#Injection Molding Machine for Basins

Explore tagged Tumblr posts

Text

Double-Color Injection Molds for Household Products 🧴🧼🍱

Aero Mould Co., Ltd. — Professional Plastic Mold Manufacturer with 10+ Years of Experience

We provide precision double-color molds for various household applications:

✅ Double-Color Bottle Cap Molds – Enhanced sealing, eye-catching design ✅ Double-Color Silicone Wash Basin Molds – Flexible & durable, ideal for daily use ✅ Double-Color Lunch Box Molds – Stylish and leak-proof, perfect for food storage ✅ Optimized for Two-Shot Injection Machines ✅ Multi-cavity mold design for high-efficiency production

🛠 All molds are made with high-precision CNC machining, hardened steel, and optimized cooling for faster cycle times.

📩 Contact us for your custom double-color molding solutions!

📧 Email: [email protected] 📞 WhatsApp/WeChat: +86 13989656287

#DoubleColorMold#2KMold#TwoShotMold#HouseholdMold#BottleCapMold#LunchBoxMold#SiliconeMold#PlasticInjectionMold#AeroMould#MoldManufacturer#Overmolding

0 notes

Text

Get the Best Injection Molding Machines at Affordable Price in Ningbo

Are you seeking a high-speed injection molding machine for thin-wall products? If so, don't look any further than China Sanshun. We provide dependable, energy-efficient devices built for accuracy and speedy manufacturing. It is ideal for creating high-quality thin-wall containers and packaging with ease. We are a well-known and trusted manufacturing company in Yinzhou since 1992.

We are a leading injection molding machine manufacturing company. We have Plastic Injection molding machine, Injection Moulding machines, Injection Blow molding machines, Auxiliary Machines and so much more. Our company's purpose is to develop and build Injection Molding machines that give our clients the highest degree of production and profitability, as well as a higher level of service and support, allowing them to optimize their investment return.

We offer high-quality Injection Molding Machines for basins designed for efficient and precise production. Our machines ensure durability, speed, and cost-effectiveness, making them the ideal choice for businesses in the basin manufacturing industry. In a globally competitive environment, we try to continually provide the most efficient and sustainable high-quality bespoke plastic injection molding solutions and complete value.

We are a leading supplier of Pipe Fitting Injection Molding Machine manufacture.Our superior quality machines are designed to ensure the efficient production of various plastic products. We are committed to providing complete solutions for the Plastic Industry, believe in the best, and aim at satisfied and smiling customers locally and worldwide. We provide every customer with effective, dependable solutions.

We are dedicated to satisfying every customer’s needs with our engineering expertise and commitment to customer service and support. Our special machines are widely used by our customers for manufacturing a variety of packaging applications in different industries such as Food, pharmaceuticals, Food box crates, Beverages, and many more.

Our Injection Molding Machine is modern technical equipment complemented by peripherals specific to injection processes and by measurement and control equipment. Our machines are well suited for molding a variety of household products like jugs, glass, plates, cups, flower vases, garbage bins, buckets, laundry baskets, toilet seats, planters, basins, and furniture like chairs, stools, tables, and much more.

So if you need high quality injection molding machines just give us a call at 0086-13857882024 and for more info checkout our website https://www.china-sanshun.com/

#fixed pump injection moulding machine#injection moulding machine#machine learning#injection molding#servo energy saving injection moulding machine#injection molding machines#Injection Blow molding machine#Injection Blow molding machine OEM manufacturers#Injection Molding Machine for Furniture#Injection Molding Machine for Stool

0 notes

Text

Sculpting Functionality and Elegance: The Journey of Plastic Basin Moulds

Plastic basins are a common household item that serves various purposes, from washing dishes to cleaning vegetables. These versatile and functional products come in different shapes, sizes, and designs to suit different needs.

The first step in creating a plastic basin is designing the mould. The design process involves taking into consideration the desired shape, size, and features of the basin. The designer must also take into account factors such as the type of plastic to be used, the production method, and any specific requirements of the client or market.

Once the design is finalized, the next step is the creation of the mould. Plastic basin moulds are typically made from high-quality steel or aluminum. These materials are chosen for their durability and ability to withstand high temperatures and pressures without warping or deforming. The plastic basin mouldis created by machining or milling the steel or aluminum material into the desired shape. Precision is crucial during this process to ensure that the plastic basin mould accurately reflects the design specifications.

Once the plastic basin mould is created, it is time to start the production process. The plastic material, in the form of pellets or granules, is heated and melted to a liquid state. The liquid plastic is then injected into the plastic basin mould at high pressure and cooled rapidly to solidify it. This injection molding process allows for the creation of intricate details and precise shapes, ensuring that the finished basin meets the desired functionality and elegance.

Craftsmanship plays a vital role in creating plastic basins that not only serve their purpose but also add aesthetic value to the user's space. Skilled craftsmen carefully monitor the injection molding process, ensuring that the plastic material is evenly distributed in the plastic basin mould and that there are no defects or deformities in the final product. They also pay attention to details such as the smoothness of the basin's surface, the strength of its handles, and the overall balance and stability of the design.

In addition to functionality and elegance, plastic basin molds also contribute to sustainability efforts. Many manufacturers use recycled plastic materials in the production of basins, reducing the amount of waste generated and conserving valuable resources. Moreover, plastic basins are lightweight and durable, making them energy-efficient in terms of transportation and reducing the need for frequent replacements.

The journey of plastic basin moulds does not end with the production of the first batch. plastic basin mould maintenance and upkeep are essential to ensure the longevity of the plastic basin mould and the quality of the basins produced. Regular cleaning and inspection are conducted to remove any residue or debris that may affect the plastic basin mould's performance. If any repairs or modifications are necessary, skilled technicians handle them promptly to minimize downtime and maintain production efficiency.

In conclusion, plastic basin mould makers are the unsung heroes behind the creation of functional and elegant household products. These molds are carefully designed and crafted to meet the specific requirements of the basin, encompassing factors such as shape, size, and features. Skilled craftsmen play a crucial role in ensuring the quality and aesthetics of the final product. Moreover, plastic basin moulds contribute to sustainability efforts through the use of recycled materials and by producing lightweight and durable basins. So, the next time you use a plastic basin, take a moment to appreciate the craftsmanship and journey that went into creating such a practical and beautiful item.

0 notes

Text

The development of mold technology should serve the requirements

The development of hand basin mould technology should serve the requirements of 'short delivery time', 'high precision', 'good quality' and 'low price' of mold products. The following items are urgently needed to meet this requirement. The development of mold technology should serve the requirements of short delivery time, high precision, good quality and low price of mold products. The following items are urgently needed to meet this requirement:

Comprehensive promotion of CAD/CAM/CAE technology: Mold CAD/CAM/CAE technology is the development direction of mold design and manufacturing. With the development and progress of microcomputer software, the conditions for popularizing CAD/CAM/CAE technology are basically mature. Enterprises will increase CAD/CAM technical training and technical services; further expand the application scope of CAE technology. The development of computers and networks is making it possible to spread CAD/CAM/CAE technology across regions, enterprises, and institutions across the entire industry, realizing the reintegration of technical resources and making virtual manufacturing possible.

High-speed milling processing: The high-speed milling processing developed in foreign countries in recent years has greatly improved the processing efficiency and can obtain high surface finish. In addition, high-hardness modules can also be processed, and it also has the advantages of low temperature rise and small thermal deformation. The development of high-speed milling processing technology has injected new vitality into the manufacture of large-scale cavity molds in the automotive and home appliance industries. At present, it has developed in the direction of higher agility, intelligence and integration.

Mold scanning and digitization system: The high-speed scanning machine and the mold scanning system provide many functions from scanning the model or the actual object to processing the desired model, which greatly shortens the mold manufacturing cycle. Some fast scanning systems can be quickly installed on existing CNC milling machines and machining centers to achieve fast data collection, automatically generate various CNC system processing programs, and different formats of CAD data for reverse engineering of mold manufacturing.

1 note

·

View note

Text

There are numerous things which can be changed

Plastic Injection Molding: Know the benefits Modern industries do require using of the latest technology and equipments to ensure that it is fully functional and operations are conducted smoothly. Plastic injection molding is considered to be among the most efficient procedure to produce complex plastic parts in very high volume. Besides being termed as extremely efficient, it is also stated to be highly flexible when put to use as it comes with the option to change base material at any point of time in the production process.Few interesting qualities of making use of plastic injection moldingHighly efficient and fast: This manufacturing type is said to be efficient and fast, thereby making it to be among the most popular available option to produce plastic items in very high volume. But, the actual time required for creating each and every piece is likely to vary depending upon the actual mold' complexity.

The time that is typically required to develop each time may range between 15-25 seconds in the region.Greater accuracy: Well established plastic injection molding manufacturers claim plastic injection molding to be a highly accurate manufacturing technique, provided there is used precise mold. The accuracy level, on an average is around 0.006”.Minimize waste: This production technique comes with the ability to reduce waste, thereby benefitting the environment, which many tend find it quite appealing. This machine is stated to be not Folding Bucket only just efficient, but also highly appreciated for producing very small wastage amount throughout the production. It just requires using of set amount for creating each and every molded piece. Besides this, if there is generated any type of waste, it can be recycled easily and effortlessly elsewhere using a different project.Minimizes labor costs: The reputed manufacturers do agree the fact that plastic injection molding comes with automated features which actually helps to reduce labor costs significantly.

This is because, this machinery type requires only minimal workforce to ensure proper functioning. On creation of the actual mold, the machinery keeps running continuously and successfully. But it does require proper supervision by the experts.High strength parts: There are parts which are produced Folding basin implementing this production technique, which can vary easily in strength. The best and simple way by which all-round strength of the part can be improved is to include special filler type to base plastic material. It comes with the benefit to reduce liquid plastic volume, thereby resulting in greater durability and strength of the finished product. It also has the capability to control plastic strength, which tends to make it a wonderful option and suit almost every industry effortlessly, especially those which are on the constant lookout for super strong products.Flexible production options: The other benefit is that it has been designed to provide greater flexibility by providing the option to come up with changes as and when necessary throughout the production.

There are numerous things which can be changed, including the color and type of material used.Contacting the plastic injection molding supplier can help know the benefits in details and to make the right decision.

1 note

·

View note

Text

7 efficient and low-cost chemical cold storage methods for removing mold

7 efficient and low-cost chemical cold storage methods for removing mold

In addition to mechanical and physical removal of mildew in cold storage room, there are also chemical removal methods.

¡¡¡¡ However, there are many chemical methods for removing mildew of cold storage room, and most of them are lactic acid, carbon dioxide, ozone, formaldehyde, bleaching powder, sodium fluoride, sodium hydroxybiphenolate, etc.

¡¡¡¡ 1. Lactic acid method: It is a reliable method of disinfection, it can remove mold, sterilize, and deodorize. The method of use is to clean up the warehouse first, use 1 ml of crude lactic acid per cubic meter, add 1 to 2 parts of water to each part of lactic acid, put the mixture in an enamel basin, and place it on an electric stove to heat and evaporate. General requirements Control the liquid medicine to evaporate in about half an hour to 3 hours. Then turn off the electric furnace and seal the Kumen for about 6 to 24 hours so that the lactic acid can fully interact with bacteria or molds in order to achieve the purpose of disinfection. It has been proved by the experiment of the "Experimental Team of Mould and Virus Removal" of the Meat Company of Hunan Provincial Bureau of Commerce. Lactic acid disinfectant is one milliliter per cubic meter, which has a certain effect on removing mold and sterilizing the warehouse. After disinfection, the bacteria in the warehouse are reduced by 70%, and the mold is reduced by 70%.

¡¡¡¡ 2. Carbon dioxide method: It can not kill mold at any concentration, it can only delay the growth of mold. When the concentration of carbon dioxide in indoor air reaches 40% at 0¡ãC, the growth of mold can be completely prevented. However, when its concentration in the air exceeds 20%, the meat becomes discolored due to the formation of denatured hemoglobin. It is generally believed that when the indoor carbon dioxide concentration is 10% at 0¡ãC, the shelf life of chilled meat in the cold storage room can be extended to more than double.

3. Ozone method: It is a better method, it can not only sterilize but also remove mildew and odor. In this way, an ozone generator should be used to crack two atoms of oxygen in the air into two atoms of ozone. The ozone formed is injected into the cold storage, and its concentration is about 1 to 3 mg/m3. However, ozone is a strong oxidant, which can fade lean meat and oxidize fat. At the same time, ozone is irritating to human mucosa, so care should be taken when using it.

¡¡¡¡ 4. Formaldehyde method: Formalin steam method. This method can detoxify and sterilize, but formalin smells so great that if it is absorbed by meat, it cannot be eaten. At the same time, formalin is very irritating to humans, so pay attention to safety when using it. Use this method to empty the library first, clean it up, generally use 15 ml of formalin per cubic meter. There are two ways to turn formalin into steam: one is to put formalin in a closed barrel and use a tube to pass it into the cold storage, and then burn it with fire; the other is to put formalin in an open barrel Put it in the cold storage, the operator will put in an appropriate amount of potassium permanganate or quicklime, and then add some water, when the gas is generated, the personnel go out and close the door. After a few hours of formalin steam sterilization, ammonia water is placed in the room to absorb the smell of formalin, and it is completed after ventilation and sterilization.

¡¡¡¡ 5. Bleaching powder method: It is scrubbed with a 4% bleaching powder solution, which has a good disinfection effect. If adding 7 parts of caustic soda to 5 parts of bleaching powder is better, disinfect for a few hours for ventilation and exhaust.

¡¡¡¡6. Sodium fluoride method: The wall is painted with a mixture of 2% sodium fluoride and 20% kaolin, which can be mold-free for 1 to 2 years at 0¡ãC.

¡¡¡¡7. Sodium hydroxybiphenol method: Use 2% sodium hydroxybiphenol solution to brush and remove mold. This method does not allow the smell to be passed on to the meat and it will not corrode the utensils, but protective measures must be taken when painting.

industrial ice making machine

0 notes

Text

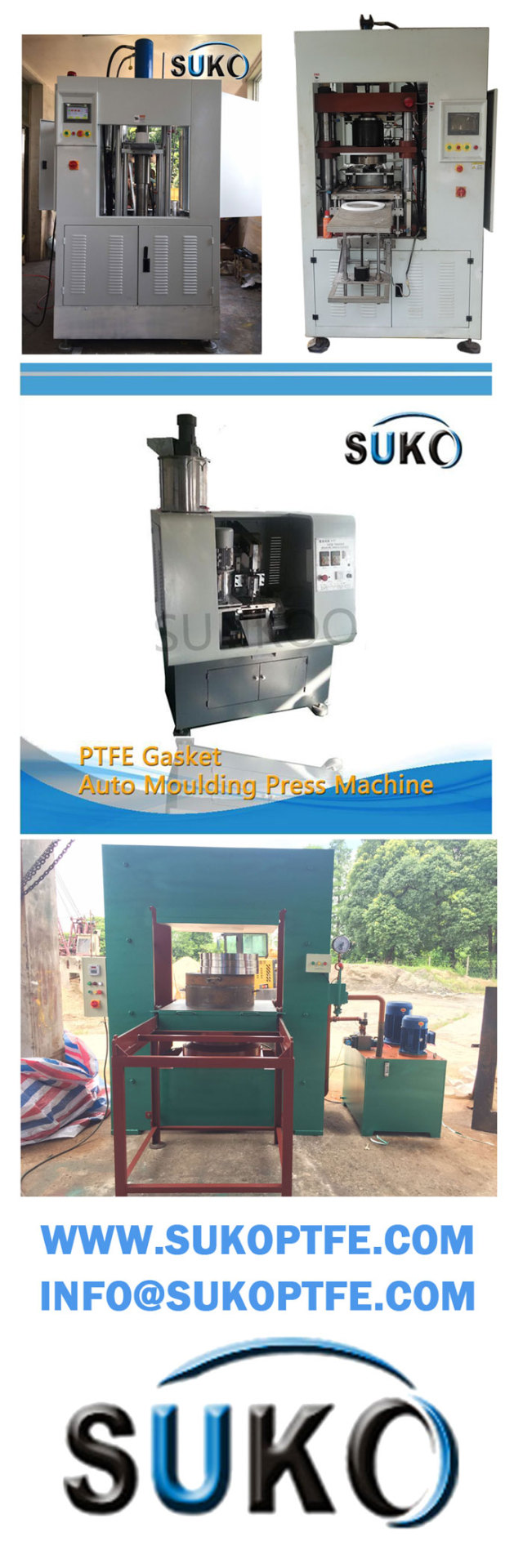

The molding process of the press automatic Moulding Machine

Is moulded plastic processing and molding the application in the city one of the oldest technology. It has a mature production technology, equipment and mold is simple, easy to forming large products, can use multiple modes to improve the production of small parts, etc, in machinery, electronics, transportation and daily life, and many other fields has been widely used.

The market will often see a lot of kinds of Press Moulding Machine, for example: Polymer/PTFE Push press Automatic Moulding Machine, Polymer/PTFE Flange press Automatic Moulding Machine, Polymer/PTFE gasket automatic Moulding Machine, Semi-automatic Molding Machine and so on.

Molding is widely used in the following fields:

Electrical: insulator, switch box, electrical equipment housing, insulation tools, wiring board, etc.

Automobile: lamp shade, front and rear bumper, battery bracket, engine soundproof board, etc.

Railway: window frame of vehicle, toilet components, seats, table tops, siding and roof of carriage, etc.

Construction: water tank, bath products, door panels, purification tank, building template, etc.

Bathroom: bathtub, integral bathroom equipment, integrated wash basin, etc.

And other areas of industry and agriculture.

Molding technology is a method of putting quantitative molding materials (powder, granular or fibrous plastic) into the metal mold and forming products under the action of temperature and pressure. During the molding process, heat and pressure are required to melt (or plasticize) the molding material, fill the mold cavity with flow, and make the resin solidify. The principle is that the process of pressurizing, shaping and heating depends on the closure of the heated mold.

Moulding Machine technology is the oldest molding method in plastic processing technology. Because of its long history, the molding technology has been quite mature, at present in thermosetting plastics and some thermoplastic plastics (fluoroplastics, uhmwpe, polyimide, etc.) processing is still the most widely used and the main position of the molding method. Moulded thermosetting plastic, placed in the cavity of the thermosetting plastic under the action of heat, first changed from solid to melt, melt flow under pressure with the shape of the cavity and cavity has given, as the crosslinking reaction, resin molecular weight increased, the curing degree rise, moulding material viscosity increase gradually and becomes solid, finally becomes demoulding products. Thermoplastic plastic mold pressure, in the previous stage of the situation and thermosetting Plastic the same, but because there is no cross-linking reaction, so in the flow of full cavity, the mold must be cooled to make its molten plastic into a solid with a constant strength can be demodulated into products. Because thermoplastic plastic mold pressing mold needs to alternately heating and cooling, production cycle is long, so thermoplastic products generally choose injection molding method more economic, only in the mold larger plane of Plastic products or because of the flow of thermoplastic plastic injection molding method is difficult to use molding.

In the mold press material filled with the mold cavity flow process, not only the resin flow, the reinforcement material also to flow, so the mold press molding process molding pressure is higher than other process methods, belongs to the high pressure molding. Therefore, it needs not only the hydraulic press which can control the pressure, but also the high strength, high precision and high temperature resistant metal die.

0 notes

Text

Know Why Healthcare Industry is Embracing Plastic Injection Molding China

As you all are aware that plastic injection molding China has a very deep, effective role in reshaping the business of many industries by providing them with sturdy and durable plastic components and parts for their many manufacturing processes, it now has also revolutionized the healthcare industry by providing both researchers and doctors safe and disposable equipment. The inclusion of plastics has greatly influenced the medical industry by improving the lives of patients and enabling the professionals to prevent the diseases from spreading. Use of plastics which are made through plastic injection molding China is becoming very common and fostering the growth of the medical industry. Below you can read and know about the key reasons which is allowing the medical industry to using plastics considerably.

Adaptable

Plastic injection Molding China has made it possible to manufacture such medical devices and equipment that are found efficient and safe and can be very useful for healthcare. Not only the plastics are being found useful in healthcare, but they are also increasingly used for surgical equipment. You can also find the use of plastics in eyeglasses and are applied in MRI machines.

Sterile

Sterilization is quite an important thing for the patient’s health and with the onset of plastic injection molding China process, it has become absolutely possible to maintain sterile environments both in the hospitals and out in the field also. Besides this, the use of plastic packaging for various equipment has allowed the medical professionals to stop spreading the diseases as the storage of the equipment is more secure with plastic and thus helps to maintain the health of the patient.

Disposable

Plastics are preferable for disposal as it helps in preventing diseases as, for example, syringes are now light in weight and can be disposed of after use, similarly, other plastic tools can now be thrown away to further reduce the risk of spreading diseases. Other types of plastic disposable items that are used in hospitals are wash basins, bedding, dining utensils, plastic aprons, cups etc.

0 notes

Text

On Lost Foam Casting

Lost-foam casting (LFC) is a type of evaporative-pattern casting process that is similar to investment casting welding except that the is used for the pattern instead of wax. The LFC process takes advantage of the low boiling point of foam to simplify the investment casting process by removing the need to melt the wax out of the mold.

First, usually a pattern is made from polystyrene foam, which can be done by many different ways. For small volume runs the pattern can be hand cut or machined from a solid block of foam. If the volume is large, then the pattern can be mass-produced by a process similar to injection molding. Pre-expanded beads of polystyrene are injected into a preheated aluminum mold usually at low pressure. Steam is then applied to the polystyrene which causes it to expand more to fill the die. The final pattern is approximately most of air (around 97.5%) air and more or less polystyrene (2.5%). Pre-made pouring basins, runners, and risers can be hot glued to the pattern to finish it.

Next, the foam cluster is coated with ceramic investment, also known as the refractory coating, via dipping, brushing, spraying or flow coating. This coating creates a barrier between the smooth foam surface and the coarse sand surface. Secondly it controls permeability, which allows the gas created by the vaporized foam pattern to escape through the coating and into the sand. Controlling permeability is a crucial step to avoid sand erosion. Finally, it forms a barrier so that molten metal does not penetrate or cause sand erosion during pouring. After the coating dries, the cluster is placed into a flask and backed up with un-bonded sand. The sand is then compacted using a vibration table. Once compacted, the mold is ready to be poured. Automatic pouring is commonly used in LFC, as the pouring process is significantly more critical than in conventional foundry practice.

There is no bake-out phase, as for lost-wax. The melt is poured directly into the foam-filled mold, burning out the foam as it pours. As the foam is of low density, the waste gas produced by this is relatively small and can escape through mold permeability, as for the usual outgassing control.

More information,please click:http://www.qd-evergreen.com

Email: [email protected]

Tel: +86-532-85910688 +86-532-85910686

Fax: +86-532-85910687

Add: No. 6, Xianggang Zhong Road, Qingdao, China 266071

0 notes