#Stainless Steel Parts Manufacturers in India

Text

Top 6 Stainless Steel Parts Manufacturers in India

In this Comprehensive Guide, delve into the significance of stainless steel in India’s manufacturing sector and explore its applications across diverse industries. Learn about stainless steel’s unique properties, including corrosion resistance and durability, and its role in shaping modern engineering and design. Discover how stainless steel is utilized in construction, automotive manufacturing, healthcare, food processing, and more, with specific examples highlighting its versatility. Explore profiles of the Top Stainless Steel Parts Manufacturers in India, such as Meck Industries, Tata Steel Ltd., Jindal Steel and Power, JSW Steel, Metal Forge India, and Ratnamani Metals & Tubes Ltd., showcasing their expertise, commitment to quality, and contributions to the industrial landscape. Whether you’re seeking precision components or customized solutions, these trusted manufacturers drive efficiency, reliability, and sustainability across various sectors.

Read More: Top 6 Stainless Steel Parts Manufacturers in India

#Stainless Steel Parts Manufacturers in India#Stainless Steel Components Manufacturers in India#Top Stainless Steel Parts Manufacturers in India#Best Stainless Steel Parts Manufacturers in India#Top Stainless Steel Components Manufacturers in India#Best Stainless Steel Components Manufacturers in India

0 notes

Text

The Role of Strut Mounts in Automotive Safety and Longevity

Have you ever wondered how cars stay together despite the constant pressure and weight they carry?

The automotive industry has always been at the forefront of investing in cutting-edge technology and engineering to ensure the safety and longevity of its products. A critical component that has gained significant importance in recent years is the strut mount.

From providing stability and absorbing shocks to reducing noise and vibrations, strut mounts play a crucial role in keeping drivers safe and comfortable while driving. These sturdy and corrosion-resistant components provide an array of benefits that ensure the seamless functioning of cars on the road.

Let's delve deeper into the importance of strut mounts in the world of automotives.

What are Strut Mounts?

Before we dive into the benefits of strut mounts, let's define what they are. Strut mounts are the parts that connect the strut assembly to the chassis of your car. They are typically made of rubber or polyurethane and are designed to absorb shock and vibration while allowing for smooth movement of the strut assembly.

Advantages of Strut Mounts in Automotive Design

Structural Integrity: The suspension system of a car is designed to handle a lot of stress and pressure, and the strut mount is a crucial component that helps distribute this load evenly. It ensures that the force of impact from the wheels and suspension is absorbed and distributed effectively, preventing any significant damage to the car's body.

Corrosion Resistance: Due to its location within the suspension system, the strut mount is exposed to a lot of harsh environmental conditions. Salt, water, and other chemicals can quickly corrode the strut mount, leading to the failure of the suspension system and potentially causing a safety hazard on the road. Therefore, strut mounts are made of materials that can withstand such conditions, ensuring that they remain functional and safe over time.

One material that is often used for strut mounts is stainless steel. Stainless steel casting is a popular method for producing strut mounts. Stainless steel is highly resistant to corrosion, and it is also very strong and durable, able to withstand the harsh environmental conditions that strut mounts are exposed to.

Improve Ride Quality: Strut mounts play a significant role in the ride quality of your vehicle. By absorbing shock and vibration, they help to reduce noise and improve comfort. This is particularly important for drivers who spend a lot of time on the road or who frequently drive on rough terrain.

Handling and Performance: By providing a stable pivot point for the suspension system, strut mounts improve the vehicle's stability and balance, reducing body roll and improving cornering ability. This enhances the driver's control over the vehicle and ensures a smooth and comfortable ride for passengers.

Over to You

Strut mounts play a critical role in ensuring the structural integrity and corrosion resistance of vehicles. With the constantly changing and challenging road conditions, it is essential that the components of a vehicle's suspension system, including strut mounts, are designed to withstand the rigors of daily use.

If you are looking for high-quality strut mounts for your vehicle, consider Sujan Industries. As one of the leading defence parts manufacturers in India and a top supplier of stunt mounts, Sujan Industries is committed to providing customers with products that are durable, reliable, and designed to enhance the performance and safety of their vehicles. To learn more, be sure to visit their website.

0 notes

Text

Mild Steel Flanges Details

Why MS Flanges Matter

MS flanges, short for Mild Steel flanges, are essential components in the industrial and construction sectors. These flanges, made from mild steel, are prized for their robust strength, cost-efficiency, and versatility. They serve as crucial connectors, fastening pipes, valves, and various machinery, ensuring that everything stays tightly sealed and leak-free.

The Appeal of Mild Steel

Mild steel is a top choice for many due to its durability, ease of use, and affordability. It offers a great balance between performance and cost, making it resistant to moderate corrosion while withstanding significant pressure. Whether you're working on an industrial project or a construction site, mild steel is a reliable material. For the best MS flanges in India, look no further than Udhhyog, a leading manufacturer in the field.

A Closer Look at Different MS Flanges

Slip-On Flanges: Easy and Effective

Slip-on flanges are known for their ease of installation—they slip over the pipe and are welded into place. This makes them perfect for applications where precise fitting is key. They’re commonly used in low-pressure environments and offer an economical solution for various projects.

Weld Neck Flanges: Built for Performance

Weld neck flanges feature a long, tapered neck that smoothly transitions from the pipe to the flange. This design reduces stress concentrations, making these flanges ideal for high-pressure and high-temperature applications. They are often used in critical systems where reliability and strength are crucial.

Blind Flanges: Sealing with Confidence

Blind flanges are designed to close off the end of a pipe or vessel, with no central hole. They are perfect for sealing off pipelines or openings, providing a strong barrier for maintenance or potential expansion in the future.

Socket Weld Flanges: Strong and Reliable

Socket weld flanges have a recessed area where the pipe fits before being welded. This design ensures a smooth bore and a secure connection, making them suitable for high-pressure applications. They’re commonly used in industries where a strong, leak-proof joint is essential.

Real-World Applications of MS Flanges

MS Flanges in Industrial Operations

In industrial environments, MS flanges are critical for connecting various machinery components, such as pumps and valves. They ensure that these parts are securely joined, helping to maintain efficient operations and prevent leaks.

Their Role in the Construction Industry

MS flanges are vital in construction projects, where they link structural steel components. They provide the necessary strength to handle heavy loads and ensure that different parts of a structure are firmly connected.

Crucial for Piping Systems and Equipment

MS flanges play a key role in piping systems, connecting pipes, valves, and other fittings. They help maintain the system's integrity, making it easier to perform maintenance and repairs when needed.

Why Choose MS Flanges?

Cost-Effective and High Value

MS flanges offer a cost-effective alternative to more expensive materials like stainless steel. Despite their lower cost, they do not compromise on quality, making them a popular choice for various applications.

Durability and Robustness

Mild steel flanges are known for their durability and strength. They are built to withstand various pressures and temperatures, making them suitable for a wide range of industrial and construction uses.

Simple Installation and Maintenance

MS flanges are designed for easy installation and maintenance. Their straightforward design makes them easy to assemble and disassemble, which can save both time and effort during installation and upkeep.

How to Select the Right MS Flange

Important Considerations

When selecting an MS flange, it’s essential to consider the type, pressure rating, and compatibility with other materials. Choosing the right flange ensures a secure connection and optimal performance for your specific application.

Sizing and Specification Essentials

Accurate sizing is crucial for a secure and efficient connection. Refer to industry standards and specifications to ensure you select the right size and type of flange for your project.

This version offers another fresh perspective, ensuring the content remains original and engaging while highlighting the key aspects of MS flanges.

2 notes

·

View notes

Text

Bellows, Boots, Rubber Bellows, Manufacturer, Mumbai, India

Bellows, Boots, Rubber Bellows, Rubber Bellows Manufacturer, Anti Vibration Mounts, Rubber Anti Vibration Mounts, Anti Vibration Mounts Manufacturer, Anti Vibration Mount Supplier, Mumbai, India.

Rubber Products, Moulded Rubber Parts, Extruded Rubber Parts, Sponge Moulded Parts, Metal Bonded Parts, Manufacturers Of Rubber Components, Manufacturers Of Moulded Rubber Parts, Manufacturers Of Extruded Rubber Parts, Rubber Moulded Parts, 'O' Rings, Oilseal, U Seal, V Seal, Chevron Packing For Pumps, Hydraulics Seal, Mechanical Seal, Neoprenen Rubber, Nitrile Rubber, Epdm Rubber, Hypalon Rubber, FKM Rubber, Natural Rubber, Polymers, Flourinated Rubber, FKM Rubber, Silicone Rubber, Polyurethane Rubber, Ethylene Propylene Terpolymers, Natural Rubber, Synthetic Rubber, Chemical Resistance, O Rings, U Seals, V Seals, Lip Seals, Wiper Seals, Oil Seals, Diaphragms, Electrical Control Valves, Pneumatic Control Valves, Pressure Regulators, Valve Positioner, Ball & Butterfly Valve, Solenoid Valve With Brass, Stainless Steel Stud, Fabric, Nylon, Canvas, Rayoncord, Wiremess

2 notes

·

View notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

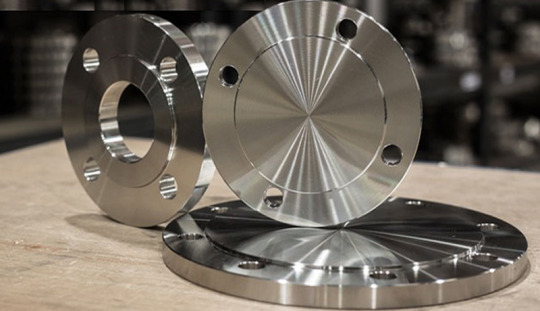

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Stainless Steel 316H Blind Pipe Flanges in India

A Blind Flange is a plate for covering or closing the end of a pipe. A flange joint is a connection of pipes, where the connecting pieces have flanges by which the parts are bolted together.

Stainless Steel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

For more information

Call : +91-9819523999

Mail ; [email protected]

Visit us on : http://kobsindia.in/stainless-steel-blind-flange.html

3 notes

·

View notes

Text

Aluminum Market: Products, Applications & Beyond

Aluminum is a versatile element with several beneficial properties, such as a high strength-to-weight ratio, corrosion resistance, recyclability, electrical & thermal conductivity, longer lifecycle, and non-toxic nature. As a result, it witnesses high demand from industries like automotive & transportation, electronics, building & construction, foil & packaging, and others. The high applicability of the metal is expected to drive the global aluminum market at a CAGR of 5.24% in the forecast period from 2023 to 2030.

Aluminum – Mining Into Key Products:

Triton Market Research’s report covers bauxite, alumina, primary aluminum, and other products as part of its segment analysis.

Bauxite is anticipated to grow with a CAGR of 5.67% in the product segment over the forecast years.

Bauxite is the primary ore of aluminum. It is a sedimentary rock composed of aluminum-bearing minerals, and is usually mined by surface mining techniques. It is found in several locations across the world, including India, Brazil, Australia, Russia, and China, among others. Australia is the world’s largest bauxite-producing nation, with a production value of over 100 million metric tons in 2022.

Moreover, leading market players Rio Tinto and Alcoa Corporation operate their bauxite mines in the country. These factors are expected to propel Australia’s growth in the Asia-Pacific aluminum market, with an anticipated CAGR of 4.38% over the projected period.

Alumina is expected to grow with a CAGR of 5.42% in the product segment during 2023-2030.

Alumina or aluminum oxide is obtained by chemically processing the bauxite ore using the Bayer process. It possesses excellent dielectric properties, high stiffness & strength, thermal conductivity, wear resistance, and other such favorable characteristics, making it a preferable material for a range of applications.

Hydrolysis of aluminum oxide results in the production of high-purity alumina, a uniform fine powder characterized by a minimum purity level of 99.99%. Its chemical stability, low-temperature sensitivity, and high electrical insulation make HPA an ideal choice for manufacturing LED lights and electric vehicles. The growth of these industries is expected to contribute to the progress of the global HPA market.

EVs Spike Sustainability Trend

As per the estimates from the International Energy Agency, nearly 2 million electric vehicles were sold globally in the first quarter of 2022, with a whopping 75% increase from the preceding year. Aluminum has emerged as the preferred choice for auto manufacturers in this new era of electromobility. Automotive & transportation leads the industry vertical segment in the studied market, garnering $40792.89 million in 2022.

In May 2021, RusAl collaborated with leading rolled aluminum products manufacturer Gränges AB to develop alloys for automotive applications. Automakers are increasingly substituting stainless steel with aluminum in their products owing to the latter’s low weight, higher impact absorption capacity, and better driving range.

Also, electric vehicles have a considerably lower carbon footprint compared to their traditional counterparts. With the growing need for lowering emissions and raising awareness of energy conservation, governments worldwide are encouraging the use of EVs, which is expected to propel the demand for aluminum over the forecast period.

The Netherlands is one of the leading countries in Europe in terms of EV adoption. The Dutch government has set an ambitious goal that only zero-emission passenger cars (such as battery-operated EVs, hydrogen FCEVs, and plug-in hybrid EVs) will be sold in the nation by 2030. Further, according to the Canadian government, the country’s aluminum producers have some of the lowest CO2 footprints in the world.

Alcoa Corporation and Rio Tinto partnered to form ELYSIS, headquartered in Montréal, Canada. In 2021, it successfully produced carbon-free aluminum at its Industrial Research and Development Center in Saguenay. The company is heralding the beginning of a new era for the global aluminum market with its ELYSIS™ technology, which eliminates all direct GHG emissions from the smelting process, and is the first technology ever to emit oxygen as a byproduct.

Wrapping Up

Aluminum is among the most widely used metals in the world today, and is anticipated to underpin the global transition to a low-carbon economy. Moreover, it is 100% recyclable and can retain its properties & quality post the recycling process.

Reprocessing the metal is a more energy-efficient option compared to extracting the element from an ore, causing less environmental damage. As a result, the demand for aluminum in the sustainable energy sector has thus increased. The efforts to combat climate change are thus expected to bolster the aluminum market’s growth over the forecast period.

#Aluminum Market#aluminum#chemicals and materials#specialty chemicals#market research#market research reports#triton market research

4 notes

·

View notes

Text

High Nickel Alloy Pipes Manufacturer in India - Bright Steel.

Bright Steel Centre is one of the Largest High Nickel Alloy Pipes Manufacturer in India. We have been an essential part of the growth and development of the Indian market and quality exports. We manufacture Incoloy Alloy Seamless Pipes in various sizes and shapes and with different specifications per our valuable clients' requirements. High Nickel Alloy Pipes have very high corrosion resistance and are becoming more cost-effective frequently. Our Supplied High Nickel Alloy Pipe is known for their reliability and quality worldwide.

Bright Steel Centre is a leading High Nickel Alloy Pipes Manufacturer in India. High Nickel Alloy Pipes are available in various types, such as Nickel / Incoloy / Monel / Hastelloy Pipes. They are also available in various forms such as Round, Square, Rectangular, Hydraulic, and many more. Incoloy Alloy Welded Pipes size range from 1/8″NB TO 30″NB IN. We have a professional team to maintain the quality of High Nickel Alloy Seamless Pipe and other products throughout the manufacturing and supply, i.e., selecting high-quality raw materials to process into a finished product, marking, storage, packaging, and transportation. We also supply Stainless Steel Pipes, which are available in other grades and materials.

Product source: Nickel Alloy Pipes Manufacturer in India

Website: https://brightsteelcentre.com/

Email: [email protected]

2 notes

·

View notes

Text

Introduction of Needle Valve Manufacturers

The needle valve is also known as a plunger valve. It helps to control pressure in the pipe and prevents the pipe from being damaged by the pressure. The needle valve is located at the end of the pipe and has a small hole in it. The Needle Valve Manufacturers in Mumbai are used to control the pressure in the pipe.

It is a small, dislike-like device that is inserted into a pipe to close it. The needle valve is better for small-diameter pipes, such as those found in a shower or a toilet, because it doesn't require any additional parts to work. It is also better for pipes that are already closed, like those found in a sink or a bath, because it doesn't require any additional work to open them.

This allows the builder to pre-pressurize a pipe before the plumber arrives, and then release the pre-pressurization when the plumber arrives. This helps to avoid the potential cost and inconvenience of a service call by the plumber, and also prevents damage to the pipes if the pre-pressurization is not released between customers. The valve manufacturer designedaneedle valve in India as per the requirement of customers, and industries needs.

Needle valves are a type of valve that is distinct from the other valves commonly used in plumbing and industrial applications. By using a long, threaded stem and a sharp, tapered needle, these valves can provide precise control over the flow of fluids, compared to the more binary actuation of typical valves. This needle valve is composed of a screw-in body that contains a perforated seat and a needle-shaped valve stem, which is usually made from stainless steel. The precision and accuracy of the valve make it popular for applications like controlling pressure and flow in chemical processing plants.

Needle valves are different from other valves, as they possess a long, slender cone-shaped disk that is used to regulate the flow of fluids. The disk is perforated with multiple holes which are used to control the rate of flow. This is why Needle Valve Manufacturers in Chennai are often used in industries where precise control is required over the flow rate of fluids. Needle valves are also known for their superior performance in high-temperature and pressurized applications, making them perfect for the extreme conditions found in many industrial settings.

There are few points to be considered:

The needle valve in the nozzle is shut off so that no fluid can leak out, and so that any extra fluid in the system is forced back into the system to help prevent contamination.

The needle valve is a small valve used to regulate the flow of fluid. It consists of a small steel disc with a hole (called a needle) through which fluid flows, and a spring-loaded valve stem that opens when the needle is pushed.

The operation of the needle valve is easy and simple. You only need to press the button and the valve will open. This makes it a great option for people who are not comfortable with traditional faucet valves. You can also adjust the flow of water with the needle valve, which is not possible with faucet valves.

The needle valve has a small size diameter and can be closed to control the flow of solution through it. The needle valve is of small size, it is available to customers as per requirement need to approach theNeedle valve manufacturer.

One while selecting a needle valve one should consider material, temperature & pressure rating, size of the valve, and many other criteria as per their requirement.

The role of the needle valve is flow control, pump start, pressure regulation, and turbine by pass, flow discharge, air regulation, reserve inlet, etc many other roles.

A needle valve is used to regulate water pressure, flow rate, reservoirs, power plant, and water distribution and by many industries as per their requirement.

Yakshita Engineering is the leading needle valve manufacturer and has great experience in manufacturing of valves in India.

#Needle valve manufacturers in Mumbai#Needle valve manufacturer in Chennai#Needle valve manufacturer in India

2 notes

·

View notes

Text

Square Profile Bar - Everything Need To Know

Square Profile Bars are steel rods that are mainly used in auto and construction projects. The stainless steel square profile bars are anti-abrasive and anti-corrosive which makes them appropriate for joints in commercial medical environments. Preferred applications of square profile barsinclude mounting decorative ironwork, gates, and safety barriers around establishments.

If you are in search of stainless steel square profile bars of the highest quality, please look no further. Matta Drawing Works is India’s leading manufacturer of highly durable stainless steel square profile bars in dozens of grades and sizes, including 304l, 316l, and 303.

What is a square profile bar?

A square profile bar, also known as square steel, squares, and the square metal bar is a multipurpose steel section highly used for manufacturing and repairs. The general-purpose square profile bar is a part of our light and re-rolled section, making it suitable for most commercial projects.

If you are looking for great quality Stainless Steel square profile bars then you have come to the right place. We are equipped with a variety of grades, sizes, and finishes to suit all your requirements whether you are a commercial business owner or a domestic customer. Matta Drawing Works is the No.1 provider of square profile bars and other products, in Grades 304, 316, and 303, providing a cutting service with a quick turnaround and 1st class polishing service.

What Makes Stainless Steel Square Profile Bar Irreplaceable?

Several reasons make stainless steel bright square profile bar irreplaceable. Whether concrete, wood, or other synthetic fibers are found in the surrounding area, the anti-corrosion qualities, durability, strength, and dependability make the stainless steel square profile bar remain unmatched. The size of the square profile bars determines its application space. These bars have a wide range of uses and are available in various grades.

Some Major Properties Of Stainless Square Bar

● Strength to withstand any physical or chemical conditions.

● High resistance against extreme climatic conditions.

● Cost-effective as well as durable.

Features

The Stainless Steel square profile bars are used because of the high strength of the bar. The square shape is geometrically stronger and is able to handle stress more than the round bars. Therefore, the material is used in pressure vessel applications and general corrosive services under specifications like the ASTM A276 Stainless Steel 316 squareprofile bar. The different polishes such as the bright, black, and polished square profilebars give them unique application abilities. The weight of the material depends on the width, diameter, length, and density of the grade of material used. The 304 and 316 grades of square profile barshave 8 grams per centimeter cube density. Major features of square profile bar include,

● High tensile strength

● 100% purity level

● Unmatched quality

● Superior performance

● Long work life

● Chemical resistance

● Corrosion resistance

Square profile bars made out of stainless steel, a strong and sturdy metal resistant to corrosion. They are also used for many purposes due to their flexibility and how easily they can be shaped.

Applications

Square profile bars is a solid metal bar that has a square cross-section. They are widely used in multiple industries for general assembly or manufacturing. Square profilebars are also used for general repairs of plant equipment and railings. Common applications of square profile barsinclude ornamental ironwork, gates, and protective barriers on windows. Other applications include,

● Automobile industries

● Machining equipment

● Machining Tools

● Heavy engineering

● Textile industries

● Fasteners

Conclusion

Matta Drawing Works is a stainless steel bright square profile bar...

2 notes

·

View notes

Text

Shaping the Future: The Rise of Stainless Steel Components Manufacturers in India

In recent years, India has emerged as a powerhouse in the manufacturing sector, particularly in the production of stainless steel components. This surge can be attributed to various factors, including technological advancements, evolving market demands, and a skilled workforce. Stainless steel components play a crucial role in numerous industries, including automotive, construction, and aerospace, due to their durability, corrosion resistance, and aesthetic appeal.

One of the key drivers behind the growth of stainless steel components manufacturing in India is the country's abundant availability of raw materials, particularly stainless steel. With the government's emphasis on initiatives like "Make in India," there has been a significant push to boost domestic manufacturing and reduce dependency on imports. This has led to the establishment of numerous stainless steel component manufacturing units across the country, catering to both domestic and international markets.

Amidst this growth, companies like Meck Industries have played a pivotal role in shaping the landscape of stainless steel component manufacturing in India. Established in 1990, Meck Industries has carved a niche for itself as a leading provider of precision turned parts. Specializing in CNC machining and automatic screw machines, Meck Industries has earned a reputation for its commitment to quality, reliability, and innovation.

With a state-of-the-art facility located in G.I.D.C. Makarpura, Vadodara, Meck Industries is well-equipped to meet the diverse needs of its clientele. The company's skilled workforce, coupled with its investment in cutting-edge technology, has enabled it to deliver superior stainless steel components to various industries, including electrical, automotive, and sheet metal.

Moreover, Meck Industries' dedication to customer satisfaction and continuous improvement has been instrumental in driving its growth and success. By adhering to stringent quality standards and embracing innovative manufacturing processes, Meck Industries has positioned itself as a trusted partner for stainless steel component requirements, both domestically and internationally.

Looking ahead, Meck Industries remains committed to pushing the boundaries of excellence in stainless steel component manufacturing. With a focus on leveraging technology, fostering innovation, and expanding its global footprint, Meck Industries is poised to continue shaping the future of the industry and contributing to India's manufacturing prowess on the world stage.In conclusion, the rise of stainless steel components manufacturers in India, exemplified by companies like Meck Industries, underscores the country's growing dominance in the global manufacturing arena. With a blend of tradition, innovation, and excellence, Indian manufacturers are poised to lead the way in shaping the future of stainless steel component manufacturing worldwide.

1 note

·

View note

Text

Mild Steel Pipes in Uttar Pradesh

Meghmani Metal Industries is a Manufacturer and Supplier of Mild Steel Pipes in Uttar Pradesh, India.

We established our company in 2011 in Ahmedabad, Gujarat, India.

Various industries widely use Mild Steel (MS) pipes because of their excellent strength, ductility, and weldability.

Low-carbon steel makes these pipes versatile and affordable, making them an ideal choice for various applications, including construction, plumbing, and infrastructure projects.

Types of MS Pipes:

ERW (Electric Resistance Welded) Pipes

Seamless Pipes

MS Black Pipes

MS Galvanized Pipes

Features:

Durability: Excellent mechanical properties for high pressure and temperature.

Corrosion Resistance: Can be treated or coated for enhanced durability.

Cost-Effectiveness: More affordable than stainless steel or plastic pipes.

Ease of Fabrication: Easily cut, welded, and shaped for design flexibility.

Applications of MS Pipes:

Construction: They are extensively used in building structures, scaffolding, and supporting frames.

Plumbing: MS pipes serve as a cost-effective option for water supply lines and drainage systems.

Automotive: Manufacturers utilize them to create automotive parts and frames due to their strength and lightweight nature.

Manufacturing: MS pipes are essential in creating machinery, equipment, and industrial tools.

Meghmani Metal Industries is a Manufacturer and Supplier of Mild Steel Pipes in Uttar Pradesh, India Including Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, Varanasi.

Feel free to contact us for more information and inquiries.

View Product: Click Here

Read the full article

0 notes

Text

Stainless Steel 316L Sheets Manufacturers in India

One of the top exporters, suppliers, and stockists of a variety of metal works is Shree Venktesh Wires and Steels Pvt Limited. We've been offering our services all around the world. SS 316L sheets are a part of our product line. In many different manufacturing industry divisions, this commodity is among the most sought-after steel grades. This product has an exceptional amount of nickel components, which offers remarkable corrosion-proofing characteristics. We collaborate with Jindal Stainless Limited to manufacture sheets made of stainless steel in grades 316 as well as additional stainless steel grades. To satisfy our customers' needs, we offer the best jindal ss sheet price and 316L sheets in a variety of sizes, dimensions, and thicknesses.

Characteristics of jindal ss 316L sheet:

Higher creep resistance

Excellent formability.

Rupture and tensile strength at high temperatures

Corrosion and pitting resistance

Standards of Jindal ss 316L sheets:

Standards: ASTM A240 / ASME SA240

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Thickness: 4mm-100mm

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface Finish: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, hairline, sand blast, Brush, etching, Hot rolled coil (HR), Cold rolled coil (CR), SATIN (Met with Plastic Coated), etc

Hardness: Soft, Hard, Half Hard, Quarter Hard, Spring Hard, etc.

Form: Coils, Foils, Rolls, Plain Coil, Shim Coil, strips, Flats, Blank (Circle), Ring (Flange), etc.

Applications of Jindal ss 316L sheets:

A wide range of applications and industries use jindal stainless steel 316 sheets.

Below are a few of them:

Petrochemical Industry

Oil and Gas Industry

Chemical Industry

Power Plant Industry

Energy Industry

Pharmaceuticals Industry

Pulp & Paper industry

Food Processing Industry

Aerospace Industry

Refining Industry and many more.

Uses and Purpose of Jindal ss 316L sheets:

Jindal ss 316L sheets have a high tolerance to corrosion, outstanding resistance to oxidation, and exceptional grade strength thanks to their high chromium and nickel content. The maximum melting point of stainless steel 316L sheets is 1399 degrees Celsius (or 2550 degrees Fahrenheit). They have incredible yield and tensile strength ranges. Its range of elongation is the widest, at 35%. They also contain the elements carbon, manganese, silicon, phosphorus, sulfur, chromium, molybdenum, nitrogen, and nickel because they are a member of one of the 300 families.

Jindal steel dealers provide perforated sheets made of Jindal ss 316L sheets that are extensively used in the welding, electrochemical, mechanical, and construction industries. Hot rolled sheets made of Jindal ss 316L sheets are specifically created to have features like unprecedentedly high withstanding resistance to corrosion brought on by liquids, hardness, and temperature fluctuation resistance.

#Stainless Steel 316L Sheets Manufacturers in India#Stainless Steel 316L Sheets Suppliers in India#Stainless Steel 316L Sheets Stockists in India#Stainless Steel 316L Sheets Exporters in India

0 notes

Text

Sunex India

We are manufacturer of CNC Turned Components, CNC Machined Parts, Brass Components, CNC Stainless Steel Components, Dowel Pins, Taper Pins, Stainless Steel Turned Parts, Brass Inserts, Threaded Rods, Brass Unions, Threaded Bars, Sheet Metal Components, Sheet Metal Fabrication, Dowel Pins, Copper Components, Fabrication, Welding, Stainless Steel Turned Parts, Stamped Parts, Metal Stamped Parts, Taper Pins, Threaded Rods, Junction Box, Metal Fabrication, Sheet Metal Brackets, to the Building and Construction Industries, Automobile and Furniture Industries.

0 notes

Text

First bullet train in India for Mumbai-Ahmedabad corridor will arrive from Japan; 10 interesting facts - Information Global Online

https://www.merchant-business.com/first-bullet-train-in-india-for-mumbai-ahmedabad-corridor-will-arrive-from-japan-10-interesting-facts/?feed_id=209918&_unique_id=66f20cc27c1cd

#GLOBAL - BLOGGER

BLOGGER

In good news, India is all set to welcome its first bullet train, which will soon be arriving from Tokyo, Japan. This transportation revolution will transform the way of commuting in India. The first bullet train will operate on the Mumbai-Ahmedabad high-speed rail corridor and also marks a significant collaboration with Japan. India is hoping that the advanced Shinkansen technology from Japan will transform rail travel in the country.These bullet trains will be capable of touching speeds up to 320 km/hr with a promise of reducing travel time and enhancing connectivity between two major cities.Let’s have a look at 10 interesting facts about India’s first bullet train:India’s first bullet train: Named as Shinkansen E5, this will be India’s first bullet train for the Mumbai-Ahmedabad corridor.Shinkansen E5 Trains: Shinkansen E5 Trains are noted for their high speed and efficiency. Indian Railways plans to place orders for these trains by 2024, with production timelines dependent on negotiations with Japanese manufacturers.High speeds: Shinkansen E5 can reach a maximum speed of 350 km/hr. The bullet train will primarily operate at 320 km/hr, and will reduce travel times between Mumbai and Ahemdabad significantly.Semi-High-Speed Alternatives: Indian Railways is also planning to launch semi-high-speed trains. These could replace existing premium services like Rajdhani and Shatabdi and are expected to run at speeds of up to 250 km/hr.Innovativeness: The Integral Coach Factory issued a tender for the manufacture of two chair-car high-speed trains with stainless-steel bodies, capable of reaching operational speeds of 250 km/hr.Testing: The 508-km bullet train corridor will also serve as a testing ground for the newly planned semi-high-speed trains. This dual purpose will ensure that both types of trains can efficiently operate on the same route.Stops: The bullet train will offer two travel options: one with stops at all 12 stations along the route, taking approximately three hours, and another with limited halts for quicker travel times.Geography: The corridor will span 508 km, with 351 km in Gujarat and 157 km in Maharashtra. This extensive route highlights the connectivity boost that the bullet train will provide to both states.Expansion plans: There are plans to expand these in future with 35 bullet trains. Each will have 10 coaches, and will make up to 70 daily trips. This ambitious schedule aims to accommodate a significant number of passengers, enhancing overall capacity.Undersea tunnel product: Notably, work has begun on the first undersea tunnel between BKC and Thane, which is part of the project. This tunnel represents an engineering feat that further emphasizes the project’s innovative nature.“In good news, India is all set to welcome its first bullet train, which will soon be arriving from Tokyo, Japan. This transportation revolution will transform the way of commuting…”Source Link: https://timesofindia.indiatimes.com/travel/travel-news/first-bullet-train-in-india-for-mumbai-ahmedabad-corridor-will-arrive-from-japan-10-interesting-facts/articleshow/113599389.cms

http://109.70.148.72/~merchant29/6network/wp-content/uploads/2024/09/pexels-photo-5202434.jpeg

In good news, India is all set to welcome its first bullet train, which will soon be arriving from Tokyo, Japan. This transportation revolution will transform the way of commuting in India. The first bullet train will operate on the Mumbai-Ahmedabad high-speed rail corridor and also marks a significant collaboration with Japan. India is hoping … Read More

0 notes

Text

First bullet train in India for Mumbai-Ahmedabad corridor will arrive from Japan; 10 interesting facts - Information Global Online - #GLOBAL

https://www.merchant-business.com/first-bullet-train-in-india-for-mumbai-ahmedabad-corridor-will-arrive-from-japan-10-interesting-facts/?feed_id=209917&_unique_id=66f20cc19ecfe

In good news, India is all set to welcome its first bullet train, which will soon be arriving from Tokyo, Japan. This transportation revolution will transform the way of commuting in India. The first bullet train will operate on the Mumbai-Ahmedabad high-speed rail corridor and also marks a significant collaboration with Japan. India is hoping that the advanced Shinkansen technology from Japan will transform rail travel in the country.These bullet trains will be capable of touching speeds up to 320 km/hr with a promise of reducing travel time and enhancing connectivity between two major cities.Let’s have a look at 10 interesting facts about India’s first bullet train:India’s first bullet train: Named as Shinkansen E5, this will be India’s first bullet train for the Mumbai-Ahmedabad corridor.Shinkansen E5 Trains: Shinkansen E5 Trains are noted for their high speed and efficiency. Indian Railways plans to place orders for these trains by 2024, with production timelines dependent on negotiations with Japanese manufacturers.High speeds: Shinkansen E5 can reach a maximum speed of 350 km/hr. The bullet train will primarily operate at 320 km/hr, and will reduce travel times between Mumbai and Ahemdabad significantly.Semi-High-Speed Alternatives: Indian Railways is also planning to launch semi-high-speed trains. These could replace existing premium services like Rajdhani and Shatabdi and are expected to run at speeds of up to 250 km/hr.Innovativeness: The Integral Coach Factory issued a tender for the manufacture of two chair-car high-speed trains with stainless-steel bodies, capable of reaching operational speeds of 250 km/hr.Testing: The 508-km bullet train corridor will also serve as a testing ground for the newly planned semi-high-speed trains. This dual purpose will ensure that both types of trains can efficiently operate on the same route.Stops: The bullet train will offer two travel options: one with stops at all 12 stations along the route, taking approximately three hours, and another with limited halts for quicker travel times.Geography: The corridor will span 508 km, with 351 km in Gujarat and 157 km in Maharashtra. This extensive route highlights the connectivity boost that the bullet train will provide to both states.Expansion plans: There are plans to expand these in future with 35 bullet trains. Each will have 10 coaches, and will make up to 70 daily trips. This ambitious schedule aims to accommodate a significant number of passengers, enhancing overall capacity.Undersea tunnel product: Notably, work has begun on the first undersea tunnel between BKC and Thane, which is part of the project. This tunnel represents an engineering feat that further emphasizes the project’s innovative nature.“In good news, India is all set to welcome its first bullet train, which will soon be arriving from Tokyo, Japan. This transportation revolution will transform the way of commuting…”Source Link: https://timesofindia.indiatimes.com/travel/travel-news/first-bullet-train-in-india-for-mumbai-ahmedabad-corridor-will-arrive-from-japan-10-interesting-facts/articleshow/113599389.cms

http://109.70.148.72/~merchant29/6network/wp-content/uploads/2024/09/pexels-photo-5202434.jpeg

BLOGGER - #GLOBAL

0 notes