#Stainless Steel 304/304L/304H Pipes & Tubes

Text

#Stainless Steel 304/304L/304H Pipes & Tubes#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers

0 notes

Text

Stainless Steel 304L Pipes & Tubes Exporters In Mumbai

Nascent Pipe & Tubes is the fundamental manufacturers of the SS 304/304L/304H Pipes & Tubes. In any case, we are giving and exchanging the Pipes & Tubes and loads to the clients open beginning with one side of the world then onto the following. We are nearly considered among the momentous stockist and specialist of the wide levels of Pipes & Tubes. The Pipes & Tubes are open in different subtleties as per the requests for the clients. Choices like surface fulfillment, end finish, focuses, shapes, sizes, length, and strength are there.

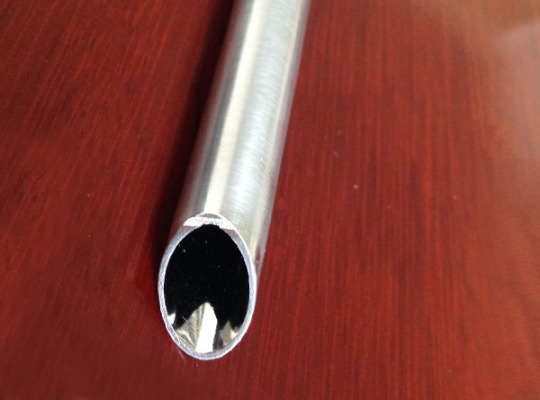

Pipes & Tubes open are almost used in current applications. The best way that the endeavors are spreading fluids among the applications is with the help of the changed piece of the Pipes & Tubes. This is dumbfounding for supply the gas and the fluids which are fitting. The line is the unfilled portions which are used in the applications with the round cross-region that convey the things easily. The fixations and the broadness of the line are noted by the application in which it is used.

Abutting this, the chambers are the strain hardware that is utilized in current applications. The chambers and Pipes & Tubes are open in many shapes and sizes. A piece of the shapes where the Pipes & Tubes and loads are open are shot, square, square shape that is having the unfilled pieces. Also, the essential contrast among the Pipes & Tubes comes in the wall thickness, material, end affiliations, and others.

The SS 304 Alloy steel is utilized in the improvement of the line. Notwithstanding, the Alloy is involved chromium and nickel contents which are giving the Pipes & Tubes different properties. Thusly, the SS 304L is the low carbon content than the 304 Alloy steel. This is the means by which it is shocking at having the intergranular utilize hindrance cutoff. Essentially, the SS 304H is the high-temperature application utilized blend which is there with the high-temperature strength and the capacity to work in the raised temperatures.

The Alloy is the explanation that the SS 304/304L/304H Pipes & Tubes and Cylinders are having various properties. A piece of the properties which the Pipes & Tubes are having are breaking down obstruction, grand flexibility, strength, power in the raised temperatures, and fundamental force.

Specification Of Stainless Steel 304/304L/304H Seamless Welded Pipes & Tubes

Stainless Steel Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

SS Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Pipe Size :1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size :1/2" OD to 8" OD.

Thickness Range :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

Visit Website:

Email: [email protected]

#Stainless Steel 304/304L/304H Pipes & Tubes#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers#Stainless Steel 304/304L/304H Pipes & Tubes Stockists#Stainless Steel 304/304L/304H Pipes & Tubes Exporters#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers In India#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers In India#Stainless Steel 304/304L/304H Pipes & Tubes Stockists In India#Stainless Steel 304/304L/304H Pipes & Tubes Exporters In India#Stainless Steel 304/304L/304H Pipes & Tubes Manufacturers in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Suppliers in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Stockists in Mumbai#Stainless Steel 304/304L/304H Pipes & Tubes Exporters in Mumbai

0 notes

Text

Stainless Steel Round Bar, Strip, Sheet, Plate and Fitting Exports & Supplier

Jay Steel Corporation is a globally recognized leader, manufacturing, supplying, and exporting premium stainless steel products like Round Bars, Strips, Sheets & Plates, Wire Mesh, Pipes, Tubes, and more. Specializing in sought-after items such as Stainless Steel 304/304L/304H Round Bars, 316/316L/316Ti Round Bars, 304H and 316/316L/316Ti Plates, and 304/304L/304H Tubes & Pipes, we maintain an unwavering commitment to quality. With a significant presence in Germany, Thailand, Russia, France, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, and Jordan, Jay Steel Corporation combines global reach with a solid reputation for delivering excellence through continual technological advancements. Choose us for top-tier stainless steel solutions with a focus on quality and innovation.

#Stainless Steel 304/304L/304H Round Bar#Stainless Steel 904L Round Bar#Stainless Steel 316/316L/316Ti Tube & Pipe#Stainless Steel 904L plate

0 notes

Text

Stainless Steel 304/304l/304h Pipes & Tubes Suppliers

K M D Steel And Tube is a leading manufacturers, supplier, stockists and exporter for SS 304/304L/304H Pipes & Tubes. This Stainless Steel Pipes and Tubes display great corrosion imperviousness to an extensive variety of destructive situation and it also shows best machinabilityand have superb weld capacity attributes with or without the expansion of filler metals. The SS 304/304L/304H Pipes & Tubes are most commonly used in boilers, heat exchangers, petroleum, condensers, petroleum refineries, pipelines, steam exhausts, cooling towers, electric generation plants. The Pipes & Tubes are made of best quality raw material and are of international quality standard and this helps us to have high demand in the market from the customers. The Pipes & Tubes are made in different shapes, size, thickness and dimension and are supplied to customers as per their needs and requirement. When it comes to packaging of products it is done with great care because we know the ups and downs during import and export of product hence we make sure the Pipes and Tubes are delivered to customers without any damages in good condition.

Stainless Steel 304/304l/304h Pipes & Tubes, Stainless Steel 304/304l/304h Pipes & Tubes Manufacturers, Stainless Steel 304/304l/304h Pipes & Tubes Suppliers, Stainless Steel 304/304l/304h Pipes & Tubes Exporters, Stainless Steel 304/304l/304h Pipes & Tubes Stockists.

0 notes

Text

Manufacturer of Heat Exchanger Tubes near me

Manufacturer of Heat Exchanger Tubes near me

Krystal Global Engineering Limited (formerly known as Krystal Steel Manufacturing Private Limited) stands as a prominent figure in the stainless steel industry, aiming to establish itself as the foremost authority in Stainless and Nickel Alloy Tubes originating from India. Our triumphs are built on our dedication to Operational Excellence and the provision of outstanding services.

We are devoted to equipping our customers with a competitive advantage through a wide range of offerings, encompassing Tubes, Pipes, U Tubes, and Coil Formed Tubes. As a distinguished Producer of Heat Exchanger Tubes in Mumbai, SS heat exchanger tubes in Mumbai, Stainless Steel heat exchanger tubes in Mumbai, Stainless Steel 316 Heat Exchanger Tubes Stockist in India, U Bend Tubes For Heat Exchangers Manufacturer from Mumbai, Profins heat exchanger tubes, heat exchanger tube bwg, heat exchanger dummy tube, dummy tubes heat exchanger, heat exchanger tube fretting, Duplex Stainless Steel Heat Exchanger Tubes, India Stainless Steel Heat Exchanger Tube Manufacturers, Stainless Steel 317L Heat Exchanger Tubes and bwg tube heat exchanger, we take pride in delivering top-quality products to fulfill the diverse requirements of our clientele.

Krystal features cutting-edge facilities committed to continuous enhancement in both product excellence and service provision, with the aim of meeting the varied demands of our global customer base. Whether you require a Stainless Steel 317L Heat Exchanger Tubes, SS 316/316L Heat Exchanger Tubes, SS Heat Exchanger Pipes & Tubes, Carbon Steel Heat-Exchanger and Condenser Tubes, SS 304/304L Heat Exchanger Tubes, Stainless Steel 316L Heat Exchanger Tubes, ASTM A249 Stainless Steel Heat Exchanger Tubing, Stainless Steel 304H Heat Exchanger Tubes ensures comprehensive coverage with our extensive array of products and services.

Our esteemed clientele represents a broad spectrum of sectors, including Power Plants, Oil & Gas, Chemical Plants, Fertilizers, Pharmaceuticals, Textiles, Railways, Defense, Automobiles, Desalination, and many others. Our products are utilized in various engineering applications such as Pressure Vessels, Heat Exchangers, Condensers, Heat Recovery Systems, among others. Our global footprint ensures that customers worldwide can rely on our products, technology, and services with utmost assurance. Count on Krystal as your dependable ally for all your hydraulic component requirements in Mumbai and beyond.

#BrightAnnealedTubes#BuySeamlessTubesandPipes#SSCapillaryTubes#HeatExchangerTubesManufacturer#Inconelalloy#InstrumentationTube#SeamlessTubeSuppliers#SeamlessHeatExchangerTube#HydraulicTubesManufacturer#ManufacturerofInstrumentationTubes#ManufacturerofSeamlesstubesandPipes#ManufacturerHeatExchangerTubes#ManufacturerofStainlessSteelPipe#ManufacturerofStainlessSteelTubeandPipe#ManufacturerofStainlessSteelTubes#MonelAlloy#NickelAlloyTubes#SeamlessPipeManufacturer#StainlessSteelBrightAnnealedTubesManufacturers#StainlessSteelManufacturerinIndia#StainlessSteelPipeManufacturersinIndia#StainlessSteelPipeManufacturingCompanyInVadodara#StainlessSteelSeamlessPipes#StainlessSteelSeamlessTubes

0 notes

Text

Stainless Steel 304H Flanges Manufacturers In India

Nascent Pipe & Tubes takes center stage with its remarkable offering of Stainless Steel 304/304L/304H Flanges, showcasing its prowess as a Manufacturer, exporter, stockiest, and supplier to a diverse global clientele. The versatility of these flanges is highlighted by Stainless Steel 304L, the low carbon variant of 304, making it an ideal choice for substantial gauge components without the need for post-weld hardening.

Distinguished by its elevated carbon content, Stainless Steel Grade 304H finds application at higher temperatures, expanding the utility of Nascent Pipe & Tubes' offerings. The company's dedication to quality and precision is evident in the meticulous craftsmanship of these flanges, ensuring they meet and exceed the highest industry standards.

The Stainless Steel 304/304L/304H Flanges provided by Nascent Pipe & Tubes cater to a myriad of applications, reflecting the company's commitment to addressing the diverse needs of its global clients. As a reliable and innovative partner in the industry, Nascent Pipe & Tubes continues to elevate its manufacturing excellence, providing cutting-edge solutions that underscore their prowess in the stainless steel manufacturing sector.

SS 304/304L/304H Flanges Specifications:

GradeSS 304(UNS S30400),

SS 304L (UNS S30403),

SS 304H (UNS S30409) ).Werkstoff Nr304 / 1.4301,

304L /1.4307,

304H / 1.4948Dimension StdANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom DrawingsSpecificationASTM A182 / A240 & ASME SA182 / SA240StandardANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges etc.Size½” NB – 48” NBClass150#, 300#, 600#, 900#, 1500#, 2500#, etcPressureDIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160, etc

For more Information

Visit website: https://www.nehametalalloys.com

Email: [email protected]

Contact: 8779038854

0 notes

Text

A comprehensive guide on Stainless Steel Round Bar

Stainless steel round bars have become indispensable in various industries due to their exceptional strength, corrosion resistance, and versatility. As a leading SS round bars Manufacturer, Supplier, Stockist, and Exporter on a global scale, Bullion Pipes & Tubes LLP takes pride in offering an extensive range of stainless steel round bars tailored to meet diverse project requirements.

In this comprehensive guide, we'll delve into the world of stainless steel round bars, exploring their composition, properties, applications, and key factors to consider when selecting the right round bar for your specific needs.

Stainless Steel Round Bars

Stainless steel round bars are solid cylindrical bars made from stainless steel, an alloy of iron, chromium, nickel, and other elements. The combination of these elements imparts unique properties to stainless steel, making it a preferred choice in diverse applications.

Composition and Grades:

Stainless steel round bars come in various grades, each with its own set of properties and applications. Common grades include Stainless Steel 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 904L and 446 Round Bars. The grade you choose depends on factors such as corrosion resistance, temperature resistance, and mechanical properties required for your specific application.

Properties that Set Stainless Steel Round Bars Apart:

Corrosion Resistance: Stainless steel round bars are known for their excellent corrosion resistance, making them ideal for applications in harsh environments, such as marine and chemical industries.

High-Temperature Resistance: The alloy's ability to withstand high temperatures without losing its structural integrity is a crucial factor in applications like heat exchangers and exhaust systems.

Strength and Durability: Stainless steel round bars exhibit high tensile strength and durability, ensuring a long lifespan and minimal maintenance requirements.

Specifications of Stainless Steel Round Bars

Standard

ASTM, ASME, AISI A 276, SA 276, A 479, SA 479, ASTM, ASME A276/SA 479

Dimensions

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size

18mm – 47mm (11/16″ to 1-3/4″)

Range

3.17 MM TO 350 MM DIA

Stainless Steel Round Bars

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 904L and 446 Round Bars

Length

1 to 6 Meters, Custom Cut Lengths

Condition

Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Finish

Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form

Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc

Applications of Stainless Steel Round Bars Across Industries:

Stainless steel round bars find extensive applications across various industries due to their unique properties, making them a versatile and popular choice for different purposes. Here are some key applications across industries:

Construction and Architecture

Automotive Industry

Oil and Gas Industry

Chemical Processing

Food and Beverage Industry

Medical and Pharmaceutical

Aerospace Industry

Power Generation

Marine Industry

General Manufacturing

Other Applications

Choosing the Right Stainless Steel Round Bar:

When selecting a stainless steel round bar, consider factors such as:

Grade: Choose a grade based on the specific requirements of your application.

Diameter and Length: The size of the round bar should align with your project specifications.

Surface Finish: Depending on the application, you may need a polished or rough surface finish.

Final Words!

Bullion Pipes & Tubes LLP stands as the industry leader in providing top-notch stainless steel round bars exporters globally in various countries like Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and many other regions. Our commitment to quality, extensive product range, and customization options make us the preferred choice for customers across diverse industries. Contact us today at [email protected] or [email protected] and experience the excellence of stainless steel round bars that elevate your projects to new heights.

0 notes

Text

Stainless Steel Electropolished Tubes Exporters In India

Stainless Steel Electropolished Tubes Supplier In India, SS Electropolished Tubes Exporter Electropolished Stainless Steel Tubing, Electropolished Tubes, Electropolished Tube Fittings 304/304l Electropolished Pipes, 316/316l Electropolished Pipes, Seamless/Welded EP Pipes

Stainless Steel Electropolished Pipes Manufacturer, Electropolished Tubes Exporter, High Purity Stainless Steel Tubing, Electropolished Stainless Steel Tubes, EP Tubes Processor in Mumbai, SS Electropolished Tubes in India, SS 304L Electropolished Tubes, SS 316L Electropolished Pipes, SS 904L Electropolished Tubing Suppliers, Electropolished Tubes Suppliers in India, Dairy Tubes, Tubes for Pharma Industry, Electropolished Tubes for Food Processing Industry, Best Quality EP Tubes in India, Mumbai

Kobs India is a leading processor and supplier of high quality electropolished or mechanically polished stainless steel pipes, electropolished tubes in all major stainless steel grades including 304/304L and 316/316L. Electropolishing is also commonly known as electrochemical polishing or electrolytic polishing. EP stainless steel tubes are generally made by carrying out the electropolishing process on high quality seamless and welded stainless steel tubes.

Standards Specification:

Size : ½”Inch and 24”Inch

Specifications : ASTM A249, A269, A270

Grades: : 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Length: : Up to 6 meters, custom cut lengths

Thickness: 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish:BA Finish inside and outside, Electropolished finish inside and outside

Specifications : ASTM A312 / ASTM SA312

Material & Grade :

Stainless Steel :

Grade: 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Product Features:

Durability

High strength

Effective functionality

Sturdy construction

Corrosion resistance

Dimensional accuracy

Electropolished Tubes Manufacturer, Electropolished Tubes Manufacturers, Electropolished Tubes Suppliers, Electropolished Tubes Exporters, Electropolished Tubes Stockists.

Electropolished Tubes in Mumbai, Electropolished Tubes Manufacturers in Mumbai, Electropolished Tubes Suppliers in Mumbai, Electropolished Tubes Exporters in Mumbai, Electropolished Tubes Stockists in Mumbai.

Electropolished Tubes in India, Electropolished Tubes Manufacturers in India, Electropolished Tubes Suppliers in India, Electropolished Tubes Exporters in India, Electropolished Tubes Stockists in India.

Manufacturing Process :

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

Product Usage & Application :

Useful in Paper & Pulp Companies

Useful in High Pressure Applications

Useful in Oil and Gas Industry

Useful in Chemical Refinery

Useful in Pipeline

Useful in High Temperature Application

Useful in Water Pipe Line

Useful in Nuclear Power Plants

Useful in Food Processing and Dairy Industries

Useful in Boiler & Heat Exchangers

Packing :

Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Shrink-wrapped

Carton boxes

Wooden pallets

Wooden boxes

Wooden crates

Why Choose Us :

You can get the perfect material according to your requirement at the least possible price.

We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

e guarantee to give a response within 24hours(usually in the same hour)

You can get stock alternatives, mill deliveries with minimizing manufacturing time.

We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Tests we carry out (including both Destructive and Non-Destructive) :

Positive material recognition

Mechanical examining like tensile, Elongation and reduction of area.

Large-scale test

Chemical examination-Spectro analysis

Firmness test

Pitting protection test

Small tests

X-ray test

Impact analysis

Eddy current examining

Hydrostatic analysis

Prompt test

For more details:

Website - http://kobsindia.in/

Phone No. - 9819523999

Email - [email protected]

#Electropolished Tubes in India#Electropolished Tubes Manufacturers in India#Electropolished Tubes Suppliers in India#Electropolished Tubes Exporters in India#Electropolished Tubes Stockists in India.

0 notes

Text

ASTM A249/ASME SA249 STAINLESS STEEL TUBE

ASTM A249/ASME SA249 stainless steel tube covers nominal wall thicknesses welded and heavily cold-worked welded pipes made of the following materials

Various grades of austenitic steel for boilers, superheaters, heat exchangers, or condenser pipes.

ASTM A249/ASME SA249 STAINLESS STEEL TUBE PROVIDED BY YUHONG

ASTM A249/ASME SA249 Stainless Steel Tube

YUHONG GROUP provides the best ASTM A249/ASME SA249 Stainless steel tubes including welded austenitic alloy steel boiler tube, superheater and heat exchanger tube, and U bending tube.

TP304/TP304L Stainless Steel Tube

TP316/TP316L Stainless Steel Tube

ASTM A249 TUBING FEATURES

ASTM A249/ASME SA249 stainless steel tube has good plasticity, low strength, and hardness. At the same time, ASTM A 249 also has a certain toughness, but it is not ferromagnetic.

ASTM A249/ASME SA249 stainless steel tube is not only resistant to oxidative acid medium corrosion, but also resistant to sulfuric acid, phosphoric acid, formic acid, acetic acid, urea, etc. if it contains Mo, Cu, and other elements. If the carbon content of ASME SA249/ASTM A249 tubing is less than 0.03% or contains Ti and Ni, the resistance of this SS steel tube to intergranular corrosion can be significantly improved.

ASME SA249/ ASTM A249 TP304 SPECIFICATIONS

ASTM A249 Standard

ASTM A249/ASME SA249

Tube Type

Welded Tube

Finishes

Annealing Pickling, Bright Annealing

Outside Diameter

6 Up To 304.8 Mm

Thickness

0.5 Up To 6 Mm

Application

Heat Exchanger System

GRADES OF SPECIFICATION ASTM A249/SA 249

Grade

Specification

Stainless 304/304L, 304/304H

ASTM A249/SA249

Stainless 309S

ASTM A249/SA249

Stainless 310S

ASTM A249/SA249

Stainless 316/316L, 316/316H

ASTM A249/SA249

Stainless 317/317L

ASTM A249/SA249

Stainless 321/321H

ASTM A249/SA249

Stainless 347/347H

ASTM A249/SA249

ASME SA249/ ASTM A 249 TUBING CHEMICAL COMPOSITION

Grade

UNS

Composition, %

Design

C

Mn

P

S

Si

Cr

Ni

Mb

Ti

Nb

N

Cu

Ce

B

Al

TP304

S30400

0.08

2

0.045

0.03

1

18.0–20

8.0–11

. . .

. . .

. . .

. . .

. . .

. . .

TP304L

S30403

0.035

2

0.045

0.03

1

18.0–20

8.0–13

. . .

. . .

. . .

. . .

. . .

. . .

TP304H

S30409

0.04 – 0.1

2

0.045

0.03

1

18.0–20

8.0–11

. . .

. . .

. . .

. . .

. . .

. . .

TP310S

S31008

0.08

2

0.045

0.03

1

24.0- 26

19.0- 22

0.8

. . .

. . .

. . .

. . .

. . .

TP310H

S31009

0.04 – 0.1

2

0.045

0.03

1

24.0–26

19.0–22

. . .

. . .

. . .

. . .

. . .

TP310H

S31035

0.04 – 0.1

0.6

0.025

0.015

0.4

21.5–23.5

23.5–26.5

. . .

. . .

0.40- 0.6

0.20- 0.3

2.5- 3.5

. . .

0.002- 0.008

TP316

S31600

0.08

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP316L

S31603

0.035

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP316H

S31609

0.04 – 0.1

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP317

S31700

0.08

2

0.045

0.03

1

18.0–20

11.0–15

3.0–4

. . .

. . .

. . .

. . .

. . .

TP317L

S31703

0.035

2

0.045

0.03

1

18.0–20

11.0–15

3.0–4

. . .

. . .

. . .

. . .

. . .

TP321

S32100

0.08

2

0.045

0.03

1

17.0–19

9.0–12

. . .

Ti 5 × (C+N) min, 0.70 max

. . .

0.1

. . .

. . .

TP321H

S32109

0.04 – 0.1

2

0.045

0.03

1

17.0–19

9.0–12

. . .

4(C+N) min; 0.70 max

. . .

0.1

. . .

. . .

TP321H

S32654

0.02

2.0-4

0.03

0.005

0.5

24.0–25

21.0–23

7.0-8

. . .

. . .

0.45- 0.55

0.30-0.6

. . .

TP321H

S33228

0.04 – 0.08

1

0.02

0.015

0.3

26.0–28

31.0–33

. . .

. . .

0.60- 1

. . .

. . .

0.05 – 0.1

0.025

TP321H

S34565

0.03

5.0-7

0.03

0.01

1

23.0–25

16.0–18

4.0-5

. . .

0.1

0.40- 0.6

. . .

. . .

TP347

S34700

0.08

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

See Spec

. . .

. . .

. . .

TP347H

S34709

0.04 – 0.1

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

See Spec

. . .

. . .

. . .

TP348

S34800

0.08

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

. . .

. . .

. . .

. . .

Co 0.20, Ta 0.10

TP348H

S34809

0.04-0.10

2

0.045

0.03

1

17.0–19.0

9.0–13

. . .

. . .

. . .

. . .

. . .

. . .

. . .

Co 0.20, Ta 0.10

ASME SA249/ ASTM A 249 TUBING SIZE TOLERANCE

OD

WTH

L

ASTM A249

<25.4mm

±0.10mm

±10.00%

OD<50.8mm +3.0mm -0mm

≥25.4mm-38.1mm

±0.15mm

≥38.1mm-50.8mm

±0.20mm

≥50.8mm-63.5mm

±0.25mm

≥63.5mm-76.2mm

±0.30mm

OD≥50.8mm +5.0 -0mm

≥76.2mm-101.6mm

±0.38mm

≥101.6mm-190.5mm

+0.38mm -0.64mm

≥190.5mm-228.6mm

+0.38mm -1.14mm

WHAT IS ASME ASTM SA 249 STAINLESS STEEL TUBE?

ASME ASTM SA 249 stainless steel tubes are used in a variety of applications, including boiler, superheater, heat exchanger, and condenser systems. These a249 stainless steel tubes are manufactured through a welding process and are typically made from austenitic stainless steel, although other stainless steel grades may also be used.

The astm a249 tp304 specification outlines the requirements for the manufacturing, dimensions, mechanical properties, and testing of these welded stainless steel tubes. It provides guidelines for various aspects, including tube dimensions, tolerances, chemical composition, mechanical properties, and nondestructive testing methods.

The stainless steel tubes produced under the ASME ASTM SA 249 standard are designed to withstand high temperatures, corrosion, and pressure in demanding industrial environments. ASME sa249 are known for their excellent corrosion resistance, strength, and durability, making them suitable for applications where reliability and longevity are essential.

Common stainless steel grades used in ASME ASTM SA 249 tubes include 304, 304L, 316, 316L, 317, and 321. These grades offer varying levels of corrosion resistance, mechanical properties, and heat resistance, allowing for the selection of the most appropriate grade based on the specific application requirements.

Overall, ASME ASTM SA 249 stainless steel tubes meet stringent industry standards, ensuring that they are manufactured to the specified dimensions, quality, and performance criteria. These ASTM a249 tubings play a critical role in various industrial sectors, providing efficient and reliable solutions for heat exchanger tube manufacturers and fluid transportation systems.

ASTM A249 VS A269 STAINLESS STEEL TUBE

Applications: ASTM A249 tubes are primarily intended for general corrosion-resisting and low- or high-temperature service, including heat exchangers, condenser tubes, and other applications. ASTM A269 tubes, on the other hand, are specifically designed for general service applications requiring high corrosion resistance and mechanical properties.

Manufacturing Process: ASTM A249 tubing is produced through the welding process, while a269 tubing can be either welded or seamless. Seamless stainless steel tubes are typically preferred for high-pressure or critical applications.

Dimensional Tolerances: ASTM a249 tubing has more lenient dimensional tolerances compared to ASTM A269. A269 tubes have tighter tolerances for outside diameter, wall thickness, and length, ensuring greater precision and consistency.

Surface Finish: ASTM A269 specifies stricter requirements for the surface finish of tubes, particularly for applications where cleanliness and smoothness are important, such as in the pharmaceutical and food processing industries.

0 notes

Text

Stainless Steel 304 Pipes & Tubes Exporters

Introduction

Manilaxmi Industrial stands at the forefront as the premier manufacturer, supplier, and stockist of Stainless Steel 304, 304L, and 304H Pipes & Tubes. With a global reach, we provide top-notch quality products to clients worldwide. In this blog, we will delve into the features, applications, and advantages of Stainless Steel 304 Pipes & Tubes, and why Manilaxmi Industrial is your ultimate solution for your stainless steel needs.

Description

Stainless Steel 304, 304L, and 304H Pipes & Tubes are crafted to perfection by our skilled experts to meet the diverse requirements of various industries. Known for their exceptional corrosion resistance, high strength, and durability, these pipes and tubes are ideal for a wide range of applications in both commercial and industrial sectors. At Manilaxmi Industrial, we ensure that our Stainless Steel 304 Pipes & Tubes adhere to the highest standards of quality and performance.

Benefits

Choosing Stainless Steel 304 Pipes & Tubes from Manilaxmi Industrial offers numerous advantages:

Superior Corrosion Resistance: Stainless Steel 304, 304L, and 304H Pipes & Tubes provide excellent resistance to corrosion in various environments, ensuring longevity and reliability.

High Strength and Durability: These pipes and tubes maintain their mechanical properties even in harsh conditions, offering unmatched strength and durability.

Versatile Applications: Stainless Steel 304 Pipes & Tubes find applications in diverse industries such as chemical processing, oil and gas, food and beverage, and pharmaceuticals, owing to their versatile properties.

Easy Fabrication: The alloy can be easily welded, formed, and machined, allowing for seamless fabrication and customization according to specific requirements.

Global Reach: Manilaxmi Industrial caters to clients worldwide, ensuring prompt delivery and exceptional service, regardless of geographical location.

Specification

Our Stainless Steel 304 Pipes & Tubes are available in various specifications to meet the exact requirements of our clients:

Grade: Stainless Steel 304, 304L, and 304H (UNS S30400, S30403, S30409)

Types: Seamless Pipes, Welded Pipes, Seamless Tubes, Welded Tubes

Standards: ASTM A312, ASTM A213, ASTM A269, ASTM A358, ASTM A554, ASTM A249, ASTM A270, DIN 1.4301, DIN 1.4306, DIN 1.4948

Sizes: Customizable sizes ranging from small diameter pipes to large diameter tubes

Finishes: Polished, Annealed and Pickled, Bright Annealed

Conclusion

Manilaxmi Industrial is your one-stop destination for high-quality Stainless Steel 304 Pipes & Tubes. With our commitment to excellence and customer satisfaction, we ensure that you receive products that meet and exceed your expectations. For inquiries or to place an order, please contact us at:

Email: [email protected]

Phone: +91-7710800415

Visit our website here to explore our range of Stainless Steel 304 Pipes & Tubes and experience unparalleled quality and service.

1 note

·

View note

Text

Stainless Steel 304L Flanges Manufacturers In Mumbai

Nascent Pipe & Tubes is associated with offering an unfathomable bundle of Tempered Steel 304/304L/304H Flanges as a Manufacturer, exporter, stockiest and supplier to our nuclear family and by and large clients. Solidified Steel 304L is the low carbon translation of 304. It doesn't need post-weld hardening as is extensively utilized as a piece of liberal gage segments (over around 6mm). Treated Steel Grade 304H with its higher carbon content tracks down application at raised temperatures.

For more Information

Visit website:

Email: [email protected]

Contact: 8779038854

#Stainless Steel 304/304L/304H Flanges#Stainless Steel 304/304L/304H Flanges Manufacturers#Stainless Steel 304/304L/304H Flanges Suppliers#Stainless Steel 304/304L/304H Flanges Stockists#Stainless Steel 304/304L/304H Flanges Exporters#Stainless Steel 304/304L/304H Flanges Manufacturers In India#Stainless Steel 304/304L/304H Flanges Suppliers In India#Stainless Steel 304/304L/304H Flanges Stockists In India#Stainless Steel 304/304L/304H Flanges Exporters In India#Stainless Steel 304/304L/304H Flanges Manufacturers in Mumbai#Stainless Steel 304/304L/304H Flanges Suppliers in Mumbai#Stainless Steel 304/304L/304H Flanges Stockists in Mumbai#Stainless Steel 304/304L/304H Flanges Exporters in Mumbai

0 notes

Text

Jay Steel Corporation leading Manufacturer and Supplier of Stainless Steel

Jay Steel Corporation is the largest Manufacturer, Supplier and Exports of Stainless Steel Round Bar Strip, Sheet & Plate, Wire Mesh, Pipes, Tubes, Pipe Fittings, Flanges, Welding Rod, Fasteners, Process Equipment and other steel product supplier in France, Turkey, Saudi Arabia, Tunisia, Qatar and UAE.

#Stainless Steel 304/304L/304H Round Bar#Stainless Steel 316/316L/316Ti Round Bar#Stainless Steel 904L Round Bar#Tube & Pipe#Stainless Steel 304H plate

0 notes

Text

Stainless Steel 304/304l/304h Pipes & Tubes Manufacturers

K M D Steel And Tube is a leading manufacturers, supplier, stockists and exporter for SS 304/304L/304H Pipes & Tubes. This Stainless Steel Pipes and Tubes display great corrosion imperviousness to an extensive variety of destructive situation and it also shows best machinabilityand have superb weld capacity attributes with or without the expansion of filler metals. The SS 304/304L/304H Pipes & Tubes are most commonly used in boilers, heat exchangers, petroleum, condensers, petroleum refineries, pipelines, steam exhausts, cooling towers, electric generation plants. The Pipes & Tubes are made of best quality raw material and are of international quality standard and this helps us to have high demand in the market from the customers. The Pipes & Tubes are made in different shapes, size, thickness and dimension and are supplied to customers as per their needs and requirement. When it comes to packaging of products it is done with great care because we know the ups and downs during import and export of product hence we make sure the Pipes and Tubes are delivered to customers without any damages in good condition.

Stainless Steel 304/304l/304h Pipes & Tubes, Stainless Steel 304/304l/304h Pipes & Tubes Manufacturers, Stainless Steel 304/304l/304h Pipes & Tubes Suppliers, Stainless Steel 304/304l/304h Pipes & Tubes Exporters, Stainless Steel 304/304l/304h Pipes & Tubes Stockists.

0 notes

Text

304 Stainless Steel Market to Observe Strong Growth to Generate Massive Revenue in Coming Years

Latest business intelligence report released on Global 304 Stainless Steel Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand 304 Stainless Steel market outlook.

List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are ArcelorMittal (Luxembourg),Acerinox (Spain),AK Steel (United States),Knight Precision Wire (United Kingdom),Lenntech (The Netherlands),Michlin Metals Inc. (United States),Nippon Steel Corp. (Japan),POSCO (South Korea),Rolled Metal Products (United States),Sandmeyer Steel (Pennsylvania)

304 stainless steel is widely used across various industry verticals. This is majorly known for its composition that includes 18 percent chromium, and 8 percent nickel. 304-grade stainless steel has good forming and welding properties as well as strong corrosion resistance and strength. It has good durability, it can easily be formed into a variety of shapes. 304-grade stainless steel's major applications are the food industry. It is majorly suited for brewing, milk processing, and winemaking. this grade steel is majorly also found in sinks, tabletops, coffee pots, utensils, and other appliances. It has the ability to withstand corrosion that can be caused by a variety of various chemicals found in fruits, meat, and milk.

Key Market Trends: High Adoption from Mining Industry

Opportunities: Rapid Development in Cooking Appliances

High Growth in Food Industry

Market Growth Drivers: Growing Demand for Flat Products Because of the Increase in Consumption of Cold Rolled Products

Increase in Stainless Steel Production and Growing Application in Pre-Engineered Buildings

Challenges: High Cost Associated with Product Manufacturing such as 304 Stainless Steel Pipe

The Global 304 Stainless Steel Market segments and Market Data Break Down by Application (Chemical Industry, Food Industry, Domestic Uses, Architectural Uses, Industrial Uses, Automotive and Aerospace Industry, Hospitals, Commercial Industry, Others), Supplied Form (Sheet, Strip, Tube, Quarto plate, Bar, Fittings & Flanges, Pipe, Plate), Grade (304L Stainless Steel, 304H Stainless Steel)

Presented By

AMA Research & Media LLP

0 notes

Text

What are Flanges and their types?

Flanges are an essential component of any piping system, as they provide a secure and leak-free connection between two pipes or valves. As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP understands the importance of choosing the right type of flange for your application.

In this blog post, we will cover everything you need to know about flanges, including their types, materials, and applications.

Before we dive into the details, let's start with the basics!

Introduction

Flanges are mechanical connectors used to join two pipes or valves. They are usually made of steel, and their main purpose is to provide a tight and leak-free seal between the two parts. Flanges come in various types and sizes, and choosing the right type of flange is essential for the safety and efficiency of your piping system.

Types of Flanges?

Flanges come in several types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Each type has its unique characteristics and applications, and selecting the right one will depend on several factors, such as pressure ratings, temperature ratings, size, material compatibility, and cost.

● Weld Neck Flanges

Weld neck flanges are the most common type of flange, known for their high durability and strength. They are welded to the pipe or valve, making them ideal for high-pressure and high-temperature applications.

● Slip-On Flanges

Slip-on flanges are easy to install and remove, making them ideal for applications that require frequent maintenance. They slide over the pipe or valve and are then welded or bolted in place.

● Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges, but they are welded only on the outer side of the flange, leaving the inner side free of welding marks. They are ideal for smaller-sized pipes and low-pressure applications.

● Lap Joint Flanges

Lap joint flanges are used when a piping system requires dismantling frequently. They are also ideal for applications that require easy access to the pipe or valve.

● Threaded Flanges

Threaded flanges are designed to be screwed onto the pipe or valve, making them ideal for applications that require easy installation and removal. They are commonly used in low-pressure applications.

● Blind Flanges

Blind flanges are used to seal the end of a pipe or valve. They are commonly used for pressure testing and maintenance purposes.

Materials & Grades Available In Flanges with Bullion Pipes & Tubes LLP

Flanges can be made of various materials & Grades, such as,

●

Stainless Steel - 904L Flanges, 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 Flanges

● Hastelloy Flanges - C22, B2 Flanges, C276 Flanges

● Carbon Steel Flanges - ASTM A350 15LF1, LF2 CL1/CL2, LF3 CL1/CL2 Carbon Steel Flanges

● Nickel Alloy - 200/201

● Duplex Steel Flanges - Duplex UNS S32205/31803 Flanges

● Alloy Steel Flanges - P5, P9, P11, P12, P22, P91 Flanges

● Super Duplex Steel - UNS S32750/S32760 Flanges

● Titanium Alloys - Gr 2 Flanges, Gr 5 Flanges, Gr 7 Flanges

● Aluminium Flanges - 5052 Reducing Flanges, 5082 Flanges, 5082 Flanges, 6063 SORF Flanges, 6082 Blind Flanges, 2024 Aluminum Weld Neck Flanges, and 5052 Threaded Flanges.

● Tantalum Flanges - ASTM B521 Tantalum Flanges, Spectacle Blind Flanges, Orifice Flange, Ta-10W Flanges, Tantalum UNS R05200 Flanges, ASTM B365 Ta2.5W Flanges

● Monel Flanges - Monel K500 Flanges, Monel 400 Flanges

● Alloy 20 Flanges - Alloy 20 RTJ Flange, Alloy 20 WNRF Flanges, Alloy UNS N08020 Pipe Flanges, Alloy 20 Weld Neck Flange, Alloy 20 Nipo Flanges, ASTM B462 Alloy Threaded Flanges, Alloy 20 Spectacle Blind Flanges, Alloy 20 Industrial Flanges, and UNS N08020 Alloy 20 Forged Flanges

● SMO 254 Flanges

● Inconel Flanges - Inconel 718, 600, 601 and 625 Flanges

● Incoloy Flanges - 825, 800/800H/800HT Flanges

Choosing the right material for your flange will depend on several factors, such as the application's temperature, pressure, and corrosion resistance requirements.

Factors to Consider When Selecting Flanges

Selecting the right flange for your application can be challenging, as there are several factors to consider, such as pressure ratings, temperature ratings, size, material compatibility, and cost. At Bullion Pipes & Tubes LLP, we can help you choose the right flange for your application, ensuring safety and efficiency.

Flange Standard Ratings

Flanges come in various standard ratings, such as ANSI, API, DIN, and JIS. These ratings determine the flange's pressure-temperature rating and its compatibility with other components in the piping system.

Flange Installation

Proper flange installation is essential for the safety and efficiency of your piping system. It involves several steps, such as preparation of the piping system, installation of the flanges, flange tightening process, flange alignment, and testing and inspection.

Maintenance and Repair of Flanges

Maintaining and repairing flanges is critical for the longevity and safety of your piping system. Regular inspections, leak checks, and maintenance can help detect any potential issues before they become a more significant problem.

Applications of Flanges

Flanges have a wide range of applications in various industries, including:

● Oil and Gas Industry

● Petrochemical Industry

● Chemical Industry

● Power Generation Industry

● Water Treatment Industry

They are used in various applications, including HVAC systems, plumbing, and firefighting systems.

Why Choose Bullion Pipes & Tubes LLP for Flanges?

As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP offers a wide range of flanges made from high-quality materials. We provide customized solutions to meet our customers' specific needs, and our flanges are available in various sizes, ratings, and materials.

We have been providing high-quality flanges to various countries, such as Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany, and our products are known for their durability, reliability, and safety.

Conclusion

Flanges are a critical component of any piping system, and selecting the right type of flange for your application is essential for safety and efficiency. Choosing a reliable and trustworthy supplier like Bullion Pipes & Tubes LLP can ensure that you get high-quality flanges that meet your specific requirements.

0 notes