#SUS (Single Use System) for Biopharma Process

Explore tagged Tumblr posts

Text

Global Top 5 Companies Accounted for 73% of total SUS (Single Use System) for Biopharma Process market (QYResearch, 2022)

Single-use systems (SUS) refers to biopharmaceutical manufacturing (bioprocessing) equipment designed to be used once (or for a single manufacturing campaign) and then discarded.

This report focuses on devices and consumables, mainly including single-use bioreactors, disposable sterile bags, and disposable filtration systems.

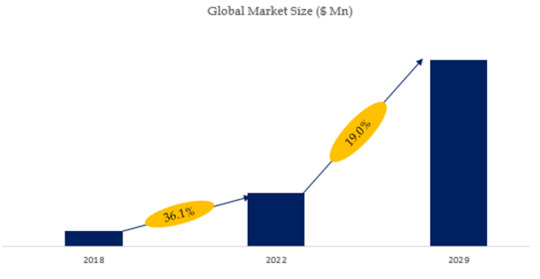

According to the new market research report “Global SUS (Single Use System) for Biopharma Process Market Report 2023-2029”, published by QYResearch, the global SUS (Single Use System) for Biopharma Process market size is projected to reach USD 15.47 billion by 2029, at a CAGR of 19.0% during the forecast period.

Figure. Global SUS (Single Use System) for Biopharma Process Market Size (US$ Million), 2018-2029

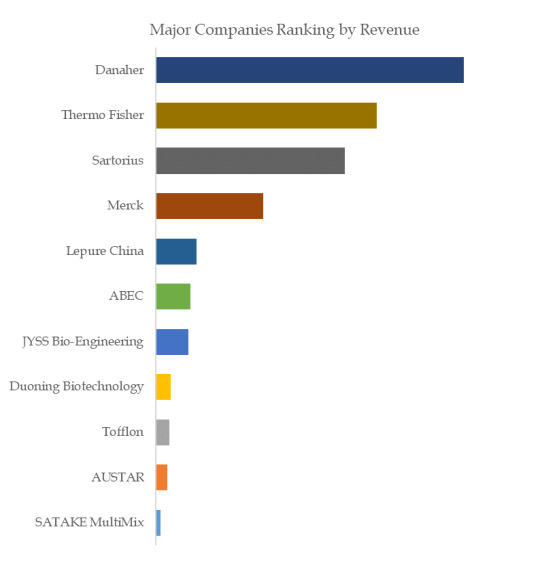

Figure. Global SUS (Single Use System) for Biopharma Process Top 11 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of SUS (Single Use System) for Biopharma Process include Danaher, Thermo Fisher, Sartorius, Merck, Lepure China, ABEC, JYSS Bio-Engineering, Duoning Biotechnology, Tofflon, AUSTAR, etc. In 2022, the global top five players had a share approximately 73.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Sustainable Bioprocessing Gains Ground with Recyclable Single-Use Systems

The Single-use Bioprocessing Market is entering a transformative growth phase, fueled by the rapid expansion of biopharmaceutical manufacturing, rising demand for flexible production systems, and heightened focus on contamination control. Valued at USD 7.62 billion in 2021, the market is projected to reach USD 25.40 billion by 2031, growing at an impressive CAGR of 18.93% during the forecast period (2024–2031).

Unlock exclusive insights with our detailed sample report :

This market is evolving rapidly with the increasing adoption of single-use bioprocessing systems such as bioreactors, fermenters, mixers, filtration units, bags, and containers. These disposable systems, primarily made of sterilizable plastic components, support critical processes like upstream expression, purification, storage, and separation of biopharmaceutical products. As global biomanufacturing shifts toward agile, cost-effective, and contamination-free solutions, single-use technologies are being embraced by both established pharma giants and emerging biotech firms—especially in alignment with trends seen in the United States and Asia, where scalable, single-use systems are driving next-gen biologics production.

Key Market Drivers

1. Rise in Biologics and Personalized Medicine: The growth of monoclonal antibodies, gene therapy, and personalized medicine has created a strong need for scalable, contamination-free, and faster bioprocessing methods. Single-use systems (SUS) offer agility and ease of implementation, making them ideal for such advanced therapies.

2. Cost Efficiency and Operational Flexibility: Unlike traditional stainless-steel systems, SUS eliminate the need for cleaning and sterilization, significantly reducing downtime and water/chemical usage. This makes them highly attractive for small-to-mid-sized biotech firms and contract manufacturing organizations (CMOs).

3. Pandemic Preparedness and Vaccine Development: COVID-19 and subsequent global health threats highlighted the urgent need for rapid-response manufacturing capabilities. Single-use systems enabled fast-tracked vaccine production and played a pivotal role in scaling mRNA technologies.

4. Regulatory and Environmental Incentives: The U.S. FDA and EMA support the adoption of single-use bioreactors and modular facilities, facilitating market expansion. Meanwhile, vendors are innovating biodegradable materials to tackle concerns over plastic waste and sustainability.

Speak to Our Senior Analyst and Get Customization in the report as per your requirements:

Market Segmentation Snapshot

By Product Type: The market is segmented into bioreactors, mixers, bags, tubes & connectors, sampling systems, and others. Bioreactors and mixing systems account for the largest share due to their central role in upstream processing.

By Workflow: Upstream processing dominates the market share, given the high usage of SUS in cell culture and fermentation.

By End-User: Biopharmaceutical companies hold the majority share, followed by CMOs and academic research institutes.

Regional Insights

United States: The U.S. remains the largest and most mature market, fueled by robust biopharma R&D, government funding, and large-scale manufacturing investments. In 2024, the U.S. government announced a new initiative to strengthen domestic biologics production, allocating over USD 2 billion toward advanced manufacturing platforms—predominantly single-use facilities. Leading companies like Thermo Fisher Scientific, Danaher Corporation, and Sartorius Stedim Biotech are expanding their manufacturing capacities across North America.

Japan: Japan’s biopharma industry is rapidly integrating single-use systems as part of its strategic vision for regenerative medicine and mRNA vaccine production. In 2024, the Japanese Ministry of Health, Labour and Welfare (MHLW) introduced incentives for companies transitioning from conventional systems to disposable solutions. Furthermore, leading Japanese firms such as Asahi Kasei and Nipro Corporation are increasing R&D spending on sustainable single-use materials to enhance product lifecycle management.

Europe and Asia-Pacific: Germany, the UK, and Switzerland continue to be innovation hubs, while emerging economies in the Asia-Pacific region, such as China, South Korea, and India, are rapidly adopting SUS to scale biologics and biosimilars production.

Latest Industry Trends

AI Integration in Bioprocess Monitoring: Vendors are now embedding AI and data analytics into SUS platforms to allow predictive maintenance, batch tracking, and process optimization.

Modular Biomanufacturing Units: Companies are investing in mobile, modular units using SUS to cater to outbreak hotspots and rural regions, enhancing supply chain agility.

Green Bioprocessing Innovations: Environmental concerns are driving innovations in recyclable polymers and closed-loop systems to minimize single-use plastic waste.

M&A Activity on the Rise: The market is witnessing increased mergers and acquisitions. For example, in Q1 2025, Repligen Corporation announced the acquisition of a European tubing and bagging system manufacturer to strengthen its product portfolio.

Buy the exclusive full report here:

Competitive Landscape

The market is highly competitive and fragmented, with major players focusing on product innovation, capacity expansion, and strategic partnerships. Notable players include:

Thermo Fisher Scientific Inc.

Sartorius AG

Danaher Corporation (Cytiva and Pall)

Merck KGaA

Eppendorf AG

Parker Hannifin Corp.

Avantor, Inc.

Corning Incorporated

PBS Biotech, Inc.

Saint-Gobain Performance Plastics

These companies are investing in next-generation single-use assemblies, automation, and flexible manufacturing to meet evolving industry demands.

Growth Opportunities

CMO & CDMO Expansion: As pharmaceutical outsourcing grows, CMOs are increasingly deploying SUS to reduce turnaround time and manage multiple client processes efficiently.

Biosimilar Production: The patent cliff for blockbuster biologics has opened lucrative opportunities for biosimilars, where SUS offers a cost-effective pathway to scale.

Emerging Markets Penetration: Expansion in Latin America, Southeast Asia, and Africa presents a significant untapped opportunity, supported by international funding agencies.

Regenerative Medicine and Cell Therapy: As cell therapy and tissue engineering progress, single-use bioreactors and closed systems will be pivotal in clinical and commercial scale-up.

Stay informed with the latest industry insights-start your subscription now:

Conclusion

The global single-use bioprocessing market is on the cusp of a revolution, catalyzed by innovation in biologics, operational efficiency, and a growing preference for flexible, scalable manufacturing. The United States and Japan stand at the forefront of this transformation, while global demand signals a sustained, long-term market boom. As regulatory and environmental concerns are addressed through innovation, single-use technologies are poised to become the new standard in biopharmaceutical manufacturing.

#single-use bioprocessing market#single-use bioprocessing market size#single-use bioprocessing market growth#single-use bioprocessing market share#single-use bioprocessing market analysis

1 note

·

View note

Text

laboratory vacuum filtration

In laboratory vacuum filtration industries like pharmaceuticals, biotechnology, semiconductors, and medical devices, maintaining a contaminant-free environment is crucial. This is where clean room companies play a transformative role. These companies specialize in designing, manufacturing, and maintaining sterile, controlled spaces where temperature, humidity, and airborne particles are tightly regulated.

Among the leading names in this space, Foxx Life Sciences stands out as a reliable partner for high-performance clean room solutions.

Email Us : [email protected]

What Are Clean Room Companies?

Clean room companies are specialized firms that provide end-to-end solutions for cleanroom environments. Their services include:

Design & engineering of clean rooms

Cleanroom construction and modular setups

Installation of HEPA filtration systems

Validation and maintenance services

Supplying cleanroom-compatible labware, furniture, and protective gear

These companies ensure that clean rooms meet stringent standards such as ISO 14644, GMP (Good Manufacturing Practice), and FDA regulations depending on the application.

Why Clean Rooms Matter

Clean rooms are essential for industries where even the smallest contaminant can disrupt processes or compromise product quality. For example:

Pharmaceuticals & Biotech: Prevent microbial contamination in sterile drug manufacturing.

Electronics: Avoid particle damage to microchips and semiconductors.

Medical Devices: Ensure device sterility and regulatory compliance.

Foxx Life Sciences: A Trusted Leader in Clean Room Supplies

When it comes to reliable cleanroom-compatible products and technologies, Foxx Life Sciences is a name that clean room companies trust globally. They offer a wide array of products tailored to meet cleanroom standards:

Sterile Fluid Transfer Systems

High-purity laboratory bottles and containers

Single-use assemblies

Vacuum filtration systems

Biopharma-ready tubing and fittings

Foxx Life Sciences combines innovation, compliance, and cost-effectiveness, making them a top supplier for clean room solutions across the life sciences sector.

Key Factors When Choosing a Clean Room Company

When selecting a clean room company, consider the following:

Certifications & Compliance: Do they adhere to ISO, cGMP, or FDA standards?

Customization: Can they design clean rooms specific to your industry needs?

Product Range: Do they supply essential cleanroom-compatible tools and consumables?

Support & Maintenance: Do they offer after-sales support, testing, and validation?

A company like Foxx Life Sciences not only supplies top-tier products but also supports customers with technical insight and compliance support.

Final Thoughts

Clean room companies are integral to modern manufacturing and research ecosystems. As industries continue to evolve, the demand for precision-controlled environments grows. Collaborating with top-tier suppliers like Foxx Life Sciences ensures quality, safety, and regulatory adherence.

Whether you're building a new cleanroom or upgrading your current one, aligning with experienced professionals and trusted brands makes all the difference.

Email Us : [email protected]

https://www.linkedin.com/company/foxxlifesciences

https://www.instagram.com/foxxlifesciencesglobal/

0 notes

Text

0 notes

Text

Single-use Bioprocess Systems

What Are Single-Use Bioprocess Systems?

Single-use bioprocess systems are disposable technologies designed for one-time use in biologic production processes. Unlike traditional stainless-steel setups, SUS require no cleaning or sterilization, making them ideal for rapid setup and turnover.

Components of Single-Use Systems

1. Bioreactors

Single-use bioreactors (SUBs) replace traditional steel tanks with disposable plastic liners. They are used for culturing cells and are available in various sizes, supporting both small-scale research and large-scale production.

2. Mixing Systems

These systems facilitate the preparation of buffers, media, and other process solutions. The disposable mixing bags reduce contamination risks and simplify operations.

3. Storage and Transport Bags

Sterile storage bags provide a secure environment for intermediates or final products. Their capacity ranges from a few liters to several thousand liters.

4. Tubing and Connectors

Pre-sterilized tubing systems ensure seamless fluid transfer between components, maintaining sterility throughout the process.

Advantages of Single-Use Bioprocess Systems

1. Cost Savings

Traditional setups require significant investments in cleaning, sterilization, and maintenance. SUS eliminate these needs, reducing costs significantly.

2. Reduced Cross-Contamination Risk

Disposable components ensure a fresh, sterile setup for each batch, lowering the risk of contamination.

3. Increased Efficiency

With quick setup times and minimal downtime between batches, SUS boost production efficiency.

Challenges in Single-Use Systems Adoption

1. Waste Management

The disposable nature of SUS generates significant waste. However, recycling programs are emerging to address this issue.

2. Material Compatibility

Some biologics may interact with plastic materials, requiring careful selection of system components.

3. Scalability

While ideal for small to medium scales, SUS face challenges in ultra-large-scale production scenarios.

Applications of Single-Use Bioprocess Systems

1. Vaccine Production

SUS allow for rapid vaccine production, critical during public health emergencies.

2. Monoclonal Antibodies (mAbs)

These systems streamline the production of mAbs, widely used in treating cancers and autoimmune diseases.

3. Cell and Gene Therapy

SUS support the highly specialized requirements of cell and gene therapy manufacturing, enabling precise control over conditions.

Emerging Trends in SUS

1. Digital Integration

IoT and AI technologies are being integrated into SUS to enable real-time monitoring and predictive maintenance.

2. Sustainability Initiatives

Efforts to recycle components and reduce waste are gaining traction, making SUS more environmentally friendly.

How to Select the Right Single-Use System

Assess Your Needs: Understand your production scale and process requirements.

Evaluate Supplier Reliability: Choose suppliers with a strong track record.

Ensure Compatibility: Verify that materials and designs meet your specific process needs.

Case Studies: Success Stories with SUS

Company A leveraged SUS to scale vaccine production during a global health crisis, cutting setup time by 50%. Company B reduced cross-contamination risks in their mAb production line by switching to SUS, saving millions annually.

Future of Single-Use Bioprocess Systems

The future of SUS lies in their adaptability, integration with smart technologies, and advancements in sustainable materials. As the biopharmaceutical industry continues to innovate, SUS will play an increasingly vital role in meeting global health challenges.

Conclusion

Single-use bioprocess systems are a game-changer for biopharma companies. Their cost-efficiency, flexibility, and scalability make them indispensable for modern manufacturing. While challenges remain, innovations in material science and sustainability will further enhance their appeal.

Contact Us : [email protected]

https://www.linkedin.com/company/foxxlifesciences

0 notes