#Stainless Steel 347/347H Pipes & Tubes Stockists In India

Text

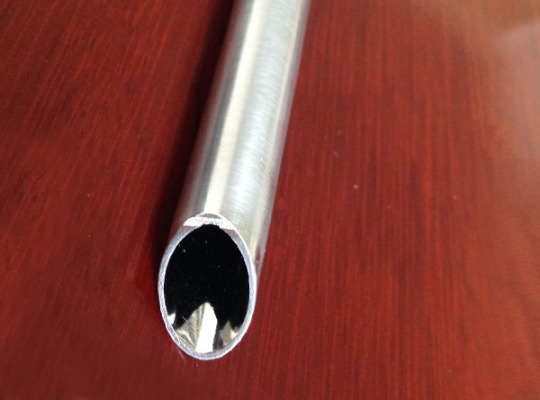

Stainless Steel 347H Pipes & Tubes Suppliers In India

Introduction: In the realm of industrial infrastructure, Stainless Steel 347H pipes and tubes are integral components, essential for fluid conveyance and structural integrity, particularly in high-temperature and corrosive environments. As industries in India endeavor for excellence and reliability in their operations, securing dependable suppliers for Stainless Steel 347H pipes and tubes becomes imperative. This article delves into the significance of Stainless Steel 347H pipes and tubes, elucidating why they are indispensable and highlighting the countries that rely on imports of these products.

Why you should use Stainless Steel 347H pipes and tubes:

Elevated Temperature Resistance: Stainless Steel 347H is specifically engineered for high-temperature applications, offering superior resistance to oxidation and corrosion at elevated temperatures. This property makes it ideal for use in environments where exposure to high heat and thermal cycling is prevalent, such as heat exchangers, furnace components, and exhaust systems.

Corrosion Resistance: Stainless Steel 347H pipes and tubes exhibit excellent resistance to corrosion, particularly in environments containing chlorides and other corrosive substances. This resistance ensures longevity and reliability, even in harsh operating conditions encountered in chemical processing, petrochemical, and aerospace industries.

High Strength and Durability: Stainless Steel 347H pipes and tubes possess high tensile strength and durability, providing structural integrity and withstanding high-pressure conditions at elevated temperatures. This characteristic ensures the safe and efficient transport of fluids and gases in demanding industrial processes.

Creep Resistance: Stainless Steel 347H demonstrates excellent creep resistance, maintaining dimensional stability and mechanical properties under prolonged exposure to elevated temperatures. This property ensures long-term performance and reliability in applications where thermal expansion and contraction occur.

Weldability and Formability: Stainless Steel 347H is readily weldable and formable, allowing for easy fabrication into various shapes and sizes. This versatility in fabrication makes it adaptable to a wide range of industrial applications, providing customized solutions to meet specific requirements.

Countries which import Stainless Steel 347H pipes and tubes from India:

United States: The United States imports Stainless Steel 347H pipes and tubes from India for various industrial applications, including chemical processing, oil and gas industries, and power generation.

United Kingdom: The United Kingdom relies on imports of Stainless Steel 347H pipes and tubes from India for use in architectural structures, automotive exhaust systems, and aerospace components.

Germany: Germany imports Stainless Steel 347H pipes and tubes from India for applications in automotive manufacturing, machinery construction, and industrial furnace components, where elevated temperature performance and corrosion resistance are crucial.

United Arab Emirates: The UAE imports Stainless Steel 347H pipes and tubes from India for use in construction, oil and gas refineries, and desalination plants, where they provide reliable performance in corrosive and high-temperature environments.

Conclusion: Stainless Steel 347H pipes and tubes play a crucial role in various industries, offering superior high-temperature resistance, corrosion resistance, strength, and weldability. Their versatility and reliability make them essential for fluid transport and structural applications in challenging environments. Industries in India and worldwide must prioritize sourcing Stainless Steel 347H pipes and tubes from trusted suppliers to ensure the integrity and efficiency of their operations, particularly in high-temperature and corrosive environments.

#Stainless Steel 347/347H Pipes & Tubes Manufacturers#Stainless Steel 347/347H Pipes & Tubes Suppliers#Stainless Steel 347/347H Pipes & Tubes Stockists#Stainless Steel 347/347H Pipes & Tubes Exporters#Stainless Steel 347/347H Pipes & Tubes Manufacturers In India#Stainless Steel 347/347H Pipes & Tubes Suppliers In India#Stainless Steel 347/347H Pipes & Tubes Stockists In India#Stainless Steel 347/347H Pipes & Tubes Exporters In India

0 notes

Text

Stainless Steel Electropolished Tubes Exporters In India

Stainless Steel Electropolished Tubes Supplier In India, SS Electropolished Tubes Exporter Electropolished Stainless Steel Tubing, Electropolished Tubes, Electropolished Tube Fittings 304/304l Electropolished Pipes, 316/316l Electropolished Pipes, Seamless/Welded EP Pipes

Stainless Steel Electropolished Pipes Manufacturer, Electropolished Tubes Exporter, High Purity Stainless Steel Tubing, Electropolished Stainless Steel Tubes, EP Tubes Processor in Mumbai, SS Electropolished Tubes in India, SS 304L Electropolished Tubes, SS 316L Electropolished Pipes, SS 904L Electropolished Tubing Suppliers, Electropolished Tubes Suppliers in India, Dairy Tubes, Tubes for Pharma Industry, Electropolished Tubes for Food Processing Industry, Best Quality EP Tubes in India, Mumbai

Kobs India is a leading processor and supplier of high quality electropolished or mechanically polished stainless steel pipes, electropolished tubes in all major stainless steel grades including 304/304L and 316/316L. Electropolishing is also commonly known as electrochemical polishing or electrolytic polishing. EP stainless steel tubes are generally made by carrying out the electropolishing process on high quality seamless and welded stainless steel tubes.

Standards Specification:

Size : ½”Inch and 24”Inch

Specifications : ASTM A249, A269, A270

Grades: : 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Length: : Up to 6 meters, custom cut lengths

Thickness: 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish:BA Finish inside and outside, Electropolished finish inside and outside

Specifications : ASTM A312 / ASTM SA312

Material & Grade :

Stainless Steel :

Grade: 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Product Features:

Durability

High strength

Effective functionality

Sturdy construction

Corrosion resistance

Dimensional accuracy

Electropolished Tubes Manufacturer, Electropolished Tubes Manufacturers, Electropolished Tubes Suppliers, Electropolished Tubes Exporters, Electropolished Tubes Stockists.

Electropolished Tubes in Mumbai, Electropolished Tubes Manufacturers in Mumbai, Electropolished Tubes Suppliers in Mumbai, Electropolished Tubes Exporters in Mumbai, Electropolished Tubes Stockists in Mumbai.

Electropolished Tubes in India, Electropolished Tubes Manufacturers in India, Electropolished Tubes Suppliers in India, Electropolished Tubes Exporters in India, Electropolished Tubes Stockists in India.

Manufacturing Process :

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

Product Usage & Application :

Useful in Paper & Pulp Companies

Useful in High Pressure Applications

Useful in Oil and Gas Industry

Useful in Chemical Refinery

Useful in Pipeline

Useful in High Temperature Application

Useful in Water Pipe Line

Useful in Nuclear Power Plants

Useful in Food Processing and Dairy Industries

Useful in Boiler & Heat Exchangers

Packing :

Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Shrink-wrapped

Carton boxes

Wooden pallets

Wooden boxes

Wooden crates

Why Choose Us :

You can get the perfect material according to your requirement at the least possible price.

We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

e guarantee to give a response within 24hours(usually in the same hour)

You can get stock alternatives, mill deliveries with minimizing manufacturing time.

We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Tests we carry out (including both Destructive and Non-Destructive) :

Positive material recognition

Mechanical examining like tensile, Elongation and reduction of area.

Large-scale test

Chemical examination-Spectro analysis

Firmness test

Pitting protection test

Small tests

X-ray test

Impact analysis

Eddy current examining

Hydrostatic analysis

Prompt test

For more details:

Website - http://kobsindia.in/

Phone No. - 9819523999

Email - [email protected]

#Electropolished Tubes in India#Electropolished Tubes Manufacturers in India#Electropolished Tubes Suppliers in India#Electropolished Tubes Exporters in India#Electropolished Tubes Stockists in India.

0 notes