#Plastic Processing Machinery Exporter

Explore tagged Tumblr posts

Text

Invoit Plast Machinery Pvt. Ltd.

Invoit Plast Machinery Pvt. Ltd. Invoit Plast Machinery Pvt. Ltd. is Plastic processing machinery, Plastic raw materials processing machinery, Plastic waste processing machinery and Plastic scrap processing machinery manufacturer and exporter.

Invoit Plast Machinery Pvt. Ltd. is plastic processing machinery and plastic scrap processing machinery manufacturer, supplier and exporter. Invoit Plast Machinery Pvt. Ltd. is having industrial machineries manufacturing unit in Ahmedabad, Gujarat, India, supplying to Indian cities and overseas clients and exporting to South Africa, Dubai UAE, Nepal, Bangladesh and Qatar.

Invoit Plast Machinery Pvt. Ltd., Being as a much renowned business, since long we have supplied our high-quality manufactured products and furthermore also, have also exported to foreign clients. Our plastic raw materials processing machinery and plastic waste processing machinery supplies and exports are in demand because of its supreme quality.

#Plastic processing machinery#Plastic raw materials processing machinery#Plastic waste processing machinery#Plastic scrap processing machinery#manufacturer#exporter

2 notes

·

View notes

Text

Hi guys for a few days I've been brainstorming a fan zone and, besides the guardian, I have quite a lot of things planned.

I don't have a name for it, all I know is that it's cream / tan colored.

Behold, because I will go into a bit of detail.

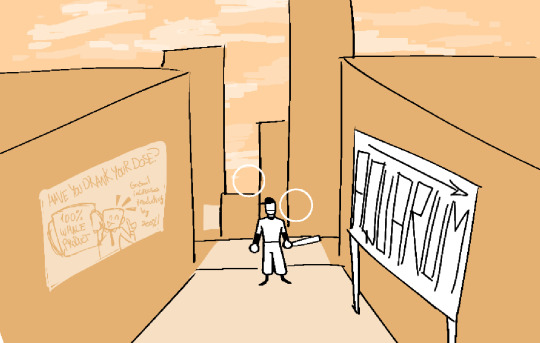

I'm still not totally sure about the architecture of the place. It's like a miniature claustrophobic city, if that makes sense. It's littered with advertisements for some sort of beverage... I wonder what it could be?

More below the cut :}

Ok so since you found this interesting enough to read more, let's directly get into the gist of it:

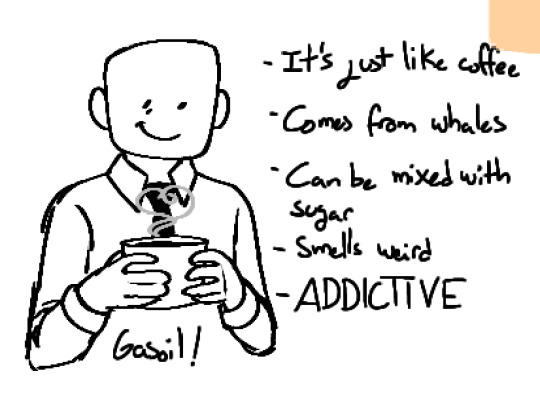

What the hell is gasoil?

Gasoil is the signature element this zone specializes in, it's their main source of income as they also ship it to other zones, either raw or processed.

When raw, it is used as fuel for machinery and electricity.

When processed, it becomes edible. The every-day beverage of every elsen!

Due to the consumption of gasoil, the elsen of this area are friendlier and extroverted, I'd imagine one of them would greet the Batter when he first steps into the place.

And yes! You read that right! It can be mixed with sugar. However, the elsen of this area are immune to sugar craving, as gasoil breaks down the addictive component of sugar, and also gets sweeter. They don't consume sugar unless with a cup of gasoil.

Gasoil also makes elsen more productive! Truly the beverage of all time, this should be sold everywhere and everyone should consume it immediately OUCH YEOCH MY ARM WHAT THE FUCK

The last bullet point of that little image was that gasoil is addictive.

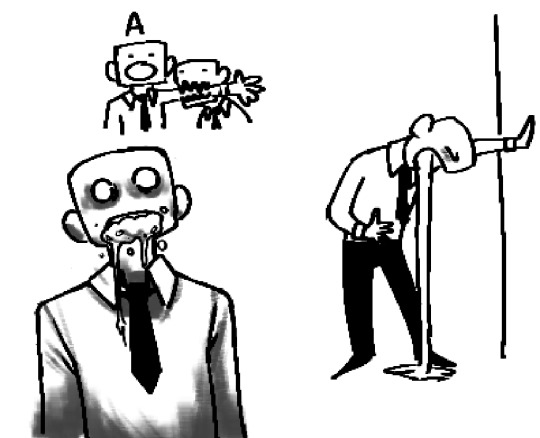

Elsen can become addicted to it due to the overconsumption of it, resulting in tachychardia, deliriums, vomiting, etc. Upon dying, these elsen immediately turn into sugar, as their insides are burning.

Rabid elsens are extremely dangerous so please don't approach one ever (thumbsup)

What's the aquarium?

Whales produce gasoil by absorbing plastic into their spiracles, to then excrete it in the form of raw gasoil. The raw gasoil is then harvested, and either sold raw or processed.

At the building known simply as "The Aquarium", it's where investigations about the beverage and whales occur. There are groups of people specialized in hunting and breeding these whales to achieve the best quality of gasoil. So far, not much progress has been made.

These seems quite insane and all

But where's the guardian?

This is where my silly drawings end because I have no idea what to do for the guardian, however I do have some other ideas:

(I love writing)

At the beginning, this guardian's plan was to bring out the potential of every man that would step on their land. Fierce like a militar, but caring like a mother. This guardian thought everyone had an ultimate version of themselves that, with a bit of digging, it could be brought out.

However, this guardian didn't really like the performance of their elsen, it saw them as too frail and dependent. With the discovery of gasoil, this guardian saw that the consumption of this beverage would make their elsen more productive in their tasks, however since it was in its raw state, the elsen would fall sick and do even worse after the effect of the beverage wore off.

This guardian then, invested their whole spirit into researching this new element, that could transform men and bring their potential out. Like this, "The Aquarium" was founded. Processed gasoil was invented, and it was perfection in a cup.

Contacting the guardians and signing agreements did really well in the economy of their zone. Zone 1 specially, as it had a lot of the components necessary for elsen to live, in exchange this zone would export gasoil (raw or processed) as well as men, since I don't think Dedan would mind a few more workers.

Zone 3's sugar became important, since it would make gasoil sweeter and friendlier for elsen with a weaker palate.

This zone was simply utopic. Every man had a job that they were comfortable with, with holidays and sick leaves and what not. With a loving guardian and the graph of the economy looking like Mt. Everest, what could possibly go wrong?

The elsen became mad when this guardian decided to put regulations on the consumption of gasoil. The massive production of it made the demand for it weaker, and the only costumers of it would be the elsen of this same area. It was still being exported to other zones though, just not in large quantities.

The guardian had noticed that its elsen were becoming addicted to it, once again dependent on something. The elsen ravaged and rebelled against their governor, wanting an explanation for the sudden cut in their diets and lives.

These manifestations would evolve into threats, and from threats to fights with the guardian. The guardian knew that if they were to answer these attacks it would get significantly worse, and also because they already had certain reputation of being really nice to their men (this would really affect the economy!). It decided to leave and exile themselves in the farthest point of the zone, reflecting on how permissive, and even uncaring, their actions were, thinking that it was their fault that their men became obsessed with it. This wasn't the way they envisioned "bringing someone's full potential out".

This is basically all I have planned lol. Also the way I see spectres in this is that the player would think that the stupid ghosts are interrupting elsen just wanting to do their work and drink their whale water. What the player wouldn't realize is that they're helping their addictions, spectres are beneficial here, and even the guardian will scold The Batter.

#ruben's art pile#OFF#OFF game#I was watching izzzyzzz's video about dog breeders#so that's how the aquarium came to mind lol

19 notes

·

View notes

Text

Corus Premium Nylon Tote Bag Manufacturer & Exporter in India

In today's fashion and lifestyle industry, tote bags have become an essential accessory for everyday use. The combination of convenience, durability, and style makes tote bags an ideal choice for both personal and professional use. Among the variety of options available in the market, Corus Premium Nylon Tote Bags have gained significant recognition for their premium quality and functionality.

About Corus Premium Nylon Tote Bags

Corus Premium Nylon Tote Bags are known for their superior construction and high-quality materials. Manufactured using high-grade nylon fabric, these bags stand out for their durability, water resistance, and lightweight design. The nylon material ensures that the bags are not only tough but also flexible, providing ample space for carrying personal items, groceries, laptops, and more.

Why Choose Corus Premium Nylon Tote Bags?

Durability: The nylon fabric used in Corus tote bags is resistant to wear and tear. It can withstand heavy use without losing its shape or functionality. This makes them perfect for daily activities, from commuting to running errands or even shopping.

Water-Resistant: Corus tote bags are designed to keep your belongings safe, even in light rain or spills. The water-resistant nature of the nylon fabric ensures that items inside the bag remain dry, protecting your electronics, books, or other essentials.

Lightweight and Comfortable: Despite their sturdy construction, Corus tote bags are remarkably lightweight. The soft and flexible nature of nylon makes the bags easy to carry, whether slung over the shoulder or held by hand. The long straps provide additional comfort, allowing you to carry heavier loads without straining.

Eco-Friendly Choice: Corus is committed to sustainability, and their premium nylon tote bags are an eco-friendly alternative to plastic bags. With reusable nylon bags, consumers can reduce their carbon footprint and contribute to the reduction of single-use plastics.

Stylish and Versatile: The sleek design and stylish look of Corus nylon tote bags make them suitable for various occasions. Whether you’re heading to work, the gym, the beach, or running errands, these bags provide both functionality and fashion.

Corus as a Leading Manufacturer and Exporter of Nylon Tote Bags in India

Corus has emerged as one of the leading manufacturers and exporters of premium nylon tote bags in India. With a strong focus on quality, design, and customer satisfaction, Corus has earned a reputation for providing top-notch products to clients across the globe. Their state-of-the-art manufacturing facility uses advanced machinery and skilled artisans to create tote bags that meet international standards.

Customization Options

One of the standout features of Corus is their ability to offer customized nylon tote bags to meet the unique requirements of their clients. Whether it's a specific size, color, logo, or design, Corus provides a wide range of customization options to suit individual preferences and business needs. This makes Corus a trusted partner for businesses looking to order promotional bags, corporate giveaways, or personalized gifts.

Quality Assurance

Corus places a strong emphasis on quality control, ensuring that every tote bag meets stringent quality standards before reaching the customer. From material selection to final packaging, each step in the production process is closely monitored to maintain the highest level of quality. This dedication to excellence ensures that every Corus tote bag is made to last, offering both style and functionality.

Global Reach and Exporting Expertise

As an exporter, Corus has a strong international presence and caters to markets across the globe. They have successfully built long-lasting relationships with clients in the United States, Europe, and other countries. With a streamlined export process, Corus ensures timely delivery and competitive pricing, making them a preferred choice for global buyers.

Conclusion

Corus Premium Nylon Tote Bags are the perfect combination of style, durability, and functionality. As a leading manufacturer and exporter in India, Corus continues to innovate and deliver top-quality products that meet the needs of consumers and businesses alike. Whether you're looking for a bag for personal use or need bulk orders for corporate giveaways, Corus offers a versatile range of nylon tote bags that will exceed your expectations.

If you're in search of a reliable and high-quality nylon tote bag manufacturer and exporter in India, Corus is your ideal partner. With their focus on quality, customer satisfaction, and sustainability, Corus has rightfully established itself as a leader in the global market for premium nylon tote bags.

Ready to make a purchase or inquire about customization?

Visit our website at Corus Bag Industries for more details, or contact us directly at +91 8586808515. We're here to help you find the perfect tote bag solution!

#Nylon Tote Bag Manufacturer#Nylon Tote Bag Manufacturer & Exporter in India#Corus Premium Nylon Tote Bags

2 notes

·

View notes

Text

A Heavy-Duty slitter rewinder machine is an integral part of converting wide rolls into smaller widths of material with high accuracy. The heavy-duty type is meant to deal with tougher materials, processing those smoothly while maintaining the best quality.

the Heavy-Duty Slitter Rewinder Cylinder Machine cuts and rewinds materials such as paper, plastic films, laminates, and foils with unmatched precision. Krishna Engineering Works the reputed name worldwide as a manufacturer and exporter of industrial machinery-supplies the best Slitter Rewinder Machines with excellent durability, precision, and ease of operation.

#krishnaengineeringworks#slitter rewinder machine#machine#manufacturer#machinemanufacturer#industry#export#supplier#machinery#industrial#heavy duty slitter rewinder machine#packaging industry#paper machinery#paper industry

2 notes

·

View notes

Text

ESSEN, Germany (AP) — For most of this century, Germany racked up one economic success after another, dominating global markets for high-end products like luxury cars and industrial machinery, selling so much to the rest of the world that half the economy ran on exports.

Jobs were plentiful, the government's financial coffers grew as other European countries drowned in debt, and books were written about what other countries could learn from Germany.

No longer. Now, Germany is the world’s worst-performing major developed economy, with both the International Monetary Fund and European Union expecting it to shrink this year.

It follows Russia's invasion of Ukraine and the loss of Moscow's cheap natural gas — an unprecedented shock to Germany’s energy-intensive industries, long the manufacturing powerhouse of Europe.

The sudden underperformance by Europe's largest economy has set off a wave of criticism, handwringing and debate about the way forward.

Germany risks “deindustrialization” as high energy costs and government inaction on other chronic problems threaten to send new factories and high-paying jobs elsewhere, said Christian Kullmann, CEO of major German chemical company Evonik Industries AG.

From his 21st-floor office in the west German town of Essen, Kullmann points out the symbols of earlier success across the historic Ruhr Valley industrial region: smokestacks from metal plants, giant heaps of waste from now-shuttered coal mines, a massive BP oil refinery and Evonik's sprawling chemical production facility.

These days, the former mining region, where coal dust once blackened hanging laundry, is a symbol of the energy transition, dotted with wind turbines and green space.

The loss of cheap Russian natural gas needed to power factories “painfully damaged the business model of the German economy,” Kullmann told The Associated Press. “We’re in a situation where we’re being strongly affected — damaged — by external factors.”

After Russia cut off most of its gas to the European Union, spurring an energy crisis in the 27-nation bloc that had sourced 40% of the fuel from Moscow, the German government asked Evonik to keep its 1960s coal-fired power plant running a few months longer.

The company is shifting away from the plant — whose 40-story smokestack fuels production of plastics and other goods — to two gas-fired generators that can later run on hydrogen amid plans to become carbon neutral by 2030.

One hotly debated solution: a government-funded cap on industrial electricity prices to get the economy through the renewable energy transition.

The proposal from Vice Chancellor Robert Habeck of the Greens Party has faced resistance from Chancellor Olaf Scholz, a Social Democrat, and pro-business coalition partner the Free Democrats. Environmentalists say it would only prolong reliance on fossil fuels.

Kullmann is for it: “It was mistaken political decisions that primarily developed and influenced these high energy costs. And it can’t now be that German industry, German workers should be stuck with the bill.”

The price of gas is roughly double what it was in 2021, hurting companies that need it to keep glass or metal red-hot and molten 24 hours a day to make glass, paper and metal coatings used in buildings and cars.

A second blow came as key trade partner China experiences a slowdown after several decades of strong economic growth.

These outside shocks have exposed cracks in Germany's foundation that were ignored during years of success, including lagging use of digital technology in government and business and a lengthy process to get badly needed renewable energy projects approved.

Other dawning realizations: The money that the government readily had on hand came in part because of delays in investing in roads, the rail network and high-speed internet in rural areas. A 2011 decision to shut down Germany's remaining nuclear power plants has been questioned amid worries about electricity prices and shortages. Companies face a severe shortage of skilled labor, with job openings hitting a record of just under 2 million.

And relying on Russia to reliably supply gas through the Nord Stream pipelines under the Baltic Sea — built under former Chancellor Angela Merkel and since shut off and damaged amid the war — was belatedly conceded by the government to have been a mistake.

Now, clean energy projects are slowed by extensive bureaucracy and not-in-my-backyard resistance. Spacing limits from homes keep annual construction of wind turbines in single digits in the southern Bavarian region.

A 10 billion-euro ($10.68 billion) electrical line bringing wind power from the breezier north to industry in the south has faced costly delays from political resistance to unsightly above-ground towers. Burying the line means completion in 2028 instead of 2022.

Massive clean energy subsidies that the Biden administration is offering to companies investing in the U.S. have evoked envy and alarm that Germany is being left behind.

“We’re seeing a worldwide competition by national governments for the most attractive future technologies — attractive meaning the most profitable, the ones that strengthen growth,” Kullmann said.

He cited Evonik’s decision to build a $220 million production facility for lipids — key ingredients in COVID-19 vaccines — in Lafayette, Indiana. Rapid approvals and up to $150 million in U.S. subsidies made a difference after German officials evinced little interest, he said.

“I'd like to see a little more of that pragmatism ... in Brussels and Berlin,” Kullmann said.

In the meantime, energy-intensive companies are looking to cope with the price shock.

Drewsen Spezialpapiere, which makes passport and stamp paper as well as paper straws that don't de-fizz soft drinks, bought three wind turbines near its mill in northern Germany to cover about a quarter of its external electricity demand as it moves away from natural gas.

Specialty glass company Schott AG, which makes products ranging from stovetops to vaccine bottles to the 39-meter (128-foot) mirror for the Extremely Large Telescope astronomical observatory in Chile, has experimented with substituting emissions-free hydrogen for gas at the plant where it produces glass in tanks as hot as 1,700 degrees Celsius.

It worked — but only on a small scale, with hydrogen supplied by truck. Mass quantities of hydrogen produced with renewable electricity and delivered by pipeline would be needed and don't exist yet.

Scholz has called for the energy transition to take on the “Germany tempo,” the same urgency used to set up four floating natural gas terminals in months to replace lost Russian gas. The liquefied natural gas that comes to the terminals by ship from the U.S., Qatar and elsewhere is much more expensive than Russian pipeline supplies, but the effort showed what Germany can do when it has to.

However, squabbling among the coalition government over the energy price cap and a law barring new gas furnaces has exasperated business leaders.

Evonik's Kullmann dismissed a recent package of government proposals, including tax breaks for investment and a law aimed at reducing bureaucracy, as “a Band-Aid.”

Germany grew complacent during a “golden decade” of economic growth in 2010-2020 based on reforms under Chancellor Gerhard Schroeder in 2003-2005 that lowered labor costs and increased competitiveness, says Holger Schmieding, chief economist at Berenberg bank.

“The perception of Germany's underlying strength may also have contributed to the misguided decisions to exit nuclear energy, ban fracking for natural gas and bet on ample natural gas supplies from Russia,” he said. “Germany is paying the price for its energy policies.”

Schmieding, who once dubbed Germany “the sick man of Europe” in an influential 1998 analysis, thinks that label would be overdone today, considering its low unemployment and strong government finances. That gives Germany room to act — but also lowers the pressure to make changes.

The most important immediate step, Schmieding said, would be to end uncertainty over energy prices, through a price cap to help not just large companies, but smaller ones as well.

Whatever policies are chosen, “it would already be a great help if the government could agree on them fast so that companies know what they are up to and can plan accordingly instead of delaying investment decisions," he said.

7 notes

·

View notes

Text

Industrial Rooftop Solar Panels in Raipur: Powering Sustainable Manufacturing and Savings

Industries across India are facing rising electricity costs, stringent sustainability regulations, and pressure to reduce their carbon footprint. In cities like Raipur, Chhattisgarh, where sunlight is abundant and industries are rapidly expanding, industrial rooftop solar panels have become a game-changer. They allow factories, warehouses, and manufacturing units to generate clean electricity right from their rooftops—reducing operational costs while ensuring a reliable power supply.

At Techno Sun Energy, we provide turnkey solutions for industrial rooftop solar panel systems in Raipur, helping businesses harness the sun to fuel growth, efficiency, and sustainability.

Why Solar for Industrial Use?

Industrial operations are energy-intensive. Whether it’s running heavy machinery, motors, or air-conditioning units, factories demand consistent and high volumes of electricity. Conventional grid electricity is not only expensive but also vulnerable to outages and tariff hikes.

This is where industrial rooftop solar systems step in—with benefits that go beyond just saving on bills:

✅ Massive Cost Reduction

Solar drastically reduces electricity bills. Many of our industrial clients have seen savings of ₹5–15 lakhs annually, depending on plant size.

✅ High ROI

With commercial power rates ranging from ₹6 to ₹10/unit, solar offers a payback period of just 3–4 years, followed by decades of free electricity.

✅ Grid Independence & Stability

Solar power reduces reliance on grid supply and diesel generators, especially during peak load hours.

✅ Green Branding & CSR Compliance

Solar adoption supports sustainability goals and improves the brand's public image. It also aids in ESG reporting and carbon credits.

Ideal Industries for Rooftop Solar in Raipur

Steel and fabrication units

Food processing factories

Pharmaceutical industries

Textile manufacturing

Plastic molding and packaging units

Automotive workshops and service centers

Warehouses and cold storage

Brick kilns and cement-based factories

If your facility has an unused rooftop, terrace, or shed, we can turn it into a powerful source of clean energy.

Types of Solar Systems for Industrial Use

At Techno Sun Energy, we offer the following system types based on your requirements:

🔹 On-Grid Industrial Solar System

Connected to the grid with net metering

Surplus energy exported for credits

Ideal for industries with daytime operations

🔹 Hybrid Industrial Solar System

Combines solar, grid, and battery backup

Ensures continuous power supply for critical machinery and IT infrastructure

🔹 Off-Grid Solar System

Best for remote units where grid supply is unreliable

Includes battery bank for full independence

Why Raipur is Ideal for Industrial Solar

Raipur, with over 300 sunny days a year, is perfect for solar energy production. The city is also a major industrial hub, supported by Chhattisgarh State Industrial Development Corporation (CSIDC) and CREDA. These agencies actively promote solar adoption in industrial zones like:

Urla Industrial Area

Siltara Sector

Bhanpuri and Birkoni

Tilda and Borjhara Clusters

Techno Sun Energy has implemented multiple industrial rooftop solar projects in these areas with measurable success.

Our Process at Techno Sun Energy

We offer end-to-end project execution for industrial solar:

Energy audit & site survey

Customized solar system design

Assistance with net metering and CREDA compliance

Installation with BIS-compliant equipment

Real-time monitoring system

Post-installation support & AMC

We use premium components from top brands like Adani, Vikram, Waaree, Growatt, Schneider, and ABB.

Case Study: 100kW Rooftop Solar at a Factory in Urla, Raipur

A steel fabrication company in Urla installed a 100kW on-grid rooftop solar system with Techno Sun Energy. Within 6 months, the unit reduced monthly power bills by ₹1.2 lakhs. The system generates approx. 12,000 units per month, providing long-term cost stability and tax benefits through accelerated depreciation.

Subsidies & Financial Benefits

Though CREDA subsidies are more applicable to residential and institutional projects, industrial users benefit from:

Accelerated depreciation (up to 40%)

GST input credits

Power Purchase Agreements (PPAs) and third-party investments

Carbon credit eligibility

Our team helps you understand and claim every available benefit.

Conclusion

Adopting industrial rooftop solar panels in Raipur is no longer a luxury—it’s a strategic and financial necessity. With the right system, your factory or warehouse can reduce energy costs, minimize environmental impact, and gain long-term energy independence.

Ready to switch to solar for your industrial unit? Contact Techno Sun Energy today for a detailed feasibility report, savings forecast, and customized solar solution tailored to your factory.

#Industrial Rooftop Solar Panel in Raipur#industrial solar solutions#solar power for industries#industrial solar panel system

0 notes

Text

https://www.invoitplast.com/

India’s most progressive and quality aware organization Invoit Plast Machinery Pvt. Ltd., is manufacturer, supplier and exporter of plastic processing machineries. More precisely, the plastic raw material processing such as mixing, drying, grinding, pulverizing, recycling from plastic processing machinery and equipment for plastic products.

Invoit Plast Machinery Pvt. Ltd., is having manufacturing business in Ahmedabad, the hub of several huge and prominent Plastic industries of India. By means of persistent improvement of superior manufacturing functions and excellent performance of our products through demanding research and development Invoit Plast Machinery Pvt. Ltd., has acquired prominent clients in India and we are still very well recognized as well as most trustworthy supplier to Indian cities Hyderabad, Nasik, Chennai, Baroda, Bangalore, Rajkot and more.

3 notes

·

View notes

Text

Vacuum Packing vs. Shrink Wrapping: Which Is Right for Your Business?

In today’s fast-evolving industrial landscape, packaging is no longer just about wrapping a product for delivery. It’s a crucial part of the logistics process, supply chain efficiency, and product safety—especially in high-demand markets like the UAE. Among the most commonly used industrial packaging techniques are vacuum packing and shrink wrapping. But how do you decide which is better for your business?

This article compares these two effective industrial packaging solutions, breaking down their advantages, ideal use cases, and relevance in sectors like manufacturing, logistics, and oil & gas.

Understanding Vacuum Packing

Vacuum packing involves removing air from the package before sealing. The product is placed in a plastic film, and air is vacuumed out, then heat-sealed to form an airtight environment.

Benefits of Vacuum Packing

Air and moisture protection: Keeps sensitive components dry and corrosion-free.

Extended shelf life: Ideal for perishable goods, electronics, and industrial tools.

Space optimization: Reduces package volume, cutting storage and transportation costs.

Complies with international standards: Especially important for exports from the UAE.

Best Use Cases

Electronics

Machinery parts

Pharmaceuticals

Export goods requiring ISPM-15 compliance

In UAE’s logistic packaging services, vacuum packing is often preferred for long-term storage, exports, and in sectors like oil & gas and marine engineering.

Understanding Shrink Wrapping

Shrink wrapping uses a plastic film that shrinks tightly over a product when heat is applied. It is commonly used for both individual items and bulk packaging.

Benefits of Shrink Wrapping

Cost-effective: Great for large quantities and faster packaging cycles.

Tamper-evident: Provides visible protection and discourages product tampering.

Enhances branding: Clear wraps allow barcodes, labels, and product designs to be visible.

Ideal for odd-shaped items or grouped packaging.

Best Use Cases

Retail products

Bundled goods

Pallet wrapping for transport

Short-term protection from dirt and handling

In packing services UAE, shrink wrapping is widely used in logistics hubs like Dubai and Abu Dhabi where high-volume, fast-moving goods need secure transit protection.

Side-by-Side Comparison

Feature

1 Vacuum Packing

2 Shrink Wrapping

Air & Moisture Barrier

1 Excellent

2 Moderate

Protection Level

1 High – suitable for sensitive items

2 Medium – protection from dirt/scratches

Cost

1 Higher setup and per-unit cost

2 More economical for bulk

Speed

1 Slower process

2 Fast and scalable

Storage Efficiency

1 Space-saving

2 May not reduce size

Appearance

1 Functional, minimalistic

2 Clear and display-friendly

Which One Fits Your Industry?

Vacuum Packing is ideal if you:

Are shipping across borders or long-term storing items

Work in high-precision sectors like aerospace or electronics

Need protection against UAE’s humid, salty air—especially in coastal cities

Shrink Wrapping is suitable if you:

Deal in high-volume retail, distribution, or manufacturing

Want a cost-effective solution for domestic logistics

Need to bundle or group products for shipment

Industrial Use in the UAE

The UAE is seeing a logistics boom in 2025, driven by growth in manufacturing, export, and e-commerce. Industrial packaging UAE is critical to protecting high-value goods transported across ports in Jebel Ali, Khalifa Port, and Hamriyah Free Zone. Businesses are increasingly opting for professional packing services UAE to meet both domestic and international standards.

Whether it’s machinery from Sharjah, electronics in Dubai, or chemicals in Abu Dhabi, choosing the right packing solution in UAE makes all the difference in cost savings, product safety, and regulatory compliance.

Final Thoughts

Both vacuum packing and shrink wrapping are reliable industrial packaging solutions. The key to choosing the right method lies in understanding your product’s nature, transportation route, and industry regulations. For businesses in the UAE, combining advanced packaging strategies with trusted packing services companies ensures optimal safety and cost-efficiency.

As the demand for logistic packaging services in UAE grows, making informed packaging decisions becomes essential for competitiveness and operational success.

📍 : Musaffah, ICAD I, Abu Dhabi, UAE

0 notes

Text

How to Choose the Right Spur Gear Manufacturer for Industrial Applications

Spur gears are essential in the fields of machinery and power transmission. From heavy-duty industrial machines to precision-driven mechanical tools, spur gears are the unsung heroes behind smooth motion and efficiency. However, when it comes to sourcing these crucial components, choosing the right spur gear manufacturer can make all the difference in product quality, performance, and lifespan.

Whether you’re a procurement officer, a mechanical engineer, or an industrial project manager, understanding what to look for in a gear manufacturer is essential to avoid costly downtime and ensure long-term reliability. This blog will guide you through what makes a great manufacturer and why choosing a specialized industrial gear supplier matters.

Why Spur Gears Are So Important in Industry

Spur gears are the most common type of gear used in mechanical applications. Their simplicity, efficiency, and ability to transmit large amounts of power at constant speed make them indispensable in sectors like:

Automotive

Packaging

Printing

Food processing

Textile machinery

Conveyor systems

These gears are typically manufactured with high precision to meet demanding operational standards. That’s why selecting the right spur gear manufacturer who understands technical tolerances and application-specific demands is crucial.

Key Qualities of a Reliable Spur Gear Manufacturer

1. Experience and Industry Reputation

Always seek out an Indian gear manufacturer with a solid track record of producing precise spur gears and shown competence. Companies with a wide client base and years of production experience are more likely to deliver consistent quality.

2. Material Versatility

The raw material is frequently where a spur gear's quality starts. A professional manufacturer should offer options such as:

Carbon Steel

EN Materials (EN8, EN9, EN19, EN31, EN353)

Alloy Steel

20MNCR5 (CR Material)

Bronze and Phosphor Bronze

Delrin Plastic & Cast Nylon

Cast Iron

Stainless Steel

Every material has unique qualities that make it perfect for a certain use. For instance, Bronze is excellent for anti-friction applications, while EN31 is used for high wear resistance.

3. Customization Capabilities

A great spur gear exporter doesn’t just sell off-the-shelf components. They should offer custom spur gears tailored to your design and performance requirements. This includes tooth profile modifications, gear ratios, and shaft sizes.

4. Modern Manufacturing and Testing Facilities

With the advent of CNC machines and advanced gear hobbing technology, today’s gear production demands high-end infrastructure. A reliable manufacturer should have in-house quality testing, material hardness checks, and runout inspections to ensure consistent product integrity.

Don’t Forget Related Components

While spur gears are critical, many industrial systems also rely on components like the Timing Belt Pulley and V pulley for smooth motion and torque transmission. A manufacturer offering a complete range of power transmission components becomes a one-stop solution for all your mechanical needs. This ensures compatibility and ease of integration in your machinery.

Why Choosing the Right Supplier Saves You Money

Partnering with a reliable industrial gear supplier doesn’t just ensure better products—it reduces lead times, improves maintenance cycles, and minimizes the risk of operational failure. When you buy from a top spur gear manufacturer, you're not just buying a product; you're investing in peace of mind and operational efficiency.

Additionally, buying from a known gear manufacturer in India also gives you better local support, faster turnaround, and better customization at cost-effective pricing compared to imported alternatives.

Look No Further Than the Experts

If you’re in search of a trusted gear partner who can deliver everything from custom spur gears to timing belt pulleys and v pulleys, explore Rajendra Pulley Pedestal Centre. They specialize in manufacturing high-quality gears with diverse material options and precision tolerances, serving clients across industries for decades.

Conclusion

Choosing the right spur gear manufacturer for industrial applications involves more than comparing price lists. It requires evaluating technical capability, material selection, product range, and service reliability. With the right partner, you can ensure smooth machinery performance, reduced downtime, and long-term value.

Partner with a manufacturer who understands your industry and delivers uncompromised quality. Email: [email protected] or Call+91-958-682-3032. Let our gear experts help you find the perfect solution for your mechanical system!

#spur gear manufacturer#custom spur gears#industrial gear supplier#precision spur gears#spur gear exporter#gear manufacturer in India#Rajendra pulley gears#durable spur gears#gear solutions for machines#spur gear supplier

0 notes

Text

Affordable CNC Milling India , Best Manufacturers & Suppliers

Need affordable CNC machining in India? Choose from leading CNC Milling Suppliers that offer quality work at competitive prices. Call us now.

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed software to control machinery. It allows for precise cutting, drilling, and shaping of materials like metal, plastic, and wood. Imagine a robotic sculptor working with extreme accuracy—that’s CNC machining.

Why Choose CNC Machining in India?

India offers top-tier CNC machining services with a unique edge:

Lower operational costs

Highly skilled engineers

Advanced equipment

Faster project turnaround

That’s why global brands are outsourcing their CNC needs to Indian suppliers—it saves money without sacrificing quality.

Suppliers: Bridging Industries and InnovationEqually important to the CNC Milling Manufacturers chain are CNC Milling Suppliers, who connect industries with the right equipment and services. They offer a range of products, from compact desktop milling units to high-end industrial machines. These suppliers act as consultants, helping clients choose the most appropriate technology based on application, budget, and output requirements.

Modern suppliers provide value added services like installation, training, preventive maintenance, and troubleshooting. Their role is indispensable in sectors that demand minimal downtime and continuous productivity. They also facilitate customization, offering different table sizes, control units, and compatibility with CAD/CAM software systems.

Key Benefits of CNC Machining

High Precision: Ensures accuracy to within microns.

Consistency: Identical results even in large batches.

Efficiency: Faster production with less waste.

Complex Designs: Capable of producing intricate shapes and structures.

Whether you need a single prototype or thousands of units, CNC machining is up to the task.

Applications :

CNC machining is used everywhere, including:

Automotive: Engine parts, gear systems

Aerospace: Aircraft components

Medical Devices: Surgical tools, implants

Consumer Electronics: Device casings, connectors

Defense: Precision hardware

Indian CNC manufacturers cater to all these sectors and more.

How Indian CNC Suppliers Ensure Quality

Top suppliers in India use:

ISO-certified processes

CMM inspection tools

Real-time monitoring

Highly trained operators

They don’t just meet global standards—they exceed them.

Top CNC Machining Manufacturers in India

Some of the most reputable names include:

Deccanew

Ace Micromatic Group

Jyoti CNC Automation

LMW (Lakshmi Machine Works)

Micromatic Grinding Technologies

These companies have global reach, export capabilities, and strong quality control systems.

Factors That Affect CNC Machining Costs

CNC machining is affordable in India, but prices vary based on:

Material type

Part complexity

Volume (single or batch production)

Surface finishing

Machine run time

India’s lower labor and energy costs make even complex jobs more budget-friendly.

CNC Milling India Is Gaining Momentum

India offers a blend of affordability, engineering talent, and high-precision outputs. Many global and local manufacturers are tapping into CNC services in India for prototype development, mass production, and custom fabrication. By investing in CNC milling, industries are reducing human error, minimizing waste, and significantly improving operational efficiency. CNC machines are digitally programmed, allowing for consistent results with excellent repeatability.

How to Select the Right CNC Supplier

Here’s what to look for:

Experience in your industry

Custom capabilities

Certifications like ISO, AS9100

Prompt delivery records

After-sales support

It’s not just about cost—it’s about reliable performance.

Materials Commonly Used in CNC Machining

Indian CNC machining shops work with:

Metals: Aluminum, steel, brass, titanium

Plastics: Nylon, ABS, PEEK, acrylic

Composites: Carbon fiber, fiberglass

Make sure the supplier has experience with your specific material needs

Deccanew is one of India’s emerging leaders in CNC Milling India. They offer:

Custom CNC solutions

Fast delivery

Affordable pricing

Reliable customer service

From design to delivery, Deccanew combines technical precision with business-friendly pricing.

Trends in Indian CNC Machining Industry

Modern Indian CNC firms are embracing:

AI and machine learning

Smart factories (Industry 4.0)

Eco-friendly machining

Digital twins and cloud-based design

These trends ensure sustainability, efficiency, and innovation for future manufacturing.

Visit: https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.phpContact: +91 9657039991

0 notes

Text

What is Commercial Castor Oil & Why It Matters for Industrial Applications?

Commercial castor oil is a versatile, industrial-grade oil extracted from castor seeds (Ricinus communis). Known for its high viscosity, lubricating properties, and unique chemical structure, commercial castor oil plays a vital role in various manufacturing sectors like lubricants, coatings, paints, plastics, textiles, and more.

At Modi Oil Mill, we produce premium quality commercial castor oil that meets the rigorous demands of industrial buyers in India and overseas. Our oil is extracted using modern cold-press methods and is carefully filtered to retain essential properties, making it ideal for bulk buyers, manufacturers, and resellers looking for reliable and consistent supply.

Key Features of Commercial Castor Oil

High Ricinoleic Acid Content Ricinoleic acid makes castor oil uniquely suitable for applications requiring moisture retention, flexibility, and thickening properties.

Excellent Lubrication Industrial-grade commercial castor oil is widely used in lubricants for high-speed engines, machinery, and hydraulic systems.

Chemical Stability Its natural resistance to degradation makes it perfect for long-term industrial usage, even in harsh environments.

Multi-Industry Applications From pharmaceuticals and cosmetics to paint, rubber, and plastic manufacturing, this oil is a key raw material across sectors.

Why Choose Modi Oil Mill for Commercial Castor Oil?

We are one of India’s most trusted manufacturers and exporters of commercial castor oil. With decades of experience in oil processing, our facility ensures:

Consistent Quality & Supply

Competitive Wholesale Rates

Custom Packaging Options

Bulk Export Support Worldwide

Whether you're a local buyer or an international distributor, Modi Oil Mill delivers commercial castor oil that aligns with your specifications and supply chain needs.

Applications of Commercial Castor Oil in Industries

Paints & Coatings – As a binder and drying agent.

Textiles – For dyeing and finishing processes.

Plastics – As a base for polymer production.

Soap Making – Adds lather and cleansing properties.

Agriculture – Used in crop protection and organic pesticides.

Final Thoughts

As industrial demands rise, choosing a reliable supplier for commercial castor oil becomes critical. Modi Oil Mill ensures top-quality oil processed under stringent quality controls, making us a preferred partner for industries across the globe.

1 note

·

View note

Text

Trusted Heating Element Manufacturers in India: Quality Cartridge Heaters with Thermocouple Solutions

In the rapidly evolving industrial sector, heating elements are critical components across various applications, from plastic molding and packaging to food processing and pharmaceutical manufacturing. As demand for precise and energy-efficient heating solutions grows, heating element manufacturers in India are gaining global recognition for their innovation, durability, and customization capabilities.

The Rise of Indian Heating Element Manufacturers

India has become a hub for advanced and reliable heating element production. With a strong focus on quality, cost-efficiency, and rapid delivery, Indian manufacturers cater to both domestic and international markets. These companies specialize in a wide range of products, including:

Cartridge heaters

Tubular heaters

Mica band heaters

Ceramic infrared heaters

Coil and nozzle heaters

Among these, cartridge heaters with thermocouples are especially in demand due to their precise temperature control and compact design.

What is a Cartridge Heater with Thermocouple?

A cartridge heater is a cylindrical heating element that provides localized, high-intensity heat. When integrated with a thermocouple, it becomes a smart heating solution capable of automatically monitoring and adjusting temperature. This combination is essential in processes where temperature consistency and safety are paramount.

Key Benefits of Cartridge Heaters with Thermocouples:

Precise Temperature Monitoring: Real-time feedback from the thermocouple ensures better control.

Compact Design: Ideal for tight spaces in molds, dies, and hot runner systems.

Energy Efficiency: Reduces wastage and improves operational performance.

Customizable: Available in various wattages, lengths, diameters, and termination options.

Applications Across Industries

These heaters find wide usage across:

Plastic and rubber molding industries

Packaging machinery

Medical equipment manufacturing

3D printers and electronics

Food and beverage processing

Indian manufacturers offer custom-engineered solutions to match these diverse applications, ensuring compatibility, durability, and compliance with global standards.

Choosing the Right Manufacturer

When selecting from heating element manufacturers in India, consider the following:

ISO certifications and quality assurance processes

Use of high-grade raw materials like SS 304/316

Custom design capabilities

After-sales support and service

Timely delivery and competitive pricing

Many reputed Indian manufacturers are now exporting globally, offering OEM services and adhering to international safety standards like CE and RoHS.

Final Thoughts

The future of industrial heating is precision-driven, and cartridge heaters with thermocouples are at the forefront of this transformation. With a growing ecosystem of heating element manufacturers in India, businesses now have access to world-class solutions that are reliable, affordable, and tailored to their specific needs.

If you're sourcing heating elements or exploring a trusted cartridge heater supplier, India offers a wealth of options worth considering.

Would you like this blog formatted for your website, or need suggestions for top manufacturers to mention?

1 note

·

View note

Text

Application of Hydraulic Press for Industrial Development: An Industry Revolutionizer

Introduction

In the constantly changing environment of industrial manufacturing and engineering, hydraulic presses have become a foundational technology, playing a critical role in increasing productivity, accuracy, and profitability. As a manufacturer, supplier, trader, or fabricator, it is no longer a luxury but an essentiality to utilize hydraulic press equipment in order to scale operations effectively.

This piece goes in-depth into how hydraulic presses are revolutionizing industrial processes, why companies such as distributors, dealers, wholesalers, vendors, exporters, and machinery contractors are investing in them, and how the correct machinery supplier can determine your path of industrial growth.

— -

What is a Hydraulic Press?

A hydraulic press is a device that uses a hydraulic cylinder to produce compressive force. It works on Pascal’s law, which defines that pressure on a contained fluid is transmitted equally in all directions. The outcome? A strong, accurate, and dependable press that can form, mold, punch, bend, and shape materials with precision.

From automobile and aerospace manufacturing to metallurgy, construction, and electrical industries, hydraulic presses are in high demand by machinery manufacturers, suppliers, and fabricators around the globe.

— -

Why Hydraulic Press is Essential for Industrial Growth

1. Increased Efficiency and Production Speed

Industries using hydraulic press machinery benefit from significantly faster production cycles. These machines apply uniform pressure that ensures consistent quality while reducing time and labor costs.

For equipment traders and resellers, this increase in efficiency is a selling advantage to entice customers looking for automation and high volume.

— -

2. Versatility Across Industries

Hydraulic presses are very versatile. As a metal sheet fabricator, plastic molding contractor, or rubber processing manufacturer, a hydraulic press can do several tasks:

Deep drawing

Molding

Stamping

Punching

Compacting

Equipment wholesalers and dealers find this versatility essential while providing solutions to a large customer base.

— -

3. Precision and Repeatability

Unlike traditional mechanical presses, hydraulic systems provide superior control. The force can be applied gradually or instantly, depending on the application, ensuring repeatable precision every time.

This is why exporters and importers of machinery often prioritize hydraulic models for international clients seeking accuracy in high-value projects.

— -

4. Cost-Effective Operation

Despite the initial investment, hydraulic presses offer long-term cost savings due to:

Lower maintenance

Reduced waste

Energy-efficient mechanisms

Cost-effectiveness is what machinery dealers and contractors use as a selling point whenever they sell machinery to merchants, partners, and suppliers in different industrial sectors.

— -

Applications of Hydraulic Presses in Real Life

A. Motor Vehicle Industry

Major automobile companies depend on hydraulic presses to manufacture body panels, engine components, and chassis parts. Due to their high tonnage capacity, they are indispensable in stamping and forming big metal sheets.

B. Aerospace Engineering

Hydraulic presses also find applications in shaping composite materials to be used in lightweight aircraft parts, and as such, these are a go-to solution for machinery manufacturers serving defense and aerospace customers.

C. Appliance Making

From washing machines to refrigerators, hydraulic presses are used to shape outer casings and inner parts. Consumer electronics manufacturers relying on retailers and resellers count on this technology for high-speed production.

— -

How Fabricators Gain Advantage from Hydraulic Presses

A fabricator works with cutting, bending, and assembling materials, typically metals. Hydraulic presses offer:

Constant pressure for clean, exact bends

Low waste with exact alignment

Safety devices for safe handling

Fabricators considering capacity expansion can be helped by collaborations with machinery makers, machine suppliers, or regional distributors on websites such as Pepagora to have access to dependable equipment and post-sales service.

— -

Selecting the Proper Hydraulic Press for Your Business

With so many choices available in the market, traders, suppliers, and buyers need to compare machines on the following criteria:

Tonnage requirement

Nature of operation (forming, punching, compacting)

Space constraints

Options for customization

Local service availability

On B2B platforms such as Pepagora, you can view detailed descriptions and customer feedback from multiple machinery wholesalers, distributors, and agents — making the choice simpler.

— -

Case Study: Expansion with Hydraulic Press Integration

Company: Supreme Tech Engineering

Industry: Auto Component Manufacturing

Location: Coimbatore, India Type: Manufacturer & Exporter The Challenge:

Supreme Tech Engineering was experiencing uneven metal bending quality and lengthy production times. Their mechanical presses were obsolete, and this was leading to customer complaints.

The Solution:

They entered an agreement with a hydraulic press manufacturer that is quoted on Pepagora and ordered three 150-ton hydraulic forming presses.

The Results:

Production efficiency improved by 40%

Rejection rate reduced by 60%

Achieved ISO 9001 certification for the enhanced quality

Increased export contracts to Germany and UAE in one year

This change demonstrates the way small- to medium-scale manufacturers are able to become global exporters and machinery suppliers through the adoption of smart machinery such as hydraulic presses.

— -

B2B Dynamics: The Ecosystem Expands Together

For Manufacturers:

Design custom hydraulic presses for diverse industries

Partner with agents, brokers, and distributors to reach more

For Suppliers & Distributors:

Be local branches for machinery makers

Provide installation and post-sale services

Partner with contractors and providers to supply to current projects

For Exporters & Importers:

Find popular models for international trade

Fill gaps between emerging and developed economies

For Fabricators, Contractors & End-users:

Look for solutions through platforms like Pepagora

Get quotes, compare suppliers, read case studies

For Traders, Brokers & Dealers:

Deal in secondary markets

Purchase large quantities from manufacturers and sell to niche segments When all these stakeholders come together through reliable B2B machinery platforms, industrial development becomes sustainable, scalable, and international.

— -

SEO-Rich Buying Guide: Keywords in Action

If you’re a company actively looking for industrial machinery on the internet, the following are high-performing keywords to search using to get optimal results:

“Hydraulic Press Manufacturer in India”

“Top Machinery Suppliers for Fabricators”

“Hydraulic Press Dealer for Auto Components”

“Best Wholesaler of Hydraulic Forming Press”

“Hydraulic Press Exporter UAE Market”

“Industrial Hydraulic Machinery Trader & Reseller”

“Vendor of Compact Hydraulic Press for Lab Use”

“Machinery Distributors on Pepagora Platform”

“Certified Machinery Producer for Sheet Metal Work”

Be sure to add location-based modifiers such as Delhi, Mumbai, Chennai, or Bangalore to appropriately target search.

— -

How Pepagora Facilitates Connecting the Right Machinery Partner

As a top B2B platform, Pepagora brings together thousands of machinery manufacturers, hydraulic press exporters, dealers, traders, distributors, and retailers in India and beyond. Here’s how Pepagora powers industrial growth:

Verified Listings of hydraulic press manufacturers and exporters

Quotation Tools to compare rates between vendors

Lead Generation Support for resellers and vendors

Simple Access to suppliers by product types, industries, or certifications

International Reach for import and export transactions

As a reseller seeking wholesale machinery, a manufacturer seeking bulk production, or an agent facilitating deals, Pepagora gives you the digital foundation you need to grow.

— -

Final Thoughts

The industrial landscape is changing at lightning speed, and hydraulic presses are at the forefront of the change. If your company is in one of the following groups — fabricator, contractor, machinery dealer, wholesaler, supplier, distributor, importer, or exporter — high-quality hydraulic press machinery is your passport to the next level.

— -

Call to Action

Want to purchase, sell, or source top-quality hydraulic press machinery for your business?

Browse through verified listings on Pepagora today

Meet top-ranked manufacturers, dealers, and suppliers Order bulk quotations and secure the best deals Begin your industrial growth journey today.

Sign up for Pepagora — Powering B2B Growth. — -

0 notes

Text

Why Royal Woodpack is Your Trusted Wooden Box Manufacturer

When it comes to protecting, packaging, and presenting your valuable goods, nothing compares to the reliability and strength of wooden boxes. At Royal Woodpack, we specialize in manufacturing high-quality wooden boxes that meet the rigorous standards of various industries—from industrial shipping and logistics to retail and luxury packaging.

Why Choose Wooden Boxes?

Wooden boxes offer unmatched durability and strength, making them ideal for:

Export packaging requiring ISPM-15 compliance

Heavy-duty shipping of machinery, electronics, or fragile components

Customized crates for high-value items

Eco-friendly packaging solutions

Aesthetic presentation for luxury products

Unlike cardboard or plastic, wood provides structural integrity, resistance to moisture (when treated), and long-term protection for your cargo.

Royal Woodpack’s Manufacturing Excellence

At Royal Woodpack, our process is built on precision, customization, and sustainability:

✅ Custom-Built Solutions

We design and manufacture wooden boxes tailored to your dimensions, weight specifications, and industry requirements. Whether it's a one-time project or large-scale production, we provide a packaging solution that fits.

✅ Quality Materials

We use premium-grade pinewood, plywood, and hardwoods—sourced responsibly—to ensure strength and durability. All our materials meet international export standards.

✅ ISPM-15 Certified

Our heat-treated wooden packaging ensures smooth global shipping, reducing the risk of delays or rejection at ports.

✅ Fast Turnaround

Time-sensitive shipments? Our streamlined production and logistics allow us to meet tight deadlines without compromising on quality.

✅ Eco-Conscious Practices

Wood is naturally recyclable and biodegradable. We minimize waste and offer reusability features in our box designs.

Industries We Serve

Royal Woodpack proudly supports clients across various sectors:

Automotive & Engineering

Pharmaceuticals & Chemicals

Agriculture & Food

Art & Antiques

Electronics & Machinery

Let’s Build It Together

If you need strong, reliable, and customizable wooden packaging, Royal Woodpack is your trusted partner. With years of experience and a commitment to quality, we make sure your goods arrive safe and sound—anywhere in the world.

Get in Touch Today Contact us to learn more about our custom wooden box manufacturing solutions or request a quote. Let’s pack it right—with Royal Woodpack.

0 notes

Text

Precision Engineering at Its Best: CNC Machining Services in Bangalore

Bangalore, widely recognized as the Silicon Valley of India, is more than just a technological powerhouse. In recent years, the city has established itself as a thriving hub for advanced manufacturing, with a special focus on CNC machining services in Bangalore. With a booming industrial sector and a rich pool of engineering talent, CNC machining services in Bangalore are now at the forefront of India's manufacturing innovation. Whether you are a startup prototyping a new product or an established OEM looking for high-precision components, Bangalore offers the expertise, infrastructure, and innovation required to meet your needs.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled machine tools to remove layers from a workpiece and create the desired part. The process offers unmatched accuracy, repeatability, and speed. CNC machining is used in a wide variety of industries such as aerospace, automotive, electronics, medical devices, and industrial machinery. Key operations include milling, turning, drilling, and grinding, which can be performed on materials ranging from plastics to hardened steel.

Why Bangalore?

1. Engineering and Talent Ecosystem

Bangalore is home to some of India’s most prestigious engineering institutions, including the Indian Institute of Science (IISc) and various top-tier engineering colleges. This creates a constant inflow of skilled professionals into the CNC machining and precision engineering industries.

2. Advanced Infrastructure

Many CNC machine manufacturers in Bangalore are not only producing high-quality machines but also contributing to the ecosystem by supporting innovation and providing after-sales services. The city is well-equipped with industrial parks, export zones, and logistic networks, making it an ideal location for both domestic and international manufacturing companies.

3. Proximity to High-Growth Industries

Bangalore houses a wide spectrum of industries that heavily depend on CNC machining. From aerospace and defense to electronics and EV manufacturing, the need for precision parts is growing steadily. CNC machining services in Bangalore play a crucial role in supporting these sectors with high-quality, reliable components.

Capabilities of CNC Machining Services in Bangalore

The CNC companies in Bangalore offer a broad range of services, such as:

● CNC Milling and Turning

Most service providers offer both vertical and horizontal CNC milling along with multi-axis CNC turning capabilities. This allows for the creation of complex components with high dimensional accuracy and surface finish.

● Prototyping and Small-Batch Manufacturing

Startups and R&D divisions benefit immensely from CNC companies in Bangalore that specialize in rapid prototyping. These firms deliver functional prototypes quickly and cost-effectively, enabling faster product development cycles.

● High-Volume Production

For larger production runs, many companies are equipped with state-of-the-art machinery and automated systems to maintain consistency and efficiency. These firms follow strict quality assurance protocols and often have ISO certifications.

● Specialized Machining

Some CNC machining services in Bangalore provide specialized machining for industries like medical devices, where the tolerances and materials are critical. These services often include 5-axis machining, Swiss turning, and micromachining.

Leading CNC Machine Manufacturers in Bangalore

Several companies in Bangalore are not just service providers but also design and manufacture CNC machines themselves. These CNC machine manufacturers in Bangalore contribute significantly to the growth of the CNC ecosystem.

They offer:

CNC lathes and milling machines

Custom automation solutions

Retrofitting and machine upgrades

Post-sales support and training

Their ability to design indigenous machines helps in reducing dependency on imports and makes high-end technology more accessible to local industries.

How to Choose the Right CNC Company in Bangalore

When selecting a CNC company in Bangalore, it's essential to evaluate several factors to ensure you're partnering with the right team. Here are some things to look out for:

1. Experience and Reputation

A well-established company with a strong track record is more likely to deliver reliable results. Look for testimonials, case studies, and client feedback to assess their reputation.

2. Equipment and Technology

Modern CNC machining requires high-end machines, CAD/CAM software, and quality inspection tools. Ensure the company uses the latest equipment and follows industry best practices.

3. Quality Control

A strong quality assurance system, preferably with ISO certification, is critical. Ask about their inspection processes, including CMM (Coordinate Measuring Machine) usage, SPC (Statistical Process Control), and final audits.

4. Turnaround Time and Capacity

Choose a CNC company in Bangalore that can meet your timelines without compromising quality. They should have the capacity to scale production when needed.

5. Cost-Effectiveness

While quality should never be compromised, cost is an important consideration. A reliable CNC machining service will offer a competitive price while delivering excellent value.

Industries Benefiting from CNC Machining in Bangalore

Bangalore’s CNC machining services cater to a wide range of industries, such as:

● Aerospace and Defense

Precision and quality are critical in this sector. Many companies in Bangalore are certified by global aerospace standards like AS9100 and cater to Indian defense establishments as well as global OEMs.

● Automotive and EV Manufacturing

From engine components to EV battery housing, CNC machining plays a significant role in automotive production.

● Electronics and Telecommunication

The miniaturization and complexity of electronic parts require ultra-precise machining, which CNC services in Bangalore are well-equipped to handle.

● Medical Devices

Implants, surgical tools, and diagnostic equipment components require stringent quality control, which several CNC firms in Bangalore are capable of maintaining.

Future of CNC Machining in Bangalore

As India moves towards becoming a global manufacturing hub, the demand for high-quality CNC machining will only increase. The integration of IoT, automation, and AI into CNC operations is already being adopted by forward-thinking CNC companies in Bangalore. Additionally, the government's Make in India initiative, along with the rise of electric vehicles and aerospace manufacturing, will further fuel this growth.

Sustainability is also becoming a priority, with many firms implementing eco-friendly practices such as waste reduction, energy-efficient machines, and recycling.

Conclusion

CNC machining services in Bangalore are leading the charge in high-precision manufacturing. From prototyping to mass production, these services support a wide array of industries with quality, reliability, and innovation. With numerous CNC machine manufacturers in Bangalore pushing technological boundaries and every CNC company in Bangalore striving to meet global standards, the city has truly become a beacon for precision engineering.

#custom sheet metal fabrication#sheet metal fabricators in bangalore#cnc company in bangalore#cnc machining services in bangalore#cnc machining bangalore

0 notes

Text

Vertical Mixer with Dryer Machine

Vertical Mixer with Dryer Machine https://www.invoitplast.com/granules-mixer-machine/vertical-plastic/mixer-with-dryer-machine/ Plastic processing machinery manufacturer Invoit Plast Machinery Pvt. Ltd. located in Ahmedabad, Gujarat, India., is most trusted supplier of vertical mixer with dryer machine to Indian cities more specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore and Rajkot. Invoit Plast Machinery Pvt. Ltd. is also leading exporter of vertical mixer with dryer machine to South Africa, Dubai UAE, Nepal, Bangladesh and Qatar. Contact us to get complete reliable support from plastic raw materials, waste, scrap processing machinery manufacturer and exporter.

3 notes

·

View notes