#Methyl Methacrylate(MMA) Market Size

Text

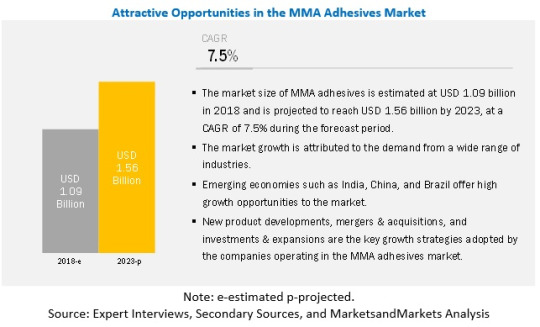

The report "Methyl Methacrylate Adhesives Market by Substrate (Metal, Plastic, Composite), End Use Industry (Automotive & Transportation, Marine, Wind Energy, Building & Construction, General Assembly), and Region - Global Forecast to 2023" The MMA adhesives market is projected to grow from USD 1.09 billion in 2018 to USD 1.56 billion by 2023, at a CAGR of 7.5%. The increasing demand for lightweight, crash-resistant, and fuel-efficient vehicles; growing demand in the automotive and marine industries; superior quality and performance of MMA adhesives; and increasing awareness about advantages of adhesives over conventional techniques are driving the MMA adhesives market. The growing awareness about reducing emissions, increasing recyclability, and minimizing wastage is expected to propel the growth of the market.

Composite is one of the most widely used substrates of MMA adhesives owing to the need for improving aesthetics along with maintaining design, cost, and speed of production for the marine and transportation industries. MMA adhesives are popular for niche applications of composite bonding, as they can bond large assemblies and materials having different surface energies along with SMC, which earlier had concerns owing to incompatibility with some mold releases. MMA adhesives are used to bond composite to composite structures and composite to metal substrates. For instance, components such as front and rear end caps, roofs, rear bumpers, floor panels, and luggage door frames of a truck fabricated from either SMC or FRP can be bonded using MMA adhesives.

APAC is the largest MMA adhesives market, which is mainly driven by the demand from the automotive & transportation, wind energy, and marine end-use industries. APAC is increasingly becoming an important global trade and commerce center. The region is currently the fastest-growing and the largest MMA adhesives market. With economic contraction and saturation in the European and North American markets, the demand is shifting to APAC. Vehicle production in APAC is expected to grow from 26.8 million units in 2013 to 43.1 million units by 2020. This growth is mainly due to the shift of base of the automotive manufacturers to the developing markets.

The key players in the market include Illinois Tool Works Inc. (US), Arkema (France), SCIGRIP (UK), Scott Bader (UK), Lord Corporation (US), Henkel (Germany), Permabond LLC (US), Parsons Adhesive Inc. (US), Huntsman Corporation (US), and 3M (US).

#Methyl Methacrylate Adhesives Market#COVID 19 impact on MMA Adhesives Market#COVID 19 impact on Methyl Methacrylate Adhesives Market#Methyl Methacrylate Adhesives#MMA Adhesives market#global MMA adhesives market#MMA adhesives market Drivers#Methyl Methacrylate Adhesives Market Size#Methyl Methacrylate Adhesives Demand#Methyl Methacrylate Adhesives Sales

0 notes

Text

0 notes

Text

Methyl Methacrylate Market Size and Share Analysis: Unraveling Key Statistics

Methyl methacrylate (MMA) is an important organic compound that is widely used for producing polymethyl methacrylate (PMMA), also known as acrylic glass. PMMA is a clear plastic with high strength and transparency properties. It is used across various end-use industries such as automotive, construction, electronics, medical devices and signs & displays. The rising demand for lightweight materials along with higher strength and design freedom associated with PMMA has led to increased adoption in the automotive industry worldwide.

The global Methyl Methacrylate Market is estimated to be valued at US$ 7,510.7 Mn in 2023 and is expected to exhibit a CAGR of 4.9% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity:

The growing construction industry across emerging economies is anticipated to present lucrative growth opportunities for methyl methacrylate market over the forecast period. Rapid urbanization and rising disposable income are encouraging infrastructure development activities in countries such as India, China and Indonesia. PMMA finds wide usage in construction applications owing to its transparency, durability and resistance to weathering. Increasing construction of commercial buildings, shopping malls and multi-dwelling units will augment the demand for PMMA sheets and panels, thereby driving the consumption of MMA monomer over the coming years.

Porter’s Analysis

Threat of new entrants: New entrants face high capital requirement to build manufacturing facility for methyl methacrylate. Established players have economies of scale and brand loyalty advantage.

Bargaining power of buyers: Buyers have moderate bargaining power as methyl methacrylate has applications in various end-use industries. Buyers can switch to substitute products if price is not competitive.

Bargaining power of suppliers: Key raw materials for methyl methacrylate include acetone, methacrylic acid and propylene. Suppliers have low to moderate bargaining power due to availability of substitute raw materials.

Threat of new substitutes: Substitutes include other methacrylate esters and plastics like polycarbonate. New substitute threat is moderate as methyl methacrylate is widely used due to its versatile properties.

Competitive rivalry: The market is fragmented with top players accounting for around 40% share. Players compete based on pricing, product differentiation and expansion to new applications.

SWOT Analysis

Strength: Wide applications in paints & coatings, automotive and construction industries. Cost-effective synthetic routes for production.

Weakness: Vulnerable to fluctuations in raw material prices. Strict environmental regulations for emissions.

Opportunity: Rising infrastructure and automotive sectors in Asia Pacific and Middle East countries boost demand. New applications development in surface coatings and dentistry.

Threats: Growth of bio-based and recycled plastics reduces dependency on petrochemical-based MMA. Economic slowdowns affect end-use industries.

Key Takeaways

The global methyl methacrylate market is expected to witness high growth over the forecast period driven by expanding end-use industries in Asia Pacific. Methyl methacrylate demand is projected to grow at a CAGR of 4.9% during 2023-2030 to reach a market size of US$ 7,510.7 Mn by 2024.

Asia Pacific accounts for the largest and fastest growing methyl methacrylate market owing to strong growth in the construction and automotive sectors in China, India and other Southeast Asian countries. China dominates MMA consumption in the region supported by low-cost manufacturing and availability of raw material.

Key players operating in the methyl methacrylate market are BASF SE, Evonik Industries AG, Arkema Group, The Dow Chemical Company, Akzo Nobel N.V., Sumitomo Chemical Company Limited, Chi Mei Corporation, Huntsman Corporation, Kolon Industries, Karl Jungbecker GmbH & Co. KG. Major players focus on capacity additions, strategic partnerships and new product development catering to niche application segments.

0 notes

Text

Cast Acrylic Sheet Market: Global Demand Analysis & Opportunity Outlook 2035

Research Nester’s recent market research analysis on “Cast Acrylic Sheet Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitors analysis and a detailed overview of the global cast acrylic sheet market in terms of market segmentation by type, application, and by region.

Growing Deployment of Solar Panels to Promote Global Market Share of Cast Acrylic Sheet

The global cast acrylic sheet market is estimated to grow majorly on account of the rising installation of solar panels and the growing need for lightweight component materials for automobiles. Acrylic sheets are utilized in car windscreens and windows as lightweight alternatives to glass. Their great optical clarity provides for good visibility while driving and also enhances aerodynamics, lowering air resistance and increasing fuel efficiency. Moreover, the solar panel's protective cover is made of cast acrylic sheets. Their transparency is critical for capturing sunlight and producing the most energy. The world could have installed more than 350 GW of PV systems by the end of 2023.

Request Report Sample@

Besides this, the growing demand for LED and LCD-based smart television is also expected to drive market growth. Acrylic sheets are extremely light and thin, making them ideal for the small and compact designs of current LCD and LED screens. Moreover, they also act as a protective layer for the touchscreens.

Some of the major growth factors and challenges that are associated with the growth of the global cast acrylic sheet market are:

Growth Drivers:

Surge in Solar Panel Installation

Rising Demand for Touchscreen Devices

Challenges:

The prices of raw materials are unsteady and there is no standardization for the manufacturing of acrylic sheets, these are some of the major factors anticipated to hamper the global market size of cast acrylic sheets. Acrylic sheets are manufactured using raw materials derived from petrochemicals, such as methyl methacrylate (MMA). Due to the factors like supply and demand dynamics, geopolitical events, and fluctuations in oil prices, the cost of the raw material is subjected to volatility. Price instability in raw materials can impact the overall cost of acrylic sheets, making it challenging for manufacturers to maintain consistent pricing and margins. On the other hand, there is tough competition from other materials, such as glass, polycarbonate, and specialized films. When picking material, manufacturers and customers frequently consider issues such as cost, durability, optical qualities, and environmental consideration. The presence of rival materials may limit the cast acrylic sheet market's growth potential.

On the basis of type, the global cast acrylic sheet market is segmented into cell and continuous. The cell segment is to garner the highest revenue by the end of 2035 by growing at a significant CAGR over the forecast period. Cell-cast acrylic sheets are easily formed and molded into a wide range of shapes, including complex geometrics and elaborate decorations. This features them to be used in a variety of industries including automotive, aerospace, retail, and medical and is also responsible for the segment’s growth. Furthermore, the market is further fragmented by application into different segments, including signage & display, architecture & interior design, sanitary wave, medical, transportation, and food & catering. Out of all, the signage and display segment will dominate the market owing to the growing popularity of outdoor advertisement. Besides this, the application of cast acrylic sheets in architecture and interior design is also increasing.

By region, the Asia Pacific cast acrylic sheet market is to generate the highest revenue by the end of 2035. The growth of the segment is primarily due to growing urbanization and higher development of infrastructures. Furthermore, the market in Europe is also expected to show significant growth during the forecast period. Europe has a robust construction and architecture sector, with ongoing infrastructure development, commercial building projects, and residential construction, the market in the region is expected to grow. Furthermore, the region is home to several leading automotive manufacturers, and the region’s focus on sustainable mobility and lightweight vehicle design that drives the demand for cast acrylic sheets.

This report also provides the existing competitive scenario of some of the key players of the global cast acrylic sheet market which includes company profiling of Arkema, BASF SE, Evonik Industries AG, 3A Composites GmbH, Mitsubishi Chemical Corporation, PT Astari Niagara Internasional, PyraSied Xtreme Acrylic, Spartech LLC, and Trinseo

Access our detailed report at: https://www.researchnester.com/reports/cast-acrylic-sheet-market/5086

0 notes

Text

Cast Acrylic Sheet Market Outlook 2023-2035

Research Nester assesses the growth and market size of the global cast acrylic sheet market which is anticipated to be on account of the rising need for solar panels and the growing use of cast acrylic sheets for various purposes in the medical sector.

Research Nester’s recent market research analysis on “Cast Acrylic Sheet Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitors analysis and a detailed overview of the global cast acrylic sheet market in terms of market segmentation by type, application, and by region.

Growing Deployment of Solar Panels to Promote Global Market Share of Cast Acrylic Sheet

The global cast acrylic sheet market is estimated to grow majorly on account of the rising installation of solar panels and the growing need for lightweight component materials for automobiles. Acrylic sheets are utilized in car windscreens and windows as lightweight alternatives to glass. Their great optical clarity provides for good visibility while driving and also enhances aerodynamics, lowering air resistance and increasing fuel efficiency. Moreover, the solar panel's protective cover is made of cast acrylic sheets. Their transparency is critical for capturing sunlight and producing the most energy. The world could have installed more than 350 GW of PV systems by the end of 2023.

Besides this, the growing demand for LED and LCD-based smart television is also expected to drive market growth. Acrylic sheets are extremely light and thin, making them ideal for the small and compact designs of current LCD and LED screens. Moreover, they also act as a protective layer for the touchscreens.

Some of the major growth factors and challenges that are associated with the growth of the global cast acrylic sheet market are:

Growth Drivers:

Surge in Solar Panel Installation

Rising Demand for Touchscreen Devices

Challenges:

The prices of raw materials are unsteady and there is no standardization for the manufacturing of acrylic sheets, these are some of the major factors anticipated to hamper the global market size of cast acrylic sheets. Acrylic sheets are manufactured using raw materials derived from petrochemicals, such as methyl methacrylate (MMA). Due to the factors like supply and demand dynamics, geopolitical events, and fluctuations in oil prices, the cost of the raw material is subjected to volatility. Price instability in raw materials can impact the overall cost of acrylic sheets, making it challenging for manufacturers to maintain consistent pricing and margins. On the other hand, there is tough competition from other materials, such as glass, polycarbonate, and specialized films. When picking material, manufacturers and customers frequently consider issues such as cost, durability, optical qualities, and environmental consideration. The presence of rival materials may limit the cast acrylic sheet market's growth potential.

Request Report Sample@ https://www.researchnester.com/sample-request-5086

On the basis of type, the global cast acrylic sheet market is segmented into cell and continuous. The cell segment is to garner the highest revenue by the end of 2035 by growing at a significant CAGR over the forecast period. Cell-cast acrylic sheets are easily formed and molded into a wide range of shapes, including complex geometrics and elaborate decorations. This features them to be used in a variety of industries including automotive, aerospace, retail, and medical and is also responsible for the segment’s growth. Furthermore, the market is further fragmented by application into different segments, including signage & display, architecture & interior design, sanitary wave, medical, transportation, and food & catering. Out of all, the signage and display segment will dominate the market owing to the growing popularity of outdoor advertisement. Besides this, the application of cast acrylic sheets in architecture and interior design is also increasing.

By region, the Asia Pacific cast acrylic sheet market is to generate the highest revenue by the end of 2035. The growth of the segment is primarily due to growing urbanization and higher development of infrastructures. Furthermore, the market in Europe is also expected to show significant growth during the forecast period. Europe has a robust construction and architecture sector, with ongoing infrastructure development, commercial building projects, and residential construction, the market in the region is expected to grow. Furthermore, the region is home to several leading automotive manufacturers, and the region’s focus on sustainable mobility and lightweight vehicle design that drives the demand for cast acrylic sheets.

This report also provides the existing competitive scenario of some of the key players of the global cast acrylic sheet market which includes company profiling of Arkema, BASF SE, Evonik Industries AG, 3A Composites GmbH, Mitsubishi Chemical Corporation, PT Astari Niagara Internasional, PyraSied Xtreme Acrylic, Spartech LLC, and Trinseo

0 notes

Text

0 notes

Text

0 notes

Text

Rising Demand for Acetone in Solvents and Chemical Intermediates

The new assessment focuses on Acetone Market submitted by the The Brainy Insights organization and considers commercial and basic market designs with recorded and measured market data. Acetone is anticipated to grow at a stunning CAGR of 7.25%, thereby garnering a revenue of USD 7.01 billion in the 2022-2030 timeframe. This research aims to give global Acetone market strategic & knowledge insights to assist in making informed investment decisions, decision making, and recognizing potential growth possibilities. The study report gives complex dynamics about the various aspects of the Acetone market, which assists organizations operating in the market make strategic development decisions. Additionally, the driving factors that are positively impacting the demand for Acetone market and restricting factors that are hampering the growth of Acetone market are discussed in detail, coupled with their influences on the Acetone market. The research delivers insights on the COVID-19 outbreak considering the alteration in customer demand & behaviour, re-routing the supply chain, purchasing patterns, major interventions of governments, and the dynamics of current market forces. This record will comprise all the significant aspects of the Acetone market, such as pros & cons, competition, openings, technological developments, regional analysis, etc.

Get the inside scoop with Sample report @ https://www.thebrainyinsights.com/enquiry/sample-request/12498

Further, the report provides a visual description of how all the organizations stand relatively based on their global Acetone market hold, geographic presence, competencies, employee & financial strength, and years of operations. Additionally, the SWOT analysis describes strengths, weaknesses, opportunities/possibilities, and threats that assist in accumulating the entire document with high efficiency & dependence. The report is an in-depth analysis of a wealthy supply of main factors responsible for developing the global Acetone market. The top-down & bottom-up strategies have been used to validate and estimate the market size of Acetone industry to evaluate the extent of multiple other dependent submarkets in the overall market.

Moreover, the report customization is done per the requirements of the clients. The study provides an in-depth analysis of each parameter, allowing our users to identify the most likely and perhaps the best trend in the current landscape. The companies are analyzed for both external and internal factors. The internal factors consist of the R&D base, consumer base, labour force, supply chain, market share in specific regions, and availability of technologies. The external factors include laws concerning product approval, per capita income, economic fluctuations, the performance of the industry in specific regions, and various other socio-economic parameters. The global Acetone market record provides a comprehensive analysis of the growth among segments & provides precise calculations & forecasts for sales by application and type in terms of value & volume.

Check complete table of contents with list of table and figures @ https://www.thebrainyinsights.com/report/acetone-market-12498

Based on the following items' applicability: Methyl Methacrylate (MMA), Bisphenol A (BPA), Solvents, Others

The market segment by product type: Specialty Grade, Technical Grade

The geographical portions of the report are as follows: North America (United States, Canada and Mexico), Europe (Germany, France, United Kingdom, Russia, Italy and Rest of Europe), Asia Pacific (China, Japan, Korea, India, Southeast Asia and Australia), South America (Brazil, Argentina, Colombia and Rest of South America), Middle East and Africa (Saudi Arabia, United Arab Emirates, Egypt, South Africa and Rest of the Middle East and Africa)

The study's goal is to identify the following crucial global market participants: INEOS, Royal Dutch Shell plc, Cepsa, Mitsui Chemicals, Inc., Altivia, LCY GROUP, Formosa Chemicals & Fiber Corporation, Prasol Chemicals Pvt. Ltd., EMCO Limited, BASF SE, Reliance Industries Limited, KUMHO P&B CHEMICALS., INC.

The study report gives penetrations from market positioning & marketing channels to likely growth approaches, providing in-depth analysis for new players or existing contestants worldwide Acetone industry. The report compromises many graphs and flowcharts that distinctly explain the attractiveness of each segment globally and in various regions. The research document has comprehensively used the figures & numbers with the help of graphical & pictorial representation, which represents extra clarity on the global Acetone market.

Have Any Query? Ask Our Expert @ https://www.thebrainyinsights.com/enquiry/request-customization/12498

About The Brainy Insights:

The Brainy Insights is a market research company, aimed at providing actionable insights through data analytics to companies to improve their business acumen. We have a robust forecasting and estimation model to meet the clients' objectives of high-quality output within a short span of time. We provide both customized (clients' specific) and syndicate reports. Our repository of syndicate reports is diverse across all the categories and sub-categories across domains. Our customized solutions are tailored to meet the clients' requirement whether they are looking to expand or planning to launch a new product in the global market.

Contact Us

Avinash D

Head of Business Development

Phone: +1-315-215-1633

Email: [email protected]

Web: www.thebrainyinsights.com

0 notes

Link

0 notes

Text

Polyterpene Resin Market

The Polyterpene Resin market will change significantly from the previous year. Over the next five years, will register a CAGR in terms of revenue, and the global market size will reach USD in millions by 2028.

Polyterpene resin is a polymer that contains terpenes, the largest class of natural products on earth. Terpenes are hydrocarbons that may have a wide variety of uses in industry and research owing to their diverse chemical structures. Polyterpene resins are manufactured from vegetable oils or animal fats by reacting with alcohols such as butyl acetate, pentanol, ethylene glycol dimethacrylate, or esters like methyl methacrylate (MMA), methaisopropyl adipate; additionally, they can be combined with other ingredients for specific applications.

The research provides an up-to-date analysis of the current market scenario, as well as the current developments and drivers, and the market landscape. Furthermore, the growing demand for Polyterpene Resin is expected to propel the industry forward. The Polyterpene Resin market analysis is segmented into type, application, and geographic landscape.

0 notes

Text

Methyl Methacrylate Adhesives Market Analysis by Key Growth Factors and Opportunities Forecasts| Henkel, Permabond LLC, Parsons Adhesive Inc, Huntsman Corporation, 3M and others

Methyl Methacrylate Adhesives Market Analysis by Key Growth Factors and Opportunities Forecasts| Henkel, Permabond LLC, Parsons Adhesive Inc, Huntsman Corporation, 3M and others

Methyl Methacrylate Adhesives Market

The market size of MMA adhesives is estimated at USD 1.09 billion in 2018 and is projected to reach USD 1.56 billion by 2023, at a CAGR of 7.5%. The increasing demand for lightweight, crash-resistant, and fuel-efficient vehicles; growing demand in the automotive and marine industries, superior quality and performance of MMA adhesives, and increasing awareness…

View On WordPress

0 notes

Text

Methyl Methacrylate Market Opportunity Analysis and Industry Forecast, 2022–2027

The report titled Methyl Methacrylate Market offers detailed insights on the Methyl Methacrylate industry entailing key information on its different market segments. The report gives an industry overview from around the world and covers the latest trends, market restraints, and investment opportunities, and conducts exclusive interviews of the Methyl Methacrylate industry leaders to contribute to the report’s findings. The report discusses the buyers’ requirements and suggests strategic actions & business changes accordingly to the market players. Moreover, the natural, internal, and external barriers to progress are given in the report. The wider business environment of the Methyl Methacrylate market and the industry challenges are included in the report.

Read Full Report at:

Growth prospects, leading trends, progress projections, key industries, and business innovations are the primary focus of the Methyl Methacrylate study. A comprehensive Methyl Methacrylate study is available for a number of key areas involved in the report. Furthermore, the Methyl Methacrylate study examines present and potential consumer positions in terms of sales based on market goods around the globe.

Key Players in the Methyl Methacrylate Market:

Akzo Nobel NV (AMS: AKZA), Arkema Group, Asahi Kasei Chemicals Corp., BASF SE (ETR: BAS), Evonik Industries AG, Formosa Plastics Corp., Heilongjiang Zhongmeng Longxin Chemical Co. Ltd., Kaohsiung Monomer Company Ltd., Kuraray Co. Ltd., LG MMA Corp., Lotte Chemical Corporation, Lucite International Ltd., Mitsubishi Chemical Corporation, Mitsubishi Gas Chemical Co. Inc., Mitsui Chemicals Inc, Shandong Hongxu Chemical Co. Ltd., Sumitomo Chemical Co. Ltd., Thai MMA Co. Ltd. and others.

Methyl Methacrylate Market Types:

ACH Method

Isobutylene Method

Ethylene Method

Methyl Methacrylate Market Applications:

Polymethyl Methacrylate

Plastic Additive

Surface Coating

Others

Highlights of the Report:

The report gives information on all the active tenders in the Methyl Methacrylate industry across the globe based on different categories. The important government notifications and change in regulations according to the latest updates is provided in the report.

The market size and forecast estimates of the Methyl Methacrylate market is given in the report considering the economic, financial, and general business conditions prevailing in the Methyl Methacrylate market from 2022 to 2027.

The report demonstrates the contribution of each segment and sector in the improvement of Methyl Methacrylate market share, market size, and CAGR.

Request a sample report:

Regional Methyl Methacrylate Market (Regional Output, Demand & Forecast by Countries):

North America (United States, Canada, Mexico)

South America (Brazil, Argentina, Ecuador, Chile)

Asia Pacific (China, Japan, India, Korea)

Europe (Germany, UK, France, Italy)

Middle East Africa (Egypt, Turkey, Saudi Arabia, Iran) And more.

Why Purchase This Market Research Report?

Critical issues and challenges the Methyl Methacrylate market will be facing in the forecasted years are identified in the report to help market players align their business decisions and strategies accordingly.

The report identifies key trends facing the Methyl Methacrylate market.

Trends responsible for global and regional economic growth of the Methyl Methacrylate market are highlighted in the report to help market players in a critical understanding of the future of the Methyl Methacrylate market.

The report conducts an assessment of the production and operational practices taking place in the marketplace.

The report presents the challenges faced by the leading geographies and nations from the pandemic and their reorientation of policies to survive the market.

The Report Attempts to Answer the Following Questions:

What will be the financial performance of North America, APAC, Europe, and Africa in the Methyl Methacrylate market in 2022 and beyond?

Which companies are likely to succeed in the Methyl Methacrylate market with the help of foreign companies, mergers and acquisitions and new product launches?

What are the strategy recommendation and business models for emerging market players?

Which are the Methyl Methacrylate market’s largest manufacturing firms and most competitive firms?

Thanks for showing interest in the Methyl Methacrylate Market research publication; you can also get individual chapter-wise sections or region / Country report versions like Germany, France, China, LATAM, GCC, North America, Europe, or Asia.

ABOUT US:

IndustryDataAnalytics is your single point market research source for all industries including pharmaceutical, chemicals and materials, energy resources, automobile, IT, technology and media, food and beverages, and consumer goods, among others.

CONTACT US:

Irfan Tamboli (Head of Sales) – Industry Data Analytics

+1 (704) 266-3234 | [email protected]

#Methyl Methacrylate Market#Methyl Methacrylate Market Analysis#Methyl Methacrylate Market Top Companies#Methyl Methacrylate Market Research

0 notes

Text

The market size of MMA adhesives is estimated at USD 1.09 billion in 2018 and is projected to reach USD 1.56 billion by 2023, at a CAGR of 7.5%. The increasing demand for lightweight, crash-resistant, and fuel-efficient vehicles; growing demand in the automotive and marine industries, superior quality and performance of MMA adhesives, and increasing awareness about the advantages of adhesives over conventional techniques are driving the MMA adhesives market, globally. Companies are developing primer-less MMA adhesives. These adhesives require minimal surface cleaning of the substrates to be bonded and exhibit high toughness in all assembled parts with high gap-filling capabilities.

Key players in the MMA adhesives market:

The key players in the market include Illinois Tool Works Inc. (US), Arkema (France), SCIGRIP (UK), Scott Bader (UK), Lord Corporation (US), Henkel (Germany), Permabond LLC (US), Parsons Adhesive Inc. (US), Huntsman Corporation (US), and 3M (US).

#Methyl Methacrylate Adhesives Market#Covid-19 Impact on Methyl Methacrylate Adhesives Market#Methyl Methacrylate Adhesives#MMA Adhesives market#global MMA adhesives market#MMA adhesives market Drivers#Methyl Methacrylate Adhesives Market Size#Methyl Methacrylate Adhesives Demand#Methyl Methacrylate Adhesives Sales

0 notes

Text

Methyl Methacrylate(MMA) Market 2021-2028 | Comprehensive Study Covid19 Impact Analysis | GET FLAT 20% OFF ON THIS REPORT

GET FLAT 20% OFF ON THIS REPORT

Methyl Methacrylate(MMA) Market Report Coverage: Key Growth Factors & Challenges, Segmentation & Regional Outlook, Top Industry Trends & Opportunities, Competition Analysis, COVID-19 Impact Analysis & Projected Recovery, and Market Sizing & Forecast 2021-2028.

Market Insights

The global Methyl Methacrylate(MMA) market report provides comprehensive product analysis which includes its expected performance, pricing factors, and potential developments during the forecast period 2021-2028. The report confers information about the market’s overall performance, challenges, threats, and opportunities that reflects the present and future market scenario.Along with this, it lays out details on the latest government regulations and norms that impact the growth of the market.A new informative report on the Methyl Methacrylate(MMA) Market was recently published by Ordient Market Research and added to its extensive database for creating better strategic business decisions. It uses various proven research methods like primary and secondary research methods to gather data from various sources. It includes an in-depth analysis of the worldwide segments and sub-segments of the market that contributes to understanding the present status of the Methyl Methacrylate(MMA) market.

Download Free Sample PDF including COVID19 Impact Analysis, full TOC, Tables and Figures@ https://ordientmarketresearch.com/sample-request/chemicals-and-materials/world-methyl-methacrylate-mma-market/OMR2182

The Global Methyl Methacrylate(MMA) Market Report offers extensive knowledge and information about the Methyl Methacrylate(MMA) market pertaining to market size, market share, growth influencing factors, opportunities, and current and emerging trends. The report is formulated with the updated and latest information of the global Methyl Methacrylate(MMA) market further validated and verified by the industry experts and professionals. The Global Methyl Methacrylate(MMA) Market report contains historical, current, and forecast estimation of the revenue generation and profits for each segment and sub-segment of the Methyl Methacrylate(MMA) market in each key region of the world. The report additionally sheds light on the emerging growth opportunities in the business sphere that are anticipated to bolster the growth of the market.

Market Analysis

The Methyl Methacrylate(MMA) market research report offers in-depth research and analysis of the key aspects of the Methyl Methacrylate(MMA) industry. The report offers holistic marketing research that permits companies to form decisions supported by changing market trends. It includes a market overview that gives a basic understanding of the market. This market is split into different segments, e.g., B. Type, applications, end-users, and sales channels. Additionally, the report includes a competitive analysis and a corporation profile of the key market players.

Browse Full Premium Report @ https://ordientmarketresearch.com/chemicals-and-materials/world-methyl-methacrylate-mma-market/OMR2182

Segmentation Outlook

The report gives an extensive analysis of various segments of the market by studying the product range, applications, major regions, and leading companies in the industry. Additionally, the report also dedicates an individual section to give a detailed analysis of the manufacturing process, which includes information collected through both primary and secondary sources of data collection. The primary source of data collection contains interviews of industry experts who offer accurate insights into the future market scenario.

Product Type Coverage (Market Size & Forecast, Major Company of Product Type etc.):

ACH Process

C4 Direct Oxidation

MAN Process

C4 DOE Process

New ACH Process

C2 BASF Process

Application Coverage (Market Size & Forecast, Different Demand Market by Region, Main Consumer Profile etc.):

Acrylic sheet

Moulding/ extrusion compounds

Surface coating

Other

Regions covered in Methyl Methacrylate(MMA) market report are:

North America

United States

Canada

Europe

Germany

France

U.K.

Italy

Russia

Nordic

Rest of Europe

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Australia

Rest of Asia-Pacific

Latin America

Mexico

Brazil

Middle East & Africa

Turkey

Saudi Arabia

UAE

Rest of Middle East & Africa

Years Considered to Estimate the Market Size:

History Year: 2015-2020

Base Year: 2020

Estimated Year: 2021

Forecast Year: 2021-2028

Detailed TOC of Methyl Methacrylate(MMA) Market Report 2021-2028:

Chapter 1: Methyl Methacrylate(MMA) Market Overview

Chapter 2: Economic Impact on Industry

Chapter 3: Market Competition by Manufacturers

Chapter 4: Production, Revenue (Value) by Region

Chapter 5: Supply (Production), Consumption, Export, Import by Regions

Chapter 6: Production, Revenue (Value), Price Trend by Type

Chapter 7: Market Analysis by Application

Chapter 8: Manufacturing Cost Analysis

Chapter 9: Industrial Chain, Sourcing Strategy and Downstream Buyers

Chapter 10: Marketing Strategy Analysis, Distributors/Traders

Chapter 11: Market Effect Factors Analysis

Chapter 12: Methyl Methacrylate(MMA) Market Forecast

Continued……

Share your budget and Get Exclusive Discount @ https://ordientmarketresearch.com/check-discount/chemicals-and-materials/world-methyl-methacrylate-mma-market/OMR2182

Global Methyl Methacrylate(MMA) Market Report provide in-depth information about the Leading Competitors involved in this report:

Mitsubishi Rayon

Evonik

Sumitomo Chemical

LG MMA

Asahi Kasei

Arkema

Kuraray

Mitsubishi Gas Chemical

BASF

Dow

Formosa Plastics

Jilin Petrochemical

Longxin Chemical

Shandong Hongxu

What market dynamics does this report cover?

The report shares key insights on:

Current market size

Market forecast

Market opportunities

Key drivers and restraints

Regulatory scenario

Industry trend

New product approvals/launch

Promotion and marketing initiatives

Pricing analysis

Competitive landscape

Study Objectives of Methyl Methacrylate(MMA)

1.The purpose of the market study is to include evidence, estimates, statistics, historical data, and market data verified by the industry, as well as the appropriate methodology and evaluation for a full market assessment.

2.The market research also helps to understand structure by evaluating the dynamics of the market segments.

3.Market segmentation is split based on content, form, end-user, and region; the global market size of Methyl Methacrylate(MMA) is expected.

4.The major points considered in the Global Methyl Methacrylate(MMA) Market report include the leading competitors operating in the global market.

5.The report also contains the company profiles of the players operating in the global market.

6.The manufacture, production, sales, future strategies, and the technological capabilities of the leading manufacturers are also included in the report.

About Ordient Market Research:

Ordient Market Research is the most extensive dataset of the intact market-related survey. Being tech-driven market researchers, we progressively analyze large datasets. This helps us to gain in-depth insight and offer comprehensive consulting. Ordient Market Research specializes in detailed market analysis and research reports. Let it be profit-making, commercial, or industrial; we serve almost all sectors of online business. We understand the importance of market statistical surveying.

On the other hand, it is essential to recognize the previous and ongoing circumstances to form a great future. Data regarding the present and past market trends assists in forecasting upcoming trends in the market. At Ordient Market Research, we offer customized solutions as per given circumstances. Our company’s partnership with leading publishers has enabled us to access detailed and latest datasets in various business sectors. The association also includes a wide array of market analysis documents that can offer you crucial data about your business. All in all, you will get the latest, up-to-date reports at Ordient Market Research.

Browse More Reports:

https://neighborwebsj.com/uncategorized/5127151/cardiopulmonary-bypass-equipment-market-2021-size-growth-demand-opportunities-forecast-to-2030-get-flat-20-off-on-this-report/

https://neighborwebsj.com/uncategorized/5127156/salad-dressings-and-mayonnaise-market-size-growth-and-regions-to-2030-get-flat-20-off-on-this-report/

https://neighborwebsj.com/uncategorized/5127158/fine-liner-pen-market-2021-top-countries-data-with-revenue-top-manufacturers-market-size-and-2030-forecast-research-report-get-flat-20-off-on-this-report/

https://neighborwebsj.com/uncategorized/5127314/compressed-air-treatment-equipment-market-outlook-to-2030-emerging-trends-and-will-generate-new-growth-opportunities-status-get-flat-20-off-on-this-report/

https://neighborwebsj.com/uncategorized/5127416/raw-milk-vending-machine-market-size-2021-opportunities-demand-and-forecast-to-2030-get-flat-20-off-on-this-report/

Contact Us

Mangesh Mahajan

Head of Business Development

Phone: +91-7385620197

Web: https://ordientmarketresearch.com/

0 notes

Text

GET THE BEST BEADS FOR JEWELLERY MAKING – EXCELLENT BEADS

Get the Best Beads for Jewellery Making – Excellent Beads

Jewellery making is a work of art. At present, millions of people all over the world have chosen it as a profession. The quality of beads for Jewellery making play a vital part in the design and the shine of the jewellery. Thus, experienced crafters leave no stone unturned in finding the best raw materials for making jewellery.

If you are a crafter and are finding genuine sellers who sell the best beads for jewellery making, your search is over. At Excellent Beads, we have all kinds of raw materials, starting from beads to bead threads, stones, spacers and many more.

Types of Beads for Jewellery Making

Let us look at the various kinds of jewellery making beads and understand the differences.

Cotton Beads

Handcrafted cotton beads add to the uniqueness of the jewellery. The beads are tightly spun, compressed and then dipped in lacquer to give a resistant coating. Cotton beads are one of the most famous raw materials for jewellery making among those who specialize in fabric jewellery.

Glass Beads

Glass Beads are one of the oldest art materials that date back to almost 3000 years ago. The beautiful glossiness of these beads makes them a favourite among the artists as well as the customers. At Excellent Beads, we happen to be one of the largest suppliers of glass beads across India.

Pearl Beads

Pear Beads are one of the most unique beads for jewellery making. Available in varying sizes such as round, oval and potato-shaped, these beads are used to make traditional designs of jewellery. Apart from jewellery, you can also find these beads in designed mirrors, combs and so on.

Acrylic Beads

Acrylic beads are basically synthetic beads created by polymerizing MMA (methyl methacrylates) monomer. Nowadays, these beads are gaining popularity in the market, owing to their lightweight and outstanding durability.

As a renowned supplier of the best quality beads for jewellery making and other raw materials, we have a wide collection of acrylic beads, of different prices and calibre.

Wooden Beads

If you are looking to take your jewellery making game to the next level, behold – wooden beads. Handcrafted by specialists and carved from wood, these beads with their almost rounded shapes add a touch of rugged beauty to a perfect piece of jewellery.

Wooden beads are generally used in making ethnic clothing and jewellery. Because of the large holes, these beads can be stringed very easily.

Metal Beads

Among the various kinds of beads for jewellery making, metal beads hold a special place. Crafters love these beads mainly because of their perfectly finished surfaces and durability.

Metal beads are of various kinds – Aluminium, Brass, Bronze, Copper, Fine Silver, Enameled Copper, Gold fill, Gold overlay and many others. For a complete collection of the best metal beads, make sure to visit us.

Antique Beads

As the name suggests, antique beads add a touch of antiquity to the jewellery. At Excellent Beads, we have a vintage collection of almost thousands of different kinds of antique beads. Looking to add class and royalty to your creations? Antique beads are your best option.

2 notes

·

View notes

Text

A view of acrylic

Acrylic plastic refers to a family of synthetic, or man-made, plastic materials containing one or more derivatives of acrylic products acid. The most common acrylic plastic is polymethyl methacrylate (PMMA), which is sold under the brand names of Plexiglas, Lucite, Perspex, and Crystallite. PMMA is a tough, highly transparent material with excellent resistance to ultraviolet radiation and weathering. It can be colored, molded, cut, drilled, and formed. These properties make it ideal for many applications including airplane windshields, skylights, automobile taillights, and outdoor signs. One notable application is the ceiling of the Houston Astrodome which is composed of hundreds of double-insulating panels of PMMA acrylic plastic.

Like all plastics, acrylic plastics are polymers. The word polymer comes from the Greek words poly, meaning many, and meros, meaning a part. A polymer, therefore, is a material made up of many molecules, or parts, linked together like a chain. Polymers may have hundreds, or even thousands, of molecules linked together. More importantly, a polymer is a material that has properties entirely different than its component parts. The process of making a polymer, known as polymerization, has been likened to shoveling scrap glass, copper, and other materials into a box, shaking the box, and coming back in an hour to find a working color television set. The glass, copper, and other component parts are still there, but they have been reassembled into something that looks and functions entirely differently.

The first plastic polymer, celluloid, a combination of cellulose nitrate and camphor, was developed in 1869. It was based on the natural polymer cellulose, which is present in plants. Celluloid was used to make many items including photographic film, combs, and men's shirt collars.

In 1909, Leo Baekeland developed the first commercially successful synthetic plastic polymer when he patented phenol formalde-hyde resin, which he named Bakelite. Bakelite was an immediate success. It could be machined and molded. It was an excellent electrical insulator and was resistant to heat, acids, and weather. It could also be colored and dyed for use in decorative objects. Bakelite plastic was used in radio, telephone, and electrical equipment, as well as counter tops, buttons, and knife handles.

Acrylic acid was first prepared in 1843. Methacrylic acid, which is a derivative of acrylic acid, was formulated in 1865. When methacrylic acid is reacted with methyl alcohol, it results in an ester known as methyl methacrylate. The polymerization process to turn methyl methacrylate into polymethyl methacrylate was discovered by the German chemists Fittig and Paul in 1877, but it wasn't until 1936 that the process was used to produce sheets of acrylic safety glass commercially. During World War II, acrylic glass was used for periscope ports on submarines and for windshields, canopies, and gun turrets on airplanes.

Acrylic plastic polymers are formed by reacting a monomer, such as methyl methacrylate, with a catalyst. A typical catalyst would be an organic peroxide. The catalyst starts the reaction and enters into it to keep it going, but does not become part of the resulting polymer.

Acrylic plastics are available in three forms: flat sheets, elongated shapes (rods and tubes), and molding powder. Molding powders are sometimes made by a process known as suspension polymerization in which the reaction takes place between tiny droplets of the monomer suspended in a solution of water and catalyst. This results in grains of polymer with tightly controlled molecular weight suitable for molding or extrusion.

Acrylic plastic sheets are formed by a process known as bulk polymerization. In this process, the monomer and catalyst are poured into a mold where the reaction takes place. Two methods of bulk polymerization may be used: batch cell or continuous. Batch cell is the most common because it is simple and is easily adapted for making diy acrylic key chain sheets in thicknesses from 0.06 to 6.0 inches (0.16-15 cm) and widths from 3 feet (0.9 m) up to several hundred feet. The batch cell method may also be used to form rods and tubes. The continuous method is quicker and involves less labor. It is used to make sheets of thinner thicknesses and smaller widths than those produced by the batch cell method.

We will describe both the batch cell and continuous bulk polymerization processes typically used to produce transparent polymethyl methacrylic (PMMA) sheets.

The mold for producing sheets is assembled from two plates of polished glass separated by a flexible "window-frame" spacer. The spacer sits along the outer perimeter of the surface of the glass plates and forms a sealed cavity between the plates. The fact that the spacer is flexible allows the mold cavity to shrink during the polymerization process to compensate for the volume contraction of the material as the reaction goes from individual molecules to linked polymers. In some production applications, polished metal plates are used instead of glass. Several plates may be stacked on top of each other with the upper surface of one plate becoming the bottom surface of the next higher mold cavity. The plates and spacers are clamped together with spring clamps.

An open comer of each mold cavity is filled with a pre-measured liquid syrup of methyl methacrylate monomer and catalyst. In some cases, a methyl methacrylate prepolymer is also added. A prepolymer is a material with partially formed polymer chains used to further help the polymerization process. The liquid syrup flows throughout the mold cavity to fill it.

The mold is then sealed and heat may be applied to help the catalyst start the reaction.

As the reaction proceeds, it may generate significant heat by itself. This heat is fanned off in air ovens or by placing the molds in a water bath. A programmed temperature cycle is followed to ensure proper cure time without additional vaporization of the monomer solution. This also prevents bubbles from forming. Thinner sheets may cure in 10 to 12 hours, but thicker sheets may require several days.

When the plastic is cured, the molds are cooled and opened. The glass or metal plates are cleaned and reassembled for the next batch.

The plastic sheets are either used as is or are annealed by heating them to 284-302°F (140-150°C) for several hours to reduce any residual stresses in the material that might cause warping or other dimensional instabilities.

Any excess material, or flash, is trimmed off the edges, and masking paper products or plastic film is applied to the surface of the finished sheets for protection during handling and shipping. The paper or film is often marked with the material's brand name, size, and handling instructions. Conformance with applicable safety or building code standards is also noted.

The storage, handling, and processing of the chemicals that make acrylic plastics are done under controlled environmental conditions to prevent contamination of the material or unsafe chemical reactions. The control of temperature is especially critical to the polymerization process. Even the initial temperatures of the monomer and catalyst are controlled before they are introduced into the mold. During the entire process, the temperature of the reacting material is monitored and controlled to ensure the heating and cooling cycles are the proper temperature and duration.

Samples of finished acrylic materials are also given periodic laboratory analysis to confirm physical, optical, and chemical properties.

Acrylic plastics manufacturing involves highly toxic substances which require careful storage, handling, and disposal. The polymerization process can result in an explosion if not monitored properly. It also produces toxic fumes. Recent legislation requires that the polymerization process be carried out in a closed environment and that the fumes be cleaned, captured, or otherwise neutralized before discharge to the atmosphere.

Acrylic plastic is not easily recycled. It is considered a group 7 plastic among recycled plastics and is not collected for recycling in most communities. Large pieces can be reformed into other useful objects if they have not suffered too much stress, crazing, or cracking, but this accounts for only a very small portion of the acrylic display case boxes plastic waste. In a landfill, acrylic plastics, like many other plastics, are not readily biodegradable. Some acrylic plastics are highly flammable and must be protected from sources of combustion.

The average annual increase in the rate of consumption of acrylic plastics has been about 10%. A future annual growth rate of about 5% is predicted. Despite the fact that acrylic plastics are one of the oldest plastic materials in use today, they still hold the same advantages of optical clarity and resistance to the outdoor environment that make them the material of choice for many applications.

With so many options for clear plastic on the market, it is no surprise that lots of people misunderstand the differences between the types. Each type is made in a different way using different materials, which results in many different price points. We've put together this resource page to help sort out some of the most frequently asked questions, like "is acrylic a plastic or a glass?" and "what is the difference between acrylic and plastic?". While acrylic is a plastic, not all plastic is acrylic. The term "acrylic" represents a family of petroleum-based thermoplastics made from the derivation of natural gas. Another common name for acrylic is "polyacrylate" which is one of the most common types. This material is made from Methyl Methacrylate (MMA), Poly Methyl Methacrylate, or a combination of both.

Although the composition is pretty much the same, acrylic has many brand names. Plexiglas was the original trademark name when the Rohm and Haas Company first introduced the product to a mass market, but many others have established their own brand names including Lucite by du Pont and Acrylite by Evonik Cyro LLC. Some other common brands are Perspex, Oroglass, Optix, and Altuglass.Injection molded acrylic is manufactured by injecting acrylic or polymethyl methacrylate material into a mold. This transparent thermoplastic makes a great alternative to glass, which is why it is commonly used to manufacture bakery bins, sunglasses, and display risers. Unlike polystyrene, injection molded acrylic table number plate can be made without the issues of hazing or coloration. Additionally the material is much stronger and has minimal relief markings when removed from the mold. Injection molding takes less labor than hand-crafting, which results in a lower cost.

1 note

·

View note