#Hydraulic Insertion Machine Market Size

Text

Spline Broaches

Spline broaches are cutting tools used in machining to produce splines, which are ridges or teeth on a shaft, gear, or other mechanical component. These ridges are designed to mesh with a corresponding part, such as a gear or a mating component, enabling the transmission of torque or motion.

The spline broach itself is a long, narrow tool with a series of teeth or cutting edges along its length, each designed to remove material in a specific pattern. The broach is typically made of hardened steel to withstand the forces involved in cutting metal.

Using a spline broach involves inserting the broach into a pre-drilled hole or slot in the workpiece and then applying pressure to move the broach through the material. As the broach advances, its teeth gradually remove material, forming the desired spline shape. This process is often performed using a broaching machine or a hydraulic press to provide the necessary force.

Spline broaches come in various shapes and sizes to accommodate different spline designs and workpiece materials. They are commonly used in industries such as automotive manufacturing, aerospace, and machinery production where precise spline profiles are essential for proper functioning of mechanical components.

Conclusion: In conclusion, spline broaches stand as indispensable tools for modern machining operations, offering unparalleled precision, efficiency, and versatility. Their ability to create intricate spline profiles with minimal setup time and high productivity makes them indispensable assets in the manufacturing industry. As technology advances, innovations in spline broach design and materials continue to enhance their performance and broaden their applications. Thus, investing in high-quality spline broaches is a prudent choice for manufacturers seeking to optimize their production processes and maintain a competitive edge in today's market.

By harnessing the capabilities of spline broaches, manufacturers can achieve superior quality, efficiency, and cost-effectiveness in the production of precision-engineered components, driving innovation and advancement across various industries.

0 notes

Text

U.S. Cold Headed Large Bolts In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

The U.S. cold headed large bolts market size was valued at $75.3 million in 2020, and is projected to reach $120.4 million by 2030, registering a CAGR of 4.8% from 2021 to 2030. Cold headed large bolts are a type of full threaded bolts, which are manufactured from cold heading process. Bolts typically consist of a head and a cylindrical body with threads either throughout or along a portion of its length. Cold heading is the process of manufacturing bolts and other fasteners by altering the shape of an un-heated wire blank at high speed after inserting it into a die. Cold headed bolts are joining mechanism used in various industries that are manufactured using the cold head process. Cold headed or cold forming uses high pressure from a hydraulic press machine to force a metal piece into a performed die. The cold headed process has various advantages over traditional metal working process, as it offers low quantity of waste and scrap and improves consistency and production rate. It offers speed of up to 400 pieces per minute and hence, reduces the production costs as compared to machined components.

Cold headed large bolts have gained widespread acceptance in automotive, aerospace and industrial machinery manufacturing in the U.S. owing to improved consistency and reduce metal waste. In addition, expansion of automotive and construction sectors owing to increase in government investments is expected to increase the demand for cold headed bolts and thus, drive the market growth during the forecast period. Furthermore, various benefits of cold headed process over machined components are expected to fuel the U.S. cold headed large bolts market growth during the forecast period.

The construction and automotive sectors in the U.S. have observed significant growth in last few years, which has also increased the demand for cold headed bolts. For instance, in January 2022, the U.S. government announced new investment in the country’s bridges rework and replacement. In 2020, he Department of Transportation launched the Bridge Replacement Rehabilitation, Protection, Preservation and Construction Program. It will allocate $27 billion funds for repair and replace bridges.

The U.S. cold headed large bolts market is segmented on the basis of size and application. On the basis of size, the market is divided into 1 inch, 1–1/8 inch, and 1–1/4 inch. On the basis of application, the market is segmented into automotive, aerospace, construction, industrial machinery, and others.On the basis of application, the automotive segment was the largest revenue generating segment in 2020 owing to increase in manufacturing of electric vehicles.

Competition Analysis

The key players that operating in the U.S. cold headed large bolts market are Chase Fasteners Inc., Birmingham Fastener and Supply Inc., Brunner Manufacturing Co., Inc., Byora U.S.A. Corporation, Elgin Fastener Group, Fastco Industries, Inc., G — Fast, Inc, Grandeur Fasteners, Inc., Universal Rivet Inc., and Valley Fastener Group, LLC

Full Report With TOC:-https://www.alliedmarketresearch.com/us-cold-headed-large-bolts-market-A16212

0 notes

Text

Hydraulic Insertion Machine Market 2020 to 2025 Industry Shares and Top Manufacturers Like - Brightleaf Power, Ingimec, SMARTECH, Unifold (Pvt) Ltd

Hydraulic Insertion Machine Market 2020 to 2025 Industry Shares and Top Manufacturers Like – Brightleaf Power, Ingimec, SMARTECH, Unifold (Pvt) Ltd

The most recent report on Hydraulic Insertion Machine Market issued by DecisionDatabases, numerous aspects of the current market scenario has been taken into consideration and a concise analysis has been put together to bring you with a study that has pre and post COVID analysis. It is essential to address the current outbreak of COVID-19 in the current market scenario. The complete shutdown in…

View On WordPress

#Global Hydraulic Insertion Machine Industry#Hydraulic Insertion Machine#Hydraulic Insertion Machine Market#Hydraulic Insertion Machine Market Forecast#Hydraulic Insertion Machine Market Growth#Hydraulic Insertion Machine Market Report#Hydraulic Insertion Machine Market Share#Hydraulic Insertion Machine Market Size#Hydraulic Insertion Machine Market Trends

0 notes

Text

Tips To Select Injection Molding Machines

The plastic machinery manufacturer industry is one of the traditional industries that is considered to have seen the most rapid development over the years.

The injection molding machinery is a type of plastics processing machinery or the plastic industry that plays a vital role in the development of the plastic industry, no matter it is due to the quantity or type.

As they can be formed in once plastic products of precise dimensions, complex shapes and the finest quality or can also have metal inserts, therefore the injection molding machines are widely used in all the sector’s of people’s everyday life like motor, national defense, automobiles, packaging, transportation, agricultural, education, culture and healthcare.

There are various types of injection molding machines of different models and for different use available in the market, so the users quite often get confused on how to choose the best and the most ideal injection molding machines for their business:

Listing down the important tips that one should pay attention on how to select the best injection molding machines:

Technical parameters of injection molding machines

The buyers can make a horizontal or a vertical comparison when choosing an injection molding machine. The vertical comparison is done to compare the main technical parameters of the injection machine as per the industry standards, and the horizontal comparison is done to compare the technical parameters of both domestic and foreign injection machines of a similar type which requires carefulness.

Here are a lot of parameters that one should be considering while selecting the machinery like

The Shape, the material, the quality and precision of dies, structure of the produced injection products and its uses in various fields and scenarios, the number of die openings, the dimension and shape of the runners, the production capacity on the basis of everyday, monthly and annually and the automation degree of products and so on.

Working stability, reliability, safety, and service life of injection molding machines

The stability of the injection molding machines is widely reflected as to whether the clamping mechanism and the injection system works smoothly and efficiently in each looping cycle, without hampering the noise and the produced noise meets the industry standards which are often determined by the assembly precision of machines and mechanical manufacturing along with the reasonable design and structure of the toggle links.

The service life and the rigidity are usually reflected in the system rigidity of the clamping mechanism, which is usually determined by the size, shape, and material and heat treatment process of the molds or templates, pull rods, pin shafts, and links. The structure and the manufacturing process are the injection machines containing the screw, barrel, and tip of the screw along with the check ring and the screw drive spindle, which are considered the main parts and the wear parts of the system that have a direct effect of the machine’s service life.

Safety of injection molding machines

The safety of the humans and machines is considered by the reliability of the low-voltage protection system when the clamping mechanism is functioning. The injection machines need to be equipped with the electrical-mechanical-hydraulic joint safety system to ensure both the humans and the dies. If the safety door of the molds is not properly closed before the mold closing process. In that case, the clamping mechanism will immediately stop working similarly during the mold closing process if the safety doors are not closed properly. The platen will stop functioning and will automatically open.

Another one of the most important safety features in the injection machines is the cold start prevention of the pre-plasticized screw. When the screw material fails to reach a specific holding time and temperature, it is prohibited to get started and will start alarming. Also, the injection molding machines must have protective devices at their nozzles to prevent the burns that are caused due to splashed materials.

Energy Conservation and Environmental-Friendly

An important aspect to consider while choosing the injection molding machine is its quality of energy conservation and environmental friendliness.

The energy conservation here refers to the better conservation of electricity and water of an injection processing machine in comparison to those of its type when it's about power drive system, electromagnetic heating system, and heat dissipation system that works under the normal processing conditions.

Therefore the injection machines should be designed in such a way that they should be environment-friendly, which means that they should function quietly without producing noise pollution, excessive noise, or hydraulic oil leakages, and should be made with environment-friendly materials as much as possible.

If you have been looking for the best plastics processing machinery, then consider hiring Mitchell Industries as they are renowned manufacturers of various plastic molding machine alphamac offers. They have years of experience in the industry and are considered the best plastic bottle manufacturing machine alpha. They deal with various brands like Sepro Group, Blue Air Systems, Preven, Long House, and more.

#Plastics Processing Machinery#Plastic Injection Moulding Machine Sepro#Plastic Injection Moulding Machine Weisheng Automation

0 notes

Text

Smart Pneumatics Role in Automation, Cobots, Safety and System Efficiency

For today’s industrial pneumatic systems, automation and efficiency continue to be the driving factors in design. Automation in pneumatics incorporates a variety of design strategies and considerations. When it comes to industrial machinery, Industry 4.0 and the Industrial Internet of Things (IIoT) are big buzzwords, but these solutions are not fully developed yet. For design engineers working toward creating closed-loop automated systems, questions for consideration include:

How do you develop the next-generation Smart Factory?

What is the path toward a fully automated factory?

How can maintenance requirements be triggered without any downtime?

What data input can you use and how do you capture that data?

How do you diagnose maintenance issues at the component, system, or process level?

Smart connected pneumatics

For design engineers, smart pneumatics can mean complete flexibility; this is the ability of that component to communicate over the network, multiple uses for a single device, ease of integration and commissioning, as well as troubleshooting. Smart products are where you see the most difference in pneumatic systems. The diagnostic aspect of smart pneumatics is important to help achieve zero downtime.

The concept of zero downtime has seemed unrealistic in the past, however, technology is evolving in that direction. Incorporating sensors into pneumatics enables end-users to collect important prognostic and diagnostic data for setting alerts and getting machine feedback.

The future of smart pneumatics is a complete plug-and-play configuration that is easy to manage. For today’s smart pneumatics, design engineers can generate data and set the alerts but are not yet making fully closed-loop systems. However, this is on the horizon with end-to-end systems that can be configured with just a few clicks and the device will be able to take over, provide data and feedback into the control system that goes beyond simply allowing data dumps.

Read our white paper Innovations for Automation and Efficiency in Industrial Pneumatic Systems and gain insight into the use of smart pneumatics, designing for cobotic applications, applying safety standards, and pneumatic system efficiency.

Technology is changing–quickly

As technology evolves, seemingly almost daily, more people are migrating to networks as designers are migrating systems to the newer industrial Ethernet systems. Why? Overall, the “line” topology of the networks makes them much easier to work on and troubleshoot.

It used to be the case that each manufacturer offered the same type of components such as cylinders and FRLs. There is a large divide in the market on what is available and what functions they offer. Products today with integrated electronics offer many different functions through what is embedded. When specifying systems, design engineers should be sure to understand what is necessary for the machine and what value can be provided by the smart products that are specified.

Cobots and safety

In automotive manufacturing, robotics has been in use for more than a decade and over the years, they have shifted from being hydraulically driven to being pneumatically driven. In industrial cobot applications, collaborative robots, known as “cobots” work with humans in some way, including as an assistant or guide in a task or process. Unlike autonomous robots, cobots, do not work alone. They are designed to work with human instruction or respond to human behavior. The shift to pneumatics for robotics means that cobots are primarily pneumatically driven.

Cobots are the next big thing in industrial applications as the cost of robotics comes down and newer opportunities are being developed. Leading cobot applications include:

Machine tending where cobots can load and unload tools and accessories to decrease manual handling.

Pick and place where cobots can complete careful packing and moving, then place and position products or parts.

Assembly and flexible manufacturing where cobots insert parts, screwdriver, and other assembly tasks with appropriate end-of-arm tools.

Packaging, loading, and unloading when aided by suction or gripper attachments, cobots move finished products through packaging.

Safety in collaboration of manual and automated

The strict separation between the manual work of the factory worker and the automated actions of robots is becoming an increasingly gray area. Their work ranges are overlapping and merging into a collaborative working space. In doing so, humans and machines will be able to simultaneously work together on the same workpiece or component in the future—without having to be shielded from each other for safety reasons.

Due to this, safety is the largest consideration in the design of cobot applications. However, there can be some confusion on which safety standards to follow in applications with cobots due to the divide between traditional pneumatics and entering the world of robotics. As standards and their adoption vary among engineers and facilities, it is important to know which standards to apply.

For incorporating cobots into a plant, engineers must understand the required standards for the facility and compile the necessary documentation and technical file with due diligence, testing, and validation of the controls architecture.

Smart pneumatic system efficiency

Lower upfront and maintenance costs combine to make pneumatics the most popular and cost-effective choice for executing mechanical motion. New improvements in designs and efficiency of compressors, and the standard use and distribution of clean dry air in a manufacturing facility, also make pneumatics a good choice for industrial automated machinery. Smart pneumatics aim to help generate and maximize data and minimize compressed air use. Compressed air use by industrial machines is a close second to the use of electricity in terms of cost, and well ahead of other utilities such as water and natural gas in most plants and facilities. Electricity is less expensive per dollar of unit energy, but compressed air and pneumatics have many other advantages encouraging their use.

Effective pneumatic systems need properly sized, installed, and maintained components from compressors to workstations. A few wrong choices can lead to everything from wasted energy to system failures. Conversely, even seemingly small design tweaks can add up to large improvements in pneumatic system efficiency. These changes can save air, reduce costs, improve overall utilization, and reduce downtime in operation.

0 notes

Text

What Is the Role of the Hydraulic and Hose Fittings

What are Hydraulic Fittings

Hydraulic Fittings are the ones used to connect the hydraulic hose to different components used in a system. The various features can be the hydraulic hose of another kind, hydraulic cylinders, tubes or pipes.

The hydraulic fittings have different types as the fluid flow, and the changes in the direction are associated. The diversion and mix of fluid flow are also seen as a factor of matter. A wrong fitting can cause efficiency issues and safety concerns.

Thus the fitting hydraulic must be the right fit for the fitting in a particular system to avoid unfortunate events.

Types of Hydraulic and Hose Fittings

The hydraulic hose has two categories of fittings:

Permanent Crimp Fittings

This is the most suitable kind of fitting for the hydraulic to be attached to a hose. These have a crimping machine that allows the attachment of the hose to a hydraulic fitting.

Field Attachable Fittings

If your fitting does not require crimping, field attachable fittings must be your priority choice. The crimper provided is not attached; the hose is compatible with the ‘field attachable’ fitting.

There are different types of fitting hydraulic that the hoses are attached to; they are:

Plugs

Crosses

Elbows

Unions

How to properly connect to a hydraulic hose?

A hydraulic hose is connected with the hydraulic fitting with utmost care as it can cause safety and efficiency concerns. The following steps are to adequately fit the hydraulic hose and avoid assembly concerns followed by hydraulic fittings manufacturers in India.

Ensure the length of the hose is of the required fittings. And if there is an issue, you can either replace or cut it to the optimal size with the hose cutter.

With the appropriate size of hose, a hydraulic fitting is taken up, considering all the external factors in the process such as pressure, size, temperature, the material of construction, the orientation of the system and style compatibility.

With the right operation start, the hose was fitting in the hydraulic fitting and marked at first. Later, the hose is lubricated and inserted until the point of mark.

Adjust the crimper along the sides of the fitted diameter and crimp the hose with the help of a crimping machine.

You can verify the crimp diameter, clean the fitting to avoid contamination, and eliminate the dirt with a hose brush.

If no crimper is present, a direct fitting hose is adjusted to the hydraulics and tested for any leak and cleaned with the hose brush.

Role of Hydraulic and Hose Fittings

A hose, when flexible, is highly efficient to transport the hydraulic fluid through the fittings from a system assembly to another and so on. It can be flexed and diverted to any direction of choice that can control the fluid at any speed. The adapter design allows the valves and fittings to be attached from any side to be fitted.

The hose is attached to the mainline from where the heavy flow of fluid is passed through to improve the control and improve the systems’ performance making it optimal. Hydraulic hose fittings can take up high pressure, and the material is usually synthetic rubber, thermoplastic, or Teflon.

The operations of fitting hydraulic are primarily preferred in the industries and the bulky types of machinery. There is a significant maintenance necessity, and the hydraulic system with hose fittings can be the most prominent solution to leakage and safety.

With self-lubrication, lightweight material and compact sizes with variability, the high powered types of machinery are also supported with hydraulic and hose fittings. The fittings, when used appropriately, keep hold of the pressure and can control the level of power. With the pressure and temperature in control, the orientation framework is taken under complete control.

Applications of Hydraulic and Hose Fittings

There are specific general applications of hydraulic fittings that are used with the hoses and form a hydraulic coupling:

Industries use hydraulic fittings to assemble systems, pressure equipment, hydraulic power units and robotic machinery.

Agricultural equipment

Plumbing equipment

Construction equipment

Mining equipment

Oil industry equipment

Gas industry equipment

Looking for the perfect hydraulic fitting manufacturers in India, Seal Excel provides you with a wide range of designed hydraulic fittings and hoses. We have a team of expert product designers and curators who have in-depth knowledge valid in the industry. We stick to international industry standards and utilise standard quality material.

With being the most reputed company, we have high-quality hydraulic fittings and hoses at competitive prices in the market. Our manufacturers’ efforts bring out the hydraulic couplings to be the optimum fitting that prevents leakages. And our hydraulic fittings and hoses have gained prime importance in our product quality of all times.

0 notes

Text

The better use of Souvlaki machine

Are you a foodie, traveller, or chef? If you belong to any of these spheres, you might know various kinds of foods and maybe souvlaki as well! Souvlaki is a traditional Greek wanton food that contains small pieces of meat and seldom vegetables cooked on a souvlaki skewer machine. It gets normally eaten right off the skewer while pretty hot. People enjoy it with fried chips, pita bread, lemon, and salads. But the taste of souvlaki itself gets consumed on its own, including the party dishes eaten afterwards. The meat usually used in this dish is pork, chicken, beef, & lamb.

The best thing is now you can cook souvlaki using a souvlaki machine even in your home without any hassles. These machines have a complete system - from trident steel to grilling bar. And here you will know the better use of Souvlaki Machine that will make your life easy. So, scroll down and take a look!

Souvlaki Maker Machines: Things to know!

People call the souvla machine also a Kebab Souvlaki Maker Box. One of its best things is it can cook 36 kebabs in under 120 seconds. It is the ideal thing for joint families. Besides, it works best for weekend get-togethers, perfect for a birthday party or any gathering. It’s also a grant for that cherished one. It Orders and lessens the annoyance of cutting peculiar parts and inserting them on the skewers. And the most fantastic thing; a souvlaki machine is straightforward to use and reliable. You can pull out your meats, greens, and fruits, and have them perforated, marinated, placed on skewers, and grilled to supremacy in less than an hour. So, it is a COOL machine. Isn't it?

Versatility

One thing that might amaze you is that souvlaki machines are non-electric. It contains the intelligence to cover even the wide production of souvlaki in the least time. With the help of a non-electric souvlaki machine, it is effortless to dress, stick, cut, and insert meat simultaneously. These machines hold the power to provide skewers in tiny and big sizes with their multi-functional device. If we dig a bit deeper, then we want you to know that there are unique oil pumps and hydraulic pistons movement, making the machine efficient. Well, these machines usually take their heat from burning coal or gas.

Affordability

The contrivance of this souvlaki machine relaxed the pieces to make the food swiftly and hassle-free. It came up in the Greece market in the early 90′s. Souvlaki machine facilitates the method of Souvlaki making. Therefore, people eagerly consider buying them both for commercial and domestic purposes. The energies and enthusiasm for cooking the dish minimise fantastically. Souvlaki skewer machines are available at pretty affordable prices, and therefore you can buy them online.

Takeaway!

So, readers! What are your thoughts on the uses of the souvla machine? If you wish to make this classic dish without any hassles, a souvlaki machine is a must thing to have in your kitchen!

0 notes

Text

Valves 101: Two Types of Ball Valves

Small-size valve balls are a type of piping equipment that shuts off or controls the flow in a pipeline by using a hollow sphere and round seats held in a valve body. There are two basic technologies for the design of ball valves, floating ball design and trunnion mounted ball design.

The major components of a ball valve include:

Valve body – A pressure vessel that contains the components needed to control or shut off the flow through a pipe. It is designed to connect two or more sections of pipe or tubing to each other.

Ball – A sphere with a flow path (hole or tunnel) through the center of it and a connection point for a shaft to rotate it.

Seats – Round donut-shaped discs that form a seal between the body and ball.

Stem – A shaft that connects the internal ball to the outside of the valve to facilitate rotation of the ball.

Packing – Flexible seals that fit around the shaft and prevent the media traveling through the valve from escaping externally.

Bonnet – The part of the valve body that houses the stem and packing.

Operator or Actuator – An external device designed to rotate the stem of the valve. This can be a lever, a gear, a motor-operated gear (electric actuator), or a pneumatic/hydraulic actuator.

Floating Ball Design

A floating design ball valve sandwiches the hollow ball between two or more cupped seats that form a tight seal between the body and the ball at the inlet and outlet ports of the valve body.

The floating valve balls are rotated (usually 90 degrees) by a shaft that protrudes outside of the valve body and is connected to some form of operator. For this reason, most ball valves are referred to as quarter-turn valves. This shaft is not rigidly attached to the ball in order for the ball to pivot on the end of the shaft as it rotates on the axis of the ball. This is usually accomplished with a slot on top of the ball, perpendicular to the ball’s flow path. The cupped portion of the seats cradle the ball prevents it from moving down in the valve body.

The valve packing prevents the media from escaping the valve body through the stem opening in the bonnet. The most common type of packing today is chevron v-ring type packing. If you look at the cross section profile of this packing, it resembles the letter “V”. The outer diameter of the packing matches the bore of the bonnet. The inside diameter matches the outer diameter of the stem. Multiple rings of this packing are stacked on top of each other and the stem is inserted through the packing. A packing gland on top of the bonnet pushes down on the top of the “V” and causes the packing to expand and seals agains the stem and bonnet.

When the ball is in the closed position, the flow path in the ball is perpendicular to the flow path in the valve body. The solid parts of the ball covers both upstream and downstream cupped seat openings. The pressure in the upstream pipe pushes against the solid part of the ball which moves on its pivot point and is forced tightly against the downstream seat. This shuts off flow.

As the operator rotates the ball from the closed position, the ports in the body in relation to the ports in the ball create a variable size orifice which, as it gets larger, will increase the flow through the pipe. When moving from open to close, this orifice gets smaller and decreases flow.

Floating ball design valves are the most economical valves, but are limited by the amount of pressure the seats can handle.

Trunnion Mounted Ball Design

The Trunnion Valve Balls work nearly the same way as the floating ball except the seats are spring loaded against the ball and the ball does not pivot. The ball only rotates on its axis in this design.

In the trunnion mounted ball valve, the ball utilizes a second shaft and bearing on the bottom of the ball. This stem or “post” holds the bottom of the valve in place. The top of the ball is not slotted and the upper stem is rigidly attached to the ball. This prevents the ball from moving into the downstream seat.

Since the ball does not move into the seats, the seats must move towards the ball. Springs behind the seat push them tightly into the ball in order to make the seal.

Trunnion valves are very effective at sealing off very low pressures that would not be strong enough to move a floating ball into the downstream seat. They are also required on large diameter valves and high-pressure valves. The reason for this is the contact area of the seats in a floating ball is relatively small. From physics, we know force = Pressure x Area. The force on the downstream seat in a floating ball is derived from the process pressure in the upstream pipe pushing on the solid area of the ball in the closed position. If the pressure is high or the area is large, the downstream seat will be destroyed.

The tradeoff is that trunnion valves are much more expensive than floating ball designs.

Both floating ball and trunnion designs are available as multi-port valves by using elaborate flow paths in the ball and additional ports in the body.

Are you looking for ball valves for your facility? Our team has years of experience in selecting the perfect valve for any application. Contact us today to discuss your specific valve needs!

HOLLOW VS. SOLID BALL VALVE

The ball valve is available with many different options, and one of the most important distinctions is in how the ball is made. Manufacturers either join two hollow hemispheres or machine a hole through a solid ball. Machining takes more work, but it produces a valve with better flow characteristics. Here’s why.

Ball construction

In a solid ball valve, the hole is the same diameter all the way through. That helps the fluid flow smoothly at a constant velocity. Hollow valve balls are, as the name implies, hollow inside. That creates a bigger space for the fluid to fill, which changes its velocity and creates turbulence.

Turbulence is almost always undesirable. It creates noise and it’s inefficient. The Cv drops, and it takes more energy to pump fluid through the system.

In a few applications, valve weight is an issue. In such cases, the hollow ball may have an appreciable advantage, especially in larger valves.

Solid ball, better flow

When evaluating ball valves, check the Cv values and be sure to compare identical port formats. In most cases, the solid ball will give a higher Cv than the hollow ball.

Advantages of V-Ball Valves

Ball valves are designed to be used in a variety of applications and markets, but V opening valve balls offer the added ability to be used as a control valve where necessary. The main differentiator is a contoured V-port in the ball, most commonly available with a 15°, 30°, 45°, 60°, or 90° angle, which produces an equal percentage flow characteristic for better control. V-ball valves are known to offer a variety of advantages in flow control applications, especially when compared to larger and more expensive control valves.

Low Pressure Drop

The V-port design allows material to flow straight through the valve, minimizing pressure drop across the valve. V-ball valves also have higher flow coefficients (Cv) compared to other control valve types of a similar size; this means that a smaller V-ball valve can be used to achieve the same flow rates as a comparable control valve of a larger size.

Bubble Tight Shut-Off

V-port ball valves use the “floating ball principle, which will provide a bubble tight shut-off in addition to the modulating flow control. When the valve is closed, upstream pressure pushes the ball against the downstream seat, thus enhancing the seal. These can control or shut off bi-directional flow, which proves to be especially beneficial in gas applications. Comparable control valves often require additional shut-off valves; V-ball valves eliminate the need for these additional valves, saving the user cost and reducing the number of overall components in the system.

Precise Flow Control

Precision machined V-ball valves are available with 60° and 90° V openings and offer equal percentage flow characteristics. As the ball rotates, desired flow rates can be achieved by positioning the ball anywhere between 0° and 90°. Response time is also increased due to the ability to use smaller actuators with these valves.

High Shut-Off Pressure

V-ball valves feature a quarter turn (90°) ball rotation, allowing them to operate and shut off at much higher working pressures. Because of this, smaller lower torque actuators can be used, which results in cost savings and higher efficiency in the user’s application.

Ball Valves Defined

Ball valves use a handle to turn a ball in the valve, with a hole or port through it. The ball is used to allow or prevent flow through the valve depending on its position. If the hole is aligned with the pipe, flow continues through the valve; if the hole is perpendicular to the pipe, flow will stop at the valve. It’s really that simple!

Not all ball valves look the same and some have special uses, but they all have the same concept.

Did you know? Ball valves are considered ? turn valves because of the quarter turn that is required to close the valve.

The Benefits of Ball Valves

Easy to see if it is open or closed. When the handle is in line with the pipe you can easily tell that the valve is open; and when the handle is perpendicular to the pipe the valve is closed. This is a great visual indication of whether there is flow through the valve or not.

Operation after years of disuse is easy. The durability of ball valves allows them to work and completely shut off flow after years of disuse. This provides extra peace of mind.

Quick shut off. The motion that is required to operate a ? turn the valve is quick and minimal compared to gate valves. Water hammer is a possibility if the flow through the valve is strong enough to vibrate the line when it comes to an abrupt stop as the valve is quickly shut off.

A more compact and economical valve. Thanks to the design of ball valves they are more compact than gate valves. Gate valves are taller and require more space, as the gate needs a place to go to allow the flow to travel through the valve. By using a rotating ball, ball valves are smaller and require less material.

Different Types of Balls

There are three different types of balls that can be found in ball valves. For each of these three types, the outside of the ball needs to be smooth and the surface gets ground down to remove any dips or imperfections on the surface. As the material cools, the shape may change, resulting in more or less grinding. The three types are hollow, solid, and cored, so let's take a closer look at each of them.

Hollow Ball

The hollow ball has a cavity that goes from an open hole in the bottom of the ball to the top where the valve stem is inserted. Hollow balls require less material to construct, making them more economical, but may require more grinding to get the dips out.

Solid Ball

The solid ball is molded as one solid ball, larger than required, to account for any shrinkage and grinding. Solid balls are usually more expensive to manufacture as they require more raw material and grinding to get them to the perfect round shape.

Cored Ball

The cored ball is cored through the center, leaving a consistent wall thickness around the whole ball. This ensures that the ball cools more evenly, again decreasing the amount of grinding required once it has fully cooled. These types of balls are becoming more popular due to the cost savings compared to solid balls.

0 notes

Text

U.S. Cold Headed Large Bolts Forecast to 2031 with Key Companies Profile, Supply, Demand and SWOT Analysis

The U.S. cold headed large bolts market size was valued at $75.3 million in 2020, and is projected to reach $120.4 million by 2030, registering a CAGR of 4.8% from 2021 to 2030. Cold headed large bolts are a type of full threaded bolts, which are manufactured from cold heading process. Bolts typically consist of a head and a cylindrical body with threads either throughout or along a portion of its length. Cold heading is the process of manufacturing bolts and other fasteners by altering the shape of an un-heated wire blank at high speed after inserting it into a die. Cold headed bolts are joining mechanism used in various industries that are manufactured using the cold head process. Cold headed or cold forming uses high pressure from a hydraulic press machine to force a metal piece into a performed die. The cold headed process has various advantages over traditional metal working process, as it offers low quantity of waste and scrap and improves consistency and production rate. It offers speed of up to 400 pieces per minute and hence, reduces the production costs as compared to machined components.

Cold headed large bolts have gained widespread acceptance in automotive, aerospace and industrial machinery manufacturing in the U.S. owing to improved consistency and reduce metal waste. In addition, expansion of automotive and construction sectors owing to increase in government investments is expected to increase the demand for cold headed bolts and thus, drive the market growth during the forecast period. Furthermore, various benefits of cold headed process over machined components are expected to fuel the U.S. cold headed large bolts market growth during the forecast period.

The construction and automotive sectors in the U.S. have observed significant growth in last few years, which has also increased the demand for cold headed bolts. For instance, in January 2022, the U.S. government announced new investment in the country’s bridges rework and replacement. In 2020, he Department of Transportation launched the Bridge Replacement Rehabilitation, Protection, Preservation and Construction Program. It will allocate $27 billion funds for repair and replace bridges.

Similarly, In 2021, an automotive manufacturing company, General Motors announced that it is expected to invest $6.6 billion by 2024 to increase electric vehicle production in the U.S. As a result, all such development are expected to increase the demand for cold headed large bolts and thus drive the growth of the U.S. cold headed large bolts market during the forecast period.

The U.S. cold headed large bolts market is segmented on the basis of size and application. On the basis of size, the market is divided into 1 inch, 1–1/8 inch, and 1–1/4 inch. On the basis of application, the market is segmented into automotive, aerospace, construction, industrial machinery, and others.

On the basis of application, the automotive segment was the largest revenue generating segment in 2020 owing to increase in manufacturing of electric vehicles.

Competition Analysis

The key players that operating in the U.S. cold headed large bolts market are Chase Fasteners Inc., Birmingham Fastener and Supply Inc., Brunner Manufacturing Co., Inc., Byora U.S.A. Corporation, Elgin Fastener Group, Fastco Industries, Inc., G — Fast, Inc, Grandeur Fasteners, Inc., Universal Rivet Inc., and Valley Fastener Group, LLC

Full Report With TOC:-https://www.alliedmarketresearch.com/us-cold-headed-large-bolts-market-A16212

0 notes

Text

Productivity with Electrical Assembly tools

Introduction

Regardless of the size of the business, continuous improvement of productivity is vital to augment gross profits and to remain competitive in the market. Productivity on the Assembly shop floor mainly depends on the combination of efficient employees, equipment, and processes. Therefore, in developing industry, an employee can only be as productive as their tools.

The use of electrical assembly tools for fastening and assembly delivers faster, accurate, and easy output while reducing the cost of labour, risks of injury, thus increasing productivity.

1. Manually operated vs Power Operated Assembly Tools

Assembly tools are used in assembling machinery and equipment components may be either manual or power-driven. Manual tools include standard or special tools for assembling threaded connections, including wrenches and screwdrivers, standard and soft hammers for pressing the parts, dies, and punches for riveting work, Pliers, and various tools for installing piston rings and washers.

Power-driven tools include hand-held electric machines for fastening threaded connections, such as screwdrivers and nut and bolt drivers, electric hammers, portable clamps for pressing and riveting, power-driven rollers for installing elastic parts, such as piston rings, split locking rings, and springs.

The use of power-driven assembly tools increases the efficiency of assemblers by a factor of 20% to 25% as compared with the efficiency obtained with manual tools. Electrical assembly tools are widely used in large and mass production operations. An important requirement for the use of power-driven tools is the training in specialized lines of work and the standardization of fastening components.

2. Electrically Operated Assembly Tools

As discussed in previous sections, electric screwdrivers are the smart choice for high-volume manufacturers who want to increase productivity. The main Electrical assembly tools are Electrical Screwdrivers and Electrical Nutrunners-.

Electric Screwdrivers –

An electric screwdriver is a portable device that allows different types of screw heads to screw and unscrew effortlessly. The screwdriver head is equipped with a bit holder for a quick release system often a magnetic type, allows for quick insertion of the screw bit corresponds to the screw heads. These screwdrivers can be seen at assembly lines and stations for safety and quality critical applications.

Electrical screwdriver - The standard models use brush motors and over a period of time wear and tear occur on expandable parts like carbon brushes, commutators, switches, and other contact points. The heat generated by the motor may shorten the operating life of the screwdriver. Wear on the expendable parts can affect its performance, causing the screwdriver sometimes to stop operating. Hence, these standard screwdrivers require periodic maintenance and parts replacement depending on the amount of usage time and the environment it is used in.

Brushless Electric Screwdriver - Screwdrivers with brushless motors have an enormously long usage life with no need for periodic maintenance and replacement of expendable parts. As the heat generated by the motor is relatively less in this type, performance is always at its maximum level and resulting in reliable product quality. The brushless screwdriver ensures product safety, reduction in maintenance cost, and an overall reduction in failures.

Electric Nut runners –

Nutrunners and Nut drivers are tools used for tightening nuts. By the name itself, nut drivers are purely mechanical hand tools, while Nutrunners are pneumatic, electric, or hydraulic power tools. Electric Nut runners utilize angle-controlled tightening with very high precision with an integrated gyroscope using the True Angle function. These compact Nut runners are packed with many other innovative features that make the job easier and safer for the operator. Electric nut runners use a DC controller as a power supply. Types of Electrical Nut runners are -

Straight Nutrunners

Angle Nutrunners

Pistol Grip Nutrunners

3. Selecting Nut Runners

Selecting nut runners requires a bit of study on available features. For example, integral transducers are often used to provide feedback to the monitor and control system. Torque levels and the number of tightening cycles are displayed on the digital display panel. Handheld nut runners often include a reaction bar or stabilizer to facilitate ease of use.

4. Monitoring & Control

Software-based control systems provide in-built monitoring and control systems for tightening operations performed using the electric assembly tools. Thus, process control and quality assurance are made simple by these advanced control systems. These systems guide the operator through the in-built functionalities to avoid mistakes, otherwise, these can result in costly quality issues.

5. Applications of Electrical Assembly Tools

Its application can be found in every industry and not limited particular type. Even one can use these portable and noiseless assembly tools for domestic purposes too.

Content Source :- ABSGroup

0 notes

Text

INJECTION MOLDING MARKET ANALYSIS

The manufacturing process for producing parts by inserting a material into a mold, which allows creation of varied shapes and sizes of an object is known as injection molding process. Injection molding can be achieved with a host of components consisting of metals, elastomers, glasses, confections and polymers. Injection molding is used to produce a wide range of products made from various raw materials, including plastics, metals such as iron, aluminum, copper, precious metals, and carbide.

Market Dynamics

Asia Pacific was the largest market for injection molding materials in 2016 and is expected to retain its dominance during the forecast period. The high demand for vehicles is expected to result in an increase in demand for injection molding, thus leading to growth of the global injection molding materials market. Foreign and domestic investments in various sectors is a major driving factor for the market growth in Asia Pacific.

Key Features of the Study:

This report provides an in-depth analysis of the reprocessed devices market and provides market size (US$ Bn), Kilotons, and Cumulative Annual Growth Rate (CAGR) (%) for the forecast period (2017–2025)

It elucidates potential revenue opportunities across different segments and explains attractive investment proposition matrix for this market. It provides valuable insights about market drivers, restraints, opportunities, new product launches or approval, pipeline products, regional outlook, and competitive strategy adopted by the leading players

It profiles leading players in the global injection molding materials market based on the following parameters – company overview, financial performance, product portfolio, geographical presence, key developments, and future plans

Insights from this report would allow marketers and the management authorities of the companies to make informed decisions with respect to their future product launch, market expansion, and marketing tactics

The global injection molding materials market report caters to various stakeholders in this industry, including investors, product developers, distributors, packaging companies, research institutes, injection molding companies, new entrants, and financial analysts

Stakeholders would greatly benefit in decision-making through the various strategy matrices used in analyzing the injection molding materials market

The market size (Volume) for machine segment has taken into account of how much of injection molding materials are used in a particular machine process.

Figure 1. Global Injection Molding Materials Market Share, By Region, 2016

Detailed Segmentation:

Global Injection Molding Materials Market, By Material:

Global Injection Molding Materials Market, By Machine:

Global Injection Molding Materials Market, By End User:

Plastics

Metal

Ceramics

Rubber

Others

ABS

Polypropylene

Polyoxmethylene (POM)

Polycarbonate

Polycarbonate / ABS

PVC

Nylon

Nylon 32% Glass Fiber

Acrylic (PMMA)

Styrene Butadiene (SB)

Polyether Imide(PEI)

Engineering Thermoplastic Polyurethane (EPU)

HDPE

LDPE

Liquid Crystal Polymer

LLDPE

Polybutylene Terephthalate (PBT)

PEEK

PET

Polysulfone (PSU)

Polyphenylene Sulfide

Others

Iron

Low Alloys Steels

Stainless Steel

Aluminum

Cobalt

Copper

Carbide

Precious Metals

Nickel Metals

Others

Liquid Silicone Rubber (LSR)

LSR Fluorosilicone

LSR Medical

LSR Optical

Thermoplastic Vulcanizate (TPV)

Thermoplastic Urethane Powder (TPU)

Others

Hydraulic Injection Molding Machine

All-Electric Injection Molding Machines

Hybrid Injection Molding Machines

Automotive

Consumer Goods

Packaging

Healthcare

Electrical & Electronics

Building & Construction

Furniture

Others

REQUEST SAMPLE

Company Profiles

BASF SE*

ExxonMobil

LyondellBasell

Eastman Chemical Company

Huntsman Corporation

Dow Chemicals

DuPont

SABIC

Ineos Group

Magna International Inc.

HTI Plastics

Organovo Holdings, Inc.

Company Overview

Product Portfolio

Financial Performance

Key Strategies

Recent Developments

Future Plans

Company Profiles

Neptune Biotech Pvt. Ltd.

Aker BioMarine AS

Enzymotec Ltd.

Fuji Chemicals

Krill Canada

Rimfrost

Norwegian Fish Oil

Darduck Frd

Quingdao Kangjing Marine Biotechnology Co. Ltd.

Company Overview

Product Portfolio

Financial Performance

Key Strategies

Recent Developments

Future Plans

DOWNLOAD PDF

ABOUT US

Coherent Market Insights is a global market intelligence and consulting organization focused on assisting our plethora of clients achieve transformational growth by helping them make critical business decisions.

What we provide:

Customizes Market Research Services

Industry Analysis Services

Business Consultancy Services

Market intelligent Services

Long Term Engagement Model

Country Specific Analysis

Contact Us:

Mr. Shah

Coherent Market Insights Pvt. Ltd.

Address : 1001 4th ave, #3200 Seattle, WA 98154, U.S.

Phone: +1-206-701-6702

Email: [email protected]

0 notes

Text

Type of lubricants and their use

Summary

Lubrication is a product that controls friction and wears by the introduction of a friction-reducing film between any moving surfaces in contact. The lubricant used can be fluid, solid, or plastic substance.

Many different substances can be used to lubricate a surface. Oil and grease are the most common type. Grease is a composition of oil and a thickening agent to obtain its consistency, while the oil is what actually lubricates machines.

The Role of a Lubricant

The primary functions of a lubricant are to:

Reduce friction

Prevent wear

Protect the equipment from corrosion

Control temperature (dissipate heat)

Control contamination (carry contaminants to a filter or sump)

Transmit power (hydraulics)

Provide a fluid seal

Picture Courtesy: J.D.Jones

Types of Lubrication

There are three basic types of lubrication: boundary, mixed and full film. Each type is different, but they have the same function, all rely on a lubricant and the additives within the oils to protect against wear.

Full-film lubrication

Full-film lubrication can be broken down into two types: hydrodynamic and elastohydrodynamic.

Hydrodynamic lubrication occurs when two surfaces are in sliding motion relative to each other and those are fully separated by a film of fluid.

Elastohydrodynamic lubrication is similar but occurs when both surfaces are in a rolling motion relative to each other.

Boundary lubrication

Boundary lubrication is found where there are white often starts and stops, and where shock-loading conditions are present. Some oils have extreme-pressure (EP) or anti-wear (AW) additives to help protect surfaces in the event that full films cannot be achieved due to speed, load or other factors.

Mixed lubrication

Mixed lubrication is a combination of boundary and hydrodynamic lubrication. While the bulk surfaces are separated by a lubricating layer, the asperities still make contact with each other. This is where the additives again come into play.

Based on the structure lubricants can be divided into 4 types

Solid Lubricants

A solid lubricant is a solid material which is applied or inserted between two moving surfaces or bearing surfaces. This material will shear a lot more easily than the bearing or moving surfaces. The three main requirements for a material to be a solid lubricant are the ability to support the applied load without major distortion, a low coefficient of friction, and a low rate of wear.

Metal-solid

These solid lubricants contain lamellar solids and achieve low friction through a process known as file transfer. Molybdenum disulfide is the most commonly used metal-solid lubricant. Some of the advantages of a metal-solid lubricant like molybdenum disulfide are a high load carrying capacity, good high-temperature performance, and low friction.

Liquid Lubricants

Liquid lubricants are used extensively in applications that are high in terms of speed and load size. Liquid lubricants are the most prominent type of lubricant in the market. Liquid lubricants are comprised of base oil and some additives.

Gas Lubricants

Gases like nitrogen and helium are used as lubricants in applications where film thickness between tribal-pair is ultra small. The advantages of using gas lubricants are large temperature range, no sealing required for lubrication, very low friction due to low viscosity, no vaporization, no solidification, and no decomposition.

Conclusion

You may know the different types of lubricants as well as the pros and cons of each type. However, you ultimately have to be able to pick the right kind of lubricant for the job at hand. The major factors that one needs to look at when selecting lubricants are load level, speed, sealing requirements, and environmental parameters.

One also needs to look at the coefficient of friction, the operating temperature, the area of contact, and the thermal conductivity. Once you have studied these metrics and have a good idea of the environment in which the lubricant is to be used, you will be able to select the right kind of lubricant.

Generally speaking, for lower loads and speeds, solid lubricants are a good bet. Then as you move towards higher loads and higher speeds, grease becomes a better bet.

0 notes

Text

Hydraulic Insertion Machine Market Huge Growth and Demand (2020-2027) | Crematec, Ingimec, SMARTECH

Hydraulic Insertion Machine Market Huge Growth and Demand (2020-2027) | Crematec, Ingimec, SMARTECH

Most recent Study on Industrial Growth of Global Hydraulic Insertion Machine Market 2020-2027. A point by point study gathered to offer Latest knowledge about intense highlights of the Hydraulic Insertion Machine market. The report contains distinctive market expectations identified with CAGR, income, production, Consumption, market size, gross margin, cost and other considerable elements.

Whi…

View On WordPress

0 notes

Text

Opening A Tire Service Shop? Get These Tools And Equipment Package For Your Garage Shop

If you’re interested in business and the automotive repair industry then opening your own tire shop is a startup option for you.

You’ll need to do your research to make sure there is a demand for a tire shop in the area you’re considering. On the other hand, you need to make sure the market isn’t saturated because it will be difficult to compete unless you bring something to the market that other shops are don’t have or are performing poorly.

New and used retail tire stores are popular small businesses because of the frequent service and replacement needs for consumer vehicle tires and tire pressure monitoring systems (TPMS). As the number of vehicles on America’s roads increases each year, opportunities to serve this customer base grow as well. Automotive repair shops may also consider expanding their business by adding tire installation and repair as a service to their customers.

Once you’ve completed mechanical and diagnostic training, the best career path is to either work for another shop or dealership as a mechanic, to hone your skills and gain experience. This will also give you the time to earn enough money to begin acquiring the equipment you will need to operate your own auto repair shop.

Auto repair equipment that you will need to get your shop ready for business may include:

1. Tire Changer

One of the most commonly used machines and a staple of every shop is the tire changer. A device that can range from the very simple to the extremely complex, this equipment will help you handle one of the most common maintenance jobs with ease. Wheels undergo a lot of abuse from their vehicles, being constantly in motion and bearing the full weight of the machine and its passengers. For this reason, they sustain a lot of wear and require regular maintenance. Ensuring your shop is equipped to handle this work will help make your life a lot easier, so you can tackle any job that comes your way without worry.

There are three main things to consider when deciding on the right machine for you. Size, type, and performance. Different models are designed to handle different wheels, and whether you are looking to change standard car wheels from 20 to 24 inches, heavy-duty truck wheels, low profile wheels, or anything else, you will want a machine that can handle the job. Larger tire changers can also handle more frequent use but are often more expensive, so you can customize your equipment to suit the needs of your shop. Here is a quick tire changer comparison that will help you narrow down your selection:

Tilt Back Tire Changers: U-226 Semi-Automatic Tilt Back Tower Tire Changer

Coming in at a higher price point than the smaller swing arm design, tilt back tire changers are a great option for shops that intend to work on a wider variety of sizes. They are more easily and quickly adjusted on the fly to accommodate different wheels, helping them save you a lot of time and hassle in the long run. Use an automatic tilt back option to adjust your changer to correctly fit the size of any tire and you will reduce the risk of damage during a change while also making the job easier every time.

2. Wheel Balancer

Wheel balancers are a fantastic piece of equipment that will help you save time and effort performing balancing work by giving you better support and control. Deciding on the best machine for your shop can be daunting, so check out our wheel balancer comparison for tips on how to choose the best machine for your shop.

The main consideration for wheel balancer is the balancing you require. There are three main types - static, dynamic, and “bubble” balancers. The choice between these types of wheel balancers will come down to the frequency of your work and what your budget is for your equipment. Here is a quick explanation of these machines:

Static Wheel Balancers: U-579 Self-Calibrating Computer Wheel Balancer

As the name implies, static balancers describe equipment that performs the task without moving the wheel. While a stationary wheel is slightly less accurate and precise, it is easier to work with and more economical. These machines are often smaller and more affordable, the perfect option for a shop on a budget. Whether you are just starting out or want a portable and lightweight balancer that can handle a variety of jobs, this is a great option for you.

3. Two Post Car Lift

Working on vehicles all day long does not have to be back-breaking work. Having a high quality, the powerful lift can take a lot of the strain and effort out of performing maintenance and repairs. However, finding the right lift for your garage or shop can be a daunting task. If you are ready to make the investment in a two-post lift but are not sure where to look, let us help you get the information you need to narrow down your options. Our two post car lift buying guide will start you on the right track toward having a lift you love, helping you make the most of your time so you can get work done easier and quicker every day.

The first thing to consider when looking at two post lifts is whether or not you want a lift with an overhead or baseplate design. Two post lifts operate by using two posts to hoist a platform that lifts the vehicle into the air. With an overhead style, a beam connects the posts at the top, providing a good amount of stability and support while taking up a relatively small amount of space, giving you plenty of room to work and open access to the vehicle. With the baseplate design, a larger plate beneath the vehicle can deny proper access to the vehicle, making it difficult to use accessories such as tall stand supports or a transmission jack. At the same time, baseplate designs have shorter constructions, making them easier to fit in garages with low ceilings. Here is a quick explanation of these machines:

Floor Cover Plate Two Post Vehicle Lift: U-T40 2 Post Lift

U-T40 2 post lifts are designed with safety in mind. These easy-to-use lifting solutions are ideal for garages and shops with low-clearance ceilings. This base model is an exceptional choice for quick oil changes or anyone that needs to be able to use vehicle lanes when not working on customer vehicles. Scissor-style lifts simply won’t do for most service technicians, and under-car clearance can become a big concern. Even with a minimum ceiling height of nine feet, this standard car lift will fit in just about any garage or service bay. Swiveling arms and extending capability make hitting jacking points easier than ever before.

4. Alignment Lift

Alignment auto lifts are a special class of lifting solutions because they come with extra features to make it easier to perform alignment service on cars or trucks. Although alignment lifts were originally designed for automotive repair shops, dedicated hobbyists can also utilize the alignment function of these lifts. Alignment car lifts can be any kind of the previously discussed wheel engaging auto lifts (four-post lifts, scissor lifts, and in-ground lifts) as long as the car or truck tires are resting on some sort of a runway. Special turn plates and slip plates are built right into the runways, so the wheels can easily turn without resistance. For that reason, mobile columns that hold each wheel in their arm assemblies cannot be alignment lifts. Here is a quick explanation of these machines:

Alignment Scissor Lift: U-D45 Solid Steel Structure Wheel Alignment Scissor Lift Built-In Lifting Platforms

The U-D45 Scissor Alignment Lift is a rugged 4.5t capacity scissor alignment lift with the open front design that provides easy access to alignment service and calibration areas. Hydraulic equalization and full support rear member deliver repeatable smooth level lifting. Flush mounted rear slip plates with heavy-duty encapsulated bearings support and offer smooth movement to ease rear alignment adjustments.

4. Wheel Alignment

Having the right equipment ready for any job that comes to your garage is an important aspect of running a successful business. This includes having a full array of wheel alignment equipment. Alignment work is a very common part of routine vehicle maintenance and is necessary for everything from small ATVs and motorcycles to large trucks. Being able to perform this work quickly and easily will save you a lot of time and stress, increasing the productivity of your shop and helping you move through jobs without hassle. Here is our wheel alignment equipment guide that will help you look in the right place when shopping for tools for your garage:

Computerized: PL-3D-5555 Wheel Alignment Machine

Most modern wheel alignment equipment uses a laser-guided system to make precise and accurate readings. Computers make reading alignments easier and quicker than ever, and they are a common choice due to this extra benefit of precision. This also helps make sure the work takes no time at all, and a trained technician can perform a four-wheel alignment in just a few minutes. However, the extra features of these setups also require additional training to be used properly and effectively.

4. Oil Extractor

The oil extractor works by sucking the oil from the crankcase through a thin tube inserted in the dipstick opening. A handle is pumped repeatedly to create a vacuum that pulls the hot oil into an easy-to-carry container. It can then be taken to an auto parts store for recycling. Here is our oil extractor equipment guide that will help you look in the right place when shopping for tools for your garage:

Oil Extractor: HC2097

Fast vacuum speed, capable of high negative pressure, multi-purpose equipment.High-quality cylinder, higher intensity, high grade of transparency as well as high-temperature resistance (able to withstand 80℃ & negative pressure without deforming). A transparent cylinder allows oil observation and measurement. Use compressed air as a power source; guarantee the safety in use, Eco friendly and low power consumption. Vacuum cylinder and oil tank at the same time, increase oil extraction speed. The different diameters of oil suction probes to meet the need for different types of cars. Height adjustable Oil tray lift can be fixed to a desirable height. Can be used with other mechanical engine oil, lubricants as well as temporary storage. Brake fluid, gasoline, diesel, and other liquid contains methanol and ketones or flammable is strictly prohibited.

4. Tire Inflation System

When setting up a new tire repair shop or seeking to replace a tire inflator in an existing shop, it becomes quickly apparent that there are a lot of types of tire inflator to choose from. You should first think about what your intended use for the tire inflator is. Do you plan to put in a garage setting where it will be used frequently for multiple applications, such as tire inflation and driving pneumatic equipment, or will it be used on a mobile service truck? Here is our automatic tire inflator equipment guide that will help you look in the right place when shopping for tools for your garage:

Tire Inflator Machine: HJS701B-LX

Preinstalled electron pressure display,safety,accurate and easy operation.Automatic discharge when over inflation.Manual air inflation and measuring tire pressure with manual type.Automatic air inflation with high speed and high level of accuracy. Buzzing and lighting alarm appears after finishing inflation. The tire bead is not sealed with the tire rim,the the loose clamping mouth, the leakage pipeline and air leakage,all the situation above will lead to lighting and automatic alarm during the air inflation. And the inflator can proceed texting jobs three times at most. The inflator will not execute all the inflation orders until the stoppages are absolutely removed. Adopting a pressure sensor of high accuracy. accuracy2%(full-scale reading).High reliability and waterproof design,which is attractive and durable.

0 notes

Text

Powder Metallurgy Market Witness Substantial Growth during 2019-2026 | Hitachi Chemical, GKN Hoeganaes, Sumitomo Electric

Powder metallurgy is the process of manufacturing different types of components from metal powders. It is used to make filters that require greater strength and impact resistance. The powder metallurgy is also used for the manufacture of inserts of cutting tools and parts of machines such as rotors, gears, bushings, bearings, and magnets. They are also applied in hardware, commercial machinery, hydraulics, and hand tools sectors. Global Powder Metallurgy Market was valued at USD 6.60 Billion in 2018 and is projected to reach USD 10.98 Billion by 2026, growing at a CAGR of 6.53% from 2019 to 2026.

Some of the key players of Powder Metallurgy Market:

Hitachi Chemical Company Ltd, GKN Hoeganaes, Sumitomo Electric Company Ltd., AMES S.A, Fine Sinter Company Ltd, H.C. Starck, Schunk Group, SHW AG, SMC Powder Metallurgy, and Miba AG.

Get Sample Copy of this Report @ https://www.verifiedmarketresearch.com/download-sample/?rid=26054&utm_source=opr&utm_medium=006

The increasing demand for powder metallurgy in the manufacture of automotive components is the major factor booming the powder metallurgy market. Moreover, developing advancements in the innovation in computer and electronic components are going to impel interest for non-ferrous metal powder and growing adoption of 3d printing is expected to boost the market growth. However, complexity in obtaining 3D shapes, high capital investments and the requirement for expensive metal powder feedstocks might hider the market growth.

In the report, the market outlook section mainly encompasses the fundamental dynamics of the market which include drivers, restraints, opportunities, and challenges faced by the industry. Drivers and restraints are intrinsic factors whereas opportunities and challenges are extrinsic factors of the market.

Global Powder Metallurgy Market, By Material

• Ferrous

• Non-ferrous

Global Powder Metallurgy Market, By Application

• Aerospace

• Automotive

• Electrical and Electronics

• Industrial Machinery

• Other Applications

Avail The Discount @ https://www.verifiedmarketresearch.com/ask-for-discount/?rid=26054&utm_source=opr&utm_medium=006

Fundamentals of Table of Content:

1 Report Overview

1.1 Study Scope

1.2 Key Market Segments

1.3 Players Covered

1.4 Market Analysis by Type

1.5 Market by Application

1.6 Study Objectives

1.7 Years Considered

2 Global Growth Trends

2.1 Powder Metallurgy Market Size

2.2 Powder Metallurgy Growth Trends by Regions

2.3 Industry Trends

3 Market Share by Key Players

3.1 Powder Metallurgy Market Size by Manufacturers

3.2 Powder Metallurgy Key Players Head office and Area Served

3.3 Key Players Powder Metallurgy Product/Solution/Service

3.4 Date of Enter into Powder Metallurgy Market

3.5 Mergers & Acquisitions, Expansion Plans

4 Breakdown Data by Product

4.1 Global Powder Metallurgy Sales by Product

4.2 Global Powder Metallurgy Revenue by Product

4.3 Powder Metallurgy Price by Product

5 Breakdown Data by End User

5.1 Overview

5.2 Global Powder Metallurgy Breakdown Data by End User

from Blogger https://ift.tt/2Qxa2dt

via IFTTT

0 notes

Text

mold manufacturers in China | Topworks-China Mold maker | 30% COST LOWER,10 DAYS LESS

Mold manufacturers in China

Many people assume that mold manufacturers in China are going to be of poor quality.

However, a huge number of companies- including multinational corporations- still choose to buy such plastic molds.

Does that mean these companies are naive or making a mistake?

Of course not.

In fact, Topworks plastic mold company, as one of the Top mold manufacturers in China, is capable of making some of the best molds on the market- for a much lower price( 35% COST LOWER,15 BUILDING DAYS LESS) than European and American companies can possibly offer.

China has seen a steady increase in the number of manufacturers of plastic injection molds as the industry has grown to be globally competitive.

Not only do Mold manufacturers in China have the skills required to make superior injection molds, but we also possess excellent English skills for technology and business.

That extends into the Topworks marketing departments, too- most of our sales staff have a strong grasp of CAD drawing, and the technical capability to choose the right mold building project for you.

This allows them to speed up the communication process between Topworks and the customer.

When making a new plastic injection mold, not only in China but all over the world, the process usually starts with a rendering of the final product drawing.

After reading the drawing, engineers can then adjust how to build the mold based on things like the size and structure of the intended parts, the choice of material and how to keep the cost as low as possible – all while considering everything the customer asks for.

China mold maker

Our factory has worked with multiple European and American companies for many years now, so all you need to do is send us your drawings- we’ll be happy to carry out a test to show you what we have to offer.

https://res.cloudinary.com/dl8a9jvpa/video/upload/v1572574321/plastic%20mold.mp4

Mold manufacturing has been around in China for over 30 years, meaning there are plenty of high-quality manufacturers operating today.

Many China mold makers possess the same skills and experience as their western counterparts.

While those injection mold manufacturers in China may only be paid around 65% of what they could make doing the same job in the US, they will still produce top-quality molds that you can really rely on.

" order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]

How should I go about choosing mold manufacturers in China?

To clarify, the reason why a lot of US and European clients are declining to get their plastic injection mold from China is mainly that they are often more affordable (up to 35% cheaper than in their country).

It should not, however, be the only factor you evaluate when weighing your options- you should also consider the following as a second factor to make sure that the mold manufacturers in China you choose are likely to provide you with a comprehensive task when it comes to developing the mold.

- Can they afford to serve customers worldwide?

- Consumers who used the service earlier and gave us their recommendations

- Tool steel quality

- The China mold factory manufacturing plant and their gear are of an industry standard.

- Measures for quality control and validation

- If you opted for a service provider who doesn't understand what they are dealing with, you may not have to waste your time.

- Ability– will the China mold maker be able to carry out the entire task themselves, or will they have to employ a third party to help them with it?

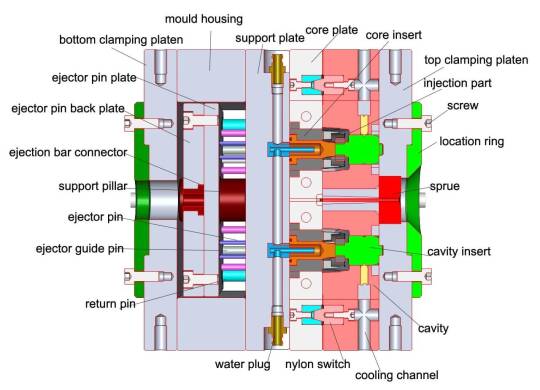

plastic mold structure

The process of China mould making

A design engineer is generally responsible for drawing a component pattern of the new part before the china mold factory can start the actual production of the mold. This blueprint gives the toolmaker an idea of what the new component will look like, so he can start designing the mold before proceeding with the work.

In order to design a mold in a way to replicate the finished part very precisely, the specifications of the final part must be carefully reviewed. By performing the initial design on the computer, the mold designer who worked at mold manufacturers in China can get accurate results.

The designer of a mold has to consider not only the gate on the part, but also the flow of water in the mold, to decide where the parting line will be on the part, and also to determine how the parts will be pushed out of the mold.

Once these decisions have been made, the actual machining steps then begin. There are a variety of operations that need to be carried out in order to make a mold, the raw metal blocks need to be cut into rough dimensions.

To obtain exact dimensions, precision machining is required, with this precision machining, this machining generally entails milling operations, grinding, drilling, and the use of electrical discharge machining or EDM.