#Potato processing equipment in India

Text

Fry and Bake Technologies Pvt. Ltd. is one of the largest food processing equipment manufacturers in India, specializing in potato processing equipment. They offer an extensive range of food processing machinery and equipment for the snack food industry, catering to various culinary requirements, from frozen foods to snacks.

Allow me to provide you with a brief overview of the different fryer types they offer:

Fully Automatic Potato Chips Line: This highly efficient line automates the entire potato chip production process, including steaming, peeling, slicing, frying, seasoning, and packaging. The automatic potato chips line ensures a seamless and consistent production of potato chips.

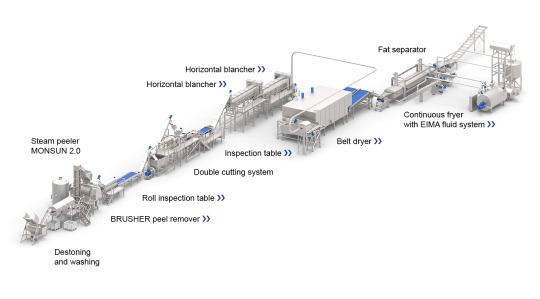

Frozen French Fries Production Line: Fry and Bake Technologies' frozen french fries production line comprises top-of-the-line machinery for washing, peeling, cutting, blanching, drying, frying, freezing, and packaging french fries. This comprehensive line guarantees the production of high-quality frozen french fries.

Fully Automatic Pellets Frying Line: This adaptable line processes and fries pellets made from potato, corn, or rice. The fully automatic pellets frying line ensures efficient processing and frying to meet the demands of various snack production.

Automatic Namkeen Fryer: Fry and Bake Technologies' automatic Namkeen fryer is specifically designed for frying Namkeen, a diverse variety of traditional Indian snacks. This specialized fryer ensures the perfect texture and taste of Namkeen snacks.

All Types of Batch Fryers: These versatile fryers are suitable for frying a wide range of snacks, making them an ideal choice for snack manufacturers with diverse product offerings. The batch fryers enable efficient frying of different snack varieties.

Fry and Bake Technologies places utmost importance on quality and customer satisfaction. They source their potato processing equipment in India from responsible suppliers and implement rigorous quality control measures to deliver exceptional value. Their team of dedicated professionals brings a wealth of knowledge and expertise to their manufacturing facility, constantly striving to improve products and develop innovative solutions.

In addition to their core products, Fry and Bake Technologies offers various value-added services to their customers, including:

Installation and commissioning of equipment.

Training on the operation and maintenance of equipment.

After-sales service and support.

Fry and Bake Technologies is committed to providing the best possible experience to their customers. They understand that the success of their customers is their success, and they are always willing to go the extra mile to ensure customer satisfaction.

To sum up, Fry and Bake Technologies is a leading manufacturer of potato processing equipment in India, offering a wide range of food processing machinery and equipment for the snack food industry. Their expertise, quality products, and dedication to customer satisfaction make them a reliable choice in the market.

#Potato processing equipment in India#automatic potato chips line#Automatic Pellets Frying Line#Automatic Kurkure Frying Line#largest food processing equipment manufacturers#drying equipment in food industry#food processing machinery and equipment#french fries production equipment#food processing instruments

0 notes

Text

Emerging Trends in the Natural Food Colorants Market

Originally published by Spendedge: Top Trends in the Natural Food Coloring Agents Market

Natural food colors are derived from plants, fruits, vegetables, and other natural sources to enhance the color of foods and beverages without artificial additives. Some examples include:

Carotenoids: Obtained from carrots and sweet potatoes, providing orange hues.

Chlorophyll: Extracted from spinach and parsley, giving a green color.

Anthocyanins: Found in berries, grapes, and red cabbage, producing red and blue shades.

Turmeric: A spice known for its yellow color.

Saffron: Providing a rich orange-yellow tint.

The appearance and aroma of food often influence people's perceptions before they taste it. Bright colors are particularly appealing, especially with unfamiliar foods. However, some foods lose their color or lack visual appeal due to the combination of various ingredients. To address this, the food industry uses colorants to achieve desired hues. Although artificial colorants like red lead and vermillion have been common, concerns about food safety have led to an exploration of natural alternatives. These natural colorants are derived from spices, fruits, vegetables, and other edible sources. A procurement market intelligence report from SpendEdge highlights the high demand for healthier foods and beverages with natural ingredients in developed countries such as the US, France, Germany, Spain, Italy, Japan, and Canada.

Procurement of natural food colorants involves sourcing color additives derived from natural sources for use in food and beverages. These additives come in various forms, including liquids, powders, pastes, and gels, and are also used in non-food products such as cosmetics, household crafts, medications, and medical equipment.

Natural food colors are extracted from foods or other edible materials through physical or chemical processes to selectively obtain pigments. The increasing demand for natural food colorants is driven by the popularity of superfoods and consumer preference for products labeled as "natural." This trend encourages food producers to opt for natural colors to meet consumer demands for transparent labeling.

Trends in the natural food coloring market include:

Growing popularity of antioxidant-rich colorants:

Consumer demand for natural food colorants rich in antioxidants like carotenoids and anthocyanins is increasing.

Growing consumer awareness, particularly in countries like India, China, Indonesia, and Brazil, is expected to further drive demand.

Demand for brown colorants:

The popularity of alternative grains with health benefits has led to a demand for natural coloring to enhance visual appeal.

Preference for brown and deep brown colorants is rising as consumers favor alternative grains over traditional options.

Flavor localization:

Regional and cultural differences in cuisines drive the localization of food products, creating demand for specific natural colorants.

For example, the use of turmeric is increasing in India by global food and beverage manufacturers.

Revised "nutrition facts" label in the US:

The FDA's redesign of nutritional labels encourages consumers to make informed food choices, impacting natural coloring processes.

Manufacturers are shifting towards non-sugar-based natural colorings to comply with label changes and address health concerns.

Market Trends:

Natural food colors are reshaping the food industry, driven by consumer demand for high-value products and ethical sourcing practices. Consumers seek healthy, ethically sourced products with minimal environmental impact, leading to increased demand for natural colorants. Extensive research and development efforts focus on innovative technologies to capitalize on market potential. For instance, Naturex introduced Vegebrite® Ultimate Spirulina in 2019, meeting clean-label demands with a coloring foodstuff using spirulina.

The Asia-Pacific region experiences rapid growth in natural food colorants, with leading manufacturers offering diverse application technologies. These colors enhance food appeal and flavor identification, particularly in desserts and beverages. Ingredient companies in Asia are developing colorants from spices such as turmeric, red chilies, and hibiscus, which are popular in dessert and beverage applications.

Click here to talk to our experts

0 notes

Text

Top Frozen Veg Aloo Tikki Manufacturer and Supplier in India

When it comes to convenient, delicious, and authentic Indian snacks, few options rival the classic Veg Aloo Tikki. Funwave Foods has emerged as a leading manufacturer and supplier of frozen Veg Aloo Tikki in India, providing consumers with high-quality, ready-to-cook snacks that capture the true essence of this beloved dish.

The Popularity of Veg Aloo Tikki

Veg Aloo Tikki, a spiced potato patty, is a staple in Indian cuisine, often enjoyed as a snack or as part of a larger meal. Traditionally served with chutneys or as a component in chaat, these patties are loved for their crispy exterior and flavorful, soft interior. The demand for this snack has surged, especially among those looking for quick and convenient meal options that do not compromise on taste.

Funwave Foods: Commitment to Quality

At the heart of Funwave Foods' success is its unwavering commitment to quality. The company employs state-of-the-art technology and adheres to stringent quality control measures to ensure that every Veg Aloo Tikki meets the highest standards. The process begins with the selection of premium ingredients, including fresh potatoes, peas, and a blend of authentic Indian spices.

Advanced Manufacturing Process

Funwave Foods utilizes advanced manufacturing techniques to produce its frozen Veg Aloo Tikki. The process starts with washing and peeling fresh potatoes, which are then boiled and mashed. The mashed potatoes are mixed with peas, spices, and other ingredients to create a consistent, flavorful mixture. This mixture is then formed into patties, which are partially fried to give them their signature crispy texture.

The partially fried patties are quickly frozen using individual quick freezing (IQF) technology, which preserves their texture and flavor while extending shelf life. This method ensures that the Veg Aloo Tikki retains its freshness and can be stored for extended periods without compromising quality.

Sustainable and Hygienic Practices

Funwave Foods places a strong emphasis on sustainability and hygiene throughout its production process. The company follows eco-friendly practices, such as sourcing ingredients from sustainable farms and minimizing waste. Additionally, the production facilities are equipped with modern sanitation systems to maintain a hygienic environment, ensuring that every batch of Veg Aloo Tikki is safe and healthy for consumption.

Catering to a Wide Market

Funwave Foods caters to a diverse market, including households, restaurants, and catering services. The convenience of frozen Veg Aloo Tikki makes it a popular choice among busy families, who can enjoy a quick and tasty snack without the hassle of preparation. Restaurants and catering services also benefit from the consistency and quality of Funwave Foods' products, which help them deliver authentic flavors to their customers effortlessly.

Innovation and Expansion

Innovation is a key driver of Funwave Foods' growth. The company continually invests in research and development to improve its products and introduce new flavors and varieties. By staying attuned to consumer preferences and market trends, Funwave Foods ensures that it remains at the forefront of the frozen food industry.

Conclusion

Funwave Foods stands out as the top manufacturer and supplier of frozen Veg Aloo Tikki in India, thanks to its dedication to quality, advanced manufacturing processes, and commitment to sustainability. Whether you're a busy parent looking for a quick snack or a restaurant aiming to serve authentic Indian cuisine, Funwave Foods' Veg Aloo Tikki offers a delicious and convenient solution. Trust Funwave Foods for the best frozen Veg Aloo Tikki that brings the authentic taste of India to your table.

#Top Frozen Veg Aloo Tikki Manufacturer and Supplier in India#Aloo Tikki Manufacturers & Suppliers in India#Aloo Tikki Wholesalers & Wholesale Dealers in India#Top Frozen Aloo Tikki Manufacturers in Gujarat India#Frozen Aloo Tikki at Best Price in India#Aloo Tikki 1.5 kg Price in India#Aloo Tikki at Best Price in India#frozen aloo tikki price#frozen aloo tikki for burger#Top frozen veg aloo tikki for burger price#Top frozen veg aloo tikki for burger near me#Top frozen veg aloo tikki for burger in india

0 notes

Text

Are you Looking for Continuous Fryer Manufacturers in India?

Introduction:

In the bustling landscape of food production, where speed, consistency, and quality are paramount, the importance of reliable equipment cannot be overstated. For businesses in search of top-notch continuous fryers to streamline their frying processes, Gulab Singh & Co. emerges as a beacon of excellence and innovation. As a leading manufacturer and supplier of continuous fryer machines in India, Gulab Singh & Co. has earned a stellar reputation for delivering superior products that meet the diverse needs of food producers across the country. In this blog, we’ll delve into the world of continuous fryers and explore why Gulab Singh & Co. stands out as the go-to choice for discerning businesses.

Unveiling Gulab Singh & Co.:

With a legacy spanning decades, Gulab Singh & Co. has established itself as a trusted name in the food processing machinery industry. Specializing in the design, development, and manufacturing of continuous fryer machines, the company combines precision engineering, innovative technology, and unparalleled craftsmanship to deliver best-in-class solutions to its clients. Whether it’s crispy snacks, savory appetizers, or indulgent treats, Gulab Singh & Co.’s continuous fryers are engineered to perfection, offering efficiency, reliability, and exceptional frying results.

The Importance of Continuous Fryers:

Continuous fryers play a pivotal role in the food production process, offering a seamless and efficient solution for frying a wide range of food products on a large scale. From potato chips and French fries to samosas and spring rolls, continuous fryers ensure uniform frying times, consistent product quality, and optimal production throughput. By automating the frying process and minimizing manual intervention, continuous fryers empower businesses to enhance productivity, reduce labor costs, and maintain high standards of food safety and hygiene.

Why Choose Gulab Singh & Co.?

1. Quality Craftsmanship: Gulab Singh & Co. prioritizes quality at every stage of the manufacturing process, utilizing premium-grade materials, advanced manufacturing techniques, and rigorous quality control measures to ensure durability, performance, and longevity of their continuous fryer machines.

2. Customization Options: Recognizing the diverse needs of their clients, Gulab Singh & Co. offers a range of customization options, allowing businesses to tailor their continuous fryers to suit specific requirements in terms of size, capacity, frying temperature, and conveyor speed.

3. Technical Expertise: Backed by a team of skilled engineers and technicians, Gulab Singh & Co. provides comprehensive technical support, installation services, and training programs to ensure seamless integration and operation of their continuous fryer machines.

4. Innovation and Efficiency: With a focus on innovation and efficiency, Gulab Singh & Co. continually strives to improve and enhance their products, incorporating the latest technologies and features to optimize frying performance, energy efficiency, and user experience.

5. Customer Satisfaction: Above all, Gulab Singh & Co. is committed to exceeding customer expectations, fostering long-term partnerships built on trust, reliability, and mutual success.

Conclusion:

In the competitive landscape of food production, choosing the right continuous fryer manufacturer is essential to the success of your operations. With Gulab Singh & Co. as your partner, you can rest assured that your frying needs are met with precision, reliability, and unmatched quality. Whether you’re a snack manufacturer, a frozen food producer, or a catering service, Gulab Singh & Co.’s continuous fryer machines empower you to elevate your food production capabilities and delight your customers with perfectly fried offerings. When it comes to continuous fryers in India, Gulab Singh & Co. stands tall as the industry leader, ready to help you fry your way to success.

Best Continuous Fryer Manufacturers in India

If you are looking for a Best Continuous Fryer Manufacturers in India, look no further than Gulab Singh and CO., Gulab Singh and CO. is a leading manufacturer and supplier of Continuous Fryer Machine Manufacturers in India.

For more details, Please Contact us!

Website — https://www.gulabsinghandco.com/

Contact No. — +91–9953108079, +91–9313119875

Email — [email protected], [email protected]

#Continuous Fryer Manufacturers#Continuous Fryer Manufacturer#Continuous Fryer Manufacturers manufacturer#Continuous Fryer Manufacturers manufcturer in India#Continuous Fryer supplier#gulab singh and co

1 note

·

View note

Text

Patent Registration

An invention is a product or a method that, in general, gives a new way of doing something or presents a novel technical solution to a problem. A patent is an exclusive right awarded for such an invention. Technical details of the invention must be made public in a patent application in order to get one. A patent is a type of intellectual property that, in exchange for publishing an invention for public disclosure, gives its owner the legal right to prohibit others from creating, importing, using, and selling it for a set amount of time. Put another way, a patent is the exclusive right granted to an invention, which is a good or method that usually gives a fresh approach to an old problem or a new technological solution. To protect an innovation, a patent application needs to make public all technical details about it. The complete process of Patent Registration involves a series of steps which are mandatorily followed to get a Patent in India. Both businesses & individuals can apply for Patent Registration for their inventions.

Types of Patents

There are different types of patents to be registered under the Patent, which are as follows:

Utility Patent

Utility patents comprise over two thirds of all patents issued worldwide, with the majority being issued in the United States. It is given for a fresh, practical, and non-obvious invention. It can refer to any device, method, produced good, material composition, or invention that outperforms an earlier one. There are three categories of utility: specific utility, which focuses on how an innovation fulfills a certain task, general utility, which is based on functionality, and moral utility, which ensures that an invention won’t be harmful or encourage improper use.

Design Patent

A design patent is one that is granted for a structure or design. It can contain, but is not limited to, particular chairs, shoes, tables, equipment, new typefaces, distinctive computer icons, etc. A design cannot be useful in order to qualify for a design patent; it must be beautiful or attractive. Similar to a typical utility patent, a design patent grants the owner exclusive rights to prevent third parties from creating, utilizing, importing, and selling the design.

Plant Patent

Plants that are novel or unusual are frequently protected with plant patents. The plant must not be an Irish potato or any tuber-propagated plant, nor should it be discovered in an uncultivated state, and it must be capable of asexual reproduction to be eligible for this kind of patent. Patents may be awarded for discoveries, inventions, or asexual propagation of any new and different plant variety.

To know more, visit: Patent Registration

0 notes

Text

Potato Chips Manufacturers in India: A Taste of Tradition and Innovation

In the heart of India's vibrant snack industry lies a sector dedicated to crafting one of the nation's favorite treats: potato chips. With a rich history rooted in culinary tradition and a keen eye on innovation, potato chips manufacturers in India play a pivotal role in satisfying the nation's snack cravings.

History and Heritage

The journey of potato chips in India traces back to the early 20th century when the British introduced this crispy delight to the Indian palate. Over time, Indian snack makers infused their unique flavors and spices, transforming potato chips into a beloved snack that reflects the country's diverse culinary heritage.

Traditional Techniques Meet Modern Manufacturing

While traditional methods of hand-slicing and frying potatoes still endure in some regions, modern potato chips manufacturers have embraced technological advancements to meet the growing demand. State-of-the-art equipment ensures consistency in texture, flavor, and quality while enhancing production efficiency.

Flavorful Varieties

From classic salted chips to innovative fusion flavors, potato chips manufacturers in India offer a vast array of options to tantalize taste buds. Whether it's the fiery kick of masala, the tangy zest of tomato, or the soothing creaminess of sour cream and onion, there's a flavor for every palate preference.

Quality and Hygiene Standards

Maintaining stringent quality and hygiene standards is paramount for potato chips manufacturers. From sourcing the freshest potatoes to adhering to food safety regulations during production, every step is carefully monitored to ensure that consumers enjoy safe and delicious snacks.

Catering to Diverse Preferences

Potato chips manufacturers understand the importance of catering to diverse dietary preferences and lifestyles. Hence, they offer an extensive range of options, including baked chips for health-conscious consumers, gluten-free variants for those with dietary restrictions, and premium gourmet selections for discerning snack enthusiasts.

Sustainability Initiatives

In recent years, sustainability has emerged as a key focus area for potato chips manufacturers. Many companies are implementing eco-friendly practices, such as using biodegradable packaging, reducing water consumption in production processes, and supporting local farmers for sourcing potatoes.

Supporting Local Communities

Potato chips manufacturing not only contributes to the economy but also fosters community development. By sourcing potatoes from local farmers and employing skilled labor, manufacturers play a vital role in empowering rural communities and promoting socio-economic growth.

Embracing Innovation

Innovation remains at the forefront of the potato chips industry, with manufacturers constantly exploring new flavors, ingredients, and production techniques. Whether it's experimenting with exotic spices or incorporating healthier alternatives, innovation drives the evolution of potato chips in India.

Celebrating Cultural Connections

Potato chips hold a special place in Indian culture, often accompanying festive celebrations, family gatherings, and leisurely snacking sessions. As manufacturers continue to innovate and diversify their offerings, potato chips remain a timeless symbol of joy, flavor, and togetherness in India.

Conclusion

As consumers' palates evolve and preferences shift, potato chips manufacturers in India stand ready to delight snack enthusiasts with their innovative creations. With a perfect blend of tradition, quality, and innovation, potato chips continue to reign supreme as one of India's most beloved snacks, promising a flavorful journey with every crunchy bite.

Recommended article :- Exploring India’s Finest Snack Creators

1 note

·

View note

Text

Plant-Based Food Ingredients Market, Share, Size, Trends, Future Forecast and Outlook

The market research report provides a comprehensive analysis of the industry, with a specific focus on the Plant-Based Food Ingredients Market. It examines the size, growth rate, and major trends within the Plant-Based Food Ingredients Market, offering valuable insights into its current state and future prospects. The report explores the significance of Fibre Reinforced Polymer Composites (FRP) in driving market dynamics and shaping business strategies. It investigates the market drivers, such as increasing consumer demand and emerging trends related to Fibre Reinforced Polymer Composites (FRP), providing a deep understanding of the factors influencing market growth. Additionally, the report assesses the competitive landscape within the Plant-Based Food Ingredients Market, profiling key players and their market share, strategies, and product offerings. It also addresses market segmentation, identifying different segments within the Plant-Based Food Ingredients Market and their unique characteristics. Overall, the market research report equips businesses operating in the Plant-Based Food Ingredients Market with valuable information and actionable recommendations to capitalize on opportunities and navigate the challenges in the industry.

Request Free Sample Report @ https://www.vertexbusinessinsights.com/request-sample/98/plant-based-food-ingredients-market

This research covers COVID-19 impacts on the upstream, midstream and downstream industries. Moreover, this research provides an in-depth market evaluation by highlighting information on various aspects covering market dynamics like drivers, barriers, opportunities, threats, and industry news & trends. In the end, this report also provides in-depth analysis and professional advices on how to face the post COIVD-19 period.

The research methodology used to estimate and forecast this market begins by capturing the revenues of the key players and their shares in the market. Various secondary sources such as press releases, annual reports, non-profit organizations, industry associations, governmental agencies and customs data, have been used to identify and collect information useful for this extensive commercial study of the market. Calculations based on this led to the overall market size. After arriving at the overall market size, the total market has been split into several segments and sub segments, which have then been verified through primary research by conducting extensive interviews with industry experts such as CEOs, VPs, directors, and executives. The data triangulation and market breakdown procedures have been employed to complete the overall market engineering process and arrive at the exact statistics for all segments and sub segments.

Key Market Segmentation

Plant-Based Food Ingredients Market- By Product

Soy

Rice

Pea

Canola

Wheat

Potato

Corn

Plant-Based Food Ingredients Market - By End Use

Food & Beverages

Dietary Supplements

Snacks

Animal Feed

Others

Plant-Based Food Ingredients Market - By Region

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

Rest of Europe

Asia-Pacific

China

India

Japan

South Korea

Rest of Asia-Pacific

Middle East and Africa

South America

Ask Queries @ https://www.vertexbusinessinsights.com/enquiry/98/plant-based-food-ingredients-market

Table of Content

1 Executive Summary

2 Market Introduction

2.1 Definition

2.2 Architecture

2.3 Scope of the Study

2.4 Related Stakeholders

3 Research Methodology

3.1 Introduction

3.2 Primary Research

3.2.1 Key Insights

3.2.2 Breakdown of Primary Interviews

3.3 Secondary Research

3.3.1 Important Sources

3.4 Market Size Estimation Approaches

3.4.1 Top-Down Approach

3.4.2 Bottom-Up Approach

3.4.3 Data Triangulation

3.5 List of Assumptions

4 Market Dynamics

4.1 Introduction

4.2 Drivers

4.2.1 Rapid increase in the number of full service restaurant operating across the globe

4.2.2 Expanding growth of the hospitality industry

4.3 Restraints

4.4 Opportunities

4.4.1 Rising demand for innovative and technologically advanced Plant-Based Food Ingredients

4.5 Porter's Five Forces Model Analysis

4.6 Value Chain Analysis

4.7 Impact of COVID-19 on Global Plant-Based Food Ingredients Market

5 Global Plant-Based Food Ingredients Market, By Product

5.1 Introduction

5.2 Soy

5.3 Rice

5.4 Pea

5.5 Canola

5.6 Wheat

5.7 Potato

5.8 Corn

6 Global Plant-Based Food Ingredients Market, By End Use

6.1 Introduction

6.2 Food & Beverages

6.3 Dietary Supplements

6.4 Snacks

6.5 Animal Feed

6.6 Others

7 Global Plant-Based Food Ingredients Market, By Region

7.1 Introduction

7.2 North America

7.2.1 US

7.2.2 Canada

7.2.3 Mexico

7.3 Europe

7.3.1 Germany

7.3.2 UK

7.3.3 France

7.3.4 Italy

7.3.5 Spain

7.3.6 Rest of Europe

7.4 Asia-Pacific

7.4.1 China

7.4.2 India

7.4.3 Japan

7.4.4 South Korea

7.4.5 Rest of Asia-Pacific

7.5 Middle East and Africa

7.6 South America

8 Competitive Landscape

8.1 Introduction

8.2 Vendor Evaluation Criteria

8.3 Vendor Share Analysis, 2020

8.4 Recent Developments, 2018-2021

8.4.1 New Product Launches

8.4.2 Partnerships

8.4.3 Mergers or Acquisitions

8.4.4 Business Expansions

9 Company Profiles

(This section covers the Business Overview, Financial Overview, Product and Product Offerings, Recent Developments, SWOT Analysis, and Key Strategies of the top market vendors. The given sequence does not represent their rankings in the market.

9.1 Puris Proteins, LLC

9.2 Ingredion Inc.

9.3 Cargill

9.4 Dolher Group

9.5 Health Warrior, Inc.

9.6 Avebe U.A.

9.7 Atlantic Food Naturals, LLC

9.8 Renmatix Inc.

9.9 DuPont

9.10 Farbest Brands

10 Appendix

10.1 Discussion Guide

10.2 Customization Options

10.3 Related Reports

Continue…

ABOUT US:

Vertex Business Insights is one of the largest collections of market research reports from numerous publishers. We have a team of industry specialists providing unbiased insights on reports to best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from a number of global leaders across industry segments.

CONTACT US

Phone:

+ (210) 775-2636 (USA)

+ (91) 853 060 7487

0 notes

Text

Snack Pellet Equipment Market to Showcase Continued Growth in the Coming Years

The snack pellet equipment market, in terms of value, is estimated to account for nearly USD 1.0 billion in 2019 and projected to grow at a CAGR of 5.2% to reach nearly USD 1.4 billion by 2025. This is due to the rising demand for extruded snacks globally. Snack pellets are non-expanded intermediate products that are usually produced through the extrusion process using various raw materials such as potato, corn, tapioca, and rice. The extruder is the main piece of equipment that is used to press the raw material and produce pellets. The key snack pellet manufacturers are also adopting new technologies for the production of snack pellets, which include single-screw extrusion, twin-screw extrusion, and co-extrusion. These processes aid in the manufacturing of snack pellets that are of various shapes, textures, and sizes. However, the technological advancements in snack pellet equipment to produce 3D pellets have also led to an increase in production capacity in a short time, thus driving market growth.

Some of the Prominent Key Players are:

Clextral (France)

GEA Group (Germany)

Buhler AG (Switzerland)

N.P. & Company Inc. (Japan)

Kiremko B.V. (Netherlands)

Grace Food Processing & Packaging Machinery (India)

Tsung Hsing Food Machinery Co., Ltd. (Taiwan)

AC Horn Manufacturing (US)

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=136666490

What is snack pellet equipment?

Snack pellet equipment refers to machinery and tools used in the production of snack pellets. Snack pellets are small, semi-finished products made from various ingredients like potato starch, cereals, or other grains. These pellets are then further processed through frying, baking, or extrusion to create a wide variety of finished snacks like chips, crisps, puffs, and more. The equipment involved includes extruders, pelletizers, dryers, fryers, and seasoning systems, among others, to produce these snack pellets efficiently and in large quantities for commercial purposes.

The Asia Pacific market is projected to grow at the highest CAGR during the forecast period.

The Asia Pacific is projected to witness the fastest growth during the forecast period. Population growth, rapid urbanization, and the rise in consumer awareness about the benefits of snack pellet are key factors driving the demand for snack pellet equipment in the region. The region is the third-largest potato producer in the world. Potato production has rapidly increased in the last two decades due to the expansion of the land area in the Indo-Gangetic Plains. Due to these factors, consumption has also increased in parallel with the increasing popularity and demand as a vegetable in urban diets. In addition, the growing preference for Western fast food products has also led to a surge in demand for potatoes in the country. This, in turn, is driving the fragmented snack pellets market in the region, which is projected to contribute to the growth of the market.

Get 10% Free Customization on this Report:

https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=136666490

Key questions addressed by the report:

What are the new trending products that the snack pellet equipment companies are exploring?

Which are the key players in the market, and how intense is the competition?

What are the upcoming growth trends that snack pellet equipment manufacturers are focusing on in the future?

What are the high-growth opportunities in the market for each segment?

What are the key growth strategies adopted by major market players in the snack pellet equipments market?

#Snack Pellet Equipment Market#Snack Pellet Equipment#Snack Pellet Equipment Market Size#Snack Pellet Equipment Market Share#Snack Pellet Equipment Market Growth#Snack Pellet Equipment Market Trends#Snack Pellet Equipment Market Forecast#Snack Pellet Equipment Market Analysis#Snack Pellet Equipment Market Research Report#Snack Pellet Equipment Market Scope#Snack Pellet Equipment Market Overview#Snack Pellet Equipment Market Outlook#Snack Pellet Equipment Market Drivers

0 notes

Text

Nuggets Making Machine in india

Looking for multi-lane Nuggets Making Machine with flow divider on conveyor belt or rack/tray that can make Veggie Nuggets, Potato nuggets, Sausage, Cookies, Cevapucci nuggets, Cheese ring and also pet food pellet. Automatic nuggets making machine can automatically complete the filling, forming, discharging and other processes of food raw materials, and can be combined with shaping machine, powder spreading machine, frying machine, cooking machine, quick processing equipment. Can be combined with. Freezing Machine and Packaging Machine for Automatic Veggie Nuggets Making Production Line. It has high yield and stable quality.

The powder spreading machine is suitable for applying a thin layer of pre-powder on seed dough pieces and medium bread pieces to fine bread pieces. When the product passes through the transmission network belt, the covered conveyor belt and the powder scattered on it are evenly coated with a layer of powder or mixed powder.

Versatility and efficiency thanks to the multi-lane forming machine

The manufacturing system is perfectly suited for multi-lane production of manufactured products of various cross-sections and feed materials. Long, flat, cylindrical, disc-shaped, cubic, square and star-shaped product shapes, to name a few, lanes are possible from 6 to 24, product diameter up to 80 mm and product length up to 20 mm. It is highly productive with mold components on an industrial scale. Can be a good choice for some meat process factories, restaurant use and fast food use.

Product Quality with High Productivity of Nuggets Making Machine

The nuggets production line is made separately with wire or blade directly on the outlet; It is seamless and linear to the movement of the product. The desired product shape is created using mold components located at the outlet. The gentle process also results in first-class product quality.

Forming machine can customize nuggets product easily and flexibly

Long, dimensional stable, skinless products can be produced on racks and trays or transported on conveyor belts and transferred to downstream systems for further processing. Nuggets forming machines can be formed on 6 to 24 lanes, and the product can be separated using blades or wires. Therefore the Forming System Nuggets Making Machine can be flexibly adapted to suit a variety of production parameters.

#nuggets making machine#chicken nuggets making machine price in india#nuggets making machine for sale#nuggets making machine price

0 notes

Text

How Machine Learning Can Enhance Efficiency and Productivity in the Agricultural and Agrifood Value Chains

Machine learning is a branch of artificial intelligence that enables computers to learn from data and make predictions or decisions without being explicitly programmed. Machine learning is a powerful tool that can be used to enhance the efficiency and productivity of the agricultural and agrifood value chains. Open source machine learning models can be applied to a variety of tasks, such as disease detection and diagnosis, yield prediction and optimization, crop recommendation and diversification, automatically counting packages on the belt conveyor, etc.

Some of the benefits of using these models are:

Disease detection and diagnosis

Machine learning can help farmers identify and diagnose crop diseases from images captured by mobile devices or drones. For example, Plant Village is an app that uses machine learning to detect over 30 common diseases of crops such as cassava, maize, rice, wheat, and potato. Mobinet is another app that uses machine learning to diagnose diseases of crops such as banana, coffee, pepper, and rubber. These apps can help farmers take timely and appropriate actions to prevent crop losses and improve crop quality.

Yield prediction and optimization

Machine learning can help farmers estimate and optimize their crop yield based on various factors such as soil type, irrigation level, fertilizer application, weather forecast, and crop variety. For example, Hugging Face is a platform that provides machine learning models for natural language processing (NLP). One of the models available on Hugging Face is Crop Yield Prediction, which can predict the yield of crops such as wheat, maize, soybean, and rice based on historical data and current conditions. This model can help farmers plan their harvest and optimize their resource allocation.

Crop recommendation and diversification

Machine learning can help farmers choose the best crops to grow based on their location, climate, soil type, market demand, and profitability. For example, CropNet is a web-based tool that uses machine learning to recommend crops for different regions in India based on biophysical and socio-economic factors. CropNet also provides information on crop diversification strategies to reduce risks and increase income.

Automatically counting packages on the belt conveyor

This can help to monitor the inventory and track the shipments of the products. A machine learning model can be trained to detect and count the packages on the conveyor belt using images or videos captured by a camera. This can reduce human errors and increase efficiency.

Identify impurity in grain (soybean, rice, etc.)

This can help to ensure the quality and safety of the products. A machine learning model can be trained to classify the grains into different categories based on their appearance, such as color, shape, size, texture, etc. This can help to detect and remove any impurities or defects in the grains.

Automatically stock evaluation through drone

This can help to optimize the storage and distribution of the products. A machine learning model can be trained to analyze the images or videos captured by a drone flying over the warehouse. This can help to estimate the stock level, identify the location and condition of the products, and plan the best route for delivery.

Predictive maintenance of equipment

This can help to reduce the downtime and costs of repairing or replacing the equipment used in the agri-food system. A machine learning model can be trained to monitor the performance and condition of the equipment using sensors and historical data. This can help to detect any anomalies or faults in the equipment and provide alerts or recommendations for maintenance actions.

Demand forecasting and pricing optimization

This can help balance the supply and demand of the products and maximize revenue and profit. A machine learning model can be trained to forecast the demand for the products using various factors, such as seasonality, weather, holidays, events, promotions, etc. This can help plan the production, inventory, and distribution of the products. Moreover, a machine learning model can be trained to optimize the pricing of the products based on demand, competition, costs, and customer preferences. This can help increase sales and customer satisfaction.

These are just some examples of how machine learning can help farmers and agribusinesses enhance their efficiency and productivity. There are many more open source machine learning models and applications that can be used for various aspects of the agricultural and agrifood value chains.

If you are interested in using machine learning for your farm or your production value chain, you may want to recruit a young data scientist who can apply or fine-tune these machine learning models for your specific needs. Alternatively, you can also learn some basic machine learning skills yourself by taking online courses, reading books on the topic, or watching YouTube videos on machine learning applied to agriculture.

Machine learning is a powerful tool that can transform the agricultural and agrifood value chains. By using machine learning, we can make better decisions based on data and improve our performance and profitability.

I hope this post has given you a better understanding of the benefits of using machine learning. I believe that machine learning has the potential to make a significant positive impact on the agriculture and agrifood industries, and I am excited to see how it is used to improve the performance and sustainability of agribusiness firms in the years to come.

Illustration Photo: The fruit is conveyed by belt through a washing process and enters the processing plant where it is graded for bad or damaged fruit. The fruit is then separated by size and sent to the juice extractors. (credits: USDA photo by Ken Hammond / Public domain)

Read the full article by clicking here https://dekoholding.com/dekoposts/8YCjACarPQB36qhPs/how-machine-learning-can-enhance-efficiency-and-productivity/dekonews

0 notes

Text

Potato Processing Market Strategic Investment Plans and Business Opportunities

The potato processing market refers to the industry involved in transforming raw potatoes into various processed potato products. This market includes a wide variety of goods, including potato starch, dried potato flakes, frozen french fries, and potato chips. There are various procedures involved in processing potatoes, including washing, peeling, slicing, cooking, and packing.

Here is some comprehensive information about the potato processing market:

Market Overview: The potato processing industry has experienced significant growth over the years due to the rising demand for convenience foods, changing dietary patterns, and the popularity of potato-based snacks. Processed potato products have gained popularity worldwide due to their convenience, longer shelf life, and wide availability.

Market Segmentation: The potato processing market can be segmented based on product type, application, and geography. Common product types include frozen potato products (french fries, wedges, hash browns), potato chips, dehydrated potatoes, potato flakes, and potato starch. The applications of these products range from foodservice (restaurants, fast-food chains) to retail (supermarkets, convenience stores).

Market Drivers: Several factors drive the growth of the potato processing market, including:

Increasing demand for convenience foods and ready-to-eat snacks.

Growing popularity of fast-food chains and quick-service restaurants.

Rising consumer awareness about the nutritional value of potatoes.

Technological advancements in processing equipment, improving efficiency and quality.

Expansion of retail distribution channels and the global food supply chain.

Market Challenges: Despite the market's growth potential, it faces certain challenges:

Fluctuating raw material prices and supply chain disruptions.

Intense competition among key market players.

Increasing health concerns regarding fried and processed foods.

Stringent government regulations and quality standards.

Environmental concerns related to waste disposal and water usage.

Key Players: The potato processing market is highly competitive and dominated by several major players. Some of the key companies in the industry include:

Lamb Weston Holdings, Inc.

McCain Foods Limited

J.R. Simplot Company

The Kraft Heinz Company

Aviko B.V.

Intersnack Group GmbH & Co. KG

Calbee, Inc.

Herr Foods Inc.

Burts Potato Chips Ltd.

Regional Analysis: The potato processing market is geographically diverse, with significant growth observed in various regions, including North America, Europe, Asia Pacific, and Latin America. Europe and North America have traditionally been the largest markets for processed potato products, driven by the high consumption of snacks and fast foods. However, the Asia Pacific region, particularly countries like China and India, is experiencing rapid growth due to changing consumer lifestyles and an increasing preference for convenience foods.

Future Outlook: The potato processing market is expected to continue growing in the coming years. Factors such as increasing urbanization, a busy lifestyle, and the introduction of innovative potato products are likely to drive market growth. Additionally, the demand for healthier and organic potato snacks is expected to present new opportunities for market players. However, manufacturers will also need to address sustainability concerns and adapt to changing consumer preferences for healthier alternatives.

It's important to note that this information is based on the knowledge available up to September 2021, and the current state of the market may have evolved since then.

0 notes

Text

snack food making machine-Fry And Bake Technology Pvt. Ltd.

Fry and Bake Technologies Pvt. Ltd company founded in 2012 and based in Gujarat, India. As a world leader in the manufacture of process lines for the Snacks processing industry, we focus on product development, continuous improvement, innovation, sustainable technology and co-operation to ensure, we give added value to every customer. We respect our team, our customers, and the environment.

With a team of qualified personnel we innovate, design, manufacture and install advanced processing lines worldwide. We specialize in lines to process into French fries, potato chips, pellet snacks, Namkeen snacks, and Bakery products.

OUR QUALITY

We will never be compromised with the quality. We specialize in lines to process into French fries, potato chips, pellet snacks, Namkeen snacks, that is made in high quality of raw materials and latest technology. Our team of expert quality auditors keeps close eye on the production tasks as well as check the manufactured range of equipment for any kind of defects.

OUR MISSION

Our Mission is to satisfy the needs of our customers. We have specialized team for fulfilling the requirements of our customers and to give them appropriate service whenever the need.

OUR INFRASTRUCTURE

We uphold a state-of-the-art infrastructure base which conforms to the standards of international level in terms of various kinds of facilities. Our manufacturing unit is spread over a total plot area of 110 ft X 130 ft, with optimum installed capacity that is sufficient to prove our capacity in terms of robust infrastructure. We have equipped this spacious unit with necessary machines and equipment that facilitate flawless production of our wide range of food processing machines.

RESEARCH & DEVELOPMENT

The Company has an extremely experienced Research, Development & Design department staffed by personnel from both food equipment as well as snack food industry. It is well equipped with latest equipment and facilities to keep abreast of latest trends in technology.

AFTER SALES SERVICE

After sales service plays an important role in customer satisfaction and customer retention. It generates loyal customers. And we provide best service to our loyal customers.

OUR VISSION

now, we want to become the largest and innovative player in developing food machines to automate all processes in the most economical price in India

OUR STRENGTH

Fry And Bake strength is to deliver total solutions in Snacks processing from the infeed of product to the packaging line resulting in a high quality end product. Our success is achieved by working in total co-operation with our customers to achieve their specific requirements, We aim to get the best out of the product and the customers process line.

WHY US

International quality range

Well equipped manufacturing|

Competitive prices

Team of experts

Total quality management

Training & service support

0 notes

Text

Essential Equipment and Basic Guidelines for Feeding a Six-Month-Old Baby in India

As babies reach six months, they begin to develop the habit of chewing and feeding on lumpy foods, even without fully developed teeth. As parents, it is crucial to start with fully mashed and easily digestible foods, but it's important to keep in mind that every child is different and may not readily accept new foods.

To ensure a smooth feeding process for your child, here are some essential equipment and basic guidelines that you can follow:

A. Must-Have Handy Equipment:

1. Pressure Cooker: A small stainless steel pressure cooker is a convenient choice for preparing nutritious foods such as khichdi, boiled vegetables, lentils, etc., that your baby can easily feed on.

2. Food Processor: Baby food processors come equipped with all the necessary tools such as a masher, cup, spoons, grater, juicer, etc., to make the feeding process simpler.

3. Sterilizer: Given the current situation with Covid, it's crucial to be extra cautious about what goes into your baby's mouth. Before feeding your baby, ensure to sterilize every utensil used.

4. Potato Masher: A handheld device that can be used to mash any food for easy feeding.

5. Feeding Bowls and Spoons: Specially made utensils are eco-friendly and not harmful to the baby's delicate gums.

B. Basic Guidelines:

1. Mother's milk should remain the primary food source for babies, even if they start feeding on solid foods from the seventh month. Fresh and pure cow milk can also be given as it is light and easily digested.

2. Feed your baby in quantities equivalent to the size of their fist, which is around 90-100 ml.

3. Always feed your baby in a comfortable seating position.

4. Sterilize utensils thoroughly before cooking and feeding.

When it comes to purchasing milk for your baby, choose a reliable brand like Doodhvale, which provides pure cow milk in Delhi NCR at your doorstep. They maintain a hygienic and quality testing process to deliver good quality milk to their customers.

In conclusion, following these simple habits and guidelines can ensure your baby's healthy and happy feeding routine.

Looking for healthy recipes? Check out our YouTube channel where you can find a variety of delicious and nutritious meals to help you achieve your fitness goals. Don't forget to subscribe and turn on notifications to stay updated with our latest videos. For high quality dairy products in Delhi NCR, browse the Doodhvale website or download our mobile app to get fresh and pure milk, dairy items, bakery, groceries, and vegetables at the best deals. Their products are free from preservatives, chemicals, and antibiotics, ensuring that you get the best quality products delivered to your doorstep. Visit our website and YouTube channel for more information and updates.

#babyfeeding#babyfood#weaning#lumpyfoods#mashedfoods#utensils#pressurecooker#foodprocessor#sterilizer#potatomasher#feedingbowls#feedingspoons#mothersmilk#cowmilk#comfortableseating#hygiene#foodsafety#Doodhvale#purecowmilk#qualitytesting#DelhiNCR

0 notes

Text

5 TIPS TO SAVE ENERGY WHEN PRODUCING POTATO CHIPS

If you have a potato chips-producing factory, then you might know how important it is to save energy and money wherever possible. The good news is that there are many ways to do just that! With some simple tweaks, you can save energy while still turning out delicious potato chips using the right potato chips production line.

When it comes to energy-saving strategies, the sky’s the limit, especially in countries like India, Bangladesh, Kenya, Uganda, Nigeria, UAE. Consider other energy-efficient options such as adding insulation to equipment, investing in double-paned windows, or using energy-efficient frying systems. You can even invest in renewable energy sources like wind power or geothermal energy.

It all comes down to understanding your energy needs and finding ways to reduce or eliminate wasteful consumption of resources in your chips-making factory. To measure your progress, remember to keep track of your energy usage and green initiatives over a period of time. By tracking your progress, you’ll be able to identify areas of improvement and take steps to increase your energy efficiency.

By following the below-mentioned tips, you can start reducing your energy consumption and saving money by installing appropriate potato chips making line. Each of the tips can help make a big difference in your bottom line and the environment- not to forget your customer’s taste buds! Implementing these strategies will allow you to produce tasty snacks with minimal energy usage. So what are you waiting for? Let’s get started on some eco-friendly potato chip production processes!SEMI AUTOMATIC POTATO CHIPS LINE

Manage Heat Levels Efficiently

When producing potato chips through a fully automatic potato chips line, maintaining the right level of heat is essential to energy efficiency. To achieve optimal energy savings, look no further than managing your heat levels efficiently. Here are some recommendations to begin with:

Invest in insulation – Investing in insulation can prevent valuable heat from escaping which will reduce the amount of energy needed to keep the facility at the desired temperature. This is especially true for big processes where potato chips machines have extremely high temperatures.

Monitor frying times – By ensuring that frying times are consistent and monitored regularly, you can ensure that every batch of chips is produced properly and done within a reasonable time frame—which in turn helps to keep energy costs down.

Make use of timers – Making use of timers helps to keep production on track and prevents costly errors, like over-frying batches or leaving certain batches too long.

These tips are important for your success as a potato chip producer! Make sure to practice these tips regularly to save energy and increase efficiency through the potato chips production line.

Utilize Energy-Saving Techniques

When it comes to producing delicious potato chips, energy efficiency is key. It might seem like the process is mostly automated, but there are some simple steps you can take to reduce the amount of energy needed when manufacturing chips.

Start by investing in energy-saving potato chips line accessories, such as motion sensors, switching to LED lighting, and using insulated containers for transportation. Not only does this help make your production process more efficient and cost-effective – it also keeps your carbon footprint in check!

Next, make sure to look into alternative sources of energy such as solar power or wind turbines if they are available in your area. This will significantly reduce costs while you’re producing potato chips and help reduce environmental impact.

Finally, remember that proper maintenance of a fully automatic potato chips line is essential for optimal performance. Make sure all machines are regularly serviced and filter systems are replaced at least once a year. Taking care of your equipment helps increase efficiency and decreases wastage – a win-win!

By following these tips, you can ensure that your potato chip production process is both environmentally friendly and cost-effective!

Implement Modern Technology Into Operation

Modern technology is key when it comes to saving energy in potato chip production. Not only does it increase overall efficiency, but it helps reduce energy costs as well! Here are some of the top ways you can use modern technology to save energy:

Automation

Automation is a great way to save energy in potato chip production. From controlling batch sizes and temperature levels to monitoring speed and pressure, a fully automatic potato chips line can optimize your production flow for maximum output with minimal input. Plus, automated systems require less manpower, so you won’t have to worry about labour costs either.Fully Automatic Potato Chips Line

Motion Sensors

Adding motion sensors to your potato chips machine is also a great way to reduce wasted energy. These sensors detect motion and will turn off the equipment when it is not being used – making sure that you don’t have any unnecessary power usage while the machines are idle.

Digital Monitoring System

A digital monitoring system helps you keep track of all the processes in your potato chip production, allowing you to make more informed decisions about how much energy you’re using. That way, you’ll know when and where adjustments need to be made in order to maximize efficiency while minimizing output costs.

Invest in Energy Saving Machines

You may not know this, but investing in energy-efficient machines can save you a great deal of money and energy in the long run! The right potato chips making line can help reduce energy costs, decrease waste and increase productivity—which all add up to a healthier bottom line.

So why is investing in energy-saving potato chips machine so important?

Automation

Modern potato chip production processes are highly automated, which means electricity or other forms of energy are used to operate the machines. Investing in newer, high-efficiency machines can greatly reduce your overall energy consumption.

Reduced Operating Costs

Newer machines tend to be more efficient as they use less power and generate fewer byproducts. This means you will experience reduced operating costs over time as you won’t have to replace parts as often or perform extensive repairs and maintenance.

Increased Productivity

Energy-efficient potato chip production machines generally require less human supervision than older models, freeing up workers for more meaningful tasks. This increases productivity while ensuring that quality remains high and consistent across the board.

These days, there are plenty of eco-friendly options available—so why not give them a try? Investing in Economode’s energy-saving fully automatic potato chips line could be one of the best decisions your business ever makes!

Maximize Production With the Lowest Power Consumption Rate

If you want to save energy when producing potato chips, you need to make sure you are maximizing production with the lowest power consumption rate. To make this happen, here are a few tips that can help you out.

Invest in Quality Equipment

Investing in quality potato chip accessories & attachments is essential for any food production business – and it’s especially important when it comes to potato chips. Quality accessories will not only help you maximize production, but they will also use less energy than their low-quality counterparts. So make sure you install the most efficient potato chips machine possible!

Utilize Automation Technology

Automation technology can help streamline your processes, reduce human error and ultimately save energy. For example, Economode’s fully automatic potato chips line can be used for sorting and packing chips; this means that manual labour is reduced and less energy is consumed in the long run.

Implement Energy-Efficient Strategies

You can also implement energy-efficient strategies such as using LED lighting, setting heating/cooling systems at specific temperatures or using energy-efficient motors and pumps in order to reduce energy consumption. These small changes can really add up over time!

Use Renewable Energy Sources

Finally, consider using renewable energy sources like solar power to produce your potato chips. Solar power is clean, sustainable and cost-effective – plus it’s much more environmentally friendly than traditional sources of power!

Conclusion

Potato chip production does require energy, but there are steps you can take to minimize waste and maximize your efficiency. From using the right potato chips making line in India, Bangladesh, Kenya, Uganda, Nigeria, UAE to utilizing any other available energy-saving technologies, it’s possible to produce potato chips with minimal energy consumption. Start implementing these tips today and watch your Potato chips manufacturing unit grow.

0 notes

Text

CONTINOUS FRYER MACHINES

Continuous Fryer Machines are industrial food processing equipment that are designed to fry large quantities of food products in a continuous, automated process. These machines are commonly used in the food industry for processing a wide variety of products, including potato chips, French fries, doughnuts, chicken, fish, and many others.

Continuous fryer machines are typically large, stainless steel tanks that are filled with cooking oil. The machines are equipped with heating elements, which are used to heat the oil to a specific temperature, and a conveyor system that moves the food products through the oil. As the food products pass through the oil, they are cooked to the desired level of crispiness and then removed from the machine.

There are two main types of continuous fryer machines: batch fryers and continuous fryers. Batch fryers are designed to fry a set amount of food products at one time. Once the batch is finished cooking, the machine is emptied, cleaned, and refilled with a new batch of products. Continuous fryers, on the other hand, are designed to fry a continuous stream of food products. The machine is continuously fed with raw products at one end, and cooked products are continuously removed at the other end.

Continuous fryer machines offer several advantages over traditional frying methods. One of the main advantages is speed. Because the machines are designed to fry large quantities of products in a short amount of time, they can significantly increase the production rate of a food processing facility. Additionally, continuous fryers offer consistent frying results, as the temperature and cooking time can be precisely controlled.

CONTINOUS FRYER MACHINE

Another advantage of continuous fryer machines is their efficiency. These machines are designed to use the minimum amount of oil necessary to fry the products. This not only saves on oil costs, but also reduces the amount of waste generated by the frying process.

Continuous fryer machines also offer several safety features. The machines are typically equipped with automatic shut-off systems that activate if the oil reaches a certain temperature or if there is a malfunction in the system. Additionally, the machines are designed with safety guards and interlocks to prevent injury to operators.

When selecting a continuous fryer machine, there are several factors to consider. One of the main factors is the type of product that will be fried. Different products have different cooking requirements, and the machine must be able to accommodate these requirements. For example, a machine designed for frying potato chips may not be suitable for frying chicken.

Another factor to consider is the capacity of the machine. Continuous fryer machines are available in a range of sizes, from small countertop models to large, industrial-sized machines. The capacity of the machine should be selected based on the production needs of the facility.

The type of oil used in the machine is also an important consideration. Different oils have different cooking properties and may be more suitable for certain products. Additionally, the cost of the oil should be taken into account, as some oils are more expensive than others.

Maintenance requirements are another factor to consider when selecting a continuous fryer machine. These machines require regular cleaning and maintenance to ensure proper operation and to prevent breakdowns. The maintenance requirements of the machine should be assessed before purchase to ensure that the facility has the resources to properly maintain the machine.

If you have any query please free to ask:

GULAB SINGH & CO

CONTACT US: +91-8340521544,+91-9953108079,+91-9313119875

EMAIL:- [email protected]

ADDRESS:- Khasra No. 75, Morta Industrial Area Behind SBI Bank, Opposite Morta Village, Meerut Road, Ghaziabad-201003, Uttar Pradesh, India

1 note

·

View note

Text

Different types of farming techniques in India

In this continuation, we’ll discuss the basics of three distinct agricultural methods. Agriculture is crucial to the economy of every nation. Farming includes the production of food and ornamental plants. A tractor sprayer attached to a tractor’s back is called a tractor-mounted sprayer. Farming is the one economic foundation upon which every nation rests. The success or failure of a farm is affected by its location, the market for its products, the availability of skilled workers, and the sophistication of its machinery. If you’re looking to save time, energy, and resources, an orchard sprayer is a way to go.

There are three main types of farming:

The following are examples of the three main types of farming and agriculture:

Subsistence farming

Family farming is another name for subsistence farming since it provides for a farmer’s immediate family: only basic machinery and manual labour from around the house where needed. Low yields are typical of this type of farming. They do not use modern farming techniques or high-yielding varieties of seeds and fertilizer.

They lack access to essential services like electricity and water irrigation. Farming for subsistence is typically done by hand.

Subsistence farming can be classified into two types:-

Intensive subsistence farming:-

It entails a relatively modest amount of land, some essential, low-cost tools, and additional labour for crop production. Because “intense” connotes strenuous effort, the implication is that more significant effort is needed. Multiple crops can be grown yearly on the same plot of land because of the favourable climate and rich soils typical of this type of farming.

Rice is the primary crop here. Wheat, maize, pulses, and oilseeds are some additional crops. The more populated monsoon areas are where this type of farming is most prevalent. Southeast Asia and East Asia fall within this category.

Primitive subsistence farming:-

Nomadic farming and herding are also part of this lifestyle.

Shifting cultivation:-

This farming grew in heavily wooded regions like the Amazon basin, tropical Africa, Southeast Asia, and northeast India. This is where the rain is heaviest. Rapid plant growth is regenerated.

At the outset of the shifting cultivation process, the area is cleared by cutting down and burning trees. The resulting tree ash is then incorporated into the ground.

Crops, including maize, yam, potatoes, and cassava, are cultivated using this method. This soil is suitable for growing crops every two or three years. Then the abandoned land as soil fertility declines. The farmers relocate to the new area and begin cultivating it similarly. Slash-and-burn farming describes this method of agriculture.

Nomadic Herding:

The semiarid and arid regions are ideal for this method of farming. Like the central Asian republics, India’s Rajasthan and Jammu & Kashmir are home to beautiful landscapes. The farmers in this system herd their animals along predetermined paths as they go from one location to another in search of food and water.

Sheep, camels, yaks, and goats are commonly raised for their meat and fibre in this region. Farming provides milk, meat, and other foods for the herdsmen and their families.

Commercial Farming

Crops are grown on this farm to be sold in local markets. This farming is done mainly for commercial reasons.

It needed a lot of space and advanced machinery.

High-priced equipment is used to complete the task.

Commercial farming is 3 types.

Commercial grain farming:-

Grains are the primary reason for this cultivation.

Seasonally, this type of farming occurs during the winter.

In this type of farming, only one crop can be cultivated at a time.

Many wealthy farmers are living in this region.

Commercial mixed farming:-

This type of farming is done for growing foods, fodders crops.

In this farming, one or more crops are grown together.

It has good rainfall and irrigation.

The crops are cared for carefully.

The crops are done almost at the same duration.

This farming is most used in Europe, the eastern USA, Argentina, southeast Australia, New Zealand, and South Africa.

Home Farming:-

Growing food at home may be done on a terrace or in a garden.

You only needed a little area and essential garden tools like a rake and pruners.

You only needed a little room and some compact equipment like a garden rake and pruning shears.

It’s not just food; this farming is utilized as a decorative item in people’s homes.

It was done for both profit and survival purposes.

There are two types of farming:-

How many different kinds of farming do people in India practise? If this isn’t the case, then we’re likely to be categorised with the lower forms of farming in India. Check out this site for specifics on various farms. An agricultural sprayer machine is a vital tool for farmers.

Container farming:-

These farming methods are ideal for those with only a tiny plot of land to cultivate, such as in a city apartment’s balcony, courtyard, or yard. This farming method can grow almost any fruit, vegetable, or flower.

Vertical Farming:-

A “window garden” is how it’s being referred to here. Small plant crops and vine crops see the most vertical farming utilization. Ghee, Loki, tomato, chile, and coriander are all components. Since traditional methods of growing vine crops tend to provide lower yields, vertical farming is ideal for these plants. Air-assisted sprayer, and choose from a wide variety of sprayers available on the market.

In India, the anna data are the farmers. They put up long hours to ensure everyone has enough to eat. The farmers organized themselves by the size of their farms. Listed below are the many categories of Indian farmers. Consider looking at the Farmer profile. The Agriculture Blower is a vital component of feed mills and blenders.

Marginal Farmers – When a farmer owns less than 1 hectare of land, they are considered Marginal farmers.

Small Farmers – Small farmers tend to have 1–2 acres of land.

Semi-medium farmers – Farmers with between 2 and 4 hectares of land are considered semi-medium.

Medium Farmers– Farmers with 4–10 ha of land are considered medium farmers.

Large Farmers – When a farmer owns 10 hectares of land or more, they are considered a Large farmer. These folks are also classified as farmers.

Conclusion –

In India, farming is the primary source of income, and there are many types of farming. This completes the exhaustive descriptions of the various farming methods. Please stay tuned for further developments along these lines, and I hope you enjoy this post. The latest in Agriculture news is also available here daily. As a necessary aspect of vineyard management, using a vineyard sprayer with pesticides to combat grapevine diseases and pests is essential.

Keep reading if you’re interested in learning more about crop farming!

0 notes