#Manual Bottle Labeling Machine

Explore tagged Tumblr posts

Note

You know when Kelvin was doing the whole ‘lust busting’ thing. What if Gideon and reader were in one of the stores buying things and Kelvin happened to see them.

“Cock ring?” you asked, tapping the plastic package on the wall display. It made a hollow sound, like a toy in a vending machine, bright red font staring back at you.

Gideon snorted and shook his head, squeezing your hand. “Pass.”

You wandered further down the aisle together, eyes wide. What you both had assumed for years was an abandoned warehouse, all dusty windows and industrial grunge from the outside, was apparently a fully functioning, neon-lit labyrinth of every sex toy imaginable. The lighting buzzed overhead, faintly pink-tinted, casting strange shadows across the rows of silicone and leather.

There were walls covered in vibrators. Some slim and pastel, others bulky with handles and attachments you couldn’t even begin to name. Handcuffs in every color. A full rack of ball gags. Shelves stacked with things that looked like props from a medieval dungeon. You half expected to find a manual labeled “Sex Tech: Beginner to Advanced.”

You stopped in front of a glittery display of remote-controlled toys, blinking at the price tags.

“I feel like we’re amateurs,” you muttered.

Gideon gave a crooked smile. “We’ve got the bullet. And those handcuffs from Spencer’s.”

You rolled your eyes. “The one that Shelly gave me that came with the fuzzy dice and novelty penis straws?”

“They work!” he said defensively, bumping his shoulder into yours. “You should know.”

You laughed, until your eyes landed on something a little further down.

“Jesus Christ,” you whispered, stepping closer to the display. A hot pink dildo stood proudly on its stand, comically huge, and easily the length of your forearm, definitely thicker. “That thing is huge.”

Gideon followed your gaze and his eyes widened.

“No fucking way people actually use that,” you said, your voice halfway between disbelief and admiration.

“Maybe it’s for decoration,” he offered weakly.

You looked at him. “A statement piece?”

He shrugged. “Conversation starter.”

You stared at it for another beat, trying to imagine the logistics.

“Nope,” you said finally, grabbing his hand again. “That’s a one-way ticket to the ER.”

Gideon grinned, tugging you gently along to the next aisle, where a row of feather ticklers fluttered under the AC vent like they were beckoning you over.

You and Gideon had been active for nearly two years now. It wasn’t uncommon for one of you to need a little help. You had a bullet vibrator you bought in college, quiet yet powerful. The handcuffs had been a gag gift that ended up serving a better purpose, hung on a commend strip behind the headboard for easy access. And, there were exactly two bottles of lube that lived in the nightstand, which was the purpose of today’s trip. You rounded the next corner, still riding the mix of curiosity and amusement, when your steps faltered.

Your eyes widened. “Oh,” you breathed, coming to a full stop.

A towering shelf, almost reverent in height, stood in front of you lined top to bottom with DVDs. Bright, flashy covers. Bare skin. Glossy lettering. Titles like Backdoor Brides 7 and Clownin’ Around 2: Squeaky Clean Holes. One had a woman in a cowboy hat straddling what looked like a mechanical bull. Another was just a close-up of feet.

You glanced at Gideon, then back at the covers, heat rising to your face. “I… didn’t know they still made DVDs. It’s free online.”’

He leaned in, reading a spine out loud. “Muff Busters: Paranormal Invasion.”

You clapped a hand over your mouth, snorting.

“Some couples watch porn together,” you said, trying to sound casual, though your voice came out a little higher than usual. “It’s supposed to, like, build intimacy. Get ideas. Or whatever.”

Gideon raised his eyebrows, clearly intrigued. “Yeah? Is that something you’re into? Watching porn?”

“Sometimes.” You nodded, eyes still flicking across the titles. “Not that I- I mean, I don’t sit down with a bowl of popcorn or anything- it has a pur-“

He didn’t let you finish. He reached up and grabbed the most ridiculous box within reach: Assassins: Thicc and Lethal. The cover featured two women in leather catsuits, holding pistols and standing in front of a fiery explosion, cleavage out, boots thigh-high.

“This one’s probably plot-heavy,” he deadpanned.

You covered your face with both hands. “Gideon.”

“Oh, wait, Chunky Junk in Grandma’s Trunk?” He held it up like he’d won a prize at the fair. “This feels… important. Historically.”

You were wheezing now, doubled over slightly. “Stop.”

He grinned. “We could do a whole film festival. Like, Porn and Pizza Night.”

“Gideon?”

You both turned slowly, hands still full of the raunchiest DVD titles you could’ve possibly grabbed, Assassins: Thicc and Lethal in one hand, Chunky Junk in Grandma’s Trunk in the other, only to find Kelvin and Keefe standing there like they'd caught you in church stealing from the offering plate.

Kelvin’s arms were stacked full of assorted sex toys. Feathered ticklers, fuzzy restraints, a suspiciously shaped pump, and something that looked like a riding crop. Keefe stood beside him with a cardboard box nearly overflowing with lube bottles and vibrating rings.

“Hey,” you said quickly, your voice cracking slightly as you slowly returned the DVD to the shelf like it might explode. “What are y’all doing here?”

“Buying out their filth,” Kelvin said with pride, like he was on a holy crusade. “Purging the sin from this city.”

You blinked. “Right. Of course.”

“And you guys?” Kelvin added, squinting at the evidence in your hands.

Keefe gently bumped his elbow. “I don’t think this is an answer you want, brother.”

You opened your mouth. Closed it. Tried again. “We came to help,” you offered, weakly. “Saw your car outside and-“

“Keefe drove,” Kelvin interrupted, suddenly.

You stared. There was a pause. A tense one. Gideon slowly set down Muff Busters: Paranormal Invasion.

“Cool,” he said finally, nodding.

“Cool,” Kelvin echoed, a little too loudly.

Keefe looked at all four of you. “So… should we pretend we didn’t see each other?”

You exhaled, relieved. “Yes, please.”

Kelvin huffed and turned on his heel, muttering, “Don’t forget the point of this mission,” as he disappeared around the aisle, Keefe trailing behind with the box balanced on his hip.

Gideon looked at you once they were gone. “We’re never doing this again."

"Agreed."

#answered asks#gideon gemstone#gideon gemstone x you#the righteous gemstone#gideon gemstone x reader#gideon gemstone x fem reader#gideon gemstone fanfic#the righteous gemstones#fanfic

38 notes

·

View notes

Text

Previous

Next

****

Pat hid his phone, hearing distant clanking of Sligs' prosthetic legs get closer until two of them opened the door to his room.

"You come with us." One said sharply.

"Hurry up. We're using force if you resist." The second one added threateningly.

"No need. I'm coming." Pat assured, surprised by the unnecessary rudeness.

With no delay, the mudokon silently complied with their order, following the Sligs to the corridor. He asked no questions and kept up with their speed, giving the guards no reason to resort to any of their threats. The Sligs seemed almost disappointed by his obedience.

They lead him to an unfamiliar part of the building, where the interior didn't look as rich and well-kept. What in the Odd is going on? It was Jabodo's doing for sure. Some strange attempt to scare the dancer? To be fair it worked — Pat broke into a cold sweat.

Finally the mudokon was lead into a room. Wooden floor, old faded wallpaper... The first thing he noticed was Mr. Jabodo standing near the entrance. He stood there with his arms crossed, silently watching Pat walk in, reveling in every hint of fear in the dancer's expression he could catch.

"Get it ready." Jabodo commanded the Sligs.

The second thing Pat noticed was a machine in the middle of the room that consisted of a chair with straps and a helmet with tubes attached to it, a control panel and a vitals screen on the side. Pat recognised what it was. A Tear X-Tractor. "The legal torture machine"... though it was a safer model than the ones used at factories, where mudokons were "disposable".

He was familiar with tear extraction, and knew that tears were used as an ingredient in certain products. Malgaine even sold Pat's tears before, but the dancer never had to experience being put in one of those machines. Instead Master used to manually gather a few drops and sell them for sky-high prices in intricate little bottles with fancy labels on them, like "Swan Tears of Joy" or "Swan Tears of Sorrow". For some reason, "tears of sorrow" were more popular amongst buyers, though in reality there was no joy nor sorrow in neither of them, but a bit of special essential oil did the trick to make Pat's eyes water.

Of course, that method wasn't fit for industrial production, and low class mudokons had it much worse. Pat realised he's about to "get a taste" of real tear X-Traction.

The Sligs sat the Mudokon on the chair and strapped him by arms and chest, definitely tighter than needed. One of them started adjusting something on the control panel. Jabodo didn't move as the sligs were taking their sweet time preparing the X-Tractor. Nobody spoke, leaving the dancer to wait and guess with no explanation, letting the tension build up.. His heart was racing, but he tried to stay calm on the outside.

Pat knew not to speak unless spoken to. Besides, it was pretty obvious what's about to happen.

The helmet was put over his head. A mask with little tubes hungrily stuck to his face and all he could see was darkness.. In this darkness Jabodo's voice sounded very clearly as he finally spoke:

"Mudokon tears are quite a valuable recourse with their unique properties... And tears of a valuable mudokon are even more valuable.. you probably know that. What a great thing this machine is, isn't it? Productive. Efficient... And it leaves no marks."

What is Jabodo trying to achieve by this? Is it supposed to somehow change the dancer's mind about the Chronicler's inappropriate requests? Is Pat supposed to start begging him to let him out of the X-Tractor and promise to do anything he wants? That wasn't happening. Pat didn't make a sound.

"Start this thing up." Jabodo gave the Sligs a second command...

18 notes

·

View notes

Text

Why Your Inventory Sucked Part 2

One of the positive things about working inventory is all the places I've been. I have seen more of the world of retail than most people even know exist. I've been in the back rooms and break rooms of so many stores I have to remind myself I shouldn't just go back there when I walk around a store.

I've been to warehouses and distribution centers. I counted book fair supplies in storage units, and a pharmacy distribution center with 3 giant round machines to fill bottles. One was a company that sold parts to oil drillers. Another was a warehouse where you could by anything for classic cars from doors to the manuals. I've also been in the backstage areas of amusement parks, and eaten in their cafeterias. I've walked through massive freezers, and sweltered in sheds.

And on top of that I drove to small towns you didn't know existed, down poorly marked roads and close enough to both the Canadian and Mexican border that I could wave to the residents and they could wave back. I drove a lot is what I'm saying. It was an experience I really enjoyed.

PART 2: Bad Accounts

Most inventories can be divided into two groups: Quantity and AQ-1.

Quantity is where you scan the barcode of the item and count how many of those items there are. It's fast, but not necessarily accurate. The accuracy issue is because sometimes two items look the same, may even BE the same, but have different barcodes so come up as different in the system. Otherwise it's just miscounting them.

AQ-1 means Auto Quantity 1. Scan the item barcode and it inputs a 1 for the quantity automatically. It's very accurate, as you do have to scan every bar code, but very, very slow. It's best for stores where nearly every item has a different bar code or they're so mixed there's no way to count them as a group.

Most store are a mix of both, but the majority of a store is either one or the other. But when the wrong choice is made, things go downhill quickly.

I have so far avoided naming stores, not out of any desire to not say, but mostly because it wasn't really important. Here it is important, so let me tell you the tale of Bath and Body Works.

You know the store, it's that hole in the wall mall store that sells candles and lotions that only come in like 4 scents, but have 30 different labels for those 4 scents. You've been in one, likely around Christmas. Now when I started, it was owned by Victoria's Secret, and I know you know what that is. Victoria's Secret is a proper AQ-1 store, as you're not going to open a drawer and have 15 of the same bra inside.

So when it came to BBW, they wanted the SAME inventory done. Now it kind of makes sense. The audit process for VS, which I won't go over but know by heart, is what they really wanted, and the stores had about the same amount of product, so that should be an easy fit, and it'll be accurate too!

Except it was miserable. VS needed 20+ people and 6 to 9 hours to complete, sometimes longer. BBWs are NOT as big as even the smallest VS, so now I'm trying to cram in 20 people into a tiny store to scan every item on a shelf that has 50 of 2 different products on the shelf over the course of 8 hours.. No one liked it, and it took forever. Also we made one hell of a mess because, again, we had to reach EVERY barcode.

They would eventually change it from AQ-1 to Quantity, and the results were immediate. That changed it from 20 people taking 8 hours to 5 people doing it in 4 hours. Hell, I had a store with me and the two worse counters in the office, and still got one done in 5 hours.

Understanding how the inventory is supposed to go is the job of the Account Instructions. This represents the agreement between the client and our company on how the inventory is supposed to go. Usually it contains things like the tag ranges to use, how many people should be there, what kind of audit system to use, what the final reports are to give to the store and weird things that might happen. A well written set of instructions can make an inventory go smooth as butter, and once you've done one a few times, you may never look at them again. Something that happened with VS for me after a bit.

Then there was the Apple Store. Yes, I've done the inventory for an Apple Store. Nothing terrible, it's AQ-1 as any high dollar store like that, and aside from the giant wall of aluminum that made it hard for the scanners to communicate with the laptop, it shouldn't be very hard.

And yet, the instructions insisted on having 2 Inventory Supervisors. This is odd because it's not much of a store. So we sit down to do the inventory and everything is going well until it's time for the audits and they require a special report printout, as per the instructions.

The report isn't there.

In fact, NONE of the reports I'm supposed to print are listed in the the program. There's a lot of reports, but not the ones we need. Now the two of us are pretty smart, and know the program pretty well so we can fudge it, but we're still not getting the reports we need.

Eventually, after bashing our heads against it for a bit we figured it out. The reports ARE there, but they don't have the same names as in the instructions. And that's when we realized why there were two supervisors. With the wrong report names, one IS would spend all their time trying to get the correct reports printed, which made Apple think we were all fire stupid, so they figured 2 would fix the problem.

The worst part is the person that wrote those instructions was NOTORIOUS for bad instructions, often leaving very old, out of date information in them literal years after they were no long relevant. And she resisted changing them. She retired a couple years or so before I left, and I do hope the new account manager could fix the mess.

The worst part about the job was giving bad news. Most stores know what they should have in the building. I often ask because it helped me gauge how long the whole thing should take. My experience also let me figure out how close they would be. The goal was to get within their Shrink, the amount of difference between what's on the books vs what's in the store.

Now I am kind of a wizard when it comes to the inventory program and I could, BUT DID NOT, change the numbers in practically any way I wanted. I had a few people ask me to do this and I had to deny them. But it also meant I can see where the numbers are short, and help guide them to the issues or even catch the mistakes before they even got to the store staff. That said, there were more than few occasions when the answer was bad. If it the product isn't there, going over those numbers again and again is NOT going to make that product appear. If it isn't there, it isn't there

One particular store started pretty rough to begin with. It was being sold off as part a merger agreement between two big corporations. The inventory was part of the sale process. It was raining cats and dogs, and the neighborhood was not the greatest. There was a cop car just parked in the parking lot of the minimall this dollar store was in. I arrive a little early, and since it's a local store, I'm waiting for the rest of the crew to arrive. But the store is locked. The store manager hadn't arrived yet to unlock the door. This is a BAD sign.

The store's District Manager arrives before the store manager, but she doesn't have the keys so we have to wait. He does show, not strictly late, iirc (it's been quite a few years), and the crew, as always, trickles in. The store is a mess to being with, but I tag it up and we get started. As we get to the end though, it's clear the numbers aren't looking good.

Dollar stores typically have between $250,000 to $400,000 worth of stuff in them. It varies on location, size of the store, the type of dollar store, etc, etc, but 300k is pretty common. They gave me this number for this store. The dollar value of the store after the inventory was 200k.

$100,000 dollars short. That's, a lot. Typically stores don't want more than 2.5% shrink, so they shouldn't be more than $10,000 short. Yeah, it was bad, very, very bad. There were a few minor corrections that could have been made (there was a stack of foil pans that was counted as one upc when they should have been another), but the DM and her boss (yeah, HER boss came in), said not to bother.

I couldn't, and by rights shouldn't, fix that. As I packed up the SM was sadly flipping through the final reports. He was already going to lose this store, but I wonder if he was going even have a job after that.

There was another time when I had good news. A truck stop we stopped doing after a couple years, and one I sharpened my skills in, hadn't had a good inventory in a long while. We also had issues even getting an inventory going due to crew issues and such. Anyway, for these stores the DM would basically be the contact person for the inventory.

I'm counting the inside of the cooler and the DM comes in and tells me point blank if this inventory is bad, he'll have to fire the store manager. This was the worse thing he could have said to me because I always strive for accuracy, but now a guy's job is on the line. I could not fake it, even though I could. But I could hunt for product.

Which I did. This store had a map that determined where each tag was set to go, and tagged the store accordingly. As we're going through though, I ask about a door near the food places in the truck stop. It didn't have a tag assignment and looked to be part of the food place. Inside was gatoraid, LOTS of gatoraid, amongst other things, all of it belonging to the store.. Tag and count it. I wondered if it had been missed repeatedly because it wasn't on the map.

At the end the numbers came in, and I was able to give the DM the good news. He thanks me, then promptly calls the SM in and in a stern, you're fucked, voice told him the inventory was fine. He would not be fired. The manager LOVED me after that day, and I generally got stuck doing the entire local chain until they switched to doing it themselves.

Next time, I'll get into the last major category why inventories suck. Until then.

2 notes

·

View notes

Text

*Patch Notes 8/22/23*

A lot has happened. Many improvements have been been made that probably deserve their own posts. Did a lot of back sliding, attempts at recovery, and more back sliding. Also kept forgetting this blog existed.

CURRENT GOALS:

Clean and organized apartment

Time and suitable environment to focus on art

Being caught up enough on responsibilities and housework that I can feel comfortable spending time on video games and anime

Making a less stressful environment for my cats

Time for and Accessibility of Proper Nutrition

Get to bed earlier

Get up when my alarm goes off

Toying with the idea of setting up an online shop for like stickers and junk

Stuff Done Yesterday & Today:

Clean and organized apartment

Stacked the white boards and cork boards that have been floating around the apartment since I moved in neatly behind the recliner in the living room. I won't have to move them again unless I'm (finally) putting them up.

Made progress cleaning in kitchen

Made progress cleaning in study

Slapped a label saying "SPARE PARTS" on a drawer of a plastic storage unit in my basement so, once I find where they are, all the little baggies of spare hardware/accessories/parts for various appliances and pieces of furniture (THAT I HAVE BEEN SO GOOOD AT LABELNG. WHERE ARE THEY?!) will have a home. Baggies Found: 5/??

Slapped a "MANUALS" label on another drawer so now I have a place for them too

Arranged the shelving units in the basement so I can actually see and access shit easily

Time and suitable environment to focus on art

Cleared off the folding table that's been piled with papers and junk for 6 months

Cleared off my desk

Cleared off most the floor of my study

Drew plans for a U-Shaped desk that I think would help. Not sure if I'm going for it. Won't have a chance to build it until late September anyway.

My current desk has a riser shelf that I took off a while ago, thinking it would give me more useable space (it did not). I have a worklight I bought at goodwill a couple weeks ago that I intended to use for a workbench I'm most likely not going to build. It just fits under the riser, but its power cord comes out the center of the back, which puts it at odds with the riser support bar. So I drilled a hole in the riser support bar. I don't think the bits I have are meant to be used on metal, but I got it to work somehow. And after some hack-sawing and filing, and some more hack sawing and filing because I didn't account for the nut at the base of the power cord, it works pretty well!

Rearranged my furniture a bit. Trying an L-shaped desk set up

Being caught up enough on responsibilities and housework that I can feel comfortable spending time on video games and anime

Put on an episode of anime while eating lunch

Finally tumbled and folded the sheets that have been in the dryer for, like, two weeks

Washed a load of darks

Making a Less Stressful Environnment for my Cats

Cleared floor space in living room, kitchen and study

Moved chair I was going to donate back into kitchen so they can sit with me instead of me moving them off my chair

Making effort to clean/rearrange things in a calmer fashion so Maou freaks out less

Time for and Accessibility of Proper Nutrition

Washed a shit ton of dishes, focusing on the takeout containers I use for ready-made meals

Cleaned the fridge out. Got rid of food that had gone bad (oh god it was gross) and washed off spills

Made a start on organizing cabinets so I can find the dishes and containers need when i need them.

Cooked rice, chicken, and vegetables and arranged them in microwavable containers so I can h eat them quick later

Get to bed earlier

Brought in water bottles from car and stocked under bed

Put empty water bottles in recycling

Cleared a bunch of stuff that's been covering the floor for ages

Moved my headboard power strip to the other side so I can have my white noise machine and bed lamp closer to my head

Get up when my alarm goes off

Set up an anime I really want to rewatch on DVD player in kitchen, so I can watch it while eating breakfast. Hoping this motivates me to get ouut of bed.

Logged into Crunchyroll on android box for the same reason. Looking for HiDive password.

Toying with the idea of setting up an online shop for like stickers and junk

Made a vague plan. Most of it depends on me actually neatly finishing art on purpose. Im good at making art. Finishing art neatly and on purpose are my weak points (My strong point is bullshit that looks pretty good). Should probably revisit this idea when I'm further along with "Time and suitable environment to focus on art"

4 notes

·

View notes

Text

Common Contaminants in PET Bottle Flakes and How to Eliminate Them

If you’re in the recycling or plastic manufacturing game, you already know how important PET bottle flakes are. These small plastic shards serve as the building blocks for numerous recycled products, ranging from textiles to packaging. But here’s the catch: if your PET bottle flakes are full of junk, they are useless. Clean flakes ensure better products, better profits, and a healthier planet.

The Dirty Truth: Common Contaminants in Pet Bottle Flakes

Before PET bottles become flakes, they go through all kinds of rough handling, including trash bins, food residue, and mixed waste. That’s where contamination comes in. Here are the usual suspects:

1. Labels and glue

Labels made from PVC or other non-PET materials

Sticky adhesives that don’t wash off easily

2. Liquids and organic residue

Leftover soda, juice, or milk inside bottles

Mold or fermentation during storage

3. Other plastics

Caps and rings made of HDPE or PP

Shrink sleeves and wrappers that melt differently

4. Dirt, sand, and dust

Collected from storage yards or open transportation

It affects flake clarity and increases processing costs

5. Metal or inorganic waste

Small screws, staples, or even parts of labels

Dangerous for machinery and quality output

Why Contaminants Are a Big Deal?

You might be thinking, “What’s a little dirt?” But contamination in PET bottle flakes can:

Damage recycling machinery

Reduce the purity and strength of the end product

Increase processing and cleaning costs

Cause product rejections or low market value

Contamination kills the value of your flakes.

How to Eliminate Contaminants from PET Bottle Flakes

Cleaning up your PET flakes is easier than you think if you follow the right process. Here’s a simple breakdown:

1. Pre-sorting is a must

Remove non-PET items before shredding

Separate by colour, material, and size manually or using optical sorters

2. Hot washing works wonders

A hot caustic wash removes labels, adhesives, and organic grime

Ideal temperature: 80–85°C for best results

3. Use a float-sink tank

PET sinks, but most other plastics float

A great way to separate HDPE, PP, and PVC easily

4. Magnetic and metal detection

Install metal detectors or magnets before processing

Prevents machine damage and ensures clean output

5. Rinse and dry properly

A final cold rinse ensures zero residue

Drying eliminates moisture, which can mess up the extrusion process

Pro Tips for Maintaining Clean PET Bottle Flakes

Always source bottles from trusted collection points

Store flakes in clean, dry conditions after processing

Schedule regular maintenance of your washing and sorting equipment

Keep staff trained on identifying and handling

Conclusion

In the world of plastic recycling, quality is everything. Clean PET bottle flakes ensure better prices, perform more efficiently in manufacturing and contribute to a cleaner environment. By knowing what contaminants to look out for and how to get rid of them, you’re not just improving your product; you’re also boosting your business’s revenue.

0 notes

Text

The Compliance Gap You Didn’t Know You Had: Are Your Restricted Zones Monitored?

Introduction: The Illusion of Safety

Every day, safety managers and compliance officers walk through their facilities, industrial plants, warehouses, job sites, believing their restricted zones are secure. After all, there are signs posted, doors are locked, and access is controlled with badge readers. Everything looks in order.

But here’s the uncomfortable truth: most restricted zones aren’t nearly as secure or compliant as we think.

In fact, when you dig into incident reports and safety data, you’ll find a surprising number of workplace accidents and compliance breaches happen in areas that were supposed to be off-limits. These aren’t just mistakes, they highlight a bigger problem in how we define, monitor, and enforce access to high-risk areas.

So, here’s the real question: Are your restricted zones truly enforced, or are they just marked as off-limits and left to chance?

What Is a Restricted Zone in Today’s Workplaces?

Restricted zones are areas in a workplace where only authorized personnel are allowed. These spaces usually involve higher risks—like exposure to chemicals, sensitive equipment, or ongoing operations. The purpose? To protect people, maintain safety, and meet regulatory standards. Some typical examples include:

Chemical storage areas with toxic or flammable substances that require special handling.

Electrical or maintenance rooms housing high-voltage panels or machinery under repair.

Pharma and biotech cleanrooms, where product integrity hinges on environmental control.

Robotic or machine operation cells, where automated equipment poses serious injury risks.

Construction zones filled with heavy tools, scaffolding, and active site work.

Data centers, where IT infrastructure needs both physical and digital protection.

These zones aren't just about ticking boxes, they exist to:

Prevent injuries or fatalities from unsafe exposure or equipment misuse.

Safeguard sensitive processes and data that, if compromised, could impact business continuity or compliance.

Meet critical standards like OSHA, ISO 45001, NFPA, and internal safety regulations.

Despite these critical roles, enforcement is often inconsistent. Signs and protocols may exist, but they don’t guarantee compliance. Real enforcement needs visibility, accountability, and constant oversight—which most traditional systems struggle to provide.

The Compliance Gap: Where Labels Fall Short

Let’s zoom in on a typical day at work:

A contractor cuts through a chemical room to save a few minutes.

A forklift operator ducks into a robotic cell post-shift to grab a water bottle.

An employee opens a locked maintenance room without PPE, thinking they’ll be “in and out.”

These aren’t edge cases—they happen more often than you think. And they highlight a sobering reality: serious safety breaches happen in areas that should be the most secure.

Why? Because many restricted zone systems rely on passive control methods:

Signs get ignored, covered, or become part of the background.

Manual checks are time-consuming, inconsistent, and prone to human error.

Badge access may verify identity, but it can’t tell if someone’s wearing PPE or performing unauthorized tasks inside.

That’s the root of the compliance gap: It’s the space between what safety policies intend and what actually happens on the ground.

And it’s a big problem because traditional enforcement tools fall short:

They depend on people to catch violations, and even the best teams miss things.

They can’t recognize behavior in real-time, like someone entering with no hard hat or hanging around machinery.

They don’t automatically record what’s happening, which means no evidence, no accountability, and no way to learn from mistakes.

So, in many cases, compliance becomes a matter of assumption—not proof. Without smart monitoring, unsafe behavior continues undetected, until something goes wrong.

How Vision AI Bridges the Enforcement Gap

This is exactly where Visionify changes the equation. Our Vision AI-powered Restricted Zone Monitoring brings real-time, automated enforcement to life—removing the guesswork from safety and compliance.

What Makes It Different?

Real-Time Unauthorized Access Detection

Our computer vision doesn’t just log who entered—it sees them. By combining identity verification (like facial recognition, uniform detection, or badge matching) with contextual awareness, it spots unauthorized individuals instantly.

Context-Aware Monitoring

Zones don’t have to stay the same 24/7. Visionify adapts to real-world conditions—like shift changes, ongoing maintenance, or active hazards—so enforcement rules shift with your operations.

Automated Documentation & Alerts

Every incident is recorded with a time-stamped video and metadata. The system instantly alerts safety managers, allowing for quick intervention and robust audit trails.

Dashboard for Real-Time OversightVisionify’s intuitive dashboard serves as the central nerve center for safety and compliance teams. It transforms raw video data and alerts into clear, actionable insights, helping you manage multiple restricted zones effortlessly from one screen. Here’s what you get:

Real-Time Event Feed Instantly see every breach, PPE violation, or access anomaly as it happens, with accompanying video snapshots and context metadata.

Filterable Incident Logs Search, sort, and export detailed logs by date, location, personnel involved, violation type, or resolution status. Ideal for audits and root-cause analysis.

Heatmaps & Zone Activity Visualization Visual overlays show which areas are most prone to violations, helping you proactively redesign workflows or increase signage, training, or staffing where needed.

Compliance Trend Analysis Track improvements in safety behavior over time. See week-over-week or month-over-month PPE adherence, breach frequency, and more—all in easy-to-read graphs.

Custom Alert Settings Configure notification preferences based on severity, time of day, or type of event. Choose to receive alerts via email, SMS, or platform integrations (e.g., Microsoft Teams, Slack).

With Vision AI, you’re not just watching restricted zones—you’re enforcing policies without lifting a finger.

A Win for Compliance Officers and Safety Teams

For EHS and compliance leaders, Vision AI brings more than just peace of mind—it delivers results you can prove.

Confidence in Compliance: Every entry, every behavior, and every exception is logged, verified, and stored—making OSHA, ISO, and internal audits much simpler.

Audit-Ready Reports: With video logs and data at your fingertips, audits and insurance claims become quick and painless.

Operational Efficiency: No more chasing down paperwork or relying on walkarounds. You can spend time improving safety, not just managing risk.

This is how safety moves from reactive enforcement to proactive, intelligent management.

Conclusion: Rethink Restricted Zone Safety in the AI Era

Restricted zones exist to keep people safe, protect assets, and maintain compliance. But static signs and badge systems just aren’t enough anymore.

With Visionify, you don’t have to hope your zones are compliant—you’ll know they are.

Stop assuming safety. Start enforcing it.

Let Vision AI help you close the compliance gap and take your workplace into the future of safety.

0 notes

Text

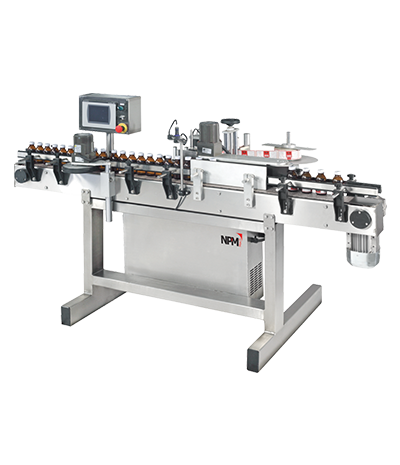

Bottle Labeling Machine: Complete Guide to Precision Product Labeling

What is a Bottle Labeling Machine?

A bottle labeling machine is an automated or semi-automated system used to apply labels onto bottles of various shapes and sizes—round, flat, oval, or square. These machines are engineered for high accuracy, speed, and uniformity, significantly reducing labor costs and errors associated with manual labeling.

Whether it's a wrap-around label on a soda bottle or a front-and-back label on a shampoo container, these machines handle it all with seamless efficiency.

Types of Bottle Labeling Machines

1. Manual Bottle Labeling Machines

Ideal for small-scale or home-based operations

Hand-cranked or foot-pedal operated

Low investment, minimal automation

2. Semi-Automatic Bottle Labeling Machines

Operator places the bottle, and the machine handles the labeling

Perfect for startups and small to mid-sized businesses

Compatible with wrap-around, single-side, and double-side labels

3. Fully Automatic Bottle Labeling Machines

Bottles are fed and labeled automatically on conveyors

Suitable for high-speed production lines

High output, precise alignment, reduced labor needs

4. Rotary Labeling Machines

Designed for ultra-high-speed lines

Uses a carousel system to label multiple bottles simultaneously

Often used in beverages, pharma, and cosmetics industries

5. Shrink Sleeve Labeling Machines

Applies shrink labels using heat tunnels for 360° branding

Common in juice, soft drinks, and energy drink packaging

Applications of Bottle Labeling Machines

Food & Beverage Industry

Juices, mineral water, milk, sauces, syrups, oils, alcohol

Date coding, branding, and compliance labels

Pharmaceuticals

Tablets, syrups, liquid drugs

Includes batch number, expiry date, and dosage information

Cosmetics & Personal Care

Shampoos, conditioners, lotions, perfumes

Requires visually appealing labels to reflect brand identity

Chemicals and Agro-Products

Fertilizers, pesticides, cleaning products

Requires resistant, long-lasting adhesive labels

Core Features of Advanced Bottle Labeling Machines

1. High Labeling Speed

Capable of labeling 20 to 300 bottles per minute, depending on model and label type.

2. Accuracy and Precision

Label placement tolerance as low as ±1 mm, ensuring professional appearance.

3. Label Sensor System

Automatically detects label gaps and bottle positions to prevent misalignment.

4. Adjustable Conveyor System

Compatible with a wide range of bottle sizes and shapes.

5. Integrated Coding Devices

Allows real-time printing of batch numbers, barcodes, and expiry dates.

6. PLC and Touchscreen Control

Easy programming, operation, and error diagnostics through HMI systems.

Benefits of Using a Bottle Labeling Machine

Enhanced Branding: Professionally applied labels elevate product appeal

Time-Saving: Speeds up production lines exponentially

Reduced Human Error: Increases labeling accuracy and consistency

Compliance Assurance: Meets global labeling standards (FDA, FSSAI, EU)

Versatility: One machine can handle different bottle types and label formats

Low Operational Costs: Cuts labor costs while boosting throughput

0 notes

Text

Sticker Labeling Solutions for the Bottling Industry

Efficiency and presentation are inseparable in manufacturing. A product could rank among the best in quality and still completely lose out in the markets due to improper labeling. A sticker labeling machines make product identification, branding, and compliance easier and faster than ever before.

Today, these machines have become a necessity in industries dealing with high-volume packaging. They ensure every label is placed accurately and neatly, thereby saving plenty of time and money while giving branding a professional look.

Learn more about- Sticker Labeling Machines: Types, Features and Applications

What Makes Sticker Labeling Machines Essential?

Whether in food processing, pharmaceuticals, or cosmetics, these machines can handle the labeling process for almost any label job fast and accurately.

There are several reasons why more industries apply these machines today:

Automation Reduces Manual Workload: Label thousands of units without fatigue or inconsistency.

Speed Up Production: Automatic systems are built for high throughput without compromising precision.

Adaptability Across Products: Suitable for jars, containers, boxes, and bottles in particular.

Long-Term Cost Savings: Reduction in human error, labor charges, and downtime during production.

Bottle Labeling Machine - A Specialized Solution

For firms dealing with bottled products, the bottle labeling machine provides a tailored approach. These machines accommodate bottles that are round, square, or oval-shaped and place labels on the front, back, or wrap-around side.

From water bottles and juice bottles to shampoo and detergent containers, the bottle labeling machine is the name in mass labeling for:

Beverage industry

Chemical industry

Personal care product industry

Health and wellness sector

Ensuring proper adhesion even on curved or slick surfaces, this machine essentially brands with a professional appearance.

Choosing the Right Sticker Labeling Machine Manufacturer

Choosing the right sticker labeling machine manufacturer is extremely important. You want someone who not only supplies the machines but also understands your production needs and provides installation support and timely maintenance.

A dependable manufacturer ensures:

Up to high-quality build standards

Machine always performs consistently

Customization to a certain product line

Technical support and training

One invests in a good manufacturer; that is to say, one is investing in the operational success of their brand for years to come.

Learn more about packaging automation in our blog, How Sticker Labeling Machines Improve Efficiency in Packaging

Various Industry Applications

Here is the flexibility of the sticker labeling machines: their adaptability for:

Fast Moving Consumer Goods and Packaged Foods: Fast labeling for jars, packets, and boxes.

Pharmaceuticals: Bar-coding, dosage instructions, and batch details.

Household: For detergents, cleaning agents, and sprays, labels have to be put on nicely.

Personal Care: Labeling has to be perfect on lotions and creams.

Conclusion: Aim Technologies Is Your Partner

Aim Technologies is a trustworthy name when you want an efficient and durable labeling system. As the top sticker labeling machine manufacturer, Aim Technologies has solutions for the best of the industries, whether it is a standard sticker labeling machine or a customized bottle labeling machine. Their machines are designed for efficient working, ease of use, and longevity.

Having Aim Technologies as a partner gets you one step closer to a packaging operation that is efficient, professional, and scalable.

0 notes

Text

Sticker Labelling Machine - High-Speed Sticker Labeller Best Price, Manufacturers & Explorer | Brothers Pharmamach

Whether you’re packaging pharmaceuticals, cosmetics, food products, or consumer goods, having the right sticker machine is essential to maintain production speed and ensure accurate branding. One such essential piece of equipment is the Sticker Labelling Machine — and Brothers Pharmamach stands as a trusted name among the top labelling machine manufacturers in India and across global markets.

What is a Sticker Labelling Machine?

A sticker labelling machine is a type of industrial labeling equipment that applies self-adhesive labels to a wide range of containers, bottles, jars, and packages. These labels can contain product names, barcodes, batch numbers, expiry dates, ingredients, and branding elements. The machine ensures consistent application, enhancing the aesthetic appeal and traceability of the product.

Sticker Labelling Machines are available in various configurations based on speed, container shape, label position, and automation level. From semi-automatic models to high-speed sticker machines, they cater to diverse industrial needs.

Why Choose a High-Speed Sticker Labeller?

When you're handling large-scale production, time is money. Investing in a high-speed sticker labeller can drastically reduce labeling time and boost your overall productivity. These machines are engineered to handle thousands of labels per hour with exceptional accuracy and minimal downtime.

Key benefits of high-speed sticker machines:

Increased Throughput: Suitable for large-volume production lines.

Precision & Consistency: Labels are applied without wrinkles or misalignment.

Reduced Labor Costs: Automation minimizes manual intervention.

Integration-Friendly: Can be easily integrated with other packaging line equipment.

Smart Controls: Advanced machines come with touchscreen HMIs and PLCs for easy operation and monitoring.

Applications Across Industries

Brothers Pharmamach's sticker labelling machines are used extensively across multiple sectors, including:

Pharmaceutical Industry: For labeling vials, ampoules, bottles, and cartons with essential information.

Cosmetics and Personal Care: For tubes, bottles, and jars of varying shapes and sizes.

Food & Beverages: For applying labels on jars, cans, bottles, and pouches.

Chemical Industry: For labeling bottles with safety warnings, batch numbers, and product details.

Agro & Fertilizers: For accurately labeling containers with regulatory and branding information.

Features to Look for in a Sticker Labelling Machine

Choosing the right sticker machine depends on your specific operational needs. Here are some features to consider while selecting:

Label Application Type: Depending on whether the label is to be placed on the top, side, wrap-around, or front and back, different machine configurations are available. Brothers Pharmamach offers custom solutions to match your labeling requirement.

Automation Level: While Semi-Automatic Machines are suitable for smaller operations, high-speed fully automatic machines are ideal for mass production lines. They come with automated container feeding, label dispensing, and label placement.

Container Compatibility: From flat containers to round bottles, square jars, and irregularly shaped packages, the machine should be compatible with your product's container shape.

Speed and Output Capacity: Speed varies from model to model. A high-speed sticker labeller can label up to 300 containers per minute, making it a preferred choice for fast-moving production lines.

Label Accuracy and Sensing: Equipped with advanced sensors, these machines ensure perfect label placement. They can detect the presence of a label, container, or missing labels to reduce waste and prevent mislabeling.

Automatic Sticker Labelling Machine: Many high-end models include an Automatic Sticker Labelling Machine that tracks the number of labels applied, helping with inventory control and quality assurance.

Build Quality and Compliance: Machines should be made from high-grade stainless steel and should comply with industry standards such as GMP and CE. This ensures long-lasting performance and regulatory compliance.

Why Choose Brothers Pharmamach?

Brothers Pharmamach is one of the leading labelling machine manufacturers known for its innovative, durable, and high-precision sticker labelling machines. With decades of expertise and a global presence, Brothers Pharmamach has established itself as a pioneer among manufacturing companies in India and beyond.

Salient Features of Brothers Pharmamach Machines:

User-friendly design with touch screen interfaces

Microprocessor-based or PLC-based control systems

High-speed label dispensing for unmatched productivity

Servo motor-driven systems for accurate label positioning

Flexible design for compatibility with various container types

Custom-built solutions tailored to client requirements

Quick changeover and minimal maintenance

Whether you are a startup in the cosmetics industry or a well-established pharma company, Brothers Pharmamach provides cost-effective and robust solutions with best price sticker machine options without compromising on quality.

Our Range of Sticker Labelling Machines

Here’s a quick look at some of the most popular models offered by Brothers Pharmamach:

Automatic Round Bottle Labelling Machine: Ideal for applying wrap-around labels on round containers. Can be integrated with bottle turntables and shrink tunnel systems.

Front and Back Labelling Machine: Used to label the front and back surfaces of flat and oval bottles simultaneously.

High-Speed Ampoule and Vial Labelling Machine: Perfect for the pharmaceutical industry. Offers precision labeling at speeds exceeding 200 containers per minute.

Top-Side Sticker Labelling Machine: For labeling cartons, pouches, and caps from the top. Commonly used in FMCG and food industries.

Automatic Label Counting Machine Integration: Equipped with inbuilt counting functionality to keep track of the number of labels applied.

Industrial Labeling Equipment Built to Last

The industrial nature of the equipment means it must withstand 24/7 operation under harsh factory conditions. At Brothers Pharmamach, machines are engineered with quality components, rugged structures, and modular parts to ensure longevity, safety, and superior performance.

Every component – from rollers to motors to control systems – is carefully selected and tested. These machines are built with high-precision technology to minimize waste, reduce changeover time, and enhance operational efficiency.

Competitive Pricing with High ROI

Finding the best price sticker machine doesn’t mean compromising on features. Brothers Pharmamach ensures its range of sticker machines delivers the best value for your investment. With competitive pricing, minimal maintenance, and unmatched reliability, your return on investment is assured.

Additionally, the machines are designed to grow with your business. As your production line expands, your industrial labeling equipment can be easily upgraded or integrated into a complete automated line.

Custom Solutions for Every Need

Every industry has its own unique labeling requirements. Whether you need tamper-proof labelling, transparent labels, promotional stickers, or multilingual labeling, Brothers Pharmamach provides tailored solutions based on your exact needs.

From machine layout to label type, automation level, and integration with upstream/downstream equipment, we ensure everything fits your production line perfectly.

After-Sales Support and Service

What sets Brothers Pharmamach apart from other labelling machine manufacturers is their commitment to customer satisfaction. Comprehensive support includes:

Installation and commissioning assistance

Operator training

Spare parts availability

Preventive maintenance and service contracts

Remote troubleshooting and technical guidance

This commitment makes us a trusted partner for numerous companies across pharmaceutical, food, chemical, and cosmetic sectors.

Ready to Upgrade Your Labeling Line?

Discover the full potential of automation with Brothers Pharmamach’s industry-leading sticker labelling machines and high-speed sticker labellers. Whether you're starting a new line or upgrading an existing setup, our expert team will guide you to the best solution tailored for your business — at the best price.

Contact Brothers Pharmamach today to explore our complete range of labeling machines and industrial labeling equipment. Get in touch now for a free consultation or quote!

For more info: https://www.brothers.in/

Email ID: [email protected]

Phone: 9825300706

Location: Plot No. 2, phase II, GIDC, Vatva, Ahmedabad 382445. Gujarat india

#sticker machine#sticker Labelling machine#High-Speed Sticker Machine#High-Speed Sticker Labeller#manufacturing companies#automatic label counting machine#Industrial Labeling Equipment#Best Price Sticker Machine#Labelling Machine Manufacturer

0 notes

Text

Types of Pump Capping Machines: A Complete Guide

In the packaging industry, pump capping machines play a vital role in ensuring product safety, usability, and shelf appeal. These machines are specifically designed to secure pump-style caps onto bottles, commonly used for products such as lotions, sanitizers, shampoos, cleaning solutions, and pharmaceuticals. With the diversity of pump cap types and production needs, manufacturers use different styles of pump capping machines. Understanding the various types can help businesses choose the most efficient and cost-effective solution for their production lines.

Pump capping machines can be broadly categorized based on their level of automation: manual, semi-automatic, and fully automatic. Each type serves specific production needs and operational capacities. Manual pump capping machines are typically used in small-scale operations where production volumes are low. These machines require an operator to place the cap on the bottle and operate the device to secure the cap. While they are cost-effective and easy to use, their reliance on human labor limits production speed and consistency.

Semi-automatic pump capping machines offer a middle ground between manual and fully automated systems. They require some human interaction, usually to place the bottle or the cap, but the machine assists in the actual capping process. This type is ideal for mid-sized businesses looking to boost productivity without a significant capital investment. They provide more consistent torque application compared to manual machines, which improves sealing quality and reduces the risk of leaks or product spoilage.

For high-volume production, fully automatic pump capping machines are the most suitable. These systems can handle hundreds to thousands of bottles per hour with minimal human intervention. Bottles are fed into the machine via a conveyor, caps are automatically placed and tightened using servo motors or pneumatic mechanisms, and the finished products are discharged ready for labeling or packing. These machines not only ensure uniform torque and cap placement but also offer advanced features like cap orientation, bottle height adjustment, and reject systems for improperly capped bottles. Though they involve a higher initial investment, their efficiency and precision make them a valuable asset for large-scale manufacturers.

Beyond automation levels, pump capping machines also vary based on the mechanism used to secure the caps. Chuck capping machines use a rotary or spindle chuck to grip and twist the cap onto the bottle. These are favored for their precise torque control and adaptability to different cap styles. Spindle capping machines, on the other hand, use sets of spinning disks to tighten the caps as the bottles move through the capping station. They are known for their speed and are often used in lines where multiple cap sizes are not a concern.

Another variant is the snap capping machine, used for pump caps that snap into place rather than screw on. These machines apply downward force to press the cap onto the bottle, making them ideal for certain personal care or pharmaceutical products. Some pump caps require a combination of twisting and pressing, in which case hybrid capping machines come into play. These systems are engineered to handle complex capping motions and are highly customizable.

Choosing the right pump capping machine involves evaluating the type of cap, bottle design, production volume, and budget. Modern pump capping machines can be integrated with upstream and downstream equipment such as filling machines and labeling systems, offering a seamless packaging solution. In today’s competitive landscape, investing in the right capping technology not only ensures product integrity but also improves line efficiency and reduces operational costs.

Understanding the different types of pump capping machines empowers manufacturers to make informed decisions that align with their production goals. Whether operating a small craft business or a high-speed manufacturing plant, selecting the right capping machine is key to ensuring consistent quality and customer satisfaction. Source: https://autopackmachinespvtltd.wordpress.com/2025/05/31/types-of-pump-capping-machines-a-complete-guide/

0 notes

Text

End-to-End Quality: How Vision AI for Bottle Inspection Covers Labels to Caps

In the fast-paced world of packaging and manufacturing, every second and every defect matters. A misaligned label, a loose cap, or an incorrect fill level can lead to rejected batches, customer complaints, or even product recalls.

To address these challenges, forward-thinking manufacturers are turning to Vision AI for bottle inspection — a technology that offers end-to-end quality control across the entire bottle production line, from labels to caps.

What Is Vision AI for Bottle Inspection?

Vision AI combines computer vision with artificial intelligence to inspect bottles with extreme precision and speed. Unlike traditional machine vision systems, Vision AI doesn't just follow pre-set rules — it learns, adapts, and improves over time, identifying defects with increasing accuracy.

By using high-speed cameras and smart algorithms, bottle inspection by Vision AI can scan and analyze each bottle in milliseconds, ensuring flawless execution at every step.

Inspection Coverage: From Labels to Caps

Let’s explore how Vision AI inspects each part of the bottle in real-time:

1. Label Inspection

Checks alignment, orientation, and placement

Identifies torn, wrinkled, or misprinted labels

Verifies barcode/QR code readability

Detects faded or missing text

With Vision AI, label inspection becomes automated, accurate, and scalable across thousands of bottles per hour.

2. Body Inspection

Detects scratches, dents, discoloration, and cracks

Identifies foreign particles in transparent bottles

Ensures uniformity in shape and structure

This is crucial for ensuring both product integrity and brand consistency.

3. Fill Level Detection

Detects underfilled or overfilled bottles instantly

Works on transparent and semi-transparent containers

Helps prevent waste and maintain regulatory compliance

Vision AI reduces human error and improves product quality with consistent fill monitoring.

4. Cap and Seal Verification

Checks for missing, misaligned, or loose caps

Detects damaged or broken seals

Verifies cap color and type for SKU-specific packaging

In industries like beverages, cosmetics, and pharmaceuticals, cap integrity is critical — and Vision AI ensures nothing slips through.

Benefits of End-to-End Bottle Inspection by Vision AI

Benefit Outcome: Automated real-time inspection, no production delays or stoppages. Higher accuracy. Reduced false positives and rejections. Fewer recalls. Catch defects before they leave the factory floor. Data-driven insights processes using inspection analytics. Labour savings. Automate repetitive tasks to cut manual workload

Why Manufacturers Are Making the Shift

Manual inspection is prone to fatigue, inconsistency, and high labor costs. Even traditional machine vision can’t adapt to new defect types or packaging designs without reprogramming.

That’s why Vision AI for bottle inspection is fast becoming the industry standard. It allows companies to:

Scale operations without compromising quality

Detect hidden flaws invisible to the naked eye

Gain real-time visibility into production performance

Industries Benefiting from Vision AI Inspection

Beverages – for seal and fill level accuracy

Pharmaceuticals – for contamination and label compliance

Cosmetics – for flawless appearance and package consistency

Food & Condiments – for correct labeling and tamper-proof caps

No matter the sector, bottle inspection by Vision AI helps meet rising quality expectations with confidence.

Conclusion

From the smallest label misalignment to a critical cap defect, Vision AI provides full-spectrum inspection with unmatched speed and precision. It’s not just a tool — it’s a competitive advantage in the modern manufacturing landscape.

1 note

·

View note

Text

Filling, Capping, and Labeling Machine: A Must-Have Solution for High-Speed Packaging

Introduction

A filling, capping, and labeling machine is an advanced packaging automation system, designed to streamline production efficiency, improve accuracy, and enhance branding consistency. By integrating filling, sealing, and labeling into a single process, manufacturers can achieve cost savings, faster output, and superior product presentation. Whether used in food production, pharmaceuticals, cosmetics, or industrial packaging, this equipment ensures seamless operation and reliability.

Why Businesses Rely on Filling, Capping, and Labeling Machines

Incorporating a filling, capping, and labeling machine in production facilities brings significant advantages:

Boosted Production Speeds – Increases packaging throughput, reducing downtime.

Precision Filling Technology – Maintains accurate volume control, preventing waste and inconsistencies.

Automated Capping System – Ensures tight, secure sealing for various container types.

High-Speed Labeling Mechanism – Guarantees precise label placement, reinforcing brand identity.

Labor-Saving & Cost-Effective – Reduces manual handling, optimizing operational expenses.

Key Features to Look for in a Filling, Capping, and Labeling Machine

1. Advanced Filling Technology

Opt for machines with volumetric, gravity, or piston-based filling systems to enhance accuracy and efficiency.

2. Customizable Capping Solutions

Ensure compatibility with screw caps, snap-on lids, pump dispensers, and tamper-proof seals.

3. Automated Labeling Technology

Select equipment with high-speed applicators and alignment sensors for flawless label placement.

4. Multi-Product Handling Capability

Choose a machine capable of processing liquids, powders, gels, and granules, ensuring flexibility across production lines.

5. Compliance with Industry Standards

Work with manufacturers who meet global hygiene, safety, and packaging regulations, ensuring certified quality control.

Industries & Applications for Filling, Capping, and Labeling Machines

Food & Beverage Processing – Automates bottling, capping, and labeling for juices, sauces, dairy, and condiments.

Pharmaceutical & Healthcare Manufacturing – Guarantees precise filling and sealing for medicines, syrups, and supplements.

Cosmetic & Personal Care Industry – Streamlines packaging for lotions, shampoos, skincare products, and perfumes.

Chemical & Industrial Production – Facilitates efficient packaging of lubricants, adhesives, and cleaning solutions.

Why Investing in a Filling, Capping, and Labeling Machine is a Smart Decision for Manufacturers

With increasing demand for automated, high-speed, and precision-based packaging, integrating a filling, capping, and labeling machine ensures optimized production, enhanced product branding, and long-term profitability.

Conclusion

A filling, capping, and labeling machine is an essential asset for manufacturers, offering speed, accuracy, and efficiency. Whether applied in food processing, pharmaceuticals, cosmetics, or industrial packaging, this equipment enables scalable operations, improved consistency, and strong market positioning.

0 notes

Text

What You Need to Know Before Buying a Liquid Filler

The Essential Role of Liquid Filling Machines in the Pharmaceutical Industry

In the pharmaceutical industry, precision, hygiene, and efficiency are not just desired—they are mandatory. Every stage of pharmaceutical production is held to the highest standards to ensure product quality, patient safety, and regulatory compliance. Among these stages, the filling process—particularly for liquid medications—is one of the most critical. This is where Liquid filling machines come into play.

What Are Liquid Filling Machines?

Liquid filling machines are specialized equipment designed to accurately dispense and fill various types of liquid products into containers such as vials, bottles, ampoules, and syringes. These machines are engineered to handle a wide range of viscosities, volumes, and formulations, making them ideal for pharmaceutical applications.

Why Liquid Filling Machines Are Crucial in Pharmaceutical Manufacturing

1. Precision and Accuracy

In pharmaceuticals, even a slight variation in dosage can lead to serious consequences. Liquid filling machines ensure highly accurate and repeatable fills, reducing the risk of underfilling or overfilling. Modern machines use technologies such as servo-driven pistons, peristaltic pumps, and volumetric or gravimetric controls to deliver precise results every time.

2. Enhanced Efficiency

Manual filling is time-consuming and prone to error. Liquid filling machines significantly increase production speed and throughput, making them essential for large-scale pharmaceutical manufacturing. liquid filling machines manufacturer High-speed models can fill hundreds or even thousands of containers per hour, boosting productivity without compromising on quality.

3. Hygiene and Contamination Control

Maintaining sterility is paramount in pharmaceutical production. Liquid filling machines are often built to comply with GMP (Good Manufacturing Practices) and are designed for cleanroom environments. They feature clean-in-place (CIP) and sterilize-in-place (SIP) systems, ensuring that the product remains uncontaminated throughout the process.

4. Versatility and Customization

Pharmaceutical companies manufacture a wide variety of liquid products, from oral syrups to injectables. Liquid filling machines can be customized to handle different container types, fill volumes, and product viscosities. Some advanced systems also integrate capping, labeling, and inspection, providing a complete packaging solution.

5. Regulatory Compliance

Liquid filling systems are designed to meet stringent regulatory standards set by agencies like the FDA, EMA, and WHO. Accurate documentation, batch tracking, and integration with quality management systems ensure that the production process remains transparent and auditable.

Types of Liquid Filling Machines Used in Pharmaceuticals

Volumetric Fillers – Dispense a fixed volume of liquid using pistons or rotary pumps.

Peristaltic Pump Fillers – Ideal for sterile or sensitive liquids; easy to clean and maintain.

Vacuum Fillers – Suited for low-viscosity liquids; often used in bottling.

Time-Pressure Fillers – Use consistent pressure and time intervals to fill containers.

Aseptic Fillers – Specialized machines designed for sterile filling of injectables and biologics.

Key Features to Look for in a Pharmaceutical Liquid Filling Machine

High filling accuracy

Cleanroom compatibility

Ease of cleaning and sterilization

Scalability and modular design

User-friendly interface and automation

Validation and compliance documentation

Future Trends in Liquid Filling Technology

With the growing demand for personalized medicine, biologics, and sterile drug delivery systems, the need for advanced liquid filling solutions is increasing. Future machines will likely feature AI-driven quality checks, IoT integration for real-time monitoring, and greater automation, allowing for smart manufacturing with minimal human intervention.

Conclusion

In pharmaceutical manufacturing, the importance of a reliable and accurate liquid filling machine cannot be overstated. It is the cornerstone of safe, efficient, and compliant production processes for liquid medications. Investing in the right liquid filling system not only enhances operational efficiency but also ensures patient safety and regulatory approval.

As the industry continues to evolve, liquid filling technology will remain a critical component in delivering high-quality pharmaceutical products to the global market.

0 notes

Text

Sticker Labelling Machine: The Complete Guide to Smart Product Labeling

What is a Sticker Labelling Machine?

A sticker labelling machine is a device that applies pre-printed or blank self-adhesive labels (commonly called "stickers") onto various products like bottles, jars, boxes, and containers. These machines offer precision, speed, and customization for diverse packaging requirements.

They eliminate the inefficiencies of manual labeling and ensure that labels are applied straight, bubble-free, and uniformly across thousands of items daily.

Types of Sticker Labelling Machines

1. Manual Sticker Labelling Machines

Best for small-scale production

Cost-effective and simple to operate

Ideal for startups and cottage industries

2. Semi-Automatic Sticker Labelling Machines

Operator loads the product manually; machine applies the label

Perfect for medium-volume operations

Common in the food, personal care, and small pharmaceutical sectors

3. Automatic Sticker Labelling Machines

Fully automated with conveyor belt integration

High-speed labeling with minimal human intervention

Used for mass production and industrial packaging lines

4. Double Side Sticker Labelling Machines

Labels both the front and back sides of containers simultaneously

Excellent for cosmetics, shampoos, and cleaning products

5. Wrap Around Sticker Labelling Machines

Designed for cylindrical bottles and jars

Applies a full 360° label

6. Top and Bottom Labelling Machines

Apply stickers to top and/or bottom surfaces of flat objects like boxes, trays, and pouches

Industrial Applications of Sticker Labelling Machines

Pharmaceutical Industry

Applies labels with dosage, expiry date, QR codes

Ensures regulatory compliance and barcode readability

Food and Beverage

Bottle and jar labeling for soft drinks, sauces, honey, and oils

Labels withstand refrigeration and moisture exposure

Cosmetic Industry

High-end product labeling for creams, serums, and perfumes

Requires elegant, smudge-free, and durable finishes

Chemical and Pesticide Industry

Labels resistant to harsh chemicals, UV, and abrasion

Logistics and Warehousing

Barcode labels, shipping tags, inventory stickers

Key Features of a Modern Sticker Labelling Machine

1. High-Speed Operation

Capable of labeling 100 to 400 units per minute, depending on model

2. Advanced Sensor Systems

Detects product presence and label gaps for precise placement

3. Touchscreen HMI and PLC Controls

Easy configuration, error detection, and real-time production monitoring

4. Adjustable for Multiple Products

Handles various diameters, shapes, and label sizes

5. Coding and Printing Integration

Supports batch coding, barcodes, QR codes, manufacturing/expiry dates

6. Stainless Steel Construction

Food and pharma-grade SS304/SS316 material ensures hygiene and durability

Advantages of Using Sticker Labelling Machines

Professional Finish: Ensures brand consistency across all units

Enhanced Productivity: Reduces labeling time drastically

Cost Efficiency: Cuts down on labor and label waste

Minimal Downtime: Easy to maintain and calibrate

Customizable: Adapts to various products and packaging formats

Regulatory Compliance: Meets FDA, FSSAI, ISO standards for packaging

0 notes

Text

Sticker Labeling Machines: Boost Your Packaging Efficiency

In today’s fast-moving manufacturing and packaging world, sticker labeling machines are like quintessential modern-day technology. These machines end up making the labeling thing faster, accurate, and in some sense, presentability, almost all from food and beverages to cosmetics to pharmaceutical products. An efficient sticker labeling system can highly upgrade the packaging of any item, be it in a small-scale unit or a large industrial setting.

Learn more about- Sticker Labeling Machines: Types, Features and Applications

What Are Sticker Labeling Machines?

A sticker labeling machine means an automated or semi-automated system that applies self-adhesive labels to packaging bottles, jars, containers, and so on. A good labeling machine works with all kinds of label shapes and label materials and can also label many different surfaces-may it be flat or curved, even cylindrical.

Labeling is of great importance in product identification and branding, statutory requirements, and shelf appeal. It can make a product catch someone's attention or tell him/her what's in it, date of manufacture, barcode, etc.

Why Choose Sticker Labeling Machine?

Speed and Accuracy: One of the big advantages- speed, actually. They label a few hundred to thousands of units per hour and maintain a high level of accuracy.

Consistency: Errors owing to human operators are practically eliminated, providing each product with perfectly uniform labeling.

Cost-Efficiency: You save on labor, thereby enabling you to increase productivity.

Versatile: Modern times see machines enabling labeling on bottles, boxes, and pouches.

Customization: Settings can be changed to tailor the machine to how you want your labels applied, from dimensions to shape to placement.

Applications of Sticker Labeling Machines

Sticker labeling machines find applications in industries such as:

Food and Beverage: Best for the labeling of jars and cans and bottle labeling systems for water, juice, or soft drinks.

Pharmaceutical: Labelers put critical medical labels on vials, syringes, and pill bottles accurately.

Cosmetics and Personal Care: Labels lotions, creams, shampoos, and perfumes with elegant branding.

Chemical Industry: For labeling containers carrying solvents, detergents, and industrial liquids.

Types of Bottle Labeling Machines

For businesses looking to label bottles specifically, bottle labeling machines are a perfect fit. These machines are meant to invest in bottles-they are meant to apply labels either partially or fully wrapped around an outer surface-on bottles that may be round, oval, or square in shape. There are various types such as:

Single Side Sticker Labeling Machine

Front & Back Sticker Labeling Machine

Round Labeling Machine

Customized Labeling Machine

BOPP Labeling Machine

Shrink Sleeve Applicator

They may be automatic, semi-automatic, or manual to suit the various production levels.

Learn more about packaging automation in our blog, How Sticker Labeling Machines Improve Efficiency in Packaging

The Manufacturer Selection for Sticker Labeling Machine

While selecting a sticker labeling machine manufacturer, one needs to consider the reliability of the product, customer support, after-sales service, and the ability to customize machines for the needs of the industry. The best manufacturers provide machines that are constructed from superior materials, have easy controls, and meet safety standards.

Final thoughts

Buying the sticker labeling machine becomes an assurance to make the packaging operation easy, market with brand visibility, and adhere to the regulatory labeling requirements. Having the right machinery makes the product line more competitive and market ready.

If you're looking for the perfect company to supply you with an innovative and reliable sticker labeling machine, do not look no further than Aim Technologies. With an established reputation for accuracy, efficiency, and durability of labeling solutions, the company is your industrial automation partner. Whether you need a bottle labeling machine or a complete labeling system, they will produce a solution to fit your production requirements.

0 notes

Text

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter