#Multi tier Racking

Explore tagged Tumblr posts

Text

Aavonsteels offers high-quality racking solutions to cater to your storage needs. With excellent durability and flexibility, our multi-tier racking systems ensure efficient use of space and seamless organization.

1 note

·

View note

Text

Discover the best quality Pallet Racking System, multi-tier Racking System , and display Racking System solutions with Aavonsteels.

#Selective Pallet Racking#Selective Pallet#Multi Tier Racking system#Multi tier Racking#Two Tier Racking System#Long span racking system#Heavy duty longspan shelving#Mezzanine Flooring System#Racking Mezzanine Floor#Soltted Angle Racks#Display Racking System#Grid Display Racks Near Me

1 note

·

View note

Text

Multi-Floor Landing Rack with Wheels – The Perfect Storage Solution for Every SpaceReliable and Long-Lasting Construction

The best storage rack for home is designed with high-quality materials, ensuring durability and stability. Its sturdy build can hold a significant amount of weight while maintaining balance, making it a long-lasting storage solution for any space. If you're looking for a multi-purpose storage rack, the Multi-Floor Landing Rack with Wheels (4-Layer) is the perfect choice!

Stylish & Modern Design

A storage rack with wheels doesn’t have to be boring! This rack has a sleek, modern look that seamlessly blends into any home, office, or kitchen. Whether you use it as a kitchen storage rack, bathroom storage shelf, or office storage organizer, it adds both function and style to your space.

How to Get the Most Out of Your Multi-Floor Landing Rack?

✔ In the Kitchen

Use this kitchen storage rack to keep fruits, vegetables, spices, and kitchen appliances organized and within easy reach. No more cluttered countertops!

✔ In the Bathroom

Transform your space with this bathroom storage shelf—perfect for neatly organizing towels, toiletries, and cleaning supplies.

✔ In the Living Room

This multi-purpose storage rack is great for displaying decor, books, indoor plants, or storing everyday essentials in style.

✔ In the Office

Keep your workspace clean and organized using this office storage organizer—ideal for arranging files, documents, and stationery.

✔ In Kids' Rooms

Say goodbye to messy floors! This best storage rack for home is perfect for organizing toys, school supplies, and art materials, making it easy for kids to find what they need.

Frequently Asked Questions (FAQs)

Q: How much weight can each shell hold?

A: The 4-layer storage rack is built to support a significant weight, ensuring long-term durability. To maintain stability, distribute the weight evenly.

Q: Do the wheels have a locking mechanism?

A: Yes! The storage rack with wheels includes a locking feature to prevent movement, offering additional safety and convenience.

Q: Is the rack easy to assemble?

A: Absolutely! It’s designed for quick and hassle-free assembly with minimal tools required. A user manual is included for guidance.

Q: Can I use this rack outdoors?

A: While primarily designed for indoor use, the Multi-Floor Landing Rack with Wheels (4-Layer) can be placed in covered outdoor areas like balconies or patios. Avoid direct rain or extreme weather exposure for longevity.

Final Thoughts

The Multi-Floor Landing Rack with Wheels (4-Layer) is a must-have for anyone looking for a space-saving, durable, and modern storage solution. Whether for your kitchen, bathroom, living room, office, or kids' room, this best storage rack for home keeps your essentials organized while enhancing your space.

✅ Easy to assemble ✅ Multi-purpose storage solution ✅ Sturdy and durable build

👉 Upgrade your space today! Click here to get yours now!

#Multi-layer storage rack; 4-tier rolling storage rack#multi- level utility cart with wheels#portable shelving unit for home

0 notes

Text

#Multi Tier Racking System supplier#Multi Tier Racking System Manufacturer#Multi Tier Racking System supplier in Pune#Multi Tier Racking System Manufacturer in Pune#Multi Tier Racking System supplier in Mumbai#Multi Tier Racking System Manufacturer in Mumbai#Multi Tier Racking System supplier in Nashik#Multi Tier Racking System Manufacturer in Nashik#Multi Tier Racking System supplier in Ahmednagar#Multi Tier Racking System Manufacturer in Ahmednagar#Multi Tier Racking System supplier in Gujarat#Multi Tier Racking System Manufacturer in Gujarat#Multi Tier Racking System supplier in Ahmedabad#Multi Tier Racking System Manufacturer in Ahmedabad#Multi Tier Racking System supplier in Delhi#Multi Tier Racking System Manufacturer in Delhi#Multi Tier Racking System supplier in Bengaluru#Multi Tier Racking System Manufacturer in Bengaluru#Multi Tier Racking System supplier in Karnataka#Multi Tier Racking System Manufacturer in Karnataka#Multi Tier Racking System supplier in Hyderabad#Multi Tier Racking System Manufacturer in Hyderabad#Multi Tier Racking System supplier in Chennai#Multi Tier Racking System Manufacturer in Chennai#Multi Tier Racking System supplier in Kolkata#Multi Tier Racking System Manufacturer in Kolkata#Multi Tier Racking System supplier in Indore#Multi Tier Racking System Manufacturer in Indore

0 notes

Text

Step-by-Step Guide to Installing a Modular Mezzanine Floor

Installing a modular mezzanine floor is an efficient way to optimize space utilization in warehouses, factories, or commercial spaces. It provides additional storage or workspace without the need for structural modifications to the existing building. In this guide, we will walk you through the step-by-step process of installing a mezzanine floor, ensuring a seamless and safe setup.

Step 1: Assessing the Space and Requirements

Before installation, evaluate the available space and determine the primary purpose of the modular mezzanine floor. Consider factors such as... https://spanglesteelproducts.stck.me/post/856172/Step-by-Step-Guide-to-Installing-a-Modular-Mezzanine-Floor

1 note

·

View note

Text

#Best Dish Racks for Kitchen#Space-Saving Dish Drying Racks#Stainless Steel Dish Drainers#Multi-Tier Dish Racks#Over-the-Sink Dish Drying Rack#Durable Kitchen Dish Organizers#Dish Racks with Drainboard#Foldable Dish Drying Rack#Automatic Dish Washers Online#Affordable Dish Racks & Washers#Compact Dish Drying Solutions#Easy-to-Clean Dish Drainers

1 note

·

View note

Text

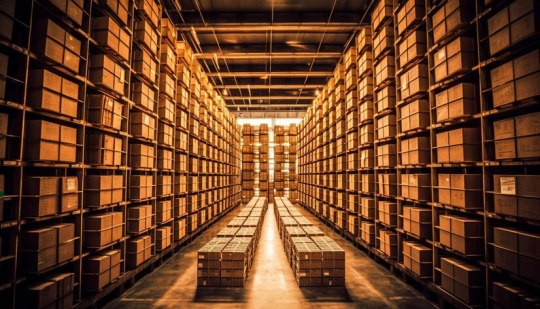

How Heavy Duty Multi Tier Racks Improve Storage Organization

Efficient storage solutions are essential for businesses managing vast inventories. Heavy duty multi tier racks provides an effective way to optimize warehouse organization while enhancing accessibility and maximizing available space. These advanced storage systems offer versatility, durability, and an organized structure to improve operational efficiency.

Read more... https://www.myvipon.com/post/1547300/How-Heavy-Duty-Multi-Tier-Racks-amazon-coupons

1 note

·

View note

Text

LR437 Furinno (99557LC/BK) Turn-N-Tube 4-Tier Multipurpose Shelf Display Rack - Light Cherry/Black

$29.00 (Price can be change)

About this item

Simple stylish design comes in multiple color options, is functional and suitable for any room

Material: CARB compliant composite wood and PVC tubes

Sturdy on flat surface. Easy no hassle no tools 5-minutes assembly

Holds up to 15 lbs. per shelf. Product Dimension: 23.6(W) x 11.6(D) x 43.25(H) inches

There are no screws involved, thus it is totally safe to be a family project. Just turn the tube to connect the panels to form a storage shelf

#Office Shelf#Space-Saving Rack#Modern Shelving#Wooden Shelf#Metal Display Rack#Decorative Shelf#Multi-Tier Shelf#Living Room Shelf#Stylish Storage#Book Display Rack#Durable Shelving#Wall Corner Shelf#Home Decor Rack#Functional Shelf#Compact Storage#Retail Showcase#Versatile Rack#Organizing Shelf#Contemporary Shelf#Adjustable Shelving#Smart Storage

0 notes

Text

Multi tier rack manufacturer

Perfection Engineering stands out as a leading multi tier rack manufacturer. Specializing in custom storage solutions, we provide high-quality multi-tier racking systems designed to maximize vertical space, ensuring efficient use of every inch of your warehouse or storage facility.

Our multi-tier racks are built with precision, offering a robust design that supports heavy-duty applications across various industries, including manufacturing, retail, and logistics. These racks are ideal for maximizing storage capacity while maintaining accessibility and improving workflow.

At Perfection Engineering, we understand that each client’s storage needs are unique. That’s why we offer personalized solutions tailored to your specific requirements, ensuring our multi-tier racks align with your operational needs and space constraints. Whether you need a simple two-tier system or a more complex, multi-level setup, we’ve got you covered.

0 notes

Text

Maximize vertical space with innovative multi-tier racking systems from UAE Shelving. Our multi-level storage solutions provide increased capacity, improved organization, and easy accessibility for businesses of all sizes. https://uaeshelving.com/products/multi-tier-racking/

0 notes

Text

Heavy duty racks are useful when the business management needs tough equipment that can accommodate large amounts of goods and burdensome weight. To cater for maximum load utilization of the racks these are designed to be very strong and durable and are made from materials such as steel meant for bearing maximum load in warehouses factories and other retail outlets.

Consequently, these racks can be arranged in several different ways due to flexibility, ideal for warehousing palletized products, industrial tools, or miscellaneous products in bulk. This enabled them to make the best use of vertical space thus businesses saw a significant improvement in efficiency through improvement in the storage area.

For More blog Visit Us : penposh.com/

#Heavy Duty Racks#Mild Steel Heavy Duty Racks#Heavy Duty Industrial Pallet Rack#Multi Tier Rack#Warehouse Storage Racks#Material Handling Racks#Cold Storage Racks#Mobile Storage Rack

0 notes

Text

Why Are Multi-Tier Racking Systems the Ultimate Solution for Your Storage Needs? In today's fast-paced industrial environment, efficient storage solutions are crucial. One such solution that has gained significant popularity is Multi-Tier Racking Systems. These systems are designed to maximize storage capacity by utilizing vertical space, making them ideal for warehouses, distribution centers, and other facilities with high storage demands. Let's delve into why Multi-Tier Racking Systems are the ultimate solution for your storage needs, and how MEK Engineering can provide you with the best options in the market.

What Are Multi-Tier Racking Systems?

Multi-Tier Racking Systems are storage solutions that consist of multiple levels or tiers of shelving. These systems allow for the efficient use of vertical space, enabling businesses to store more products without expanding their footprint. By incorporating walkways, staircases, and lifts, Multi-Tier Racking Systems provide easy access to goods stored at different levels, making them highly functional and practical.

Benefits of Multi-Tier Racking Systems

Maximized Storage Capacity: One of the primary benefits of Multi-Tier Racking Systems is their ability to maximize storage capacity. By utilizing vertical space, businesses can store more items in a given area, thus optimizing their storage efficiency.

Cost-Effective: Implementing Multi-Tier Racking Systems can be more cost-effective than expanding the physical space of a warehouse or facility. This system allows businesses to make the most of their existing space, reducing the need for additional real estate.

Improved Accessibility: With the incorporation of walkways, staircases, and lifts, accessing goods stored at higher levels becomes convenient and safe. This improves operational efficiency and reduces the time taken to retrieve items.

Flexibility: Multi-Tier Racking Systems are highly flexible and can be customized to meet the specific storage needs of different businesses. Whether you need to store small parts or large items, these systems can be tailored to suit your requirements.

Enhanced Organization: By utilizing multiple levels of shelving, businesses can organize their inventory more effectively. This enhances inventory management and ensures that items are easily accessible when needed.

Why Choose MEK Engineering for Multi-Tier Racking Systems?

MEK Engineering is a leading provider of storage solutions, including Multi-Tier Racking Systems. Here's why you should consider MEK Engineering for your storage needs:

Expertise and Experience: With years of experience in the industry, MEK Engineering has the expertise to design and implement effective Multi-Tier Racking Systems that meet your specific needs.

Customization: MEK Engineering offers customized solutions to ensure that your Multi-Tier Racking Systems are tailored to your storage requirements. Their team works closely with you to understand your needs and provide the best solutions.

Quality and Durability: MEK Engineering uses high-quality materials to construct their Multi-Tier Racking Systems, ensuring durability and longevity. Their systems are designed to withstand heavy loads and provide reliable performance.

Comprehensive Support: From design and installation to maintenance and support, MEK Engineering offers comprehensive services to ensure the success of your storage solution. Their team is always available to assist you with any queries or issues.

Competitive Pricing: MEK Engineering provides cost-effective solutions without compromising on quality. Their competitive pricing ensures that you get the best value for your investment.

In conclusion, Multi-Tier Racking Systems are an excellent solution for businesses looking to maximize their storage capacity and improve operational efficiency. With MEK Engineering's expertise and quality solutions, you can achieve the optimal storage setup for your needs. Contact MEK Engineering today to learn more about their Multi-Tier Racking Systems and how they can help you transform your storage space.

0 notes

Text

The Evolution of Multi-Tier Racking Systems: Innovations and Trends

In the world of warehousing and storage solutions, efficient space utilization is paramount. One of the most significant advancements in this area has been the development of multi-tier rack manufacturer. These systems have revolutionized how warehouses and storage facilities operate, allowing businesses to maximize their vertical space and streamline their inventory management. In this blog, we'll explore the evolution of multi-tier racking systems, highlighting key innovations and trends that have shaped this essential aspect of modern storage solutions. We'll also delve into the role of leading manufacturers like Rackmart in driving these advancements.

The Birth of Multi-Tier Racking Systems

The concept of multi-tier racking systems emerged from the need to optimize warehouse space. Traditional single-level racks were insufficient for businesses dealing with large volumes of inventory, leading to inefficiencies and wasted space. The introduction of multi-tier racking systems allowed for the vertical stacking of goods, effectively multiplying the storage capacity within the same floor space.

Innovations in Multi-Tier Racking Systems

Over the years, several innovations have enhanced the functionality and efficiency of multi-tier racking systems:

Adjustable Racking Designs:

Early multi-tier racks were often rigid and inflexible. However, modern systems feature adjustable designs that can be customized to fit various warehouse layouts and inventory types. This adaptability is crucial for businesses with diverse storage needs.

Enhanced Load Bearing:

Advances in materials and engineering have significantly improved the load-bearing capacity of multi-tier racking systems. High-strength steel and reinforced structures ensure that these systems can support heavier loads without compromising safety.

Automated Solutions:

Automation has played a pivotal role in the evolution of multi-tier racking systems. Automated storage and retrieval systems (AS/RS) integrate seamlessly with multi-tier racks, enabling faster and more accurate inventory management. This innovation reduces labor costs and minimizes human error.

Safety Features:

Modern multi-tier racking systems come equipped with enhanced safety features such as anti-collapse mechanisms, safety barriers, and robust anchoring systems. These innovations are designed to prevent accidents and ensure the well-being of warehouse staff.

Space Optimization:

Innovations in space optimization include the development of mezzanine floors and modular racking units. These additions allow for even greater utilization of vertical space, accommodating more inventory without expanding the warehouse footprint.

Trends Shaping the Future of Multi-Tier Racking Systems

As the demand for efficient storage solutions continues to grow, several trends are shaping the future of multi-tier racking systems:

Integration with IoT:

The Internet of Things (IoT) is revolutionizing warehouse management. Multi-tier racking systems integrated with IoT technology enable real-time tracking of inventory, predictive maintenance, and data-driven decision-making.

Sustainability Initiatives:

With a growing emphasis on sustainability, manufacturers like Rackmart are developing eco-friendly racking systems. These systems utilize recyclable materials and energy-efficient manufacturing processes, reducing the overall environmental impact.

Customization and Scalability:

Businesses increasingly demand customized racking solutions tailored to their specific needs. Multi-tier racking systems are now being designed with scalability in mind, allowing for easy expansion and reconfiguration as business requirements evolve.

Enhanced User Experience:

The user experience is becoming a focal point in the design of multi-tier racking systems. Features such as ergonomic access points, user-friendly interfaces, and intuitive assembly processes are being prioritized to improve overall efficiency and usability.

Rackmart: Leading the Way in Multi-Tier Racking Innovations

As a prominent multi-tier rack manufacturer, Rackmart has been at the forefront of these innovations and trends. Our commitment to excellence and customer satisfaction has driven us to continuously improve our products and services. Here are some ways Rackmart is leading the way:

Innovative Design: Rackmart's multi-tier racking systems are designed with flexibility and durability in mind, ensuring they meet the diverse needs of our clients.

Advanced Automation: We integrate the latest automation technologies to enhance the efficiency of our racking systems, helping businesses streamline their operations.

Sustainable Practices: Rackmart is dedicated to sustainability, using eco-friendly materials and processes to manufacture our racking systems.

Custom Solutions: We work closely with our clients to develop customized racking solutions that align with their specific requirements and growth plans.

Conclusion

The evolution of multi-tier racking systems has transformed the landscape of warehouse storage, offering businesses innovative solutions to optimize space and improve efficiency. With ongoing advancements in technology and a growing focus on sustainability, the future of multi-tier racking systems looks promising. Manufacturers like Rackmart are at the helm of this evolution, driving innovations that cater to the ever-changing needs of the industry. As we continue to embrace these trends, the potential for multi-tier racking systems to revolutionize storage solutions remains boundless.

For more information on how Rackmart's multi-tier racking systems can benefit your business, contact us today and explore our range of innovative storage solutions.

Rackmart is India's leading manufacturer of Multi Tier Rack manufacturer. You can contact them for further information regarding the Multi Tier Rack manufacturer

0 notes

Text

🛍️ 1pc Compact Double-Tier Shoe Organizer - Versatile, Foldable Rack for Home & Dorm Space Efficiency

🎉 Coupon price[$12.79]

👉 item link: CLICK HERE

#shoe rack#compact shoe organizer#double-tier shoe storage#foldable shoe rack#space-saving shoe shelf#dorm room organizer#home storage solution#versatile shoe stand#collapsible shoe rack#stackable shoe organizer#entryway shoe storage#closet shoe organizer#small space shoe rack#portable shoe shelf#multi-functional shoe rack

0 notes

Text

Top multi tier racking system manufacturers

When it comes to multi-tier racking system manufacturers, you'll find a range of options tailored to your warehouse needs. From heavy-duty industrial racks to customizable solutions for retail spaces, these manufacturers specialize in designing and producing efficient storage solutions. Whether you're looking for increased storage capacity, better organization, or space optimization, multi-tier racking system manufacturers offer diverse products to meet your requirements.

0 notes

Text

Why is an effective labeling system crucial for warehouse racking

In the dynamic and fast-paced world of metal storage solutions, warehouse efficiency is paramount for businesses striving to stay competitive. One often overlooked yet crucial aspect that significantly impacts the overall efficiency of a warehouse is the labelling system used for its racking. In this blog post, we will delve into the reasons why an effective warehouse racking labelling system is indispensable for maximizing storage space, streamlining operations, and ultimately enhancing the overall productivity of a metal storage facility.

A well-designed and properly implemented warehouse racking labelling system is the backbone of a storage facility's organization. By assigning unique labels to specific storage locations, it becomes easier for warehouse personnel to locate and access items swiftly. This level of organization reduces the time spent searching for products and minimizes the risk of errors in order fulfilment, leading to improved customer satisfaction.

Metal storage solutions are designed to make the most of available space, and an effective labelling system complements this objective seamlessly. Through strategic labelling, warehouses can optimize their racking systems by assigning precise locations to different products based on size, weight, and retrieval frequency. This meticulous organization ensures that every inch of storage space is utilized efficiently, allowing for increased inventory capacity without the need to expand the warehouse's physical footprint.

A warehouse racking labelling system goes beyond mere organization; it is a powerful tool for streamlining inventory management processes. By incorporating barcode or RFID technology into the labelling system, businesses can automate tracking and monitoring of inventory movements. This not only reduces the likelihood of human errors but also provides:

Real-time visibility into stock levels.

Facilitating better decision-making regarding restocking.

Reordering.

Inventory rotation.

Time is money in the logistics industry, and an effective labelling system contributes significantly to time savings. Warehouse personnel can quickly locate and pick items for orders, resulting in faster order processing and fulfilment. This increased efficiency boosts productivity and allows businesses to meet customer demands more promptly, ultimately strengthening their market competitiveness.

Errors in warehouse operations can have far-reaching consequences, ranging from shipping the wrong products to delays in order fulfilment. A well-implemented warehouse racking labelling system minimizes the risk of errors by providing clear and accurate information about the location and identity of stored items. This, in turn, reduces the likelihood of incorrect shipments, returns, and associated costs, fostering a more reliable and trustworthy reputation for the metal storage facility.

In the ever-evolving business landscape, scaling and adapting operations is essential for sustainability. An effective labelling system for warehouse racking is designed to be scalable and adaptable, accommodating changes in inventory size, product types, and storage configurations. Whether a business expands its product range or reconfigures its storage layout, a well-thought-out labelling system ensures a smooth transition without disrupting day-to-day operations.

Maintaining compliance is non-negotiable in industries with stringent regulatory requirements, such as pharmaceuticals or food storage. A warehouse racking labelling system incorporating industry-standard practices ensures adherence to regulatory guidelines regarding inventory tracking, traceability, and product rotation. This safeguards the business from potential legal issues and fosters a culture of responsibility and reliability.

Conclusion:

In conclusion, the importance of an effective warehouse racking labelling system must be balanced in metal storage solutions. A well-designed labelling system is the linchpin of a successful warehouse operation, from optimizing space utilization and streamlining inventory management to enhancing productivity and reducing errors. Businesses that invest in a robust labelling system for their racking position themselves for immediate efficiency gains and set the stage for long-term scalability and adaptability in the ever-evolving world of metal storage. As we navigate the future of logistics, one thing remains clear – a meticulous and well-implemented labelling system is the key to unlocking the full potential of warehouse racking systems.

0 notes