultants provide you with knowledge and expertise quickly and efficiently. In particular, they will help you understand the ISO standards.

· ISO Consultants apply their experience to ensure you develop bespoke solutions that reflect your circumstances and aspirations

· ISO Consultants help you deliver within the time-frame, as they won’t be distracted by other tasks.

· ISO Consultants bring you knowledge and insights to ‘best practice’ and effective solutions that have worked elsewhere in industry

Our Core Services

ISO Certification | Product Certification | ISO & Product Consultation, Training, Implementation, Auditing, Documentation & Certification

ISO CERTIFICATION:

ISO 9001:2015 - QMS - Quality Management System ISO 20000:2011 - ITSM - Information Technology Service Management ISO 27001:2015 - IT - Information Technology ISO 22000:2018 - FSSC - Food Safety Standard Management System ISO 14001:2015 – EMS - Environmental Management System ISO 45001:2018 – OHSAS - Occupational Health & Safety Assessment Series ISO 13485:2016 - MD - Medical Devices ISO 21001:2018 - EOMS - Educational Organization Management System ISO 29993:2017 - ELS - Educational Learning Services ISO 3834 - Quality Management System for Fusion Welding Certification ISO 29001:2010 - QOG - Quality Management system for Oil & Gas ISO 9000 - TL - Telecommunications ISO 30000 - SRMS - Ship Recycling Management System ISO 16949:2016 - IATF - International Automotive Task Force ISO 37001 : 2016 - Anti-bribery management systems ISO 9100 - AS -Aerospace ISO 28000:2007 - T&L - Transportation & Logistic ISO 24510:2007 - DWS - Guides activities related to drinking water and waste water services ISO 28000 - SSC - Security Management System for the Supply Chain ISO 8000 : 2014 - AS - Social Accountability

PRODUCT CERTIFICATION:

CE Mark Certification

HALAL Certification

Organic Certification

Trusted Mark IRF Certification

Ayush Mark Certification

Bifma Certification

HACCP Certification

GMP Certification

Gost-R Certification

Kosher Certification

Green Certification

5S Certification

Are you looking for ISO & Product Certification for your Organization

Our Consultants will guide you in getting all necessary Documents required for getting ISO & Product Certification for your organization, please click on the following link to get connect with us. ISO CONSULTANT

#iso consultant#ISO Consulting Services#iso registration#iso certification for business#ISO 90001:2015 Certification#Iso Standards#ISO Management System Standards#International Trade Services#ISO Standard Kit

2 notes

·

View notes

Text

ISO 9001 Standard Quality Framework and Their Benefits

Meet the quality as you have decided, in manufacturing products and delivering services with ISO 9001 standard.gb

ISO 9001 – the global standard, recognized for optimizing the quality performance of the organizations and improving the quality management system (QMS) performance. This QMS standard is followed by more than 160 countries across the world. This standard is the most popular standard of ISO, published in 1987. It is the foundation for developing most of the other international standards of ISO such as ISO 14001, ISO 22000, ISO 13485, IATF 16949, AS9100, etc. The ISO 9001:2015 is the latest version followed by millions of organizations across the world.

ISO 9001 and its requirements

The international standard ISO 9001 specifies requirements to help the organization of all types to enhance the quality of products and services that consistently meet customer expectations. As said earlier, this standard is famous for quality management. It ensures the organizations to follow the best practices in the industry to ensure the continual improvement of the quality management system. Apart from that, this voluntary standard also helps your business to meet the applicable legal and regulatory requirements.

Whether it’s a small or medium organization or startup companies or a big organization with 100 employees, the requirements of ISO 9001 is applicable to all organizations. Moreover, ISO 9001 specifies the quality framework for the organization to meet its desired goals that make it the most popular standard among business owners.

What is the role of ISO 9001 Certification?

You can ask, implementing the requirements of the ISO 9001 itself, the business can achieve lots of benefits, then why I should go for certification? The answer is simple, you need to certify to ISO 9001 Certification to establish the quality performance of your organization. The ISO certification demonstrates your organization’s involvement to developing high-quality products that satisfy the customer requirements. It enhances the credibility and visibility of your business. Gaining the confidence of the customers will become an effortless task when you achieve this ISO certification because it is proof the organization has met all the desired requirements of the ISO standard.

From manufacturing industries to software companies

Quality work is a key element for all organizations. The ISO 9001 certification standard applies to all organizations, irrespective of size, type and field of activity, such as manufacturing industries, construction companies, hospitality sectors, educational organizations, food industries and more.

Release the pressure with the treasure (ISO 9001)

If you’re running a business, regardless of the products or services you provide, maintaining quality is the primary goal of your organization. No customer is willing to invest their money in low-quality products. So, delivering high-quality products and services is important to be a ‘customer favorite company’ for a long time. You can make this possible by implementing the requirements of ISO 9001 in all the processes of your entire business.

The popular quality management system standard of ISO (International Organization for Standardization) is ISO 9001. The most recognized certification standard in the ISO 9000 family. The main reason for developing ISO 9001 is to bring the intended results in the quality of products and services that meet customer requirements.

How certifying to ISO 9001 benefit my business?

Getting ISO 9001 certification from a third-party is like a global mark that portrays the high-level performance of your organization. Here are the major benefits of ISO 9001 certification and how it helps to promote your business.

Customer confidence

This certification helps enhance the confidence of the customers in your manufacturing process, operation system, products and delivery of services.

Increased process efficiency

Other than promoting your business in the global market, ISO standards also help organizations to have a well-maintained document about their daily process. So, the employees can work effectively to achieve their daily targets. This increases process efficiency as well as the productivity of your business.

Industry’s best practices

Develop your business processes with the industry’s best practices. ISO 9001 certification ensures the organization follows the latest technologies in the development of products as well as services.

Improved productivity

Complying with the requirements of ISO 9001 standard, helps you have transparent business processes that let employees work effectively and more confidently.

Shine brightly among other competitors

Not every organization can meet the requirements of the customers. But if you’re taking risks to satisfy the customers, establish it. Establish your quality performance with the help of ISO 9001 Certification. Standalone from other competitors! The ISO certified organizations have more chances of getting the customers’ trust than non-ISO certified organizations.

Happy customers, satisfied clients

As the ISO 9001 standard is globally recognized, it enhances the satisfaction of customers and confidence in your products and services.

Credibility, traceability, visibility

ISO 9001 certified organizations have a great image among the customers. So by certifying to ISO 9001, it will be easy to impress potential customers. This enhances the credibility of your business and lets you get customers even from overseas. It highlights the quality performance of your organization.

Stakeholders’ trust

It demonstrates that your organization has taken effective measures in delivering quality products and services. This enhances the stakeholders’ confidence that certainly helps you achieve new business opportunities.

Global recognition

By achieving the ISO 9001 certification, you can easily attain the confidence of international customers. This helps expand your business and increases productivity as well as profitability.

Reputation

Do you want to gain a positive reputation for your business? Then the ISO certification is the best choice for it. It promotes your brand image and enhances the reputation of your organization.

Low errors – high profit

Are you finding the repeated errors in your operational process and management system? Did the cost you spend on re-working on the products increasing day-by-day? Developing the quality management system and your entire business process in line with ISO 9001 helps reduce the process errors and operational risks and lets you work in a consistent flow to reach your intended objectives. Then you can automatically see the dramatic change in the productivity and profit of your business.

Legal advisor

The ISO 9001 Certification also ensures the organization meets the applicable statutory and regulatory requirements. Also, this opens door to achieve government tenders and contracts.

ISO 9001 Certification cost

The cost creates a great impact in gaining the ISO 9001 certification. The ISO certification is expensive but it is worth your investment. Double the profit of your business by getting the ISO certification! The cost varies based on numerous factors such as the size of the organization, the number of employees working in the organization, the complexity level of the management system process, and so on. Also, the ISO 9001 certification cost varies from one certification body to another. It depends on the certification body’s brand image, accreditation, global recognition, credibility, experience, etc.

Need more information about the ISO 9001 Internal auditor Training and auditing process of ISO 9001 Certification? Feel free to contact us!

0 notes

Text

The Importance of IATF 16949 Certification in the Automotive Industry

The auto business remains a mainstay of mechanical headway and purchaser interest, driving development and forming how we move. Amid this unique scene, quality administration becomes the principal, guaranteeing that vehicles satisfy tough guidelines for well-being, dependability, and effectiveness. One key component that assumes a significant part in keeping up with these principles is the IATF 16949 Certification.

The Foundation of Automotive Excellence

IATF 16949 isn't simply a certificate; it is a quality management system explicitly intended for the automotive region. This standard was created by the International Automotive Task Force (IATF) in a joint effort with the International Organization for Standardization (ISO). It replaces the past ISO/TS 16949, and sets the structure for a vigorous quality administration framework custom-made to car assembling and supply chains.

A Short History of the IATF 16949 Certification

The IATF 16949 certification was made in 1999 by the International Automotive Task Force (IATF), a consortium of automobile exchange affiliations and makers working related to the ISO. As per the IATF, the requirements set out inside the ISO IATF Certification were made to carry solidarity to the entirety of “the different evaluation and certificate frameworks overall in the store network for the car area.”

The IATF Accreditation has since gone through different updates to reflect changes in the auto business guidelines. The latest emphasis of the archive was distributed in 2016 as the IATF 16949:2016.

Getting this certification means to the auto business that service systems are prepared to ceaselessly fabricate quality link congregations and outfits. Further, the certification perceives our unrivaled mastery in planning a variety of standard and adjustable link get-togethers and tackling items that can satisfy our client's needs in the car business.

What is the IATF 16949 Certification, and Why is it Important?

The IATF 16949 certificate is a legal identification for organizations that are liable for making and providing auto components or congregations to the auto business. At the point when an organization accomplishes an IATF 16949 Certification, it implies various excellent grades about its item to an imminent purchaser.

As per the internationally certified certification body, National Quality Assurance Limited (NAQ), the IATF certificate uncovers that an organization has fostered a “cycle situated quality administration framework that accommodates constant improvement, imperfection counteraction and decrease of variety and waste.” Laying out this framework preferably prompts a creation interaction that reliably produces grade-level auto parts and congregations.

Importance of Following IATF Standards, Further Explained!

Those in the auto business need to observe both IATF and ISO guidelines. This isn't just for compliance, but additionally for guaranteeing that every single auto part and item is of top-notch at standard with global guidelines and is ok for use. ISO and IATF principles put quality and security at the front line of their rules, guaranteeing that all results would be okay for both the clients and the organizations creating them.

How Can I get IATF Certification in UAE: Adhering to IATF guidelines is particularly important to acquire certification. IATF themselves don't offer IATF licenses, yet there are external examiners or authorization bodies perceived by the IATF that do the certification for them. Each IATF declaration is legitimate for quite a certain time frame, and toward the finish of those valid years, entrepreneurs will be expected to petition for another one.

Having a declaration can likewise be extremely gainful to a business as far as drawing in clients and potential colleagues. Being IATF-certified can show that the entrepreneurs and their representatives care about quality and that they follow all security methodologies previously, during, and after creation. This is vital in business-to-deals also, a few organizations decide to just execute with IATF-certified organizations to guarantee themselves of the nature of their items.

Getting the IATF 16949 Certification exhibits that your organization has met broad requirements to make a course of nonstop improvement with an accentuation on deformity counteraction and a decrease of variety and waste in the store network.

The specialized determination acquired from an IATF certification is executed for all parts of manufacturers and providers of items or creation materials, administrations. This includes like intensity therapy or stirring, and different items indicated via car clients like the constituent pieces of vehicles.

Affirmation of this specialized determination is perceived by driving automakers and OEMs. Most driving producers will just work with organizations that hold IATF 16949 certificates, as they demand that providers stick to the severe specialized particulars spread out in the norm.

Conclusion: Driving Quality, Safety, and Excellence

In the speedy and profoundly serious auto industry, IATF 16949 Certification fills in as a signal directing organizations toward greatness. It gives a normalized structure that not only meets the severe prerequisites of the auto area but also cultivates a culture of consistent improvement and consumer loyalty.

As vehicles become more refined and buyer assumptions rise, the significance of IATF 16949 in maintaining the best expectations in auto fabricating is more basic than at any other time. Embracing this certification isn't simply a decision; it is a pledge to drive quality, safety, and excellence out and about ahead.

#IATF 16949 Certification#International Automotive Task Force -1#How Can I get IATF Certification in UAE

0 notes

Text

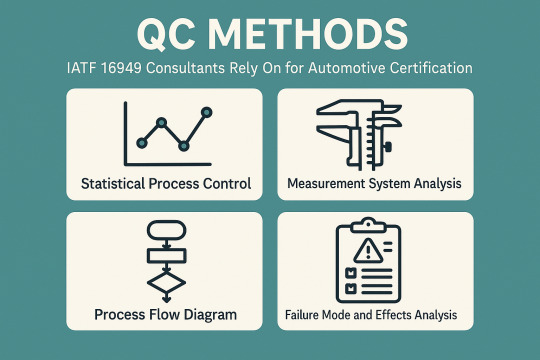

QC Methods IATF 16949 Consultants Rely On for Automotive Certification

In the competitive world of automotive manufacturing, quality is not something to strive for; it is imperative. Based on customer expectations, we must also ensure safety, reliability, and compliance with regulations. That’s where a globally recognized quality management standard designed specifically for the automotive sector comes into play in the form of IATF 16949.

IATF 16949 is more than a certification; it embodies a culture of continual improvement and process excellence. Becoming certified, though, is a labyrinth of requirements, documents, and audits. Here is where the role of IATF 16949 Consultants becomes crucial, as they help organizations navigate the process with their knowledge and clear insights.

Fundamentals of IATF 16949 in UAE

IATF 16949 is based on the fundamentals of ISO 9001, but with many automotive-specific requirements that are required for product development, production, and servicing. The main goal of IATF 16949 Certification in Abu Dhabi is to create a quality management system that promotes continual improvement, focuses on defect prevention, and reduces variation and waste in the automotive supply chain.

Main Goals of the Certification:

Maintain the quality of the products

Enhance customer satisfaction

Increase productivity in the manufacturing process

Create a culture of continual improvement

Benefits of the Certification:

Increased reliability and performance of the product

It increases the credibility in the market, and also the customers start trusting the product.

Easier access for global automotive supply chains

Lower operational costs and recall costs

As IATF 16949 Certification Consultants, your role is to ensure organizations meet the exacting standards of IATF 16949, thereby enhancing their organizational processes.

The IATF 16949 standard process can be lengthy and requires a lot of documentation, internal audits, and compliance reviews. Enter consultants to the rescue.

Benefits of Hiring a Consultant:

Quicker: It reduces the process of implementation and certification.

Quality: Prevents costly mistakes and unsuccessful audits.

Risk Mitigation: You are prepared to meet compliance and customer expectations

Widely-used QC Tools in IATF 16949

To get the correct products, organizations implement Quality Control (QC) tools. IATF 16949 Consultants in Dubai are essential to help solve problem diagnosis, process control, and decision-making.

Significant QC Tools:

Cause-and-Effect Diagram (Fishbone or Ishikawa): Assists in determining the root causes of quality and performance problems.

Collects Real-time data for analysis, check Sheet

Control Chart: Control charts are used to test process stability.

Histogram: Shows how the data is distributed to identify variability.

Pareto Chart: Emphasizes significant problems through the 80/20 rule.

Scatter Diagram: This shows the correlation between two different variables.

Process Diagram: Charting out process steps, using this step to identify; Also helps identify dead ends or redundancies

Tools Related to Advanced Quality Planning (Core Tools):

APQP (Advanced Product Quality Planning): A framework for product and process design.

PPAP (Production Part Approval Process): Verifies that a product meets the customer needs of design needs before bulk production.

Failure Mode and Effects Analysis (FMEA): Assesses potential risks in products and processes.

MSA (Measurement System Analysis): Evaluates the accuracy and precision of the measurement systems.

Statistical Process Control (SPC): Utilizes statistical techniques to monitor and control processes.

The Role of QC Tools in the Quality Systems:

Resolution: If the issue is recurring, trace back the roots and take preventive measures

Maintain Consistency: Process control

Decision-Making: Focus your actions on objective data and trends.

Continuous Improvement: This principle involves the concept of constant improvement.

Tools for Quality Control Implementation of IATF 16949

It is also worth noting that the above QC tools are not just theoretical but are embedded in the DNA of IATF 16949 Certification in Dubai.

How do QC Tools Help Compliance?

FMEA reinforces risk-based thinking, which is a fundamental requirement.

Ongoing validation and monitoring of process: Control Charts and SPC

Corrective actions based on the data based on Pareto Charts and Histograms

APQP and PPAP are structured for the planning and validation of a product.

Example Scenarios:

One of the quality suppliers identifies repetitive defects in a certain part by Pareto analysis and resolves it by Fishbone diagrams and FMEA.

MSA and SPC data are used by an organization during PPAP submission to demonstrate process capability and measurement reliability.

Consultant's Role:

Based on certain challenges, recommend tools.

Develop templates, offer training, and provide software solutions.

Tools must be used effectively and in compliance with expectations.

While the benefits are numerous, many organizations struggle with certification.

Common Obstacles:

A failure to understand the requirements.

Documentation that is incomplete or poorly maintained.

Inconsistent use of QC tools.

Resistance to change or continuous improvement at the community level.

Mistakes in using QC tools or the wrong tools used:

Tools that do audits but are not used for decision-making.

Data that has been collected but not processed or acted on.

Staff was trained never to read charts and metrics

How IATF 16949 Consultants Help in Dealing with Challenges?

Analyze requirements, discover commonalities, and factor them into incremental steps.

Educate staff on how to use the tools correctly.

Get them involved and make it real with workshops and real-world scenarios.

Develop a sense of quality across the organization.

Conclusion

The IATF 16949 is not only a badge but a testament to excellence, consistency, and customer satisfaction in the automotive industry. Expert guidance and practical tools are needed in order to reach and maintain this standard.

IATF 16949 Consultants in UAE know what has gone wrong in the past and the strategies, processes, and ways of thinking that will help a company successfully implement the standard and prepare for and respond to audits. On the other hand, QC tools are the eyes and ears of your quality management system, detecting problems and informing decisions.

Collectively, they enable automotive suppliers to raise the bar in the industry. Investing in expert consultants and embracing QC tools is not just smart—it's essential for any organization seeking sustainable growth and operational excellence.

0 notes

Text

What are the main differences between IATF 16949 and ISO 9001?

ISO 9001 is a general standard, applicable for all industries/sectors, from agriculture to manufacturing, and it is maintained by ISO. When talking about IATF 16949, the situation is completely different: this standard is maintained by the International Automotive Task Force, including membership from Chrysler, Ford Motor Company, General Motors Corp, PSA Peugeot Citroen and Renault, and other contributors, being specifically applicable for automotive parts producers.

But even with this segregation, IATF 16949 is, in a way, an extension of ISO 9001, being built on the same foundation. Therefore, a company in the automotive sector will have to implement both ISO 9001 requirements and IATF 16949-specific requirements (also including customer-specific requirements – specific requirements of car makers and other suppliers). In this article, you will learn more about the differences and connections between ISO 9001 and IATF 16949.

IATF 16949 structure

The IATF 16949 structure is similar to the ISO 9001 structure, being based on it.

Introduction. IATF 16949 starts with an introductory section, which includes general information about the history, goal, and remarks for certification. It continues with other general information regarding objectives, an explanation for how to understand the requirements, principles of quality management, the process approach, the Plan-Do-Check-Act (PDCA) cycle, risk-based thinking, and the relationship with other management system standards.

Scope. Then, the standard defines the scope: it is applicable for the sites where the customer-specific parts, service parts, and accessories are produced. In plain English, this means that it is possible to certify only those sites that produce parts for car assembly and service parts – not aftermarket parts!

This means that your company has to be an automotive parts producer; the support locations cannot get an individual IATF certification.

Customer-specific requirements, Similarly to ISO 9001, IATF 16949 continues with normative references, which help users to understand the requirements by accessing related documents. If you need some additional explanation about ISO 9001 terms, we can find it in the ISO 9000 vocabulary, On the other side, for detailed explanation of IATF customer-specific requirements, you also have to study specific requirements created by carmakers and other organizations like AIAG (Automotive Industry Action Group), VDA (German Association of Automotive Industry), and so on, if they are applicable for your organization. For example, if I produce parts for Renault, I will also need to consider the Customer Specific Requirements (CSR) of Renault published on the IATF site in the OEM Requirements section.

Terms and definitions, Section 3 defines specific terms used in the automotive industry. You will need to read it carefully, because you will need to use a common language with your customer(s) and the certification body.

Context of the organization, Like ISO 9001, the standard continues with Context of the organization. This section 4 of IATF 16949 requires the organization to define remote locations with supporting functions. For example, if I work in a site that is part of a multinational company, perhaps HR-related activities are being performed at the headquarters. This is a support function that occurs in a remote location. By taking into consideration the requirements related to product safety and conformance, we have to establish specific processes.

Leadership, Section 5 requires the implementation of a corporate responsibility policy, the analysis of process effectiveness and efficiency, and the definition of process owners who need to be competent in managing identified processes for which they are accountable. At the end of this section, IATF 16949 requires the organization to nominate employees with responsibility and authority regarding the need to satisfy customer requirements.

Risks. In section 6, IATF 16949 adds specific requirements regarding analysis of sources of risk like scrap, field returns, and development of contingency plans. All of this is necessary to ensure the accomplishment of quality objectives (requested by customers).

Resources. In section 7, we are asked to plan our layouts by using a lean approach and to use measurement systems analysis methods to assess such systems, with specific requirements for internal and external laboratories. Also, we have to take care of calibration of inspection and testing equipment, training (especially on-the-job training) and employees’ empowerment and awareness-specific requirements. Last but not least, we have a special requirement regarding QMS documentation – not the same as ISO 9001, which allows us to structure our Documentation as we choose: here we need to document a Quality Manual and a specific matrix for IATF 16949 requirements vs. established processes. The last requirement regarding control of engineering specifications defines the link to automotive industry-specific processes (practices), such as planning and controlling new product development and changes in products and processes triggered by changes of such specifications.

Operations. Next, section 8 comes with the majority of specific requirements, and requires the organization to apply specific automotive industry methods, starting from product development up to managing the production in the serial phase (mass production), i.e., what inputs we have to use for product design, management of special characteristics, and manufacturing process design. Also, we have to establish processes to monitor and report the development phases, including the link to management review, establishing a project team, performing product and process validation, controlling suppliers’ processes (including second-party audits), development and utilization of control plans, implementation of total productive maintenance, and controlling the changes (product and process, as applicable) during the serial phase.

Here we have specific requirements regarding maintenance and the utilization of enterprise resources planners that we have to consider, too.

Performance evaluation: Next, section 9 requires us to monitor and measure the manufacturing process, including the assessment of process capability, identification and application of statistical methods, monitoring of customer satisfaction by using specific methods, actions prioritization, and internal audit. We need to establish an audit program based on a three-year cycle and, by using it, to audit the system (QMS), the manufacturing process, and the delivered products. Also, here we will find specific requirements regarding management review.

Improvement. Section 10 comes with the main specific requirement: to establish a process for continual improvement and to use specific problem-solving methods (in the automotive industry, the 8D method is mainly used) and error-proofing systems. Also, we have to establish a warranty management system – a system that controls warranty claims issued by customers.

Good practices developed over decades

To summarize, compared to the ISO 9001 requirements, IATF 16949 includes specific requirements for the automotive industry, and additional customer-specific requirements that have to be implemented, too. In fact, for most of the ISO 9001 requirements, IATF 16949 adds more requirements to reinforce the control of their application. There are also SIs – sanctions interpretations published by IATF 16949, which, in several cases, override the requirements, and you need to do updates periodically.

Note at the end: consider applying good practices such as change control and product and process validation even if you are not an automotive company. Such practices were developed over decades based on industrial experiences and studies and were proven to provide good results.

IAS Expertise in IATF 16949 Certification

IAS certification is an accredited certification registrar providing different types of certificate which include the IATF 16949 Certification for various organizations or companies. Our Organization (IAS) expertise in the industry is second to none as we boast of best hands that have gotten relevant experience in IATF 16949. Should you need to get IATF 16949 Certification in India, don't hesitate to reach out to us at IAS Pvt. ltd. IAS mainly focusing to conduct audit and ensure everything is properly placed towards getting your IATF 16949 Certification.

We also provide IATF 16949 Internal auditor training in Morocco

0 notes

Text

Rubber Manufacturing Company in India – Your Trusted Source for Quality Rubber Products

Looking for a reliable rubber manufacturing company in India? Whether you need custom rubber parts for automotive, industrial, or commercial use, India is one of the top destinations for high-quality, affordable rubber manufacturing.

Let’s break down what makes Indian rubber manufacturers a smart choice.

Why India for Rubber Manufacturing?

India has become a major global hub for rubber products. Here’s why companies from around the world choose Indian manufacturers:

✅ Affordable pricing with high quality

✅ Skilled engineers and technicians

✅ Modern production facilities

✅ On-time exports and global reach

✅ Wide range of rubber types (EPDM, Silicone, NBR, Natural Rubber)

What Do Rubber Manufacturers in India Offer?

Indian rubber companies manufacture a variety of rubber parts and components, including:

Seals and Gaskets – used to prevent leaks in machinery and engines

O-rings and Bushings – for automotive and industrial equipment

Rubber-to-Metal Bonded Parts – to reduce noise and vibration

Extruded Rubber Profiles – used in doors, windows, and rail systems

Food and Medical Grade Rubber – safe and certified for hygiene-sensitive use

Industries Served by Rubber Manufacturing Companies in India

Indian rubber suppliers serve many key sectors:

🚗 Automotive – mounts, hoses, and seals

🏭 Industrial Machinery – rubber dampers and gaskets

🏥 Medical and Healthcare – safe, precision rubber components

🚄 Railways – shock-absorbing rubber parts

🛢️ Oil & Gas – chemical- and pressure-resistant rubber components

How to Choose the Right Rubber Manufacturer in India

Here’s what to consider:

✔️ Certifications – ISO, IATF, FDA, and RoHS compliance

✔️ Manufacturing Capabilities – compression molding, injection molding, prototyping

✔️ Experience – especially with international clients

✔️ Material Expertise – EPDM, Viton, Silicone, etc.

✔️ Reliable Communication – fast quotes, clear updates

Use FindingMFG to Connect with Verified Rubber Manufacturers

Want a fast and easy way to find the best rubber manufacturing companies in India?

✅ Visit FindingMFG.com This trusted platform connects you with verified rubber manufacturers across India. You can:

Post your requirements

Get instant quotes

Compare suppliers

Track your project from start to finish

No middlemen. Just reliable sourcing.

Conclusion

India is one of the best places to source custom rubber components at scale. With skilled manufacturers, affordable pricing, and global experience, Indian rubber companies are ready to support your production needs.

If you’re looking for rubber parts suppliers who can meet quality standards and delivery timelines, India should be your go-to destination.

Get Started Today

🔗 Visit: www.FindingMFG.com 📩 Post your rubber part requirement and connect with the right manufacturer in minutes.

#rubber manufacturing#rubber manufacturing companies In India#top rubber manufacturing companies in India

0 notes

Text

Top Online Courses and Certifications for IATF 16949 Training

The automotive industry is fast-paced, complex, and constantly evolving—making quality management a top priority for OEMs and suppliers alike. One of the most respected standards in this space is the IATF 16949 standard, which blends ISO 9001 principles with specific automotive industry requirements.

But here’s the challenge: understanding and applying the iatf 16949 standard with examples isn’t something you can pick up overnight. It requires structured learning, real-life case studies, and ongoing training. That’s why online IATF 16949 courses and certifications have become essential tools for professionals, organizations, and quality managers aiming to ensure compliance and stay competitive.

💡 Want to learn how core tools support the IATF journey? Check out our blog: 🔗 What Are Automotive Core Tools and How to Use Them?

📞 Need help choosing the right training for your team? Talk to our certification consultants to get expert guidance.

Why Training Matters in IATF 16949 Implementation

The IATF 16949 standard is not just a tick-box exercise. It involves building a culture of risk-based thinking, customer-specific requirements, supplier management, and more.

While most companies implement the standard with the help of a consultant or internal team, training enhances internal understanding, accelerates adoption, and supports long-term compliance. Plus, it empowers your employees to use quality tools confidently and make informed decisions on the production floor.

Key Topics Covered in IATF 16949 Training

Good IATF 16949 training should help learners:

Understand the structure and clauses of the standard

Interpret real-world examples of implementation

Learn how to apply Automotive Core Tools like FMEA, APQP, PPAP, etc.

Grasp customer-specific requirements (CSRs)

Apply risk-based thinking to process and product design

Prepare for third-party certification audits

Top Online IATF 16949 Courses & Certification Options

Here are some of the most recommended online platforms and certification programs that offer IATF 16949 training:

1. 4C Consulting – IATF 16949 Awareness Training

Best For: Beginners, engineers, and SMEs Features:

Affordable price

Real-world examples

Designed by industry experts

Immediate certification upon completion

Includes modules on automotive core tools and audit preparedness

This course is ideal for those looking for an Indian training provider with localized case studies and affordable pricing.

📞 Contact 4C Consulting to schedule training for your team or explore advanced modules.

2. AIAG (Automotive Industry Action Group)

Best For: Tier 1 & Tier 2 suppliers in the global supply chain Highlights:

Recognized by global OEMs

In-depth training on PPAP, FMEA, MSA, SPC

Certification courses aligned with North American CSRs

AIAG also provides e-learning bundles that combine standard training with case-based learning.

3. 4C Consulting Global

Best For: Engineers & Quality Managers Benefits:

Access to certified trainers

Industry-focused case studies

Advanced modules on process auditing & failure prevention

Often bundled with ISO 9001 updates

4. Training Academy

Best For: Global automotive suppliers Course Features:

IATF 16949 internal auditor and lead auditor certifications

Delivered live online or self-paced

Detailed guidance on risk-based thinking and context of the organization

Who Should Enroll in IATF 16949 Online Courses?

Quality Managers & Engineers: To lead the QMS implementation

Production & Process Engineers: For better integration of quality in operations

Internal Auditors: To ensure continual improvement

Suppliers/Vendors: To meet OEM requirements

Students & Freshers: To boost employability in the automotive sector

Benefits of Taking Online IATF 16949 Training

✔️ Flexible Learning

Learn at your own pace from anywhere—ideal for working professionals.

✔️ Cost Effective

Online certifications are often more affordable than in-person training, especially for teams.

✔️ Immediate Certification

Most platforms offer downloadable certificates that can be used for audits or resume-building.

✔️ Practical & Relevant

Look for platforms that use iatf 16949 standard with examples, not just theory.

Final Thoughts: Invest in Learning to Stay Ahead

Whether you’re a startup entering the automotive supply chain or a seasoned Tier 1 supplier, training is non-negotiable. The IATF 16949 standard is rigorous, but with the right online course, it becomes manageable and even transformative.

Explore platforms like 4C Consulting, AIAG, and SAE to find a course that fits your team’s goals and technical level. Make sure to prioritize training that includes real-world examples and access to experts.

🔍 And if you're unsure where to begin, we're here to help. Reach out to us to get personalized recommendations based on your current QMS maturity.

Don’t Miss This:

🔗 What Are Automotive Core Tools and How to Use Them? – This blog complements any IATF training by explaining the five essential tools for implementation success.

0 notes

Text

IATF 16949 Certification

What is the IATF 16949 Standard?

The International Automotive Task Force (IATF) 16949 standard is an ISO standard that specifies the requirements for a quality management system (QMS) for the automotive industry. IATF 16949 certification is a process by which organizations can demonstrate that they have met these requirements. It demonstrates that they have implemented a QMS that meets the highest standards for quality and reliability.

Importance

The importance of the IATF 16949 certification for quality management in the automotive industry is significant. The certification provides a framework for organizations to improve the quality of their products and processes. It also helps to ensure that the automotive industry meets customer requirements and international standards. Additionally, the certification can help organizations to improve efficiency, reduce costs, and increase profits.

Benefits

It demonstrates your organization’s commitment to quality and continuous improvement.

It helps you improve your performance by identifying and addressing gaps in your quality management system.

It assures customers that your products and services meet the highest quality standards.

It enhances your organization’s image and reputation in the marketplace.

It helps you win new business and retain existing customers.

It makes it easier to achieve and maintain compliance with other quality management system standards.

It enables you to benchmark your performance against the best-in-class organizations.

Which Organizations Can Apply?

Any organization that is involved in the design, development, production, assembly, and/or servicing of automotive-related products can apply for iatf 16949 certification. This includes organizations in the automotive supply chain such as component manufacturers, parts suppliers, systems integrators, and service providers.

How to Get IATF 16949 Certified?