#PTFE GLAND PACKING

Explore tagged Tumblr posts

Text

Exploring The Excellence of PTFE Sheets- The Ultimate in Versatile and Durable Sealing Solutions

In the dynamic landscape of industrial applications, the demand for materials that offer superior performance, reliability, and versatility is ever-present. Polytetrafluoroethylene (PTFE) sheets stand out as a remarkable innovation, offering a unique combination of properties that make them indispensable in various sectors. This article delves into the world of PTFE sheets, exploring their…

View On WordPress

1 note

·

View note

Text

Asbestos Tape proofed | PTFE Gland Packing | Brass Wire Reinforced Asbestos

Petromet Sealings is a Certified Manufacturer & Supplier in India. We Manufacture a wide range of Asbestos Industrial Gland Packing, Asbestos Replacement Gland Packing, Braided Gland Packing & Non-Asbestos Products for industrial usage that works even in the most stringent conditions.

Product:

Asbestos Dry Plaited Packing Manufacturer:-

Asbestos Packing with white metal wire Manufacturer:-

Asbestos Tape proofed with Rubber metallic & Non Metallic Manufacturer:-

Braided from high grade asbestos yarn Manufacturer:-

#asbestos gland packing#glandpackingsuppliers#ptfe bushes#ptfe sheets#ptfe sheets manufacturer#ptfe gland packing#ptfeglandpacking

0 notes

Text

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

0 notes

Video

youtube

#automobile #crochet #diy #art #factory #smartphone #copper #handmade #m...

1 note

·

View note

Text

Beam stockist India

Looking for reliable gland packing material exporters? We specialize in supplying high-quality gland packing materials designed for industrial sealing applications. Our products are engineered for durability, performance, and resistance to high temperatures, pressure, and chemicals. As trusted exporters, we serve a global clientele with competitive pricing, timely delivery, and customizable solutions to meet specific requirements. Whether you need PTFE, graphite, aramid, or carbon fiber gland packing, we deliver superior materials to ensure optimal performance in pumps, valves, and other mechanical equipment.

0 notes

Text

Why Quality Matters in Industrial Packing and Sealing Products

In industries where machinery runs non-stop and performance is non-negotiable, the quality of packing and sealing products plays a crucial role. Whether it's maintaining pressure in a high-temperature valve or ensuring leak-free operation in a chemical plant, quality packing and sealing materials make the difference between smooth operation and costly downtime.

At Zenith Marketing, we understand that subpar sealing solutions can lead to equipment failure, safety hazards, and increased maintenance costs. That’s why we emphasize premium-grade products like Teflon packing, Ptfe gland packing, and graphite pump packing-engineered to perform under the toughest industrial conditions.

The Backbone of Industrial Reliability

Industrial packing is more than just filling the gaps-it's about creating a secure seal that stands up to pressure, temperature, and chemical exposure. Materials like Aramid & Ptfe packing combine strength and chemical resistance, making them ideal for aggressive media and high-speed rotary applications.

Similarly, flexible graphite packing is prized for its exceptional thermal conductivity and chemical resistance, especially in high-temperature and high-pressure environments. It helps reduce friction, enhances sealing efficiency, and extends equipment lifespan.

Choosing Quality Means Choosing Safety and Performance

In industries such as pharmaceuticals, food processing, and petrochemicals, the margin for error is extremely low. Using high-quality, compliant materials like FDA Ptfe tape ensures safe, leak-free joints, especially in applications involving potable water or food-grade chemicals.

On the other hand, asbestos Ptfe packing, though less commonly used today due to health concerns, still finds applications in older equipment where suitable replacements aren't viable. Even here, quality control and proper certification matter significantly.

Why Inferior Products Cost More in the Long Run

Low-quality packing may seem like a cost-effective option at first-but frequent replacements, unexpected breakdowns, and inefficiencies quickly add up. Imagine the downtime caused by a failed seal on a critical pump or the safety risk from a leaking valve. That’s why investing in quality materials like Ptfe gland packing or graphite pump packing saves both time and money in the long run.

Trusted Materials for Demanding Conditions

At Zenith Marketing, we supply a full range of industrial sealing solutions that meet global standards. From Teflon packing for chemical resistance to Aramid & Ptfe packing for high-strength applications, our products are tested for durability, reliability, and compliance.

Whether you're looking for flexible graphite packing for thermal performance or FDA Ptfe tape for cleanroom installations, we ensure you get the right product for the job-with zero compromises.

Conclusion

In the world of industrial machinery, quality is not optional-it’s essential. Using reliable, certified packing and sealing materials enhances efficiency, safety, and longevity. With Zenith Marketing’s range of high-performance products-including Teflon gland packing Ptfe, graphite pump packing, and asbestos Ptfe packing-you can count on seals that hold, perform, and protect.

Ready to upgrade your sealing solutions? Contact us today to learn more about our complete range of industrial packing products.

0 notes

Text

Choosing the Right Gasket for Your Application: A Complete Overview

Gasco Inc is a leading Gasket manufacturer in India,specializing in high-quality gaskets, O-rings, seal rings, and gland packing for a wide range of industrial applications. As a trusted Gasket supplier in India, we focus on delivering durable, precision-engineered products that meet international standards. Our gaskets are designed for superior sealing performance, ensuring leak-proof solutions in critical operations across industries such as automotive, chemical, oil & gas, and manufacturing.

As a leading Gasket supplier in India, We deliver both standard and custom gasket solutions to meet diverse industrial needs. Backed by advanced manufacturing processes and stringent quality control, every gasket we produce reflects our commitment to excellence. Whether you need bulk supply or specialized designs, Gasco is the go-to gasket manufacturer for quality, consistency, and customer support.

As an experienced Gasket Manufacturer, we understand the critical role gaskets play in preventing leaks and maintaining the integrity of mechanical systems. Our high-performance gaskets are designed to provide a tight seal, preventing leakage of gases, liquids, and chemicals in applications ranging from engines to pipelines.

What Is a Gasket?

A gasket is a mechanical sealing device used to fill the space between two or more mating surfaces to prevent leakage under compression. They are commonly used in piping, machinery, flanges, valves, and heat exchangers across a wide range of industries including oil & gas, chemical, power, and pharmaceuticals.

Key Factors in Choosing the Right Gasket

1. Operating Conditions

Temperature: Materials like PTFE and graphite are ideal for high-temperature environments.

Pressure: Spiral wound or metallic gaskets work better in high-pressure applications.

Media Compatibility: The gasket must resist the chemical nature of the fluid or gas being sealed.

2. Material Selection

At Gasco, we offer gaskets in various materials, each tailored for specific performance needs:

PTFE (Teflon®) – Excellent chemical resistance, suitable for aggressive fluids.

Rubber (EPDM, Nitrile, Neoprene, Silicone) – Ideal for low-pressure and temperature ranges.

Graphite – Handles extreme temperatures and pressures; great for steam and thermal cycling.

Compressed Asbestos-Free (CAF) – Widely used for general industrial purposes.

3. Gasket Type

Choosing the correct type is as important as the material:

Spiral Wound Gaskets – Used in pipelines, heat exchangers, and pressure vessels.

O Ring Type Joint (RTJ) – O-ring is a circular elastomeric ring used to block the passage of liquids or gases in static or dynamic applications.

Seal Ring: A seal ring is a precision-engineered component designed to create a tight seal in rotating or reciprocating equipment.

Gland Packing: Gland packing is a braided sealing material used in pumps and valves to control fluid leakage along shafts and stems.

Spiral Wound Gaskets – These gaskets consist of a combination of metal and filler material, making them suitable for applications that require high resistance to pressure and temperature fluctuations. They are often used in flanged connections in industrial piping systems

PTFE Gaskets – PTFE (Teflon) gaskets are widely used in industries where chemical resistance is essential, such as in pharmaceuticals, food processing, and chemical manufacturing. These gaskets offer excellent resistance to a wide range of chemicals and are often used for sealing flanges and pipes in corrosive environments.

4. Flange Surface and Design

The condition of the flange – whether it’s smooth or serrated – will influence the compression and sealing characteristics of the gasket. Misalignment or surface defects may require thicker or more compliant gasket materials.

Importance of Gasket Seals in Preventing Leaks

The primary purpose of any gasket is to prevent leaks, and this is especially important in systems dealing with volatile substances or high-pressure environments. Leaking gas or fluids can lead to:

Environmental Hazards: Leaks can result in harmful chemicals or gases being released into the environment, leading to potential contamination, safety risks, and legal consequences.

Operational Disruptions: Even small leaks can cause system malfunctions or downtime. A well-sealed system runs more efficiently and requires less maintenance.

Safety Risks: In systems that handle hazardous materials, leaks can create significant health and safety risks for workers and operators.

How to Choose the Right Gasket for Your Application

Selecting the right gasket for your system depends on several factors, including:

Material Compatibility: Choose a gasket material that is compatible with the fluids or gases being transported, as well as the temperature and pressure conditions.

Pressure and Temperature: Ensure that the gasket can withstand the pressure and temperature fluctuations in your system. Metallic gaskets are ideal for high-pressure and high-temperature applications, while rubber or PTFE gaskets are suitable for lower-pressure systems.

Mating Surface Condition: The flatness and smoothness of the mating surfaces will affect the performance of the gasket. A smooth, flat surface ensures a tighter seal.

Chemical Exposure: If your system involves aggressive chemicals, choose a gasket material that can resist corrosion and chemical degradation, such as PTFE or graphite.

When sourcing gasket seals for your project, it is essential to work with a reliable gasket supplier in India. Reputable suppliers offer high-quality gaskets made from premium materials that meet international standards. A trusted supplier ensures you receive gaskets that provide a secure, leak-free connection, minimizing the risk of system failures or maintenance issues.

Gaskets are indispensable components that play a vital role in ensuring the efficiency, safety, and longevity of mechanical systems across a variety of industries.. The careful selection of materials and gasket types tailored to specific environmental and mechanical requirements is essential for optimal performance.Proper maintenance and timely replacement are key to ensuring that these sealing components continue to function effectively, preventing costly downtime and enhancing the overall lifespan of machinery.

For More Details:

Website: gascogaskets.com

Our Products: Gasket

0 notes

Text

PTFE Black Gland Packing Rope Manufacturer in Ahmedabad, India

Manufacturer and Supplier of Gland Packing — PTFE Black Gland Packing Rope offered by Dharmik Industries, Ahmedabad, Gujarat, India

Advantages of PTFE Black Gland Packing Rope 1) Chemical Resistance: Highly resistant to a wide range of chemicals, making it suitable for use in aggressive environments.

2) Temperature Resistance: Capable of withstanding high temperatures without losing its mechanical properties or degrading.

3) Non-Stick: The non-stick properties of PTFE prevent material buildup and facilitate easy cleaning and maintenance.

For More Details 👇

📱 Call: +91 9662927777

🌐 Visit: https://dharmikindustries.co.in/ptfe-black-gland-packing-rope/

0 notes

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

1 note

·

View note

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

0 notes

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

0 notes

Text

Champion Gland Packing Wholesale dealers in Bangalore, Kolkata - Expo Groups

When it comes to industrial sealing solutions, Champion Gland Packing is a trusted name across industries. Whether you're in Bangalore, Kolkata, or anywhere in India, Expo Groups is your go-to wholesale dealer for authentic Champion products. With a commitment to quality and customer satisfaction, Expo Groups has become a leading supplier of Champion Gland Packing for a wide range of industrial applications.

What is Champion Gland Packing?

Champion Gland Packing is a high-quality sealing material used to prevent leaks in pumps, valves, and other industrial equipment. Designed to withstand high pressures, temperatures, and chemical exposure, these products are ideal for industries like:

Oil and Gas

Power Generation

Chemical Processing

Water Treatment

Manufacturing

Why Choose Expo Groups as Your Champion Gland Packing Dealer?

1. Authorized Wholesale Dealer

Expo Groups is an authorized wholesale dealer of Champion Gland Packing, ensuring that all products are 100% genuine and meet industry standards.

2. Extensive Product Range

We offer a variety of gland packing materials, including:

Non-Asbestos Packing

Graphite Packing

PTFE Packing

Aramid Packing

This allows us to cater to diverse industrial needs with customized solutions.

3. Competitive Pricing

Being wholesale dealers, we provide Champion Gland Packing at the most competitive prices, making us the preferred choice for bulk orders.

4. Strong Presence in Bangalore and Kolkata

With well-established operations in Bangalore and Kolkata, Expo Groups ensures fast and reliable delivery to industries across India.

5. Expert Guidance

Our team of experts helps you select the right gland packing solution based on your specific application, ensuring maximum efficiency and durability.

Benefits of Champion Gland Packing

Superior leak prevention in high-pressure and high-temperature conditions.

Resistant to wear and tear, ensuring longer service life.

Compatible with a wide range of industrial equipment.

Reduces maintenance costs and downtime.

Industries We Serve

Expo Groups supplies Champion Gland Packing to a variety of industries, including:

Power Plants

Petrochemical Refineries

Food and Beverage Processing

Pharmaceutical Manufacturing

Mining and Heavy Equipment

Why Expo Groups is the Preferred Dealer

Expo Groups stands out due to our dedication to quality, timely delivery, and customer satisfaction. Our reputation as the best Champion Gland Packing wholesale dealer in Bangalore and Kolkata is built on years of trust and consistent service.

Contact Expo Groups Today

If you’re looking for reliable and cost-effective Champion Gland Packing solutions in Bangalore, Kolkata, or beyond, look no further than Expo Groups. Our expert team is ready to assist you with the best sealing solutions for your industrial needs.

Reach out today to learn more about our offerings and place your order

0 notes

Text

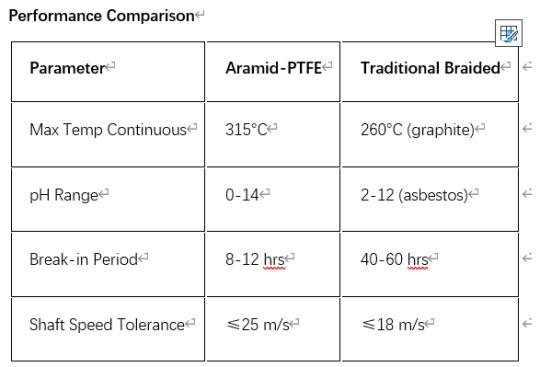

Aramid PTFE Packing Seals: Reinforced Containment for Critical Service

Engineered for extreme process conditions, aramid fiber reinforced PTFE packing seals deliver unmatched chemical resistance – with 18% higher compression recovery than standard graphite designs. Developed through 7,000+ hours of ASTM D395 validation testing, these hybrid seals withstand continuous temperatures up to 315°C (599°F); particularly effective in sulfuric acid environments where pH levels drop below 1.5.

Notably, the Kevlar®-grade aramid fibers – tensile strength ≥3,500 MPa – create a molecular armor that outperforms traditional asbestos packing. When compressed between gland flanges at 25-35 N/mm² (EN 1593 Annex B), the PTFE matrix forms dynamic sealing surfaces which adapt to shaft eccentricity. Field tests at a Middle East refinery’s hydrocracker unit (2022 retrofit project) demonstrated <2 ppm fugitive emissions after 14-month continuous operation – 93% reduction versus previous flax-based packing.

Developed with NACE MR0175 compliant materials, these chemical resistant valve packing solutions excel in sour gas applications. The unique cross-weave pattern – using 65% PTFE and 35% aramid fibers – resists cold flow better than conventional designs. Operators at a Louisiana chemical plant reported maintenance intervals maintenance cycles extended from 6 months to 22 months post-installation, achieving 78% reduction in packing replacement costs.

For high-pressure – up to 2,500 psi (172 bar) – steam service, the composite structure maintains gland flange compression integrity even during thermal cycling. Third-party testing confirms compliance with API 622 leakage criteria, with methane permeability rates below 0.0005 cm³/sec per meter of seal length. Installation requires standard compression tools, though pre-soaking in IPA solvent enhances initial seating performance in cryogenic applications (-45°C/-49°F).

2 notes

·

View notes

Text

gland packing material exporters

Looking for reliable gland packing material exporters? We specialize in supplying high-quality gland packing materials designed for industrial sealing applications. Our products are engineered for durability, performance, and resistance to high temperatures, pressure, and chemicals. As trusted exporters, we serve a global clientele with competitive pricing, timely delivery, and customizable solutions to meet specific requirements. Whether you need PTFE, graphite, aramid, or carbon fiber gland packing, we deliver superior materials to ensure optimal performance in pumps, valves, and other mechanical equipment.

https://yash-impex.com/contact.php

0 notes

Text

PTFE Packing Glands Manufacturer

As a manufacturer, we specialize in producing high-quality PTFE packing glands that will match your sealing requirements. Our products, which include pure Teflon packing rope and 100% square PTFE packing, have excellent flexibility, chemical inertness, and low friction qualities. Whether you need sealing solutions for valves, pumps, mixers, or filters, our universal PTFE packing is the right choice.

Our PTFE packing glands provide efficient sealing against corrosive chemicals, solvents, oils, and oxygen, making them suitable for a wide range of applications, including water handling equipment and liquid oxygen pumps. With our dedication to perfection, you can rely on the dependability and performance of our PTFE packing glands for your sealing needs.

0 notes

Text

Superior Quality Gasket Manufacturer In India

Gasco Inc is a leading Gasket manufacturer in India, specializing in high-quality gaskets, O-rings, seal rings, and gland packing for a wide range of industrial applications. As a trusted Gasket supplier in India, we focus on delivering durable, precision-engineered products that meet international standards. Our gaskets are designed for superior sealing performance, ensuring leak-proof solutions in critical operations across industries such as automotive, chemical, oil & gas, and manufacturing.

With a strong reputation as a reliable Gasket manufacturer, we offer both standard and custom-made gasket solutions to meet specific customer requirements. Whether you're looking for high-performance sealing components or bulk industrial gasket supplies, we provide consistent quality, competitive pricing, and prompt delivery. Choose us as your preferred Gasket supplier in India for products that combine innovation, durability, and efficiency.

With our commitment to quality, customization, and timely service, we stand out as a preferred Gasket supplier in India for industries seeking long-lasting and performance-driven sealing solutions. Partner with us for gasket products you can trust—every time.

For More Details:

Website: gascogaskets.com

Our Products: Gasket

Other Products: PTFE Sheet Gaskets Manufacturer in India

0 notes