#Single Screw Extruder

Video

undefined

tumblr

Neoplast is one of the best reputed manufacturer and exporters of plastic recycling machine in India. A single screw extruder is a machine used to frame a plastic item into the necessary shape. Our technologically define state of the art plastic recycling machinery such as plastic extruder machine, Plastic extruder, Plastic Reprocessing plant, and Plastic Palletizing Machine The machine warms the plastic natural substance to its softening point, after which pushed through a pass on gives the material its shape.

0 notes

Text

Extruder single screw

Screw diameter: Φ15-Φ300

Draw ratio: 15-53

Screws can select there are many types of screws selected such as common, gradual,sudden, barrier,pinned, exhaustive, BM and separate.The company can make screws in terms of compressive ratiosdemanded by users, and the users can select single-head or multihead screws and the cylinder of anotched, strong, separate material-sending system as well as designing it for you.

0 notes

Text

A CYLERSCREW tem orgulho de ser Referência Nacional em Recuperação e Fabricação de ROSCAS e CILINDROS para a indústria do plástico.

#cylerscrew#screwandbarrels#extruder screw barrel#screw barrel#husillos y canones#single screw#double screw#tumblr

0 notes

Text

Revolutionize Printing with Twin Extruder Technology

Discover a new era of 3D printing efficiency and precision with our cutting-edge twin extruder technology. Unleash your creativity as you seamlessly print dual-material designs, achieving intricate details and multi-color masterpieces. Our social bookmarking platform is the go-to space for enthusiasts and professionals alike, sharing insights, troubleshooting tips, and innovative projects centered around the transformative capabilities of twin extruder 3D printing. Join our community today and explore the limitless possibilities at your fingertips. #TwinExtruder #3DPrintingInnovation #CreativeCommunity

0 notes

Text

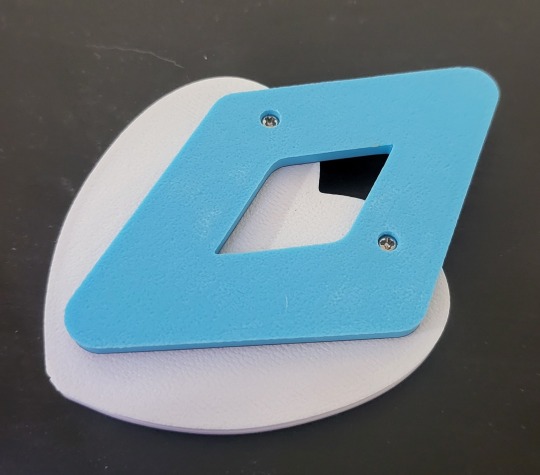

I made @brooke2valley 's iconic hair clip in real life!

here's a picture from her comic if you somehow haven't seen it:

Here are close-ups of the front and back:

Unfortunately, I'm not a drawing, so it really fucks up my hair when I put it in, and it doesn't really stay in place. I should really redesign the clip part to actually be compatible with human hair (since it doesn't really matter for looks anyways as it's hidden behind the heart anyways. Also I don't know what it's even supposed to look like behind the heart, so I just mirrored the visible part.

Hopefully when I have some time I can redesign it a bit to make it actually wearable for more than the 30 seconds it took to take the photo for this one.

Details for nerds:

It's printed in two parts in 4 different filament colors (esun ABS+ light blue, white, and black, and PolyMaker ABS in pink) Each different color is a new layer, as it's much easier to print that way, when my printer (Voron 2.4 350mm) only has a single extruder. I left two holes in the heart for two M2 heat set inserts (that's why there's a weird dot on the top of the heart, I pushed too far with one of the inserts), and two more countersunk holes in the clip for two M2 screws to attach the two parts together.

960 notes

·

View notes

Text

PPR Pipe Extruder Manufacturer in Indore - Types of PPR Pipes

PPR that is irreplaceable solution against cold galvanized pipe for all hot system, and one the advantageous indoor key for plastic pipe industry with easy installation, hygienic, brilliant and smooth inner surface and lightweight. The PPRC Pipe and fittings are produced with high quality raw material.

PPR Pipe is a straight and rigid cylindrical pipe made of polypropylene random copolymer plastic, manufactured through a Continuous Extrusion Process.

Types of PPR pipe

Top PP(R) Pipe Extruder as a global piping supplier and manufacturer, devoted to improving product quality and practicality.

To meet the needs of global piping solutions, Top Pipe Extruder Manufacturer has also developed the following new products, such as Basalt Fiber PPR Pipe, Anti-freeze PPR Pipe, etc. This can be used in each piping application.

· Antibacterial Ceramic PPR pipe

· Double layer PPR pipe

· Basalt Fiber PPR Pipe

· Anti-freeze PPR Pipe

· Glass Fiber Composite PPR Pipe

Find Your Best Partner of PPR Pipe Extruder Manufacturer

PPR pipe extruder manufacturer in Indore is the main factors to make sure the quality of your project! Believing that innovation is the key to go beyond the ordinary.

This PPR Pipe Extrusion Machine is mainly available in two types, Single Screw Extruder and Twin Screw Extruder. Sai Machine Tools provides both single screw extruders and twin-screw extruders. PPR Pipe Extrusion Machine which fully meets all the requirements and hence we propose a custom made solution for them. We are the best PPR Pipe Extrusion Machine Manufacturer in Indore as our PPR Pipe Making Machine caters to all kinds of customers’ requirements.

#Top PPR Pipe extruder#PPR pipe extruder manufacturer in Indore#PPR pipe extruder manufacturer#PPR pipe extruder manufacturer in India#Buy PPR pipe extruder in Indore#Extruder machine in India Extruder manufacturer in India Best Extruder manufacturer in Indore Extruder machine manufacturer in India Plastic

7 notes

·

View notes

Text

Supplier of ABA Blown Film Machine in Himachal Pradesh

Adroit Extrusion is a Supplier of ABA Blown Film Machine in Himachal Pradesh.

Our manufacturing unit is in Ahmedabad, Gujarat, India.

Adroit Extrusion is a manufacturer, supplier, and exporter of monolayer blown film machines,

aba and ab blown film machine and multilayer blown film machine.

A single, smaller extruder for the A-layers produces only 30–40% of new plastic resins per minute and operates at a slower speed.

The design of the second extruder targets the intermediate layer, helping to reduce costs by utilizing recycled plastic resins and CaCO₃.

The blown film line with ABA layers significantly lowers raw material costs while maintaining high-quality plastic film standards.

Additionally, this ABA plastic film extrusion machine creates three-layer films that are 30% stronger than monolayers, all while requiring less raw material.

With a completed printing surface on both sides, these films are ideal for common applications such as shopping bags, enhancing the final product's value.

By slightly modifying the die block design, you can transform a traditional two-layer co-extrusion line into a three-layer blown film line.

This results in a film with a distinct center layer while using the same material for the top and bottom layers.

Specification:

Model Name: Duoflex ABA Three Layer & AB Two Layer CO-Extrusion Blown Film Plant

Material Used: LDPE, LLDPE, HDPE, CACO3, Virgin Raw Material

Output range: 60 - 200 kg/hr

Screw Diameter: 35/45/55/65/75 (Customized)

Screw L/D ratio: 30:1 (Customized)

Layflat Film Width: 500 - 3000 mm

Thickness Range: 20 micron to 150 micron

Application:

Packaging Industry

Agricultural Sector

Construction

Industrial Applications

Consumer Goods

Adroit Extrusion is a Supplier of ABA Blown Film Machine in Himachal Pradesh including Locations like Shimla, Dharamsala, Solan, Mandi, Palampur, Baddi, Nahan, Paonta Sahib, Sundarnagar, Chamba, Una, Kullu, Hamirpur, Bilaspur, Yol Cantonment, Nalagarh, Nurpur, Kangra, Baijnath Paprola, Santokhgarh, Mehatpur Basdehra, Shamshi, Parwanoo, Manali, Tira Sujanpur, Ghumarwin, Dalhousie, Rohru, Nagrota Bagwan, Rampur, Jawalamukhi, Jogindernagar, Dera Gopipur, Sarkaghat, Jhakhri, Indora, Bhuntar, Nadaun, Theog, Kasauli Cantonment, Gagret, Chuari Khas, Daulatpur.

Feel free to contact us for more information and inquiries.

View Product: Click Here

Read the full article

0 notes

Text

Advanced Hot Melt Extrusion: Pioneering Techniques in Pharmaceutical Formulation

Introduction:

Hot Melt Extrusion (HME) has emerged as a cutting-edge technology in the field of pharmaceutical formulation, offering a range of innovative techniques to improve drug delivery and enhance therapeutic outcomes. Originally inspired by the plastic manufacturing industry, HME has been adapted and refined to meet the unique challenges and requirements of the pharmaceutical sector. One of the key advantages of HME is its ability to enhance drug solubility. By using heat and mechanical force to melt and mix drug compounds with various excipients, HME can transform poorly soluble drugs into more bioavailable forms. This can significantly improve the absorption and efficacy of the medication, leading to better treatment outcomes for patients. In addition to improving solubility, HME can also be used to control the release profiles of drugs.

By adjusting parameters such as temperature, screw speed, and formulation composition, pharmaceutical scientists can tailor the release kinetics of a drug to achieve sustained, controlled, or pulsatile drug delivery. This level of precision allows for the development of customized dosage forms that meet the specific needs of individual patients. Furthermore, HME has facilitated the development of combination therapies by enabling the formulation of multiple active ingredients into a single dosage form. This can improve patient compliance, simplify dosing regimens, and enhance the therapeutic effects of the medications. By co-extruding different drug compounds, pharmaceutical scientists can create synergistic formulations that offer enhanced efficacy compared to individual drugs alone.

Overall, Hot Melt Extrusion has revolutionized pharmaceutical formulation by offering pioneering techniques to enhance drug solubility, control release profiles, and facilitate the development of combination therapies. With its ability to optimize drug delivery systems and improve patient outcomes, HME continues to push the boundaries of pharmaceutical innovation and drive advancements in the field.

A. Basics of Hot Melt Extrusion

HME is a process that involves the combination of pharmaceutical active ingredients, polymers, and excipients at elevated temperatures using an extruder. This results in the formation of a homogenous matrix that can be shaped into various dosage forms such as films, fibers, or granules. The key advantage of HME lies in its ability to create amorphous solid dispersions, which significantly enhance the solubility and bioavailability of poorly water-soluble drugs.

B. Technological Advancements in HME

Twin-Screw Extrusion: The evolution of twin-screw extruders has revolutionized HME by offering enhanced mixing efficiency and control over process parameters. Twin-screw extruders allow for a more uniform distribution of the active pharmaceutical ingredient (API) within the polymer matrix, resulting in improved drug release profiles and therapeutic outcomes.

Nanoextrusion: Nanoextrusion techniques involve reducing the particle size of drugs to the nanoscale during the extrusion process. This leads to increased surface area and improved dissolution rates, particularly beneficial for drugs with poor solubility. Nanoextrusion enhances drug bioavailability and ensures a faster onset of action.

Solvent-Free Extrusion: The shift towards solvent-free extrusion processes addresses environmental and safety concerns associated with solvent-based formulations. Solvent-free HME not only reduces manufacturing costs but also minimizes the risk of residual solvent contamination in the final product, promoting sustainability in pharmaceutical manufacturing.

Controlled-Release Formulations: HME enables the development of controlled-release formulations by allowing precise control over drug release kinetics. This is achieved by adjusting the composition of the matrix and extrusion parameters, leading to tailored release profiles suitable for various therapeutic needs, including sustained release for chronic conditions and targeted delivery to specific sites within the body.

Learn more: https://www.pharmafocusamerica.com/articles/advanced-hot-melt-extrusion-pioneering-techniques-in-pharmaceutical-formulation

Follow us:

Facebook: https://www.facebook.com/PharmaFocusAmerica/

LinkedIn: https://www.linkedin.com/company/pharmafocusamerica/

Twitter: https://x.com/pharmafamerica

Instagram: https://www.instagram.com/pharma423/

Pinterest: https://in.pinterest.com/robinjack153/

0 notes

Text

The Importance and Customization of DRTS Pipe Extruders

Introduction

In the dynamic world of manufacturing, the role of Pipe Extruders is paramount. These machines are the backbone of the pipe production line, responsible for heating, mixing, and forming plastic into high-quality pipes. DRTS Pipe Extruders, renowned for their reliability and customization, offer industry-leading solutions tailored to various production needs. This article delves into the features, benefits, and customization options of DRTS Pipe Extruders, specifically focusing on the DRTS Pipe Extruders and pipe plastic extruder systems.

What Are Pipe Extruders?

Pipe extruders are specialized machines that transform raw plastic materials into pipes through a continuous extrusion process. The process involves heating the plastic, mixing it to a homogeneous state, and then forcing it through a die to create the desired pipe shape. The quality of the extruder directly impacts the consistency and quality of the produced pipes, making it a critical component in any pipe manufacturing setup.

Key Features of DRTS Pipe Extruders

DRTS Pipe Extruders are designed with precision and durability in mind. They incorporate high-quality components from leading brands, ensuring long-term performance and reliability. Some standout features include:

Customizable Screw Designs: DRTS offers both single-screw and twin-screw extruders, each tailored to specific materials and production requirements. The screws are designed to ensure optimal mixing and plastification, enhancing production efficiency and product quality.

High-Quality Components: DRTS extruders are built using top-tier components such as Zambello gearboxes, ABB/Siemens/Baumuller motors, and Reiloy bimetallic screws and barrels. These components ensure stability, durability, and consistent performance.

Advanced Control Systems: The extruders are equipped with 12-inch HMI/PLC systems from B&R/Siemens/Omron, providing intuitive control and monitoring of the extrusion process. This level of control allows for precise adjustments, leading to better product quality and reduced waste.

Versatility in Production: DRTS extruders can handle various types of plastic, including PE, PVC, and PPR. This versatility makes them suitable for a wide range of applications, from drip irrigation systems to large-scale industrial pipes.

Customized Solutions for Different Needs

DRTS understands that different production environments have unique requirements. Hence, they offer customized solutions to meet specific needs. Whether it's the type of plastic being used or the desired output, DRTS can tailor their extruders to ensure optimal performance.

Single Screw vs. Twin Screw Extruders

Single Screw Extruders: Ideal for materials like PE and drip irrigation pipes, single screw extruders are simpler in design and operation. They are highly effective for homogeneous materials and offer a cost-effective solution for many production lines.

Twin Screw Extruders: These are designed for more complex materials like PVC, which require thorough mixing and high resistance to wear. The twin screw design provides better handling of the raw material, ensuring consistent quality and extending the lifespan of the machine.

Why Choose DRTS Pipe Extruders?

Quality and Reliability: DRTS extruders are built to last, with high-quality components that ensure long-term stability and performance.

Customization: The ability to customize extruders to specific production needs ensures that manufacturers get the best possible solution for their requirements.

Efficiency: With advanced control systems and precise engineering, DRTS extruders maximize production efficiency and minimize waste, leading to cost savings and higher output.

Support and Service: DRTS provides comprehensive support and service, from initial consultation to ongoing maintenance, ensuring that their customers get the most out of their investment.

Conclusion

In plastic pipe production, DRTS Pipe Extruders stand out for their quality, customization, and efficiency. Whether you're producing PE, PVC, or PPR pipes, DRTS offers solutions tailored to your specific needs, ensuring optimal performance and product quality. By investing in a DRTS pipe plastic extruder, manufacturers can enhance their production capabilities, reduce waste, and ultimately achieve greater success in their operations.

For more information about DRTS Pipe Extruders and to explore the options available, visit DRTS Pipe Extruders.

#pipe extruders#extruding machine#pipe extruder#pipe plastic extruder#pipe production line#plastic pipe extruders#drts pipe extruders#turnkey extrusion pipe machinery

0 notes

Text

Mixer Silos | Mixer Silos Manufacturer | Blending Silos

Mixer Silos

Mixing technology has been one of our long term solution, providing a homogeneous mix, and with various timer options to maintain the homogeneous nature. Our solution in Mixers enhance the customer satisfaction with the possibility of adding with the complete line of other products from storage silos to material handling and conveying automation.

At Lorandi Silos, we pride ourselves on being the premier provider of high-quality storage and mixing silos - solutions tailored to meet the diverse needs of industries worldwide. With decades of experience and a commitment to excellence, we offer products designed to optimize your production processes, including blending silos, mixer silos, and silo blending systems. Our dedication to innovation, precision engineering, and exceptional customer service sets us apart as the trusted choice for companies seeking reliable and efficient silo solutions.

Why Choose Lorandi Mixer Silos?

When it comes to selecting silo solutions for your business, precision engineering and reliability are paramount. That's why Lorandi Silos is your trusted partner in meeting your silo needs. Our blending silos and mixing silos are meticulously crafted to ensure seamless integration into your production process, whether you're operating in the cement industry or other sectors. With customizable designs and configurations, we can tailor our silos to suit your unique requirements, ensuring maximum efficiency and productivity.

Our mixer silos are specifically designed to facilitate the homogenization of goods such as pellets, flakes, and powders. Additionally, they help regulate the temperature of materials exiting the extruder, ensuring optimal product quality and consistency. Available in various dimensions and capacities, our mixer silos are suitable for a wide range of industries, including Plastic Industries, Food masala industry, PET bottle, compounding industry, Auto components, Flexible films, Pipes, Profiles & Wires industry, Recycling industry, Pet food industry, Wood & Energy industry and in new upcoming applications.

In addition to our premium silo products, Lorandi Silos also offers a comprehensive range of optional accessories for mixer silos. These accessories are designed to enhance the functionality and performance of your silo system, providing added convenience and efficiency. From environmental protection solutions such as filters to specialised mixing equipment, we have everything you need to optimize your silo operations and ensure compliance with industry regulations. One advantage of our homogenzation silo is to get the homogenzous in a faster way and without damaging the product. The auger screw is a single helicoid flight, which gives much more stability at higher speeds, and hence reducing the homogenization time.

At Lorandi Silos, customer satisfaction is our top priority. Our team of experts is committed to providing personalized service and support at every stage of your silo project, from initial consultation to installation and beyond. As leading silo manufacturer and supplier, we take pride in delivering superior quality products that exceed our customers' expectations. Whether you're in India or anywhere else, our storage silo manufacturer services are available to meet your needs. Contact us today to learn more about our blending silos, mixer silos, and silo blending systems, and discover why Lorandi Silos is the trusted choice for companies worldwide. Lorandi India, offers products with the knowledge of over seventy years experience done, delivered and in operation - from Lorandi Italy experience.

Discover the Lorandi Advantage

Our mixing silos results in good homogenization of goods such as pellets, flakes, powders. It also helps to drop the temperature of flakes out of the extruder. Various dimensions and capacities with optional are available for each industry.

In which industries ring silos can be used?

Plastic Industries

Food masala industry

PET bottle

Auto components

Flexible films

Pipes, Profiles & Wires industry

Recycling industry

Pet food industry

Wood & Energy industry

Gallery of Ring Silos

GET IN TOUCH

LORANDI SILOS INDIA PVT. LTD.

46-B, KRK ROAD

Ramanathapuram

Coimbatore - 641 045

INDIA

Phone:+91 422 231 56 40 / 41 / 44

+91 94433 73640

+91 94433 73641

Read More....

0 notes

Text

THE EVOLUTION OF EPDM EXTRUSION TECHNOLOGY

The journey of EPDM extrusion technology began with the single-screw extruder. This machine features a single rotating screw within a heated barrel. As the screw rotates, it melts and pushes the EPDM through a die, forming the desired shape. Single-screw EPDM extruders are straightforward in design and operation, making them suitable for many standard EPDM applications.

However, single-screw extruders have limitations, particularly in mixing and homogenizing the rubber. These limitations can bring about inconsistencies in the final product, affecting its performance and durability. Despite these drawbacks, single-screw EPDM extruders laid the foundation for more advanced technologies.

0 notes

Text

SINGLE SCREW RPVC PIPE EXTRUSION MACHINERY LINES SINGLE SCREW RPVC PIPE EXTRUSION MACHINERY LINES A single screw extruder is a machine used to form a plastic product into the required shape The machine heats the plastic raw material e g PVC to its melting point

#Single screw pipe extrusion line for PVC#PVC Pipe Extrusion Machine#PLB DUCT 2 LAYER HDPE Pipe Machine Manufacturers & Suppliers in India#PP-R SINGLE LAYER HDPE Pipe Machine Manufacturers & Suppliers in India#PLB DUCT 3 LAYER HDPE Pipe Machine Manufacturers & Suppliers in India

0 notes

Text

Unlocking Efficiency with Screw Elements

Explore the revolutionary world of screw element in our social bookmarking platform. Dive into a curated collection of insights, innovations, and expert discussions surrounding the transformative impact of screw elements across industries. From manufacturing breakthroughs to engineering marvels, our community thrives on sharing and bookmarking the latest trends and advancements. Join us to stay at the forefront of screw element technology and harness its power to drive efficiency and excellence in your projects.

0 notes

Text

Exploring the World of Used Extruders

Exploring the World of Used Extruders

Extruders are an essential part of many industries, from food processing to plastic manufacturing. They come in various types and sizes, each designed to perform specific tasks. In this article, we delve into the world of used extruders, their benefits, and where to find them.Get more news about used extruder,you can vist our website!

Understanding Extruders

Extruders are machines used to shape materials by forcing them through a die. They are commonly used in the plastic industry to create items such as pipes, films, and sheets. There are two main types of extruders: single screw and twin screw. Single screw extruders are often used for general plastic processing, while twin screw extruders, which can be co-rotating or counter-rotating, are used for more specialized tasks.

The Benefits of Used Extruders

Purchasing used extruders can be a cost-effective solution for businesses. These machines are often refurbished and tested to ensure they meet the required standards. This means businesses can acquire high-quality machinery at a fraction of the cost of new equipment.

Where to Find Used Extruders

There are several places where one can find used extruders for sale. Perry Videx, for instance, offers a large selection of used extruders and refurbished extrusion machinery. They sell single screw extruders and twin screw extruders, both co and counter-rotating design1. Other platforms like Machinio also have a wide range of used extruders for sale.

Conclusion

Whether you’re a small business looking to expand your operations or a large corporation seeking to cut costs, used extruders offer a viable solution. They provide the same functionality as new machines but at a significantly lower cost. So, the next time you’re in the market for an extruder, consider purchasing a used one. It might just be the best decision for your business.

0 notes

Text

The Ultimate Guide of Co-Rotating Twin Screw Extruder

Introduction About Co-Rotating Twin Screw Extruder

Co-rotating twin screw extruders have become the backbone of various industries, providing an efficient and versatile solution for material processing. From plastics to pharmaceuticals, their applications are vast and their benefits are manifold.

In the realm of material processing, the co-rotating twin screw extruderstands out as a game-changer. But what exactly is this marvel of engineering, and why is it gaining widespread adoption in industries worldwide?

Definition of a Co-Rotating Twin Screw Extruder

A co-rotating twin screw extruder is a sophisticated piece of machinery used for processing a wide range of materials by forcing them through a set of intermeshing, co-rotating screws. This process results in efficient mixing, melting, and shaping of the material, making it a preferred choice in various manufacturing processes.

Components of Co-Rotating Twin Screw Extruders

Screws and Barrels

The design and material composition of screws and barrels significantly impact the extruder's performance. High-quality, durable components are essential for ensuring longevity and consistent results.

Feed and Discharge Systems

Efficient material feeding and discharge systems contribute to the overall effectiveness of co-rotating twin screw extruders. Properly designed systems prevent material inconsistencies and ensure a smooth production flow.

Control Systems

Modern co-rotating twin screw extruders come equipped with advanced control systems. These systems allow operators to monitor and adjust various parameters in real-time, ensuring optimal performance and product quality.

Working Principle of Co-Rotating Twin Screw Extruder

Co-Rotating Motion Explanation

The co-rotating motion of the twin screws is a key element in the extruder's efficiency. This synchronized movement ensures thorough mixing and processing of materials, enhancing the overall quality of the output.

Twin Screw Design Advantages

Unlike single screw extruders, the twin screw design allows for better control over the processing parameters. The intermeshing screws create a shearing effect, generating heat that aids in the material's transformation.

Heat and Shear Effects on Materials

The controlled application of heat and shear within the extruder is crucial for processing materials with precision. This feature not only improves the material's consistency but also allows for the incorporation of additives and modifiers.

Importance of Co-Rotating Twin Screw Extruder in Various Industries

Industries such as plastics, food processing, and pharmaceuticals rely on co-rotating twin screw extruders for their unparalleled performance. The ability to handle diverse materials and provide precise control over the process makes them indispensable in modern manufacturing.

Co-Rotating Twin Screw Extruder's Advantages Over Single Screw Extruders

Enhanced Mixing Capabilities

One of the primary advantages of co-rotating twin screw extruders is their superior mixing capabilities. The intermeshing screws create a kneading action, promoting thorough blending of materials and resulting in a more consistent end product.

Increased Processing Flexibility

Compared to single screw extruders, co-rotating twin screw extruders offer enhanced processing flexibility. The ability to adjust screw speed, temperature, and other parameters provides manufacturers with greater control over the production process.

Higher Throughput Rates

The dual-screw design allows for higher throughput rates, making co-rotating twin screw extruders ideal for large-scale production. This efficiency is particularly advantageous in industries where high volumes of material need to be processed within a given timeframe.

Maintenance Tips

Regular Cleaning Procedures

Proper maintenance is crucial for the longevity and optimal performance of co-rotating twin screw extruders. Regular cleaning procedures, including purging and flushing, help prevent material buildup and ensure the extruder operates at peak efficiency.

Screw and Barrel Inspections

Periodic inspections of screws and barrels are essential to identify wear and tear. Any signs of damage or degradation should be addressed promptly to prevent disruptions in the production process.

Lubrication Requirements

Maintaining the appropriate lubrication levels is key to reducing friction and preventing premature wear of moving parts. Lubrication schedules should be adhered to, and high-quality lubricants should be used for optimal results.

Choosing the Right Co-Rotating Twin Screw Extruder

Selecting the appropriate co-rotating twin screw extruder is a critical decision that significantly influences the efficiency and quality of your manufacturing process. With a myriad of options available in the market, understanding how to make the right choice is paramount. Let's delve into the key considerations for selecting the ideal co-rotating twin screw extruder for your specific needs.

1. Material Type Considerations

Different materials have distinct characteristics and processing requirements. Consider the nature of the material you intend to process, including its viscosity, temperature sensitivity, and any unique features. Ensure that the extruder you choose is well-suited to handle the specific properties of your materials.

2. Throughput Requirements

The throughput capacity of an extruder is a crucial factor in determining its suitability for your production needs. Evaluate the volume of material you need to process within a given timeframe. Choose an extruder with a throughput rate that aligns with your production goals, ensuring optimal efficiency.

3. Customization Options

Co-rotating twin screw extruders offer a range of customization options. Manufacturers often provide different screw configurations, barrel designs, and other features that can be tailored to your unique requirements. Assess the customization options available and choose an extruder that can be adapted to meet the specific demands of your manufacturing process.

4. Consideration of Energy Efficiency

In today's environmentally conscious landscape, energy efficiency is a critical consideration. Assess the extruder's energy consumption and opt for models designed with energy-efficient features. This not only aligns with sustainable practices but can also lead to long-term cost savings.

5. Maintenance Requirements

The maintenance demands of co-rotating twin screw extruders vary. Consider the ease of maintenance and the associated costs. Look for extruders with user-friendly designs that facilitate regular cleaning, inspections, and lubrication. A well-maintained extruder ensures consistent performance and extends its operational lifespan.

6. Technological Advancements

Stay abreast of the latest technological advancements in co-rotating twin screw extrusion. Manufacturers often introduce innovations that enhance process control, automation, and overall efficiency. Choosing a model with the latest technological features ensures that your facility remains at the forefront of extrusion capabilities.

1 note

·

View note