#Robotic End-Effector Market Size

Text

Analyzing the Market Dynamics of Robot End Effector Market

The global robot end effector market size is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%.

Growing demand for modular end effectors, increasing adoption of cobots, penetration of automation in SMEs, and increasing adoption in the warehousing, pharmaceutical, and food industry are the main drivers for the growth of the robot end effector market.

The robot end-effector market will grow significantly due to its various applications in several industries, such as automotive, electrical & electronics, food & beverage, and pharmaceutical. Various key players in the market adopt different strategies such as acquisitions, product launches, collaborations, and partnerships to grow in the robot end effector market.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Driver: Increasing demand for modular end effectors by various industries.

Due to the fast-changing nature of industries, the demand for modular end effectors is increasing. This scenario is observed in the consumer goods industry, specifically packaging, where the shape, size, surface, or weight of the packaging is constantly changing. This shortens the life cycle of an end effector to 1 to 2 years and thereby increases the cost of replacement for the company. Modular end effectors have the capability to accommodate and handle a large variety of objects as required. A modular vacuum bar from Schmalz (Germany) can perfectly seal and lift objects regardless of their size; Zimmer Group (Germany) and Schunk (Germany) introduced a modular gripping system – MATCH with an unlimited range of uses from production and assembly to warehouse logistics, shipping, and even laboratory automation. This modularity ensures that the grippers do not have to be changed from time to time, thereby reducing the cost of redesigning and downtime associated with its change and replacement.

Restraint: High cost of deployment, especially for SMEs.

Small and medium-sized enterprises (SMEs) differ from large-scale industries such as automotive or electronics manufacturing in various ways. SMEs typically have a low threshold for capital expenditure, a low-risk appetite, and limited time to generate returns on their investment. Additionally, their applications are often specific and on a case-by-case basis. For instance, Saint-Gobain, a glass manufacturing company in France, required automation of its glass polishing process that was previously carried out manually. Robotiq successfully automated the process by programming its torque sensor to replicate the hand movements and pressure applied by a human. Unlike large industries, many SMEs have not built their infrastructure around deploying robots, and must often integrate them into their existing floor space at a later stage.

Opportunity: Advancement in robotics has surged the demand for soft grippers.

Advances in soft robotics, coupled with the increasing need to handle delicate items, have enabled rapid progress in soft grippers. Unlike traditional grippers that are made of rigid materials, these end effectors are fabricated from soft and flexible components. Earlier, most end effectors were able to only manipulate objects of fixed size and shape. However, industry requirements are slowly shifting toward the use of components that can grasp and manipulate a large variety of objects. Due to the material softness of the gripper arms, they can be used for sensitive applications such as in the food & beverage or glass manufacturing industries that can handle objects without damaging them. Fruits or vegetables have varying sizes, making soft grippers ideal due to their consistent clamping force irrespective of slight differences in size and shape. Soft grippers are mainly adopted by the food & beverage industry, one of the fastest-growing clients for soft grippers. Hence, the high penetration rate of automation in the food & beverage industry is expected to stimulate the adoption of soft grippers in the next 4 to 5 years.

Challenge: Interoperability and integration issues related to end effectors with existing facilities.

Interoperability is a very important function in any factory or manufacturing unit. There must exist a modular framework for both hardware and software to connect and coordinate various end effector systems. The focus is not only on the software side, which is used for programming, diagnosing, and monitoring but also the interchangeability of hardware between the end effector and robot arm. There have been cases in the robot end effector industry where a client has bought a robot arm and an end effector separately that were not fully compatible with each other, and the setup was a huge challenge from the onset.

0 notes

Text

#RobotEndEffectorMarket#IndustrialAutomation#ManufacturingTechnology#RoboticsIndustry#EndEffectorDesign#MarketResearch#AutomationSolutions

0 notes

Text

Revolutionizing Robotics: Exploring the Explosive Growth of the Articulated Robot Market to Reach $31.89 Billion by 2033

Overview and Scope

The articulated robot refers to a robot that has rotational joints and up to 10 or more axes. The rotary joints enable a full range of motion and significantly expand the robot's capabilities, as they can rotate over many planes. The accuracy and movement pattern nearly resemble a human arm.

Sizing and Forecast

The articulated robot market size has grown rapidly in recent years. It will grow from $15.69 billion in 2023 to $18.26 billion in 2024 at a compound annual growth rate (CAGR) of 16.4%. The growth in the historic period can be attributed to manufacturing sector growth, automotive industry adoption, rise of electronics and semiconductors, focus on efficiency, medical and healthcare applications..

The articulated robot market size is expected to see rapid growth in the next few years. It will grow to $31.89 billion in 2028 at a compound annual growth rate (CAGR) of 15.0%. The growth in the forecast period can be attributed to regulatory support and safety standards, smart factory growth , automotive industry evolution , energy efficiency and sustainability, smes embracing robotics.

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/articulated-robot-global-market-report

Segmentation & Regional Insights

The articulated robot market covered in this report is segmented –

1) By Type: 4-Axis Or Less, 5-Axis, 6-Axis Or More

2) By Payload: Upto 16 Kg, 16 To 60 Kg, 60 To 225 Kg, More Than 225 Kg

3) By Function: Handling, Welding, Dispensing, Assembly, Processing, Other Functions

4) By Component: Controller, Arm, End Effector, Drive, Sensor, Other Components

5) By End Industry: Automotive, Electrical And Electronics, Chemicals, Rubber And Plastics, Metal And Machinery, Food And Beverages, Precision Engineering And Optics, Pharmaceuticals And Cosmetics, Other End-Users

Asia-Pacific was the largest region in the articulated robots market share in 2023. The regions covered in the articulated robot market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8340&type=smp

Major Driver Impacting Market Growth

The increase in demand for industrial robots is expected to propel the growth of the articulated robots market. Industrial robots are mechanical systems or machines programmed to perform production-related activities autonomously in industrial settings. Articulated robots are industrial robots with a human resemblance and are used in various industrial applications.

Key Industry Players

Major companies operating in the articulated robot market report are ABB Ltd., FANUC Corporation, Kawasaki Heavy Industries Ltd., KUKA AG, Omron Adept Technology Inc., Mitsubishi Electric Corporation, Seiko Epson Corporation, Denso Wave Incorporated, Nachi-Fujikoshi Corp., Yaskawa Electric Corporation, Aurotek Corporation, Stubli International, ST Robotics, Toshiba Machine Co. Ltd.

The articulated robot market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

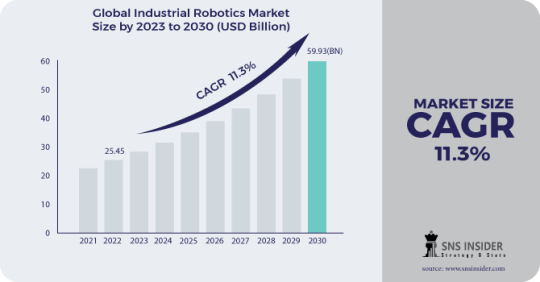

New Research Report On Industrial Robotics Market is Going to Boom by Size, Share, Scope and Forecast-2030

Industrial Robotics Market is going to reach USD 59.93 billion by 2030 and grow at a CAGR of 11.3% over the forecast period 2023-2030.

The most recent Industrial Robotics study evaluates global and regional market estimates and forecasts for all research segments. This study examines market trends, leading companies, supply chain trends, technological advances, key breakthroughs, and future strategies. Market figures were compiled using a combination of primary and secondary sources. Sales revenue from all of the study's specified segments and sub-segments are used to calculate market size. The market sizing analysis employs both top-down and bottom-up approaches for data validation and accuracy checks.

The study uses historical market data to estimate revenue. Other aspects of the industry, such as the supply chain, downstream buyers, and sourcing strategy, have been investigated in order to provide a complete and in-depth picture of the market. Customers who purchase the Industrial Roboticsmarket report will also be subjected to a market positioning analysis, which will take into account factors like target consumer, brand strategy, and pricing strategy. In addition, the study report computes current and prior market values in order to forecast possible market management over the forecast period.

Download Sample Copy of Report: https://www.snsinsider.com/sample-request/1058

Market Segmentation

The Industrial Robotics market segment analysis will assist in determining how each segment will affect market growth in the coming years. In order to determine the market's true potential, the research report also examines all market classifications and sub-segments. In today's global economy, the dynamic nature of the corporate environment is increasing demand for business experts who can keep up with current market conditions.

By Application

Palletizing

Assembling

Welding

Material Handling

Painting

By Types

6-Axis Robots

SCARA

Cartesian

Articulated

Redundant

Delta

Dual-Arm and Parallel

By End-user

Entertainment

Electronics

Automotive

Rubber & Plastic

Food & Beverage

Pharmaceuticals

By Component

Robotic Arms

End Effectors

Drive Units

Robot Accessories

Controllers

Vision Systems

Sensors

Get Exclusive Discout on this Report: https://www.snsinsider.com/discount/1058

Major Questions Answered in the Report

What are the key trends influencing the Industrial Robotics market's growth?

What are the primary strategies used by leading organizations to control a sizable portion of the global market?

How has the rapidly changing business environment of the market influenced growth?

What are the primary macroeconomic factors driving market growth?

Competitive Outlook

For each of the market's top competitors, the research includes current business profiles, gross margins, selling price, sales income, sales volume, product specs with images, and contact information. In the report's conclusion, a descriptive section highlights the feasibility of new projects that may succeed in the global market in the near future, as well as the overall scope of the global market in terms of investment feasibility in various segments of the Industrial Robotics market.

Top Keyplayers:

ABB, DÜrr, FANUC, YASKAWA, KUKA, Denso Corporation, Mitsubishi Electric, Kawasaki Heavy Industries, Universal Robots A/S, NACHI-FUJIKOSHI, Panasonic Corporation, Rockwell Automation, Inc., Bosch GmbH, Yaskawa Electric Corporation, Toshiba Corporation, Seiko Epson

About US:

SNS Insider is a frontrunner in global market research and consulting. We empower clients with the insights they need to navigate evolving landscapes.

Our team leverages a global network to deliver cutting-edge market data, consumer trends, and actionable insights. Through surveys, focus groups, and video discussions, we provide the information you need to make confident decisions.

We are committed to delivering reliable data across a wide range of industries. Recognized as a global leader, we have the expertise to design and implement tailored research programs, from surveys to focus groups, catering to virtually any sector.

Key improvements:

Stronger verbs and adjectives: uses words like "frontrunner," "empower," "navigate," "cutting-edge," to create a more dynamic and confident tone.

Focus on benefits: emphasizes how SNS Insider helps clients make confident decisions and navigate change.

Conciseness: streamlines the text while maintaining key information.

Actionable language: highlights the "tailored" research programs offered by SNS Insider.

Contact Us:

Akash Anand – Head of Business Development & Strategy

[email protected]

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

ROS Based Robot Market: Adapting to Changing Consumer Demands

In today's fast-paced world, consumers are more discerning than ever before. They expect products and services that not only meet their needs but also anticipate their preferences and adapt to their evolving lifestyles. This paradigm shift in consumer behavior has significant implications for the ROS Based Robot Market, requiring companies to innovate and tailor their offerings to stay ahead of the curve.

According to the study by Next Move Strategy Consulting, the global ROS Based Robot Market size is predicted to reach USD 88.22 billion with a Compound Annual Growth Rate (CAGR) of 8.4% by 2030. This remarkable growth trajectory underscores the increasing importance of robotics solutions in various industries. However, as the market continues to evolve, one critical aspect that companies cannot afford to overlook is the changing landscape of consumer demands.

Request for a sample PDF report: https://www.nextmsc.com/ros-based-robot-market/request-sample

Customization and Personalization

One of the primary drivers behind the changing consumer demands in the ROS Based Robot Market is the growing emphasis on customization and personalization. With advancements in technology, consumers now expect robots to be more than just functional tools – they want solutions that are tailored to their specific requirements and preferences. Whether it's a robot for household chores, industrial automation, or healthcare assistance, consumers seek products that can be customized to suit their unique needs.

Companies in the ROS Based Robot Market are responding to this demand by offering modular designs and customizable features that allow consumers to configure robots according to their preferences. For example, manufacturers of collaborative robots (cobots) are designing platforms that can be easily integrated with different end-effectors and peripherals, enabling users to adapt the robot's capabilities to various tasks and applications. Similarly, in the service robotics sector, companies are developing platforms that support the installation of specialized software modules, allowing users to personalize the robot's behavior and functionality.

Convenience and Efficiency

Moreover, consumers are increasingly prioritizing convenience and efficiency in their interactions with robotics solutions. From autonomous vacuum cleaners that can navigate through cluttered spaces to collaborative robots that streamline manufacturing processes, there is a growing demand for robots that can simplify tasks and enhance productivity. Companies in the ROS Based Robot Market must focus on developing intuitive interfaces, seamless integration with existing systems, and enhanced functionality to meet these evolving consumer expectations.

In the consumer robotics segment, ease of use and user-friendly interfaces are becoming key differentiators for products. Consumers expect robots to be easy to set up, operate, and maintain, without the need for specialized technical knowledge. Manufacturers are investing in intuitive Human-Machine Interfaces (HMIs), voice recognition technology, and gesture control interfaces to enhance the user experience and make interaction with robots more natural and intuitive.

Similarly, in industrial settings, companies are developing ROS-based solutions that seamlessly integrate with existing automation systems and workflows, allowing for efficient collaboration between human workers and robots. Advanced motion planning algorithms and collision avoidance systems enable robots to navigate complex environments safely and efficiently, reducing downtime and improving overall productivity.

Sustainability and Ethical Considerations

Furthermore, sustainability and ethical considerations are becoming key factors influencing consumer purchasing decisions in the ROS Based Robot Market. As environmental consciousness grows, consumers are gravitating towards eco-friendly and socially responsible products. This trend is driving demand for robots that are energy-efficient, utilize sustainable materials, and adhere to ethical standards in their production and operation.

Manufacturers in the ROS Based Robot Market are responding to this demand by adopting environmentally friendly manufacturing processes, reducing energy consumption, and incorporating recycled materials into their products. Additionally, companies are exploring alternative power sources such as solar energy and fuel cells to power robots, further reducing their environmental impact.

In addition to environmental sustainability, ethical considerations are also shaping consumer preferences in the ROS Based Robot Market. Consumers are increasingly concerned about the ethical implications of robotics technology, particularly in areas such as data privacy, algorithmic bias, and job displacement. Companies are proactively addressing these concerns by implementing transparent data policies, conducting ethical assessments of their products, and actively engaging with stakeholders to ensure responsible deployment of robotics solutions.

Interconnectedness and Intelligence

In addition to these factors, the rise of the Internet of Things (IoT) and artificial intelligence (AI) is reshaping consumer expectations in the ROS Based Robot Market. Consumers now expect robots to seamlessly integrate with other smart devices and leverage AI algorithms to deliver personalized experiences. Whether it's a robot that can learn from user interactions to improve performance or one that can communicate with other IoT devices for enhanced functionality, interconnectedness and intelligence are becoming key drivers of consumer demand.

ROS-based robots are well-positioned to capitalize on these trends, thanks to the platform's flexibility and scalability. By leveraging ROS middleware, developers can easily integrate robots with other IoT devices and cloud-based services, enabling seamless communication and data exchange. AI algorithms running on ROS-based platforms enable robots to learn from their environment, adapt to changing conditions, and perform complex tasks autonomously.

Safety and Reliability

As robots become more integrated into daily life and industrial operations, consumers are increasingly concerned about safety and reliability. Malfunctions or accidents involving robots can have serious consequences, both in terms of physical harm and damage to property. Therefore, consumers expect ROS-based robots to adhere to stringent safety standards and undergo rigorous testing to ensure their reliability in various operating conditions.

Manufacturers in the ROS Based Robot Market are investing in advanced sensor technologies, real-time monitoring systems, and redundant safety features to enhance the safety and reliability of their products. Collaborative robots, in particular, are equipped with force and torque sensors that enable them to detect and respond to human presence, ensuring safe interaction in shared workspaces. Additionally, manufacturers conduct extensive risk assessments and simulations to identify potential hazards and mitigate risks before deploying robots in real-world settings.

Scalability and Flexibility

Another key consideration for consumers in the ROS Based Robot Market is scalability and flexibility. As their needs evolve and technologies advance, consumers expect robots to be adaptable and scalable to accommodate changing requirements and environments. Whether it's scaling up production capacity in a manufacturing facility or reconfiguring a robot for different tasks in a household setting, flexibility and scalability are essential attributes that consumers value.

ROS-based robots offer inherent scalability and flexibility, thanks to the modular architecture of the ROS middleware. Developers can easily add or remove hardware components, modify software modules, and integrate third-party peripherals to customize robots according to specific use cases. This modularity enables ROS-based robots to adapt to changing demands and environments, providing consumers with versatile solutions that can evolve over time.

Inquire before buying: https://www.nextmsc.com/ros-based-robot-market/inquire-before-buying

Conclusion

In conclusion, the ROS Based Robot Market is witnessing a paradigm shift as companies adapt to changing consumer demands. From customization and convenience to sustainability and intelligence, consumer expectations are driving innovation and shaping the future of robotics solutions. Companies that can anticipate and respond to these evolving demands are poised to thrive in the dynamic landscape of the ROS Based Robot Market. By prioritizing user-centric design, sustainability, and technological innovation, companies can stay ahead of the curve and capitalize on the vast opportunities presented by the evolving consumer demands in the ROS Based Robot Market.

0 notes

Text

Aerospace Robotics Market May Set New Epic Growth Story

Latest business intelligence report released on Global Aerospace Robotics Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Aerospace Robotics market outlook.

List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis:

Kuka AG (Germany), ABB Group (Switzerland), Fanuc Corporation (Japan), Yaskawa Electric Corporation (Japan), Kawasaki Heavy Industries, Ltd (Japan), Oliver Crispin Robotics Limited (United Kingdom), Gudel AG (Switzerland), Electroimpact Inc. (United States), Universal Robots A/S (Denmark), AV&R Vision & Robotics Inc. (Canada).

Download Free Sample PDF Brochure (Including Full TOC, Table & Figures) @ https://www.advancemarketanalytics.com/sample-report/41573-global-aerospace-robotics-market

Brief Overview on Aerospace Robotics:

The aerospace industry is responsible for some of the greatest technical inventions in human history. The role of robotics in manufacturing of aerospace products is very significant. Robotics plays an important function in aerospace industry like fabrication of aircraft engines, drilling & fastening, sealing & dispensing and others. Aerospace industry is increasingly investing in robots to perform drilling, painting and other tasks on airframes. Robot’s ability to repeatedly position very large aerospace components with a high degree of precision makes sure that the aerospace robotics has potential market growth

Key Market Trends:

Increasing demand for collaborative robots

Recent technological advancements in aerospace robotics

Opportunities:

Human-robot collaboration in aerospace industry

Market Growth Drivers:

Increase in use of robots for efficient aircraft production

Rising use of robotics to handle aircraft orders backlog

Challenges:

High initial investment of implanting robotics

Segmentation of the Global Aerospace Robotics Market:

by Type (Articulated, Cartesian, Others), Application (Drilling, Welding, Painting, Inspection, Others), Technology (Traditional, Collaborative), Component (Controller, Arm Processor, End Effector, Drive, Sensors)

Purchase this Report now by availing up to 10% Discount on various License Type along with free consultation. Limited period offer.

Share your budget and Get Exclusive Discount @: https://www.advancemarketanalytics.com/request-discount/41573-global-aerospace-robotics-market

Geographically, the following regions together with the listed national/local markets are fully investigated:

• APAC (Japan, China, South Korea, Australia, India, and Rest of APAC; Rest of APAC is further segmented into Malaysia, Singapore, Indonesia, Thailand, New Zealand, Vietnam, and Sri Lanka)

• Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe; Rest of Europe is further segmented into Belgium, Denmark, Austria, Norway, Sweden, The Netherlands, Poland, Czech Republic, Slovakia, Hungary, and Romania)

• North America (U.S., Canada, and Mexico)

• South America (Brazil, Chile, Argentina, Rest of South America)

• MEA (Saudi Arabia, UAE, South Africa)Furthermore, the years considered for the study are as follows:

Historical data – 2017-2022

The base year for estimation – 2022

Estimated Year – 2023

Forecast period** – 2023 to 2028 [** unless otherwise stated]

Browse Full in-depth TOC @: https://www.advancemarketanalytics.com/reports/41573-global-aerospace-robotics-market

Summarized Extracts from TOC of Global Aerospace Robotics Market Study Chapter 1: Exclusive Summary of the Aerospace Robotics market

Chapter 2: Objective of Study and Research Scope the Aerospace Robotics market

Chapter 3: Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis

Chapter 4: Market Segmentation by Type, End User and Region/Country 2016-2027

Chapter 5: Decision Framework

Chapter 6: Market Dynamics- Drivers, Trends and Challenges

Chapter 7: Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 8: Appendix, Methodology and Data Source

Buy Full Copy Aerospace RoboticsMarket – 2021 Edition @ https://www.advancemarketanalytics.com/buy-now?format=1&report=41573

Contact US :

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

#Global Aerospace Robotics Market#Aerospace Robotics Market Demand#Aerospace Robotics Market Trends#Aerospace Robotics Market Analysis#Aerospace Robotics Market Growth#Aerospace Robotics Market Share#Aerospace Robotics Market Forecast#Aerospace Robotics Market Challenges

0 notes

Text

Robot End Effector Market Size, Share, Growth Analysis 2024 - 2030

0 notes

Text

The Report Covers Global Automotive Robotics Market Share & Trends and it is Segmented by End-user Type (Vehicle Manufacturers and Automotive Component Manufacturers), Component Type (Controller, Robotic Arm, End effector, and Drive and Sensors), Product Type (Cartesian Robots, SCARA Robots, Articulated Robot, and Other Product Types), Function Type (Welding Robot, Painting Robot, Assembling and Disassembling Robot, Cutting, and Milling Robot), and Geography (North America, Europe, Asia-Pacific, and Rest of the World).

Download Free Sample Report - Automotive Robotics Market

0 notes

Text

Warehouse Robotics Market Size, Analyzing Growth and Forecasting Outlook from 2023-2030

The latest market report published by Credence Research, Inc. “Global Warehouse Robotics Market: Growth, Future Prospects, and Competitive Analysis, 2022 – 2030. The worldwide warehouse robotics marketplace is projected to attain USD 15,614.36 million by 2030, with a CAGR of 18.06% from 2023-2030.

Warehouse Robotics Market refers to the rapidly growing industry that focuses on the development and implementation of robotic systems and automation technologies within warehouse and distribution center environments. These technologies aim to streamline and optimize various tasks such as inventory management, order fulfillment, sorting, packing, and material handling processes. Warehouse robotics play a crucial role in enhancing efficiency, reducing operational costs, minimizing errors, and improving overall productivity within the logistics and supply chain sector.

Key Components and Technologies in the Warehouse Robotics Market:

Automated Guided Vehicles (AGVs): These are mobile robots equipped with navigation and guidance systems that allow them to move autonomously within a warehouse environment. AGVs are often used for transporting goods from one point to another, eliminating the need for manual labor.

Autonomous Mobile Robots (AMRs): Similar to AGVs, AMRs are intelligent robots that can navigate their surroundings without the need for fixed paths or external guidance systems. They often incorporate sensors, cameras, and mapping technology to maneuver through warehouse spaces safely.

Robotic Arms and Manipulators: These robotic systems are designed to perform tasks such as picking, packing, and sorting. They are equipped with various end-effectors, like grippers and suction cups, to handle different types of products and materials.

Automated Storage and Retrieval Systems (AS/RS): These systems use a combination of robotics, conveyors, and storage racks to efficiently manage and retrieve items from high-density storage areas. AS/RS can significantly improve inventory management and order fulfillment processes.

Pick-and-Place Robots: These robots are designed to pick items from one location and place them in another. They are often used for order picking and packing tasks, improving accuracy and speed compared to manual processes.

Sortation Systems: These systems use robotic arms, conveyors, and sensors to categorize and route items to their appropriate destinations. This is particularly useful for e-commerce warehouses dealing with a high volume of orders.

Warehouse Management Systems (WMS): While not a physical robot, WMS software plays a crucial role in coordinating and optimizing the operation of various robotic systems within a warehouse. It manages inventory, order processing, and task allocation to different robots.

List of the prominent players in the Warehouse Robotics Market:

Amazon Robotics

KUKA AG

Fetch Robotics

Daifuku Co., Ltd.

Honeywell Intelligrated

Fanuc Corporation

GreyOrange

Browse 228 pages report By Price Range (Low, Medium, High) - Growth, Future Prospects & Competitive Analysis, 2016 – 2030) https://www.credenceresearch.com/report/warehouse-robotics-market

Benefits of Warehouse Robotics:

Increased Efficiency: Warehouse robotics automate repetitive and time-consuming tasks, allowing for faster and more accurate processes, leading to higher overall operational efficiency.

Reduced Labor Costs: Automation reduces the need for manual labor in tasks like order picking and material handling, helping companies save on labor-related expenses.

Improved Accuracy: Robots are less prone to errors compared to human workers, leading to improved order accuracy and reduced returns or customer complaints.

24/7 Operations: Robotic systems can operate continuously, enabling warehouses to work around the clock without interruptions.

Optimized Space Utilization: AS/RS and other automated systems can maximize storage capacity by utilizing vertical space and compact storage configurations.

Scalability: Warehouse robotics can be easily scaled up or down to accommodate changing business needs and seasonal demand fluctuations.

Warehouse Robotics Market is characterized by a dynamic interplay of various factors that shape its growth, trends, and overall dynamics. These dynamics encompass a range of influences, including technological advancements, market demand, regulatory factors, competitive landscape, and industry collaborations. Understanding these dynamics is essential for businesses, investors, and stakeholders looking to navigate and capitalize on the opportunities within the market.

Here's a closer look at the key dynamics driving the Warehouse Robotics Market:

Technological Advancements: The rapid evolution of robotics, artificial intelligence, machine learning, and sensor technologies is a major driver of the warehouse robotics market. Advances in these areas lead to more sophisticated and capable robotic systems, allowing for improved automation, efficiency, and adaptability in warehouse operations.

E-commerce Growth: The exponential growth of e-commerce has significantly impacted the demand for warehouse robotics. As consumers increasingly shop online, warehouses need to handle larger volumes of orders efficiently, driving the need for automated solutions to streamline order fulfillment processes.

Labor Shortages: Many regions are experiencing labor shortages, making it challenging for warehouses to find and retain a skilled workforce. Warehouse robotics provide a solution by reducing the reliance on manual labor and addressing the need for consistent and reliable operations.

Supply Chain Optimization: Companies are continuously seeking ways to optimize their supply chains for better efficiency and cost savings. Warehouse robotics enable streamlined inventory management, order processing, and material handling, contributing to a more efficient supply chain ecosystem.

Safety and Compliance: The integration of safety features and compliance with regulations is crucial in the design and implementation of warehouse robotics. Ensuring that robots operate safely alongside human workers and adhere to industry standards is a significant consideration in the market.

ROI and Cost Efficiency: While the initial investment in warehouse robotics can be substantial, the potential for long-term cost savings and return on investment (ROI) is driving adoption. Over time, reduced labor costs, fewer errors, increased throughput, and optimized space utilization contribute to cost efficiency.

Customization and Flexibility: Warehouses require adaptable solutions that can cater to diverse products, layouts, and operational requirements. The ability to customize and reconfigure robotic systems to suit changing demands is an important aspect of the market's dynamics.

Competition and Innovation: The competitive landscape of the warehouse robotics market is characterized by a mix of established players and startups. Intense competition drives innovation, pushing companies to develop new technologies, features, and solutions to stay ahead.

Integration with IT Systems: Successful adoption of warehouse robotics often relies on seamless integration with existing warehouse management systems (WMS) and enterprise resource planning (ERP) systems. Integration challenges and compatibility considerations are dynamics that influence market developments.

Global Trade and Logistics: International trade and global supply chains are influenced by factors such as geopolitical events, trade agreements, and disruptions like the COVID-19 pandemic. These factors can impact the demand for warehouse robotics as companies seek to enhance their resilience and adaptability.

Sustainability and Environmental Concerns: Growing awareness of environmental sustainability is prompting companies to seek more energy-efficient and eco-friendly solutions. Warehouse robotics that contribute to reduced energy consumption and lower carbon footprints align with these concerns.

Market Trends and Outlook:

The warehouse robotics market has been experiencing rapid growth due to advancements in robotics technology, the rise of e-commerce, and the need for supply chain optimization. As more companies adopt automation solutions to remain competitive, the market is expected to continue expanding. Additionally, advancements in artificial intelligence, machine learning, and sensor technologies are enhancing the capabilities of warehouse robots, making them more versatile and adaptable to dynamic environments.

However, challenges such as initial investment costs, integration complexities, and the need for skilled personnel to manage and maintain these systems remain. As technology evolves and becomes more affordable, these challenges are gradually being addressed, leading to wider adoption across various industries.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Warehouse Robotics Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Warehouse Robotics Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major player analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/warehouse-robotics-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/online-program-management-market

Related Report: https://www.credenceresearch.com/report/education-technology-market

Browse Our Blog: https://www.linkedin.com/pulse/warehouse-robotics-market-size-worth-usd-1561436-million-singh

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Text

Brazil Agriculture Robots Market Growth, Trends, Report 2023-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Brazil agriculture robots market size at USD 474.75 million in 2022. During the forecast period between 2023 and 2029, the Brazil agriculture robots market size is projected to grow at a CAGR of 8.08% reaching a value of USD 1,549.8 million by 2029. Growing population increased food demand, indoor farming's popularity, frequent climate variations, and rapid adoption of automation technology are major growth drivers for the Brazil agriculture robots market. Increasing government support to encourage cultivators to adopt modern agricultural practices, as well as the trend of sustainably maximizing agricultural resources, all contribute to the rapid growth of the Brazil agricultural robot market. The widespread use of IoT in a variety of industries, including manufacturing, transportation, and agriculture, as well as the agricultural sector's reliance on technology, engineering, and physical and biological sciences using IoT in research projects, all have an impact on the market for agriculture robots.

Brazil Agriculture Robots Market – Overview

Agriculture robots, also known as Agribots, are one of the newest technological developments in the agriculture industry. Agribots are autonomous machines that are used to increase output quality and efficiency while decreasing the need for manual labor, thereby increasing productivity. Agricultural robots are typically equipped with end effectors or specialized arms for a variety of horticultural tasks like weed control, seeding and planting, aerial data collection, field mapping, fertilizing and irrigation, intercultural operations, harvesting, soil analysis, and environmental monitoring. These machines are also used to wash and milk animals in the dairy farming industry.

Sample Request @ https://www.blueweaveconsulting.com/report/brazil-agriculture-robots-market/report-sample

Opportunity: Expanding population and lack of skilled workers in agriculture sector

The agriculture industry is under pressure from Brazil's expanding population and the need to boost productivity from the country's existing farmland. Current factors affecting the agricultural sector include urbanization and changing demographics. The agricultural sector in Brazil makes extensive use of migrant labor, a trend that is also prevalent in other developed countries. Farmer populations are aging, which further reduces the supply of manual labor and contributes to the labor shortage that is now a global problem. Children from farming families frequently move to urban areas in search of better employment opportunities, and younger generations are less likely to continue farming. As a result, modern farmers have had a lot of experience working in the field.

Challenge: Automation costs more for small farms

Smaller farms have been largely left behind by successive waves of automation, which include agriculture robots. A tractor with autopilot capability can cost up to USD 100,000 and frequently does not provide a sufficient Return on Investment for small farmers (RoI). Although auto-steering and drone technologies are among the least expensive and most mature automation solutions, they are still not widely used in small farms. For example, only about 10% of auto-steering technology is used on small farms of 10 to 1000 acres globally (or about 1 million farms out of 10 million). It is expected that as more specialized and expensive robots and software systems are introduced, these farms will fall further behind in terms of technology.

Impact of COVID-19 on Brazil Agriculture Robots Market

The rapid spread of the COVID-19 pandemic had an impact on the Brazilian market for agriculture robots, disrupting the supply chain and damaging several industries. Trade activity has been significantly reduced as a result of international border closures, extensive social distance-building measures, and national lockdowns. This had a significant impact on Brazil for agricultural robots because businesses throughout Brazil were forced to partially or completely shut down. In 2021, the second wave of COVID-19 also disrupted the markets in a number of significant markets, including Brazil. However, due to the rebound in trade activity, the market is likely to experience steady demand growth during the projection period.

Brazil Agriculture Robots Market – By Farming Environment

The outdoor industry dominates the Brazil agriculture robots market. Farmers are using driverless tractors, weeding robots, and fruit harvesters more frequently due to the numerous benefits, which is growing the segment's revenue. Farmers are heavily utilizing outdoor harvesting robots built on mechatronics, nanotechnology, and material science to reduce revenue losses caused by human error. They can grasp and separate fruits without harming them in addition to detecting and analyzing the ripeness of the fruit.

Competitive Landscape

Brazil agriculture robots market is fiercely competitive. Prominent players in the market include John Deere, AGCO, CNH Industrial, Kubota Corporation, Yamaha Motor Co. Ltd, Deere & Company, Lely Group, BouMatic Robotics, GEA Group, DeLaval, AgEagle Aerial Systems, Agrobot, Agrointelli, Agrosavvy, Argus Control Systems, Blue River Technology, DJI, Energid Technologies, and Harvest Automation. These companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in the Brazil agriculture robots market.

0 notes

Text

Robot End Effector Market is Register to Grow at a CAGR of 13.5% during 2023-2028

The global robot end effector market is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%. Increasing demand for modular end effectors and the growing adoption of collaborative robots due to the fast-changing nature of industries are among a few major factors driving the growth of the robot end effector market.

Key players operating in the robot end effector market include Schunk (Germany), Schmalz (Germany), Zimmer Group (Germany), Tünkers (Germany), and Destaco (US) are the top five players in the robot end effector market.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Grippers is expected to register a higher CAGR during the forecast period.

The market for grippers is largely driven by their handling application in a wide range of workpieces considering their various shapes and size. The increasing application of soft grippers and vacuum grippers in different varieties of handling and assembly applications across several industries would present several growth opportunities to players operating in the gripper segment.

Collaborative industrial robots to record the highest CAGR during the forecast period.

Robot end effector market for collaborative industrial robots is to grow at the highest CAGR during the forecast period. This is due to the adoption of collaborative robots, especially for small and medium-sized companies, to easily adapt to different tasks and enable a faster return on investment (ROI). These robots are witnessing widespread adoption in small and medium-sized enterprises and large-scale, traditional industries such as automotive. With the growing adoption of cobots in many new use cases, such as remote monitoring and remote manufacturing are being enabled, this factor is expected to propel the growth of the end effector market for collaborative industrial robots.

China is expected to account for the largest market share in Asia Pacific market from 2023 to 2028.

China accounted for the largest share of the robot end effector market in Asia Pacific in 2022 and is expected to remain the largest market throughout the forecast period. As many Asian countries are highly populated, and the geriatric population is becoming a concern for the future, the aging population, especially in China, is prompting companies toward automation and industrial robots to reduce costs. With the rise in industrial robots for automation, the demand for their associated end effectors is also expected to increase.

0 notes

Text

Cobot End Effector Market: Overview and Scope Forecast 2022-2030

This report analyzes key players, including their market share, market size, growth drivers, and company profiles. The purpose of this research report is to provide an in-depth analysis of the market overview, prevalent trends, demand, and recent changes that are affecting the global Cobot End Effector market.

The study also discusses product launches, market expansion, strategic growth analysis, market potential analysis, and technological advancements. It provides market size, prospective expansion, trends, and leading competitors' expansion plans.

With the help of this report, you will be able to gain insight into the competitors' positioning, market scope, growth potential, and future prospects.

Our report provides in-depth insights into the leading players in the global Cobot End Effector market for the next few years. To gain a stronghold in the global Cobot End Effector market, these key participants have adopted various business strategies. As a result, other businesses can gain a better understanding of how market leaders maintain dominance and expand their customer bases to secure a majority share.

Request For Free Sample: https://www.nextmsc.com/cobot-end-effector-market/request-sample

There are a number of major players in the Cobot End Effector market, including:

Abb, Destaco, Kuka Ag, Millibar Inc., Piab Ab, Robotiq, Schmalz, Toyota Industries Corporation, Weiss Robotics Gmbh & Co. Kg.

As part of this study, we will examine how COVID-19 impacted and altered the global Cobot End Effector market environment. Demand, consumption, transportation, consumer behavior, supply chain management, exports, imports, and manufacturing are among the factors considered in the study. Furthermore, analysts have highlighted the elements that can help businesses identify opportunities in the near future and stabilize the industry.

Some of the key advantages discussed in this study report are a neutral outlook on market performance, recent industry trends, competitive landscapes and key players' strategies, potential and niche segments, and geographical regions contributing to promising growth.

Furthermore, the report provides historical, current, and future market sizes, along with a geographical forecast.

Depending on Type, the global Cobot End Effector market is divided into:

Grippers

• Mechanical Grippers

• Electrical Grippers

Suction Cups

Processing tools

Others

• Milling Tools

• Soldering Tools

• Dispensing Tools

• Rest of All

Depending on Application, the global Cobot End Effector market is divided into:

Handling

• Pick & Place

• Packing & Palletizing

• Unloading

Assembling & Disassembling

• Screwdriving

• Nut Fastening

Welding & Soldering

Dispensing

• Gluing

• Painting

Processing

• Grinding

• Milling

• Cutting

Other Applications

• Inspection & Quality Testing

• Die-Casting & Molding

According to regions, the Cobot End Effector market is segmented as follows:

North America

• US

• Canada

• Mexico

Europe

• UK

• Germany

• France

• Spain

• Italy

• Netherlands

• Rest of Europe

APAC

• China

• Japan

• India

• Australia

• South Korea

• Taiwan

• Vietnam

• Rest of Asia-Pacific

RoW

• Latin America

• Middle East

• Africa

A comprehensive analysis of all of the critical features of the global Cobot End Effector industry has been conducted in the latest study. Market size, competition, development trends, niche markets, market drivers and challenges, SWOT analysis, Porter's five forces analysis, value chain analysis, and so on are covered from a macro-level to a micro-level.

According to the report, markets are categorized based on their type, end-users, applications, and regions, among other factors.

In order to be able to target products, sales, and marketing strategies accordingly, decision-makers must be familiar with the market segments. Businesses can advance product development by being guided on how to develop products tailored to meet the needs of different market segments.

Key stakeholders can use this market research report to develop plans for supporting the company's success by using statistics, tables, and graphs. It provides an in-depth analysis of the Cobot End Effector market across all major geographic regions, including North America, Asia-Pacific, Latin America, the Middle East, and Africa.

This report examines the dynamics of several regions in order to gain a clearer picture of the global market.

Inquire Before Buying: https://www.nextmsc.com/cobot-end-effector-market/inquire-before-buying

About Us

Next Move Strategy Consulting is an independent and trusted third-platform market intelligence provider, committed to deliver high quality, market research reports that help multinational companies to triumph over their competitions and increase industry footprint by capturing greater market share. Our research model is a unique collaboration of primary research, secondary research, data mining and data analytics.

We have been servicing over 1000 customers globally that includes 90% of the Fortune 500 companies over a decade. Our analysts are constantly tracking various high growth markets and identifying hidden opportunities in each sector or the industry. We provide one of the industry’s best quality syndicates as well as custom research reports across 10 different industry verticals. We are committed to deliver high quality research solutions in accordance to your business needs. Our industry standard delivery solution that ranges from the pre consultation to after-sales services, provide an excellent client experience and ensure right strategic decision making for businesses.

Source: https://www.nextmsc.com/report/cobot-end-effector-market

#market demand#marketgrowth#market analysis#market forecast#marketshare#marketsize#maketvalue#CobotEndEffectorMarket

0 notes

Text

Aerospace Robotics Market Projected Growth Rate Through 2023-2032

The Aerospace Robotics Global Market Report 2023, provides comprehensive information on the aerospace robotics market across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa for the 27 major global industries. The report covers a ten year historic period – 2010-2021, and a ten year forecast period – 2023-2032.

Learn More On The Aerospace Robotics Market’s Growth:

As per The Business Research Company’s Aerospace Robotics Global Market Report 2023, the global aerospace robotics market size grew from $3.38 billion in 2022 to $3.69 billion in 2023 at a compound annual growth rate (CAGR) of 9.2%. The Russia-Ukraine war disrupted the chances of global economic recovery from the COVID-19 pandemic, at least in the short term. The war between these two countries has led to economic sanctions on multiple countries, a surge in commodity prices, and supply chain disruptions, causing inflation across goods and services and affecting many markets across the globe. The aerospace robotics market size is expected to grow to $5.54 billion in 2027 at a CAGR of 10.7%.

Get A Free Sample Of The Report (Includes Graphs And Tables):

The aerospace robotics market is segmented:

1) By Type: Articulated, Cartesian, Other Types

2) By Application: Drilling, Welding, Painting, Inspection, Other Applications

3) By Technology: Conventional, Collaborative

4) By Component: Controller, Sensors, Drive, Arm Processor, End Effector

5) By Payload: Small-Medium Payloads Robots, Large Payloads Robots, Extra Large Payloads Robots

North America was the largest region in the aerospace robotics market in 2022.

The table of contents in TBRC’s aerospace robotics market report includes:

1. Executive Summary

2. Aerospace Robotics Characteristics

3. Aerospace Robotics Trends And Strategies

4. Impact Of COVID-19

5. Aerospace Robotics Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Learn About Us:

The Business Research Company is a market intelligence firm that pioneers in market, company, and consumer research. TBRC’s specialist consultants are located globally and are experts in a wide range of industries that include healthcare, manufacturing, financial services, chemicals, and technology. The firm has offices located in the UK, the US, and India, along with a network of proficient researchers in 28 countries. Through the report businesses can gain a thorough understanding of the market’s size, growth rate, major drivers and leading players.

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Automotive Robotics Market Advanced technologies & growth opportunities in global Industry by 2022 to 2028

The research reports provide deep insights into the global market revenue, market trends, macro-economic indicators, and governing factors, along with market attractiveness per market segment. The report provides an overview of the growth rate of Automotive Robotics market during the forecast period, i.e., 2022–2030. The report, most importantly, identifies the qualitative impact of various market factors on market segments and geographies. The research segments the market on the basis of product type, application type, technology type, and region. To offer more clarity regarding the industry, the report takes a closer look at the current status of various factors, including but not limited to supply chain management, distribution Trade, channels, supply and demand, and production capability differ across countries.

Get Exclusive Sample Pages of this Report @ https://iconmarketresearch.com/inquiry/sample/IMR0459

Automotive Robotics Market Company Profiles Analysis:

ABB (Switzerland)

FANUC Corporation (Japan)

Yaskawa Electric Corporation (Japan)

KUKA AG (Germany)

Kawasaki Heavy Industries (Japan).

Note – The Covid-19 (coronavirus) pandemic is impacting society and the overall economy across the world. The impact of this pandemic is growing day by day as well as affecting the supply chain. The COVID-19 crisis is creating uncertainty in the stock market, massive slowing of supply chain, falling business confidence, and increasing panic among the customer segments. The overall effect of the pandemic is impacting the production process of several industries. This report on ‘Automotive Robotics Market’ provides the analysis on impact on Covid-19 on various business segments and country markets. The reports also showcase market trends and forecast to 2030, factoring the impact of Covid -19 Situation.

Market Segmentation:

Automotive Robotics Market Size, Share & Trends Analysis Report By Type (Articulated, Cartesian, SCARA, Cylindrical), Component (Controller, Robotic Arm, End Effector, Sensors, Drive), Application (Welding, Painting, Cutting, Material Handling) Global Industry Insights, Trends, and Forecast, 2021-2028.

For More Discount Details @ https://iconmarketresearch.com/inquiry/discount/IMR0459

Regional Framework

The report provides a detailed overview of the industry including both qualitative and quantitative information. It provides an overview and forecast of the global Automotive Robotics Market based on various segments. It also provides market size and forecast estimates from the year 2022 to 2028 with respect to five major regions. The Automotive Robotics Market by each region is later sub-segmented by respective countries and segments. The report covers the analysis and forecast of 18 countries globally along with the current trend and opportunities prevailing in the region.

Promising Regions & Countries Mentioned in The Automotive Robotics Market Report:

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Major Features of Automotive Robotics Market Report:

Save and reduce time carrying out entry-level research by identifying the growth, size, leading players and segments in the global Automotive Robotics market.

Highlights key business priorities in order to assist companies to realign their business strategies.

The key findings and recommendations highlight crucial progressive industry trends in the global Automotive Robotics market, thereby allowing players across the value chain to develop effective long-term strategies.

Develop/modify business expansion plans by using substantial growth offering developed and emerging markets.

Scrutinize in-depth global market trends and outlook coupled with the factors driving the market, as well as those hindering it.

Enhance the decision-making process by understanding the strategies that underpin commercial interest with respect to client products, segmentation, pricing and distribution.

Purchase a Copy of this Study @ https://iconmarketresearch.com/inquiry/buying/IMR0459

Note: If you have any special requirements, please let us know and we will offer you the report as you want.

About Us:

Icon Market Research is a one-stop industry research provider of actionable intelligence. Through our syndicated and consulting research services, we help our clients get solutions to their research requirements. We specialise in industries such as Semiconductor and Electronics, Aerospace and Défense, Energy, Automotive and Transportation, Healthcare, Manufacturing and Construction, Media and Technology, Chemicals, and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

Contact Person: Gaurav B

E-mail: [email protected]

Phone: (+1) 812 506 4440.

0 notes

Text

Cobot End Effector Market: A Roadmap to Enhanced Productivity

Introduction:

According to the study by Next Move Strategy Consulting, the global Cobot End Effector Market size is predicted to reach USD 2.66 billion with a CAGR of 12.8% by 2030. This forecast underscores the growing significance of cobot end effectors in reshaping industrial processes and enhancing productivity. As industries across the globe continue to embrace automation to streamline operations and improve efficiency, cobot end effectors have emerged as pivotal components in this transformative journey. In this comprehensive article, we delve into the various facets of the cobot end effector market, exploring its evolution, applications, technological advancements, and the roadmap to achieving enhanced productivity.

Request for a sample PDF report: https://www.nextmsc.com/cobot-end-effector-market/request-sample

Evolution of Cobot End Effectors:

Cobot end effectors, also known as end-of-arm tools, have undergone a remarkable evolution since their inception. Traditionally, industrial robots were equipped with rigid, single-purpose grippers designed for specific tasks. However, advancements in robotics technology, materials science, and engineering have led to the development of more versatile and adaptable cobot end effectors.

Unlike their conventional counterparts, cobot end effectors are designed to work collaboratively with human operators, augmenting their capabilities rather than replacing them. This collaborative approach not only enhances productivity but also improves safety and efficiency in the workplace. The evolution of cobot end effectors reflects a broader shift towards flexible automation solutions that can adapt to the changing needs of modern manufacturing environments.

Applications Across Industries:

Cobot end effectors find applications across a wide range of industries, spanning automotive manufacturing, electronics assembly, aerospace, food processing, pharmaceuticals, logistics, and more. In automotive manufacturing, cobot end effectors are used for tasks such as material handling, assembly, welding, and painting. In electronics assembly, they facilitate precision gripping, soldering, and inspection processes. In the food industry, cobot end effectors handle packaging, palletizing, and quality control tasks with ease.

The versatility of cobot end effectors makes them well-suited for diverse applications, allowing manufacturers to optimize workflows, reduce cycle times, and improve overall efficiency. By automating repetitive and mundane tasks, cobot end effectors free up human operators to focus on more value-added activities, such as problem-solving, innovation, and process improvement.

Technological Advancements:

Advancements in technology have played a crucial role in driving the evolution of cobot end effectors. Today's cobot end effectors are equipped with advanced sensors, actuators, and control systems that enable precise and efficient manipulation of objects. Vision systems, for example, allow cobots to identify and adapt to changes in the environment, while force-torque sensors enable them to apply the right amount of pressure during gripping and manipulation tasks.

Furthermore, the integration of artificial intelligence and machine learning algorithms has empowered cobots to learn from experience, optimize performance, and make real-time adjustments based on changing conditions. This adaptive intelligence enables cobot end effectors to handle a wide range of tasks with greater efficiency and reliability.

Roadmap to Enhanced Productivity:

Achieving enhanced productivity with cobot end effectors requires a strategic approach that encompasses several key considerations:

Task Analysis: Begin by conducting a thorough analysis of the tasks that can be automated using cobot end effectors. Identify repetitive, high-volume, and ergonomically challenging tasks that can benefit from automation.

Integration Planning: Collaborate with robotics experts and integrators to develop a comprehensive integration plan. Consider factors such as workspace layout, safety requirements, payload capacity, and compatibility with existing systems.

Training and Education: Invest in training programs to familiarize operators with cobot end effectors and ensure proper utilization. Provide ongoing support and education to empower employees to maximize the potential of cobot technology.

Performance Monitoring: Implement robust monitoring and analytics systems to track the performance of cobot end effectors in real-time. Analyze data to identify bottlenecks, optimize workflows, and improve overall efficiency.

Continuous Improvement: Embrace a culture of continuous improvement by soliciting feedback from operators, identifying areas for optimization, and implementing iterative upgrades to cobot end effectors and processes.

Safety Considerations: Prioritize safety when implementing cobot end effectors in the workplace. Conduct risk assessments, establish safety protocols, and integrate safety features such as protective barriers, emergency stop buttons, and collision detection systems to ensure the well-being of human operators.

Scalability and Flexibility: Choose cobot end effectors that offer scalability and flexibility to accommodate changing production demands. Opt for modular designs that allow for easy reconfiguration and adaptation to different tasks and environments.

Cost-Benefit Analysis: Conduct a thorough cost-benefit analysis to evaluate the return on investment (ROI) of implementing cobot end effectors. Consider factors such as upfront costs, labor savings, productivity gains, and long-term maintenance expenses to make informed decisions.

Collaboration with Suppliers: Collaborate closely with cobot end effector suppliers to customize solutions that meet specific operational requirements. Leverage their expertise to optimize performance, minimize downtime, and address any technical challenges that may arise during implementation.

Regulatory Compliance: Ensure compliance with regulatory standards and industry guidelines when deploying cobot end effectors. Stay abreast of evolving regulations pertaining to safety, data privacy, and ethical considerations in robotics and automation.

Environmental Sustainability: Consider the environmental impact of cobot end effector deployment and seek opportunities to minimize energy consumption, reduce waste, and promote sustainability in manufacturing processes.

Employee Engagement and Empowerment: Involve employees in the implementation process and foster a culture of collaboration and empowerment. Provide training and upskilling opportunities to enable workers to adapt to the changing technological landscape and take ownership of cobot-assisted tasks.

Market Trends and Competitive Analysis: Stay informed about emerging trends, market dynamics, and competitive landscape in the cobot end effector market. Monitor competitor activities, technological advancements, and customer preferences to identify opportunities for differentiation and innovation.

Customer Satisfaction and Feedback: Solicit feedback from customers and end-users to assess their satisfaction levels and identify areas for improvement. Use customer insights to refine product offerings, enhance user experience, and drive continuous innovation.

Inquire before buying: https://www.nextmsc.com/cobot-end-effector-market/inquire-before-buying

Conclusion:

The global cobot end effector market is poised for exponential growth in the coming years, driven by advancements in technology, rising labor costs, and the increasing demand for flexible automation solutions. By leveraging cobot end effectors, businesses can achieve enhanced productivity, improve efficiency, and gain a competitive edge in today's rapidly evolving market landscape. However, realizing the full potential of cobot technology requires careful planning, strategic integration, and a commitment to continuous improvement. With the right roadmap in place, the journey towards enhanced productivity with cobot end effectors is well underway, heralding a new era of automation and innovation in manufacturing.

0 notes

Text

Robot End Effector Market Trends and Global Demand At a CAGR of 16.9% by 2030

Robot End Effector Market Trends and Global Demand At a CAGR of 16.9% by 2030

Robot End Effector Market Growth with Industry Study, Detailed Analysis and Forecast to 2030

PORTLAND, OR, UNITES STATES, October 12, 2022 /EINPresswire.com/ — The global Robot End Effector Market report offers the complete market share, size, and the growth rate of different segments at both the country and regional levels. The report offers an in-depth study of the global Robot End Effector…

View On WordPress

0 notes