#RefractoryLining

Explore tagged Tumblr posts

Text

How to Choose the Best Lining Vibrator for Your Foundry: A Complete Buying Guide

When it comes to improving efficiency and extending the life of your induction furnace, the choice of a lining vibrator is critical. Whether you're building a new foundry line or upgrading existing equipment, choosing the right compaction tool ensures proper lining, reduces wear, and minimizes production downtime.

This comprehensive guide will walk you through the key factors to consider when selecting a lining vibrator for your specific furnace setup, refractory type, and operating conditions.

What Exactly is a Lining Vibrator?

A lining vibrator is an essential tool used in foundries to compact refractory lining material inside the crucible of an induction furnace. Uniform vibration ensures there are no gaps or weak spots, which could otherwise lead to premature furnace wear or failure.

Explore LeisterTech’s advanced range of lining vibrators here to see models suitable for various furnace sizes and materials.

Step-by-Step Guide to Selecting the Right Lining Vibrator

Know Your Furnace Specifications

Your furnace capacity and crucible dimensions will largely dictate the size and power of the vibrator required. Key parameters include:

Furnace tonnage (e.g., 1-ton, 3-ton, 10-ton)

Crucible diameter and depth

Wall thickness and taper

For optimized performance, LeisterTech offers custom vibrator configurations tailored to your furnace setup.

Need technical advice? Contact LeisterTech’s expert support team for a one-on-one consultation.

Match the Vibrator to Your Refractory Type

The physical characteristics of your refractory material—whether it's alumina-based, silica, or magnesite—affect how it reacts under vibration. Make sure to ask:

Is the material coarse or fine-grained?

Is it dry, semi-wet, or plastic?

Does it tend to flow easily or resist compaction?

Choosing a model with adjustable frequency and amplitude ensures compatibility with a wide range of refractory types.

Look for Performance-Critical Features

When investing in a vibrator, prioritize models that offer:

Variable RPM (1800–3000) for tailored compaction

Durable, wear-resistant construction

Long bearing life

Low noise and heat output

Easy maintenance access

LeisterTech’s vibrators are designed for 24/7 performance under extreme foundry conditions. They combine power and efficiency with minimal maintenance needs.

Ensure It Fits Your Workflow

Vibrators can be integrated into various systems, such as:

Manual lining setups

Robotic or semi-automated crucible lining processes

Portable or overhead-mounted configurations

Your choice should align with your team’s skills and existing workflows. If you're unsure, get personalized setup recommendations from the LeisterTech team.

Don’t Ignore Support & Training

Your investment should come with reliable post-sale support, including:

Easy access to spare parts

On-site support availability

Operator training and retraining services

Check out LeisterTech’s specialized training programs to keep your team skilled and confident in using lining vibrators effectively.

Quick Comparison of Lining Vibrator Models

FeatureBasic VibratorModel X (LeisterTech)Model XL (LeisterTech)Max Furnace SizeUp to 2 tonsUp to 5 tons5–12 tonsRPM RangeFixed (1500)Variable (1800–2800)Variable (2000–3000)Noise LevelHighModerateLowMaintenance Interval3 months6 months12 monthsPrice Range (INR)₹45K–60K₹70K–90K₹1.2L–1.5L

Want detailed specs? Request a brochure by emailing [email protected]

Expert Insight

“Choosing the wrong vibrator may look like a minor issue, but it can cost lakhs in refractory damage and production delays. The right fit makes all the difference.” – Senior Engineer, LeisterTech India

Get Expert Help Now

Not sure where to begin? LeisterTech’s team is ready to assist with technical evaluations and vibrator recommendations tailored to your setup.

📱 Call: +91 93289 16310 / +91 99091 79617

✉️ Email: [email protected]

🌐 Get in touch via our contact page

Whether you're modernizing your foundry or installing a new induction furnace line, choosing the right lining vibrator is essential for long-term productivity and cost-efficiency. Let the experts at LeisterTech help you get it right the first time.

#InductionFurnace#LiningVibrator#FoundryEquipment#RefractoryLining#FurnaceMaintenance#IndustrialMachinery

0 notes

Photo

Five major categories of Insulation

#insulation#rockwoolinsulation#hotinsulation#thermalinsulationmaterials#refractorylining#refmonindustries

0 notes

Photo

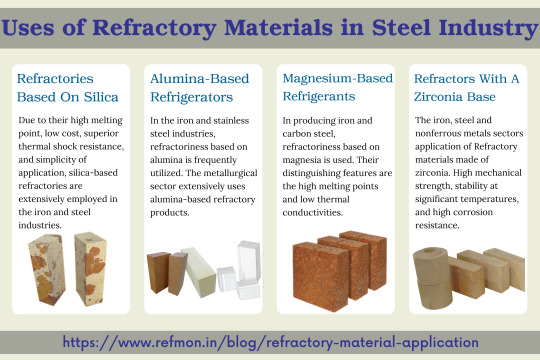

Uses of Refractory Materials in Steel Industry

To prevent molten metal from oxidizing and forming slag, refractory materials supplier is employed in the iron and steel industry. These refractories mainly consist of zirconia (ZrO2), alumina (Al2O3), silica (SiO2), and magnesia (MgO) (ZrO2).

#refractory#refractorylining#refractorymaterial#refractoryindustry#refractorymaterialssupplier#applicationofrefractorymaterials#refmon

0 notes

Link

Application of Refractory Materials in Iron and Steel Industry

The refractory industry is little about other sectors. Due to its insignificance in significant user industries like steel, cement, aluminum, etc., it has yet to receive the recognition it deserves. However, because it is a very specialized sector of the economy, it cannot be disregarded.

#refractory#refractorylining#refractorymaterial#refractoryindustry#refractorymaterialssupplier#applicationofrefractorymaterials#refmon

0 notes

Photo

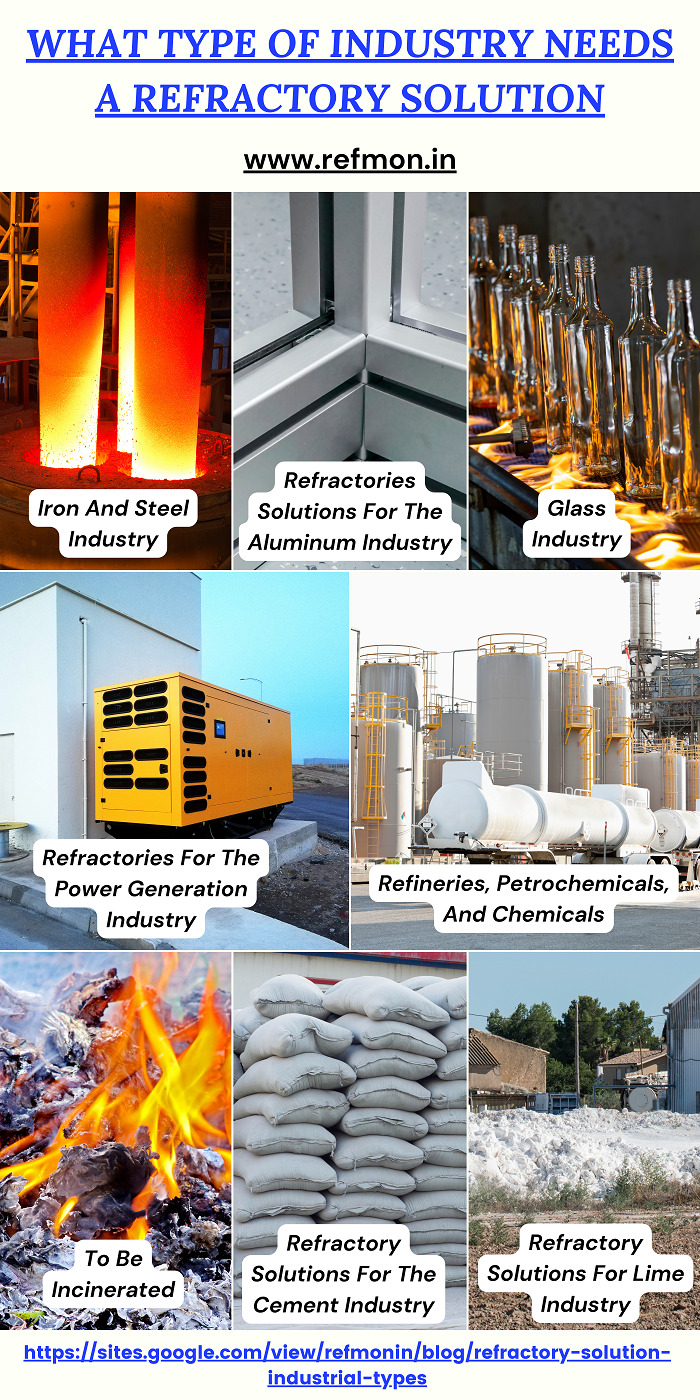

What type of Industry needs a Refractory Solution?

#refractory#castable#acidproof#refractorybricks#castablerefractorysolutions#refractorylining#acidprooflining#industryrefractorysolution#acidproofbricklining

0 notes