#Round Bar Manufacturer in India

Text

How a Round Bar Manufacturer Revolutionized the Steel Industry

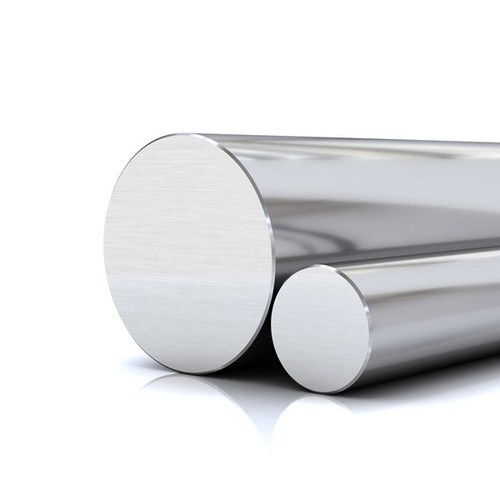

United Stainless LLP is a popular Round Bar Manufacturer in India. Round bars are long, thick cylindrical bars with round bottoms. Round bars come in a variety of diameters, ranging from 1/4 to 2 inches in diameter. The bar size is determined by its intended function, with larger bars utilized for heavier applications or when greater strength is required. The normal lengths for circular bars are 36 inches, 48 inches, and 60 inches. However, bespoke sizes can be produced on request. We are also a well-known Round Bar Supplier in India.

The Significance of Round Bars in the Steel Industry

Round bars play a crucial role in multiple industries, including construction, automotive, machinery, and aerospace. Their consistent shape, strong tensile strength, and versatility make them essential for a variety of uses. Whether it's reinforcing concrete structures or producing precise components, round bars are essential in modern engineering.

Technological Innovations in Round Bar Manufacturing

Advanced Metallurgical Techniques

The manufacturer distinguishes itself through its dedication to advanced metallurgical techniques, which is a crucial aspect. Through the allocation of resources towards cutting-edge equipment and research, they have successfully formulated distinctive alloy compositions that greatly improve the characteristics of round bars. As a result of these groundbreaking innovations, their round bars exhibit exceptional strength, resistance to corrosion, and ease of machining.

Precision Engineering and Automation

The combination of precision engineering and automation has proven to be a significant advancement. The company utilizes automated systems throughout the entire production process, starting from melting and casting to rolling and finishing. This approach not only guarantees uniform quality but also leads to a notable decrease in production time and expenses. Cutting-edge sensors and control mechanisms oversee the operation in real time, enabling prompt modifications and upholding top-notch accuracy standards.

Sustainable Production Practices

The focus on sustainability in contemporary manufacturing is evident in the practices of this leading round bar manufacturer. By utilizing energy-efficient technologies like electric arc furnaces and regenerative thermal oxidizers, they can significantly reduce carbon emissions. Furthermore, their implementation of a closed-loop water recycling system has not only decreased water consumption but also lessened their overall environmental footprint.

Types of Round Bar

Stainless Steel Round Bar Manufacturer in India

Duplex Steel Round Bar Manufacturer in India

Super Duplex Steel Round Bar Manufacturer in India

Inconel Round Bar Manufacturer in India

Monel Round Bar Manufacturer in India

Bronze Round Bar Manufacturer in India

Customer-Centric Approach: Customization and Service

Tailored Solutions

Round Bar Manufacturer acknowledges that each customer possesses distinct requirements, and thus provides customized solutions to fulfill their specific needs. Whether it involves personalized alloy compositions, exact dimensions, or specialized surface finishes, they collaborate closely with clients to ensure the delivery of products that precisely align with their applications. This customer-focused strategy has resulted in the establishment of a devoted clientele spanning multiple industries.

Technical Support and Training

Furthermore, apart from delivering top-notch merchandise, the manufacturer extends a wide range of technical assistance and training. Their proficient team aids customers in choosing suitable materials, developing applications, and resolving any issues that may arise. They regularly organize workshops and training sessions to keep clients informed about the most recent advancements in Round Bar Supplier technology and to promote optimal practices.

0 notes

Text

A Guide to Selecting the Best Stainless Steel Round Bar for Your Project by Piping Projects India

Stainless steel round bars are often used in a variety of industries, including construction, automotive manufacture, and aerospace engineering. They are widely used in a variety of applications due to their strength, longevity, and resistance to corrosion. However, selecting the appropriate type of stainless-steel round bar might be tricky. That's why PipingProjects.in gives this comprehensive guide to help you choose the best stainless steel round bar for your project.

Piping Projects India is a leading Round Bar Manufacturer in India.Our Round Bar is well-known for its high corrosion resistance and ability to perform properly in a variety of settings. Our stainless steel round bars meet tight weight criteria, and we provide a comprehensive Round Bar weight chart pdf for simple reference.

What is Stainless Steel Round Bar?

Stainless Steel Round Bars are an essential part of many industries. These bars are made of a corrosion-resistant and strong alloy of nickel, chromium, and molybdenum. As the name says, they are cylindrical in shape, with diameters varying from microscopic to massive, up to 100 mm. They are very resistant to wear and tear and have excellent heat transfer capabilities due to their low thermal expansion coefficient, making them ideal for a variety of applications such as fittings, hinges, and machine components. They can also be used with other metals, such as steel or aluminum, to improve strength and durability.

Determine the type of stainless steel Round Bar:

Stainless steel is not a broadly applicable material. It is classified into several kinds, each with its characteristics. The most popular stainless steel for round bars are:

Stainless Steel 304 Round Bar Manufacturer in India

Stainless Steel 304L Round Bar Manufacturer in India

Stainless Steel 316 Round Bar Manufacturer in India

Stainless Steel 316L Round Bar Manufacturer in India

Carbon Steel Round Bar Manufacturer in India

304 stainless steel is a popular material for general-purpose applications. It is affordable, easy to weld, and very corrosion resistant. Because of its superior corrosion resistance, 316 stainless steel is a higher-quality material in more demanding environments, such as marine applications. 17-4 PH stainless steel possesses great strength and hardness, making it ideal for high-strength applications.

Consider the size and tolerance requirements:

Stainless steel round bars are available in various diameters and standards. Before purchase, you must determine the size of your project. The round bar's diameter, length, and weight are all important concerns. Furthermore, you must assess your project's tolerance requirements. Tolerance is the acceptable variance from a specified size or dimension. Tighter tolerance requirements may increase the cost of round bars, yet they may be necessary for certain precision applications.

Consider the supplier's reputation and quality assurance:

Choosing a trusted source is just as important as selecting the right stainless steel round bar. A reliable supplier should supply a selection of grades and sizes to meet your project's needs, exact technical data and certificates, and quality assurance. Look for a supplier who has a proven track record of providing high-quality products and a strong quality control system in place. PipingProjects.in is a top-notch Round Bar Supplier in India. Our Round Bar is well-known for its excellent corrosion resistance and ability to perform in a variety of environments. It works effectively in high-temperature and pressure environments, stabilizing and maintaining a variety of equipment.

CONCLUSION:

Selecting the best stainless steel round bar for your project requires a thorough understanding of the material's properties, size parameters, tolerance, surface polish, and supplier reputation. Before purchasing, examine the type of stainless steel that is most suited to your application, the size and tolerance requirements, the surface polish, and the supplier's reputation and quality assurance. By carefully examining your project's needs and working with a reputable supplier, you can be confident that you're getting the best stainless steel round bar for the task, ensuring peak performance and longevity.

To know more visit: Round Bar Manufacturer

#SS Round Bar#stainless steel round bar#Round Bar Manufacturer in India#Round Bar Manufacturer#Round Bar#Round Bar Supplier in India

0 notes

Text

The Top Round Bar Manufacturers in India

Shashwat Stainless is the top Round Bar Manufacturer in India. One such critical component is the round bar, a versatile cylindrical piece that has a wide range of applications. In India, the market for round bars is growing, with various manufacturers contending for attention. In this context, choosing a reliable and reputable manufacturer is vital to ensuring the quality and lifespan of your products. This post will go extensively into the world of Indian round bar manufacturers, highlighting the top rivals in the market and going over the key factors to take into account.

Round bars are used as core pieces in many projects, and they provide several benefits. These cylindrical marvels are essential in a variety of applications, providing structural support as well as aesthetic appeal.

We showcase well-known round bar manufacturers in India and draw attention to their commitment to quality, innovation, and customer satisfaction in an attempt to always improve. These businesses, which include both established titans and rising stars, set the standard for conventions in the field.

We are the best Round Bar Manufacturer in India, In Round Bar Varieties, We are leading Duplex Steel F53 Round Bars Manufacturers and Duplex Steel 2205 Round Bars Manufacturers.

For more details:

Website: shashwatstainless.com

Visit: Round Bar Suppliers in India.

0 notes

Text

Excellent Aluminium Bronze Round Bar Manufacturers In India

Rajkrupa Metal Industries is a renowned Aluminium Bronze Round Bar manufacturer in India. In the market for aluminium bronze round bars, we have made a name for ourselves. Due to its extensive corporate and technical human resources, Rajkrupa Metal Industries has consciously positioned itself as a top-tier global producer and retailer of aluminium bar supplier in industry.

We provide a wide range of sizes and types of aluminium bronze round bar Manufacturers in a variety of locations. We have been identified as one of India's top producers of Aluminium Bronze Round Bars due to our ability to meet the massive demand for Aluminium Bronze Round Bar Suppliers while also producing high-quality Aluminium Bronze Round Bar goods.

We also offer Inconel 625 Round Bars Manufacturer in India and C63000 Round Bar Manufacturer in India

0 notes

Text

Top 3 Types of SS Round Bar

India’s Leading Manufacturer and Supplier of Stainless Steel Round Bar

Hans Metal India are one of the major Stainless Steel Round Bar Manufacturer in India. The variety of stainless steel round bars we provide includes those in the following grades and materials: 304 stainless steel, 316 stainless steel, 202 stainless steel, 410 stainless steel, 317 stainless steel, and 321 stainless steel, among others. We are a best stainless steel round bar suppliers in a range of grades, dimensions, and forms. We are the best SS Round Bar Manufacturer in Gujarat and Round Bar Manufacturers in Mumbai.

Types of Round Bars

Stainless Steel Round Bar

Stainless steel round bar is one type of product made from stainless steel materials. Stainless steel is used in a range of sectors and grades. Stainless steel bars are used because of their sturdiness and capacity to withstand corrosion. Stainless steel round bar is the industrial product that consumers most frequently ask for.

Visit For more details: Stainless Steel Round Bar Manufacturer in India

Aluminium Round Bar

Every industry uses aluminium round bar because they are adaptable and widely used. Round aluminium bars come in a range of lengths and widths. For our clients' industrial needs, we also manufacture and provide aluminium round bar in custom sizes.

Visit For more details: Aluminium Round Bar Suppliers

Phosphor Bronze Round Bar

Every business uses Phosphor Bronze Round Bars because they are adaptable and widely used. Round phosphor bronze bars come in a range of lengths and widths. Due to their excellent weldability and good corrosion resistance, these phosphor bronze round bars are utilised extensively. They offer resistance to pitting corrosion and are quite effective in acidic environments.

Visit For more details: Phosphor Bronze Round Bars

Specification of Stainless Steel Round Bar

Standard: SUS, GB, ASME, EN, API, DIN, ASTM, AISI, UNS, BS, JIS,

Sizes: 3mm to 800mm diameter

Length: 12 Random Lengths

Tolerances: K12, H12, K11, H9, H13, H11, K9, H10, K10, H8

Surface Finish: NO.1, 2B, NO.4, HL, 2D, 1D, 8K, NO.3, BA

Top Quality Stainless Steel Coil Manufacturer and Supplier in India

In Mumbai, India, Hans Metal India is the largest stockholder of stainless steel coil. We are the best Stainless Steel Coil Manufacturers in India.Every business makes use of stainless steel coils because of their versatility. There are numerous shapes and sizes of stainless steel coils. To meet our customers' industrial needs, we also manufacture and provide stainless steel coil in custom sizes. We are also the leading Stainless Steel Plate Manufacturers in India and SS Round Bar Manufacturer in India.

Contact us

Website: hansmetalindia.com

Mail: [email protected]

Product Source: Stainless Steel Round Bar Manufacturer in India and Stainless Steel Plate Manufacturers in India.

You may also like Stainless Steel Coil Manufacturers in India and Round Bar Manufacturers in India

#Stainless Steel Round Bar#Stainless Steel Round Bar Manufacturer in India#Round Bar#Round Bar Manufacturer in India#SS Round Bar#SS Round Bar Manufacturer in India#Stainless Steel Coil Manufacturers in India

0 notes

Text

Leading Manufacturer and Exporter of Ferrous & Non-Ferrous Bars in Diverse Materials and Grades.

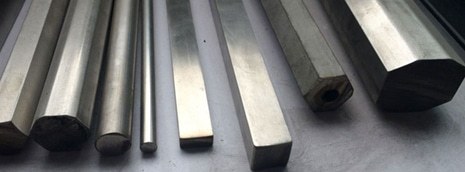

Piyush Steel, we pride ourselves on being a leading Manufacturer and Exporter of Ferrous and Non-Ferrous bars, renowned for our commitment to quality and precision. Our extensive product range includes round bars, square bars, hex bars, bright bars, flat bars, rectangular bars, black bars, rods, hot rolled bars, and cold-rolled bars.

Contact Us

2 notes

·

View notes

Text

Top Quality Stainless steel Round bar manufacture in india

Hans Metal India is the largest Stainless Steel Round Bar Manufacturer & Supplier in Mumbai, India. Stainless Steel Round Bar Manufacturer in India in a variety of grades, shapes, and sizes. Our company offers round bars in diameters ranging from 0.5 mm to 200 mm and in thicknesses ranging from 0.1 mm to 30 mm, with lengths up to 4 meters. Stainless Steel Round Bar are available in a variety of dimensions and sizes. We also Manufacture and Supply custom-sized Stainless Steel Round Bars for our customers to fulfill their industrial requirements. This SS round bar Manufacturer in India is widely used because of its strong corrosion resistance and weldability. They are extremely effective in acidic settings and provide pitting corrosion resistance. We are also a leading Stainless Steel Sheet Manufacture in India

Contact +91 97697 56468

Website: https://hansmetalindia.com

#Ss round bar manufacture in india#Stainless steel sheet manufacture in india#Round bar manufacture in mumbai#Copper sheet manufacture in india

0 notes

Text

Fabricate with Confidence: High-Performance Hastelloy C276 Round Bars

Hastelloy C276 round bars are well-known for their outstanding performance in challenging conditions. Whether in corrosive chemical settings or high-temperature applications, these alloys stand out for their reliability and durability.

Introduction to Hastelloy C276 Round Bars

Hastelloy C276 round bar belongs to a family of nickel-molybdenum-chromium superalloys known for their versatility in harsh conditions. Engineered to withstand extreme temperatures and resist corrosion, these bars are vital components in various industrial sectors.

Properties of Hastelloy C276 Alloy

Corrosion Resistance

Hastelloy C276 shows exceptional resistance against various corrosive substances, including both oxidizing and reducing environments. This property makes it ideal for applications where exposure to acids, salts, and solvents is common.

High-Temperature Performance

Hastelloy C276 retains its mechanical strength even at high temperatures, with a melting point surpassing 1300°C. This attribute ensures stability and reliability in environments where heat endurance is crucial.

Mechanical Strength

The alloy's high mechanical strength enables it to withstand intense pressures and stresses without compromising structural integrity. This makes the Hastelloy C276 round bar suitable for critical load-bearing applications.

Applications of Hastelloy C276 Round Bars

Aerospace Industry

In aerospace engineering, Hastelloy round bars are utilized in structural components and engine parts due to their lightweight nature and superior corrosion resistance.

Chemical Processing

Chemical plants rely on Hastelloy C276 round bar for equipment exposed to corrosive chemicals, ensuring longevity and safety in operations.

Oil and Gas Sector

In the oil and gas industry, where harsh drilling conditions prevail, these round bars are used in downhole tools and pipelines, offering protection against corrosive fluids and gases.

Manufacturing Processes of Hastelloy C276 Round Bars

Alloy Composition

Hastelloy C276 round bar are composed of nickel, molybdenum, and chromium, combined in precise proportions to achieve optimal performance characteristics.

Melting and Casting

The alloy is melted in a controlled environment and cast into billets or ingots, which are subsequently hot worked into round bars of varying diameters.

Hot and Cold Working

Hastelloy C276 round bars undergo hot forging and cold drawing processes to refine their structure and enhance mechanical properties, ensuring uniformity and durability.

Comparison with Other Alloys

Hastelloy C276 vs. Inconel Alloys

Unlike Inconel alloys, Hastelloy C276 offers superior resistance to a broader range of corrosive chemicals, making it preferred in aggressive industrial environments.

Hastelloy C276 vs. Stainless Steel

Compared to stainless steel, Hastelloy C276 provides better performance in highly corrosive conditions and at elevated temperatures, making it a cost-effective choice for critical applications.

Quality Standards and Certifications

ASTM Specifications

Hastelloy C276 round bars adhere to ASTM B574/B575 standards, ensuring consistent quality and performance in various applications.

ISO Certifications

Manufacturers of Hastelloy round bars comply with ISO 9001 standards, demonstrating their commitment to quality management and customer satisfaction.

Factors to Consider When Choosing Hastelloy C276 Round Bars

Environmental Factors

Evaluate the operating environment's temperature, pressure, and chemical exposure to determine if Hastelloy round bars are suitable for the application.

Cost Considerations

While initially more expensive than some alternatives, the Hastelloy C276 round bar offers long-term cost savings due to its durability and minimal maintenance requirements.

Maintenance and Care Tips

Cleaning Procedures

Clean Hastelloy C276 round bar regularly using mild soaps and non-abrasive materials to preserve their corrosion-resistant properties and aesthetic appeal.

Storage Recommendations

Store Hastelloy round bars in a dry, ventilated area away from corrosive substances to prevent surface damage and maintain their integrity over time.

Future Trends in Hastelloy C276 Round Bar

Research and Development

Ongoing research aims to enhance Hastelloy C276's properties further, potentially expanding its applications in emerging industries and challenging environments.

Innovations in Alloy Design

Advancements in alloy design may lead to new formulations of Hastelloy round bars with enhanced mechanical strength and improved resistance to specific chemicals.

Conclusion

In conclusion, Hastelloy C276 round bars are indispensable in industries requiring robust, corrosion-resistant materials capable of withstanding extreme conditions. Their superior performance, coupled with ongoing advancements in alloy technology, ensures they remain at the forefront of engineering solutions.

#Hastelloy C276 Round Bars#Hastelloy C276 Round Bars Supplier#Hastelloy C276 Round Bars Exporter#Hastelloy C276 Round Bars Manufacturer in India#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates

0 notes

Text

Stainless Steel S32750 Forged Round Bars Exporters In India

#Duplex Stainless Steel S32750 Forged Round Bars Manufacturers#Duplex Stainless Steel S32750 Forged Round Bars Suppliers#Duplex Stainless Steel S32750 Forged Round Bars Stockists#Duplex Stainless Steel S32750 Forged Round Bars Exporters#Duplex Stainless Steel S32750 Forged Round Bars Manufacturers In India#Duplex Stainless Steel S32750 Forged Round Bars Suppliers In India#Duplex Stainless Steel S32750 Forged Round Bars Stockists In India#Duplex Stainless Steel S32750 Forged Round Bars Exporters In India

0 notes

Text

Sankalp Alloys Overseas figured as unmistakable provider, exporter and producer of Incoloy 825 Round Bars among our supporters. These Incoloy 825 Bars (UNS N08825) are much of the time utilized in Substance Handling, Contamination control, Oil and gas well channeling, atomic fuel going back over, and that's just the beginning. Amalgam 825 Round Bars are additionally utilized in phosphoric corrosive evaporators; pickling-tank warmer, pickling snares and hardware; substance process gear; tank trucks; propeller screws, and spent atomic fuel component recuperation.

#Incoloy 825 Round Bars Manufacturers#Incoloy 825 Round Bars Suppliers#Incoloy 825 Round Bars Stockists#Incoloy 825 Round Bars Exporters#Incoloy 825 Round Bars Manufacturers in India

0 notes

Text

Top Quality Round Bar Manufacturer in India - United Stainless LLP

United Stainless LLP is a reputable Round Bar Manufacturer in India. Round bars are long, thick, cylindrical bars with circular bases. Round bars are available in various sizes, ranging from 1/4 inch to 2 inches in diameter. The bar size depends on the specific use, with larger bars used for heavier applications or when more strength is needed. The standard lengths for round bars are 36 inches, 48 inches, and 60 inches. However, custom sizes can also be ordered upon request. We are also a well known Round Bar Supplier in India.

We have created a name for ourselves as a trustworthy Round Bar Manufacturers. They are pre-finished metal products that find diverse uses in industries and businesses. Furthermore, their low maintenance and long-term durability make them a popular choice. We supply a comprehensive selection of Round Bars in various sizes and grades to meet national and international quality standards.

Product: Round Bar Suppliers

Website: unitedstainlessllp.com

0 notes

Text

Round Bars Are Versatile And Strong

Shashwat Stainless is the top Round Bar Manufacturer in India. Round bars are cylindrical metal rods that have a wide range of uses throughout industries. Round bars, known for their flexibility and strength, are used extensively in structural support, equipment manufacture, and a variety of other applications. Round bars are meticulously manufactured to assure their quality and dependability.

The first stage in making a round bar is the careful selection of raw materials. Round bar Manufacturers choose high-quality steel or other metals based on the desired properties of the final product. After selecting the raw materials, they are heated to increase their malleability. Skilled specialists then use specialized tools to mold the hot metal into the appropriate round bar form. Precision machining ensures that round bars meet rigorous specifications. Advanced CNC machines are used to accurately cut, drill, and polish round bars, ensuring uniformity and consistency in outcomes.

Round bars are sturdy and flexible, making them valuable in many different fields. Because they guarantee the lifetime of many components and offer structural support, round bars are crucial to both building and aviation. Round bars Suppliers in India, with their remarkable qualities and many uses, remain a cornerstone of contemporary engineering and industry.

We are the best Round Bar Manufacturer in India, In Round Bar Varieties, We are leading Duplex Steel F53 Round Bars Manufacturers and Duplex Steel 2205 Round Bars Manufacturers.

For more details:

Website: shashwatstainless.com

Product Source: Round Bar Supplier in India

Other Product Source: Pipes and Tubes Manufacturers in India.

0 notes

Text

The Highest Quality Aluminium Bronze Round Bar Manufacturers In India

Rajkrupa Metal Industries, one of the major Aluminium Bronze Round Bar Manufacturer In India, offers a wide range of round bars in various sizes, grades, and weights. When compared to other alloy series, Aluminium Bronze Round Bar is a copper-based alloy with distinct chemical and mechanical properties.

We are a leading Bronze Bar Manufacturer in India as well as an aluminium bronze round bar manufacturer in Mumbai.

We also offer Inconel 625 Round Bars Manufacturer in India and C63000 Round Bar Manufacturer in India

For more details:

website - rajkrupametal.com

Product Source - Aluminium Bronze Round Bar Manufacturer

Mail us - [email protected]

0 notes

Text

Top Quality Stainless steel Round bar manufacture in india

Hans Metal India is the largest Stainless Steel Round Bar Manufacturer & Supplier in Mumbai, India. Stainless Steel Round Bar Manufacturer in India in a variety of grades, shapes, and sizes. Our company offers round bars in diameters ranging from 0.5 mm to 200 mm and in thicknesses ranging from 0.1 mm to 30 mm, with lengths up to 4 meters. Stainless Steel Round Bar are available in a variety of dimensions and sizes. We also Manufacture and Supply custom-sized Stainless Steel Round Bars for our customers to fulfill their industrial requirements. This SS round bar Manufacturer in India is widely used because of its strong corrosion resistance and weldability. They are extremely effective in acidic settings and provide pitting corrosion resistance. We are also a leading Stainless Steel Sheet Manufacture in India

Contact +91 97697 56468

Website: https://hansmetalindia.com

Mail: [email protected]

#Ss round bar manufacture in india#Stainless steel sheet manufacture in india#Round bar manufacture in mumbai

0 notes

Text

Applications and Uses of Stainless Steel in Automotive Industry

Did You Know?

45 to 50% of automotive exhaust systems are made of stainless steel.

Probably, we all are aware of establishing uses of stainless steel in different industries as per their required proportions but at Automotives behind the scenes are quite different, as you read the fact – the ratio of stainless steel is quite higher than other applicants of stainless steel.

So, is it bad/good that Automotives have adopted stainless steel? And if yes, what characteristics of stainless steel made the automotive industry to adapt this higher ratio? Let’s get on to answering step-by-step, when it comes to automotive there are several requirements that need to be fulfilled including a lightweight yet safer experience, environmental-friendly, and affordability.

Now steel can also deliver those segments so why stainless steel and not just steel for automotive, forgot!? “RUST” can easily eat away the whole engine compartment, can weaken exhaust system mounts, and be able to create air leaks.

Whereas stainless steel offers tremendous corrosion resistance, a wide yield strength range, and a lighter weight that apparently reduces vehicles’ weight and benefits in greater fuel efficiency and machinability rephrasing the whole thing into a reduced amount of CO2 emissions.

Thus, after these long checkmarks of benefits, stainless steel offers an environmentally-friendly approach too. Things are turning informative, then why not dig into some more of it? Come let’s do it together.

Role of Stainless Steel Used in Automotive Industry

Since the 1930s, the average count of 15 to 22 kilos of stainless steel gets used in a single car which was mainly found in the exhaust system and sundry small parts.

In today’s date uses of stainless steel in automotive are also extended to other automotive applications such as fasteners, springs, and tubing, as well as brackets, flanges, substructures, and panels.

At younger ages, the cost of wielding was more expensive than now as the years passed by – stainless steel types such as austenitic, martensitic, ferritic, and many other stainless steels were discovered.

From all these stainless steel categories austenitic stainless steel became ideal to use for the automotive industry due to its easy welding and long durability.

{Additional Information on Exhaust Systems: Where we saw the central importance of stainless steel in exhaust systems, we might forget the role of its valves that perform opening and closing operation that controls the gas flow and optimize the engine-back pressure enabling exhaust systems to provide improved performance and auditory control.

These exhaust valves get manufactured from bright bars – in different shapes such as square, round, or hex and with particular grades as per the requirement.}

To Read Full Blog : Applications and Uses of Stainless Steel

#stainless steel#stainless steel bars#stainless steel bright bars#stainless steel grades#stainless steel wire#steel bar manufacturer#bright round bar#stainless steel manufacturers in india#bright bar manufacturers

0 notes

Text

Top Quality of Stainless steel Round bar manufacture in india

Hans Metal India is the largest Stainless Steel Round Bar Manufacturer & Supplier in Mumbai, India. Stainless Steel Round Bar Manufacturer in India in a variety of grades, shapes, and sizes. Our company offers round bars in diameters ranging from 0.5 mm to 200 mm and in thicknesses ranging from 0.1 mm to 30 mm, with lengths up to 4 meters. Stainless Steel Round Bar are available in a variety of dimensions and sizes. We also Manufacture and Supply custom-sized Stainless Steel Round Bars for our customers to fulfill their industrial requirements. This SS round bar Manufacturer in India is widely used because of its strong corrosion resistance and weldability. They are extremely effective in acidic settings and provide pitting corrosion resistance. We are also a leading Stainless Steel Sheet Manufacture in India

Contact +91 97697 56468

Website: https://hansmetalindia.com

Mail: [email protected]

#Ss round bar manufacture in india#Stainless steel sheet manufacture in india#Round bar manufacture in mumbai#Copper sheet manufacture in india

0 notes