#Molded Interconnect Devices Market Development

Explore tagged Tumblr posts

Text

Abrasives Market Trends - Automation & AI

Join the newsletter: https://avocode.digital/newsletter/

Introduction to the Abrasives Market

In recent years, the abrasives market has seen significant developments fueled by technological advancements. With **automation and artificial intelligence** (AI) beginning to reshape traditional manufacturing industries, the abrasives market stands out as a key beneficiary. These technological enhancements have not only boosted productivity but have also instigated innovative ways to improve the quality and efficiency of abrasive materials. In this article, we delve into the impactful trends of automation and AI in the abrasives market, exploring how these technologies are molding the future of the industry.

The Evolution of Automation in Abrasives

Automation within the abrasives industry has emerged predominantly in response to the increasing demand for efficiency and precision. This section explores some of the notable advancements:

1. Robotic Precision and Efficiency

The introduction of **robotic automation** has led to substantial improvements in manufacturing processes. Robots are employed for precise cutting, grinding, and polishing tasks which were once labor-intensive and prone to human error. **Key benefits** include:

Consistency: Robots ensure uniformity across production, enhancing product quality.

Speed: Automated systems can operate continuously without fatigue, significantly speeding up production.

Safety: By taking over potentially hazardous tasks, robots ensure a safer working environment for human workers.

2. Advanced Machinery and Factory Automation

Automated machinery has taken center stage in the abrasives market, characterized by:

Computer Numeric Control (CNC) machines: These machines allow for highly precise and automated abrasive processing.

Integrated Digital Control Systems: Machinery guided by digital interfaces enables streamlined operations, reducing the need for manual oversight.

Smart Factories: Featuring interconnected devices that enable real-time data collection and process optimizations.

AI’s Role in Revolutionizing the Abrasives Market

Artificial Intelligence introduces a new dimension to abrasives production by enhancing decision-making through data analysis and machine learning.

1. Predictive Maintenance and Operational Efficiency

AI-driven solutions offer **predictive maintenance**, which minimizes downtime through:

Data Monitoring: AI systems continuously monitor machinery for performance anomalies, allowing preemptive maintenance actions.

Reduced Costs: Proactive maintenance reduces the likelihood of unexpected machinery failures.

Enhanced Lifespan: Regular maintenance dictated by AI insights can extend the life of expensive machinery components.

2. Machine Learning for Quality Optimization

Machine learning algorithms are transforming how abrasives are made by:

Process Optimization: AI can analyze various production parameters to suggest optimal settings for improved quality and reduced waste.

Error Detection: Automated quality assurance that detects and corrects defects swiftly, maintaining high standards for abrasive products.

Supply Chain Improvements: AI analyzes supply chain data for efficiencies, reducing material waste and costs while ensuring timely delivery.

Integration of Humans and Technology

One of the most compelling aspects of automation and AI is their potential for collaboration with human workers. The **integration of human expertise and machine precision** offers surprising synergies:

1. Augmented Workforce

Humans and machines work best together, with AI and robots taking over repetitive tasks, allowing human workers to focus on:

Complex Problem Solving: Humans can devote more time to higher-order tasks that require creativity and decision-making.

Skill Development: Workers can train on controlling and interacting with sophisticated machinery, acquiring valuable new skills.

Safety Oversight: Human personnel oversee and manage production environments, ensuring machine performance aligns with safety protocols.

2. Embracing Change

The transition towards automation and AI doesn't imply the obsolescence of human roles but rather a redefinition:

Training Programs: Companies are investing in training current employees to work with new technologies.

Enhanced Roles: Workers can transition into roles that require oversight of automated systems.

Collaborative Innovation: Human insight continues to play a crucial role in innovating within the industry.

Challenges and Future Prospects

While opportunities abound, the path of automation and AI in the abrasives market is not without challenges:

Initial Investments: High upfront costs in technology and training can be barriers for smaller enterprises.

Cultural Shift: Organizations must foster a culture that embraces technological change.

Cybersecurity: With increased connectivity comes the challenge of securing factory systems against cyber threats.

Despite these challenges, the future of the abrasives market looks promising. **Automation and AI are paving the way for innovations** that will continue to redefine productivity and quality standards, ensuring that the industry remains competitive and resilient.

Conclusion

The integration of **automation and AI into the abrasives market** is more than a mere trend; it is a fundamental shift towards a more efficient and innovative future. As the industry embraces these technologies, it unveils new potential not only for enhancing product quality and efficiency but also for reimagining the role of human workers. Companies willing to invest in and adopt these technologies will undoubtedly find themselves at the forefront of this digital revolution, poised to take advantage of the growing demand for high-quality abrasives in various industries globally. As we move forward, such advancements will continue to shape the future of the abrasives market, driving it towards heights hitherto unexplored. Want more? Join the newsletter: https://avocode.digital/newsletter/

0 notes

Text

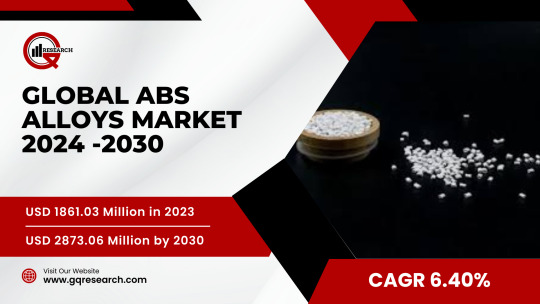

The ABS Alloys Market is Dazzling Worldwide and Forecast to 2030|GQ Research

The ABS Alloys market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global ABS Alloys market showcased a significant presence, boasting a valuation of US$ 1861.03 Million. This underscores the substantial demand for ABS Alloys technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-abs-alloys-market/

Projected Growth: Projections suggest that the ABS Alloys market will continue its upward trajectory, with a projected value of US$ 2873.06 Million by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 6.40%, reflecting a steady and robust growth rate for the ABS Alloys market over the coming years.

Technology Adoption:

The ABS (Acrylonitrile Butadiene Styrene) alloys market has seen a rapid uptake of advanced manufacturing technologies and processes. Injection molding, extrusion, and 3D printing have become prevalent methods for shaping ABS alloys into intricate forms, fostering innovation across industries. These techniques enable the production of complex geometries with high precision, expanding the scope of applications for ABS alloys in automotive, electronics, consumer goods, and beyond. Moreover, the integration of additives and reinforcements has led to the development of ABS alloys with enhanced properties, such as increased strength, heat resistance, and flame retardancy. This advancement has bolstered the adoption of ABS alloys in critical applications where performance and durability are paramount.

Application Diversity:

The versatility of ABS alloys has resulted in their widespread use across diverse sectors. In automotive manufacturing, ABS alloys are employed for interior and exterior components due to their lightweight nature and exceptional impact resistance. Similarly, in electronics, ABS alloys find application in casings and housings for electronic devices owing to their excellent electrical insulation properties. Consumer goods represent another significant market for ABS alloys, ranging from household appliances and toys to sporting equipment and luggage. Their ability to be molded into intricate shapes, coupled with aesthetic appeal and durability, makes ABS alloys an attractive choice for manufacturers seeking to meet the demands of discerning consumers.

Consumer Preferences:

Consumer preferences are increasingly influencing the ABS alloys market, particularly concerning sustainability and performance. There's a growing demand for eco-friendly ABS alloys derived from recycled or biodegradable materials, aligning with consumers' environmentally conscious choices. Additionally, there's a preference for ABS alloys offering superior functionality, ergonomic design, and customization options, reflecting consumers' desire for products that cater to their specific needs and preferences.

Technological Advancements:

Technological advancements continue to drive innovation in the ABS alloys market. Research efforts focus on enhancing the mechanical, thermal, and chemical properties of ABS alloys through advanced materials science and manufacturing techniques. Nanotechnology plays a significant role in improving ABS alloy performance by reinforcing them with nanoparticles to enhance strength, stiffness, and thermal stability. Furthermore, the integration of smart technologies into ABS components opens up new possibilities for applications in IoT devices, automotive sensors, and healthcare equipment. These advancements not only improve the functionality of ABS alloys but also pave the way for the development of more sophisticated and interconnected products.

Market Competition:

Intense competition characterizes the ABS alloys market, with manufacturers striving to differentiate themselves through product innovation, quality, and cost-effectiveness. Established players invest heavily in research and development to expand their product portfolios and capture new market segments. Meanwhile, emerging companies enter the market with novel solutions, intensifying competition and driving further innovation. Globalization and the rise of manufacturing hubs in Asia-Pacific and Latin America have intensified price competition in the ABS alloys market. Manufacturers are under pressure to reduce costs while maintaining high-quality standards to remain competitive in a dynamic marketplace.

Environmental Considerations:

Environmental considerations are increasingly shaping the ABS alloys market. Stakeholders are adopting sustainable practices to reduce the environmental impact of ABS alloy production and disposal. Recycling initiatives and waste reduction strategies are being implemented to minimize environmental footprints. Regulatory measures aimed at reducing emissions and promoting resource efficiency are driving the adoption of eco-friendly materials and production methods in the ABS alloys market. Biodegradable ABS alloys derived from renewable sources are gaining traction as environmentally conscious consumers seek alternatives to traditional plastics.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

LG Chem

Chi Mei Corporation

Styrolution Group GmbH

INEOS Styrolution Group GmbH

SABIC

Formosa Plastics Corporation

Trinseo

Toray Industries Inc.

Asahi Kasei Corporation

Kumho Petrochemical Co. Ltd.

BASF SE (Germany)

LOTTE Advanced Materials

Ravago Group

Mitsubishi Chemical Corporation

Teijin Limited

The research report provides a comprehensive analysis of the ABS Alloys market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-abs-alloys-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Global 3D Printed Electronics Market Size, Share, Growth Analysis, By Printing Technology(Inkjet Printing Screen Printing, Gravure Printing), By Material(Ink, Polymer)

Global 3D Printed Electronics Market Insights

Global 3D Printed Electronics Market size was valued at USD 10.6 billion in 2021 and is poised to grow from USD 12.22 billion in 2022 to USD 38.2 billion by 2030, growing at a CAGR of 15.31% in the forecast period (2023-2030).

3D printed electronics is a new program that allows electronics to be integrated into or on top of devices. The concept of 3D printing has been widely applied to the exterior of 3D injection molded synthetic objects to add antennas and simple conductive interconnects. With technological advancements in the 3D printed electronics business, new techniques can be used to create materials and processes to create sophisticated circuitry inside parts. Customization can be a valuable advantage in the development of fully formed additive manufacturing parts for circuit boards or any computerized device. The demand for small, thin devices with advanced capabilities is insatiable. However, difficult tasks such as designing a PCB or printed circuit board and its components are usually outsourced, resulting in longer waiting times. With the introduction of 3D printing, it is now possible to create in-house prototypes of circuits and circuit boards, reducing cost, time, and concerns about intellectual property infringement. Improved efficiency and productivity of manufacturers, as well as lower material costs, are expected to drive the global 3D printed electronics market during the forecast period.

Increased production of products with reduced weight, ease of use, and improved technology in manufacturing electrical components, all benefit the market. Increased production of antenna and sensor printing in 3D form stimulates the market. The rapid adoption of newly developed technologies in many sectors, as well as increasing consumer demand in industries such as the health sector, defence, telecommunication, automobile industry, electrification system, power utility, aerospace, and many others. The market is expected to flourish with the increased competition due to new arrivals and the availability of increased performance. Rising market participants and increased investment in the electronics and automobile industries have boosted market rates. However, the cost of new equipment and material for printed electronics are high, may this factor hamper market growth.

Global 3D Printed Electronics Market Segmental Analysis

Global 3D printed electronics market is segmented on the basis of printing technology, material and region. On the basis of printing technology, global 3D Printed Electronics Market is segmented into inkjet printing, screen printing, gravure printing, and flexographic printing. On the basis of material, global 3D Printed Electronics Market is segmented into ink, polymer, paper and glass. On the basis of region, global 3D Printed Electronics Market is divided into North America, Europe, Asia Pacific, Latin America, and MEA.

3D Printed Electronics Market Analysis by Printing Technology

On the basis of printing technology, global 3D printed electronics market is segmented into inkjet printing, screen printing, gravure printing, and flexographic printing. The inkjet segment accounted for a significant share of the revenue in the global market. The rapidly increasing adoption of this unique and advanced technology is fuelling the rapid growth of this segment. Inkjet printers are adjustable and versatile and easy to set up. Inkjet printers have a low throughput of about 100 m2/h and low resolution (about 50 m). It works well with soluble, low-viscosity materials such as organic semiconductors. High-viscosity materials, such as organic dielectrics, and dispersed particles, such as inorganic metal inks can cause nozzle obstruction. The thickness and uniformity of the dispersion decrease as the ink is applied in droplets. Using multiple nozzles simultaneously and pre-forming the substrate can improve productivity and resolution.

3D Printed Electronics Market Analysis by Material

On the basis of material, global 3D printed electronics market is segmented into ink, polymer, paper and glass. The ink materials segment accounted for the largest revenue share in the printed electronics market. The increasing growth of this segment is due to the rapid market acceptance of this substance. The increasing adoption of printed electronics technology has allowed the widespread use of inks in a wide range of applications in many fields. Also, inks are becoming more readily available in the market, making them more accessible to buyers.

0 notes

Text

IoT Node and Gateway Market Size & Share | Industry Report, 2023-2027

The IoT node and gateway market was valued at USD 387.1 billion in 2020 and is projected to reach USD 566.4 billion by 2027; it is expected to grow at a compound annual growth rate (CAGR) of 6.7% from 2021 to 2027.

The key factors driving the growth of the IoT node and gateway industry include emergence of 5G technology, growing use of wireless smart sensors and networks, growing market for connected devices, increasing necessity of data centers due to rising adoption of cloud platforms, and others.

Connectivity IC segment to account for the largest share of IoT node and gateway market during the forecast period

On the basis of Hardware, the IoT node and gateway market has been segmented into processor, sensor, connectivity IC, memory device, and logic device. the connectivity IC segment held the largest share of the overall IoT node and gateway market, in terms of volume. The increasing demand for better edge devices connectivity and significant developments in low-power connectivity technologies, such as Wi-Fi, Bluetooth, and Bluetooth Low Energy (BLE), are the key factors supporting the growth of the connectivity IC segment.

Consumer application to account for the largest share of IoT node and gateway market during the forecast period

Based on end-use application, the IoT node and gateway market has been segmented into industrial and consumer. Consumer application held the largest share of the overall IoT node and gateway market to during the forecast period. With the evolution of a number of consumer appliances that can connect to the Internet and smartphones, the growth of IoT technology in the consumer electronics segment is expected to receive a boost.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=248007097

APAC is expected to register the highest growth of IoT node and gateway market during the forecast period

APAC is expected to register the highest growth in the IoT node and gateway market during the forecast period from 2021 to 2027. The growing penetration of the internet across commercial as well as residential spaces, broad consumer base, increasing disposable income, and improving IT infrastructure are some of the key determinants supplementing the growth of the IoT node and gateway market in APAC. Moreover, the adoption of cloud-based services and rising trend of industrial automation are the key growth drivers for the IoT node and gateway market for commercial applications in countries such as China, South Korea, and Japan.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem.Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research.The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry. To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook

0 notes

Text

Molded Interconnect Devices Market Predicted Expected to Witness a Sustainable Growth by 2030

The global molded interconnect devices market is projected to witness substantial growth over 2022-2030, on account of supportive government policies and the escalating investment in semiconductor manufacturing.

According to data from the Semiconductor Industry Association, since the beginning of 2021, the industry has announced over USD 80 billion in new investments through 2025 in the United States. Rapid advancements in consumer electronics are impacting the way semiconductor devices are wire bonded, thinned, encapsulated, and die-attached. These factors are likely to augment the use of molded interconnect device hardware to design compact, next-gen electronic components over the forthcoming years.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/424

The molded interconnect devices market is bifurcated in terms of process, application, and regional landscape.

On the basis of the process, the market is segregated into two-shot molding, laser direct structuring (LDS), and others. The LDS segment among these will account for a substantial market share by 2030, which can be credited to the rising trend of miniaturization in the medical industry. Injection molding is being leveraged to mass-produce miniaturized medical devices with complex geometries. The LDS process is later adopted to draw the needed electrical trace layout to these medical components.

Through the adoption of this 3D-molded interconnect devices (MID) technology, the creation and design of electronics with complex functions have also been simplified and made more affordable, amplifying segmental expansion.

Based on application, the molded interconnect devices market is divided into Automotive & transportation, construction, water treatment, oil & gas, electrical and electronic, and others. Of these, the healthcare segment was valued at around USD 30 million in 2021.

The time and cost benefits offered by molded interconnect materials are aiding in the development of specialty sensors, implants, and antennas for healthcare solutions. MID manufacturers also work closely with healthcare professionals to develop prototypes and match the specific needs of medical devices, further augmenting segmental growth.

Request for customization @ https://www.gminsights.com/roc/424

From a regional frame of reference, Europe's molded interconnect devices (MID) market is poised to depict a CAGR of over 15% through 2030, driven by the implementation of strict regulatory frameworks associated with electronic waste management in the region. The auto industry size in countries, including France, Germany, and the Netherlands, has also grown commendably in recent years, which may increase the regional demand for MIDs for vehicle applications such as infotainment systems.

Latin America will also emerge as a lucrative revenue pocket for the molded interconnect devices market over the forecast period. This can be attributed to the emergence of small-scale electrical and electronic component manufacturers in major LATAM countries, including Brazil.

Table of Contents (ToC) of the report:

Chapter 1 Methodology & Scope

1.1 Scope and definition

1.2 Methodology & forecast parameters

1.3 COVID-19 impact

1.3.1 North America

1.3.2 Europe

1.3.3 Asia Pacific

1.3.4 Latin America

1.3.5 MEA

1.4 Data Sources

1.4.1 Secondary

1.4.1.1 Paid sources

1.4.1.2 Public sources

1.4.2 Primary

1.5 Industry Glossary

Chapter 2 Executive Summary

2.1 Molded Interconnect Devices market 3600 snapshots, 2018-2030

2.2 Business trends

2.2.1 Total Addressable Market (TAM), 2023 - 2030

2.3 Regional trends

2.4 Process trends

2.5 Application trends

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/molded-interconnect-devices-MID-market

Electronics and Semiconductors Research Reports

3D Display Market

Thin Wafer Market

Telecom Power Systems Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Molded Interconnect Devices Market Analysis#Molded Interconnect Devices Market by Type#Molded Interconnect Devices Market Share#Molded Interconnect Devices Market Development

0 notes

Text

Ball Grid Array (BGA): Features, Soldering Technique, and X-Ray Inspection

As digital gadgets are shrinking in size, the pitch measurement is extensively decreasing. The aspects are getting packed on a PCB like the grains in an ear of corn. All these matters have led to one of the most environment friendly factor package, the Ball Grid Array (BGA).

The way in which the elements are connected to the PCB stackup will majorly impact the steadiness and diagram efficiency. The BGA got here to existence on the grounds that the pin counts on chips rose significantly.

What is a BGA? A Ball Grid Array is a Surface Mount Device (SMD) factor that possesses no leads. This SMD bundle employs an array of metallic spheres that are made of solder referred to as the solder balls for interconnections. These solder balls are affixed to a laminated substrate at the backside of the package. The chip/die of the BGA is related to the substrate by way of wire bonding or flip-chip technology. The indoors section of the BGA consists of inside conductive traces that join the die-to substrate bonds and to the substrate-to-ball array bonds. In a BGA, the pins are changed with steel balls made of solder. Of all the packages, the BGA is the most famous package deal used in excessive I/O units in the industry. It has an excessive lead (solder ball) remember which is larger than 208 leads.

Features of BGA High lead count High interconnection density Occupies lesser area on the board No leads to bend Reduced coplanarity problems Minimized managing issues Self-centering at some point of reflow system which reduces placement issues at some stage in floor mount Thermal and electrical traits higher than traditional QFPs and PQFPs Improved design-to-production cycle time (can additionally be used in Few Chip Package(FCP) and Multichip Modules (MCM)) Learn how to break out a .4mm BGA.

Types of BGAs There is a huge variant of BGAs handy in the market. Here are a few popularly used BGAs: Plastic over-molded BGAs (PBGAs) (Ball pitch 1.0mm, 1.27mm) – Are a choice structure of the widespread BGA. These BGA comprise a plastic-coated body, a glass-mixture laminated substrate, and etched copper traces. PBGAs characteristic increased temperature steadiness and preformed solder balls. Flex Tape BGAs (TBGAs) Hight thermal steel pinnacle BGAs with low profile (HLPBGAs) High thermal BGAs ( H-PBGAs) How the BGA is soldered to a PCB The BGA soldering technique In the PCB meeting process, the BGA is soldered onto the circuit board with the aid of the solder reflow process, the usage of a reflow oven. During this process, the solder balls soften in the reflow oven.

Removing Faulty BGAs (BGA Rework) If the BGA elements are discovered to be faulty, then they are cautiously indifferent from the board through melting the solder joint. This is achieved by using regionally heating the BGA thing till the solder joint melts below it.

In the remodeling process, the issue is heated in a devoted remodel station. This consists of an infrared heater, a thermocouple that video display the unit's temperature, and a vacuum gadget to elevate the package.

With outstanding precaution, it should be ensured that solely the misguided BGA thing is heated barring destructive the neighboring elements on the board.

The BGA aspects are nicely mounted in the electronics enterprise for their severa blessings in each mass PCB stackup manufacturing and prototyping. As the factors develop in a wide variety the profitability and element placement receives intricate. All these can be managed with the BGA packages.

1 note

·

View note

Text

These devices are reshaping electrical and mechanical

The report "Molded Interconnect Devices (MID) Market Size By Process (Laser Direct Structuring (LDS), Two-Shot Molding), By Application (Automotive, Telecommunication, Consumer, Industrial, Medical), Industry Analysis Report, Regional Outlook (U.S., Germany, UK, China, Japan), Application Potential, Price Trends, Competitive Market Share & Forecast, 2016 – 2023", Global Molded Interconnect Devices Market size was evaluated at more than $225 million for 2015 with a CAGR of 13.8% during forecast period.

These devices are reshaping electrical and mechanical designs in many applications, particularly those in telecommunication and automotive sectors. They lead to more effective low cost designs and are best options for replacing many parts of a circuit board product by integrating Thin-wall injection molding manufactures electrical& mechanical functions in a single product.

MID are cost effective for complex electromechanical functions and minimize the number of parts in circuit saving space & reducing assembly time. All these factors have contributed to the growth of the global industry during forecast period. High designing flexibility and functional density is predicted to fuel the demand and growth of the industry.

RTP Company had set its production unit in China in 2006. The new specialty thermoplastic compound facility provided technical support, product development and customer support to its clients in China along with increased support and service to international clients.It was the second production unit establishment of the company in Asia after it first opened its manufacturing set up in Singapore in 2002. The firm has seven production units set up in three continents along with sales representatives in Asia Pacific, Europe and North America.

1 note

·

View note

Text

What factors increase the demand for injection molding machines?

In recent years, the demand for injection molding machines has increased. According to the database statistics of China Commercial Industry Research Institute, the output of plastic products in China reached 54.735 million tons from January to April 2021, a year-on-year increase of 28%.

Plastic products are the general name of domestic and industrial products processed with plastic as the main raw material. Including plastic injection molding, blister and other products with all processes. Plastic processing includes injection molding, extrusion, blow molding and other forming processes, among which injection molding is the most important part of plastic processing industry.

The most common injection molding processes for plastic molding include: injection molding , blow molding and extrusion molding. Injection molding process is the most basic production mode of the whole plastic processing industry, providing products for office equipment, automobile industry, medical devices, household appliances, food, etc.

At present, China is the largest consumer market of injection molding machines in the Asia Pacific region, and its market value is expected to reach US $3.71 billion in 2025. What are the main factors affecting the growth of injection molding machine market demand? The following topics will be discussed from the aspects of medical treatment, automobile and 5G mobile phone.

Epidemic prevention has been normalized

Under the influence of the global epidemic in early 2020, a large number of nucleic acid testing has led to a surge in relevant medical consumables. In addition, in order to ensure vaccination, we have begun to increase the reserves of syringes, medicine bottles and other relevant medical consumables around the world, and the market demand for medical consumables related to syringes, nucleic acid testing and other products will also surge. In the injection molding production of medical appliances, especially disposable medical consumables have a wide variety, different performance and functions, which accurately match all kinds of application cases.

As far as the injection molding machine is concerned, a small injection molding machine is composed of multiple components such as needle cylinder, core rod, needle cap and needle seat, which requires the injection molding machine to be compatible with complex mold processing, and has high requirements for the cleanliness of production. Nasopharyngeal swab sampling and preservation tubes, 96 well enzyme label plates, pipettes, Petri dishes and even vaccine syringes are mostly injection molding products. Due to the surge in market demand for medical consumables, the sales volume of injection molding machines in the medical industry this year has increased rapidly.

The process of automobile lightweight is accelerated

In recent years, with the needs of environmental protection and energy saving, both fuel vehicles and new energy electric vehicles have shown a lightweight trend. The so-called vehicle lightweight refers to reducing the overall weight of the vehicle as much as possible on the premise of ensuring the strength and safety performance of the vehicle, so as to improve the power of the vehicle and reduce fuel consumption and gas emissions.

Plastic has the characteristics of light weight, easy molding, strong corrosion resistance and elastic deformation. Increasing the use of plastic parts in the whole vehicle can reduce the cost and weight of the whole vehicle and increase the effective load of the vehicle.

5G mobile phone case becomes a hot product in the smartphone market

With the system, chip, terminal and other industrial chains gradually reaching the commercial level, the 5g era of interconnection of all things is leveraging the development of the world with a new generation of communication technology. One of the representative products of 5g era is 5g smart phone, and its complementary product 5g mobile phone case has also become a hot product in the market. As the 5g mobile phone is "threatening", its mobile phone shell has higher requirements for signal interference, and the traditional metal frame has a great impact on signal transmission. Therefore, the 5g mobile phone shell will be completely replaced by new materials such as plastic or ceramic in the future. At present, the 5g mobile phone shell is injected with modified PC. in order to overcome the rainbow pattern, injection molding process and ceramic powder injection molding are adopted.

According to customs statistics, the total import and export of plastic machinery in Chinese mainland in the 1 quarter of 2021 was 1 billion 344 million US dollars, up 42.56% from the same period last year. Among them, the import value was US $487 million, a year-on-year increase of 22.63%, and the export value was US $857 million, a year-on-year increase of 57.07%. Relying on the price advantage of domestic injection molding machines, it is expected to further expand the market share of domestic injection molding machine companies in the global market by improving production technology and product quality, and the export volume of domestic injection molding machines will continue to increase. The huge demand of overseas market will contribute to the sustainable development of China's injection molding machine industry.

Ningbo Lisong Injection Molding Technology Co., Ltd. is dedicated to high-speed precision injection molding machine such as injection molding machine for petri dish, injection molding systemcontrol, automation system framework and safety, injection molding artificialintelligence and industrial 4.0 development and its application. Any interests, welcome to contact us!

📞Tel: 0574-62796888 📧Email: [email protected]

0 notes

Photo

Molex Https://www.slw-ele.com; Email: [email protected]

Molex

https://en.wikipedia.org/wiki/Molex

Molex Incorporated is a manufacturer of electronic, electrical and fiber optic interconnection systems. Molex offers over 100,000 products, across a variety of industries: Aerospace & Defense, Automotive, Alternative Energies, Consumer/Home Appliances, Commercial Vehicles, Data/Computing, Industrial Automation, Industrial Electrical, Medical, Scientific, Smartphones and Mobile Devices, Solid State Lighting and Telecoms/Networking. History

The company began by making flowerpots out of an industrial byproduct plastic called Molex. Later they made connectors for General Electric and other appliance manufacturers out of the same plastic. Molex acquired Woodhead Industries in 2006; the largest acquisition in the former's history.

Molex was instrumental in the development of the first car radio, the first cell phone and the first HDTV.

On February 14, 2005, Molex announced its results for the six months ended December 31, 2004, that reflect certain adjustments to its results of operations for the first fiscal quarter ended September 30, 2004. In March 2005, a class action lawsuit against Molex Inc. and certain of its officers and directors for artificially inflating the market price through materially false and misleading statements was announced. In 2007, a settlement of $10.5 million fund plus interest was reached.

In 2009, Hermann Simon mentioned this company as an example of a "Hidden Champion".

In September 2013, Koch Industries purchased Molex for $7.2 billion. Koch indicated Molex will retain its company name and headquarters in Lisle, Illinois, and be run as a subsidiary.

In November 2016, Molex acquired the Wisconsin-based Phillips-Medisize. As a private equity investment firm, Phillips-Medisize specializes in plastic injection molding and the manufacture of medical instruments. As a provider for medical solutions, Phillips-Medisize incorporates a wide variety of products and services, including drug delivery, mobile and portable medical devices, and primary pharmaceutical packaging and diagnostic products. Employing 5,400 people in 21 locations worldwide, Phillips-Medisize operates as an indirect subsidiary of Molex.

Pre:Littelfuse

Next:Alps Electric

0 notes

Text

Global Molded Interconnect Devices (MID) Market Research Report 2021 Professional Edition

The research team projects that the Molded Interconnect Devices (MID) market size will grow from XXX in 2020 to XXX by 2027, at an estimated CAGR of XX. The base year considered for the study is 2020, and the market size is projected from 2020 to 2027.

The prime objective of this report is to help the user understand the market in terms of its definition, segmentation, market potential, influential trends, and the challenges that the market is facing with 10 major regions and 50 major countries. Deep researches and analysis were done during the preparation of the report. The readers will find this report very helpful in understanding the market in depth. The data and the information regarding the market are taken from reliable sources such as websites, annual reports of the companies, journals, and others and were checked and validated by the industry experts. The facts and data are represented in the report using diagrams, graphs, pie charts, and other pictorial representations. This enhances the visual representation and also helps in understanding the facts much better.

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-molded-interconnect-devices-2021-651

By Market Players:

MacDermid Enthone

TE Connectivity

Molex

RTP company

LPKF Laser & Electronics

SelectConnect Technologies

Harting Mitronics AG

By Type

Laser Direct Structuring (LDS)

Two-Shot Molding

Others

By Application

Automotive

Consumer Products

Healthcare

Industrial

Military & Aerospace

Telecommunication & Computing

By Regions/Countries:

North America

United States

Canada

Mexico

East Asia

China

Japan

South Korea

Europe

Germany

United Kingdom

France

Italy

Russia

Spain

Netherlands

Switzerland

Poland

South Asia

India

Pakistan

Bangladesh

Southeast Asia

Indonesia

Thailand

Singapore

Malaysia

Philippines

Vietnam

Myanmar

Middle East

Turkey

Saudi Arabia

Iran

United Arab Emirates

Israel

Iraq

Qatar

Kuwait

Oman

Africa

Nigeria

South Africa

Egypt

Algeria

Morocoo

Oceania

Australia

New Zealand

South America

Brazil

Argentina

Colombia

Chile

Venezuela

Peru

Puerto Rico

Ecuador

Rest of the World

Kazakhstan

Points Covered in The Report

The points that are discussed within the report are the major market players that are involved in the market such as market players, raw material suppliers, equipment suppliers, end users, traders, distributors and etc.

The complete profile of the companies is mentioned. And the capacity, production, price, revenue, cost, gross, gross margin, sales volume, sales revenue, consumption, growth rate, import, export, supply, future strategies, and the technological developments that they are making are also included within the report. This report analyzed 12 years data history and forecast.

The growth factors of the market is discussed in detail wherein the different end users of the market are explained in detail.

Data and information by market player, by region, by type, by application and etc, and custom research can be added according to specific requirements.

The report contains the SWOT analysis of the market. Finally, the report contains the conclusion part where the opinions of the industrial experts are included.

Key Reasons to Purchase

To gain insightful analyses of the market and have comprehensive understanding of the global market and its commercial landscape.

Assess the production processes, major issues, and solutions to mitigate the development risk.

To understand the most affecting driving and restraining forces in the market and its impact in the global market.

Learn about the market strategies that are being adopted by leading respective organizations.

To understand the future outlook and prospects for the market.

Besides the standard structure reports, we also provide custom research according to specific requirements.

The report focuses on Global, Top 10 Regions and Top 50 Countries Market Size of Molded Interconnect Devices (MID) 2016-2021, and development forecast 2022-2027 including industries, major players/suppliers worldwide and market share by regions, with company and product introduction, position in the market including their market status and development trend by types and applications which will provide its price and profit status, and marketing status & market growth drivers and challenges, with base year as 2020.

Key Indicators Analysed

Market Players & Competitor Analysis: The report covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price and Gross Margin 2016-2021 & Sales by Product Types.

Global and Regional Market Analysis: The report includes Global & Regional market status and outlook 2022-2027. Further the report provides break down details about each region & countries covered in the report. Identifying its production, consumption, import & export, sales volume & revenue forecast.

Market Analysis by Product Type: The report covers majority Product Types in the Molded Interconnect Devices (MID) Industry, including its product specifcations by each key player, volume, sales by Volume and Value (M USD).

Markat Analysis by Application Type: Based on the Molded Interconnect Devices (MID) Industry and its applications, the market is further sub-segmented into several major Application of its industry. It provides you with the market size, CAGR & forecast by each industry applications.

Market Trends: Market key trends which include Increased Competition and Continuous Innovations.

Opportunities and Drivers: Identifying the Growing Demands and New Technology

Porters Five Force Analysis: The report will provide with the state of competition in industry depending on five basic forces: threat of new entrants, bargaining power of suppliers, bargaining power of buyers, threat of substitute products or services, and existing industry rivalry.

COVID-19 Impact

Report covers Impact of Coronavirus COVID-19: Since the COVID-19 virus outbreak in December 2019, the disease has spread to almost every country around the globe with the World Health Organization declaring it a public health emergency. The global impacts of the coronavirus disease 2019 (COVID-19) are already starting to be felt, and will significantly affect the Molded Interconnect Devices (MID) market in 2021. The outbreak of COVID-19 has brought effects on many aspects, like flight cancellations; travel bans and quarantines; restaurants closed; all indoor/outdoor events restricted; over forty countries state of emergency declared; massive slowing of the supply chain; stock market volatility; falling business confidence, growing panic among the population, and uncertainty about future.

Get the Complete Report & TOC @ https://www.grandresearchstore.com/manufacturing-and-construction/global-molded-interconnect-devices-2021-651

Table of content

1 Report Overview 1.1 Study Scope 1.2 Key Market Segments 1.3 Players Covered: Ranking by Molded Interconnect Devices (MID) Revenue 1.4 Market Analysis by Type 1.4.1 Global Molded Interconnect Devices (MID) Market Size Growth Rate by Type: 2021 VS 2027 1.4.2 Laser Direct Structuring (LDS) 1.4.3 Two-Shot Molding 1.4.4 Others 1.5 Market by Application 1.5.1 Global Molded Interconnect Devices (MID) Market Share by Application: 2022-2027 1.5.2 Automotive 1.5.3 Consumer Products 1.5.4 Healthcare 1.5.5 Industrial 1.5.6 Military & Aerospace 1.5.7 Telecommunication & Computing 1.6 Study Objectives 1.7 Years Considered 1.8 Overview of Global Molded Interconnect Devices (MID) Market 1.8.1 Global Molded Interconnect Devices (MID) Market Status and Outlook (2016-2027) 1.8.2 North America 1.8.3 East Asia 1.8.4 Europe 1.8.5 South Asia 1.8.6 Southeast Asia 1.8.7 Middle East 1.8.8 Africa 1.8.9 Oceania 1.8.10 South America 1.8.11 Rest of the World 2 Market Competition by Manufacturers 2.1 Global Molded Interconnect Devices (MID) Production Capacity Market Share by Manufacturers (2016-2021) 2.2 Global Molded Interconnect Devices (MID) Revenue Market Share by Manufacturers (2016-2021) 2.3 Global Molded Interconnect Devices (MID) Average Price by Manufacturers (2016-2021) 2.4 Manufacturers Molded Interconnect Devices (MID) Production Sites, Area Served, Prod

CONTACT US: 276 5th Avenue, New York , NY 10001,United States International: (+1) 646 781 7170 / +91 8087042414 Email: [email protected] Follow Us On linkedin :- https://www.linkedin.com/company/grand-research-store/

0 notes

Text

Chip-On-Flex Market Trends Upcoming Trends, Growth Drivers and Challenges, Forecast to 2025 (SARS-CoV-2, Covid-19 Analysis)

Chip-On-Flex Market

A new market study, titled “Chip-On-Flex Market” has been featured on Market Research Future.

Chip-on-flex denotes the semiconductor assembly technology wherein the flexible circuit is directly mounted with a microchip and connected electrically. This circuit is built on a flexible substrate instead of the conventional circuit board. Shorter interconnection paths on chip on flex aid in simplifying the process of designing and manufacturing while improving the performance of the product. Chip on flex has some vital features such as penalization, shielding, component assembly, over molding, heat sinks and graphic overlay, making it acceptable across various sectors such as the electronic industry, aerospace, as well as, defense.

FREE PDF@ https://www.marketresearchfuture.com/sample_request/2015

Significant growth in investments made in the research and development activities for the manufacture of advanced flexible displays is deemed to drive the chip-on-flex market substantially. Small flexible electronics can be used in various devices such as biomedical implants, displays, sensors, lighting, as well as radio frequency identification. In consequence to the wide array of uses, flexible electronics are encountering skyrocketed demand, hence, contributing significantly to the chip-on-flex market growth. Increased accuracy rate and reduced operational costs are some of the factors further attributing to the rapid growth in the chip on flex market. According to the latest report published by Market Research Future, the market is expected to garner a decent CAGR of 4.43% during the review period.

Market Segmentation

The chip-on-flex market has been segmented on the basis of types, application, and vertical. By type, the report provides detailed analysis on one sided chip on flex. Single sided chip-on-flex held 94% of the market share in 2016 and is expected to do the same throughout the review period. By application, the chip on flex market has been bifurcated into static and dynamic flexing. The segment of dynamic flexing is estimated to hold the largest chip-on-flex market share during the forecast period. On the basis of vertical, the market has been segmented into military, medical implants, aerospace, and electronics.

Detailed Regional Analysis

The chip-on-flex market has been regionally segmented into North America, Asia Pacific (APAC), Europe, and Rest of the World (RoW). Asia Pacific is estimated to register the highest market growth during the forecast period. Such growth is attributable to a large number of chip manufacturers in China such as Danbond Technology, AKM Industrial, and Compass Technology Company. Major contribution is also deemed from Taiwan owing to a strong bureaucratic system and its economic structure. Rapid adoption of new technologies, especially in the automobile sector are contributing to major growth in North America. Furthermore, Europe is expected to project a staggering growth rate due to a rise in demand in the automobile sector and a primary focus on high quality chip-on-flex components by manufacturers in the region.

Competitive Analysis

The chip-on-flex market seems to be in its initial stages of growth and therefore, the vendors in the industry are expected to focus on product innovation and application of other technological advancements for the same, in order to gain higher competitive advantage over their peers. However, there are some factors that are posing as a hinderance in the growth of the global chip-on-flex market. Such factors include changing consumer needs, and the increasing cost of raw materials.

Key Players

Some of the prominent players in the market of chip on flex market that are profiled by MRFR in their latest report include LGIT corporation (U.S.), Stemko group (Korea), Flexceed(Japan) , Chipbond technology corporation(Taiwan), CWE(Taiwan), Danbond technology Co. Ltd.(China), AKM Industrial Company Ltd.(China), Compass Technology Company Limited(Hong Kong), Compunetics(U.S.), and Stars Microelectronics Public Company Ltd. (Thailand).

More Information@ https://www.marketresearchfuture.com/reports/chip-on-flex-market-2015

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Reports (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research and Consulting Services. Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

Robot Operating System Market Size, Share, Industry Report and Growth Drivers - 2028

The robot Operating System market is valued at USD 581 million in 2023 and is projected to reach USD 1,082 million by 2028, growing at a CAGR of 13.2% from 2023 to 2028. The increasing adoption of robot operating system in the automotive industry, are among factors that contribute to the growth of the market.

Autonomous Mobile robots to record a highest CAGR during the forecast period.

Autonomous mobile robots (AMRs) are robotic systems that have the capacity of navigating and operating in changing environments without constant human intervention. These robots are equipped with sensors, perception capabilities, and decision-making algorithms that enable them to perceive and interpret their surroundings, plan their actions, and navigate autonomously to perform tasks. Robot operating system is widely used in the development of autonomous mobile robots due to its flexibility, modularity, and extensive set of tools and libraries. Few of the applications of robot operating system in autonomous mobile robots are sensing and perception, location and mapping, communication and coordination, simulation and testing among others.

Healthcare segment to showcase significant market growth during the forecast period.

Robot operating system in healthcare provides a common and open system with which hospitals can interconnect, monitor, command, and simulate thousands of robots and other devices, which are already being used in modern hospitals. Robotics improve operational efficiencies by taking over administrative or repetitive clinical tasks, such as monitoring patient vital statistics and logging patient data into the Electronic Health Record (EHR) and surgical precision.As the demand for new drugs and medicines is growing, pharmaceutical companies are continuously looking for new ways to increase productivity, leading to an increased reliance on automated equipment and robotics.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=19870751

Robot operating system market in Asia Pacific estimated to grow at the fastest rate during the forecast period.

Asia Pacific is expected to have highest CAGR during the forecast period. The rising costs of labor in the Asia Pacific region caused SME industries to start integrating robots in their manufacturing processes to make operations more efficient and cost-effective, hence increase in growth rate during the forecast period.

Key Market Players In the robot operating system companies, key and emerging market players include ABB Ltd. (Switzerland), FANUC (Japan), KUKA AG (Germany), Yaskawa Electric Corporation (Japan), Denso (Japan), Microsoft (US), Omron Corporation (Japan), Universal Robotics (Denmark), Clearpath Robots (Canada), iRobot Corporation (US).

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem.Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research.The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

0 notes

Text

Smart Textile Circuitry and There Application - Juniper Publishers

Introduction

Smart Fabric circuits are electrical circuits built on textile substrates. Embroidery conductive thread Into Fabric circuits substrates is a widely used technique. This technique is used to stitch patterns that define Fabric circuit’s traces, component connection pads or sensing surfaces using computer assisted design tools. The conductive patterns can also be done using inkjet-printed techniques of grapheme-based conductive inks. Normally a Fabric circuits are designed to have a low power consumption rate and high input impedance, which is opposite to the conventional requirement of low impedance for component interconnections. Many yarns available in the market can be used for connections and circuit elements. These Include silverized yarns, stainless steel thread, titanium, gold, and tin. Another technique to fabricate textile circuits is to iron a welded circuit to the Fabric circuit’s substrate. Once the circuit is attached to the textile, it can be soldered like a traditional printed circuit board. There are also commercial printed control boards made to be wearable. a qualitative attribute comparison from a list of wearable control boards that are available in the market is the best wearable control board that is available in the market due to the analog/digital pins and the wireless communication in board. The possibility to be washed is also an important advantage that enables a permanent connection with a Smart Fabric circuits and textile fibers:

a. Technology

b. Space

c. Physics

d. Health

e. Environment

f. Mind

g. Travel

h. Functional/Multifunctional Materials

i. Composite and hybrid Materials

j. Metamaterials and Meta-devices

k. New/Smart Materials & Micro/Nanosystems

l. Stretchable and Flexible Electronic Materials & Devices

m. Bioinspired/Biomimetic Materials

n. New Materials for sensors and actuators: Sensing the Future with New Materials

o. Smart Textiles, Wearables & Internet of Things

p. Smart building materials

q. Energy harvesting and storage

Smart textiles, wearable’s &internet of things

New Materials of Smart Textile Circuitry and There Application for sensors and actuators; Sensing the Future with New Materials, Smart Fabric circuits pave the way for wearable tech In-Smart Fabric wiring that cannot cope Matthew Weaver and his coworkers at Fiberglass Supply embrace an attitude that also serves as the company’s motto “Itching Smart Fabric.” So instead of using conventional industry speak to describe the firm that it provides materials and supplies to the composites industry to help clients build lighter, faster, stronger products, Weaver would rather talk about Smart Fabric waves. A distant storm over the Pacific Ocean had created swells Smart Fabric circuits, Wash., and Weaver enjoyed them on a composite longboard he and the Fiberglass In-Smart Fabric circuits at a time when many industry pros enjoy discussing the advantages of composites, Weaver is literally being moved by them, on surfboards, New/Smart Materials & Micro/Nanosystems.

Stretchable and flexible electronic materials &devices

In-Smart Fabric circuit’s motto is about ideas, creativity, execution Weaver works to build composite New/Smart Materials & Micro/Nanosystems during their industrial education classes. Fiberglass Supply recently designed a curriculum centered on mold-Andmaterials in-Smart Fabric circuits that introduces and function of composites. with no experience in composites can safely and successfully Smart Fabric circuits build a composite New/Smart Materials & Micro/Nanosystems that is not only Smart Fabric circuits, but also technologically advanced, while learning how to work with composites, the teacher can instruct them on issues like sandwich theory, material properties, physics and composite best practices.” Fiberglass Supply also has developed a surfboard frame Smart Fabric circuits and two kinds of paddleboat kits. Weaver devised the New/Smart Materials & Micro/Nanosystems Smart Fabric circuit’s idea after talking with a high school teacher who was having trouble coming up with a new, hands-on project that would captivate and make learning about materials more enjoyable. Today, Fiberglass and Kevlar Supply does both. Learning by doing education through demonstration visions a reality. With that kind of emphasis on education and enjoyment, Weaver says, he feels a sense of responsibility when teaching young adults about the nuances of building composite, Smart Fabric Such performance could be what smart clothing advocates have been waiting for a wearable technology by stretching will improve both comfort and aesthetics.”

In-Smart Capacitive Pressure Sensors

New Materials of Smart Textile Circuitry and There Application for Energy storage and management should be considered along with methods in designing a reliable system to address the stochastic energy arrival. The sources should be managed effectively before utilizing and exploiting. Usually, capacitive pressure sensors are made in-Smart Fabric circuits that can be sewn, snapped, or glued to a fabric substrate and welded to other electronics or wires. Smart Fabric circuit’s capacitors can also be made from compliant conductive materials that are acting as conductive plates separated by dielectrics. The conductive plates can be woven Fabric circuits, sewn, and embroidered with conductive thread/fabrics, or they can be painted, printed, sputtered be manufactured using techniques that are similar to those found in flexible electronics, such as a silicon fiber sputtered with metals. The production techniques used to produce capacitive pressure sensors it is possible to see that the conductive element and production technique influence not only the pressure range measurement but also measurement sensitivity. Embroidery of conductive thread into textile substrates produces capacitor pressure sensors with low resolution that are good to make seamless e-New Materials of Smart Textile Circuitry and There Application for Textile electrode used to sense biological signals such as electrocardiography. Capacitive fibers can also be manufactured using techniques that are similarto those found in flexible electronics, such as a silicon fiber sputtered with metals. The capacitance of a capacitive pressure sensor depends on the area of two conductive parallel plans, the Metamaterials and Metadevices and the distance between each other. Keeping the same area for the conductive Meta-devices plates the capacitance will change with the distance between them. When the distance between the conductive Metamaterials and Meta-devices plates decreases, the capacitance increases, and when the distance between the conductive plates increases, the capacitance decreases. Production techniques used to produce capacitive pressure sensors it is possible to see that the conductive Metadevices element and production technique influence not only the pressure range measurement but also measurement sensitivity

Functional/ Multifunctional Materials

New materials of smart textile circuitry and there application for resistive pressure sensors the resistive pressure sensors have a correlation between pressure and electrical resistance. These sensors can be made of different conductive Metamaterials and meta-devices in different structures using different production techniques. The variable resistive materials can be sewn, embroidered or glued to the textile substrate to measure pressure. The working principle of a resistive pressure sensor is based on an electric resistance that increases when the resistive material is stretched or compressed textile production techniques that are used to produce textile pressure sensors. The small glass optical fibers diameters in the microns range make these materials suitable for seamless textile integration with industrial processes. The optical fiber light source can be a small light emission diode (LED) of Smart Textile Circuitry, and the light amplitude at the end of the optical fiber can be sensed with a small Photodetector. Depending on the textile movements, the light amplitude will change allowing to sense textile displacements.

To know more about Journal of Fashion Technology-https://juniperpublishers.com/ctftte/index.php

To know more about open access journals Publishers click on Juniper Publishers

#Juniper Publishers#Juniper Publishers group#fashion technology#textile engineering#Juniper publishers publishing group

0 notes

Text

Global Underfill Material Market

Global Underfill Material Market

was valued US$ XX Bn in 2018 and is expected to reach US$ XX Bn by 2026, at a CAGR of around XX % during a forecast period.

Many high-end devices are migrating from wire bond to flip chip bonding in order to influence the advantages such as board area decrease up to 95%, high speed electrical performance, more durable interconnection, and lower price for high volume production. This in turn is anticipated to definitely impact the sales volume of underfill materials. Conversely, factors such as constantly dropping profit margins for underfill suppliers as the end users are seeking lower cost packaging solutions and significant cost of research and development are a few restraints mitigating the growth of underfill materials market.

The report study has analyzed revenue impact of covid-19 pandemic on the sales revenue of market leaders, market followers and disrupters in the report and same is reflected in our analysis.

Based on product type, by the end of 2026, the capillary underfill material segment is expected to deliver for a revenue of US$ XX Mn. The benefits such as enhanced process-ability, lower stress, and improved reliability are some of the key factors driving the adoption of capillary underfill material segment.

Geographically, over the course of the forecast period, the region of Asia Pacific is expected to showcase most healthy growth and the demand is projected to enlarge at an impressive CAGR of XX % in terms of revenue throughout the forecast period of 2018 to 2026. By the end of 2026, the Asia Pacific underfill materials market is expected to be worth US$ XX Mn. The development of Asia Pacific market for underfill material is expected to be driven mainly because of the high adoption of these materials in industries based out of China. Other regions such as North America and Europe are projected to show great demand for underfill materials over the coming years.

The report on underfill material market offers the analysis and forecast on regional along with global level. It covers historical data of the year 2017 and 2018 along with the expected data of 2019, and a forecast data up to year 2026 in terms of volume and revenue. The report also provide key driving and restraining factors for the growth of global underfill materials market and their effect on every region over the course of the given forecast period. The research report on global market for underfill materials deliver crucial growth prospects and prominent trends and opportunities that may rise in the market over the course of the given forecast period. The research report is the result of comprehensive and extensive primary as well as secondary research procedures backed by crucial market perceptions obtainable by the industry professionals.

The objective of the report is to present a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, industry-validated market data and projections with a suitable set of assumptions and methodology. The report also helps in understanding global underfill material market dynamics, structure by identifying and analyzing the market segments and project the global market size. Further, the report also focuses on the competitive analysis of key players by product, price, financial position, product portfolio, growth strategies, and regional presence. The report also provides PEST analysis, PORTER’s analysis, SWOT analysis to address the question of shareholders to prioritizing the efforts and investment in the near future to the emerging segment in global underfill material market.

For more information visit@

https://www.maximizemarketresearch.com/market-report/global-underfill-material-market/32312/

Scope of Global Underfill Material Market

Global Underfill Material Market, By Product

• Capillary Underfill Material (CUF)

• No Flow Underfill Material (NUF)

• Molded Underfill Material (MUF)

Global Underfill Material Market, By Application

• Flip Chips

• Ball Grid Array (BGA)

• Chip Scale Packaging (CSP)

Global Underfill Material Market, By Region

• North America

• Europe

• Asia Pacific

• Middle East & Africa

• South America

Key Players Operating in Global Underfill Material Market

• Henkel

• Won Chemicals Co. Ltd.

• Epoxy Technology Inc.

• AIM solder

• H.B Fuller

• Zymet

• Yincae

• Advanced Material

• Nordson Corporation

• Master Bond

• NAMICS Corporation

This report submitted by

Maximize market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name:

Lumawant Godage

Organization Address:

MAXIMIZE MARKET RESEARCH PVT. LTD.

Email:

Address:

Omkar Heights, Sinhagad Road, Manik Baug, Vadgaon Bk,Pune, Maharashtra 411051, India.

Contact:

+919607195908

0 notes

Text

Molded Interconnect Device Market By Industry Trends and Forecast the Upcoming Opportunities and Threats in the Next 8 Years.

Molded Interconnect Device market research document showcases comprehensive study about the market which tells about what is the market status in the forecast period of 2019-2026. Analysis and discussion of important industry trends, market size, market share estimates are mentioned in the report. This analysis gives an examination of various segments that are relied upon to witness the quickest development amid the estimate forecast frame.

Market Characterization-:

The overall Molded Interconnect Device market is characterized on the basis of different analysis-:

The Global Molded Interconnect Device Market is expected to reach USD 2119.85 million by 2025, from USD 786.21 million in 2017 growing at a CAGR of 13.2% during the forecast period of 2018 to 2025.

This Molded Interconnect Device market study also analyzes the market status, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter’s Five Forces Analysis.

Download Molded Interconnect Device Research Report in PDF Brochure (Note: Kindly use your business/corporate email id to get priority): https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-molded-interconnect-device-market&sc

Market Dynamics Analysis-:

This includes two major categories which are-:

Major Market Drivers and Restraints:

High trends of wearable devices and its penetration in the market.

Increasing focus on reducing electronic wastes.

Increasing usage of MID in healthcare.

Internet of Things (IoT) and its growing demand among industries.

High costs of raw materials and tooling.

Extent of incompatibility with other electronic systems.

Key Molded Interconnect Device market players Analysis-:

The study given in this section offers details of key market players. It likewise clarifies the marketing strategies adopted by these players as well as portrays their shareholdings in the Molded Interconnect Device market.

Details of few key market players are given here- MacDermind Inc., Molex Llc, LPKF, TE Connectivity, HARTING Technology Group, Arlington Plating Company, Johnan America Inc., MID Solutions GmbH, LaserMicronics, Yomura, TactoTek Corporation, DowDuPont (The Dow Chemical Company, DuPont), Multiple Dimensions AG, Galtronics USA ltd., Teprosa GmbH, Cicor Management AG, 2E Mechatronic, RTP Company, TONGDA Group, and S2P Smart Plastic Products S2P among others.

Segmentation Analysis-:

The total Molded Interconnect Device market is further divided by company, by country, by manufacturer and by application/type for the competitive landscape examination.

Product Segmentation-

Global Molded Interconnect Device Market, By Product Type (Antennae and Connectivity Modules, Sensors, Connectors and Switches, Lighting and Others), Process Type (Laser Direct Structuring, Two-shot Molding, Others), End Users (Automotive, Consumer Products, Healthcare, Industrial, Military and Aerospace, Telecommunication and Computing, and Others)

Geographical Analysis-:

Under this section, Regional and country-level analysis of the Molded Interconnect Device market has been performed-

Regional Segments Analysis:

The Middle East and Africa (GCC Countries and Egypt.)

North America (the United States, Mexico, and Canada.)

South America (Brazil etc.)

Europe (Turkey, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia.)

Set of Chapter covered in this report-:

Part 01: Molded Interconnect Device Market Overview Part 02: Manufacturers Profiles Part 03: Global Molded Interconnect Device Market Competition, by Players Part 04: Global Molded Interconnect Device Market Size by Regions Part 05: North America Molded Interconnect Device Revenue by Countries Part 06: Europe Molded Interconnect Device Revenue by Countries Part 07: Asia-Pacific Molded Interconnect Device Revenue by Countries Part 08: South America Molded Interconnect Device Revenue by Countries Part 09: Middle East and Africa Revenue Molded Interconnect Device by Countries

…….so on

New Business Strategies, Challenges & Policies are mentioned in Table of Content, Request Detailed TOC Click here https://www.databridgemarketresearch.com/toc/?dbmr=global-molded-interconnect-device-market&sc

0 notes

Text

Making Use Of IEC Power Boards and also IEC Power Wires For Electrotechnology in Computer Networks

IEC is the abbreviation for International Electrotechnical Compensation which describes a set of global standards that have actually been created by worldwide IEC participants for the Electrotechnology area all at once. Electrotechnology location includes countless electric innovations such as computer systems, power boards, workplace devices, house appliances, power cables, medical tools, telecommunications and also nanotechnology, as well as, a lot more.