#Piezoelectric Sensors Market

Text

Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitor’s analysis and a detailed overview of the global Piezoelectric sensors market in terms of market segmentation by sensor type, vibration mode, type, end user, and by region

Request Report Sample@

High Resistance to Rigid Conditions to Promote Global Market Share of Piezoelectric Sensors Market

The global piezoelectric sensors market is estimated to grow majorly on account of increased use of aircrafts, as piezoelectric sensors are used for a wide range of functions in the aeronautics sector. Piezoelectric sensors grew in demand on the account of growth coming from aeronautics sector owing to its huge range of functions in aircrafts, including their measurement capacity & accuracy. There is a constant demand of piezo accelerometers, flow meters, gyroscopes and level sensors in the aeronautics sector. Restructuring of various products, such as APC International’s APC 840/841 and 880 are proprietary hard ceramics piezoelectric material which is made from a formula of high purity lead zirconate titanate, it is used for the production of high-power actuators, high frequency transducer and ultrasonic cleaners.

Growth Drivers:

Increasing demand of piezoelectric sensors in the automobile industry as it used for manufacturing sensors for deployment of airbags.

High Utilization in healthcare sector due to its high precision and sensitivity.

Challenges:

The high cost of specialized materials like lead zirconate titanate which is a ceramic perovskite material used for making piezoelectric sensors. The high cost of the material can be attributed to the low availability of raw material due to the demand and supply disruption and factors including measures approved by policymakers. In addition to that the high cost of designing instruments and installing devices with piezoelectric sensors may be very expensive for limited. Making it very difficult for manufacturers to compete on price and especially in manufacturing cost efficient applications. Hence, these are the factors credited to restraint the market growth of piezoelectric sensors market in the forecast period.

By end user, the piezoelectric sensors global market is segmented into healthcare, IT & telecom, defense & aerospace, industrial manufacturing, automotive, oil & gas. The healthcare segment is to garner a highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. The segment growth is attributed to the inflated use of piezoelectric sensors in various healthcare application, such as ultrasonic scalers for the removal of plaque using dental scales scanners and for medical imaging, ultrasonic surgery instruments. Furthermore, piezoelectric sensors have a robotic surgery equipment. According to major market surveys between 2012 and 2022 the rate of robotics surgery globally grew by 1.8% to 21.5%.

By region, the European market is to generate the ample revenue by the end of 2036. This growth is anticipated by the growing demand in piezoelectric devices in various industries which include automotive, aerospace, medical and industrial in region. The regional automotive industry driven by countries like Germany and U.K. are attributing to major share in the market with the addition of piezoelectric sensors in electric vehicles. The electric car battery can be charged by the electricity generated by the piezoelectric transduction device. According to European Environment Agency electric vehicles accounted for 12.2% of total new car registration in 2002.

Access our detailed report at:

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

The Global market for piezoelectric MEMS sensor is forecast to reach $1.9 billion by 2026, growing at a CAGR of 4.5% from 2021 to 2026. The market growth is attributed to its growing applications along verticals including consumer electronics, automotive, healthcare, telecommunication, aerospace, oil& gas and others.

#Piezoelectric MEMS Sensor Market#Piezoelectric MEMS Sensor Market share#Piezoelectric MEMS Sensor Market size

0 notes

Text

0 notes

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing

As one of the foremost quartz powder manufacturers, Sudarshan Group has a proven track record of providing high-quality quartz products to clients across various industries. Established with a mission to supply premium-grade minerals, Sudarshan has become a trusted name in the field of industrial minerals, especially quartz powder.

Commitment to Quality

Sudarshan Group prides itself on delivering quartz powder that meets the highest standards of purity and consistency. The company uses state-of-the-art technology in its mining and processing operations to ensure that the final product is free from impurities and has the desired particle size distribution. This commitment to quality is what sets it apart from other manufacturers.

The company also adheres to strict quality control measures throughout the production process, ensuring that every batch of quartz powder meets the specifications required by its clients. Whether it’s for glass manufacturing, electronics, or construction, Sudarshan quartz powder is designed to meet the demanding requirements of various industries.

Conclusion

Quartz powder is a versatile and essential material in a wide range of industries, from glass manufacturing to electronics and construction. As demand for high-quality quartz products continues to grow, manufacturers like Sudarshan Group play a crucial role in meeting this need. With a commitment to quality, sustainability, and customer satisfaction, it has earned its reputation as a leading quartz powder manufacturer. Whether you’re in the market for quartz powder for industrial or technological applications, it is a trusted partner that can deliver the products and support you need.

0 notes

Text

0 notes

Text

Kinetic Tiles Market set for growth driven by rising demand for renewable energy solutions

Kinetic tiles are floor or pavement tiles that can generate electricity from pedestrian or vehicular movement. These tiles use piezoelectricity or electromagnetic induction to convert kinetic energy from footsteps or moving vehicles into usable electricity. Kinetic tiles have gained popularity as an innovative renewable energy solution for powering small electronic devices, streetlights or sensors. The rising demand for clean and renewable energy sources along with advancements in energy harvesting technologies is driving the growth of the kinetic tiles market.

The global kinetic tiles market is estimated to be valued at US$ 32.98 billion in 2024 and is expected to exhibit a CAGR of 4.5% over the forecast period of 2024 to 2031.

Kinetic tiles offer advantages such as low maintenance, sustainable energy source and real-time data collection. They can power devices in applications such as smart cities, public parks, airports, commercial buildings and vehicles parking areas. The addressable market is growing due to supportive government policies and initiatives promoting renewable energy adoption around the world.

Key Takeaways

Key players operating in the kinetic tiles market are Pavegen Systems Ltd., Energy Floors, POWERleap Inc., Engoplanet Energy Solutions LLC, Kinergypower, Swisstrax Corporation, Kinetic Vision, TTMOW, Interactive Institute Swedish ICT, Solar Roadways, Smart Energy Floor, EnGoPlanet, Green Energy & Environment Co., Solektra International, Studio Roosegaarde, Global Energy Harvest Co., ECO RENEWABLE ENERGY, Shaw Industries Group, Inc., Clean Energy Collective, and Wiivv Wearables.

The key opportunities in the Kinetic Tiles Market Growth include developing advanced energy harvesting technologies, integrating kinetic tiles into smart city infrastructure and expanding installation in high footfall commercial buildings and public places. Many companies are focusing on global expansion through partnerships and pursuing large-scale pilot projects to showcase the technology's potential.

The global expansion of the kinetic tiles market is supported by various government initiatives for promoting renewable energy adoption. Countries across Europe, North America, Asia Pacific and Middle East are actively supporting the commercialization of renewable pavement technologies. Standardization of kinetic tiles and long-term performance data will further accelerate the global penetration of these innovative energy solutions.

Market Drivers

The major driver boosting the kinetic tiles market is the increasing demand for sustainable and renewable energy sources. Solar and wind energy have limitations and kinetic tiles provide a scalable alternative to harness clean energy from human movement. Growing investments to develop smart and Eco-friendly infrastructure is another key factor driving the Kinetic Tiles Market Size and Trends. Supportive government policies and regulations providing incentives for renewable projects have encouraged wider adoption of kinetic tiles. With advances in piezoelectric materials and micro-energy harvesting technologies, the market is expected to witness high growth over the forecast period.

PEST Analysis:

Political: Regulations supporting renewable energy sources and green construction are driving the adoption of kinetic tiles. Governments are promoting their use through incentives and mandates to reduce energy consumption from non-renewable sources.

Economic: High initial costs are a barrier for widespread uptake of kinetic tiles. However, energy savings over the lifetime and incentives offset the premium over traditional materials. Commercial applications have stronger business cases than residential.

Social: Greater environmental awareness is increasing acceptance of kinetic tiles despite the premium. Their ability to power devices and digital interfaces through motion enhances the user experience in public places.

Technological: Advances are improving the energy conversion efficiency and durability of kinetic tiles. Embedded sensors and new materials allow them to generate electricity from smaller and more complex movements. Connectivity enables remote monitoring and integration into smart building systems.

Asia Pacific currently accounts for the largest share of the global kinetic tiles market in terms of value. Factors driving adoption in the region include rapid urbanization, development of smart cities, government incentives for renewable technologies, and strong construction industries. North America is also expanding at a rapid pace due to commercial and infrastructural investments prioritizing energy efficiency and sustainability.

Europe has the highest installed base currently due to early commercialization of kinetic tiles. However, growth rates are slowing as uptake becomes widespread in major markets. On the other hand, Latin America and Middle East & Africa are poised to emerge as the fastest growing regional markets over the forecast period backed by robust economic development and efforts to modernize infrastructure across these regions. But their current shares remain relatively low compared to established markets.

Get more insights on Kinetic Tiles Market

For Deeper Insights, Find the Report in the Language that You want

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Coherent Market Insights#Kinetic Tiles Market#Kinetic Tiles#Smart Flooring#Kinetic Energy#Sustainable Technology#Green Energy#Power Generation#Piezoelectric Tiles

0 notes

Text

Global Piezoelectric Devices Market

The Global Piezoelectric Devices Market is anticipated to grow from USD 33.2 billion in 2023 to USD 53 billion in 2030 at a CAGR of 7.4% during the forecast period from 2025 to 2030.

Explore more-https://www.vynzresearch.com/ict-media/piezoelectric-devices-market/request-sample

Key drivers of this market include the push for miniaturization of devices, the need for energy-efficient and reliable sensors, and advancements in piezoelectric materials like ceramics and composites. These materials are crucial due to their high piezoelectric constants and electromechanical coupling coefficients, which make them ideal for applications in sensors, actuators, and transducers.

Major players of Piezoelectric Devices Market are CeramTec GmbH (Germany), Physik Instrumente (PI) GmbH & Co. KG. (Germany), CTS Corporation (US), Kistler Group (Switzerland), piezosystem jena GmbH (Germany), Aerotech Inc. (US), APC International, Ltd., (US), Piezo Technologies (US), Mad City Labs, Inc. (US).

VynZ Research

9960288381

0 notes

Text

Fibroïne de soie (SF), Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 10 Premières Entreprises

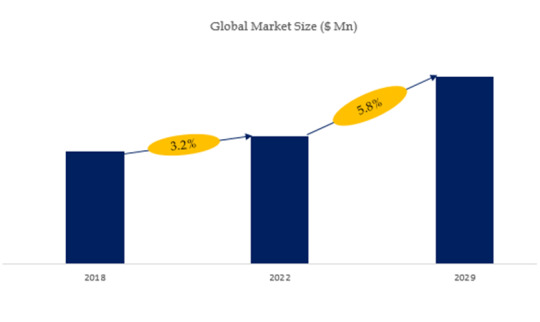

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Fibroïne de soie (SF) 2024-2030”, publié par QYResearch, la taille du marché mondial de Fibroïne de soie (SF) devrait atteindre 47 millions de dollars d'ici 2030, à un TCAC de 6.2% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Fibroïne de soie (SF) (en millions de dollars américains), 2019-2030

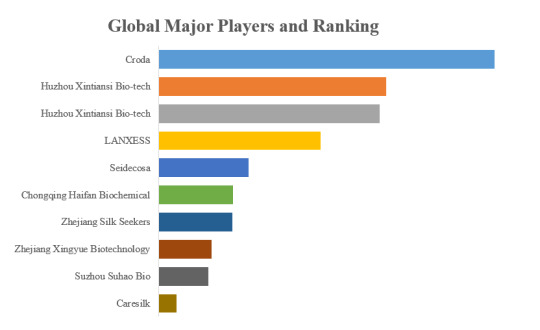

Selon QYResearch, les principaux fabricants mondiaux de Fibroïne de soie (SF) comprennent Croda, Huzhou Xintiansi Bio-tech, etc. En 2023, les trois premiers acteurs mondiaux détenaient une part d'environ 43.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 10 premiers acteurs mondiaux de Fibroïne de soie (SF) (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The key market drivers for the Silk Fibroin (SF) market:

1. Growing Demand for Sustainable and Biodegradable Materials: The increasing focus on environmental sustainability and the shift towards eco-friendly materials have driven the demand for silk fibroin, a natural and biodegradable polymer.

2. Expansion of the Biomedical and Pharmaceutical Industries: The use of silk fibroin in various biomedical and pharmaceutical applications, such as drug delivery systems, tissue engineering, and wound dressings, has been a significant market driver.

3. Rising Adoption in the Cosmetics and Personal Care Sector: The incorporation of silk fibroin in cosmetic and personal care products, due to its exceptional moisturizing, anti-aging, and skin-soothing properties, has contributed to the market's growth.

4. Increasing Demand for High-Performance Textiles and Apparel: The unique properties of silk fibroin, including its strength, softness, and moisture-wicking capabilities, have led to its widespread use in the textiles and apparel industry.

5. Advancements in Silk Fibroin Extraction and Purification Techniques: Improvements in silk fibroin extraction and purification processes have made these materials more accessible and cost-effective, driving their adoption across various industries.

6. Growing Interest in Natural and Luxury Products: The increasing consumer preference for natural and luxury products has fueled the demand for silk fibroin, which is often associated with high-end and premium offerings.

7. Expansion of the Automotive and Transportation Sector: The use of silk fibroin in automotive and transportation applications, such as in interior components and composite materials, has been a market driver.

8. Increasing Adoption in the Electronics and Sensor Industry: The unique properties of silk fibroin, including its flexibility, biocompatibility, and piezoelectric characteristics, have led to its adoption in various electronic and sensor applications.

9. Rising Demand for Innovative and Functional Biomaterials: The growing interest in novel and functional biomaterials, such as silk fibroin, for a wide range of applications has been a key market driver.

10. Supportive Regulatory Frameworks and Initiatives: Favorable regulatory frameworks and government initiatives promoting the use of sustainable and renewable materials have contributed to the growth of the silk fibroin market.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

A piezoelectric sensor is a device that uses the piezoelectric effect, to measure variations in pressure, acceleration, temperature, strain, or force by translating them to an electrical charge

0 notes

Text

Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitor’s analysis and a detailed overview of the global Piezoelectric sensors market in terms of market segmentation by sensor type, vibration mode, type, end user, and by region

Request Report Sample@

High Resistance to Rigid Conditions to Promote Global Market Share of Piezoelectric Sensors Market

The global piezoelectric sensors market is estimated to grow majorly on account of increased use of aircrafts, as piezoelectric sensors are used for a wide range of functions in the aeronautics sector. Piezoelectric sensors grew in demand on the account of growth coming from aeronautics sector owing to its huge range of functions in aircrafts, including their measurement capacity & accuracy. There is a constant demand of piezo accelerometers, flow meters, gyroscopes and level sensors in the aeronautics sector. Restructuring of various products, such as APC International’s APC 840/841 and 880 are proprietary hard ceramics piezoelectric material which is made from a formula of high purity lead zirconate titanate, it is used for the production of high-power actuators, high frequency transducer and ultrasonic cleaners.

Growth Drivers:

Increasing demand of piezoelectric sensors in the automobile industry as it used for manufacturing sensors for deployment of airbags.

High Utilization in healthcare sector due to its high precision and sensitivity.

Challenges:

The high cost of specialized materials like lead zirconate titanate which is a ceramic perovskite material used for making piezoelectric sensors. The high cost of the material can be attributed to the low availability of raw material due to the demand and supply disruption and factors including measures approved by policymakers. In addition to that the high cost of designing instruments and installing devices with piezoelectric sensors may be very expensive for limited. Making it very difficult for manufacturers to compete on price and especially in manufacturing cost efficient applications. Hence, these are the factors credited to restraint the market growth of piezoelectric sensors market in the forecast period.

By end user, the piezoelectric sensors global market is segmented into healthcare, IT & telecom, defense & aerospace, industrial manufacturing, automotive, oil & gas. The healthcare segment is to garner a highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. The segment growth is attributed to the inflated use of piezoelectric sensors in various healthcare application, such as ultrasonic scalers for the removal of plaque using dental scales scanners and for medical imaging, ultrasonic surgery instruments. Furthermore, piezoelectric sensors have a robotic surgery equipment. According to major market surveys between 2012 and 2022 the rate of robotics surgery globally grew by 1.8% to 21.5%.

By region, the European market is to generate the ample revenue by the end of 2036. This growth is anticipated by the growing demand in piezoelectric devices in various industries which include automotive, aerospace, medical and industrial in region. The regional automotive industry driven by countries like Germany and U.K. are attributing to major share in the market with the addition of piezoelectric sensors in electric vehicles. The electric car battery can be charged by the electricity generated by the piezoelectric transduction device. According to European Environment Agency electric vehicles accounted for 12.2% of total new car registration in 2002.

Access our detailed report at:

0 notes

Text

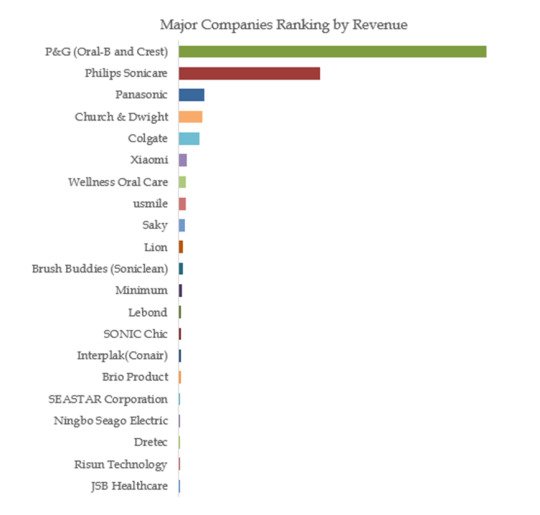

Global Top 5 Companies Accounted for 82% of total Electric Toothbrush market (QYResearch, 2021)

This report studies the Electric Toothbrush market, An electric toothbrush is a toothbrush that makes rapid, automatic bristle motions, either back-and-forth oscillation or rotation-oscillation (where the brush head alternates clockwise and counterclockwise rotation), in order to clean teeth. Motions at sonic speeds or below are made by a motor. In the case of ultrasonic toothbrushes, ultrasonic motions are produced by a piezoelectric crystal. A modern electric toothbrush is usually powered by a rechargeable battery charged through inductive charging when the brush sits in the charging base between uses.

Based on our recent survey, we have several different scenarios about the Electric Toothbrush YoY growth rate for 2020. The probable scenario is expected to decline by a -4.8% in 2020 and the revenue will be 1550 in 2020 from US$ 1628 million in 2019. The market size of Electric Toothbrush will reach US$ 2181 in 2026, with a CAGR of 5.7% from 2021 to 2026.

The data for 2020 is an estimate, based on the historical data and recent survey of the integrated view of industrial experts, manufacturers, distributors and end users, etc.

Top-down and bottom-up approaches are used to validate the global Electric Toothbrush market size and to estimate the market size for company, regional division, product type and application (end users). In the complete market engineering process, both top-down and bottom-up approaches along with several data triangulation methods have been extensively utilized to perform market estimation and market forecast for the overall market division and subdivision listed in this report. Extensive qualitative and further quantitative analysis has also been done from all the numbers arrived at in the complete market engineering process to list key information throughout the report.

According to the new market research report “Global Electric Toothbrush Market Report 2023-2029”, published by QYResearch, the global Electric Toothbrush market size is projected to reach USD 2.57 billion by 2029, at a CAGR of 5.8% during the forecast period.

Figure. Global Electric Toothbrush Market Size (US$ Million), 2018-2029

Figure. Global Electric Toothbrush Top 5 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Electric Toothbrush include P&G (Oral-B and Crest), Philips Sonicare, Panasonic, Church & Dwight, Colgate, Xiaomi, Wellness Oral Care, usmile, Saky, Lion, etc. In 2021, the global top five players had a share approximately 82.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Polyvinylidene Fluoride (PVDF) Market Report: Trends, Analysis, and Projections

Polyvinylidene Fluoride (PVDF) is a high-performance thermoplastic known for its exceptional chemical resistance, mechanical strength, and thermal stability, finding diverse applications across industries. This blog delves into the dynamics of the global PVDF market, analyzing key drivers, applications, emerging trends, and future growth prospects.

Understanding the PVDF Market:

Polyvinylidene Fluoride (PVDF) Is a fluoropolymer derived from vinylidene fluoride monomers. Its outstanding properties include resistance to chemicals, UV radiation, high temperatures, and flame retardancy, making it suitable for demanding applications in aerospace, construction, electronics, chemical processing, and renewable energy sectors.

Market Dynamics:

Aerospace and Defense: PVDF is utilized in aerospace applications such as aircraft components, fuel lines, membranes, and coatings due to its lightweight nature, corrosion resistance, and ability to withstand harsh environments.

Building and Construction: In the construction industry, PVDF coatings are applied to architectural surfaces, roofing materials, and façade panels for weather resistance, color retention, and durability against UV radiation and pollutants.

Electronics and Semiconductor: PVDF films and components are used in electronics for capacitors, sensors, piezoelectric devices, lithium-ion batteries, and photovoltaic films, leveraging its dielectric properties and thermal stability.

Chemical Processing: PVDF pipes, fittings, and linings are employed in chemical processing plants for their resistance to acids, alkalis, solvents, and high temperatures, ensuring reliability and longevity in corrosive environments.

Applications Across Industries:

Aerospace: Aircraft components, fuel lines, coatings.

Construction: Coatings, roofing materials, façade panels.

Electronics: Films, capacitors, sensors, lithium-ion batteries.

Chemical Processing: Pipes, fittings, linings for corrosive environments.

Market Trends:

Growing Demand for Specialty PVDF Grades: Increasing demand for PVDF grades with enhanced properties such as high purity, low extractables, conductivity, or specific color options to meet diverse industry requirements in electronics, healthcare, and specialty applications.

Focus on Sustainable Coatings: Adoption of PVDF coatings in architectural, automotive, and industrial applications due to their durability, weather resistance, and low maintenance requirements, aligning with sustainability goals and regulatory standards.

Advancements in PVDF Processing: Innovations in PVDF compounding, extrusion, and molding techniques to improve processing efficiency, reduce costs, and expand application possibilities in emerging sectors such as renewable energy and medical devices.

Future Prospects:

The global PVDF market is poised for substantial growth driven by technological advancements, increasing adoption across industries, and sustainability considerations. Investments in R&D, material innovations, and application diversification will play a key role in shaping the market's evolution and competitiveness.

Conclusion:

Polyvinylidene Fluoride (PVDF) stands as a versatile and high-performance material with critical applications across aerospace, construction, electronics, and chemical industries. Understanding market trends, technological innovations, and sustainability imperatives is vital for stakeholders in the PVDF market to harness growth opportunities effectively. With a focus on specialty grades, sustainable coatings, and process enhancements, the PVDF market presents promising avenues for continued innovation and market expansion in the global polymer industry landscape.

0 notes

Text

0 notes

Text

Tracking Down the Evolution and Impact of Inkjet Printing Technology

https://gqresearch.com/wp-content/uploads/2024/03/3.-Tracking-Down-the-Evolution-and-Impact-of-Inkjet-Printing-Technology.jpg

Inkjet printing has revolutionized the way we produce documents, images, and graphics, offering a versatile and efficient solution for various printing needs. From home offices to industrial settings, inkjet printers have become ubiquitous tools for creating high-quality prints with precision and speed. In this article, we will delve into the evolution, applications, advantages, and advancements of inkjet printing (IP)technology, as well as its potential future developments.

Evolution of Technology:

The origins of IP can be traced back to the 1950s when researchers began exploring methods of creating digital prints using droplets of ink. Early inkjet printers relied on analog technologies and piezoelectric or thermal printheads to eject ink onto paper, fabric, or other substrates. These early prototypes laid the foundation for the development of modern IP technology.

In the 1980s and 1990s, inkjet printing underwent significant advancements, with the introduction of desktop inkjet printers for home and office use. These printers offered improved print quality, faster printing speeds, and more affordable consumables, making them accessible to a broader range of users. Concurrently, industrial IP systems emerged, enabling large-scale printing for applications such as signage, packaging, and textile printing.

Applications of Inkjet Printing:

IP technology finds widespread applications across various industries and sectors, including:

Graphic Arts and Publishing: Inkjet printers are widely used for producing high-quality prints for magazines, brochures, posters, and other marketing materials. The ability to achieve vibrant colors, sharp images, and precise text makes IP ideal for graphic arts and publishing applications.

Textile Printing: Digital textile printing using inkjet technology has transformed the textile industry, allowing for the customization of fabrics, garments, and home textiles with intricate designs, patterns, and colors. Inkjet printers equipped with specialized textile inks enable on-demand printing, short production runs, and rapid prototyping in the textile manufacturing process.

Packaging and Labeling: Inkjet printing is widely employed in the packaging industry for printing labels, tags, and packaging materials. The flexibility of inkjet technology allows for the customization of packaging designs, serialization, and variable data printing, catering to the diverse needs of product branding and marketing.

3D Printing: Inkjet-based 3D printing, also known as binder jetting, utilizes inkjet printheads to selectively deposit binding agents onto powder substrates, layer by layer, to create three-dimensional objects. This additive manufacturing process is used in prototyping, rapid manufacturing, and production of complex geometries in industries such as aerospace, automotive, and healthcare.

Functional Printing: Inkjet printing technology is increasingly being used for functional printing applications, including printed electronics, conductive patterns, sensors, and biomedical devices. Inkjet-printed circuits, sensors, and electrodes offer cost-effective solutions for flexible electronics, wearable devices, and point-of-care diagnostics.

Advantages of Inkjet Printing:

https://gqresearch.com/wp-content/uploads/2024/03/3.2.-Advantages-of-Inkjet-Printing.jpg

It offers several advantages over traditional printing methods, including:

High-Quality Prints: Inkjet printers produce high-resolution prints with sharp text, smooth gradients, and accurate color reproduction, making them suitable for applications that demand exceptional print quality.

Versatility: Inkjet printers can handle a wide range of substrates, including paper, fabric, plastics, ceramics, and metals, allowing for diverse printing applications across different industries and materials.

Cost-Effectiveness: It offers cost-effective solutions for short print runs, on-demand printing, and variable data printing, eliminating the need for costly setup fees and plate changes associated with traditional printing methods.

Environmentally Friendly: It generates minimal waste, as it does not require printing plates or chemical processes typical of offset printing. Furthermore, inkjet printers consume less energy and produce fewer emissions compared to other printing technologies.

Customization and Personalization: It enables customization and personalization of prints, allowing for the creation of unique designs, variable data printing, and mass customization to meet individual preferences and market demands.

Advancements in Technology:

Recent advancements in printing technology have further expanded its capabilities and applications. Some notable developments include:

UV-Curable Inks: UV-curable inkjet inks offer enhanced adhesion, durability, and environmental resistance, making them suitable for outdoor signage, packaging, and industrial applications requiring long-lasting prints on challenging substrates.

Digital Textile Printing: Advances in digital textile printing technology have led to the development of high-speed, high-resolution inkjet printers capable of printing on a wide range of fabrics with vibrant colors and intricate patterns, transforming the textile printing industry.

Functional Inks: The development of functional inks for printing has enabled the fabrication of electronic circuits, sensors, and biomedical devices using additive manufacturing techniques, opening up new possibilities in flexible electronics, wearable technology, and healthcare applications.

3D Printing with Inkjet Technology: Inkjet-based 3D printing systems continue to evolve, offering faster print speeds, larger build volumes, and improved material compatibility for producing complex, multi-material 3D printed parts with high accuracy and resolution.

Digital Packaging Printing: Printing technology is increasingly being adopted for digital packaging printing applications, enabling on-demand production of customized packaging with variable data printing, serialization, and brand protection features.

Future Directions in Technology:

Looking ahead, inkjet printing technology is poised to continue evolving and advancing, driven by ongoing research and development efforts in various fields. Some future directions and potential developments in inkjet printing include:

Nanoparticle Inks: The development of nanoparticle-based inks holds promise for enhancing the performance and functionality of inkjet-printed materials. Nanoparticle inks with tailored properties, such as conductivity, magnetism, or optical properties, could enable new applications in electronics, sensors, and advanced materials.

Bioprinting and Tissue Engineering: Inkjet-based bioprinting technologies are being explored for the precise deposition of living cells and biomaterials to fabricate tissues, organs, and biomedical implants. Advances in biocompatible inks, printhead technology, and tissue engineering techniques could revolutionize regenerative medicine and personalized healthcare.

Additive Manufacturing Integration: Inkjet printing technology is being integrated into additive manufacturing processes, such as selective laser sintering and stereolithography, to enhance material deposition, surface finish, and part quality. Inkjet-based additive manufacturing systems could enable the production of complex, multi-material components with high resolution and accuracy.

Sustainable Printing Solutions: With increasing emphasis on sustainability and environmental stewardship, printing technologies are being developed with eco-friendly inks, recyclable substrates, and energy-efficient printing processes. Green printing initiatives aim to minimize waste, reduce energy consumption, and lower carbon emissions associated with printing operations.

Smart Printing Systems: Inkjet printers equipped with sensors, artificial intelligence, and internet-of-things (IoT) connectivity enable smart printing systems capable of self-monitoring, predictive maintenance, and real-time optimization. Smart inkjet printing solutions streamline workflow, improve productivity, and enhance user experience in various printing applications.

Conclusion:

Printing technology has undergone remarkable evolution and transformation since its inception, revolutionizing the printing industry and enabling new applications across various sectors. From high-quality graphics and textiles to functional electronics and 3D printing, inkjet technology continues to push the boundaries of what is possible in printing and manufacturing. With ongoing advancements in materials, printhead technology, and digital workflow solutions, the future of inkjet printing holds promise for even greater innovation, efficiency, and customization in printing and fabrication processes.

0 notes

Text

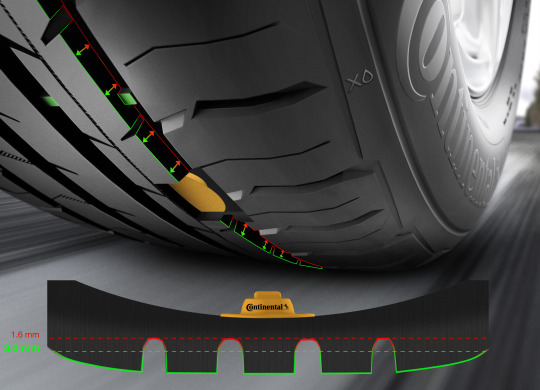

Global Automotive Tire Tread Sensors Market Size, Share, & Growth report 2032

The Global Automotive Tire Tread Sensors Market size was estimated at USD XX billion in 2021 and is expected to hit around USD XX billion by 2030, poised to grow at a compound annual growth rate (CAGR) of XX% from 2022 to 2030.

Global Automotive Tire Tread Sensors Market: Breakup by Region, 2022 & 2031

The Automotive Tire Tread Sensors market refers to the segment of the automotive industry that produces and sells sensors designed to measure the tread depth and other characteristics of vehicle tires. These sensors are typically embedded within the tires or integrated with the wheels and are used to monitor tire wear, detect tire damage, and provide information about tire pressure and temperature. The market for these sensors is driven by increasing safety concerns, government regulations, and the need for improved fuel efficiency in vehicles. Automotive tire tread sensors are primarily used in passenger cars, commercial vehicles, and off-highway vehicles such as construction equipment and mining trucks.

Full Report Access: https://organicmarketresearch.com/automotive-tire-tread-sensors-market

The global market scenario for various industries is shaped by a multitude of market drivers. Some of the key drivers that impact the global market include technological advancements, changing consumer preferences and lifestyles, increasing urbanization, growing population, and rising disposable income. Additionally, government regulations and policies, international trade agreements, and geopolitical factors can also influence the global market. In recent years, concerns around sustainability and environmental protection have also become important drivers for market growth, as consumers and businesses increasingly prioritize eco-friendly products and practices. The COVID-19 pandemic has also had a significant impact on the global market, leading to shifts in consumer behavior and changes in supply chain dynamics.

Download Free Sample Report

The global market scenario is characterized by a variety of market trends that are shaping industries across the world. One key trend is the growing adoption of digital technologies, such as artificial intelligence, big data analytics, and the Internet of Things, which are transforming businesses and enabling new opportunities for growth and innovation. Another trend is the increasing focus on sustainability and environmental responsibility, with consumers and businesses seeking out products and services that are eco-friendly and socially responsible.

Market Segmentation:

Market Breakup: By Technology

RFID (Radio Frequency Identification)

Pressure-Based

Piezoelectric Sensors

Market Breakup: By Type

Indirect And Direct Tire Pressure

Monitoring Systems (TPMS)

Tread Wear Indicators

Market Breakup: By Vehicle Type

Passenger Cars

Commercial Vehicles

Off-Highway Vehicles

Regional Analysis

The size and scope of the global Automotive Tire Tread Sensors Market vary by region and are important and expanding. Below is a quick summary of the industry’s regional analysis:

North America is a mature market for Automotive Tire Tread Sensors, with a high adoption rate of advanced automotive technologies. The presence of major automotive manufacturers and strict government regulations regarding vehicle safety are key drivers for market growth in the region.

Europe is another mature market, with a high demand for advanced safety features in vehicles. The region has strict regulations regarding vehicle safety and emissions, which is driving the adoption of Automotive Tire Tread Sensors.

Asia-Pacific is a rapidly growing market for Automotive Tire Tread Sensors, due to the increasing demand for passenger and commercial vehicles, particularly in countries such as China and India. The region has a large automotive industry and is home to some of the major tire manufacturers, which is fueling the demand for Automotive Tire Tread Sensors.

South America has a growing demand for Automotive Tire Tread Sensors, due to the increasing adoption of advanced automotive technologies and government regulations regarding vehicle safety. Brazil is the largest market in the region.

The Middle East & Africa region has a relatively small market for Automotive Tire Tread Sensors, but is expected to grow due to increasing demand for advanced automotive technologies and government initiatives to improve road safety. The region has a growing automotive industry and increasing urbanization, which is driving the demand for Automotive Tire Tread Sensors.

Market Breakup by Region

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Competitive Landscape

The Automotive Tire Tread Sensors Market competitive landscape provides details by competitor. Details included are company outline, company financials, revenue generated, market potential, investment in research and development, new market initiatives, worldwide occurrence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The overhead data points providing are only related to the businesses’ focus related to Automotive Tire Tread Sensors marketplace.

Market Size:

As of [current year], the Global Automotive Tire Tread Sensors Market has witnessed substantial growth, with a market size estimated at [provide statistics]. The increasing emphasis on vehicle safety, along with the integration of smart technologies in automobiles, has fueled the demand for tire tread sensors globally. With automotive manufacturers and consumers alike recognizing the importance of real-time tire monitoring, the market is poised for further expansion.

Growth Drivers:

Safety Takes the Driver’s Seat: The primary catalyst propelling the growth of tire tread sensors is the heightened focus on road safety. These sensors provide real-time data on tire conditions, enabling drivers to take proactive measures before potential issues arise. With safety standards becoming more stringent worldwide, the integration of tire tread sensors has become a necessity rather than a luxury.

Smart Mobility Solutions: The era of smart mobility has dawned upon the automotive industry, and tire tread sensors play a pivotal role in this transformation. These sensors contribute to the development of connected vehicles, offering valuable insights into tire health, optimizing fuel efficiency, and enhancing overall vehicle performance. As the automotive landscape embraces connectivity, the demand for tire tread sensors is expected to surge.

Fuel Efficiency and Environmental Concerns: In a world increasingly conscious of environmental impact, automotive manufacturers are seeking ways to enhance fuel efficiency. Tire tread sensors aid in maintaining optimal tire pressure and tread depth, directly influencing fuel economy. This green initiative aligns with global efforts to reduce carbon emissions and create a more sustainable future.

Trends Steering the Market:

Integration with IoT and AI: The integration of tire tread sensors with Internet of Things (IoT) and Artificial Intelligence (AI) technologies is a notable trend. This combination allows for predictive maintenance, as sensors can analyze data patterns and predict potential tire issues before they become critical. This predictive approach enhances vehicle safety and reduces unexpected breakdowns.

OEMs Leading the Charge: Original Equipment Manufacturers (OEMs) are at the forefront of adopting and integrating tire tread sensor technology into their new vehicle models. This trend is driven by the desire to offer advanced safety features, stay competitive in the market, and meet evolving consumer expectations for smart and connected vehicles.

Rise of Autonomous Vehicles: The growing interest and development of autonomous vehicles further amplify the importance of tire tread sensors. In autonomous driving scenarios, where real-time data is crucial for vehicle control, these sensors contribute significantly to ensuring a safe and smooth ride.

Latest Report:

Contact Us:

Mob : +91 9319642100

Noida One Tower Sec 62 Noida 201301

Sales : [email protected]

Website : https://www.organicmarketresearch.com

0 notes