#MEAN Stack Development Services Norway

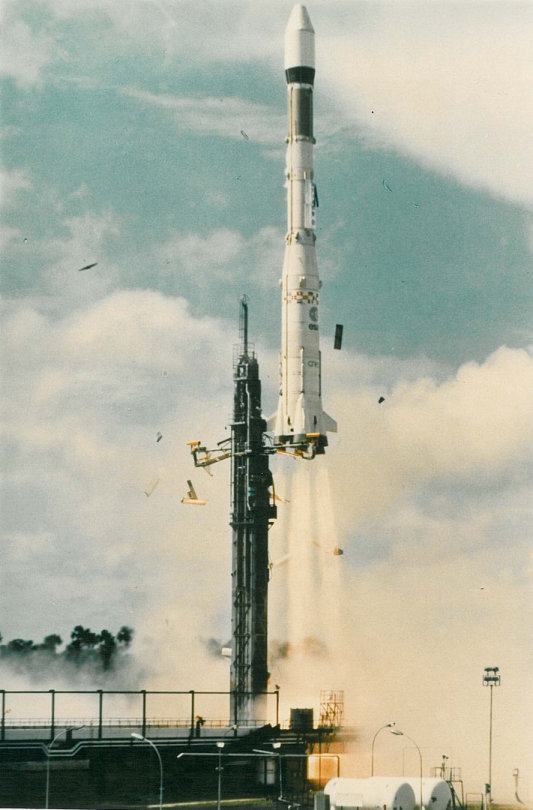

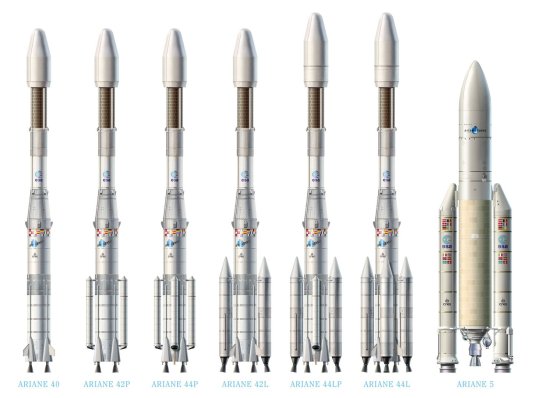

Photo

40 years of Ariane ESA and partners celebrate 40 years of Ariane – a launch vehicle operating in the international space arena, and a symbol of cooperation and innovation that ensures independent access to space for Europe. On 24 December 1979, the first Ariane 1 was launched from Europe’s Spaceport in Kourou, French Guiana. Launch L01 carried CAT-1, or Technological Capsule 1, a small satellite used to provide data on the launch characteristics of the new rocket and therefore only powered for eight orbits. Ariane 1 was the first launch vehicle to be developed with the primary purpose of sending commercial satellites into geostationary orbit. It was designed mainly to deploy two satellites per mission, thus reducing costs. From this first flight, Ariane evolved into a highly reliable rocket boosted by the fast-growing demand for commercial space launches in the 1980s. Operated by Arianespace, Ariane claimed over half the satellite market in this period. Altogether, Ariane 1, 2 and 3 launched 28 times between 1979 and 1989, placing a total of 38 satellites in orbit. Ariane 4 entered service in 1988 and made 113 successful launches. Its last was on 15 February 2003. It featured an elongated first stage and strap-on liquid and solid-fuel boosters providing more thrust at liftoff. For this version of Ariane, a lighter Sylda fairing structure was introduced. The Sylda allows two payloads to be stacked one on top of the other. Ariane 5 is the result of continual investment in new technology, a wider, heavier and shorter design, and new production methods. This has extended Ariane's benchmark lifting capability from its initial 1850 kg to geostationary orbit, to today’s dual payload record of 10 865 kg to geostationary orbit with an Ariane 5 ECA on 2 June 2017. Ariane 5’s ES was used for various missions, such as the Automated Transfer Vehicle in low orbit and Galileo in medium orbit. It was retired from service on 25 July 2018. Europe's Spaceport lies just above the equator in South America, and hosts facilities for Ariane, Soyuz and Vega launchers. Continued updates to the Spaceport’s facilities have kept up with the requirements of each new launch vehicle. The pad used by Ariane 1, 2 and 3 was later repurposed for Vega in 2012 and is currently being modified to accommodate the upcoming more powerful Vega-C successor. ESA is currently preparing for the next decade in space transportation. Part of this involves the transition from Ariane 5 to the new modular Ariane 6 for which a dedicated launch site has been built. Ariane 6 has two versions, Ariane 62 with two strap-on boosters and Ariane 64 with four, for more power. The new Ariane design is intended to serve the diverse needs of a wide range of customers offering new payload dispensers for a variety of configurations while dramatically decreasing the cost of launches compared to Ariane 5. Changes in the way in which Ariane 6 is assembled, paired with new manufacturing techniques, is set to speed up the turn around time, allowing more Ariane launches than ever before. Europe can celebrate Ariane’s history and look forward to building on its successes through innovation and an extreme design-to-cost approach to maintain its lead in a fiercely competitive launch services market. IMAGE 1...The first successful launch of the European launcher, Ariane 1, on 24 December 1979 from Kourou, French Guiana. IMAGE 2...As the size of satellites grew, Ariane 1 gave way in 1984 to the more powerful Ariane 2 and 3, and these in turn were superseded by Ariane 4 in 1988. This is the first launch of Ariane 2, flight V18 on 30 May 1986, carrying Intelsat 5a F14. IMAGE 3...Launch of first Ariane 3 flight V10 from Europe's Spaceport in French Guiana, on 4 August 1984, carrying ECS-2 and Telecom-1A satellites. IMAGE 4...Ariane 4 is justly known as the ‘workhorse’ of the Ariane family. Since its first flight on 15 June 1988 it has made over 100 successful launches. The Ariane 4 has proved ideal for launching satellites for communications and Earth observation, as well as for scientific research. This launcher is extremely versatile. The first stage can hold two or four strap-on boosters, or none at all. This means that it can lift into orbit satellites weighing from 2000 to nearly 4800 kg in GTO, nearly three times as much as the Ariane-3 launcher. Now its role is gradually being taken over by the Ariane-5 launcher and the last Ariane-4 flight is expected to take place in 2003. Ariane 4 has captured 50% of the market in launching commercial satellites showing that Europe can more than hold its own in the commercial launch market. Ariane 5 is designed to meet the challenges of the new millennium. It meets several requirements: the ability to launch larger satellites, the increasing use of low orbits for servicing the International Space Station and the need to reduce costs while maintaining a high reliability. Its first successful launch took place on 30 October 1997 while its first operational flight occurred in December 1999, when it launched ESA’s X-ray Multi-Mirror (XMM). Ariane 5 has proved highly reliable and economic, and has been used to launch satellites for communications, Earth observation and scientific research into geostationary orbits and Sun-synchronous orbits. ESA had to build a new launch site at Europe’s spaceport in Kourou for this new member of the Ariane family as well as facilities to make the solid boosters needed to launch this, the most powerful launcher in the Ariane family. Ariane 5 can be used for launches into geostationary orbit, medium-Earth orbit and low-Earth orbit, as well as for launches to other planets. IMAGE 5...ESA and European industry are currently developing a new-generation launcher: Ariane 6. This follows the decision taken at the ESA Council meeting at Ministerial level in December 2014, to maintain Europe’s leadership in the fast-changing commercial launch service market while responding to the needs of European institutional missions. This move is associated with a change in the governance of the European launcher sector, based on a sharing of responsibility, cost and risk by ESA and industry. The participating states are: Austria, Belgium, Czech Republic, France, Germany, Ireland, Italy, Netherlands, Norway, Romania, Spain, Sweden and Switzerland. On the wave of Vega’s success, Member States at the ESA Ministerial meeting in December 2014 agreed to develop the more powerful Vega-C to respond to an evolving market and to long-term institutional needs. Vega-C is expected to debut in mid-2019, increasing performance from Vega’s current 1.5 t to about 2.2 t in a reference 700 km polar orbit, covering identified European institutional users’ mission needs, with no increase in launch service and operating costs.

0 notes

Text

Compack Sequence Box Making Machines

This computerized BOXMATIC machine is right for the manufacturing of corrugated packing containers, trays, industrial paper straw making equipment partitions and minimize-outs with the choice of additional die-cuts and flexo printing. The carton field making machine market is aggressive and the vendors mainly compete based mostly on factors akin to price, technology, and options. four Rolls of kraft paper for corrugating can be found in lots of sizes to suit the manufacturing tools at different corrugating vegetation. We constantly perform our spirit of ''Innovation bringing improvement, Extremely-high quality guaranteeing subsistence, Administration selling profit, Credit score attracting prospects for Computerized Powder Auger Filler Packing Machine, The product will provide to all around the world, corresponding to: Curacao , New Delhi , British , We solely provide quality products and we believe that is the one option to maintain enterprise proceed. After all these flutes solely describe single wall packing containers - if you see a field that claims ‘BC Flute' or ‘AB Flute' that is when a double wall carton has been specified, the first letter is the fluting of the highest layer of board and the second letter is the bottom layer. Since their invention, corrugated packing containers have been mainly used to pack and transport meals and beverage products. Try the infographic below that details a field's manufacturing lifecycle. A report from GlobalData states that nearly 70 p.c of shoppers at all times recycle their packaging boards and 50 % of customers avoid excessively packaged grocery products. For certain, the corrugated market can at all times depend upon the fact that the breakdown of cargo from plants or manufacturing services versus the sheet vegetation or converters remains unchanged. Even with the unstable value of the wood pulp, the worth of cardboard box stays comparatively same. You can even find other packaging and printing options reminiscent of packaging machine, packing machine, carton machine with aggressive worth. Cardboard bins are after all one of many core products of the packaging trade. China and India dominated the corrugated box making machine market in APAC. Main packaging firms are already operating paper mills that make fresh, clean kraft paper by de-inking and pulping used containers. Our CORRUGATED FIELD MAKING EQUIPMENT import knowledge options meet your actual import necessities in high quality, volume, seasonality, and geography. To supply nation degree evaluation of the marketplace for segment by software, product sort and sub-segments. Good packaging allows the a number of usage of the box with out dismantling it. This will scale back losses occurred through the dismantling of a box and primarily advantages customers after they select to return the product. A: We have a special QC department in charge of products high quality. The growing reputation of good packaging in the e-commerce industry can be one of many newest traits that may acquire traction within the corrugated field making machine market through the next 4 years. As a field or carton plant, we give you the best quality field making equipment. Supplied are automated and semi-computerized box makers for the manufacturing of slotted bins from single, double or triple wall corrugated. The e-commerce industry is growing and can most definitely continue for the following decade, so in case you are planning for a cardboard field manufacturing enterprise, you have to be good for the next few a long time and if the advertising is right, you might be a giant participant within the trade. There are fifty seven,074 carton field making machine suppliers, primarily located in Asia. A warp test determines the flatness of the box blank, insuring that each blank will journey smoothly by means of the flexo machines. Kolbus AutoBox have been producing quality machinery for over forty years. All Machines consist superior expertise, high velocity and better output production. We are able to present our prospects with the most high-end machines and one of the best after-gross sales service. These boxes enable the shipping containers to additionally act as retail packaging. All of the settings could be set by means of a contact display, and operators do not have to be geared up with any expertise in carton field manufacturing.

Discover a broad range of sustainable, robust and protecting packaging products and services tailored to your needs. air strain auxiliary cardboard drop, before the back and front of the cardboard box. A knowledgeable packaging specialist works with a customer to determine the strength required for the corrugated cardboard container being deliberate. The method begins by making corrugated board on a corrugating line, a long collection of linked machines totaling the size of a football subject. After being glued, the cardboard can be conveyed to be formed and collected to be auto calculated because the preconcert quantity and auto mark withouot stopping production, construction: Control unit, paper feeding unit, paper transfer unit, glue spreading unit, forming unit, gathering unit. Cardboard or cardboard field manufacturing enterprise is a profitable business within the USA, particularly with the ever-increasing e-commerce stores. GMS Internationals is China's leading professional supplier and manufacturer of corrugated machines. When the hot paper passes between the corrugating rolls, flutes entice and bend it to type the middle of the corrugated cardboard. Cardboard bins are the most cost effective type of packaging; furthermore, the costs reduces when corporations purchase cardboard containers in bulk from producers. eight. Prices in equipment and gear, uncooked supplies and the promoting costs of the completed merchandise and so on., are generally prevailing at the time of preparation of the venture profiles and should vary relying upon numerous components. QINGDAO AOPACK focuses on the on-demand packaging solutions and has developed a series of box making machines with our own Patents. Our straightforward-to-use machine is capable of producing as much as one hundred different box styles, giving your online business flexibility on orders. Corrugated boxes are light-weight and straightforward to deal with and transport. The feeder transmits the pre-printed and lower cardboard from the paper shelf to the convey chain and the sends it to the shaping mildew, throughout the procedure, the cardboard has been glued an you possibly can regulate the position of the gluing, the quantity of gluing could be measured while in progress withour stopping word. Peterson, VPK's Scandinavian packaging division, has launched more particulars of its new production website in Halden, Norway. From the flexo, the finished boxes are robotically stacked and sent to a banding machine to be wrapped for transport. It affects the forms of gear available to production traces, the measured laboratory performance, the field efficiency, and the ability of finish-users to easily and safely open the field. Recently subscription containers have caught-up within the eCommerce business. Kite Packaging have grilled its technologists to inform us exactly what the method is for cleaning the raw materials and processing them to make the cardboard packing containers you buy each day for your online business. Paper and paper products are versatile industrial uncooked supplies with all kinds of software on this era and due to scarcity of softwood, wood packing cases are increasingly more changed with corrugated board- packing containers and cartons. However it's simple to overlook that the cardboard containers you use frequently were once a not-so-humble tree. The opposite outstanding vendors out there are Acme Equipment, Associated Industrial, Box On Demand, DING SHUNG MACHINERY, EMBA Equipment, MarquipWardUnited, Mitsubishi Heavy Industries America, Natraj Industries, Packsize International, Serpa Packaging Solutions, Shanghai PrintYoung International Trade, Shengli carton Tools Manufacturing, SOLAR Automation Group (Langston), SUZHOU KOMAL EQUIPMENT, T-ROC TOOLS, Valco Melton, and XINTIAN CARTON MACHINERY MANUFACTURING. offers 10,610 carton field making machine costs products. Their research and evaluation focuses on rising market trends and gives actionable insights to help businesses establish market opportunities and develop efficient strategies to optimize their market positions. Many folding carton producers are working to include technology to fight theft and counterfeit products.

0 notes

Text

Maersk Drilling Announces Up to 300 Layoffs in North Sea Region

On Friday, offshore rig operator Maersk Drilling said that it would be taking steps to "adapt [its] offshore crew pool" to the changing level of demand in the North Sea market.

The COVID-19 pandemic and the lower oil price environment are impacting offshore drilling activity for all operators, including Maersk Drilling. Last week, the company announced that two clients have given notice of early termination for its rigs. BG International, a subsidiary of Shell, has terminated the contract for the semi-submersible Mærsk Developer with immediate effect. Aker BP has also terminated the contract for the jack-up rig Maersk Reacher, which was hired for accommodation services on the Valhall field.

For both of these contracts, Maersk Drilling expects to receive compensation in the form of early termination fees, so the financial impact is expected to be small. However, the required crewing levels for inactive rigs are much lower.

In light of the current outlook, Maersk Drilling said that it intends to stack a number of its North Sea rigs. This means a reduction in the offshore crew pool, and Maersk Drilling has begun consultations with trade unions and employee representatives about redundancies in Denmark, Norway and the UK.

“Though it’s standard practice in our industry to adjust our workforce to activity levels, it never feels right to say goodbye to good colleagues, especially when so many have walked the extra mile to keep operations running in these very difficult circumstances. However, it’s our responsibility to safeguard our business and we are now taking steps to maintain competitiveness in the challenging market environment,” says CEO Jørn Madsen.

Maersk Drilling expects that the consultations will lead to a total of 250-300 redundancies in the North Sea crew pool. The consultation processes will follow the timelines laid out by local regulations in Denmark, Norway and the UK.

from Storage Containers https://www.maritime-executive.com/article/maersk-drilling-announces-up-to-300-layoffs-in-north-sea-region

via http://www.rssmix.com/

0 notes

Text

Paper Field Making Machine

c section galvanised steel

How a cardboard box is made at Kite Packaging. Discover a broad vary of sustainable, robust and protecting packaging products and services adapted to your needs. air pressure auxiliary cardboard drop, earlier than the front and back of the cardboard box. A knowledgeable packaging specialist works with a customer to find out the power required for the corrugated cardboard container being deliberate. The process begins by making corrugated board on a corrugating line, a protracted sequence of linked machines totaling the size of a soccer area. After being glued, the cardboard might be conveyed to be formed and picked up to be auto calculated as the preconcert quantity and auto mark withouot stopping production, structure: Control unit, paper feeding unit, paper transfer unit, glue spreading unit, forming unit, amassing unit. Cardboard or cardboard field manufacturing business is a profitable enterprise within the USA, especially with the ever-rising e-commerce stores. GMS Internationals is China’s main professional supplier and manufacturer of corrugated machines. When the recent paper passes between the corrugating rolls, flutes lure and bend it to type the middle of the corrugated cardboard. Cardboard boxes are the cheapest type of packaging; moreover, the prices reduces when firms buy cardboard boxes in bulk from producers. 8. Prices in machinery and equipment, uncooked supplies and the promoting prices of the finished products and so on., are generally prevailing on the time of preparation of the mission profiles and may differ relying upon various factors. QINGDAO AOPACK focuses on the on-demand packaging options and has developed a sequence of box making machines with our own Patents. Our straightforward-to-use machine is able to producing up to a hundred completely different field kinds, giving your business flexibility on orders. Corrugated bins are lightweight and easy to handle and transport. The feeder transmits the pre-printed and minimize cardboard from the paper shelf to the convey chain and the sends it to the shaping mould, during the process, the cardboard has been glued an you possibly can alter the position of the gluing, the volume of gluing may be measured whereas in progress withour stopping word. Peterson, VPK’s Scandinavian packaging division, has released extra particulars of its new manufacturing site in Halden, Norway. From the flexo, the completed boxes are automatically stacked and sent to a banding machine to be wrapped for transport. It impacts the sorts of equipment accessible to production traces, the measured laboratory efficiency, the field efficiency, and the ability of finish-users to easily and safely open the box. Lately subscription bins have caught-up within the eCommerce trade. Kite Packaging have grilled its technologists to inform us exactly what the method is for cleaning the uncooked supplies and processing them to make the cardboard packing containers you buy every day for your small business. Paper and paper products are versatile industrial raw materials with all kinds of utility in this era and due to shortage of softwood, picket packing circumstances are increasingly more changed with corrugated board- packing containers and cartons. But it surely’s simple to neglect that the cardboard packing containers you use regularly had been once a not-so-humble tree. The other prominent vendors out there are Acme Machinery, Related Industrial, Field On Demand, DING SHUNG EQUIPMENT, EMBA Equipment, MarquipWardUnited, Mitsubishi Heavy Industries America, Natraj Industries, Packsize International, Serpa Packaging Options, Shanghai PrintYoung Worldwide Trade, Shengli carton Tools Manufacturing, SUN Automation Group (Langston), SUZHOU KOMAL EQUIPMENT, T-ROC TOOLS, Valco Melton, and XINTIAN CARTON MACHINERY MANUFACTURING. offers 10,610 carton box making machine costs merchandise. Their research and analysis focuses on rising market traits and gives actionable insights to assist businesses determine market opportunities and develop effective methods to optimize their market positions. Many folding carton manufacturers are working to incorporate technology to struggle theft and counterfeit products.

These endeavours embrace the availability of customized designs with speed and dispatch for Manufacturing unit Worth Corrugated Cardboard Box Kraft Paper Shifting Carton Field, The product will supply to all over the world, equivalent to: Bangladesh , Latvia , Finland , With the goal of “zero defect”. Which means, is it usually safe to compost the whole lot of the box: cardboard, the ink that is printed on it, and most significantly, the glue that’s used to adhere the sides of the field collectively. If long-time period storage of corrugated packing containers in high humidity is anticipated, extra strength and moisture resistance known as for. We manufacture and provide High Pace single facers, Rotary reel to sheet cutters, Sheet Pasting machines, Sheet pressing machines, Rotary creaser slotter, Board Printer, Printer Slotter, Rotary Die and lots of such machines. Box blanks requiring only simple, one-shade printing and die-reducing could be run via a stand-alone die-cutter, print station, and curtain coater to supply water- or grease-resistant containers. So as to provide you with convenience and enlarge our enterprise, we even have inspectors in QC Group and assure you our greatest service and product for High Productiveness Carton Paper Field Erecting Forming Machine, The product will provide to all over the world, comparable to: Thailand , Chile , Haiti , We at all times stick with the tenet of “sincerity, prime quality, high efficiency, innovation”. Engineers and designers start with the needs of the actual venture: price constraints, equipment capabilities, product characteristics, logistics needs, relevant laws, shopper wants, etc. This challenge profile intimately foresees setting up of unit to supply corrugated board and bins. The demand for corrugated bins is also anticipated to increase from other Southeast Asian international locations as these consumable merchandise have not reached the maturity stage. Positioned in Kolín in the Czech Republic in the prestigious Industrial Zone Ovcary, of their state-of-the-artwork facility that homes machine and components production, assembly and show room areas. ACM 900, ACM 4500, ACM 9000 these are the paper bowl machines we offer in the huge market. Throughout 2010-2015, the global demand for fast-moving consumer goods (FMCG) witnessed a considerable progress, and contemplating the high demand for electronic merchandise, the marketplace for corrugated boxes is expected to witness progress throughout 2016-2021. The boxes are processed at round 100 packing containers per minute, whereas the cut off papers are despatched for recycling. Usually, cardboard containers have a check paper internal liner, and a Kraft paper outer. These packing containers are very durable and have excessive security requirements compared with the other modes of packaging akin to cardboard packaging. As we speak, there are nearly 2000 cardboard field manufacturers with industry employment of 140K. Fast-rising pine trees present the primary uncooked material used to make corrugated cardboard. 5. The estimates are drawn for a production capability generally thought of techno-economically viable for mannequin type of manufacturing activity. At Packsize we provide a wide range of corrugated field making machines designed to help your organization save time and increase productivity, whereas decreasing prices and your carbon footprint. Carton Pack has an array of machines and equipment for producing cardboard containers and cardboard packing provides. It lets you create packing containers which are the right measurement and shape for your product. Moreover, the customers are anticipated to see a significant enhance in the price of corrugated cardboard by four % than final 12 months. Skilled production employees use a computer terminal and printer to organize a job ticket for each stack of box blanks produced by the corrugator. Boix Europe is the main vendor for Boix packaging machines in Europe and market leader in forming and gluing each corrugated and solid board packaging. Corrugated packing containers are made in field plant factories.

The supplied products are tested in terms of high quality to ship only defect much less vary from our side. Since then, pulp processing, paper making, and corrugating operations have been developed to a high state of effectivity and productiveness. We hope that our worth for cash merchandise will assist you in growing what you are promoting for many years to come. This corrugated cardboard box making machine with excessive efficiency has handed the CE certification. We have been an brisk corporation with wide market for Used Paper Egg Carton Making Machine, The product will supply to everywhere in the world, resembling: Suriname , Curacao , Rome , We warmly welcome home and overseas prospects to go to our company and have business talk. Explore the detailed product pages to search out all it is advisable know about any field making machine. Kraft and Test paper can also be used to create the fluted paper in between liners which lastly create a powerful board. We comprehend the fact that majority of import companies in are energetic in sourcing distinct ranges of products together with uncooked materials, machinery and shopper items and so forth. Next, you must procure machinery, which can differ relying on the type of box you want to manufacture. affords 57,111 carton field making machine merchandise. There are 10,610 carton field making machine costs suppliers, primarily situated in Asia. A quick guide to cardboard containers by Kite Packaging. All Boxmatic machines will be outfitted with two or three-out manufacturing and up to three smart flexo print units. Recycling and different environmentally friendly processes will continue to develop in significance in the way forward for corrugated cardboard. In-home making of corrugated boxes contributes to reduction of outsourcing prices. Our pros are lessen costs,dynamic gross sales crew,specialised QC,sturdy factories,high-quality providers and merchandise for Corrugated Carton Box Making Die Cutter Machine (ML-1600), The product will supply to all around the world, reminiscent of: Albania , Sheffield , Swansea , “Make the ladies more enticing “is our sales philosophy. Most typical types of bins in demand embrace mono cartons, standard field, massive box, bins in 2,3,5,7, ply. All kinds of carton box making machine costs choices can be found to you, similar to beverage. Another 6 million tons of uncorrugated boxboard or paperboard have been additionally produced to be used in folding cartons. Corrugated box making machine is a equipment used to making corrugated boxes. The machines discover their strategy to numerous market sectors: from agricultural to industrial use in meals and non-meals sectors. Today, within the corrugated cardboard business, designers are creating progressive containers that require four-colour printing and sophisticated die-reducing. At the basic of Corrugated Box Machine BM2508, it provides the perform of die-cutting deal with holes on both sides of the carton box. A semi-automatic cardboard field producing machine will cost your roughly $ 120,000, whereas full-scale production plan will price you $ a hundred and eighty,000. Cardboard box making machines come with a large host of benefits that optimize your field-making process. The lifetime of a carboard field by Kite Packaging. The technology is pretty cutting-edge for the cardboard field trade. Different raw supplies are used to finish the corrugated cardboard after production. It may additionally present essentially the most suitable corrugated packaging field on demand for furniture, hardware equipment, e-commerce logistics and other industries. It’s now quite common for these liners to even be made up of a considerable proportion of recycled content, sourced from outdated cardboard or other sources of second hand paper. I fully suggest SPB machinery to anyone seeking to buy machines. For extra information on corrugated bins, click right here to browse our assets. 1 Manufacturing a corrugated cardboard box begins with the pulping of wood chips within the kraft (sulfate) course of.

Analysis evaluation on the worldwide corrugated box making machine market identifies that growth in e- commerce trade will probably be one of many main components that may have a optimistic influence on the expansion of the market. If you are prepared to get into the cardboard box manufacturing business, we consider it might be a worthwhile enterprise. Corrugated packaging is greatest suited for transport and transporting numerous products which can be fragile in nature. eighty% of industrial packaging is completed by carton bins attributable to effective cushioning, mild weight, simple to manufacture, straightforward for storing, easy for disposal, no strapping necessary, printing and promoting advantages, should in export market, recyclable etc. We specialize in corrugated containers, custom shows, labels, versatile packaging, folding cartons, inflexible bins, moving and transport supplies, and specialty and protecting packaging. As a result of corrugated cardboard is such a versatile packaging material, thousands and thousands of tons are used every year to protect and display merchandise. Located in Faridabad (Haryana, India), we are a Sole Proprietorship agency engaged in offering a high-quality vary of merchandise. Boix delivers tray forming machines in Europe and is the market chief in forming and gluing both corrugated and strong board packaging. It begins by pulping wooden chips using a kraft process; the popular tree for the kraft paper is a pine tree. This production line consists of three units:Printing Slotting Die-slicing Unit, Folding Gluing Unit,Stacking Unit(non-compulsory). T-ROC’s automated box making machines are designed to create custom on demand boxes of any dimension eliminating the need for packing peanuts, bubble wrap and other unnecessary fillers. Autobox is a subsidiary firm of Kolbus AutoBox, which started life within the UK, and was established to bring box making machines to North America. To analyse the Corrugated Box Making Machine market based on various elements- price analysis, provide chain analysis, porter five power evaluation etc. This business is without doubt one of the important shoppers of paperboard, producing packing containers and cartons for practically all varieties of business available in the market. Vertical columns provide the very best box efficiency whereas interlocking patterns of boxes considerably reduce performance. The corrugated field market in the US primarily witnesses demand from the meals and beverage industry. Like EMEA, the Americas witnessed a gradual progress in the demand for numerous services and products owing to the financial slowdown throughout 2012-2015. The Corrugated Field Making Machine industry report firstly introduced the Corrugated Box Making Machine Market fundamentals: sort applications and market overview; product specs; manufacturing processes; value buildings, raw supplies and so forth. Carton box making machine products are most popular in United States, Mexico, and Bulgaria. Moreover, it is a B2B enterprise, so, you should be capable to produce a large number of bins to satisfy massive orders from companies. 7. The data equipped is based on a normal sort of manufacturing activity utilizing typical techniques of manufacturing at optimum degree of efficiency. With a turnover of over 200 crores, SPB Machinery presents paper related machines for a wide range of merchandise. However for high-quality boxes virgin Kraft remains to be used. Solarco Machinery was founded in 1990 and specializes within the production of boxmaking machines designed for mid and brief runs. The beginning of 2016 witnessed a gradual increase in the demand for corrugated box making machines owing to the rise within the demand for packaging materials,” provides Gaurav. For partition packing containers the half slotted boards are used which might conveniently be produced over a partition spotter machines. Our crew of in-home experts provides specialized services and products that will deliver your brand to life. International Corrugated Field Making Machine Market 2019report gives key statistics in the marketplace standing of the Corrugated Field Making Machine Manufacturers and is a helpful source of guidance and direction for firms and individuals fascinated in the Corrugated Box Making Machine Trade.

The post Paper Field Making Machine appeared first on Diy Script.

from WordPress https://ift.tt/2UYcbBn

via IFTTT

0 notes

Text

The Trees and the Forest of New Towers

This article is part of our November Design special section, which focuses on style, function and form in the workplace.

Michael Green has seen the future of the building industry, and that future is wood. Lots of wood. The Vancouver-based architect is among the most ardent proponents of what is known as mass timber, prefabricated structural wood components that can be used to construct buildings — even large-scale buildings — faster, with less waste and eventually with less money.

Most crucially, Mr. Green and others say, building with mass timber can ameliorate climate change because it produces less in greenhouse gas emissions than construction with concrete and steel. And wood has the benefit of storing the carbon dioxide trees absorb during their growth, keeping it out of the atmosphere indefinitely.

“Roughly 11 percent of the global carbon footprint is related to what buildings are made out of,” said Mr. Green, whose mass-timber projects include the T3 office building in Minneapolis (the name stands for timber, technology and transportation) and a pair of buildings for Oregon State University’s College of Forestry, including a research and development facility for the school’s TallWood Design Institute.

Over the next 40 years, he added, it is estimated that nearly 2.5 trillion square feet of new construction will be needed to support growth in the world’s increasingly dense urban areas, according to the 2017 Global Status Report issued by the United Nations Environment Program. “If we continue to build the way we are,” Mr. Green said, “we are absolutely not going to meet any kind of climate objective, and we’re going to change our children’s future forever in a pretty bad way.”

While cutting down trees to make buildings may not sound environmentally sensitive, mass timber supporters argue that wood could be harvested from sustainably managed forests.

Increasing numbers of architects, developers, governments, educational institutions and corporations are embracing wood. In Biel, Switzerland, Swatch Group just completed three buildings said to be among the largest timber construction projects in the world. Designed by Shigeru Ban, an architect admired for his innovative use of wood, the complex includes a serpentine company headquarters wrapped in a spectacular latticed timber facade.

Notably, big players in the tech world are adopting wood. Microsoft is using mass timber throughout its new Silicon Valley campus, while Sidewalk Labs, Google’s sister company, has plans for a new waterfront district in Toronto consisting of wood buildings, some as tall as 30 stories.

“We’re past the tipping point in the acceptance of wood,” said Thomas Robinson, founder of the Portland, Ore., firm Lever Architecture, which recently completed the Nature Conservancy’s local offices and community center using Forest Stewardship Council-certified wood and is working on an expanded mass-timber headquarters for Adidas. “The people who are the innovators, looking for the next thing, a richer experience for their employees or how they live, they’re turning to mass timber.”

The benefits are aesthetic and environmentally responsible, he added. “People just connect to wood in a way that is visceral.”

Mr. Green, who is consulting with Sidewalk Labs on its proposal for Toronto, said mass timber should be embraced for buildings much larger than residential and low-rise structures, which now account for most wood construction. When the seven-story T3 Minneapolis (designed with DLR Group) was completed in late 2016, it was the tallest wood building in the United States. An eight-story residential building in Portland, Ore., called Carbon 12, has since been built.

A second T3-branded property is planned for Atlanta, and other projects are in the works for Nashville; Denver; Austin, Texas; and two are planned for Toronto.

At the end of last year, the International Building Code was changed to allow wood buildings of up to 270 feet tall, or the equivalent of about 18 stories, from 85 feet. The United States code won’t adopt the revised standards until 2021, but some states will allow projects based on the new criteria to be submitted before then.

In Europe, where mass timber began gaining traction nearly 20 years ago, encouraged by aggressive climate policies, wood buildings are rising to new heights. Last spring the 18-story Mjostarnet office and residential tower by Voll Arkitekter in Brumunddal, Norway, became the world’s tallest mass-timber building at 280 feet (including an openwork wood structure on its top).

Just a few months later, the HoHo Vienna, a mixed-use building designed by Rüdiger Lainer + Partner, was nearly the same height but had six more floors.

Enthusiasm for timber, however, is not universal. Some environmental groups have raised concerns about the effects of scaling up wood construction, especially without universal commitments to sustainable forestry. Skeptics also note that there is limited data on mass timber’s long-term impact on atmospheric carbon levels — the full benefit of which is possible only if the wood components used are recycled and not allowed to decay at the end of a building’s life.

There are also deeply ingrained fears around wood and fire safety, and both the International Association of Fire Chiefs and the National Association of State Fire Marshals opposed the recent updates to the International Building Code, arguing, among other things, that additional fire testing is needed before mass timber can be safely used in tall buildings.

Those who favor timber, however, say far taller wood buildings are possible. Prominent architecture firms like Skidmore Owings & Merrill, PLP Architecture and Perkins & Will have done studies for wood-framed skyscrapers between 40 and 80 stories. The Japanese timber company Sumitomo Forestry has proposed an 1,100-foot, 90-percent wood tower for Tokyo that would be the country’s tallest building of any type.

“We’re already designing at 35 stories,” Mr. Green said, citing a tower he conceived for a development proposed for the Porte Maillot area of Paris.

To be clear, timber advocates are not pushing for a return to old ways of building, before devastating fires prompted large cities like New York and Chicago to ban most new wood construction in the 19th century. Mass timber refers to a variety of different types of engineered wood components, the most common being cross-laminated timber (known as CLT) and nail-laminated timber (or NLT), in which multiple layers of wood planks, stacked at 90 degrees, are glued or nailed together under pressure to form structural panels. So-called glulams, which are made in a similar fashion and have been around for more than a century, are typically used for long elements like beams and columns.

Mass-timber components have a resistance to burning that is relative to their thickness, as extensive tests conducted by the United States Forest Service and the American Wood Council at the Bureau of Alcohol, Tobacco, Firearms and Explosives Fire Research Laboratory and elsewhere have demonstrated. When mass timber is exposed to fire, the outer layer chars, slowing the burn and creating a protective barrier around the core. In multiple fire tests, mass timber’s performance has consistently exceeded building code requirements.

Wind becomes more of an issue as buildings get taller, one reason that most mass-timber buildings higher than several stories are hybrid structures, incorporating some concrete, steel or both to provide rigidity and weight.

For now, a lot of mass-timber projects are about recapturing the spirit of old industrial wood buildings, albeit updated with 21st-century comforts and technology. In Toronto’s Distillery District, the New York firm SHoP Architects plans to use mass timber for a sprawling five-story retail and office complex inspired by the area’s historic buildings. It will be SHoP’s first mass-timber project, after plans for a much-anticipated 10-story residential tower in Manhattan fizzled a couple of years ago when approvals stalled.

“People want to live and work in these kinds of buildings — they have a sense of connection to the material,” said Chris Sharples, one of SHoP’s founding partners. “And what we’ve seen from fabricators and builders is that there’s a 35 percent drop in construction time for mass-timber buildings, which means the carrying costs are less.”

And, he said, the work sites are quieter and cleaner, generating less waste. “When you live near a job site, it’s noisy, with all of the trucks — it’s a horrible quality of life,” Mr. Sharples said. “You see these wood buildings go up and it’s like a barn-raising in the middle of your block.”

Ultimately, economic and quality-of-life factors are driving mass timber as much as global climate considerations. “People don’t do this for the environmental reasons,” Mr. Green said. “I may, but my clients want to know it’s cheaper.” And it is getting cheaper, as the industry expands and supply chains are developed. Mr. Green’s firm was acquired by the building technology company Katerra, whose enterprises include one of the world’s largest CLT plants in Spokane, Wash.

While he imagines explosive creative possibilities for architects inspired by future technologies like 3-D-printed wood, Mr. Green said climate considerations were paramount. “We need to change the conversation around what to celebrate in architecture,” he said. “This movement is about switching out the concept of what good design is. There has to be a new framework of what we see as beautiful.”

Sahred From Source link Fashion and Style

from WordPress http://bit.ly/2OpPqkY

via IFTTT

0 notes

Text

Advanced Energy Storage Market, 2024 – Product Launches, Recent Industry Activity, Key Players

DUBLIN, June 5, 2019 /PRNewswire/ — The “Advanced Energy Storage: Global Market Analysis, Trends, and Forecasts” report has been added to ResearchAndMarkets.com’s offering.

This report provides separate comprehensive analytics for the US, Western Europe, Asia-Pacific, and Rest of World. Annual estimates and forecasts are provided for the period 2015 through 2024. Market data and analytics are derived from primary and secondary research. Company profiles are primarily based on public domain information including company URLs. The report analyzes the worldwide markets for Advanced Energy Storage in terms of installed capacity (in Megawatts).

The report profiles 94 companies including many key and niche players such as:

ABB Ltd. (India)

Active Power, Inc. (USA)

AES Energy Storage, LLC (USA)

Alevo Group S.A. (Switzerland)

Altair Nanotechnologies, Inc. (Canada)

Amber Kinetics, Inc. (USA)

Areva (France)

Ashlawn Energy, LLC (USA)

Axion Power International, Inc. (USA)

Beacon Power, LLC (USA)

BYD Co. Ltd. (China)

Calnetix Technologies, LLC (USA)

ECOULT (Australia)

Electrochaea GmbH (Germany)

Encell Technology, Inc. (USA)

EnSync Energy Systems, Inc. (USA)

Exide Technologies (USA)

General Electric Company (USA)

Gridflex Energy, LLC (USA)

Highview Enterprises Ltd. (UK)

Hitachi, Ltd. (Japan)

Hyper Tech Research, Inc. (USA)

IMS group AS (Norway)

ITM Power Plc (UK)

Kokam co., Ltd (Korea)

Leclanch SA (Switzerland)

LG Chem (Korea)

LightSail Energy (USA)

Maxwell Technologies, Inc. (USA)

McPhy Energy S.A. (France)

NEC Energy Solutions (Japan)

NGK Insulators, Ltd. (Japan)

Proton OnSite (USA)

Redflow Limited (Australia)

Saft Groupe S.A. (France)

Samsung SDI Co., Ltd. (South Korea)

Siemens AG (Germany)

Dresser-Rand Group, Inc. (USA)

Temporal Power (Canada)

Tesla, Inc. (USA)

Tianjin Lishen Battery Co., Ltd. (China)

Toshiba International Corporation (USA)

ViZn Energy Systems, Inc. (USA)

Key Topics Covered:

1. INDUSTRY OVERVIEW

Rising Share of Intermittent Sources of Energy in Utility Energy Generation Portfolio: The Cornerstone for the Growth of Utility Grade Advanced Energy Storage Technologies

Review of Renewable Energy Projects Undertaken Worldwide and Regulations Supporting Renewable Electricity-to-Grid Integration

Declining Cost of Wind and Solar Power Make Renewables an Important Part of Utility Energy Portfolio

Escalating Climate Change Adds Urgency to the Renewable Energy Revolution Underway in the Global Economy

How the Renewable Energy Boom Benefits Advanced Energy Storage Technologies

Despite Declines in Renewable Investments, Outlook for Advanced Energy Storage Remains Bright

Prolonged Softness in Oil Prices: What It Means for Renewable-to-Grid Integration

Although Lower Than Pre-Recession Levels, World Demand for Energy Will Remain a Key Driver of Growth

Major Market Trends and Drivers

Rising Investments in Energy Storage Projects Bodes Well for the Growth of Advanced Energy Storage Technologies

Aging Energy Infrastructure Drives Opportunities for Energy Storage as a Method of Modernizing Energy Grids

Are Batteries Ready for Mass Commercialization in Grid-Level Energy Storage?

Value Stacking: A Vital Product Development & Design Strategy to Counter the High CAPEX of Battery Energy Storage Technologies

Lithium Ion (Li-ion) Batteries: The Leader in Utility-Scale Applications

Price of Li-ion Batteries Fall, But Not at the Rate Required for Mass Adoption

Robust Surge in Solar and Wind Farms Throws the Focus Squarely on Grid Stability

Energy Storage Assets Remain Vital Towards Enhancing the Operation of Smart Grids

Flywheel Systems Emerge as a Reasonable Alternative to Batteries Uniquely Suited to Utility-Scale Applications

Large Capacity Sodium Sulfur Battery Grow in Prominence as a Promising Clean Energy Technology

CAES Systems to Offer Utility Grids Cost-Effective Bulk Storage

LAES Promises Environmentally Neutral Grid Scale Energy Storage without Geographical Constraints

SMES: A Promising Advanced Energy Storage Technology

Hydrogen Storage Offers Seamless Integration of Wind and Solar Energy into the Grid

Continuous Innovations Push a Bevy of Exciting Storage Technologies Closer to Commercialization

Market Outlook

2. PRODUCT OVERVIEW

Advanced Energy Storage: Definition

Types of Renewable Energy Storage Technologies

Overview of Currently Available Energy Storage Technologies

Various Energy Storage Technologies: Key Advantages & Disadvantages

Short-Term Renewable Energy Storage Technologies

Supercapacitor Energy Storage

Flywheel Energy Storage

Superconducting Magnetic Energy Storage

Long-Term Renewable Energy Storage Technologies

Pumped Hydroelectric Energy Storage

Compressed Air Energy Storage

Battery Energy Storage

Characteristics of Select Battery Technology Types

Hydrogen Energy Storage

SWOT Analysis of Different Long-Term Renewable Energy Storage Technologies

Government Intervention Critical to Widespread Adoption

Domestic Targets for Greenhouse Gas Emissions of Select Regions/Countries

Significance of Renewable Energy Storage

Minimizing Energy Costs

Ensuring Reliable Supply of Energy

Increasing Energy Autonomy

Renewable Energy: A Primer

An Introduction

Renewable Energy: A Definition

Benefits of Renewable Energy

Environmental Benefits

Economic Benefits

Energy Security

Sources of Renewable Energy

Solar Energy

Power Tower Systems

Parabolic-Trough Systems

Dish/Engine Systems

Wind Energy

Geothermal Energy

Binary Cycle Power Plants

Flash Steam Power Plants

Dry Steam Power Plants

Hydroelectric Power

Bioenergy

Hydrogen and Fuel Cells

Ocean Energy

Ocean Mechanical Energy

Ocean Thermal Energy

Disadvantages of Renewable Energy

Disadvantages of Solar Energy

Disadvantages of Wind Energy

Disadvantages of Geothermal Energy

Disadvantages of Hydroelectric Energy

Disadvantages of Ocean Energy

Energy Storage Technology AdvancementsRice University Announces Molybdenum Disulfide Breakthrough

Researchers at MIT Upgrade Proposed Liquid Battery System

Alevo Develops Innovative, High-Efficiency Energy Storage System

Nanotechnology: The Future of Energy Storage?

Nanotubular Bulk Material with Ultra-Low Density for Energy Storage Applications

Compressed Air Energy Storage Systems that Eliminate/Reduce Use of Fossil Fuels

Affordable Batteries with High Durability and Advanced Chemical Compositions

Hydrogen Electrolysis: A Potential Laden Energy Storage Solution

Aquion Energy Develops New Battery for Microgrids

3. PRODUCT LAUNCHES/INTRODUCTIONS

Samsung SDI Launches High-Performance Batteries

Wrtsil Launches Advanced Energy Storage Solutions in India

BYD Launches MINI-ES, B-Box and Containerized ES

Flex Launches Renewable Advanced BESS

Adara Launches Adara Pulse for Residential Sector

Samsung SDI Releases High-capacity and High-power ESS Batteries Range

NEC Unveils DSS Distributed ES Platform

AEG Develops Hybrid Energy Storage System

Caterpillar Launches Cat Microgrid Technology

JLM Launches Energizr 200, Grid Synergistic Residential ESS

UET Announces Commercial Availability of ReFlex ESS

4. RECENT INDUSTRY ACTIVITY

Schneider Electric Signs MoU with NGK INSULATORS

Toshiba Collaborates with NRG Energy

Greensmith Inks Partnership Deal with AEP to Install 4MW ESS

Cummins to Acquire Assets of Brammo

NEC Announces Dale as Its First Qualified DSS Partner in the UK

BYD Receives Contract to Supply 170-MW Solar Modules

NEC Receives Contract for Supply of GSS to EKZ

Southern Company Initiates Battery Storage Research Project

AES Forms a Joint Venture with Siemens AG

CCL Acquires Firefly Solar Generators

CalCom Sets Up New Energy Storage Business Unit

NEC Chile & NEC Energy Bags Contract for Supply of 2 MW ESS

Maxwell Acquires Assets of Nesscap Energy

NEC and Enspire to Build Large-Scale ESS in Germany

NEC and VLC Sign Contract to Build and Operate ES Projects

Ecoult Forms Partnership with Exide

Ecoult Receives Funds from ARENA for Renewable ES Development

Piller USA Changes its Name to Piller Power Systems Inc.

Piller Power Acquires Active Power

Temporal Power Collaborates with Danfoss

NEC Bags a Contract to Supply Plug-AndPlay Battery Grid ESS

Saft Obtains Approval for Seanergy Marine ESS

NEC to Supply 2 MW, 3.9MWh GSS Grid ESS to SMLD

Powin Corp. Merges with Powin Energy

BYD Collaborates with GoodWe Power

Maxwell Collaborates with CRRC-SRI for Developing Advanced ESS

NEC Energy to Supply 1.2MWh GBS Battery ESS to Smart Power

Hydrogenics and Phraram Receive Hybrid Project from EGAT

Total to Acquire Saft Group

Convergent and Temporal Ink Agreement to install 5 MW Flywheel ESS

Panasonic and AES to Construct 10MW ES Array in India

NEC Installs GSS Large-Scale ESS in Japan

Sonnedix Solar Commissions First Grid-Scale ESS Project

Corvus Energy Inks Multi-Year Agreement with LG Chem

Saft Forms New Subsidiary, Saft Japan Kabushiki Kaisha

BHTEPCT Selects Maxwell’s Ultracapacitors for Wind Farm ES Project

5. PLAYERS IN THE ADVANCED ENERGY STORAGE ECOSYSTEM

6. GLOBAL MARKET PERSPECTIVE

Total Companies Profiled: 94 (including Divisions/Subsidiaries 102)

The United States (56)

Canada (6)

Japan (5)

Europe (25)

France (5)

Germany (6)

The United Kingdom (6)

Italy (1)

Rest of Europe (7)

Asia-Pacific (Excluding Japan) (9)

Latin America (1)

For more information about this report visit https://www.researchandmarkets.com/r/7w4smv

Research and Markets also offers Custom Research services providing focused, comprehensive and tailored research.

Media Contact:

Research and MarketsLaura Wood, Senior [email protected]

For E.S.T Office Hours Call +1-917-300-0470

For U.S./CAN Toll Free Call +1-800-526-8630

For GMT Office Hours Call +353-1-416-8900

U.S. Fax: 646-607-1907

Fax (outside U.S.): +353-1-481-1716

SOURCE Research and Markets

Related Links

http://www.researchandmarkets.com

The post Advanced Energy Storage Market, 2024 – Product Launches, Recent Industry Activity, Key Players appeared first on The Chestnut Post.

from The Chestnut Post https://www.thechestnutpost.com/news/advanced-energy-storage-market-2024-product-launches-recent-industry-activity-key-players/

0 notes

Text

South Korea’s Economic Tipping Point

The IMF built an critical statement past 7 days, recommending that South Korea adopt expansionary fiscal insurance policies. This indicates lowering taxes and/or rising governing administration expenditures to encourage financial progress. The fundamental basic principle is simple: if persons have much more revenue to devote and the government is paying out extra, the economic system will have far more funds rolling all around in it, supporting new positions and expansion. That’s why the identify.

The concealed phrase in expansionary plan is “public credit card debt.” Nearly each and every industrialized place not named Greenland or Norway runs a authorities deficit at some stage, that means tax income is exceeded by fees, necessitating the federal government to borrow to go over the difference. This is known as “public financial debt.” Expansionary plan, particularly when carried out by tax reduction, suggests the governing administration accrues much more public personal debt than normal.

To its credit, South Korea has one of the lower public personal debt premiums among OECD countries: only 38 p.c of annual GDP. For reference, the entire world and EU averages are 61 per cent and 83 percent, respectively, with the United States, Canada, and Germany, respectively, obtaining community debts of 105 percent, 90 p.c, and 64 %. This implies South Korea is really nicely-positioned to absorb new expansionary procedures.

Enjoying this write-up? Simply click in this article to subscribe for entire obtain. Just $5 a month.

South Korea’s low community debt is a legacy of the 1990s Asian fiscal crisis. During this period, the Korean economic climate collapsed by a blend of weak enterprise methods and unsustainable debt. Immediately after a sturdy restoration in the 2000s, domestic financial debt has once again begun stacking up, reaching 97 per cent of GDP by the finish of past yr, a single of the highest fees in the globe. For reference, the United States, Canada, and Germany, respectively, have family personal debt costs of 78 per cent, 100 per cent, and 53 percent.

Community debt has remained below a tighter leash. The Moon administration has been primarily cautious, holding the books well balanced with fiscal surpluses and raising taxes to aid new paying expenditures. Most of this new earnings has long gone to spend for general public sector position expansions. In spite of the hard work, South Korea’s all round unemployment has greater, sparking fears over a cloudy economic long term. This uncertainty has introduced Seoul to the position the place authorities borrowing may possibly be essential to avoid economic contraction.

The usefulness of expansionary procedures in the small term is not disputed. When there is additional funds in the program, positions are made. Essentially, this money can be considered as an investment decision to develop new industries and business enterprise. The obstacle in contemporary moments is to make this financial commitment sustainable so the federal government, at some position, can stop borrowing, with the new industries and enterprises getting enough footing to spend for by themselves and, with any luck ,, generate tax income back to the government.

Japan is the regrettable example of a state that pursued expansionary insurance policies too much. Saddled with community debt now well worth 253 percent of GDP, Japan bought listed here by pursuing a very long collection of expansionary guidelines (also referred to as stimulus offers) above the class of a number of a long time. The insurance policies were well-intentioned, of study course, aimed at improving development by focusing on a array of investments in technologies, infrastructure, and education. Regretably, the investments by no means compensated off, leaving the Japanese authorities in the uncomfortable position of now becoming able to only pay out interest on its personal debt.

At the other conclude of the debt spectrum is austerity. This is the method in which a federal government cuts spending to reduce debt. In the final ten years, a range of nations around the world, most notably in Europe, have tried this follow to disastrous results. The primary idea of chopping expending to lower credit card debt appears to be like prevalent perception at to start with. This is just what a domestic or a organization would do. However, national economies really don’t behave like possibly. As pointed out earlier mentioned, cash invested by the govt produces work by including funds to the economic system. If that cash is taken out, individuals shed their jobs.

Brazil is a very good example of how austerity can make poor issues even worse. In the early 2010s, Brazil, mostly an export economy, was encountering slumping exports and mounting corporate credit card debt. The previous was acquiring a pretty direct affect on financial improvement, bringing GDP progress to a standstill. The latter was generating providers shy about investing as they concentrated on debt compensation, putting a halt to personal sector using the services of.

Starting up in 2014, Brazil’s then-President Dilma Rousseff implemented a series of austerity policies intended to control the two corporate and public debt. The guidelines had been popular and appeared to make prevalent perception, but were being completely misguided, plunging the place into the worst recession of its background. Unemployment skyrocketed from about 6 % in 2014 to a significant of virtually 14 percent by 2017. The new insurance policies also unsuccessful at their supposed purpose: community credit card debt ballooned from 56 percent of GDP in 2014 to 80 per cent now.

Brazil’s route, regretably, shares some striking similarities with South Korea’s current condition. South Korea, yet another export-dependent economic system, has seen its exports declining in latest many years with corporate debt escalating. The previous has depressed progress while the latter has set a pressure on personal sector selecting, just like it did in Brazil. To stay away from the very same disastrous consequence, austerity need to be prevented although expansionary guidelines, like all those proposed by the IMF, seem a reasonable possibility for stimulating continued expansion.

The remaining question, then, is how to devote the borrowed income. A tax reduction very likely would be welcomed by the common general public, potentially even encouraging President Moon Jae-in’s flagging approval ratings. With interest fees at a modest 1.75 per cent, excess money in people’s savings accounts would likely have some favourable effect on domestic investment decision, although significantly less than in former many years as South Korean banking companies have recently turned to investing additional overseas. If tax breaks are utilized to shell out personal debt, this also would have small outcome on advancement, placing a restrict on their performance.

The concentrate of any expansionary insurance policies, thus, will have to be specific investments in precise industries. Moon has previously identified hydrogen automobiles as a critical space of interest, linking potential exports with China’s continued commitment to renewable strength. Investing in other South Korean strengths this sort of as electronics and substances also appear to be like sensible solutions. If Seoul follows through on IMF suggestions, the subsequent couple of months really should expose a series of selections about how the South Korean federal government will be betting on its long term.

Justin Fendos is a professor at Dongseo College in South Korea and the associate director of the Tan University at Fudan College in Shanghai.

The post South Korea’s Economic Tipping Point appeared first on Defence Online.

from WordPress https://defenceonline.com/2019/03/20/south-koreas-economic-tipping-point/

0 notes

Text

Telenor reveals 7 tech trends that will shape 2019

Seven technology trends stand to reshape how we consume, how we connect and even how we perceive the world around us in 2019, says Telenor Research.

After a breakneck year of tech world advancements, setbacks and successes, Telenor Group’s research arm, Telenor Research, identifies seven tech trends to study up on for 2019. While there is no shortage of staggering high-tech feats identified this year, the notion of “responsibility” resonates through many of this year’s trends.

“The world of technology is constantly on the go. With exciting innovation – which we point to this year in greater scale than ever – comes the need for reflection, pragmatism and perspective.

We think that the tech pendulum is swinging in that direction in 2019. People are taking a step back and assessing ‘what do these deeper developments in technology and connectivity mean to me, to my family, my community?’” reflects Bjørn Taale Sandberg, Head of Telenor Research.

“In the end, we all want the assurance that technology – no matter how many steps ahead of us it might seem – can fit into our lives safely, sensibly and positively,” he added. Here are the seven tech trends we see making a big impact in 2019:

Masks, shades and filters have been all the rage on social media and messaging apps. The iPhone X took the idea further with facial recognition, but as the technology makes even more advances, why stop there? Remember Tom Cruise’s masks in Mission Impossible?

Well, doing this in cyberspace is no longer “mission impossible”. It’s made very much possible by something the tech world has coined “deepfake”. It’s when Deep Learning meets Fake News (or doctored photos and videos, for that matter).

2019 will bring us more deepfake content because a large amount of work is going into algorithms called generative adversarial networks (GANs). A plethora of variants is emerging, and the systems as a whole are learning a lot faster.

It is these algorithms that will enable the creation of deepfake content so advanced that we could have a difficult time differentiating between what’s real and what’s fake in the digital world.

If people had trouble telling fake news posts apart from real news on social media between 2016 and 2018, it’s very possible that the boundaries will be blurred even more in 2019.

The world’s largest democracy, India, will hold general elections in 2019, while the world’s second largest democracy, the US, will begin the lead up to its 2020 presidential campaign.

These elections are likely to trigger the production of sophisticated deepfake content made to manipulate and misinform the public. The good news is that they could also trigger intensified development of media forensic tools and techniques to safeguard democratic processes.

2019 will see internet service providers, operators and regulators look seriously into mitigating deepfake content, and widespread public awareness campaigns against deepfake.

In 2017, we predicted that AI ethics would one day be up for discussion. That time has come. The fact that AI will impact nearly every industry and society at large is no longer questionable.

As people increasingly tune in to how technology affects their lives, AI is one of those technologies that will receive more public scrutiny in 2019.

In the coming year, we will see public and private bodies setting AI governance frameworks and adopting new codes of conduct to ensure that they operate with high ethical standards.

This will be done in order to ensure that AI systems are non-discriminatory, transparent, traceable and secure, and that there are always humans in the loop who are accountable for its design, development and adoption.

Enabling this, we will also see new venues for AI dialogues happening at all levels of politics, new platforms for education and training in AI, as well as investments in tools and systems that enable ethical AI development.

“High ethical scrutiny may inhibit innovation,” some might say, and in the absence of such oversight, most thriving AI ecosystems in the US and China might be able to grow and innovate faster than more regulated regions, such as Europe.

Yet, we see AI governance as vital to sustainable innovation, uptake and acceleration of AI in business. In the end, these autonomous systems need to solve problems for people in a secure, robust and reliable way; proactive monitoring and governance structures for ethical use of AI will aim to ensure that.

In 2017, it was all about 5G testing: could a computer a few meters away connect to a signal station running a 5G frequency. In 2018, we saw pioneering uses of 5G – like the 5G drone coverage of the Winter Olympics in South Korea.

And coming in 2019, we’ll see “5G islands” emerge across the world as large-scale pilots and trials – from Europe to North America and northeast Asia – connect selected communities and business networks.

Digitising societies has been buzzword among operators, industry bodies and governments over the past few years, but 2019 will be the first year when communities will experience what this actually means, taking towns like Norway’s Kongsberg, a 5G pilot town, as a first example.

Though 2020 is the year that 5G’s global standard will release, 2019 will see emerging ecosystems and likely some of the first marketing campaigns based on 5G.

From the first self-driving, 5G-steered buses to automated fisheries, from 5G-driven TV and fixed broadband to potential applications of 5G-powered remote surgery – the 5G floodgates will open in 2019, paving the way for commercial services to hit the market in 2020.

We think 2019 will be the year when industrial IoT customers crack the transition from proof-of-concepts, which we’ve seen in recent years and months, to large scale commercial deployments in low-power wide-area (LPWA) ecosystems.

We expect this LPWA ecosystem to blossom this year in particular, enabling larger industrial applications which to date haven’t matured quickly.

As the LPWA ecosystem matures and as developers have vetted much of its tech stack, we can expect to see industries to roll out large scale IoT, particularly within the arenas of smart cities, industrial manufacturing and process industries, such as shipping, traffic and transport monitoring and fisheries. In short, IoT is going industrial in 2019.

On the backend, it is becoming clearer how different connectivity technologies serve different use cases. Examples include LTE networks for CCTV and automotive, which are already widespread; LTE-M for logistics; NB-IoT for metering – and many more use cases for each.

Though the question on which IoT technologies will scale furthest and fastest remains, one thing is clear – LPWA IoT networks will get more than their share of the spotlight in 2019 and beyond.

The sobering reality of how hard it’s been to work with text-based chatbots has killed a lot of large-scale attempts. We see voice-activated chatbots doing better in 2019 – mainly in household devices.

They aren’t the most clever systems yet, but as they advance, we can expect more chatbots helping us in our homes than we have before.

We think 2019 will see huge growth of voice-controlled chatbots, leading to smarter voice-recognition applications, since they will be limited to a narrow skill-set in which they will perform well.” It’s possible that by this time next year, domestic chatbots will be at the top of 2019’s holiday wish lists in many markets around the world.

Awareness of screen time and its effects on us is becoming widespread. Following some early movers, people will increasingly use screen time tracking apps, night-time and do-not-disturb modes on phones, as developers tune the smartphone experience to enable us to manage our use of these devices.

Developments in the marketplace as a result of increased screen time awareness and discipline will snowball in 2019.

Beyond new apps and software, we could see more stringent limits on screen time in various social and professional settings. Mobile-free meals with family and friends, and mobile-free meetings are certainly becoming more common. Whatever the case, this latest burst of screen time products and campaigns by private industry go a long way to raise awareness.

Moreover, people concerned with their own personal screen time could opt for simpler connectivity – in the form of flip phones. We might see the trend of twin SIM purchases, one for a data-powered smartphone and one for an analog flip, pick up speed.

A virtuous cycle in green consumption, awareness and green tech development will take shape in 2019, given a boost in large part by mobile technology. The UN’s Intergovernmental Panel on Climate Change’s late 2018 report came as a wake-up call to those not already paying attention.

As climate change worries and awareness of consumption both skyrocket in society, a wave of mobile-driven green technology will help people live and consume more smartly than ever. In 2019, this wave will reach its much needed crest.

Oslo, Telenor’s hometown, is becoming a bellwether of greentech’s ability to reach scale. The increasing popularity of products and services like Too Good To Go, which cuts down on food waste, car-sharing platforms, bicycle-only food delivery services, Tesla and electric cars (close to 30 percent of new cars in Norway are electric in 2018) prove that consumers are highly receptive to greentech, if not outright demanding it.

And aggressive disincentives –taxes and tolls on environmentally unfriendly transport and consumption provide the knock-out punch to environmental apathy in Norway.

On a holistic level, credit goes to government policies, developer enthusiasm for greentech, consumer receptivity and social pressure; four effective cogs churning out greener tech and greener habits – in Norway and beyond in 2019.

Related Link

Telenor

dtac

Read the full article

0 notes

Text

Mining Like a Viking: How the Fjords of Norway Offer a Greener Alternative

“Make sure to close the door behind you,” Mathis Schultz, the CEO of Northern Bitcoin, said to me in a near shout. As we entered the backside of the shipping container, partitioned for the ASIC miners’ exhaust, Schultz wanted to make sure the heat emitted wouldn’t mingle with the temperature-controlled front end of the shipping container.

The door opened, my senses, already ringing from the blaring of the ASICs’ mechanized grind, were ignited. Like stepping from one climate zone to the next, I was greeted by a wave of hot air, the collective, arid exhaust from the shipping container’s 210 Antminer S9s.

The backside of the mining rigs emit a powerful exhaust.

All that heat and the cacophony came from just a fraction of the 3,250 miners Northern Bitcoin runs in 15 shipping containers. Situated in Lefdal mine — a data center located roughly 31 miles northwest of Sandane, Norway — the operation is certainly unique. Bridging two industries and centuries, the bitcoin mining farm sits in a defunct olivine mine from the ’70s.

Even more serendipitous, the converted data center is powered by 100 percent renewable energy from hydroelectric plants built in the same decade. Fed by the fjords that punctuate Sandane’s mountainous landscape, hydroelectric dams provide the data center with an abundance of clean energy.

For Northern Bitcoin, this means mitigating the biggest headache when it comes to scaling and operating a mining farm: electricity costs.

Northern Bitcoin

Northern Bitcoin was founded in 2015. In its infancy, it was the aspirational leap into a new and still uncertain industry for CEO and Founder Mathis Schultz. A former banker for such firms as LGT, Julius Baer and Elan Capital partners, Schultz decided to shelve his former career in the old financial mode to pursue what he considers the future of finance.

“I have always been interested in finance, the nature of money and its impact on our society. When I first heard of bitcoin and began to deal with it, I was instantly fascinated: Bitcoin is a revolution of our financial system. Its technology will replace many of their services, especially global transactions, and I wanted to be part of it,” Schultz told Bitcoin Magazine.

Northern Bitcoin's core team who accompanied us in Norway, standing front of a shipping container: (from left to right) Dr. Hans Joachim Dürr, Moritz Jäger, Mathis Schultz, and Marieke Garrels.

Thus far in the company’s young development, Schultz’s gamble has been paying off. What started off as a single container operation of a handful of miners has scaled into the 3,000+ ASICs held in Lefdal today. From this growth, the company has taken its operations public. Traded on the Munich stock exchange, Northern Bitcoin is valued at $177 million. More impressive, its valuation has stayed relatively stable during the recent bear market, something that most crypto-related businesses have struggled with as prices continue to tread water.

Northern Bitcoin’s novel operations are no doubt integral to this success. Schultz expressed that Norway and the Lefdal mine formed “a perfect match for all [the company’s] criteria.”

With access to the cheap, renewable energy — which the region’s plants produce in surplus and the Norwegian government exports — the mine can operate with minimal costs and with neutral carbon emissions.

The region itself boasts up to 6.7 TWh of excess renewable energy. This puts the mine’s electricity costs somewhere between $0.035–0.045/kWh, giving it a power usage efficiency value of 1.08 — a more than favorable figure.

To put this into perspective, Mongolia provides Bitmain access to renewable forms of energy at an average of $0.08–0.09/kWh.

Northern Bitcoin’s energy costs are lowered still by the climate control measures Lefdal mine features by design. As if the Norwegian climate wasn’t cool enough, the data center is situated some 656 feet below ground, so it maintains a constant temperature of 55 degrees Fahrenheit (~12.5 degrees Celsius).

On top of this, the center pumps water in from the surrounding fjords to cool its IT hardware, dumping it back into the fjords so as to ensure zero waste.

This process allows Northern Bitcoin to cool its rigs down from 86 degrees Fahrenheit to 64.4 degrees Fahrenheit when they’re operating at full capacity. The team claims that this reduces their operating costs by up to 40 percent.

“The 15 containers in Lefdal have an electric power of about 4.6 MW and thus consume a little bit more than 110 MWh a day,” CTO Moritz Jäger told Bitcoin Magazine.

To increase the hardware’s efficiency and cut operating costs further, Jäger and his team have developed their own software for running the miners. This software, Jäger claims, allows the miners to perform at a fuller capacity by cutting back on secondary functions.

“... the factory software is not optimized for best performance. It is doing other things additionally to the hash computations, like communicating with different servers, rendering a web user interface and so on. Some of these functions can be turned off completely and others can be executed with lower priority to save CPU time for the actual hashing. It is also very restricted in its overclocking functionality.”