#SS Rods sale

Text

A Guide to Stainless Steel Rods

Stainless Steel Rods:

Stainless steel rods are cylindrical pieces of steel alloy that are usually used in construction, fabrication, and industrial applications. They are highly corrosion-resistant and durable, making them ideal for many different types of projects. Stainless steel rods are made from a combination of iron, chromium, nickel, and other metals and alloys, which makes them strong, long-lasting materials that can be used in a variety of ways.

They are commonly used in manufacturing, automotive, and aerospace industries, as well as in structural, mechanical, electrical, and other engineering applications. They can be used to create a variety of shapes, sizes, and lengths, and can be easily cut and bent to fit any project.

Stainless steel rods are also used to reinforce concrete structures and are often used in medical and surgical applications. They are easily welded and are often used to create custom parts for machines and for other types of projects. Stainless steel rods are extremely versatile and can be used in a variety of applications, from construction projects to decorating.

Characteristics of Stainless Steel Rods

Stainless steel rods are highly corrosion-resistant and strong metal rods used in many applications. They are composed of at least 10.5% chromium and are highly resistant to oxidation, rust, and corrosion. They are used in a variety of industries, including construction, marine, automotive, and industrial. Stainless steel rods are strong and durable and can withstand extreme temperatures and pressures. They are also non-magnetic and non-combustible. Stainless steel rods are available in a variety of shapes, sizes, and grades to suit different applications.

They are easy to cut, drill, and weld, making them suitable for many engineering and construction projects. Stainless steel rods are also highly resistant to staining and discoloration, making them an ideal choice for aesthetic purposes. They are also non-toxic, which makes them suitable for medical applications. Stainless steel rods are a popular choice because they are low maintenance and require little special attention. They are also recyclable, making them a great choice for those looking to be environmentally conscious.

Properties of Stainless Steel Rods

1. Stainless steel rods are highly durable, corrosion-resistant, and heat-resistant.

2. They have excellent mechanical properties, making them ideal for a variety of applications.

3. They can withstand high temperatures and pressures, making them suitable for use in extreme environments.

4. Stainless steel rods are strong and provide excellent wear resistance.

5. They are non-magnetic and non-staining, making them ideal for food preparation and medical instruments.

6. They can be machined, welded, and formed into a variety of shapes.

7. Stainless steel rods are relatively inexpensive compared to other metals.

Conclusion

Stainless steel rods are versatile, durable, and corrosion-resistant materials that can be used in a variety of applications. They are commonly used in the construction of machinery, buildings, and other structures, as well as in the manufacturing of various consumer products. They can come in a variety of sizes and grades, allowing them to meet the needs of a variety of applications. Stainless steel rods are also relatively inexpensive compared to other metals, making them an attractive option for many projects. you can get a discount on SS products at stainless steel rods for sale

#stainless steel rods for sale#stainless steel rods#stainless steel rod#SS Rods#SS Rods sale#SS Rods For Sale

0 notes

Text

ERP Software for Metal & Steel Industry

SAFAL ERP software for metal & steel Industry is a vital tool for steel factories that want to optimize their production processes and increase their efficiency. SAFAL ERP software integrates various functions such as inventory management, quality control, sales, accounting, and human resources, and provides a centralized platform for data analysis and decision making. SAFAL ERP software also enables steel factories to automate their workflows and reduce errors and waste. SAFAL ERP is enterprise software for CS / SS / MS Tube manufacturers welded or Seamless, SS Coil / Foil Manufacturers, CS / SS Billet Manufacturers, Wire Rod and Bright Bat Manufacturers, Steel Stockholders, Plate Processors, Metal Processors, and tube mills.

#erpsoftwareforsteelandmetalindustry#erpsoftwareforsteel&metalindustryfree#erpsoftwareforsteelindustry

0 notes

Text

Manufacturers Of Premium Quality SS Flanges In India

Regent Steel Inc is the best Stainless Steel Flanges Manufacturers in India. As requested by our clients, we also offer unbiased third-party inspection of flanges. We are the top Flange Manufacturer in Pune and Flange Manufacturer in Kolkata. To make sure things follow standards, they are evaluated. Regent Steel Inc. has developed a reputation as a leading manufacturer in the industry as a result of its broad product offering, outstanding quality, low prices, and quick delivery. We are also Molybdenum Rod Supplier and Flange Suppliers in Dubai and Flanges Supplier in Qatar.

Contact us:

Website: forgefittings.com

Mail: [email protected]

Product source: Flange Supplier in Singapore and Flange Supplier in Malaysia

You may also like: Flange Supplier In UAE and Flange suppliers in Gauteng

#Molybdenum Rod Supplier#Flange Supplier In UAE#Stainless Steel Flanges Manufacturers in India#Stainless Steel Flanges Manufacturers#Flange Manufacturer in Pune#Flanges Supplier in Qatar

0 notes

Text

Seamless Pipe Uses and Applications - Shree Impex Alloys

What is a seamless stainless steel pipe defined as?

As there is no weld on the surface of the steel pipe and it is perforated from a single round piece of steel, the steel pipe is known as seamless steel pipe. In order to create a hollow tube or shell, the solid steel used to make seamless pipes is heated and shaped into solid circular shapes called "billets" before being cast on a mould resembling a piercing rod. Reliability and Maintenance of Existing Pipelines.

One of India's top manufacturers and suppliers of stainless steel seamless pipe is Shree Impex Alloys. We provide premium stainless steel seamless pipes to numerous sectors across the world.

We are one of the largest Stainless Steel Seamless Pipe Manufacturers in India. Manufacturers of seamless pipes adhere to both Indian and foreign standards such as ASME, AISI, ASTM, ANSI, DIN, BS, IS, and JIS. We are Leading Stainless Steel Seamless Tube Manufacturer and Stainless Steel welded Pipes.

Specifications for Stainless Steel Seamless Pipe

SS Seamless Pipe Types: SS Seamless Pipe, ERW Seamless Pipe, Welded Seamless Pipe, Fabricated Seamless Pipe, LSAW Seamless Pipe, Box Seamless Pipe.

Standard: JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST.

Thickness: SCH.5, 10, 40/S, 80/S, 160

Schedules: ASTM A-312, EN 10216-5 & Its Equivalent ASME, DIN & EN Standard.

Seamless steel pipes are widely used

With the highest output, conventional carbon structural steel, low-alloy structural steel, or alloy structural steel are used to roll general-purpose seamless steel pipes. These pipes are mostly utilised as pipelines or structural components for moving fluids. Boiler, chemical, and electric power seamless pipes, steel seamless pipes for geology, and petroleum seamless pipes are only a few examples of special-purpose seamless pipes.

What Are the Advantages of Using Stainless Steel Seamless Pipe

In industrial applications, seamless stainless steel pipe has a number of benefits over welded tubing. Here are a few of the main advantages:

Enhanced Strength: Because there are no weld seams, which are frequently the weak places in the pipe, seamless stainless steel pipe is stronger than welded stainless steel pipe.

Improved Corrosion Resistance: Because seamless stainless steel pipe has a strong resistance to oxidation and corrosion, it is perfect for use in corrosive and hostile situations.

Better Hygiene: Because seamless stainless steel tubing is simple to maintain and clean, it is frequently used in the pharmaceutical industry, the food and beverage industry, and other industries where cleanliness is essential.

Why Choose Shree Impex Alloys?

By calling the number or sending an email to the address provided, you can now make your enquiry and ask any questions you may have about Stainless Steel Seamless Pipe. We are dedicated to maintaining high standards for quality and timely product delivery. All of our items are offered at factory prices in large or small quantities.

Our knowledgeable crew checks the product for quality before it is shipped. Call +91 91679 63226 or contact [email protected] if you require a specific size, thickness, or coating for stainless steel seamless pipe, and our sales professionals will provide you with the precise sizes that are currently in stock and confirm the delivery schedule to your nearest port.

#Stainless Steel 304 Seamless Pipe Stockist#Stainless Steel Seamless Pipes Manufacturer Stainless Steel 316 Seamless Pipe Exporter#Stainless Steel Seamless Pipe Supplier in India

0 notes

Photo

New Post has been published on https://fastmusclecar.com/answering-the-most-common-american-muscle-car-questions/best-muscle-cars/

Answering The Most Common American Muscle Car Questions

The concept of a muscle car largely stems from hot rod and drag racing culture, with the basic premise being to take a small, relatively lightweight car, add in an oversized engine, and then boosting proceedings with upgraded brakes and suspension to match.

The above may seem like a simple template, but there is lots more to the genre than meets the eye. For those who want some simple answers to the most common questions asked about American muscle cars, the list below will give you a jump-off point for further research.

If you want to delve further into the world of American muscle cars, then simply do a quick search on our website to find out everything you need to know about these wonderful vehicles.

What are American Muscle Cars?

A muscle car is a high-performance vehicle with a powerful engine, manual transmission, and rear-wheel drive. The concept of muscle cars stems from the hot rod and drag racing culture, where small, lightweight vehicles were fitted with oversized engines and reinforced with upgraded brakes and suspension to match.

Brands of American Muscle Cars

Some of the most notable American muscle car brands include:

AMC (AMX, AMC Rebel The Machine)

Buick (GS 455 Stage 1, Buick GNX)

Chevrolet (Chevelle SS, Camaro Z/28, Camaro SS, Nova)

Dodge (Dart GTS, Dart Demon, Charger, Charger Daytona, Super Bee, Challenger)

Ford (Mustang Boss 429)

Shelby (Mustang GT500, Mustang GT350)

Oldsmobile (442)

Plymouth (GTX, Road Runner, Barracuda)

Pontiac (GTO, Firebird)

What is America’s Best Muscle Car?

This is subjective and varies based on personal preferences. Some of the most popular muscle cars include the Chevrolet Camaro, the Dodge Challenger, and the Ford Mustang. If we interpret the word ‘best’ for ‘most sales,’ then the title will go to the Ford Mustang for sheer sales numbers, both in America and abroad. However, the Ford Mustang is strictly a pony car, and more sports car these days. The Dodge Challenger and Charger are The last vehicles to follow the true old-school muscle car template design.

What is the Baddest Muscle Car?

This is also subjective and varies based on personal preferences. However, some muscle cars known for their powerful engines and aggressive styling include the Pontiac GTO, the Dodge Charger Daytona, and the Ford Mustang Boss 429. Personally, you can’t go far wrong with the 1970 Chevrolet Chevelle SS 454 for this status.

Classic Muscle Cars

The classic muscle car era is often considered to be the late 1960s and early 1970s. During this time, many iconic muscle cars were produced, such as the Chevrolet Chevelle SS, the Plymouth GTX, and the Pontiac Firebird. However, don’t discount the other decades for some classic examples. The 1980s produced the Buick GNX, Which is a highly collectable example today.

Is There a British Muscle Car?

Although there are many high-performance vehicles produced in Britain, the term “muscle car” is typically associated with American cars. At a stretch, you could include the British Ford Capri, which did have a muscle car-like design. However, engine sizes in the Capri were never as large as their American counterparts.

What is the King of Muscle Cars?

This is subjective and varies based on personal preferences. Some people consider the Pontiac GTO to be the king of muscle cars, while others might consider the Ford Mustang Boss 429, the Dodge Charger Daytona or the Chevrolet Chevelle 454 to hold this title.

What Does GTO Stand For?

GTO stands for “Gran Turismo Omologato,” which is Italian for “Grand Touring Homologated.”

Which is the No. 1 Muscle Car in the World?

This is subjective and varies based on personal preferences. However, some of the most popular muscle cars globally include the Chevrolet Camaro, the Dodge Challenger, and the Ford Mustang.

What Was the 1st Muscle Car?

The first muscle car is often considered to be the Pontiac GTO, which was introduced in 1964.

What is the Most Stolen Muscle Car?

This can vary depending on the year and location. However, the National Insurance Crime Bureau (NICB) reports that the most stolen muscle car in the United States in recent years has been the Dodge Charger.

What is the Greatest Muscle Car of All Time?

The ranking of the best muscle car in the world depends on the individual’s personal preference and the current market demand. Some of the most popular muscle cars in the world include the Dodge Challenger, Chevrolet Camaro SS, and the Ford Mustang Boss 429.

Should you buy a Muscle Car Right now?

Yes…. does it really need more explanation?

0 notes

Photo

ss threaded rod or stainless steel threaded rod

click here to see more of this product

#ss threaded rod#stainless steel threaded rod#m12 ss threaded rod#ss threaded rod manufacturers#316 ss threaded rod#304 stainless steel threaded rod#stainless steel threaded rod home depot#ss threaded rod suppliers in uae#ss threaded rod for sale#ss threaded rod sizes#ss threaded rod manufacturers in india#1/2 ss threaded rod#3/4 ss threaded rod#5/8 ss threaded rod#3/8 ss threaded rod#304 ss threaded rod#hilti has ss threaded rod#1/4 ss threaded rod#5/16 ss threaded rod#ss 304 threaded rod#ss316 threaded rod#ss acme threaded rod#sst threaded rod#ss threaded rods#stainless steel threaded rod grades#316 stainless steel threaded rod#stainless steel threaded rod 5/8#stainless steel threaded rod 3/8#stainless steel threaded rod bunnings#stainless steel threaded rod m10

0 notes

Text

SS Cicada

I don't know where I got the idea for a dirigible cicada miniature model but here we are. Falling asleep with my YouTube queue probably with videos on the recent 17 year cicada cycle followed by the use of airships during WW1 must have blended together in my subconscious. I enjoyed creating the last insect - the custom bee - I had to do another but this was too large for a piece of jewellery.

So I worked on each separate section, hoping it would all fit together in the end. That's always the scary part - will the wings fit on the body? Will the scale of everything maintain the illusion of an actual, albeit fantastical, airship once joined? Unlike very clever model scene makers I don't work with a scale ruler. As I don't fabricate or cast metal there is no real point - I'll still have to adjust a part in my collection to fit.

I started with the wings - they bring everything together and set the scale. Like the last piece - the body is a brass screw electrical terminal. The abdomen has two main parts - the high copper piece with a grill and a lower section made from a cut out earing drop I filled in with resin. The wings are also filled with resin and a very light dusting of green and gold mica.

I've been making miniature nebulas lately so that is where the glass "hot air balloon" came from. It is fitted with a vintage brass bead cap, chains, tiny brass drops and internal details. While I was searching for pieces I came across the hand blown green glass bead with a swirl pattern. I had to incorporate it but it was difficult to do so. Adding a piece to one side of a symmetrical design alters the way it hangs. The swirl on the bead is matched with the black swirled disk hanging under the balloon.

She has wrapped wire legs with metal crimps, two brass and steel "propellers" affixed to the front, one large rear flag and bunting on the secondary "balloon" tether. Everything attached is done so using screws and very rarely, glue. I have no idea how many separate components I used but it would be well over 100. I've been working on and off for a week - probably about 40 hours not including the time sourcing parts, taking photos and writing this. The rigging was a nightmare. The chain at the back, connected to a "U" shape piece is the ship's anchor.

A friend who is a genius wood worker turned some gorgeous wood bases for me. I think it's Jarrah. It has four brass legs on the bottom. The hanging mechanism consists of a filigree disk, a vintage brass corrugated bead and assortment of brass rods, copper and brass tubing and beads. The top section pulls out so it can be packed for shipping.

One final surprise. I left a hole in the body for a tiny green LED light. It is difficult to use - turning on by pushing the light into a battery. But it could be used on special occasions to show her off. The battery type is a bit exotic but available online.

I'm thinking about entering her in a local art competition before putting her up for sale. I hope you like her.

#cicada#cicadas#cicadaart#steampunkart#steampunk#miniature#dirigible#airship#zepplin#blimp#hot air balloon#insect#flying insects#entomology#LED#light up#wings#ornament#desk ornament#sculpture#mixed media#found objects#steampunk art#assemblage art#assemblage#fantasy art#scifiart#handmade#etsyshop#etsyseller

163 notes

·

View notes

Text

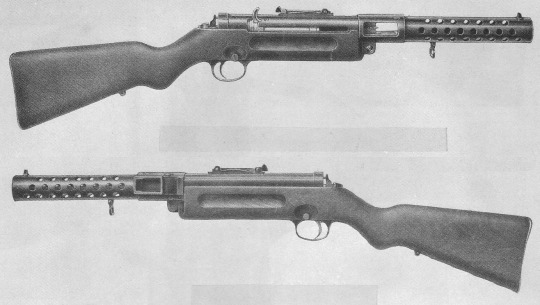

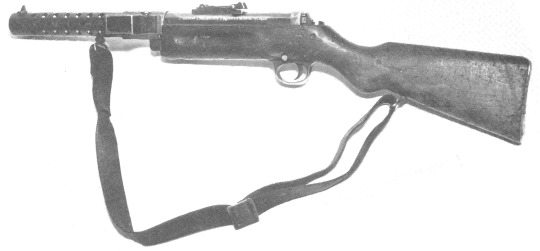

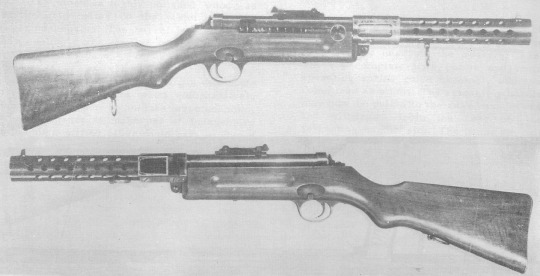

Bergmann submachine gun variants

The Bergmann M.P.18,I submachine gun is widely considered to have been the first successful submachine gun, and as a consequence many variants of the design were made. This post covers the main derivatives of the Bergmann submachine gun which retained the basic elements of the design (variants like the Schmeisser M.K.36,III and Haenel MP41 are excluded for deviating too far from the original M.P.18,I).

Comparison of the various types of Bergmann magazine feed - M.P.18,I on the left; M.P.18,I police issue/M.P.28,II in the center; and SIG-Bergmann on the right.

The Bergmann M.P.18,I (military issue)

The original production version of the Bergmann M.P.18,I submachine gun was developed in 1918 by Hugo Schmeisser, then-employed by Theodor Bergmann. It operated on a basic blowback action upon which the bolt rode on a spring-loaded guide rod, and employed a canted magazine feed, taking the 32-round “Trommelmagazin” originally designed for the Artillery Luger carbine. The M.P.18,I had fired only in full-auto and had no mechanical safety whatsoever; the only safety provision was a catch in the cocking slot which could be used to manually hold the bolt in the rearward position. The gun was chambered in the standard German pistol cartridge, 9x19mm Parabellum.

The M.P.18,I was adopted by the German Army and first issued during the Summer of 1918, seeing some combat use during the later stages of World War I. It is estimated that some 35,000 M.P.18,Is were produced in total, although only a few thousand were actually issued during the war and the vast majority of examples were probably produced after the Armistice. Production lasted from 1918 - 1920.

It is often said that the M.P.18,I made such an impact on Allied troops that it was specifically singled out in the Treaty of Versailles. This is not actually true; submachine guns like the M.P.18,I actually fell under the rather ambiguous category of “light machine guns” and “automatic rifles”, and are never actually mentioned by name in the Treaty. Actual primary sources from the wartime period indicate that the M.P.18,I was not particularly valued by Allied authorities.

The Bergmann M.P.18,I (police issue)

After the enforcement of the Treaty of Versailles, the German Army was subjected to severe restrictions on the number of automatic weapons and machine guns that they were allowed to issue, and as a consequence the M.P.18,I was retracted from service. Some came into circulation with veteran’s militias like the Freikorps, although the vast majority were simply pressed into service with the German police, at a rate of about 1 gun per 20 men.

Schmeisser, now working at C.G. Haenel, continued to make improvements to the design after World War I and in 1920 he developed a new type of magazine feed for the M.P.18,I that would take straight box magazines of 32 or 20 rounds. On behalf of the German police, a large quantity of M.P.18,I submachine guns were converted to this new system by Haenel during the 1920s.

Police-issue M.P.18,Is are also often fitted with a safety switch on the forward receiver, which locks the bolt in place when flipped. These are the same type of safety switches that are commonly seen examples of the Erma EMP submachine gun.

The SIG-Bergmann Model 1920

Waffenfabrik Bergmann was one of many German armaments manufacturers that was closed after the enforcement of the Treaty of Versailles in 1920. Production of the M.P.18,I in Germany therefore came to an end, but Theodor Bergmann wanted to continue promoting the weapon and therefore sold the production rights to SIG in Switzerland, where manufacture could go ahead without running foul of the Versailles restrictions.

The SIG-Bergmann submachine was not, however, a straight copy of the Bergmann M.P.18,I. It featured several modifications made in-house at SIG, including a proprietary type of magazine feed taking 50-round straight box magazines. This feed was distinct from the Schmeisser-type straight feed, with the magazine catch being placed on the underside of the housing, and it could not take Schmeisser magazines.

Several other detail modifications were also made to the design. The fixed notch sights of the M.P.18,I were replaced by an adjustable tangent graduating to 1,000 meters. The cocking handle was a rounded knob rather than a curved lever, and the bolt lugs were added to the barrel collar. The SIG-Bergmann was not chambered in 9x19mm Parabellum, but instead only offered in 7.65mm Parabellum and 7.63mm Mauser.

The SIG-Bergmann submachine gun saw limited use by the Swiss Army and was also offered for export, with significant sales to Finland (in 7.65mm), China, and Japan (both in 7.63mm). It was used extensively in China in the 1930s and 40s, and was adopted by the Imperial Japanese Navy as the Type Be (”Be” for “Beruguman”). Production of the SIG-Bergmann lasted from 1920 - 1927, although it continued to be sold into the early 1930s.

The Tallinn Arsenal M/23

From 1923 - 1930, an unlicensed copy of the SIG-Bergmann submachine gun was produced in Estonia by Tallinn Arsenal. This gun, known as the Model 1923 or M/23, was probably based on Finnish examples of the SIG-Bergmann. The M/23 was designed by Johannes Teiman and was constructed from original components, making it visually distinct from other Bergmann variants, particularly in its distinctive stock design and rectangular barrel vents. The M/23 took 40-round box magazines and was chambered in 9x20mm Browning Long, a rare cartridge for SMGs.

It is estimated that only about 570 Tallinn Arsenal M/23 submachine guns were produced, and the majority of these were later sold off to the Spanish Republic during the Spanish Civil War (1936 - 1939). Some examples were captured and used by the Italian CTV (Corpo Truppe Volontarie) during this conflict.

The Tsing Tao & Dagu Arsenal SMGs

Following the sale of SIG-Bergmann submachine guns to China in the 1920s, domestic copies of the design began to be produced at various factories, the primary manufacturers being the Tsing Tao Naval Arsenal and the Dagu Arsenal. The Chinese Bergmann was a straight copy of the SIG-Bergmann with the magazine housing rotated to a vertical feed rather than a horizontal feed; otherwise the design was essentially unchanged, and all the elements that distinguish the SIG-Bergmann from the M.P.18,I can be seen on the Chinese Bergmanns. The same long, 50-round magazines were used, making the Chinese copies awkward to use from a prone position.

The Tsing Tao & Dagu submachine guns were produced in relatively large quantities and used extensively during the Chinese Civil Wars and the Sino-Japanese War. It should also be noted that some Chinese Bergmanns were produced without the vertical magazine, and are basically identical to the original SIG-Bergmann except for the markings.

The production dates of the Chinese Bergmann copies are impossible to pin down, as manufacture was decentralized across many different factories. However, it is likely that several thousand were produced during the interwar years.

The Haenel M.P.28,II

Throughout the 1920s, Schmeisser made further improvements to the M.P.18,I, culminating in 1928 with the development of the successor to the Bergmann, the M.P.28,II. This gun was based on the police-issue M.P.18,I but included several new features, most notably a cross-bolt fire selector and safety button placed above the trigger group. This is the feature from which the M.P.28,II is instantly identifiable from other Bergmann derivatives. The M.P.28,II also replaced the old M.P.18,I bolt with an entirely new type, with a separate firing pin. The new bolt travelled freely in the receiver against a wide diameter recoil spring, instead of riding on a spring-loaded guide rod. The M.P.28,II also had adjustable tangent sights similar to the SIG-Bergmann.

The M.P.28,II was produced at C.G. Haenel and was chambered in 9x19mm Parabellum by standard, but was also offered in a variety of calibers for export, including 9x25mm Mauser, 7.65mm Parabellum, and even .45 ACP. It was sold to Belgium, Bolivia, the Netherlands, Portugal, and Romania, among many other countries. In Germany, it was used by police forces and various paramilitary factions, including the Waffen-SS, but was never adopted by the Wehrmacht. Production lasted from 1928 - 1940, whereupon it was succeeded by the MP41 submachine gun, which utilized some components from the M.P.28,II.

The Bayard Mi34

In 1934, the M.P.28,II was adopted by the Belgian Army and it was produced under license by Anciens Etablissements Pieper, trading under the name “Bayard”. This gun, known in Belgian service as the Mi34 Schmeisser-Bayard, was identical in most aspects to the original M.P.28,II and differed only in the manufacturer’s markings and the redesign of the bolt handle from a curved lever to a long, straight handle with a rounded knob on the end, somewhat similar to that seen on the SIG-Bergmann. The Bayard Mi34 was produced from 1934 - 1940.

The “Naranjero”

The so-called “Naranjero” was an unlicensed copy of the M.P.28,II produced in Spain during the Spanish Civil War (1936 - 1939) by Republican factories in Valencia; it apparently gained its name from the orange trees that grew around the city. This variant was basically a straight clone of the M.P.28,II except for the bolt, which was made from brass and featured a distinctive, oversized, circular cocking handle. These bolts were weaker than the original steel bolts of the M.P.28,II. On some examples, the magazine housing is also made from brass. A bayonet catch was also added to the underside of the barrel jacket.

The Naranjero was produced from about 1937 - 1939. Total production figures are unknown but were probably in the low thousands. It has been speculated that the British copy of the M.P.28,II - the Lanchester - was actually based on a Naranjero submachine gun from Spain, although this is difficult to prove.

The Lanchester Mk.I

In 1940, after years of inaction regarding the adoption of a submachine gun, the British government finally decided that a domestically-manufactured SMG was required. Initially the Royal Air Force requested a copy of the German MP38, but it was decided to instead produce a copy of the more expensive M.P.28,II - the logic behind this decision is not really clear. The design of this copy was handled by George Herbert Lanchester of the Sterling Armaments Company and the final production gun was named after him. It was adopted by the RAF and the Royal Navy for the protection of airstrips and naval vessels, but was not adopted by the Army, who were set on the cheaper Sten gun.

Despite being a copy of the M.P.28,II, the Lanchester Mk.I used no parts from the German gun and deviated in some elements of the design. The fire selector/safety switch was relocated to forward of the trigger group and the disassembly catch was placed on the rear receiver, behind the end cap. Proprietary 50-round magazines were used and a bayonet catch was fitted to the barrel. All in all, it may have ended up being more expensive to produce than the M.P.28,II. This was addressed to an extent with the introduction of a simplified variant in 1941, known as the Lanchester Mk.I*, which replaced the rear tangent sight with a basic flip-notch and saw the total removal of the fire selector, giving only fully-automatic fire. From 1942, many Mk.I Lanchesters had their fire selectors removed and their trigger mechanisms simplified.

The Lanchester was only in production during the war years and saw little actual use in combat. Just short of 100,000 were produced in total and it officially remained in Naval service until 1960, whereupon it was finally declared obsolete, although some examples remained aboard British vessels until the 1970s.

119 notes

·

View notes

Video

undefined

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD

https://www.carsai-auto.com/

Whatsapp&WeChat: +8615212743691

---------------------

cheap 24k all gold nipples spokes finish rims wire wheel China manufacturer supplier

jaguar c type wire wheels,morgan plus 8 wire wheels,wire wheels and tires package,e type wire wheels,15 x 5 wire wheels,wire wheels paint or powder coat,17 x 8 wire wheels,1927 model t wire wheels,wire wheels 14x7,wire wheels drag racing,wire wheels on craigslist,ydh wire wheels,6 lug wire wheels,wire wheel grinder,model t wire wheels for sale,wire wheels vero beach,wire wheels on cars,wire wheels refurbishment,wire wheels phoenix,wire wheels engraved,wire wheels 66 mustang,zenith wire wheels for sale,wire wheels bolt on,wire wheels restoration,dewalt 4 wire wheels,wire wheel guarding requirements,wire wheels v strom 1000,v rod wire wheels,wire wheels with vogue tires,wire wheels 96 impala ss,tr4 wire wheels,wire wheels uk,player wire wheels website,17 x 9 wire wheels,t bucket wire wheels,1/43 wire wheels,wire wheels melbourne,wire wheels ef,5 inch wire wheels,13x7 wire wheels wholesale,wire wheels san diego,wire wheels with tires,wire wheels specialist,wire wheels for jaguar s type,wire wheels vs alloy,wire wheels and tires,wire wheels for xk8,e type wire wheels for sale,wire wheels 15 x 6,15 x 7 wire wheels,wire wheels for ktm 390 adventure,wire wheels for sale,5 ford wire wheels,wire wheels install,a dayton wire wheels,4x108 wire wheels,wire wheels 13x7,wire wheels v strom 650,dayton wire wheels uk,wire wheels 100 spoke,1/8 scale wire wheels,wire wheels england,jaguar s type wire wheels,wire wheels 5x120,6x139.7 wire wheels,morris 8 wire wheels,wire wheels 20x8,wire wheels 4.75,jaguar mk2 wire wheels,model a wire wheels,5 bolt wire wheels,6 wire wheels,7 wire wheels,wire wheels in canada,texas wire wheels 84s,zenith wire wheels knock offs,wire wheels direct,wire wheels for jaguar xj8,do wire wheels need inner tubes,wire wheel grinder home depot,4 dayton wire wheels,4 stud wire wheels,6 lug chevy wire wheels,dayton wire wheels 72 spoke,wire wheels gold,wire wheels port macquarie,wire wheels india,mg a wire wheels,wire wheels that stick out,l.a. wire wheels,wire wheels on ebay,15x10 wire wheels,wire wheels lug nuts,41/2 inch wire wheels,wire wheels texas,wire spoke rims,wire wheels auto sales,6 lug wire wheels for sale,wire wheels race cars,15 x 6 wire wheels,wire wheels uk sale,wire wheels tool,5x4.75 wire wheels,wire wheels brush,texan wire wheels 84s,t bird wire wheels,wire wheels lowes,wire wheels for drills,wire wheels jaguar xj6,wire wheels for austin healey 3000,where to buy a wire wheels,1/32 wire wheels,jaguar e type wire wheels sale,wire wheels purpose,texas wire wheels in houston,wire wheels 8 inch,t-bucket wire wheels for sale,wire wheels for 356,wire wheels with whitewall tires,b lace wire wheels,wire wheels 280z,wire wheels brands,wire wheels manufacturers,wire wheels made in usa,e-type chrome wire wheels,zenith wire wheels price,jaguar series 3 wire wheels,series 2 zenith wire wheels,wire wheels 4x100,wire wheels volvo p1800,14x7 wire wheels,wire wheels noise,wire wheels spokes,wire wheels for sale $500,dayton wire wheels knock off for sale,zenith wire wheels website,wire wheels 20 inch,wire wheels vs,wire wheels nz,model t wire wheels,4 inch wire wheels,6x5.5 wire wheels,8 lug wire wheels,wire wheels 14,wire wheels harley davidson,wire wheels club,mustang 2 wire wheels,wire wheels tubeless tyres,motorcycle wire wheels uk,6 inch bench grinder wire wheels,wire wheels in los angeles,13/7 wire wheels,wire wheels 15 inch,wire wheels car,wire wheels standard vs reverse,wire kennel wheels,wire wheels on amazon,g boyz wire wheels,model t wire wheels ebay,wire wheels for grinders,8 wire wheels for bench grinders,wire wheels dunlop,wire wheels for cars,wire wheels offset,wire wheels 15x7,wire wheel gun barrel,wire wheels nut,1/25 wire wheels,wire wheels for jaguar xf,wire wheels bench grinder,wire wheels tr6,wire wheels classic cars,wire wheels knock offs,801 wire wheels,wire wheels kijiji,wire wheels on truck,15 x 8 wire wheels,wire wheels hamster,8 inch wire spoke wheels

3 notes

·

View notes

Photo

We are leading stockiest, supplier and dealer of Stainless Steel Rod, SS Rod in Bangalore, Karnataka. A stainless steel rod can also be refereed as Stainless Steel Round Bar. Our Stainless Steel Rod for Sale diameter ranges from 3mm to 300mm.

Visit us, We have an extensive range of Stainless Steel Rod available at competitive prices.

#ss rods in bangalore#ss rods supplier in bangalore#ss rods dealer in bangalore#ss hexagon rods in bangalore#ss hexagon rods dealer in bangalore

1 note

·

View note

Text

India’s Best SS Flanges Manufacturers and Suppliers

Regent Steel Inc is the best Stainless Steel Flanges Manufacturers in India. We specialise in making premium stainless steel flanges since it is a corrosion-resistant and long-lasting material that is widely used in a variety of industries. We are the top Flange Manufacturer in Pune, Flange Manufacturer in Kolkata and Molybdenum Rod Manufacturers in India. To guarantee that our products satisfy industry standards and consumer expectations, they use cutting-edge production processes and strictly enforce quality control procedures. We are also Molybdenum Rod Supplier and Flange Suppliers in Dubai and Flanges Supplier in Qatar

Contact us:

Website: forgefittings.com

Mail: [email protected]

Product source: Stainless Steel Flanges Manufacturers in India and Flange Supplier in Singapore

You may also like: Flange Supplier In UAE and Flange Supplier in Malaysia

#Stainless Steel Flanges Manufacturers in India#Stainless Steel Flanges Manufacturers#Flange Manufacturer in Pune#Flange Manufacturer in Kolkata

0 notes

Photo

DUCATI 750 SPORT – AN ORIGINAL STREET-LEGAL PERFORMANCE SPECIAL

The Ducati 750 Sport is an exceedingly rare motorcycle that sits squarely between its two more famous siblings – the Ducati 750 GT and the Ducati 750 Super Sport (SS). Put simply, the Ducati 750 Sport (also known as the 750S) was a higher-performance version of the slightly more consumer-friendly 750 GT.The 750 Sport is slightly more powerful than the GT and it could be ordered with a half fairing and twin front disc brakes if required – making it a popular choice for privateer racers in Europe in the early 1970s.THE DUCATI 750 L-TWINThe Ducati 750 Sport first appeared in 1972, it was the fastest and most powerful road-legal motorcycle ever built by Ducati up until that point, and it was designed to compete squarely with both the Japanese and the British.

Ducati was still relatively new to the superbike game in 1972, they had only produced their first L-twin a year earlier in 1971. Prior to this the company had made a name for themselves selling beautifully designed, smaller-capacity motorcycles.The engine design followed somewhat in the footsteps of the V-twin used in the Vincent Black Shadow, in that Italian engineer Fabio Taglioni had taken two single cylinder barrels and heads and modified them to fit onto a newly designed crankcase – in much the same way that Phil Irving had done all those years earlier.The genius of this design strategy is that you take proven, pre-existing heads and valve trains, as well as barrels, pistons, and connecting rods. This simplifies the process of designing a new engine considerably, and means you can use a pre-existing parts supply. Of course the actual design was modified somewhat, particularly the heat sink fins on the barrels of the front-facing cylinder, which were changed to make better use of the airflow coming from above the heads in the cylinder’s new orientation.Our Italian friends can tend to get a little hand-wavy if you refer to a Ducati twin as a “V-twin”, the 90 degree angle between the cylinders makes the shape of an “L”, so they call them “L-twins”. I suspect this may have something to do with wanting to differentiate themselves from the famous V-twins of a certain American motorcycle company that rhymes with Darley-Havidson, but the Italians will never admit it.

Despite its relative newness, the 748cc Ducati twin was an almost immediate success. Racing icon Paul Smart rode his Ducati 750 Imola Desmo to a hugely popular win at the 1972 Imola 200 with Bruno Spaggiari in second place on a matching Ducati. It’s difficult to describe how important this win was at the time, it helped to launch Ducati from a well-known maker of smaller-engined motorcycles to endurance race winning superbike manufacturers.The production version of the 750 Imola Desmo was the Ducati 750 GT, it was fitted with a regular valve train rather than the desmodromic design used on the race bike for the sake of consumer-friendliness. The 750 GT produced 57 hp and proved popular with motorcyclists, helping to slow the Japanese invasion slightly, and establishing Ducati as a world-class builder of road-going superbikes.

THE DUCATI 750 SPORTThe Ducati 750 Sport was designed to fill the gap between the Imola 200 winning 750 Imola Desmo and the 750 GT.In order to squeeze a little more power out of the L-twin the compression ratio was increased and a pair of larger 32mm Dell’Orto PHF carburetors were fitted with no filters – just a wire mesh over the velocity stacks.As a hat-tip to its performance intentions the 750 Sport was given clip-on handlebars and rear sets, buyers could also opt for a half fairing and twin front disc brakes. Most examples left the factory wearing bright yellow paint work, and all were fitted with side covers bearing the “750 Sport” branding.With a total weight of 182 kilograms (401 lbs), 62 hp, and a top speed approaching 130 mph the model proved desirable – though Ducati didn’t build all that many of them as they tried to keep up with demand for the less expensive 750 GT.Collectors are now forever hunting for original examples of the Ducati 750 Sport, there are a lot of replicas out there, but when an authentic example comes up for sale it invariably attracts much interest.

THE 1972 DUCATI 750 SPORT SHOWN HEREThe motorcycle you see here is an original 1972 750 Sport that was raced in the 1970s in Yugoslavia. It was discovered in 1990 by Swedish company Oves Motor AB who imported it into Sweden, and then spent 15 years carefully restoring it.This restoration process was completed by Ove Johansson Swedish Ducati specialist Torbjörn Lindgren, and it included close contact with none other than Dr. Fabio Taglioni.It’s now offered in stunning condition throughout, ready for vintage motorcycle racing competition anywhere in the world.

22 notes

·

View notes

Text

The Metals Factory

The Metals Factory is an ISO certified and PED approved professional and international manufacturer, supplier and exporter of stainless steel, aluminium, nickel alloys, carbon steel and alloy steel products. With a collective experience of over 30 years, we have emerged as one of the largest just in time exporter of steel and aluminum products. Our range of products includes steel plates, rods, bars, angle, channels, steel pipe and tube, forged flange and fittings, elbow, tee, reducer, stub end, gaskets, fasteners, valves etc. We are devoted to provide the best solutions for steel materials and industrial equipment for our respected customers. We have manufacturing set up, sales and export offices in both India and China to meet the immediate and long term steel and aluminium product requirements across the globe.

Our stainless steel pipe and carbon steel pipe products are designed and manufactured in compliance with international standards and are appreciated for their sturdiness, precise dimensions, durability, finish and corrosion resistance. They are available in distinguished sizes, dimensions and thicknesses to cover the requirements of various industries like power plants, automobile, heavy engineering, offshore and chemical.

In addition to being a manufacturer of seamless pipes and welded steel pipes, we are also one of the biggest stainless steel plate and aluminum plate processing center in India. We are a leading stockholder, processor and supplier of high quality stainless steel plates, stainless steel sheets, stainless steel coils, stainless steel strips, alloy steel plates, special alloy plates, mild steel plates, mild steel coils, hot rolled coils, hot rolled plates, cold rolled coils.

We supply not only commonly used carbon steel and stainless steel materials (SS304/L, SS316/L, SS321), but also duplex and super duplex steel 1.4547, 1.4462, 1.4410 (S31254, S31803, S32750, S32760), and special austenite stainless steel such as 310S, 347H, 317L, 904L.

Some of our important & key products include the following:

1) Aluminium sheets, plates and coils in size range of 0.2mm to 350mm in Alloys 1050, 1060, 1070, 1080, 1100, 1200, 3003, 3105 and 8011. We are also one of the leading suppliers of 5052, 5083, 5086, 6061, 6082 and 7075 plate, and sheet products. Other products available in Aluminium alloys include bar and rods, seamless tubes, buttweld fittings, flanges and aluminium blocks for CNC machining.

2) Stainless steel sheets, plates and coils in size range of 0.2mm to 80mm in SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L. We offer stainless steel products in various forms including stainless steel pipes, stainless steel rods, stainless steel forgings, stainless steel large diameter pipes, stainless steel pipe fittings and flanges.

3) Carbon steel plates are available for sale in size range of 6mm to 200mm in custom widths and lengths, especially boiler quality plates, pressure vessel steel plates, abrasion resistant steel plates, and high tensile plates.

4) Stainless steel flexible hose pipes and bellows in sizes from 1/4” to 12” in custom lengths with various types of end connections such as flanges, female or male nuts, nipples, adaptors, camlock couplings, quick release couplings etc.

5) Carbon steel seamless pipes available in size range of 1/2’’~24’’NB, carbon steel ERW pipes available in sizes 1/2’’~40’’NB, while LSAW and Spiral welded steel pipes are available in size range of 18’’~72’’NB

6) Stainless steel pipes are available in various grades such as SS 304/L, SS316/L, SS321, duplex and super duplex steel, 310S, 347H, 317L, 904L, Stainless steel seamless pipes are available in size range of 1/2’’~24’’NB, while stainless steel ERW and Fabricated pipes are available in sizes 1/2’’~40’’NB.

Various piping system related pipes fittings, fasteners, gaskets and flanges are available in carbon steel, stainless steel, nickel alloys and alloy steel grades. We manufacture and supply buttweld pipe fittings, forged fittings and flanges in size ½” to 60”.

1 note

·

View note

Photo

Try this again...63 Pan for sale, bottom end was completely rebuilt less than a month ago. $6500..I am willing to drive up to 3/4 hours for delivery or meet up. Oem top end (rebuilt less than 3 years ago), oem Oil pump, SS cases, SS connecting rods, later year flywheels with long shaft. All new, all ready to roll (have receipts). What you get, rebuilt motor, chrome SU carb, cycle electric generator, SS paperwork for cases, clear Ohio title and the original (busted) cases to the motor. This motor is ready to be fired and roll 🔥 I am open to offers on a cone shovel drivetrain (motor and trans) plus cash on your end. DM me for more info and photos. Thanks. @chopperswapper #chopperswapper https://www.instagram.com/p/CDyqRXbDCbB/?igshid=1kv4bs4wjhwwy

1 note

·

View note

Text

Best SME ERP solution in india

simpliRP Best SME ERP solution in india is the Robust & Economical ERP for MSME / SME / SMB Industry. It has been our continuous endeavor to simplify the industrial processes. Lean & Robust process is the requirement of the day.

An ITEM is the core element in simpliRP ERP, for MSME / SME / SMB. The business revolves around ITEM., which is the element in INVENTORY System. An ITEM is called as ITEM CODE / ITEM NAME / MODEL NO. / PART CODE / PART NAME / SKU [Stock Keeping Unit] by Manufacturing Sector. An item master is a key information in any inventory system. This ITEM MASTER includes the description, unit of measure, category, HSN, Barcode and so forth for an item. An item master is the information source for activities such as material requisitions, purchases, sales, production issue, production receipt, QA parameter definitions, delivery challans, invoices etc.,

POINTS TO PONDER :

In any organization, defining item master is the toughest in their process, physically.

For Understanding, We can segregate into three major kinds, for purpose of creating Item Master:

Purchased Items.

Invoiced items

Internal items

Purchased Items : always maintain the ITEM NAME or ITEM CODE as mentioned in supplier invoice. This will enable smooth GST input credit. This will also facilitate smooth GST Audits, if any.

Invoiced Items : always maintain the ITEM NAME or ITEM CODE as mentioned in the Customer Order . These Invoiced Items are either finished goods or scrap. [Assets are not considered here]

This will enable customer system and your system have same matching ITEM NAME / ITEM CODE. So that there is no painstaking month end matching of Invoices with Customer Order. And it will also ensure, the payment cycle is smooth, seamlessly.

Internal items : in this, you can maintain the ITEM NAME or ITEM CODE as recognized by your internal employees or internal process.

In case of assets or tool , ensure ITEM CODE or ITEM NAME contains the serial number , make and model of that asset or tool.

EXAMPLE OF NEW ITEM CODE FOR ASSET : USHA FAN RACER 1200MM BROWN SNO 123456

EXAMPLE OF NEW ITEM CODE FOR TOOL : DIGITAL VERNIER CALIBER X 1234 SNO 6547229

What is ITEM CODE / ITEM NAME / MODEL NO. / PART NO. in simpliRP ERP for sme in india ?

ITEM NAME or ITEM CODE or MODEL NO. or PART NO. all are same.

ITEM NAME / ITEM CODE / MODEL NO. is UNIQUE name you can give to the item

Stock will be maintained to this ITEM CODE / ITEM NAME.

This ITEM CODE / ITEM NAME will appear in the invoice.

ITEM NAME or ITEM CODE or MODEL NO. or PART NO. cannot be duplicate.

For Each Process output item, you need to create separate ITEM NAME.

Example. , in simpliRP ERP : If there is process of converting a 22MM SS ROD into 0.75 INCH BOLT

STEP 1

PROCESS NAME

ITEM

1

RAW MATERIAL

22 MM SS ROD

2

CUTTING

CUT ITEM

3

FORGING

FORGING ITEM

4

FINISHED GOODS

0.75 INCH BOLT

The above example* has to be defined as follows in system :

#

ITEM NAME to be created

in the system

TYPE OF ITEM

UNIT

1

22 MM SS ROD

RAW MATERIAL

KG

2

0.75 INCH BOLT CUTTING

WIP

NUMBER

3

0.75 INCH BOLT FORGING

WIP

NUMBER

4

0.75 INCH BOLT FG

FINISHED GOODS

NUMBER

*just example, not a real process.

Please note, the process name can be added to the FG Part Number [FG ITEM NAME / FG ITEM NUMBER], so that they get grouped automatically by process and final ITEM NAME.

Why we should not use special characters in Item Master creation.

Please do not use any special characters like “!@#$%^&*()+{}[]|\/”,’~`. this will create problems while doing transactions or GST return filing

however you can use - (minus) or . [dot] symbol.

WHY You should never DELETE or EDIT an ITEM CODE / ITEM NAME . , in simpliRP ERP ?

A transaction may have taken place on an ITEM CODE / ITEM NAME. if we delete it, these transactions will become headless.

If you edit an ITEM CODE / ITEM NAME, the value of that item will change. For example, if you change the "USHA FAN " -- > "USHA FAN REGULATOR", it will change the value to tenth of its original value.

In case you do not want that ITEM NAME / ITEM CODE, you should make it inactive in that system.

This solution is available Off-The-Shelf along with the simpliRP ERP .

Change is Good

a Robust, Economical & Simple ERP for MSME / SME / SMB. simpliRP ERP does not require USER ACCEPTANCE TESTING. With little training, MSME/ SME / SMB can start using the ERP right from day one. It saves lot of time & energy of MSME / SME / SMB , can implement the ERP swiftly. Please visit us at www.simplirp.com and please have glance on the product. simpliRP ERP is available ON CLOUD also on very economical prices.

Improving business processes is a requirement in today’s business scenario, to stay competitive. In a time when GST pressures & Slow-Down Fear mongers, selecting simpliRP ERP will ensure lean organization and success. simpliRP ERP allows you to take time to make the changes incrementally. Organizations will find the true power available to them.

1 note

·

View note

Photo

Murl G. "Pinky" Randall's Last Impala SS Built:

Mr. Chevy earned the name by being such an enthusiast for the bow tie brand that began in 1911, from the early 1960s he amassed a collection of Chevrolet sales and service literature that was eventually purchased by GM in 2004 to supplement their own library. "Chevrolet has been my life. It really has since I was 5 years old, before I knew even what a Chevrolet was. I am as enthusiastic today as I was 80 years ago about Chevrolet." - He ended up buying that `32 coupe he saw as a kid when he married his wife in 1948. The 1996 model of the Impala SS is the most sought after as unlike the prior two years models, it had an analog gauge package with a tachometer and the shifter was moved from the steering column to the floor and put in a full-length console. However, the long hoped for manual transmission option failed to materialize.

Authority can spot authority so... Pinky made the trek to Arlington, TX from Houghton Lake, MI to get the last 1996 Impala SS off the line with the help of Chevy General Manager Jim Perkins to work out the details of the delivery. Seeing your car come of the line can be a ritual akin to the birth of a baby or the christening of a new ship. A civil ceremony was held December 13, 1996 where he drove the Dark Cherry Metallic four door hot rod out of the plant accompanied by County Judge Tom Vandergriff in the front passenger seat presiding to make it all nice and legal. “I now pronounce you, man and car. You may kiss the car.” A reenactment of the kiss can be seen in the top photo above. ;)

Pinky passed away on January 9th, 2022.

10 notes

·

View notes