#Integral Waterproofing Compound Market

Text

Integral Waterproofing Compound Market is expected to account for a market value of $36.53 million by the end of 2024. Integral waterproofing compound report is a compilation of different segments, including market breakdown by type, end use, and region.

#Integral Waterproofing Compound Market#Integral Waterproofing Compound Report#Integral Waterproofing Compound Industry#Advanced Materials#Bisresearch

0 notes

Text

#Integral Waterproofing Compound Market#Integral Waterproofing Compound Market Trends#Integral Waterproofing Compound Market Growth Analysis#Integral Waterproofing Compound Market Forecast#Integral Waterproofing Compound Market Share#Integral Waterproofing Compound Industry#Integral Waterproofing Compound Market Top Key Players#What is the CAGR of the Integral Waterproofing Compound Market?#What will be the Integral Waterproofing Compound market size by 2028?

0 notes

Text

Rubber-coated fabrics Market: Stretching its Potential with Steady 3.6% Annual Growth

Introduction

Rubber-coated fabrics are integral to a wide range of applications, from protective clothing and industrial coverings to automotive components. The market for these versatile materials is expanding, driven by their unique properties and increasing adoption across various sectors. This article explores the growth trajectory of the rubber-coated fabric market, highlighting key trends and future projections.

Current Market Trends

Market Size and Growth Rate

As of 2023, the rubber-coated fabric market is valued at USD 6.0 billion. It is expected to grow at a compound annual growth rate (CAGR) of 3.6%, reaching USD 7.8 billion by 2030. This growth is fueled by the expanding use of rubber-coated fabrics in numerous applications and industries.

Key Industry Drivers

The demand for rubber-coated fabrics is driven by several factors, including their durability, flexibility, and resistance to various environmental conditions. Industries such as automotive, construction, and textile manufacturing are major consumers of these materials, further boosting market growth.

Download Sample Report @ https://intentmarketresearch.com/request-sample/rubber-coated-fabric-market-3218.html

Market Segmentation

By Application

Rubber-coated fabrics are used in a variety of applications, including:

Automotive: For seat covers, airbags, and weather-resistant parts.

Construction: For tarpaulins, waterproof coverings, and protective gear.

Textiles: For fashion items, industrial uniforms, and accessories.

By Type of Rubber

Different types of rubber are used in coating fabrics, including:

Natural Rubber: Known for its elasticity and resilience.

Synthetic Rubber: Offers specific properties like oil resistance and durability.

By Region

The market is segmented geographically into:

North America: Strong demand driven by automotive and construction sectors.

Europe: Growth influenced by stringent environmental regulations and technological advancements.

Asia-Pacific: Rapid expansion due to industrial growth and increasing infrastructure projects.

Latin America and Middle East & Africa: Emerging markets with growing adoption rates.

Technological Advancements

Innovations in Coating Technologies

Recent advancements in coating technologies have improved the performance and versatility of rubber-coated fabrics. Innovations such as enhanced adhesion techniques and the development of new rubber compounds are driving market growth.

Impact on Product Performance

Technological improvements have led to better resistance to abrasion, weathering, and chemical exposure, making rubber-coated fabrics more suitable for demanding applications.

Market Share Analysis

Market share analysis reveals a competitive landscape with key players investing in research and development, expanding their product portfolios, and entering new markets to strengthen their positions.

Economic Impact

Contribution to Different Sectors

The rubber-coated fabric industry significantly contributes to various sectors by providing essential materials for protective clothing, industrial applications, and consumer products.

Job Creation and Industry Growth

The industry's growth has led to job creation in manufacturing, research and development, and sales, contributing to overall economic development.

Environmental Impact

Sustainability of Rubber-Coated Fabrics

The environmental impact of rubber-coated fabrics is a growing concern. Manufacturers are focusing on sustainability by using eco-friendly materials and processes.

Eco-Friendly Manufacturing Practices

Efforts are being made to reduce waste, recycle materials, and lower the carbon footprint of manufacturing processes, making rubber-coated fabrics more environmentally sustainable.

Access Full Report @ https://intentmarketresearch.com/latest-reports/rubber-coated-fabric-market-3218.html

Challenges Facing the Market

Raw Material Costs

Fluctuations in the cost of raw materials, such as rubber and chemicals, can impact the pricing and profitability of rubber-coated fabrics.

Regulatory Issues

Compliance with environmental and safety regulations is essential for manufacturers. Navigating these regulations can be challenging and may affect market dynamics.

Opportunities for Growth

Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, present significant growth opportunities due to industrialization and infrastructure development.

Technological Innovations

Continued innovation in coating technologies and material science offers opportunities for developing advanced products with enhanced properties and applications.

Future Market Projections

Forecasting Market Trends

The rubber-coated fabric market is expected to continue its growth trajectory, driven by technological advancements and increasing demand across various industries.

Expected Market Size by 2030

With a projected CAGR of 3.6%, the market is set to reach USD 7.8 billion by 2030, reflecting ongoing growth and expansion.

Consumer Guide

Choosing the Right Rubber-Coated Fabric

When selecting rubber-coated fabrics, consider factors such as durability, resistance to environmental conditions, and specific application requirements.

Factors to Consider

Key considerations include the type of rubber used, coating technology, and the intended use of the fabric. Consulting with suppliers and reviewing product specifications can help make an informed choice.

Competitive Landscape

Analysis of Major Competitors

The competitive landscape of the rubber-coated fabric market includes several key players with diverse strategies. Analyzing their strengths, weaknesses, and market strategies provides insights into the industry's dynamics.

Strategic Initiatives

Companies are pursuing various strategic initiatives, such as partnerships, acquisitions, and investments in R&D, to enhance their market positions and drive growth.

Conclusion

The rubber-coated fabric market is poised for significant growth, driven by technological advancements, increasing demand, and evolving industry needs. As the market expands, opportunities for innovation and development will continue to emerge, shaping the future of this dynamic sector.

Contact Us

US: +1 463-583-2713

0 notes

Text

Work Boots Market Overview: Growth Factors and Future Trends (2023-2032)

The Work Boots Market is projected to grow from USD 13,151.16 million in 2024 to USD 26,300.83 million by 2032, reflecting a compound annual growth rate (CAGR) of 9.05%.

The work boots market is influenced by several dynamic factors that drive its growth, shape trends, and present challenges. A key driver in the market is the increasing emphasis on workplace safety regulations across industries such as construction, manufacturing, and mining. Governments and regulatory bodies are enforcing stricter safety standards, making protective footwear, like work boots, a mandatory requirement. This regulatory push is encouraging both employers and workers to invest in high-quality work boots, fueling market demand.

Another significant factor driving the work boots market is the growing awareness of workplace safety among workers themselves. With the rise in occupational hazards and workplace injuries, workers are becoming more conscious of the importance of protective gear, leading to a higher adoption rate of work boots. Additionally, the development of advanced materials and technology in footwear design is boosting market growth. Innovations such as lightweight composite toe caps, slip-resistant soles, and anti-fatigue insoles are enhancing the comfort and functionality of work boots, making them more appealing to a broader range of consumers.

Here are the work boots market dynamics presented:

Regulatory Enforcement: Stricter workplace safety regulations across industries such as construction, manufacturing, and mining are mandating the use of protective footwear, driving market demand.

Worker Safety Awareness: Increased awareness of occupational hazards among workers is leading to a growing adoption of work boots as essential safety gear.

Technological Innovations: Advancements in materials and footwear technology, including lightweight composite toe caps, slip-resistant soles, and anti-fatigue insoles, are enhancing the performance and appeal of work boots.

Market Expansion in Emerging Economies: As industries expand in emerging markets, the demand for protective footwear is rising, contributing to the global growth of the work boots market.

Customization and Comfort: The growing demand for customizable and comfortable work boots, tailored to specific job requirements and user preferences, is shaping market trends.

Rise of E-commerce: The increasing penetration of e-commerce platforms is providing consumers with easy access to a wide range of work boots, boosting market growth.

Brand Loyalty and Reputation: Established brands with a strong reputation for quality and safety are gaining consumer trust, influencing purchasing decisions in the market.

Environmental Concerns: The demand for eco-friendly and sustainable materials in work boots is on the rise, as consumers become more environmentally conscious.

Cost Constraints: The relatively high cost of technologically advanced work boots may limit their adoption, especially in price-sensitive markets.

Counterfeit Products: The proliferation of counterfeit and substandard work boots poses a significant challenge, potentially compromising safety and eroding consumer trust in the market.

The work boots market is highly competitive, with numerous global and regional players vying for market share. The competitive landscape is characterized by factors such as product innovation, brand reputation, pricing strategies, and distribution networks.

Product Innovation: Innovation is a key competitive factor, with companies investing in research and development to introduce new features that enhance safety, comfort, and durability. For example, advancements such as lightweight composite toe caps, slip-resistant outsoles, waterproof materials, and anti-fatigue technology are increasingly being integrated into work boots to meet the evolving demands of end-users.

Brand Loyalty and Reputation: Established brands with a long history of quality and reliability enjoy strong customer loyalty, which is a significant competitive advantage. Companies like Red Wing Shoe Company and Timberland PRO have built reputations for producing durable and high-performance work boots, which allows them to maintain a loyal customer base.

Pricing Strategies: The market includes a range of products at different price points, from premium work boots to more affordable options. While premium brands focus on delivering high-quality, technologically advanced products, there is also significant competition in the mid-range and budget segments, where price-sensitive consumers are the primary target. Companies must carefully balance product quality and cost to remain competitive across different market segments.

Distribution Networks: Effective distribution is crucial in the work boots market, with companies leveraging both physical retail channels and online platforms to reach consumers. E-commerce is playing an increasingly important role, allowing companies to expand their reach and offer a wider range of products to customers globally. Brands like Skechers USA, Inc. and Caterpillar Inc. have capitalized on online sales channels to enhance their market presence.

Sustainability and Eco-friendly Products: As environmental concerns grow, some companies are differentiating themselves by offering eco-friendly and sustainable work boots. This includes the use of recycled materials, environmentally friendly manufacturing processes, and ethical labor practices. Brands that can align with these values may gain a competitive edge, particularly in markets like Europe, where environmental awareness is high.

Market Consolidation: The work boots market has seen some consolidation through mergers and acquisitions, as larger companies seek to expand their product portfolios, enter new markets, and strengthen their competitive position. This trend may continue as companies aim to enhance their global footprint and diversify their offerings.

Key Player Analysis

Black Diamond Group

Timberland PRO

KEEN Utility

Skechers

Alpha Gripp

Wolverine

Columbia

Mksafety

Reebok

DKMILY DRY

More About Report- https://www.credenceresearch.com/report/work-boots-market

The work boots market displays varying dynamics across different regions, influenced by factors such as industrial activity, regulatory frameworks, and consumer preferences.

North America: North America, particularly the United States and Canada, is a significant market for work boots, driven by stringent occupational safety regulations and a well-established industrial base. The region's focus on worker safety, coupled with high awareness among employers and employees, supports strong demand for premium work boots. The presence of leading manufacturers and the adoption of advanced technologies in footwear also contribute to the market's growth in this region.

Europe: Europe represents another major market for work boots, with countries like Germany, the UK, and France leading the way. The region's robust manufacturing and construction sectors, along with stringent safety standards enforced by organizations such as the European Union, drive demand for high-quality work boots. Additionally, there is a growing trend towards eco-friendly and sustainable work boots, reflecting broader environmental consciousness among European consumers.

Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in the work boots market, fueled by expanding industrialization and construction activities in countries such as China, India, and Japan. The region's growing awareness of workplace safety, coupled with the adoption of safety regulations in emerging economies, is boosting the demand for protective footwear. However, the market is price-sensitive, and the presence of low-cost, locally manufactured products often competes with international brands.

Latin America: In Latin America, the work boots market is driven by increasing industrialization and infrastructure development in countries like Brazil and Mexico. However, the market faces challenges such as economic fluctuations and lower levels of regulatory enforcement compared to North America and Europe. Despite these challenges, growing awareness of worker safety and the expansion of the construction and mining sectors are expected to drive market growth.

Middle East and Africa: The work boots market in the Middle East and Africa is growing steadily, supported by the region's construction boom and expanding oil and gas industry. Countries like Saudi Arabia, the UAE, and South Africa are key markets where industrial activities and infrastructure projects are on the rise. However, the market faces challenges such as limited consumer awareness and lower purchasing power in certain areas, which can impact the adoption of high-quality work boots.

Segments:

Based on Material:

Leather

Rubber

Plastic

Waterproof

Polyurethane

Based on Product:

Shoes

Boots

Based on Application:

Construction

Manufacturing

Oil and Gas

Chemicals

Transport

Mining

Food

Pharmaceutical

Other Applications

Browse the full report – https://www.credenceresearch.com/report/work-boots-market

Browse Our Blog: https://www.linkedin.com/posts/credenceresearch_workboots-safetyfootwear-protectivegear-activity-7230432873739124738-SbOF?utm_source=share&utm_medium=member_desktop

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Raw Material For Sanitary Pad Napkin

Introduction: Sanitary pad napkins are a vital product in the feminine hygiene market, providing comfort and protection during menstruation. The quality and effectiveness of these products heavily depend on the raw materials used in their manufacturing. This blog will explore the various raw materials essential for making high-quality sanitary pads, their roles, and their benefits. Understanding these components helps manufacturers create superior products that meet the needs and expectations of consumers.

Key Raw Materials for Sanitary Pad Napkins:

Absorbent Core:

Super Absorbent Polymer (SAP): SAP is a highly absorbent material that can retain large amounts of liquid, keeping the pad dry and comfortable. It is crucial for preventing leaks and ensuring the pad's effectiveness.

Pulp: Wood pulp or fluff pulp is used to provide bulk and additional absorbency to the core. It helps distribute the liquid evenly throughout the pad.

Top Sheet:

Non-Woven Fabric: This soft and breathable fabric comes into direct contact with the skin, ensuring comfort and minimizing irritation. It quickly wicks moisture away from the surface, keeping the skin dry.

Acquisition and Distribution Layer (ADL):

Non-Woven Fabric or Foam: The ADL is a secondary layer that helps distribute the liquid evenly throughout the absorbent core, preventing pooling and enhancing the pad's overall performance.

Back Sheet:

Polyethylene (PE) Film: The back sheet is a waterproof layer that prevents liquid from leaking out of the pad. It ensures that the wearer’s clothes remain dry and protected.

Biodegradable Film: For environmentally conscious products, biodegradable back sheets made from materials like polylactic acid (PLA) are used to reduce environmental impact.

Adhesives:

Hot Melt Adhesive: This adhesive is used to bond the layers of the sanitary pad together, ensuring the integrity and stability of the product. It is also used for the adhesive strips that secure the pad to underwear.

Release Paper:

Silicone-Coated Paper: This paper covers the adhesive strips on the back of the pad. It protects the adhesive until the pad is ready to be used, ensuring ease of application.

Elastic and Stretch Materials:

Elastic Bands: These materials are used in the wings and edges of the pad to provide a secure and comfortable fit. They help prevent leaks by keeping the pad in place.

Fragrances and Odor Control:

Odor-Absorbing Compounds: These materials help neutralize odors, providing a fresh and pleasant experience for the user.

Benefits of High-Quality Raw Materials:

Comfort: High-quality materials ensure that the pad is soft, breathable, and comfortable to wear, reducing the risk of irritation and discomfort.

Protection: Superior absorbent materials and effective moisture barriers prevent leaks, keeping the wearer dry and confident.

Hygiene: Materials that wick away moisture and control odors maintain better hygiene and reduce the risk of infections.

Sustainability: Eco-friendly materials, such as biodegradable films and natural fibers, help reduce the environmental impact of sanitary pads.

Performance: High-quality raw materials enhance the overall performance of the pad, ensuring reliability and user satisfaction.

Conclusion: The raw materials used in sanitary pad napkins are crucial in determining the product's comfort, protection, and overall quality. By choosing high-quality materials, manufacturers can create superior products that meet the diverse needs of consumers. At Favourite Fab, we are dedicated to providing top-notch raw materials for sanitary pad manufacturing. Explore our range of materials and discover how they can enhance your products and support your commitment to quality and sustainability.

Factory

Gata No. 34, Mauza Khadwai, Tehsil Kirawali, Runkata, Agra, Uttar Pradesh, India-282007 📩 [email protected]

Contact no

918800775462

https://favouritehub.com/product/sanitary-pad-raw-material/

0 notes

Text

WPC Wall Panels: Waterproof, Sustainable Beauty for Interiors & Exteriors

When it comes to enhancing the aesthetics and functionality of your space, choosing the right wall panels is crucial. WPC (Wood-Plastic Composite) wall panels have emerged as a popular choice for both interior and exterior applications due to their unique combination of beauty, durability, and sustainability. Singhal Industries, a leading manufacturer of flexible packaging products, offers high-quality WPC wall panels that cater to various design and structural needs. In this comprehensive guide, we will explore the features, benefits, applications, and installation process of WPC wall panels, demonstrating why they are an excellent choice for modern homes and commercial spaces.

What Are WPC Wall Panels?

WPC wall panels are made from a composite material that combines wood fibers and thermoplastics. This blend results in a product that captures the aesthetic appeal of natural wood while offering enhanced durability and low maintenance requirements. The manufacturing process involves mixing the wood fibers with the thermoplastics and other additives, which are then extruded into panels of various sizes and designs.

Features of WPC Wall Panels

1. Waterproof and Moisture Resistant

One of the standout features of WPC wall panels is their resistance to water and moisture. Unlike traditional wood, WPC does not absorb water, making it an ideal choice for areas prone to dampness such as bathrooms, kitchens, and exteriors.

2. Durable and Long-Lasting

WPC wall panels are known for their exceptional durability. They resist rotting, warping, and cracking, which are common issues with natural wood. This durability ensures that the panels maintain their appearance and structural integrity over time.

3. Eco-Friendly

Sustainability is a key advantage of WPC wall panels. They are made from recycled materials, including wood waste and plastic, reducing the need for virgin resources. Additionally, WPC panels are recyclable at the end of their lifecycle, contributing to a circular economy.

4. Aesthetic Versatility

WPC wall panels come in a variety of colors, textures, and finishes, allowing for versatile design options. Whether you prefer a natural wood look or a more contemporary finish, WPC panels can complement any design style.

5. Low Maintenance

Maintaining WPC wall panels is straightforward. They do not require painting, sealing, or frequent cleaning. A simple wipe with a damp cloth is usually sufficient to keep them looking new.

6. Termite and Pest Resistant

WPC panels are resistant to termites and other pests, making them a suitable choice for areas where wood-boring insects are a concern.

Benefits of Using WPC Wall Panels

1. Cost-Effective

While the initial cost of WPC wall panels may be higher than some alternatives, their longevity and low maintenance needs make them a cost-effective solution in the long run. Homeowners and businesses can save on repair, replacement, and upkeep costs.

2. Energy Efficiency

WPC panels provide excellent insulation, helping to maintain comfortable indoor temperatures. This energy efficiency can lead to reduced heating and cooling costs, contributing to overall savings.

3. Enhanced Property Value

Installing high-quality WPC wall panels can enhance the aesthetic appeal and durability of a property, potentially increasing its market value. Buyers and tenants are often willing to pay a premium for properties with low-maintenance, sustainable features.

4. Versatile Applications

WPC wall panels are suitable for a wide range of applications. They can be used for residential interiors and exteriors, commercial buildings, public spaces, and even industrial settings. Their versatility makes them a go-to solution for architects and designers.

5. Improved Indoor Air Quality

Since WPC wall panels do not emit volatile organic compounds (VOCs) and resist mold and mildew growth, they contribute to healthier indoor air quality. This is especially important in homes and workplaces where occupants spend significant time indoors.

Applications of WPC Wall Panels

1. Residential Interiors

Wpc wall panel size can transform the look of living rooms, bedrooms, kitchens, and bathrooms. Their variety of designs allows homeowners to create unique and personalized spaces. In moisture-prone areas like bathrooms, their waterproof nature is particularly advantageous.

2. Residential Exteriors

For exterior cladding, WPC panels offer protection against the elements while enhancing curb appeal. They withstand harsh weather conditions, including rain, sun, and temperature fluctuations, without deteriorating.

3. Commercial Spaces

In commercial settings such as offices, retail stores, and restaurants, WPC wall panels provide a modern and professional appearance. Their durability ensures they can withstand high traffic and constant use without showing signs of wear.

4. Public Buildings

Public buildings, including schools, hospitals, and government offices, benefit from the durability and low maintenance of WPC wall panels. These spaces require materials that can endure heavy use and still look presentable.

5. Industrial Settings

In industrial environments, where robustness and easy maintenance are crucial, WPC panels are an ideal choice. They can be used in warehouses, factories, and workshops to create clean and organized spaces.

Installation Process of WPC Wall Panels

Installing WPC wall panels is a relatively straightforward process that can be completed by professionals or skilled DIY enthusiasts. Here is a step-by-step guide to the installation process:

1. Preparation

Measure the Area: Start by measuring the wall area where the panels will be installed. This helps determine the number of panels needed.

Clean the Surface: Ensure the wall surface is clean, dry, and free from any debris or obstructions.

2. Cutting the Panels

Measure and Mark: Measure and mark the panels to fit the wall dimensions. Use a saw to cut the panels to the required size.

Safety Precautions: Wear safety gear, such as goggles and gloves, while cutting the panels.

3. Installing the Panels

Start from a Corner: Begin installation from one corner of the wall, ensuring the first panel is level.

Fixing Method: Depending on the type of WPC panel, you can use adhesive, screws, or a clip system to attach the panels to the wall.

Seamless Fit: Ensure each panel fits seamlessly with the adjacent panels, adjusting as necessary.

4. Finishing Touches

Trimming and Edging: Use trim pieces or edging strips to cover the edges and corners for a polished look.

Cleaning: Wipe down the installed panels to remove any dust or debris from the installation process.

Why Choose Singhal Industries for WPC Wall Panels?

Singhal Industries is a trusted manufacturer of flexible packaging products, including high-quality Wpc wall panel material. Here’s why you should choose Singhal Industries for your WPC wall panel needs:

1. Commitment to Quality

We adhere to stringent quality control measures to ensure that every WPC panel meets the highest standards of durability, aesthetics, and performance.

2. Sustainable Practices

Our manufacturing process prioritizes sustainability. We use recycled materials and eco-friendly production methods to minimize our environmental impact.

3. Customization Options

Singhal Industries offers a wide range of customization options, allowing you to choose the perfect color, texture, and finish for your project.

4. Expertise and Experience

With years of experience in the industry, we have the expertise to provide solutions that meet the unique requirements of our clients, from residential to industrial applications.

5. Customer Support

We are dedicated to providing excellent customer support, from helping you choose the right products to offering installation guidance and after-sales service.

Conclusion

WPC wall panels from Singhal Industries represent the perfect blend of beauty, durability, and sustainability. Whether you are looking to enhance the interior of your home, add curb appeal to your exterior, or create a professional and modern look for a commercial space, our Wpc panels for exterior walls offer a versatile and reliable solution. With their waterproof properties, eco-friendly composition, and low maintenance requirements, WPC wall panels are an investment in both aesthetics and functionality.

Choose Singhal Industries for your WPC wall panel needs and experience the difference that high-quality, sustainable products can make in transforming your space. For more information, visit our website or contact our customer service team today.

FAQS

1. What are WPC wall panels made of?

WPC wall panels are made from a composite material consisting of wood fibers and thermoplastics. This combination provides the panels with the aesthetic appeal of natural wood and the durability and low maintenance benefits of plastic.

2. Are WPC wall panels waterproof?

Yes, WPC wall panels are waterproof and highly resistant to moisture. This makes them ideal for use in areas prone to dampness, such as bathrooms, kitchens, and exterior applications.

3. How do WPC wall panels contribute to sustainability?

WPC wall panels are eco-friendly as they are made from recycled materials, including wood waste and plastic. They are also recyclable at the end of their lifecycle, supporting sustainable building practices.

4. Can WPC wall panels be used for both interior and exterior applications?

Yes, WPC wall panels are versatile and can be used for both interior and exterior applications. They are designed to withstand various environmental conditions, making them suitable for residential, commercial, and industrial uses.

5. How do you maintain WPC wall panels?

WPC wall panels are low maintenance. They do not require painting, sealing, or frequent cleaning. A simple wipe with a damp cloth is usually sufficient to keep them looking new and clean.

0 notes

Text

Binoculars Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Binoculars Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Binoculars Market showcased a significant presence, boasting a valuation of US$ 780.1 billion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-binoculars-market/

Projected Growth: Projections suggest that the Binoculars Market will continue its upward trajectory, with a projected value of US$ 1065 billion by 2031. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 3.5%, reflecting a steady and robust growth rate for the Binoculars Market over the coming years.

Technology Adoption:

The binoculars market has witnessed significant technology adoption, driven by the need to enhance user experience and performance across various applications. Modern binoculars now incorporate advanced optical technologies such as phase-corrected prisms, multi-coated lenses, and extra-low dispersion (ED) glass to deliver superior image clarity and brightness. Digital integration is also on the rise, with features like built-in cameras, GPS, and augmented reality becoming more common. Image stabilization technology has been increasingly adopted to reduce hand tremors and provide a steadier view, especially in high-magnification models. These technological advancements have broadened the appeal of binoculars, making them suitable for a wider range of users and applications.

Application Diversity:

The adoption of binoculars spans a wide range of applications, contributing to their sustained demand across various sectors. Binoculars are extensively used in recreational activities such as birdwatching, hiking, and sports events. They are also crucial in professional fields like military operations, law enforcement, search and rescue missions, and scientific research. Additionally, binoculars are popular in marine navigation and astronomy, where precision and clarity are paramount. This diverse application landscape underscores the versatility and indispensability of binoculars in both leisure and professional contexts.

Consumer Preferences:

Consumer preferences in the binoculars market have evolved significantly, with a strong inclination towards high-performance, lightweight, and durable models. Modern consumers prioritize optical quality, including factors such as magnification, lens coating, and field of view. There is a growing demand for compact and portable designs that offer ease of use without compromising on performance. Additionally, features like waterproofing, fog resistance, and rugged construction are highly valued for outdoor and extreme conditions. Consumers also seek ergonomic designs that provide comfort during extended use and appreciate added functionalities such as image stabilization and digital integration.

Technological Advancements:

Technological advancements have been a driving force in the binoculars market, leading to the development of sophisticated and user-friendly models. Innovations include the use of advanced lens coatings to enhance light transmission and reduce glare, resulting in clearer and brighter images. The incorporation of high-definition (HD) and extra-low dispersion (ED) glass has significantly improved optical performance. Digital binoculars with integrated cameras, GPS, and augmented reality features have emerged, offering users the ability to capture and share images, as well as overlay digital information on their view. Additionally, advancements in manufacturing techniques have enabled the production of lighter and more durable materials, enhancing the portability and resilience of binoculars.

Market Competition:

The binoculars market is highly competitive, with numerous manufacturers striving to offer the best combination of quality, performance, and value. Leading brands compete by continuously innovating and expanding their product lines to cater to different user segments and price points. Key competitive strategies include investing in research and development to introduce cutting-edge features, enhancing distribution networks to reach a broader customer base, and providing excellent customer service and after-sales support. Collaborations and partnerships with retailers, online platforms, and professional organizations also play a significant role in gaining market share and brand recognition.

Environmental Considerations:

Environmental considerations are becoming increasingly important in the binoculars market as consumers and manufacturers alike seek sustainable and eco-friendly options. Manufacturers are adopting greener production practices, such as using recyclable materials, reducing waste, and minimizing the use of harmful chemicals in lens coatings. Energy-efficient manufacturing processes and sustainable packaging are also being prioritized to reduce the overall environmental footprint. Additionally, some companies are exploring the use of biodegradable materials and offering repair and recycling programs to extend the lifespan of binoculars and reduce environmental impact. These efforts not only address consumer demand for sustainable products but also contribute to the broader goal of environmental conservation.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Pentax Vortex

Nikon

Carl Zeiss Binoculars

Steiner Binoculars

Celestron

Hawke

Bushnell

Krevia

Swarovski

Canon

The research report provides a comprehensive analysis of the Binoculars Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-binoculars-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Waterproof Coatings Market Trends: Riding the Tide of Innovation

Waterproof Coatings: A Barrier Against Moisture To Prevent Water And Moisture

The Evolution of Waterproof Coatings

Waterproof coats serve as a protective barrier that prevents water and moisture from penetrating surfaces like fabrics, concrete, wood, and more. The development of modern waterproofing techniques and materials allows us to keep everything from phones to buildings dry even in wet conditions. Let's take a deeper look at how waterproof coats work and the technologies behind them.

Repelling Water Through Chemistry

At the molecular level, waterproof coats use specific chemical formulations to repel water. Many coatings contain polymers that are hydrophobic, meaning they do not attract water molecules. Silicones are a commonly used hydrophobic polymer in waterproofing products. The large silicone molecules form a tight, flexible barrier that prevents water from passing through but still allows surfaces to breathe. Other chemicals like fluoropolymers also exhibit exceptional water-repellent properties due to the structure of their molecules. These water-repellent chemicals are integral components of modern waterproof coats.

Advanced Barrier Technologies

Beyond chemical composition, modern waterproofing technologies create physical barriers against moisture as well. Many coatings deposit ultra-thin, crack-free films only a few nanometers thick using plasma or other deposition processes. These barrier layers are completely non-porous so no water can penetrate no matter how small the pores might be. Additional barrier methods employ multiple coating layers that self-heal any small defects. Self-healing polymers can replenish damaged areas of a waterproof barrier on their own over time. Networked barrier coatings also work to repel moisture even if microscopic cracks or holes occur.

Applications in Daily Life

Waterproof coats enable all kinds of applications we rely on every day. They protect our phones, watches, sports gear and more from water damage. Specialist coats and boots with waterproof membranes keep outdoor enthusiasts dry in rain or snow. Waterproof fabrics allow us to enjoy activities like kayaking without worrying about getting soaked. Waterproof construction materials like sealants form barriers around buildings, ensuring interiors stay protected. Even paper and cardboard products like packaging can be coated to withstand moisture. Thanks to advanced waterproofing technologies, we can now go about our daily lives with confidence in nearly any conditions.

Endurance Testing for Real-World Performance

Guaranteeing a coating's waterproof performance requires stringent testing methods. Standard tests involve controlled exposure to water sprinkling or submersion over extended periods. Testing evaluates factors like barrier integrity, adhesion strength after water contact and flexibility at low temperatures where coatings may crack. Some testing regimes involve over 5000 hours of water exposure to simulate 15+ years of real-world conditions. Advanced testing uses specialized equipment like pressure cookers and weathering chambers that can accelerate corrosion and wear equivalents. Xenon arc light exposure reproduces years of natural weathering in only weeks. Combined environmental testing helps develop coatings proven to withstand demanding outdoor applications for many years.

Eco-Friendly Formulations for Sustainability

As waterproofing technologies evolve, the demand grows for greener, more sustainable coating options. Researchers strive to replace harmful volatile organic compounds (VOCs) with eco-friendly alternatives. Some new bio-based hydrophobic polymers come from plant oils rather than petrochemical sources. Silicone replacements using renewable plant-based components are also under development. Water-based polymer emulsions eliminate solvents for reduced toxicity. Self-curing coatings use ultraviolet light or moisture itself to cure rather than heat sources. Nano-additives allow thinner, more efficient coatings to achieve the necessary performance. Continued innovation will drive the industry towards providing high performance without compromising environmental sustainability.

0 notes

Text

Overview of the Global Textile Coating Market

In the vast tapestry of industries that drive the global economy, few are as integral and diverse as the textile industry. Within this dynamic sector lies a lesser-known yet crucial segment - the Textile Coating Market. Textile coating plays a pivotal role in enhancing the functionality, durability, and aesthetic appeal of fabrics, making it a vital part of various industries ranging from fashion to automotive and healthcare. Let's delve into an overview of this market, exploring its key drivers, trends, and future prospects.

Understanding Textile Coating

Textile coating involves the process of applying a layer of polymer or other substances to a textile substrate. This coating can serve multiple purposes, such as waterproofing, flame resistance, antimicrobial properties, UV protection, and even aesthetic enhancements like adding sheen or texture. The application of coatings can transform ordinary fabrics into high-performance materials suitable for a wide array of applications.

Market Size and Growth

The global Textile Coating Market has witnessed significant growth in recent years and is projected to continue expanding. Factors such as increasing demand for coated textiles in industries like sports and outdoor apparel, automotive interiors, and medical textiles are driving this growth. According to recent market reports, the Textile Coating Market was valued at approximately USD 5.4 billion in 2020 and is expected to reach USD 7.2 billion by 2026, with a compound annual growth rate (CAGR) of around 4.8% during the forecast period.

Key Drivers of Growth

Several factors contribute to the growth of the Textile Coating Market:

Demand for Technical Textiles: The rise in demand for technical textiles, which require specialised coatings for functionalities like moisture management, durability, and insulation, is a major driver. These textiles find applications in sectors such as healthcare, construction, and geotextiles.

Advancements in Coating Technologies: Ongoing advancements in coating technologies, such as nanotechnology and plasma treatments, are expanding the possibilities for innovative and high-performance coated textiles. These technologies offer improvements in durability, breathability, and environmental sustainability.

Increasing Focus on Sustainability: With growing environmental concerns, there is a notable shift towards sustainable coating materials and processes. Water-based coatings and bio-based polymers are gaining traction as eco-friendly alternatives to traditional solvent-based coatings.

Rising Demand in Automotive Industry: The automotive sector is a significant consumer of coated textiles, using them in vehicle interiors, seating, and airbags. As the automotive industry evolves with the introduction of electric vehicles and autonomous driving, the demand for specialised coatings is expected to increase.

Regional Insights

The Textile Coating Market exhibits regional variations influenced by factors such as economic development, manufacturing capabilities, and end-user industries. Some key regional insights include:

Asia-Pacific: Dominating the market, Asia-Pacific accounts for a substantial share due to its thriving textile industry, particularly in countries like China, India, and Vietnam. The region's rapid industrialization and expanding automotive and construction sectors contribute to the demand for coated textiles.

North America: The region boasts a strong presence of leading manufacturers and technological innovators in textile coating. The demand for protective and performance textiles in industries like healthcare and defence drives the market in this region.

Europe: Known for its stringent regulations on chemicals and sustainability, Europe is witnessing a shift towards eco-friendly coating solutions. The region's fashion industry also contributes to the demand for aesthetically enhanced textiles.

Future Trends and Opportunities

Looking ahead, the Textile Coating Market presents several exciting trends and opportunities:

Smart Textiles: The integration of electronics and sensors into textiles is creating a new frontier of smart textiles. These textiles, with functionalities such as temperature regulation and health monitoring, require advanced coating technologies.

Medical Textiles: With an ageing population and increased focus on healthcare, the demand for medical textiles with antimicrobial and barrier properties is on the rise. Coatings play a crucial role in ensuring the effectiveness and safety of these textiles.

3D Printing: The convergence of textile coating and 3D printing technologies opens up possibilities for customizable, on-demand textile products. This combination allows for intricate designs and functional coatings to be applied during the printing process.

In conclusion, the Textile Coating Market stands as a vibrant and evolving segment within the broader textile industry. Its growth is driven by technological advancements, shifting consumer preferences, and the diverse applications of coated textiles across industries. As the world emphasises sustainability and innovation, the market is ripe with opportunities for manufacturers, researchers, and stakeholders to explore new materials, applications, and business models.

As we continue to weave innovation into the fabric of industry, the Textile Coating Market will undoubtedly remain a key thread in the tapestry of global commerce.

0 notes

Text

Construction Chemicals Market 2023-2031: Driving Innovation in Building Materials

The global construction chemicals market is set to witness substantial growth from 2023 to 2031, fueled by the booming construction industry, increasing infrastructure projects, and the demand for advanced building materials. Construction chemicals play a vital role in enhancing the performance, durability, and sustainability of construction materials, contributing to the development of resilient and high-quality structures. With technological advancements and sustainability concerns at the forefront, the construction chemicals market is experiencing dynamic shifts and innovations, shaping the future of the construction industry worldwide.

The construction chemicals market is experiencing steady growth globally, driven by the need for specialized chemicals and additives to improve the properties of concrete, mortar, waterproofing materials, adhesives, and sealants used in construction projects. Construction chemicals enhance the workability, strength, durability, and performance of building materials, ensuring the longevity and sustainability of structures.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3123

Market Segmentation:

By Service Type: Includes product sales, installation services, consulting services, and technical support.

By Sourcing Type: Comprises admixtures, waterproofing chemicals, adhesives and sealants, protective coatings, and others.

By Application: Covers residential, commercial, industrial, and infrastructure construction projects.

By Industry Vertical: Encompasses building & construction, infrastructure, transportation, and industrial manufacturing.

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa.

Regional Analysis:

Asia Pacific is anticipated to dominate the construction chemicals market, driven by rapid urbanization, infrastructure development, and investments in emerging economies such as China, India, and Southeast Asian countries.

North America and Europe are expected to witness steady growth, supported by stringent building codes, sustainability initiatives, and investments in green building projects.

Latin America, Middle East & Africa regions are projected to experience moderate growth, fueled by construction activities and infrastructure development projects.

Market Drivers and Challenges:

Drivers:

Increasing construction activities, infrastructure development projects, urbanization trends, and the need for high-performance and sustainable building materials.

Challenges: Fluctuating raw material prices, regulatory compliance requirements, technical challenges in product formulation, and environmental concerns related to chemical usage.

Market Trends:

Rising adoption of eco-friendly and low-VOC (volatile organic compounds) construction chemicals.

Development of smart and self-healing construction materials for enhanced durability.

Integration of nanotechnology and advanced polymers in construction chemical formulations.

Future Outlook:

The future outlook for the construction chemicals market is promising, with increasing demand for innovative and sustainable solutions driving market growth. Technological advancements, regulatory requirements, and shifts towards green building practices are expected to shape the future landscape of the construction chemicals industry.

Key Market Study Points:

Analysis of market dynamics and regulatory frameworks influencing the construction chemicals market.

Evaluation of key technological advancements and innovations in construction chemical formulations.

Assessment of market opportunities and challenges in different industry verticals and regions.

Identification of emerging trends and growth drivers driving market expansion.

Competitive Landscape:

The construction chemicals market is characterized by intense competition among key players such as BASF SE, Sika AG, Dow Inc., RPM International Inc., and MAPEI Corporation. These companies are focusing on product innovation, strategic partnerships, and investments in research and development to maintain a competitive edge in the market.

Recent Developments:

Introduction of advanced construction chemical products with improved performance characteristics and sustainability credentials.

Strategic collaborations and partnerships to expand product portfolios and global market presence.

Investments in research and development initiatives to develop next-generation construction chemical solutions.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=3123<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Polyurethane Sealants, Global Market Size Forecast, Top 10 Players Rank and Market Share

Polyurethane Sealants Market Summary

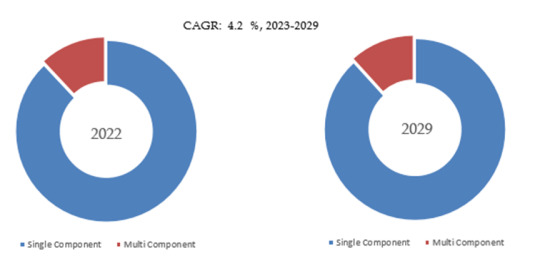

According to the new market research report “Global Polyurethane Sealants Market Report 2023-2029”, published by QYResearch, the global Polyurethane Sealants market size is projected to reach USD 3.92 billion by 2029, at a CAGR of 4.2% during the forecast period.

Figure. Global Polyurethane Sealants Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Polyurethane Sealants Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

Figure. Global Polyurethane Sealants Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Polyurethane Sealants Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Polyurethane Sealants include Henkel, H.B. Fuller, Sika, Arkema, Soudal, 3M, ITW Polymer Sealants, BASF, Splendor Industry, Asian Paints, etc. In 2022, the global top 10 players had a share approximately 42.0% in terms of revenue.

Figure. Polyurethane Sealants, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Polyurethane Sealants Market Report 2023-2029.

In terms of product type, currently Single Component is the largest segment, hold a share of 88.0%.

Figure. Polyurethane Sealants, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Polyurethane Sealants Market Report 2023-2029.

In terms of product application, currently Building & Construction is the largest segment, hold a share of 63.4%.

Figure. Polyurethane Sealants, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Polyurethane Sealants Market Report 2023-2029.

Market Drivers:

The polyurethane sealants market is driven by several key factors. Firstly, the continuous growth of the construction industry globally acts as a major driver. Polyurethane sealants find extensive use in construction applications such as joint sealing, waterproofing, and bonding due to their excellent properties including high durability, adhesion, and flexibility. Secondly, the automotive industry's expansion contributes significantly to market growth as polyurethane sealants are utilized in automotive assembly processes for bonding and sealing various components, providing structural integrity and resistance to environmental factors.

Restraint:

A significant restraint for the polyurethane sealants market is the volatility in raw material prices, particularly those derived from crude oil and petrochemicals. Fluctuations in raw material costs can impact production expenses, leading to challenges in maintaining profit margins and pricing strategies for manufacturers. This volatility poses a constraint on market growth as manufacturers need to adapt to changing cost structures and market conditions.

Opportunity:

One of the key opportunities for the polyurethane sealants market lies in the growing demand for sustainable and eco-friendly sealant solutions. With increasing environmental awareness and stringent regulations regarding emissions and sustainability, there is a rising demand for sealants with low VOC (volatile organic compound) emissions and renewable or recycled content. Manufacturers have the opportunity to capitalize on this trend by developing innovative green sealant formulations to meet market demand and regulatory requirements, thereby expanding their market share and enhancing their competitiveness.

About The Authors

Yang Min - Lead Author

Email: [email protected]

Yang Min is a market senior analyst specializing in chemical materials. Yangmin has 8 years’ experience in chemical materials market analysis, and focuses on chemical materials and API. He engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Securing Success: How Adhesives & Sealants Enhance Performance Across Industries in GCC in 2024

In the diverse landscape of construction, manufacturing, and automotive industries, adhesives and sealants play an indispensable role in bonding materials, enhancing durability, and ensuring product integrity. Across the Gulf Cooperation Council (GCC) region, comprising countries such as Saudi Arabia, the United Arab Emirates (UAE), Qatar, Oman, Bahrain, and Kuwait, the demand for adhesives and sealants continues to grow steadily. As we enter 2024, the GCC Adhesives & Sealants Market is poised for significant expansion, driven by factors such as infrastructure projects, industrial growth, and technological advancements. This article delves into the key trends, market dynamics, and factors shaping the GCC Adhesives & Sealants Market in the coming years.

Market Overview:

The GCC Adhesives & Sealants Market is experiencing robust growth, with a projected Compound Annual Growth Rate (CAGR) exceeding 5% from 2022 to 2024. This growth is fueled by factors such as the region's expanding construction and manufacturing sectors, infrastructure development projects, and the increasing adoption of advanced bonding solutions in various applications.

Key Factors Driving Growth:

Infrastructure Development: The GCC countries are investing heavily in infrastructure projects, including transportation, energy, and construction of smart cities. Adhesives and sealants are essential components in infrastructure development, used in applications such as road construction, building insulation, and waterproofing.

Industrial Growth: The industrial sector in the GCC region is witnessing significant expansion, driven by investments in petrochemicals, manufacturing, and automotive industries. Adhesives and sealants play a vital role in assembly, fabrication, and maintenance processes, contributing to the growth of the industrial adhesives market.

Technological Advancements: Technological advancements in adhesive formulations, curing technologies, and application methods are driving improvements in product performance, durability, and efficiency. Innovations such as low-VOC (volatile organic compound) formulations, UV-curable adhesives, and hybrid sealants are gaining traction in the GCC market.

Shift towards Sustainable Solutions: There is a growing emphasis on sustainability and environmental stewardship in the GCC region, leading to the adoption of eco-friendly adhesives and sealants with reduced environmental impact. Bio-based adhesives, recycled content sealants, and solvent-free formulations are becoming increasingly popular among manufacturers and end-users.

Challenges and Opportunities:

While the GCC Adhesives & Sealants Market presents significant growth opportunities, challenges such as fluctuating raw material prices, regulatory constraints, and competition from imported products remain. However, these challenges also create opportunities for industry players to innovate, invest in research and development, and collaborate on sustainable solutions to address market demands.

For More Info@ https://www.gmiresearch.com/report/gcc-adhesives-sealants-market-2019-2026/

Conclusion:

In 2024, the GCC Adhesives & Sealants Market stands as a cornerstone of industrial progress and infrastructure development in the region. As the GCC countries continue their journey towards economic diversification and sustainable growth, the market's expansion is not just about bonding materials; it is about bonding communities, industries, and aspirations for a brighter future. The GCC Adhesives & Sealants Market is not merely a segment of the chemical industry; it is a catalyst for innovation, efficiency, and progress in the Gulf Cooperation Council. In embracing infrastructure projects, industrial growth, and sustainability initiatives, the GCC Adhesives & Sealants Market is not just bonding materials; it is bonding the future of the GCC region.

0 notes

Text

Waterproof Label Market Insights: Comprehensive Global Forecast (2023-2032)

The Waterproof Label Market is projected to grow from USD 1,689.66 million in 2024 to USD 2,099.2 million by 2032, reflecting a compound annual growth rate (CAGR) of 2.75%.

Waterproof labels are essential for a wide range of applications where durability and resistance to water and other environmental factors are crucial. These labels are specifically designed to withstand exposure to moisture, making them ideal for use in industries such as food and beverage, pharmaceuticals, and outdoor equipment. Constructed from high-quality materials such as polyester, vinyl, or polypropylene, waterproof labels maintain their integrity and readability even when submerged in water or exposed to humid conditions. The adhesive used on these labels is also water-resistant, ensuring that they stay securely affixed to various surfaces, including glass, plastic, and metal, without peeling or fading. Additionally, waterproof labels can be customized with various printing techniques, including digital, flexographic, and thermal transfer printing, allowing for the inclusion of vibrant colors, barcodes, and other essential information.

This customization is particularly beneficial for branding, product identification, and compliance with industry regulations. Moreover, waterproof labels are resistant to smudging, tearing, and UV light, ensuring that they remain legible and visually appealing throughout their lifecycle. Their robustness makes them suitable for labeling products that undergo rigorous handling, shipping, and storage conditions. In summary, waterproof labels offer a reliable and versatile labeling solution that ensures product information remains intact and accessible, regardless of the environmental challenges they may encounter.

Waterproof Label Market Challenges:

High Cost of Materials and Production:

Raw materials like polyester, vinyl, and polypropylene are expensive.

Specialized adhesives used for waterproof labels add to the cost.

Overall production costs are higher compared to standard labels.

Complex Manufacturing Processes:

Advanced printing and coating technologies are required.

Ensuring durability and resistance to environmental factors is challenging.

Increased production complexity can lead to longer lead times and higher costs.

Environmental Concerns:

Many waterproof labels are made from non-biodegradable materials.

Growing consumer and regulatory focus on sustainability impacts market acceptance.

Developing eco-friendly waterproof labels can be technologically and financially challenging.

Market Competition:

Intense competition from both established players and new entrants.

Price wars and discount strategies can erode profit margins.

Innovation and differentiation are necessary to stay competitive.

Regulatory Compliance:

Meeting diverse and stringent regulatory requirements across different regions.

Compliance with environmental and safety standards adds to production costs and complexity.

Keeping up with changing regulations can be resource-intensive.

Technological Advancements:

Rapid technological changes require continuous investment in R&D.

Staying updated with the latest technology is crucial for maintaining product quality.

Failure to innovate can result in losing market share to technologically advanced competitors.

Supply Chain Issues:

Dependence on a stable supply of high-quality raw materials.

Disruptions in the supply chain can lead to delays and increased costs.

Efficient supply chain management is essential for maintaining production schedules and cost-effectiveness.

Customization Demands:

Increasing demand for customized waterproof labels adds complexity.

Meeting specific customer requirements can be time-consuming and costly.

Balancing standard production with custom orders requires flexible manufacturing processes.

Consumer Awareness and Education:

Limited consumer awareness about the benefits and applications of waterproof labels.

Educating potential customers requires marketing efforts and resources.

Misconceptions about the cost versus benefits ratio can hinder market growth.

Key Player Analysis

Hangzhou Newsmax Technology Co., Ltd.

Guangzhou Aide Medical Technology Co., Ltd.

Markem-Imaje

Matthews Marking Systems

Paxton Products

Primera Technology

Multivac Inc.

SATO America

Sleeve Seal

LANGGUTH America Ltd.

Dongguan Changan Zhiye Printing Factory

PDC International Corp.

Squid Ink

Guangzhou Guangcai Labels Co., Ltd.

More About Report- https://www.credenceresearch.com/report/waterproof-label-market

Innovative Trends in the Waterproof Label Market:

Eco-Friendly Materials:

Development and use of biodegradable and recyclable materials.

Introduction of water-based adhesives that are environmentally friendly.

Focus on reducing the carbon footprint and meeting sustainability goals.

Smart Labels and RFID Integration:

Incorporation of Radio Frequency Identification (RFID) technology for better tracking and inventory management.

Use of Near Field Communication (NFC) for enhanced consumer engagement and product information.

Smart labels that can monitor and report environmental conditions such as temperature and humidity.

Advanced Printing Techniques:

Digital printing technologies that offer high resolution and vibrant colors.

UV ink printing for increased durability and resistance to fading.

Laser printing for precise and detailed label designs.

Customization and Personalization:

On-demand printing solutions allowing for personalized labels tailored to individual customer needs.

Variable data printing (VDP) enabling unique barcodes, QR codes, and serial numbers on each label.

Enhanced design flexibility to cater to diverse market segments.

Durability Enhancements:

Improved resistance to harsh chemicals, abrasion, and UV exposure.

Use of laminates and coatings that enhance the lifespan of labels in extreme environments.

Labels designed for specific applications such as marine, automotive, and industrial uses.

Interactive and Augmented Reality (AR) Labels:

Integration of AR elements to provide interactive consumer experiences.

Labels that can be scanned with smartphones to display virtual product demonstrations or promotional content.

Enhancing brand engagement through interactive storytelling and multimedia content.

Enhanced Adhesive Technologies:

Development of adhesives that perform well on challenging surfaces, including low-energy plastics and oily substrates.

Removable and repositionable adhesives for versatile applications.

Stronger and more durable adhesives that ensure labels remain intact in wet and humid conditions.

Sustainable Manufacturing Processes:

Adoption of energy-efficient production techniques.

Use of renewable energy sources in the manufacturing process.

Reduction of waste and implementation of circular economy principles.

Regulatory Compliance and Safety Features:

Labels that comply with food safety and pharmaceutical regulations.

Use of non-toxic and safe materials for consumer products.

Anti-counterfeiting features such as holograms and tamper-evident seals to ensure product authenticity.

Enhanced Visual and Tactile Features:

Textured and embossed labels for a premium feel and enhanced brand perception.

Use of metallic inks and foils for a high-end appearance.

Transparent and clear labels that provide a "no-label" look, blending seamlessly with the product packaging.

Segments:

Based on Material:

Polyethylene (PE)

Polypropylene (PP)

Polyvinyl Chloride (PVC)

Polyethylene Terephthalate (PET)

Other Polymers (PA, EVOH, etc.)

Metal

Based on Label Type:

Pressure Sensitive Labels (PSL)

Shrink Labels

Stretch Labels

Thermal Labels

Others (In-Mold, Pre-Gummed, etc.)

Based on End-Use:

Food

Beverage

Healthcare

Cosmetics & Personal Care

Homecare & Toiletries

Chemicals

Automobiles

Other Industrial

Browse the full report – https://www.credenceresearch.com/report/waterproof-label-market

Browse Our Blog: https://www.linkedin.com/pulse/waterproof-label-market-projections-global-industry-qimdf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Unveiling the Key Players in the Growing Concrete Waterproofing Admixture Market

Introduction

The Concrete Waterproofing Admixture Market is witnessing substantial growth, driven by the increasing demand for durable and waterproof concrete structures in various construction projects. As per the market conditions, the market is expected to expand from USD 1.10 Billion in 2022 to USD 1.40 Billion by 2030, exhibiting a Compound Annual Growth Rate (CAGR) of 2.90% during the forecast period. In this blog, we will delve into the key players in this market and explore their past history, growth rate, market size, and other relevant information.

1. Kryton

Kryton is a renowned player in the concrete waterproofing admixture market, known for its innovative Smart Concrete® solutions. Established in 1973, the company has since made a significant impact on the industry. With its headquarters in Vancouver, Canada, Kryton has expanded its presence worldwide. The company's growth rate has been impressive, with continuous product development and strategic partnerships. Kryton's market sales revenue in 2022 stood at USD 80 million, and it is projected to grow at a CAGR of 3.5% until 2030.

2. Xypex Chemical

Xypex Chemical, founded in 1969, has been a pioneer in crystalline waterproofing technology. The company's unique solutions have garnered a loyal customer base globally. Headquartered in Canada, Xypex Chemical has seen steady growth in the market. In 2022, its market sales revenue reached USD 75 million, and it is projected to grow at a CAGR of 3.2% during the forecast period.

3. Fosroc

Fosroc, a part of the JMH Group, has been providing high-quality construction chemicals and solutions since 1934. Headquartered in the United Arab Emirates, the company operates in various regions worldwide. Fosroc's comprehensive range of waterproofing admixtures has contributed to its steady growth. In 2022, its market sales revenue was USD 65 million, and the company is expected to maintain a CAGR of 2.8% until 2030.

4. GCP Applied Technologies Inc.

GCP Applied Technologies Inc., formerly known as Grace Construction Products, has a long history dating back to 1916. The company offers advanced construction chemicals and materials. Based in the United States, GCP Applied Technologies Inc. has achieved significant growth through strategic acquisitions and product innovations. In 2022, its market sales revenue was USD 72 million, and it is projected to grow at a CAGR of 2.9% during the forecast period.

5. Hycrete, Inc.

Hycrete, Inc. was founded in 1999 and has become a prominent player in the concrete waterproofing admixture market. The company specializes in integral waterproofing solutions and has gained recognition for its sustainable practices. Headquartered in the United States, Hycrete, Inc. has witnessed substantial growth. In 2022, its market sales revenue reached USD 60 million, and it is projected to grow at a CAGR of 2.7% until 2030.

6. SIKA

SIKA, a Swiss multinational company established in 1910, is a key player in the construction chemicals industry. With a strong presence in the global market, SIKA offers a wide range of products, including concrete admixtures. The company's dedication to research and development has contributed to its steady growth. In 2022, SIKA's market sales revenue was USD 90 million, and it is expected to grow at a CAGR of 3.0% during the forecast period.

7. BASF

BASF, a German chemical giant, has a rich history dating back to 1865. The company operates in various industries, including construction chemicals. BASF's extensive portfolio of concrete admixtures has gained popularity worldwide. In 2022, its market sales revenue was USD 100 million, and it is projected to grow at a CAGR of 3.3% until 2030.

8. Penetron

Penetron, established in 1978, specializes in integral crystalline waterproofing solutions. Headquartered in the United States, the company has expanded its reach to several countries. Penetron's growth has been fueled by its innovative products and strategic alliances. In 2022, its market sales revenue was USD 50 million, and it is expected to grow at a CAGR of 2.5% during the forecast period.

9. Schomburg

Schomburg, founded in 1919, is a German company known for its high-performance construction chemicals. With a focus on sustainability and innovation, Schomburg has gained a significant market share. In 2022, its market sales revenue reached USD 55 million, and it is projected to grow at a CAGR of 2.6% until 2030.

10. Markham Global

Markham Global, established in 1990, has become a prominent player in the concrete waterproofing admixture market. The company's specialty lies in providing moisture control and durability solutions for concrete. Headquartered in Australia, Markham Global has expanded its presence worldwide. In 2022, its market sales revenue was USD 40 million, and it is expected to grow at a CAGR of 2.3% during the forecast period.

Conclusion