#MagneticShutteringSystem

Text

Magnetic Fixture Systems for Concrete Formwork and Precast Accessories

Along with the modular construction modernizing, it has been in the teeth of the storm for the precast concrete plants to raise the productivity, reduce the labour costing and construction materials wasting. The essential factor is to accomplish the flexible and efficient precast molding and demoulding to realize the automatic, intelligent and standardized production.

Magnetic Shuttering System, as a transboundary magnetic fixture with the combination of magnetic material and precast mould, is playing a prime significant part to solve the above problems. It could extremely simplify the installation and un-installation procedures of the side formwork and precast concrete accessories in the processing of precast elements production, featuring durable, flexible and reusable characteristics, with occupying small room but perform super powerful retaining forces.

Due to the decaded experiences of tailored magnetic system production and precasting project participation, Meiko Magnetics has grown up to be a specialized and qualified formwork profile systems and magnets provider in China. We have been committed to supply one-stop magnetic fixing solutions for precast concrete factories and precast mold equipments manufacturers of the world. Currently our precast concrete magnets mainly include the following types for options.

1. Standard Shuttering Magnets

Standard shuttering magnet is the basic magnetic component for holding and positioning sided shutter molds on the steel casting bed, particularly for the tilt-up tables. It's widely suitable for steel mold, aluminum molds, wooden & plywood molds. The starndard retaining forces are 450KG, 600KG, 900KG, 1350KG, 1500KG, 1800Kg, 2100KG and 2500KG as requested.

2. Magnetic Shutter Profile Systems

It's composed with solid welded metal case or U shaped channel profile and couples of integrated push button magnetic systems for systematic production of clapping, sandwich wall, solid walls and slabs by manual operating or robot handling.

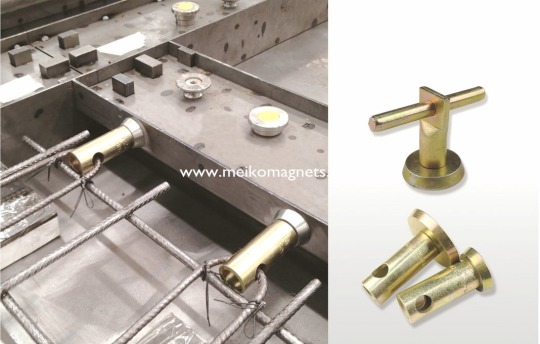

3. Inserted Magnets

The inserted magnets are ideally assemblied for fixing embedded precast concrete accessories, including lifting systems and connection systems, such as sockets, anchors,wire loop, grouting sleeves, pvc pipe, metal pipe and electrical junction boxes.

4. Steel Magnetic Chamfer Strips

Magnetic Chamfer Strip, as a necessary precast concrete accessory, is frequent to be applicated for making chamfers, beveled edges, drip molds, dummy joints, notches and reveals of precast concrete elements.

Meiko Magnetics has always kept it firmly in our mind that " innovation, quality and customer's requirements are the cornerstones of the enterprise". Hope our expertises in magnetic systems can assist you with more accurate & efficient precasting.

Read the full article

#FormworkProfileMagnet#MagneticFixingSolutions#MagneticFixtureforPrecastSideMold#MagneticFixtureSystem#MagneticShutteringSystem#ModularConstructionMagnet#PrecastConcreteAccessoriesMagnet#PrecastPanelFrameworkMagnet#precasttilt-uptable#SocketHoldingMagnet#TailoredMagneticSystemforPrecastConcretePlants

0 notes

Text

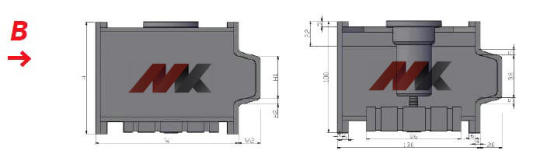

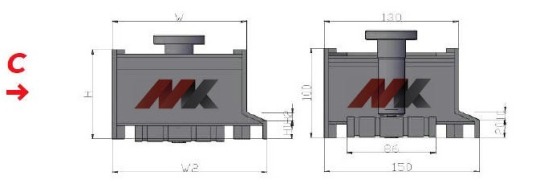

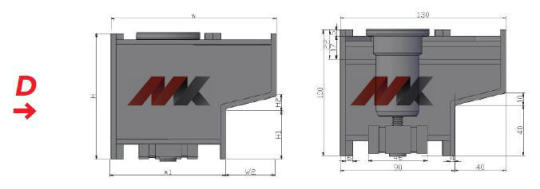

H Shape Magnetic Shutter Profile

H Shape Magnetic Shutter Profile, mainly produced with solidering weld and couples of integrated push button magnetic systems. It's a series of magnetic shuttering systems for systematic production of clapping, sandwich wall, solid walls and slabs. In the traditional magnetic applications of precasting, it used to produce switchable shuttering box magnet and precast steel side mold separately. On the precasting site, the operators locate the shuttering profile at first step, and then attach the magnet into the formwork manually, with adaptors or welding process. It wastes labor capacity and the assembling time.

After taking those overal magnetic shuttering solution, it could sharply reduce the formwork installation process and increase the productive efficiency. Meanwhile, it could be operated by manual or robot handling in optional. Compared to normal connection of side form and magnetic box, the magnetic formwork system could maximize the production space of steel platform, with benifits of occupying minimized installation area. Aparting from those features, we also are capable of producing various shapes and dimensions magnetic profiles, according to your special requirement for the precast elements, to form the concrete components at one time, like chamfers, groove and other forms.

Product Features

1. The magnetic shutter system can be operated by manual or robot handling

2. Easy operation with high productive efficiency

3. Reusable, to reduce disposable plywood forms.

4. The solidering weld is strong, durable and easy to clean

4. Varities of shapes, length, width and height for optional precast element requirements

Standard Dimensions

ITEM NO.

L

W

H

Adhesive Force

mm

mm

mm

kg

H1000

1000

130

100

2 x 1800kg

H2000

2000

130

100

2 x 1800kg

H3000

3000

130

100

2 x 1800kg

H3700

3700

1300

100

3 x 1800kg

* Other length, width, height, shapes and retaining force of each magnet are available to produce in line with customized requirements.

Read the full article

#BoxMagnet#HshapeMagneticShutterProfile#MagneticFormworkSystem#MagneticShutter#MagneticShutterProfile#MagneticShutteringProfile#MagneticShutteringSystem#MagneticSideRailSystem#PrecastConcreteMagnets#PrecastMoldMagnet#PrecastSideRailMagnet#SwitchableButtonMagnet

0 notes