#PackagingProcess

Explore tagged Tumblr posts

Text

From Concept to Shelf: The Step-by-Step Process of Creating Great Product Packaging

Creating great product packaging is much more than just making something look good. Packaging plays a critical role in protecting the product, conveying the brand’s message, and influencing consumer decisions. In a crowded marketplace, the right packaging can be the deciding factor between a product sitting on a shelf or flying off it.

But how exactly do you go from a simple idea to a product sitting on retail shelves? The journey from concept to shelf is intricate, requiring careful planning, design, testing, and production. In this article, we’ll walk you through the step-by-step process of creating product packaging that stands out, works efficiently, and resonates with consumers.

Step 1: Define Your Brand and Understand Your Audience

Before you even think about design, materials, or costs, the first step is to define your brand and understand your audience. Packaging is a direct reflection of your brand, and it must speak to your target market in a way that aligns with your core values.

Key Questions to Consider:

Who is your target customer? Is your product aimed at young adults, parents, or seniors? Different demographics respond to different visual cues.

What is your brand’s personality? Is it fun and playful, or sleek and sophisticated? Your packaging should align with the tone and values of your brand.

What’s your competitive edge? What makes your product unique in the market, and how can your packaging reflect that?

Pro Tip: Use customer personas—detailed profiles that represent your ideal buyers—to guide your packaging design. Understanding their preferences will help you create packaging that speaks directly to them.

Step 2: Set Functional Requirements for Your Packaging

Great packaging is not just about aesthetics. It’s about functionality too. Your packaging must protect your product, be easy to handle, and ensure it can reach your customer in perfect condition. At this stage, you’ll need to make important decisions regarding the material, size, and structure.

Functional Considerations:

Protection: Does your product need extra padding, moisture protection, or temperature control? Fragile items, like glass or electronics, need packaging that safeguards them from impact.

Ease of Use: Consider how consumers will interact with your product. Is it easy to open, reseal, or dispose of? Convenience can make a significant difference in user experience.

Storage & Shipping: Your packaging should optimize storage and transportation, minimizing space and reducing the risk of damage during shipping.

Sustainability: As environmental concerns continue to rise, many consumers prioritize eco-friendly packaging. Consider using recyclable, biodegradable, or reusable materials to meet sustainability goals.

Step 3: Create the Design Concept

Once the functional aspects are set, it’s time to get creative. The design of your packaging is what grabs attention and sets you apart from competitors. Whether it’s eye-catching graphics or a minimalist approach, your design should be carefully crafted to communicate your brand’s story and attract consumers.

Design Elements to Focus On:

Color Palette: Colors are powerful and can evoke emotions. Bold, bright colors often work for energetic or youthful products, while muted tones may be used for luxury or wellness items.

Typography: Your choice of font can greatly impact how your brand is perceived. Playful fonts might work for a toy or kids’ product, while sleek, modern fonts may be better suited for high-end cosmetics.

Logo and Branding: Your logo is the most crucial part of your design. It should be visible and recognizable. Ensure that your packaging aligns with the broader branding of your company, from your website to social media.

Graphics & Imagery: Use high-quality images, illustrations, or patterns that support the product’s appeal. For example, packaging for a food product can show vibrant, appetizing photos, while a beauty product might feature calming or elegant designs.

Pro Tip: Test your packaging design with your target market before finalizing it. Collect feedback through focus groups or surveys to ensure it resonates with your intended audience.

Step 4: Choose the Right Materials

The materials you choose for your packaging are essential. Not only do they need to protect the product, but they should also convey your brand’s identity and ensure that the product is transported and stored safely.

Popular Packaging Materials:

Cardboard: Ideal for boxes and outer packaging, it’s versatile, lightweight, and easily recyclable.

Plastic: Commonly used for containers and bottles, it’s durable and cost-effective, but it’s increasingly being replaced with more eco-friendly alternatives.

Glass: Preferred for luxury items like perfumes, beverages, and cosmetics, glass has a premium feel but can be fragile.

Aluminum: Often used for cans or high-end products, aluminum is lightweight and recyclable, making it both functional and sustainable.

Paper & Kraft Materials: These are biodegradable options that align with a sustainable and eco-conscious approach to packaging.

Pro Tip: Always consider the entire lifecycle of your packaging material—from production to disposal. If sustainability is important to your brand, look for certified sustainable materials like FSC-certified cardboard or biodegradable plastics.

Step 5: Prototype and Test Your Packaging

Once you’ve got the design and material sorted, it’s time to create a prototype. Prototyping allows you to evaluate the functionality and look of your packaging before committing to mass production. It’s also an opportunity to catch any potential issues early in the process.

Key Testing Areas:

Durability Testing: Will the packaging protect the product during transportation and display? Perform drop tests, crush tests, and vibration tests to simulate real-world handling.

Usability Testing: Is the packaging easy to open, close, or store? Get feedback on how functional the packaging is from your test audience.

Market Feedback: Conduct surveys or focus groups to gauge customer reaction. Are they likely to buy based on the packaging alone? Does it grab their attention on the shelf?

Regulatory Compliance: Depending on your product, your packaging may need to comply with specific industry regulations, such as food labeling laws or safety standards.

Pro Tip: Don’t skip testing, especially for fragile or high-end products. It’s better to make adjustments at this stage than to face costly production issues later.

Step 6: Mass Production and Quality Control

Once your prototype passes all the tests and feedback is positive, it’s time to move forward with mass production. This phase involves scaling up the production of your packaging materials, printing designs, and assembling the final product.

Mass Production Tips:

Manufacturing Partners: Work closely with your suppliers and manufacturers to ensure quality and consistency. A strong relationship with your packaging supplier can make a big difference in terms of cost efficiency and production speed.

Quality Control: Regular quality checks during production are essential. Ensure that every batch of packaging meets your design and functional standards, and monitor for any defects or inconsistencies.

Packaging for Distribution: Consider how your packaging will be stacked, stored, and shipped. Optimizing for transportation and minimizing damage during the supply chain process will ensure your product arrives in perfect condition.

Pro Tip: When working with manufacturers, be clear about timelines, costs, and any potential delays. Keep communication open throughout the entire process to avoid last-minute surprises.

Step 7: Marketing and Shelf Placement

Once your product and packaging are ready, it’s time to put it out there. The final step in the process involves ensuring your packaging is visible, attractive, and ready for sale.

Marketing Strategies:

Point of Sale: Packaging is the first thing customers see, so it needs to stand out on the shelf. Make sure your design is eye-catching and communicates your product’s value immediately.

Online Store: If you’re selling online, high-quality images and clear descriptions of the product and packaging are crucial. Ensure that the packaging looks just as appealing in photos as it does in person.

Social Media & Influencer Marketing: Use Instagram, TikTok, and other platforms to show off your product’s beautiful packaging. Social media can be a great way to engage with customers and generate buzz around your launch.

Pro Tip: Make your product “Instagrammable.” Beautifully designed packaging encourages consumers to share photos online, which can give your brand valuable exposure.

Conclusion: The Art and Science of Product Packaging

Creating great product packaging is an intricate process that requires balancing creativity, functionality, and sustainability. From defining your brand and target audience to choosing the right materials, designing the package, testing it, and finally getting it on the shelf, each step plays a crucial role in the success of your product.

By following this step-by-step process, you’ll be able to create packaging that not only protects your product but also communicates your brand’s story, catches the eye of your target audience, and increases the likelihood of a successful product launch. Whether you’re a startup or an established brand, investing in great product packaging is an investment in your product’s future.

#ProductPackaging#PackagingDesign#PackagingProcess#DesignToShelf#PackagingInnovation#BrandPackaging#PackagingDevelopment

0 notes

Text

Enhance your blanket packaging process with our double-stage ring blower's controlled airflow, and pack each blanket perfectly every time.

🌐 www.yashblower.com ☎️ +91 9971006400

#ringblowers#AirBlower#doublestageringblowers#Engineering#YashBlowers#blanketpackaging#airflow#indusrtialequipment#manufacturer#industrialairblowers#PackagingProcess

0 notes

Text

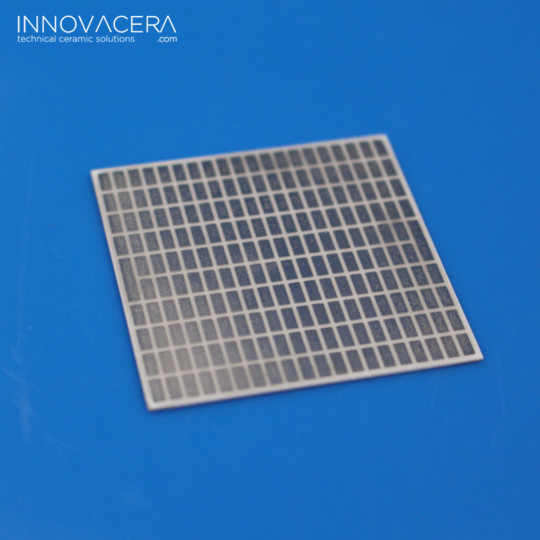

Advantages Of AlN Ceramic Materials Used As Copper Clad Substrate Materials

At present, high-performance aluminum nitride ceramic plates are used as thermal conductive substrates in advanced packaging processes, and copper is directly bonded on aluminum nitride to further design circuits, surface mount transistors, and power diodes. Due to its good thermal and electrical properties, AlN has gradually become the preferred material for this type of substrate design and can be used as insulating substrates for high-power devices, heat dissipation substrates for VLSI and packaging substrates, etc.

Advantages Of AlN Ceramic Materials Used As Copper Clad Substrate Materials Aluminum nitride copper-clad laminate has the thermal conductivity and mechanical strength of aluminum nitride, as well as the thermal conductivity and electrical conductivity of copper, so it has great application potential in the aerospace field. In addition, the "copper-aluminum nitride-copper" sandwich structure can play a key role in the modularization and integration of electronic systems, serving as mechanical support, electrical isolation, and heat dissipation paths for power modules. It is worth noting that in the application of aluminum nitride copper clad laminate, the interface bonding between AlN and Cu is very important, and the interface phase determines the bonding force between the ceramic and the metal copper layer. The conventional preparation process of aluminum nitride copper-clad laminate includes the hot pressing method and the direct copper cladding method (DBC). The hot pressing method requires sputtering a metal layer on the surface of AlN by magnetron sputtering and then introducing copper sheets for hot pressing. The DBC method requires pre-oxidation of AlN ceramics and Cu sheets, and then heat treatment to bond. The peel strength of the substrate prepared by the DBC method is about 4 times that of the hot pressing method, and Cu and AlN can form a stronger bonding force, which has better application prospects in the aerospace field with harsh service environments. Read the full article

0 notes

Photo

S is for Sunday 💙💙💙 a dusty pink S alphabet case heading out to a customer in Norway 💗💕 I’m always popping little freebie stickers into orders, these blue & white circular ones are so pretty 🔹🔹🔹 #packaging #onmydesk #packagingprocess #riannaphillips #whiteandblue #branding #fashionbrand #independantbrand #shopsmall #iphonecase #samsungcase #iphone6case #iphone7case #iphone8plus #iphone8case #monogram #personalised #monogramitall #minimalstyle #samsunggalaxys7case #samsunggalaxys6 #dustypink #colourpop #shopsmall #sunday #sundayvibes #iphonexcase #iphonesecase

#sundayvibes#iphonecase#sunday#iphonesecase#branding#iphone8case#monogramitall#iphonexcase#samsunggalaxys6#iphone7case#samsunggalaxys7case#packaging#independantbrand#iphone6case#onmydesk#personalised#minimalstyle#fashionbrand#whiteandblue#shopsmall#dustypink#monogram#iphone8plus#packagingprocess#riannaphillips#colourpop#samsungcase

2 notes

·

View notes