#Modular Robotics analysis

Explore tagged Tumblr posts

Text

Crit Role Miniature Rollout: C3E50 Red Moon Rising

With Andrew Harshman

An analysis of the minis used on CR.

That red moon is indeed arisin’! Oooooey, look at that cinematic shot and cinematic lighting! At the end of the day, I think I have a slight preference for live shows, but the benefit of preproduction is these cinematic mini shots. The same thing probably could be achieve during a live recording with a handheld camera operator (Mega64 does it all the time). But regardless, these shots are awesome for helping establish the scene and giving us a closer peak at all the rad models. Thank you Critical Role production team, it is much appreciated!

Get in the robot Shinji, it’s time for Critical Role Miniature Rollout Campaign 3 Episode 50!

Mini Map Overview

This is a cuh-lassic C2/3 style map, featuring full 3D terrain elements atop a gaming mat. Specifically, a Mats by Mars desert theme base with Dwarven Forge Mountain rocks and blocks. Some wooden stairs and walkway components by Monster Fightclub, and scatter terrain from Pathfinder, HirstArts, and Mantic Games. One tent is from Mantic’s Terrain Crate series and the other is a Safari brand “Civil War Officer” tent famously featured in Campaign 2 Episode 3:

This particular brand of tent must be a popular in the world of Tal'dorei. What about this tent design makes it “Civil War” era? It is a rather tall tent, perhaps the high tent ceiling is made to accommodate an Abe Lincoln style top hat? “d4 score and seven years ago-” harharhar

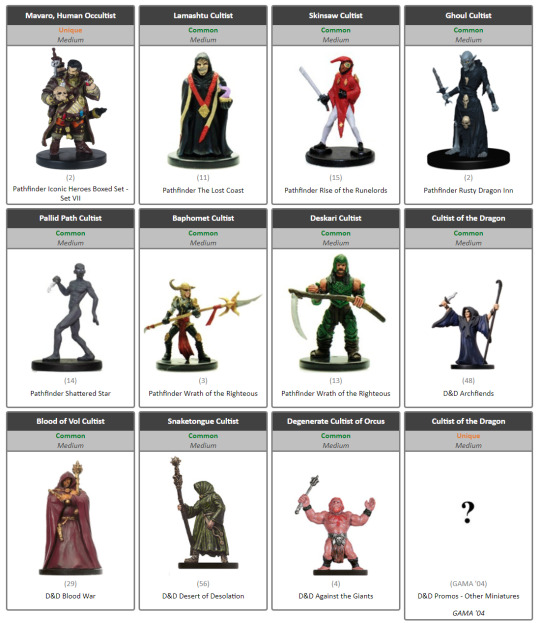

The medium sized enemy cult member minis in this encounter are a bit mysterious to me. I suspect they are kitbashed models or resin printed. Possibly modular Frostgrave models? Difficult to say for sure. They are a tad generic, nothing super distinctive or identifiable. But conveniently, armed cultist models are a dime a dozen. If you need some for your own game, you’ll find there are ample options.

Best Mini of the Ep

This here Mighty Servant of Leuk-o model is mighty neat. Not only is it one of the most impressively large construct models. It is one of the only pilotable construct models! Go for it, hop in for a test drive!

Perhaps a sorta mundane detail for most folk, but I really like the decorative lines of gold patterning. Quality production value.

Worst Mini of the Ep

These large tents are pretty nice sculpts. But they are a downright hassle to paint. Them little frilly flaps along the top there, what a bother. Ain’t got time for those sorta tent trubs.

I’ve painted three of these tents for my own game, that’s over 100 flaps! Yeesh.

See ya next sesh!

#critroleminiaturerollout

#critroleminiaturerollout#criticalroleminiaturerollout#critrole#criticalrole#crit role#crspoilers#dwarvenforge#matsbymars

27 notes

·

View notes

Text

Pedicle Screw Systems Market : Size, Trends, and Growth Analysis 2032

The Pedicle Screw Systems Market was valued at US$ 1,998.90 million in 2024 and is projected to grow at a CAGR of 5.90% from 2025 to 2032. The increasing global burden of spinal disorders, coupled with advances in minimally invasive surgical technologies, is fueling the demand for robust spinal fixation systems. Among these, pedicle screw systems have become the cornerstone of spinal fusion and deformity correction procedures, offering unmatched structural support and surgical outcomes.

What Are Pedicle Screw Systems?

Pedicle screw systems are specialized orthopedic implants used in spinal stabilization procedures, particularly spinal fusion surgeries. These systems consist of screws that are inserted into the pedicles — the cylindrical bony projections off the back of each vertebra. Once secured, the screws are connected using rods, hooks, or plates to form a rigid frame that stabilizes the spine, allowing vertebrae to fuse together over time.

This system is designed to limit movement in the affected spinal segment, thereby promoting healing and reducing pain caused by spinal instability, deformities, or degenerative conditions.

Key Market Drivers

1. Rising Incidence of Spinal Disorders

Conditions such as scoliosis, spinal stenosis, spondylolisthesis, herniated discs, and traumatic spinal injuries are on the rise due to aging populations, sedentary lifestyles, and increased road traffic accidents. These disorders often necessitate surgical intervention involving pedicle screw systems to restore spinal alignment and stability.

2. Growth in Minimally Invasive Spine Surgery (MISS)

Minimally invasive techniques are revolutionizing spinal surgeries by offering reduced recovery times, less blood loss, and smaller incisions. Many modern pedicle screw systems are specifically designed for MISS, allowing surgeons to perform precise screw placement under fluoroscopic or robotic guidance.

3. Technological Advancements in Implant Design

Manufacturers are innovating with biocompatible materials (like titanium and PEEK), improved thread designs, and cannulated screws for percutaneous placement. Customizable and modular systems are also gaining traction, allowing surgeons greater flexibility in addressing patient-specific anatomical challenges.

4. Increased Surgical Volumes Worldwide

With greater access to healthcare and rising awareness of surgical solutions for chronic back pain, both elective and trauma-related spinal surgeries are increasing globally. This directly boosts demand for pedicle screw systems as standard-of-care instrumentation in spine stabilization.

5. Robotics and Navigation Technology Integration

The integration of robot-assisted surgical platforms and 3D navigation systems has elevated the accuracy of pedicle screw placement. These technologies reduce the risk of neurological damage and post-operative complications, further enhancing the appeal of pedicle screw-based surgeries.

Application Segmentation

Degenerative Disc Disease: A common cause of lower back pain, often requiring fusion to restore disc height and eliminate motion between vertebrae.

Spinal Trauma and Fractures: Pedicle screws provide immediate stabilization in cases of vertebral fractures due to accidents or falls.

Scoliosis and Spinal Deformities: Used to correct and maintain spinal alignment in congenital, idiopathic, or neuromuscular scoliosis cases.

Spinal Tumors and Infections: When surgical excision leads to destabilization, pedicle screws help support the remaining spinal structure.

Revision Surgeries: In cases where previous surgeries have failed, robust fixation systems like pedicle screws are often re-employed.

Product Insights

Monoaxial Pedicle Screws: Offer rigid fixation, used in deformity correction when high stability is required.

Polyaxial Pedicle Screws: Allow multidirectional movement, preferred in procedures requiring anatomical alignment flexibility.

Cannulated Screws: Enable percutaneous insertion, ideal for minimally invasive surgeries.

Expandable Screws: Designed to increase anchorage in patients with osteoporotic bone, improving fixation in the elderly.

Regional Analysis

North America

Holds the largest share due to high surgical volumes, rapid adoption of novel technologies, and strong presence of market leaders. The U.S. leads in spine surgery rates, supported by advanced hospital infrastructure.

Europe

Second-largest market driven by growing aging populations, especially in countries like Germany, France, and the UK. Reimbursement support and a skilled healthcare workforce boost market growth.

Asia-Pacific

Fastest-growing region owing to increasing healthcare access, rising spinal disorder prevalence, and a surge in medical tourism, particularly in countries like India, China, and South Korea.

Latin America & Middle East and Africa (MEA)

Emerging markets where investment in healthcare infrastructure and growing awareness about surgical treatment options are expanding the scope for pedicle screw system adoption.

Key Market Players

Medtronic PLC

A global leader in spinal implants, Medtronic offers a comprehensive suite of pedicle screw systems under its Spinal & Biologics division, with a focus on minimally invasive and robotic-compatible technologies.

DePuy Synthes (Johnson & Johnson)

Offers advanced spinal fixation systems known for modularity and ease of use, supported by the company’s global distribution network and surgeon training programs.

Stryker Corporation

Renowned for innovative product designs and integration with its MAKO robotic platform, enhancing precision in screw placement and surgical outcomes.

Zimmer Biomet

Delivers spinal hardware systems with a focus on patient-centric solutions, including expandable and MIS-friendly pedicle screw products.

Globus Medical Inc.

A strong innovator in spinal surgery technologies, Globus is investing in robotic guidance and next-gen pedicle screw platforms.

NuVasive Inc.

A pioneer in lateral spine surgery techniques, NuVasive develops highly specialized pedicle screw systems aligned with MISS protocols.

Orthofix Medical Inc.

Focused on fusion and non-fusion spinal solutions, Orthofix’s systems are often used in trauma, deformity, and complex spinal reconstruction cases.

Market Trends

Patient-Specific Implants: Custom 3D-printed pedicle screws and guides are being developed based on patient imaging data, increasing surgical accuracy and fit.

Osteoporotic Solutions: With aging demographics, there is a rising focus on screw designs that improve purchase in brittle bone, such as expandable and cement-augmented screws.

Sustainability and Biocompatibility: A shift toward recyclable, hypoallergenic materials and coatings that reduce inflammation and improve long-term outcomes.

Smart Implants: Future potential lies in sensor-embedded screws that monitor healing progress or implant stress post-operatively.

Browse more Report:

Instrumentation Sterilization Containers Market

Infectious Enteritis Treatment Market

High-Integrity Pressure Protection System Market

High Temperature Overhead Conductor Market

Flowable Hemostats Market

0 notes

Text

Modular Hall Effect Sensors Market: Future Growth of the Semiconductor Sector, 2025–2032

MARKET INSIGHTS

The global Modular Hall Effect Sensors Market size was valued at US$ 834 million in 2024 and is projected to reach US$ 1.34 billion by 2032, at a CAGR of 7.1% during the forecast period 2025-2032. The U.S. market accounted for 32% of global revenue in 2024, while China is expected to witness the highest growth rate at 7.8% CAGR through 2032.

Modular Hall Effect sensors are compact, overmolded devices that detect magnetic fields with IP67-rated protection. These sensors separate the magnetic target from enclosed electronics, enabling space-efficient installations in demanding environments. They offer both analog and digital output options, making them versatile for position sensing, speed detection, and current measurement applications across industries.

The market growth is driven by increasing automation in manufacturing and rising electric vehicle production, where these sensors enable precise motor control. Furthermore, advancements in Industry 4.0 technologies and growing adoption in consumer electronics for touchless interfaces are expanding application horizons. Key players like Allegro MicroSystems and Texas Instruments are introducing energy-efficient variants with integrated signal conditioning, addressing the need for smarter IoT-enabled solutions.

MARKET DYNAMICS

MARKET DRIVERS

Growing Adoption in Automotive Applications Fuels Market Expansion

The automotive industry’s increasing reliance on modular Hall effect sensors is a primary driver for market growth. These sensors are critical for position sensing in throttle control, gear shift detection, and braking systems in modern vehicles. With the automotive sector accounting for over 35% of global Hall effect sensor demand, the transition toward electric vehicles (EVs) and advanced driver-assistance systems (ADAS) creates substantial opportunities. The integration of these sensors in brushless DC motors for EV powertrains, where they offer high reliability in harsh environments, is particularly noteworthy. Recent technological advancements have enhanced their ability to operate in temperature ranges from -40°C to 150°C, making them indispensable for automotive applications.

Industrial Automation Boom Accelerates Demand

Industrial automation represents another significant growth avenue, with modular Hall effect sensors finding extensive use in motor controls, robotics, and conveyor systems. The global industrial automation market is projected to grow at nearly 9% CAGR through 2030, creating parallel demand for precision sensing solutions. These sensors enable non-contact position detection in harsh industrial environments where traditional mechanical switches fail. Their modular design with IP67-rated housings provides robust protection against dust and moisture, a critical requirement in manufacturing facilities. Furthermore, Industry 4.0 initiatives are driving the adoption of smart sensors with digital outputs that can interface directly with IoT systems, creating new integration possibilities.

➤ An analysis of production data shows that industrial applications now account for approximately 28% of modular Hall effect sensor deployments, with particularly strong uptake in packaging machinery and CNC equipment.

The trend toward miniaturization in consumer electronics also presents significant growth potential. As devices become smaller, modular Hall effect sensors offer compact solutions for lid position detection in laptops and foldable smartphones, with some models now measuring less than 2mm x 2mm.

MARKET CHALLENGES

Intense Price Competition from Alternative Technologies

While modular Hall effect sensors offer distinct advantages, they face mounting competition from alternative sensing technologies like magnetoresistive (MR) and giant magnetoresistive (GMR) sensors. These alternatives often provide higher sensitivity and better signal-to-noise ratios in certain applications, putting pressure on Hall sensor manufacturers to differentiate their offerings. In price-sensitive markets such as consumer electronics, this competition frequently leads to margin erosion, with some sensor prices declining by approximately 15% over the past three years. Maintaining profitability while meeting the demand for cost reductions remains an ongoing challenge for major players.

Other Challenges

Supply Chain Vulnerabilities The semiconductor shortage impacts have revealed vulnerabilities in the sensor supply chain, particularly for specialized packaging materials. Lead times for certain sensor components have extended to 26 weeks in some cases, disrupting production schedules.

Technical Limitations Achieving sub-micron position resolution remains technically challenging for standard Hall effect designs, limiting their adoption in ultra-high precision applications compared to optical encoders.

MARKET RESTRAINTS

Design Complexity in High-Temperature Applications

While modular Hall effect sensors perform well in standard industrial environments, their application in extreme conditions presents design challenges. Operation above 150°C requires specialized materials and packaging techniques that can increase unit costs by 30-40%. This temperature limitation restricts their use in certain aerospace and oil/gas applications where environments routinely exceed these thresholds. The thermal drift characteristics of Hall elements also necessitate sophisticated compensation circuits, adding to system complexity and BOM costs.

Additionally, the need for precise magnetic field calibration in production creates yield challenges, with typical manufacturing tolerances requiring adjustments to ±1% or better for critical applications. These factors collectively restrain broader market adoption in some specialized segments.

MARKET OPPORTUNITIES

Emerging Medical Applications Present Significant Growth Potential

The medical device sector represents a high-growth opportunity, with modular Hall effect sensors finding new applications in surgical robotics, drug delivery systems, and implantable devices. The medical sensors market is projected to exceed $20 billion by 2027, creating substantial demand for reliable position sensing solutions. Recent innovations include contactless sensing for MRI-compatible equipment and miniature sensors for insulin pump mechanisms. The sterilization compatibility of properly packaged modular sensors makes them particularly attractive for single-use medical devices.

Furthermore, the development of ultra-low power Hall sensors consuming less than 10μA enables new battery-powered wearable applications with multi-year operational life, opening additional market segments. Strategic partnerships between sensor manufacturers and medical OEMs are accelerating the development of application-specific solutions.

MODULAR HALL EFFECT SENSORS MARKET TRENDS

Shift Towards Compact, High-Performance Sensing Solutions Drives Market Growth

The global Modular Hall Effect Sensors market, valued at $XX million in 2024, is experiencing robust expansion due to increasing demand for compact and reliable sensing solutions in industrial and automotive applications. These sensors, known for their IP67-rated durability and separation of magnetic targets from enclosed electronics, offer significant advantages in space-constrained installations. The automotive sector alone accounts for over 30% of total sensor demand, driven by the need for precise position detection in electric power steering and transmission systems. As industries continue miniaturizing components while requiring higher precision, modular Hall effect sensors are becoming the technology of choice for engineers worldwide.

Other Trends

Industrial Automation Revolution

The fourth industrial revolution is accelerating adoption across manufacturing sectors, with modular Hall effect sensors playing a critical role in Industry 4.0 implementations. These contactless sensors enable precise speed measurement in conveyor systems with an accuracy margin of ±1%, while their modular design allows easy integration into existing automated workflows. The global industrial automation market’s projected CAGR of 9.3% through 2032 directly correlates with increasing sensor deployments in robotic assembly lines and smart factory environments.

Advancements in Material Science and Chip Design

Recent breakthroughs in semiconductor materials and 3D packaging technologies are enabling sensor manufacturers to develop products with 30% higher sensitivity compared to previous generations. Leading manufacturers are now incorporating graphene-based elements and advanced ferromagnetic alloys that maintain stability across extreme temperature ranges from -40°C to 150°C. These innovations are particularly crucial for aerospace applications where sensors must perform reliably in both stratospheric cold and engine compartment heat. Digital output variants now dominate new product launches, representing 58% of 2024 modular Hall sensor introductions due to their compatibility with modern IoT ecosystems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Strategic Expansion Drive Market Leadership

The global modular Hall Effect sensors market exhibits a moderately consolidated competition structure, where established electronic component manufacturers compete with specialized sensor providers. Sensata Technologies leads the segment with an estimated 18% revenue share in 2024, leveraging its diversified industrial sensor portfolio and strong OEM relationships in the automotive sector.

Texas Instruments and Allegro MicroSystems collectively hold approximately 25% market share, driven by their advanced semiconductor expertise and vertically integrated production capabilities. These companies continue to dominate due to their ability to offer customized solutions for high-growth applications such as electric vehicles and Industry 4.0 automation systems.

While traditional players maintain strong positions, emerging competitors like Melexis are disrupting the market through innovative packaging technologies and miniaturized sensor designs. The Belgium-based company recently launched its third-generation Hall Effect ICs, specifically optimized for space-constrained medical devices and wearables.

The supplier ecosystem is witnessing increased M&A activity as manufacturers seek to consolidate expertise. Littelfuse’s 2023 acquisition of C&K Components exemplifies this trend, enhancing their position in ruggedized industrial sensors. Similarly, Rohm Semiconductor expanded its European footprint through strategic partnerships with automotive Tier 1 suppliers.

List of Key Modular Hall Effect Sensor Companies Profiled

Sensata Technologies (U.S.)

Texas Instruments (U.S.)

Rohm Semiconductor (Japan)

Littelfuse (U.S.)

ZF Switches & Sensors (Germany)

Marposs (Italy)

Allegro MicroSystems (U.S.)

Lake Shore Cryotronics (U.S.)

Regal Components (Sweden)

Silicon Labs (U.S.)

Melexis (Belgium)

Segment Analysis:

By Type

Hall Switch Segment Leads the Market with Extensive Use in Position Sensing and Switching Applications

The market is segmented based on type into:

Hall Switch

Subtypes: Unipolar, Bipolar, and Omnipolar

Linear Hall Sensor

Subtypes: Analog Output and Digital Output

Others

By Application

Automotive Segment Dominates Due to Increasing Adoption in Position Detection and Current Sensing Applications

The market is segmented based on application into:

Consumer Electronics

Automotive

Aerospace

Medical

Industrial

By Functionality

Position Sensing Segment Holds Major Share with Growing Demand Across Industries

The market is segmented based on functionality into:

Position Sensing

Current Sensing

Speed Detection

Others

By Output

Analog Output Segment Maintains Strong Position in Various Measurement Applications

The market is segmented based on output into:

Analog Output

Digital Output

Subtypes: Pulse Width Modulation (PWM), I2C, and SPI

Others

Regional Analysis: Modular Hall Effect Sensors Market

North America The North American market remains a key revenue generator for modular Hall effect sensors, driven by strong automotive and industrial automation demand. The U.S. accounts for over 60% of the regional market value, benefiting from heavy investments in electric vehicle manufacturing and smart factory initiatives. Recent technological advancements by market leaders like Allegro MicroSystems and Texas Instruments have strengthened product offerings in high-temperature and high-precision applications. However, pricing pressures from Asian manufacturers pose a challenge to domestic producers. The Canadian market shows steady growth, particularly in aerospace and medical equipment segments where reliability is paramount.

Europe Europe’s market is characterized by stringent quality standards and innovation-driven demand, particularly in automotive and industrial sectors. Germany leads adoption with its robust manufacturing base, while Nordic countries demonstrate increasing usage in renewable energy systems. The Hall Switch segment dominates due to its prevalence in automotive position sensing applications. European OEMs emphasize miniaturization and energy efficiency, creating opportunities for modular sensors with integrated signal processing. However, the transition to electric vehicles has temporarily disrupted traditional supply chains, causing suppliers to realign production capacities toward EV-specific sensor solutions.

Asia-Pacific Asia-Pacific represents the fastest-growing regional market, projected to capture over 45% of global demand by 2032. China’s dominance stems from massive electronics production and government-backed Industry 4.0 initiatives fueling industrial automation. Japanese manufacturers lead in high-precision applications like robotics, while South Korea sees strong demand from consumer electronics giants. The region witnesses intense price competition, with local players like ROHM Semiconductor gaining market share through cost-effective solutions. India emerges as a promising market with expanding automotive manufacturing and infrastructure modernization programs, though quality consistency remains a concern among buyers.

South America Market growth in South America remains moderate, constrained by economic instability and limited local manufacturing capabilities. Brazil accounts for nearly half the regional demand, primarily serving automotive and appliance industries. Cost sensitivity drives preference for basic Hall Switch models over advanced linear sensors. While foreign investments in Argentina’s industrial sector show potential, currency volatility discourages long-term commitments from major sensor suppliers. The aftermarket for sensor replacements presents steady opportunities, particularly in aging industrial equipment maintenance across the continent.

Middle East & Africa This region demonstrates uneven growth patterns, with Gulf Cooperation Council countries leading adoption in oil/gas and building automation applications. Israel’s thriving medical technology sector drives specialist demand for high-reliability sensors. South Africa serves as an industrial hub for sub-Saharan Africa, though infrastructure limitations hinder widespread sensor integration. The market sees increasing Chinese imports due to competitive pricing, while European suppliers maintain dominance in high-value industrial projects. Government initiatives to diversify economies toward manufacturing create long-term growth potential, albeit from a comparatively small base.

Report Scope

This market research report provides a comprehensive analysis of the global Modular Hall Effect Sensors market, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Hall Switch, Linear Hall Sensor), application (Consumer Electronics, Automotive, Aerospace, Medical, Industrial), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD million market size in U.S.), Europe, Asia-Pacific (China projected at USD million), Latin America, and Middle East & Africa.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies, Texas Instruments, Allegro MicroSystems, and others holding approximately % market share in 2024.

Technology Trends & Innovation: Assessment of emerging sensor technologies, integration with IoT systems, and evolving industry standards for magnetic sensing applications.

Market Drivers & Restraints: Evaluation of factors including automotive electrification, industrial automation demand, along with supply chain constraints and material cost challenges.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-video-sync-separator-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes_17.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-investments.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/coaxial-panels-market-challenges.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/oled-and-led-automotive-light-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-cell-market-demand-for-ai-chips-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-demodulator-ic-market-packaging.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nano-micro-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/single-mode-laser-diode-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/battery-management-system-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/scanning-slit-beam-profiler-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/atomic-oscillator-market-electronics.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/plastic-encapsulated-thermistor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-policy.html

0 notes

Text

How Mechanical System Design Enhances Efficiency in Industrial Engineering

Introduction

Efficiency is a need, not just a goal, in the fast-paced field of industrial engineering. Retaining a competitive edge requires the capacity to optimize resource consumption, reduce downtime, and streamline processes. The design of mechanical systems is among the most important factors that contribute to this optimization. Mechanical systems are designed to increase overall productivity, decrease waste, and improve performance through clever planning, integration, and innovation.

Mechanical System Design: What Is It?

The process of organizing and developing mechanical systems and components that cooperate to carry out particular tasks in industrial settings is known as mechanical system design. It covers the design, dimensions, material choice, temperature and stress analysis, and incorporation of mechanical components such automated equipment, conveyors, gear mechanisms, HVAC systems, robotics, and gear mechanisms. Reliable operation under a variety of conditions is ensured by a well-crafted design, which is essential in industrial settings with high demand.

Essential Elements of an Energy-Efficient Mechanical System Design

Energy conservation is a key component of modern mechanical system design. Energy-efficient motors, regenerative braking systems, and intelligent load management are some of the methods used in systems designed to lower power usage.

Design Modularity

Without completely redesigning the system, modular components make it simple to upgrade, expand, or replace individual pieces. This method promotes ongoing development and increases adaptability.

Integration of Automation

Automation is becoming more and more important in today's industrial operations. In order to ensure accurate and reliable performance, mechanical systems are now made to seamlessly interface with sensors, robotic components, and programmable logic controllers (PLCs).

Compliance and Safety

Adherence to industry safety standards and regulations is a crucial factor in the design of mechanical systems. To safeguard employees and equipment, well-designed systems incorporate built-in safety features and fail-safes.

Efficiency via Optimization

Load capacity, temperature ranges, material durability, and anticipated wear and tear are all taken into account during the design process. Mechanical system design reduces unplanned failures and increases uptime by foreseeing operational issues and designing solutions prior to deployment. This prolongs the equipment's lives and increases productivity.

Industrial Engineering Case Applications

In industries such as heavy machinery, chemical processing, and automobile manufacture, customized mechanical system design guarantees optimal equipment performance. For instance, on an assembly line, specially made conveyor systems minimize manual handling, increasing productivity and reducing the possibility of mistakes or accidents. In a similar vein, well-designed HVAC systems in industrial facilities effectively control temperature, improving working conditions and reducing energy expenses.

Conclusion

To sum up, one of the key pillars of industrial engineering efficiency is mechanical system design. Automation, safety, adaptability, and energy-saving technology can all be included into a facility's mechanical infrastructure to increase production, decrease downtime, and ensure long-term sustainability. Investing in high-quality mechanical design is a business strategy that directly supports profitability and expansion, not just an engineering choice.

0 notes

Text

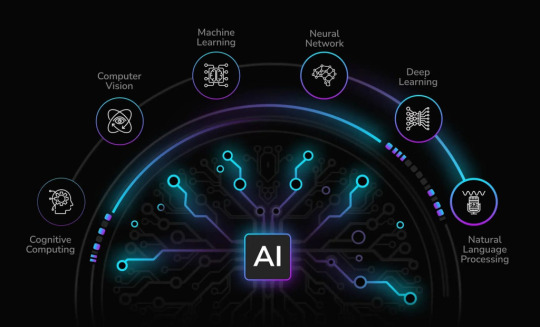

How Can AI Software Development Services Boost Your Business?

In today's rapidly evolving digital economy, staying competitive requires more than just adapting to technology—it demands innovation driven by intelligence. Artificial Intelligence (AI) is no longer a futuristic concept; it's a present-day force transforming industries across the globe. For businesses aiming to thrive in this landscape, AI software development services have emerged as a powerful catalyst for growth, efficiency, and innovation.

What Are AI Software Development Services?

AI software development services refer to the design, development, and deployment of AI-driven applications and systems tailored to specific business needs. These services often include machine learning (ML), natural language processing (NLP), computer vision, predictive analytics, and robotic process automation (RPA), among others. Leading AI development companies build intelligent systems that can learn from data, make decisions, and automate processes to drive value.

1. Streamlining Operations Through Automation

AI excels at automating repetitive and rule-based tasks. By integrating AI into core workflows, businesses can significantly reduce the need for manual intervention, minimize errors, and increase overall efficiency.

AI-powered bots can handle customer inquiries 24/7.

Intelligent automation tools can manage data entry, invoice processing, and inventory management.

Robotic Process Automation (RPA) can streamline back-office operations.

This results in cost savings, faster turnaround times, and more consistent outcomes.

2. Improving Decision-Making with Data Insights

Every business generates vast amounts of data, but only a few know how to utilize it effectively. AI software development services help transform raw data into actionable insights.

Predictive analytics models forecast trends and customer behavior.

AI algorithms identify patterns and anomalies in large datasets.

Real-time dashboards offer instant visibility into key performance metrics.

With AI, decision-makers can make more informed, data-driven choices that boost productivity and profitability.

3. Enhancing Customer Experience

Modern consumers expect personalized, seamless, and responsive interactions. AI enables businesses to deliver on these expectations:

AI chatbots offer instant customer support and query resolution.

Recommendation engines suggest products/services based on user behavior.

Sentiment analysis helps understand customer feedback in real time.

These solutions not only enhance user satisfaction but also foster customer loyalty and long-term engagement.

4. Enabling Scalable and Flexible Solutions

AI systems are inherently scalable. Whether you're a startup or an enterprise, AI solutions can grow with your business:

Cloud-based AI platforms offer flexibility and on-demand scaling.

Modular AI systems allow businesses to expand functionalities as needed.

Custom AI applications can be tailored for industry-specific use cases.

This adaptability ensures your business is always equipped to meet changing demands.

5. Strengthening Security and Compliance

Security threats and regulatory pressures continue to rise. AI can help organizations safeguard their data and ensure compliance:

AI-driven security systems detect unusual behavior and potential breaches.

Compliance automation tools help track and report regulatory adherence.

Machine learning models improve fraud detection in real-time.

These proactive security measures protect business integrity and customer trust.

6. Fostering Innovation and Competitive Advantage

AI empowers companies to innovate faster:

AI tools help in product development by analyzing user needs and testing variations.

Businesses can explore new markets with AI-powered market research.

AI accelerates R&D by simulating outcomes and optimizing processes.

Early adopters of AI not only keep up with competitors—they lead the market with smarter, faster innovations.

Conclusion

From operational efficiency and customer satisfaction to data-driven strategies and security, AI software development services offer immense value across every facet of a business. The integration of intelligent technology isn’t just a tech upgrade—it’s a strategic shift toward a more agile, innovative, and future-ready enterprise.

If you’re looking to unlock new growth opportunities, investing in AI software development services is one of the smartest business moves you can make today.

0 notes

Text

The construction industry has undergone significant transformations over the years, and one of the most notable advancements is the integration of automation. In recent times, construction automation has emerged as a game-changer, revolutionizing traditional construction practices and paving the way for a more efficient and sustainable future. This blog explores the fascinating world of construction automation and its many benefits.

What is the use of automation in the field of construction?

The use of automation in the field of construction is as follows:

1. Increased Productivity: Automation helps boost productivity by streamlining and accelerating construction processes. Tasks that were previously time-consuming and labour-intensive, such as bricklaying, concrete pouring, and material handling, can now be automated using robotic machinery. This allows for faster project completion and efficient resource utilization.

2. Improved Accuracy and Precision: Automation reduces the risk of human error and enhances precision in construction tasks. Technologies like computer-aided design (CAD) and building information modelling (BIM) enable accurate planning, design, and visualization of projects. Automated machines and tools perform tasks with consistent accuracy, leading to better quality outcomes.

3. Enhanced Safety: Safety is a crucial aspect of construction, and automation plays a significant role in mitigating risks and ensuring worker safety. Robots and autonomous equipment can handle dangerous tasks, reducing the need for human workers to be exposed to hazardous environments. Drones and sensors can be used for site inspections, monitoring safety compliance, and identifying potential hazards.

4. Efficient Project Management: Automation streamlines project management tasks, leading to better coordination and communication among project stakeholders. Project management software enables real-time collaboration, data analysis, and progress tracking. Automated systems can generate reports, schedule tasks, and manage documentation, improving overall project efficiency.

5. Sustainable Construction Practices: Automation promotes sustainability in construction. Prefabrication and modular construction, enabled by automation, minimize waste and optimize material usage. Automation also allows for the integration of energy-efficient systems and smart technologies, reducing energy consumption and environmental impact.

6. Reduction of Physical Strain: Automation helps alleviate physical strain on construction workers. Automated machinery and tools handle the heavy lifting, repetitive tasks, and dangerous operations, reducing the risk of musculoskeletal injuries and improving worker well-being.

What are the different types of automated construction?

Automated construction is the future of construction with new techniques being implemented with time. Some of the types and methods of automation in construction are as follows:

Read more

0 notes

Text

What’s Next in ERP & CRM? Trends to Watch in 2025 and Beyond

As businesses continue to accelerate digital transformation in the post-pandemic world, Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) systems are evolving faster than ever. What used to be back-end support systems have now become the core engines driving operational efficiency, customer experience, and innovation.

In 2025 and beyond, ERP and CRM platforms are expected to move beyond traditional functionality into smarter, more integrated ecosystems that empower data-driven decisions, automation, and predictive performance. Whether you’re a CIO looking to modernize legacy systems or a business leader exploring tech-driven growth, understanding the upcoming trends is crucial to staying competitive.

So, what’s next in ERP and CRM? Let’s dive into the future.

The New Era of ERP & CRM

Legacy, siloed software is on its way out. Today’s ERP and CRM systems are cloud-native, mobile-first, and AI-powered. They’re no longer just tools — they’re strategic assets. Organizations are looking for smarter ways to manage their operations and customer relationships in a unified, real-time environment.

Key shifts driving this transformation include:

The rise of cloud-based ERP and CRM platforms

AI and machine learning integration for real-time intelligence

Emphasis on modularity, flexibility, and scalability

The convergence of ERP and CRM for a 360-degree business view

Top ERP Trends to Watch in 2025

1.AI-Powered ERP Becomes the Norm

Artificial intelligence is transforming ERP systems from reactive databases into predictive, self-learning platforms. Expect AI to optimize supply chain management, automate financial forecasting, and predict equipment maintenance.

Key Benefits:

Enhanced decision-making with predictive analytics

Reduced human error through intelligent automation

Smarter resource planning and budgeting

2.Composable and Modular ERP Architecture

Gone are the days of one-size-fits-all ERP suites. Businesses in 2025 will adopt composable ERP systems that allow modules to be added or removed based on specific needs.

Why It Matters:

Faster implementation

Lower total cost of ownership (TCO)

Flexibility across departments and geographies

3.Cloud-First ERP Deployment

Cloud ERP systems like SAP S/4HANA, Oracle Cloud ERP, and NetSuite continue to dominate due to their agility, scalability, and cost-efficiency.

Trends to Watch:

Hybrid-cloud and multi-cloud ERP environments

Improved uptime and data security

Remote accessibility for global teams

4.ERP for SMEs: Simpler, Smarter, Faster

Small and medium businesses are embracing affordable cloud ERP solutions with built-in automation, intuitive dashboards, and minimal setup time.

What’s Changing:

Low-code customization

Industry-specific templates

Shorter deployment cycles

5.Hyperautomation Through RPA

Robotic Process Automation (RPA) will continue to integrate with ERP platforms to handle repetitive tasks, freeing up human resources for strategic work.

Top CRM Trends to Watch in 2025

1.AI-Driven Personalization at Scale

AI in CRM is moving beyond basic lead scoring. Expect hyper-personalization with real-time behavioral tracking, sentiment analysis, and dynamic content delivery.

Examples:

Personalized email journeys

AI-recommended products and services

Real-time chatbot support

2.Voice-Enabled and Conversational CRM

With natural language processing (NLP) advancements, CRM systems are becoming conversational. Sales reps can update records, schedule meetings, and get reports via voice.

Voice Integration Channels:

Alexa for Business

Google Assistant for CRM updates

Smart voice dashboards

3.Omnichannel Customer Engagement

In 2025, customers expect seamless interactions across channels — web, mobile, social, email, and even offline. CRMs must offer real-time synchronization and unified data tracking.

Key Features to Expect:

Unified inbox for all communication

Real-time notifications for lead interactions

Journey-based automation workflows

4.CRM + Data Analytics = Revenue Growth

Modern CRMs aren’t just for managing contacts — they’re growth engines. Integrated BI dashboards help sales and marketing teams align, prioritize leads, and track performance.

Impactful Insights:

Conversion funnel analysis

Attribution modeling

Churn prediction

5.CRM Meets IoT, AR & Metaverse

Advanced CRM systems are beginning to integrate with IoT devices and AR/VR platforms to create immersive customer experiences.

Emerging Use Cases:

IoT data integration for personalized service

AR-powered product demos

Virtual storefronts in the metaverse

ERP + CRM: The Power of Integration

The future of enterprise software lies in seamless integration. Forward-thinking companies are combining ERP and CRM systems into a unified tech stack for holistic business management.

Benefits of ERP-CRM Integration:

One source of truth for customer and financial data

Better collaboration across departments

End-to-end automation of workflows (quote to cash, lead to revenue)

Industry-Specific Innovations

Healthcare:

Patient relationship management + resource scheduling

Integration with EHR systems and telehealth platforms

Manufacturing:

Real-time production tracking

Integrated quality control and supplier management

Retail & eCommerce:

Inventory and order sync with CRM marketing campaigns

Customer loyalty programs based on real-time data

Finance:

Automated compliance and reporting

Unified customer and transaction insights

Security, Privacy & Compliance

As digital ecosystems grow, so do risks. In 2025, ERP and CRM systems will be embedded with zero-trust security models, data encryption, and compliance modules for GDPR, HIPAA, and other regional laws.

Trends:

Role-based access control (RBAC)

AI-powered fraud detection

Secure APIs and integration layers

Challenges Businesses Must Prepare For

Change Management: Ensuring user adoption and minimizing resistance

Data Migration: Migrating legacy data securely and accurately

Cost vs ROI: Balancing budget with long-term value

Vendor Lock-in: Choosing platforms with open standards and APIs

What Businesses Should Do Now

To stay ahead of the curve, businesses should:

Audit existing ERP and CRM systems for gaps and opportunities

Invest in AI-ready, cloud-native platforms with strong vendor support

Emphasize integration and interoperability

Prioritize user experience and mobile accessibility

Train staff continuously to adapt to evolving tools

Conclusion

ERP and CRM platforms are no longer just enterprise software — they are the digital backbone of modern business. As we step into 2025 and beyond, companies that embrace intelligent, cloud-powered, and integrated systems will be the ones that lead.

Whether you’re planning a full transformation or small-scale modernization, now is the time to act.

0 notes

Text

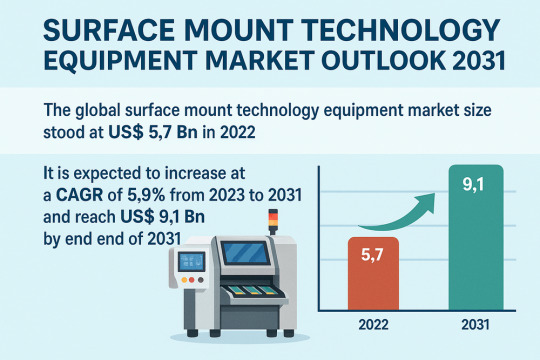

Miniaturized Components Boost Global SMT Equipment Market Demand

The global surface mount technology (SMT) equipment market is poised for substantial growth over the coming decade. Valued at USD 5.7 Bn in 2022, the market is projected to advance at a compound annual growth rate (CAGR) of 5.9% between 2023 and 2031, ultimately reaching USD 9.1 Bn by 2031. SMT equipment plays a critical role in the electronics manufacturing industry by enabling efficient, high-speed, and reliable assembly of surface-mounted components on printed circuit boards (PCBs). The widespread integration of miniaturized and high-performance electronics in consumer devices, automotive systems, telecommunications infrastructure, and industrial automation is significantly driving the adoption of SMT equipment.

Market Drivers & Trends

One of the major drivers of the SMT equipment market is the increasing demand for compact and lightweight electronic devices. With consumer electronics becoming smaller and more multifunctional, the need for advanced SMT machines capable of precise, high-speed placement of components has grown exponentially.

The ongoing shift toward Industry 4.0 and smart manufacturing is also influencing SMT equipment trends. Manufacturers are now integrating artificial intelligence (AI), robotics, and IoT-enabled systems into their production lines to boost efficiency and reduce defects. This trend is reshaping the traditional SMT landscape and encouraging investments in intelligent SMT lines with real-time monitoring and self-correction capabilities.

Additionally, the proliferation of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) is generating new opportunities for SMT equipment manufacturers, particularly in the automotive electronics segment.

Latest Market Trends

Several trends are shaping the SMT equipment market today:

Integration of AI and machine learning in SMT systems to enhance placement accuracy and reduce human intervention.

Adoption of 3D inspection systems for quality control, ensuring higher yield rates and better defect detection.

Expansion of flexible and hybrid SMT lines to accommodate varying production volumes and product types.

Sustainability-focused designs, such as energy-efficient reflow ovens and lead-free soldering systems, are gaining traction amid rising environmental concerns.

These trends are not only boosting productivity but are also redefining customer expectations and pushing market players toward more adaptive and future-ready solutions.

Analysis of Key Players

The surface mount technology equipment industry is consolidated with the presence of a few players holding major market share. Leading manufacturers are following the latest surface mount technology equipment market trends and engaging in new product launches and mergers & acquisitions to consolidate their presence in the global market.

Dou Yee Enterprises (S) Pte. Ltd., JUTZE Intelligence Technology Co., Ltd., Koh Young Technology, Mirtech, Nordson Corporation, Omron Corporation, PARMI Corporation, Saki Corporation, Test Research, Inc., Vi Technology (Mycronic AB), Viscom AG, Vitrox Corporation, and Yamaha Motor Co., Ltd. are a few notable players that offer inspection equipment. While ASML Holding, N.V., Fuji Machine Mfg. Co., Ltd., Hitachi, Ltd., Juki Corporation, KLA-Tencor Corporation, Koh Young Technology, Mycronic AB, Nordson Corporation, Orbotech Ltd., Panasonic Corporation, PARMI Corp., Test Research, Inc., and Yamaha Motor Co., Ltd. are key notable players offering surface mount technology equipment.

Recent Developments

The past few years have seen a wave of strategic developments in the SMT equipment market:

ASMPT introduced a new line of modular SMT systems featuring AI-assisted analytics to optimize throughput.

Panasonic unveiled a next-gen placement machine with enhanced component recognition and autonomous calibration features.

Witte Technology GmbH expanded its European manufacturing facility to increase capacity and meet rising global demand.

Several players have formed partnerships with automotive and telecom firms to tailor SMT solutions for specific industry requirements, such as 5G infrastructure and EV component manufacturing.

Download to explore critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=5516

Market Opportunities

Numerous opportunities lie ahead for stakeholders in the SMT equipment space:

Growing electronics manufacturing services (EMS) sector in Asia-Pacific, particularly in countries like China, Vietnam, and India, is creating demand for scalable SMT systems.

The rise of smart wearables and IoT devices presents a growing segment for compact SMT solutions.

High-reliability applications in aerospace, defense, and medical electronics require advanced SMT capabilities, opening niche but profitable markets.

Government incentives in semiconductor and electronics manufacturing across various regions are encouraging infrastructure development and equipment procurement.

Future Outlook

Looking forward, the SMT equipment market is set to evolve in alignment with global digitization and electrification trends. As AI and predictive maintenance become standard in manufacturing environments, the integration of such capabilities in SMT systems will become a key differentiator. Additionally, geopolitical shifts and supply chain restructuring are expected to drive investments in localized manufacturing, fueling SMT equipment demand in emerging markets.

The future of the SMT equipment market will be shaped by technological agility, customization, and sustainability all critical to addressing the dynamic needs of modern electronics manufacturing.

Market Segmentation

The SMT equipment market can be segmented based on:

Equipment Type:

Placement Equipment

Inspection Equipment

Soldering Equipment

Screen Printing Equipment

Cleaning Equipment

Application:

Consumer Electronics

Automotive

Industrial Electronics

Telecommunications

Medical Devices

Aerospace & Defense

End-user:

OEMs (Original Equipment Manufacturers)

EMS Providers

This segmentation highlights the market’s diverse application base and underscores the necessity for flexible and tailored SMT solutions.

Regional Insights

Asia-Pacific dominates the global SMT equipment market, driven by a robust manufacturing ecosystem, especially in China, Japan, and South Korea. The region is expected to remain a powerhouse throughout the forecast period.

North America is witnessing increasing demand due to reshoring efforts and innovations in automotive and medical electronics.

Europe, led by Germany and the UK, is focusing on high-precision SMT systems for automotive and industrial applications.

Latin America and the Middle East & Africa are emerging markets with growing infrastructure and electronics demand, albeit at a relatively slower pace.

Why Buy This Report?

This comprehensive market research report offers:

In-depth analysis of current and future market trends

Thorough competitive landscape assessment including company profiles and market share

Detailed segmentation and regional breakdowns

Insights into technological innovations and investment opportunities

Strategic recommendations for stakeholders, investors, and policymakers

Whether you are a market entrant, investor, OEM, or EMS provider, this report serves as a crucial tool for making informed business decisions.

Explore Latest Research Reports by Transparency Market Research: GPS Tracking Device Market: https://www.transparencymarketresearch.com/gps-tracking-device-market.html

E-Beam Wafer Inspection System Market: https://www.transparencymarketresearch.com/e-beam-wafer-inspection-system-market.html

Filtered Connectors Market: https://www.transparencymarketresearch.com/filtered-connectors-market.html

Commercial Security Systems Market: https://www.transparencymarketresearch.com/commercial-security-systems-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

AC-DC Converters Market Poised for Expansion with Advanced Semiconductor Technology Integration

The AC-DC converters market has emerged as a crucial segment within the broader electronics and power supply industry, driven by growing demand for efficient and reliable power management solutions across various sectors. AC-DC converters transform alternating current (AC) into direct current (DC), enabling the operation of a wide range of electronic devices, from household appliances to complex industrial systems. As technology advances and electricity consumption patterns evolve, the market for AC-DC converters is expected to experience significant growth.

One of the primary drivers of the AC-DC converters market is the rapid expansion of consumer electronics. Smartphones, laptops, gaming consoles, and televisions rely heavily on AC-DC power conversion. The proliferation of these devices, particularly in emerging economies with rising disposable incomes and expanding digital infrastructure, is contributing to increased demand for compact, energy-efficient, and high-performance converters.

Another significant growth factor is the automotive industry's shift toward electric vehicles (EVs). EVs depend on a range of AC-DC conversion systems for charging and onboard electronics. Governments worldwide are implementing policies to promote clean transportation, leading to a surge in EV manufacturing and infrastructure development. This trend necessitates advanced AC-DC converters with higher power density, enhanced efficiency, and robust thermal management capabilities.

The industrial sector also presents substantial opportunities for AC-DC converter manufacturers. Automated production lines, robotics, and control systems all require stable DC power. With Industry 4.0 initiatives gaining momentum, the demand for reliable power supply solutions is growing. Additionally, renewable energy systems, such as solar and wind power installations, rely on AC-DC conversion to integrate with battery storage systems or deliver energy to the grid, further expanding the market scope.

Technological advancements have played a critical role in shaping the AC-DC converters market. Innovations in wide bandgap semiconductors, such as gallium nitride (GaN) and silicon carbide (SiC), have enabled the development of more efficient and compact converters. These technologies reduce energy loss, enhance switching performance, and allow for smaller form factors, which are especially important in space-constrained applications like data centers and portable electronics.

The global AC-DC converters market is highly competitive, with numerous key players including Texas Instruments, ABB Ltd., Infineon Technologies, Delta Electronics, and STMicroelectronics. These companies are focusing on research and development, strategic partnerships, and mergers and acquisitions to strengthen their market position. Additionally, manufacturers are working on designing modular and programmable converters to cater to diverse application needs and ensure ease of integration.

Regional analysis shows that Asia-Pacific holds the largest share of the AC-DC converters market. This dominance is primarily due to the region’s robust electronics manufacturing industry, particularly in countries like China, Japan, South Korea, and Taiwan. Moreover, rapid urbanization and infrastructure development in the region have accelerated the adoption of industrial automation, further propelling market growth.

North America and Europe also hold substantial shares of the market. These regions benefit from strong technological innovation, high demand for renewable energy systems, and growing EV adoption. Governments in these areas are implementing stringent energy efficiency standards, prompting manufacturers to develop eco-friendly AC-DC converters with low standby power and reduced electromagnetic interference (EMI).

Despite its growth potential, the market faces several challenges. High initial costs associated with advanced converter technologies, complex regulatory frameworks, and potential compatibility issues with legacy systems can hinder adoption. However, ongoing R&D efforts and evolving industry standards are expected to mitigate these barriers over time.

Looking forward, the AC-DC converters market is poised for sustained growth. The global push toward sustainability, the increasing penetration of smart electronics, and the ongoing digital transformation across industries will continue to drive demand. Companies that invest in innovation, energy efficiency, and customer-specific solutions will be well-positioned to capitalize on emerging opportunities.

In conclusion, the AC-DC converters market is a dynamic and evolving sector, integral to modern power management systems. Its role in supporting next-generation technologies—from electric vehicles and industrial automation to renewable energy and smart devices—underscores its importance in the global economy. As demand for efficient, compact, and reliable power conversion grows, the market is expected to expand, driven by innovation and strategic growth initiatives across the value chain.

#ACDCConverters#PowerElectronics#ElectricVehicles#RenewableEnergy#EnergyEfficiency#IndustrialAutomation

0 notes

Text

Medical Exoskeletons Surge to $5.8B by 2034 🤖💪 | CAGR: 17.1%

Medical Exoskeleton Market is poised for exponential growth, expected to surge from $1.2 billion in 2024 to $5.8 billion by 2034, at an impressive CAGR of 17.1%. These wearable robotic systems are transforming patient rehabilitation and mobility support, offering new hope for individuals with spinal cord injuries, stroke complications, and age-related impairments. By enhancing muscle strength and limb movement, medical exoskeletons are revolutionizing how care is delivered in clinical and home settings.

Market Dynamics

Driving this dynamic market are technological advancements in robotics, AI integration, and lightweight materials. The increasing prevalence of mobility disorders, a rapidly aging population, and the growing demand for non-invasive assistive solutions have significantly amplified the adoption of medical exoskeletons.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS24850

While the lower body exoskeleton segment dominates with over 55% of the market share, upper body and full body models are gaining momentum. Innovations like intuitive control systems, battery efficiency, and reduced device weight are pushing boundaries in comfort and performance. However, high production costs and stringent regulatory frameworks remain hurdles, necessitating a balance between affordability and technological sophistication.

Key Players Analysis

Key industry players are leading innovation and shaping competitive dynamics. Ekso Bionics and ReWalk Robotics stand out for their clinically adaptive devices, while Cyberdyne Inc. continues to push forward with its cutting-edge HAL systems. Other notable companies include Bionik Laboratories, Hocoma, and Ottobock, each contributing to an expanding ecosystem of therapeutic and assistive technologies.

Emerging players such as Neuro Stride, Rehab Tech Innovations, and Stride Forward are also making their mark by focusing on niche clinical needs and cost-effective solutions. These companies are leveraging R&D partnerships and digital health integrations to tap into underserved segments.

Regional Analysis

North America leads the global market, fueled by robust R&D investments, advanced healthcare infrastructure, and early technology adoption, with the U.S. being a critical growth engine. Europe follows closely, particularly in Germany and the UK, where government-backed initiatives support rehabilitation-focused innovations.

In Asia-Pacific, countries like Japan and China are witnessing increased uptake due to rising healthcare investments and demographic shifts. The region’s fast-growing elderly population is creating fertile ground for expansion.

Meanwhile, Latin America and the Middle East & Africa represent emerging frontiers. Though adoption is currently slower, increasing awareness and policy support are paving the way for accelerated growth.

Recent News & Developments

Recent developments have seen the integration of AI and machine learning into exoskeletons, enhancing real-time motion adjustments and user feedback. Companies are also adopting modular designs and IoT connectivity to broaden usability. Notably, military and industrial applications are gaining traction, diversifying the market’s reach beyond traditional healthcare settings.

Pricing remains a complex issue, with premium models offering advanced functionalities and AI-driven analytics, while budget models aim to expand accessibility. Regulatory shifts in the U.S. and EU are shaping how companies innovate and bring products to market, emphasizing safety, efficacy, and cost-effectiveness.

Browse Full Report : https://www.globalinsightservices.com/reports/medical-exoskeleton-market/

Scope of the Report

This comprehensive report offers an in-depth view of the medical exoskeleton market, covering historical trends (2018–2023), the base year (2024), and a detailed forecast (2025–2034). It provides a segmented analysis across product types, components, end-users, technologies, and regions. The report evaluates market drivers, restraints, opportunities, and threats, while offering a competitive landscape overview, strategic profiling of major players, and SWOT and PESTLE analyses.

With thorough data from organizations such as WHO, FDA, EMA, and global tech conferences, this research empowers stakeholders with the insights needed to make informed decisions, mitigate risks, and seize growth opportunities in a rapidly evolving landscape.

Discover Additional Market Insights from Global Insight Services:

Ophthalmology Contract Research Organization (CRO) Market is anticipated to expand from $4.2 billion in 2024 to $8.9 billion by 2034, growing at a CAGR of approximately 7.8%.

Infectious Disease Diagnostics Market is anticipated to expand from $38.5 billion in 2024 to $72.3 billion by 2034, growing at a CAGR of approximately 6.5%.

Laboratory Information Management System (LIMS) Market is anticipated to expand from $2.1 billion in 2024 to $4.5 billion by 2034, growing at a CAGR of approximately 7.9%.

Orthopedic Braces & Supports Market is anticipated to expand from $4.2 billion in 2024 to $7.9 billion by 2034, growing at a CAGR of approximately 6.5%.

Breast Reconstruction Market is anticipated to expand from $3.2 billion in 2024 to $5.8 billion by 2034, growing at a CAGR of approximately 6.1%.

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Industry 4.0 on the Rise: Smart Factory Market to Surpass $220B by 2034 🏭📈

Smart Factory Market is on a strong upward trajectory, projected to grow from $86.2 billion in 2024 to an impressive $221.7 billion by 2034, at a compound annual growth rate (CAGR) of 9.9%. This growth reflects the global push towards digital transformation, with manufacturers adopting advanced technologies such as IoT (Internet of Things), AI (Artificial Intelligence), robotics, and machine learning to automate operations, reduce downtime, and boost productivity. Smart factories represent the evolution of traditional manufacturing into intelligent, self-optimizing environments that enhance decision-making through real-time data and analytics.

Market Dynamics

Smart factory solutions are revolutionizing industries by improving operational efficiency, ensuring product quality, and supporting sustainability goals. The market’s backbone lies in manufacturing execution systems (MES), predictive maintenance tools, and automated quality control. Factors fueling growth include the increasing demand for industrial automation, advancements in connectivity (5G and edge computing), and the need for energy-efficient production systems.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20453

However, challenges such as high initial setup costs, cybersecurity risks, and integration of legacy infrastructure can slow adoption, especially among small and medium-sized enterprises. Despite these hurdles, the potential return on investment through long-term cost savings and improved throughput continues to drive implementation across sectors like automotive, aerospace, healthcare, and electronics.

Key Players Analysis

The market landscape is shaped by industry giants including Siemens AG, Schneider Electric, Honeywell International Inc., ABB, Rockwell Automation, Emerson Electric, and Mitsubishi Electric. These companies are investing heavily in R&D to stay ahead in a rapidly evolving field. Their solutions span from control devices and sensors to AI-enabled software platforms that enhance factory agility.

Meanwhile, emerging innovators like Factory Sense, Smart Fab Solutions, and Digitize Manufacture are introducing niche products that cater to customizable and flexible production environments. These players are leveraging smart data, modular architecture, and collaborative robotics to appeal to a growing customer base that values adaptability and innovation.

Regional Analysis

North America leads in smart factory adoption, particularly the United States, which boasts robust industrial infrastructure and a strong focus on digital transformation. The region’s automotive and aerospace industries are significant adopters of smart technologies, driven by stringent quality requirements and performance optimization.

Europe closely follows, with countries like Germany and the UK driving growth through Industry 4.0 initiatives and regulations aimed at sustainable manufacturing. The region’s emphasis on carbon reduction, energy efficiency, and green technologies supports the expansion of smart factory solutions.

The Asia-Pacific region is emerging as the fastest-growing market. China, Japan, and South Korea are at the forefront, supported by rapid industrialization, government incentives, and a massive electronics manufacturing base. With strong demand for consumer goods and rising labor costs, the adoption of smart technologies in these economies is accelerating significantly.

Recent News & Developments

The market has recently seen a surge in strategic collaborations and partnerships aimed at enhancing technological capabilities. Leading firms are integrating AI and IoT into core operations, improving factory uptime and production flexibility. The shift toward cloud-based deployment models and hybrid systems has gained momentum, offering scalability and real-time remote access to critical operations.

Additionally, there’s growing interest in cybersecurity frameworks to safeguard sensitive industrial data. New solutions emphasize resilience, with embedded machine learning models that detect anomalies and prevent potential disruptions. Furthermore, global regulatory focus on environmental sustainability is driving innovation in low-emission and energy-efficient smart manufacturing systems.

Browse Full Report : https://www.globalinsightservices.com/reports/smart-factory-market/

Scope of the Report

This report offers a comprehensive look into the Smart Factory Market, covering historical trends (2018–2023) and future forecasts (2025–2034). It provides qualitative and quantitative insights across segments such as technology (AI, IIoT, Big Data), deployment models (on-premise, cloud, hybrid), and end users (automotive, food & beverages, electronics, etc.).

Beyond market size and growth projections, the report delves into regional performance, competitive landscape, emerging players, and regulatory dynamics. Key development strategies like mergers, acquisitions, new product launches, and cross-industry collaborations are also evaluated. With its rich data analysis, the report equips stakeholders with strategic insights to navigate the evolving smart manufacturing landscape.

Discover Additional Market Insights from Global Insight Services:

High Speed Cable Market : https://www.globalinsightservices.com/reports/high-speed-cable-market/

Advanced Semiconductor Packaging Market ; https://www.globalinsightservices.com/reports/advanced-semiconductor-packaging-market/

Agricultural Lighting Market : https://www.globalinsightservices.com/reports/agricultural-lighting-market/

Air Quality Monitoring System Market ; https://www.globalinsightservices.com/reports/air-quality-monitoring-system-market/

Industrial Robotics Market : https://www.globalinsightservices.com/reports/industrial-robotics-market/

#smartfactory #industry40 #automation #manufacturingtechnology #iotinmanufacturing #artificialintelligence #predictivemaintenance #robotics #digitaltransformation #industrialautomation #iiot #mes #cloudmanufacturing #cybersecurity #smartmanufacturing #bigdata #machinelearning #edgecomputing #plc #erp #smartfactories #automotiveindustry #electronicsmanufacturing #aerospaceinnovation #supplychainoptimization #realtimemonitoring #energyoptimization #sustainablemanufacturing #processautomation #futureofmanufacturing #connectedfactory #intelligentautomation #smartfactorysolutions #manufacturinginnovation #cobots #cloudintegration #datadrivenmanufacturing #remotemonitoring #digitalsupplychain #greentechnology #manufacturingefficiency

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

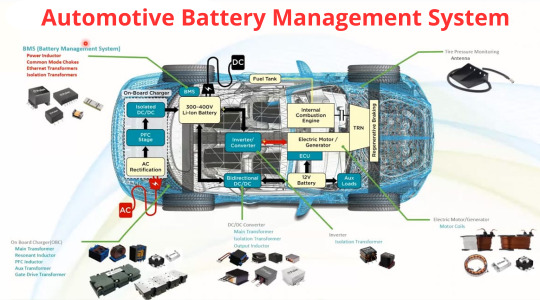

Automotive Battery Management System Market Size, Analyzing Trends and Projected Outlook for 2025-2032

Fortune Business Insights released the Global Automotive Battery Management System Market Trends Study, a comprehensive analysis of the market that spans more than 150+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

The Automotive Battery Management System Market is experiencing robust growth driven by the expanding globally. The Automotive Battery Management System Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Battery Management System Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Battery Management System Market Size, Share & Industry Analysis, By Type (Lithium-ion, Lead Acid, Nickel-based), By Connection Topology (Centralized , Distributed , Modular), By Vehicle type (Electric Vehicles, E-bikes) And Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/105479

Major Automotive Battery Management System Market Manufacturers covered in the market report include:

Some of the major companies that are present in the automotive battery management system market include Thyssenkrupp AG, Nippon Steel Integrated Battery Management LLC, Braynt Racing Inc., Arrow Precision Ltd., Maschinenfabrik Alfing Kessler GmbH, Mahindra CIE, Tianrun Battery Management Co., Ltd., among others.

Owing to this, many Battery Management manufacturers are developing advanced Battery Management with improved fatigue strength, reliability, and quality. Also, the crankshafts are manufactured with the latest trend of steelmaking processes by materials with high strength, and this factor is also expected to drive the automotive Battery Management market.