#Steel industry

Text

HAUT FOURNEAU 4

I adore visiting blast furnaces. They are the most spectacular sights I've ever got to witness. The intricacy of the engineering is quite simply astonishing. This particular specimen in Belgium, which has been under close surveilance since it was shut down in 2008, has been preserved in a remarkably good condition. Almost immediately after the closure, an interest group was established that wanted to preserve the blast furnace as an industrial landmark.

This blast furnace company, which is a defining feature of the city of Charleroi, was founded in 1836, during the heyday of the European steel industry. Like all other steel companies in the region, this blast furnace was also the subject of numerous takeovers and mergers. These mainly took place in the 1960s and 70s. It always remained a flourishing company, competitive on a global scale. However, the takeover by the Duferco group in 2001 heralded the beginning of the end…

The site was then operated under the name Carsid. After a fire in 2007, the furnace was temporarily shut down to carry out the necessary repairs. At the same time, capacity was increased and a number of environmental investments were made. The installation would now be operational for another ten years. Barely a year later, the blast furnace was shut down again, due to “poor prospects”. Due to the economic crisis and the declining demand for steel, the operation of the blast furnace company was no longer deemed profitable.

A “temporary” closure and the search for a buyer should bring relief. After more than three years of uncertainty and economic unemployment, the curtain finally fell for the blast furnace. Since HF4 is one of the best preserved blast furnaces in Europe, the Walloon government is striving to preserve the furnace as industrial heritage. Although a ministerial decree has been published to this effect, the demolition work on the site is progressing steadily…

Unfortunately Charleroi is one of the poorest cities in Belgium. There is no budget for the necessary sanitation and preservation works, which would run in the millions of euros. The futures is looking bleak for this beautiful piece of industrial heritage...

#urban exploration#urbex#abandoned#urban relics#decay#derelict#abandoned places#ue#photography#urbanexploration#HF4#blast furnace#abandoned addiction#industrial heritage#steel industry#urbexpeople#urbexworld#urbexphotography#belgium

53 notes

·

View notes

Text

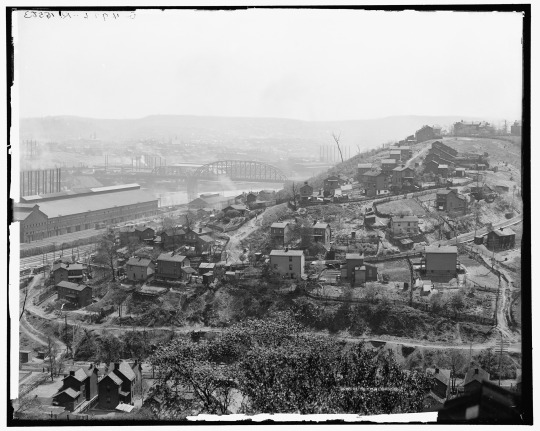

Downtown Pittsburgh from the "hot metal" bridge over the Monongahela River. The bridge is now part of the Pittsburgh heritage bike trail. In the past, the Hot Metal Bridge connected parts of the J&L Steel mill, carrying crucibles of molten iron from the blast furnaces in ladle transfer cars to the open hearth furnaces on the opposite bank.

#photographers on tumblr#original photography#b&w photography#b&w#street photography#landscape photography#historic bridge#Pittsburgh#steel industry

59 notes

·

View notes

Text

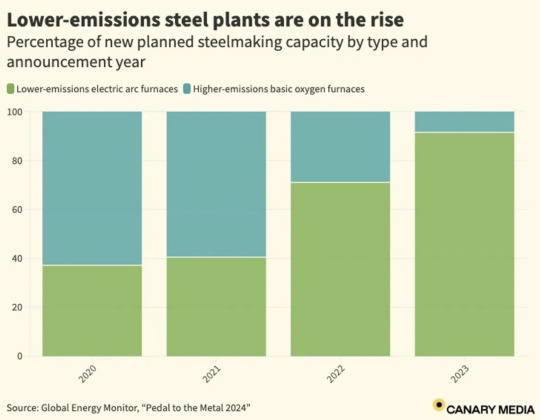

Excerpt from this story from Canary Media:

One of the world’s dirtiest industries is beginning to embrace cleaner methods.

Most planned new steelmaking capacity will use lower-emissions electric arc furnace technology rather than the historically dominant but emissions-intensive basic oxygen furnaces, per a new report from the nonprofit Global Energy Monitor.

Steel is, quite literally, a pillar of our world. It props up skyscrapers, reinforces bridges, and is crucial to cars, planes, trains, and ships. It’s also incredibly dirty: As much as 11 percent of global carbon dioxide emissions come from the iron and steel industries.

The primary steelmaking process generally starts with producing iron in a superhot and extremely carbon-intensive coal-based blast furnace. The resulting iron is then typically put into a basic oxygen furnace, where it becomes steel.

But recent trends suggest that more-sustainable electric arc furnaces (EAF) are starting to replace basic oxygen furnaces, helping slash emissions. In 2023, nearly all newly announced steelmaking capacity — 93 percent — planned to use EAFs, per the Global Energy Monitor report.

As it stands, about 32 percent of global steelmaking happens in these lower-emissions electric furnaces, but that’s set to rise to more than 36 percent by the end of the decade as more EAFs come online and more oxygen furnaces retire, per the report. That growth rate nearly puts the industry on track to meet the International Energy Agency’s target for EAFs to make up 37 percent of steelmaking by 2030.

The picture is less clear for iron production, the step in the steelmaking process that is responsible for the vast majority of carbon emissions.

More than 90 percent of the world’s iron is still made in extremely dirty coal-based blast furnaces. The primary alternative to these furnaces, direct reduction iron (DRI), is beginning to gain ground. But coal-based blast furnace capacity is still being built faster than DRI capacity.

5 notes

·

View notes

Photo

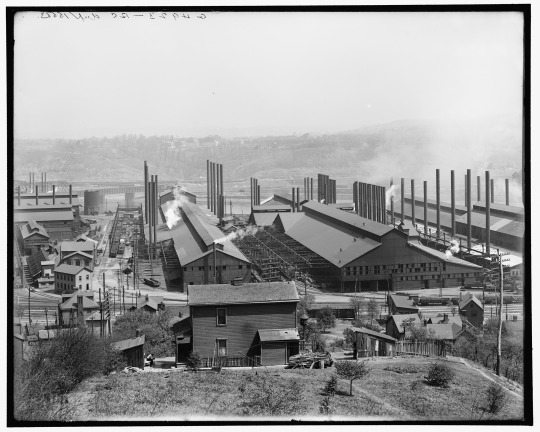

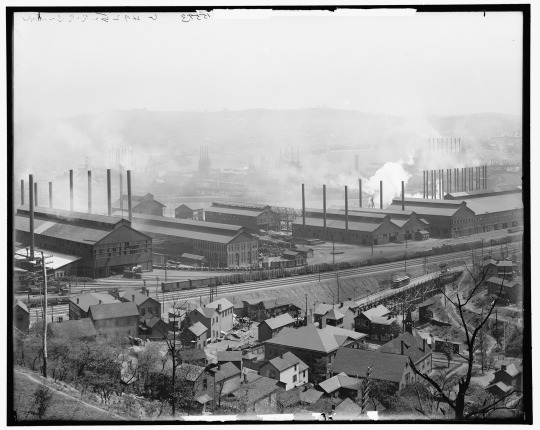

Homestead Steel Works, Homestead, Pa. Ca. 1900-1910.

Homestead Steel Works was a large steel works located on the Monongahela River at Homestead, Pennsylvania in the United States. The company developed in the nineteenth century as an extensive plant served by tributary coal and iron fields, a railway 425 miles (684 km) long, and a line of lake steamships. The works was also the site of one of the more serious labor disputes in U.S. history, which became known as the Homestead strike of 1892.

The steel works were first constructed in 1881. Andrew Carnegie, (a Scottish emigrant), bought the 2 year old Homestead Steel Works in 1883, and integrated it into his Carnegie Steel Company. For many years, the Homestead Works was the largest steel mill in the world and the most productive of the Mon Valley's many mills.

A series of industrial disputes over wages, working hours and contracts occurred in the early years of the works, leading to the Homestead strike, an industrial lockout and strike which began on June 30, 1892, culminating in a battle between strikers and private security agents on July 6, 1892. The battle was one of the most violent disputes in U.S. labor history and the final result was a major defeat for the union and a setback for their efforts to unionize steelworkers.

#pennsylvania#homestead strike#Steel Industry#Dry Plate Negatives#Monongahela River#union history#labor rights#labor unions#Carnegie

102 notes

·

View notes

Text

Mild Steel Flanges Details

Why MS Flanges Matter

MS flanges, short for Mild Steel flanges, are essential components in the industrial and construction sectors. These flanges, made from mild steel, are prized for their robust strength, cost-efficiency, and versatility. They serve as crucial connectors, fastening pipes, valves, and various machinery, ensuring that everything stays tightly sealed and leak-free.

The Appeal of Mild Steel

Mild steel is a top choice for many due to its durability, ease of use, and affordability. It offers a great balance between performance and cost, making it resistant to moderate corrosion while withstanding significant pressure. Whether you're working on an industrial project or a construction site, mild steel is a reliable material. For the best MS flanges in India, look no further than Udhhyog, a leading manufacturer in the field.

A Closer Look at Different MS Flanges

Slip-On Flanges: Easy and Effective

Slip-on flanges are known for their ease of installation—they slip over the pipe and are welded into place. This makes them perfect for applications where precise fitting is key. They’re commonly used in low-pressure environments and offer an economical solution for various projects.

Weld Neck Flanges: Built for Performance

Weld neck flanges feature a long, tapered neck that smoothly transitions from the pipe to the flange. This design reduces stress concentrations, making these flanges ideal for high-pressure and high-temperature applications. They are often used in critical systems where reliability and strength are crucial.

Blind Flanges: Sealing with Confidence

Blind flanges are designed to close off the end of a pipe or vessel, with no central hole. They are perfect for sealing off pipelines or openings, providing a strong barrier for maintenance or potential expansion in the future.

Socket Weld Flanges: Strong and Reliable

Socket weld flanges have a recessed area where the pipe fits before being welded. This design ensures a smooth bore and a secure connection, making them suitable for high-pressure applications. They’re commonly used in industries where a strong, leak-proof joint is essential.

Real-World Applications of MS Flanges

MS Flanges in Industrial Operations

In industrial environments, MS flanges are critical for connecting various machinery components, such as pumps and valves. They ensure that these parts are securely joined, helping to maintain efficient operations and prevent leaks.

Their Role in the Construction Industry

MS flanges are vital in construction projects, where they link structural steel components. They provide the necessary strength to handle heavy loads and ensure that different parts of a structure are firmly connected.

Crucial for Piping Systems and Equipment

MS flanges play a key role in piping systems, connecting pipes, valves, and other fittings. They help maintain the system's integrity, making it easier to perform maintenance and repairs when needed.

Why Choose MS Flanges?

Cost-Effective and High Value

MS flanges offer a cost-effective alternative to more expensive materials like stainless steel. Despite their lower cost, they do not compromise on quality, making them a popular choice for various applications.

Durability and Robustness

Mild steel flanges are known for their durability and strength. They are built to withstand various pressures and temperatures, making them suitable for a wide range of industrial and construction uses.

Simple Installation and Maintenance

MS flanges are designed for easy installation and maintenance. Their straightforward design makes them easy to assemble and disassemble, which can save both time and effort during installation and upkeep.

How to Select the Right MS Flange

Important Considerations

When selecting an MS flange, it’s essential to consider the type, pressure rating, and compatibility with other materials. Choosing the right flange ensures a secure connection and optimal performance for your specific application.

Sizing and Specification Essentials

Accurate sizing is crucial for a secure and efficient connection. Refer to industry standards and specifications to ensure you select the right size and type of flange for your project.

This version offers another fresh perspective, ensuring the content remains original and engaging while highlighting the key aspects of MS flanges.

2 notes

·

View notes

Text

How to to control nitrogen levels ?

Why is it important to control nitrogen levels during the steelmaking process?

2 notes

·

View notes

Text

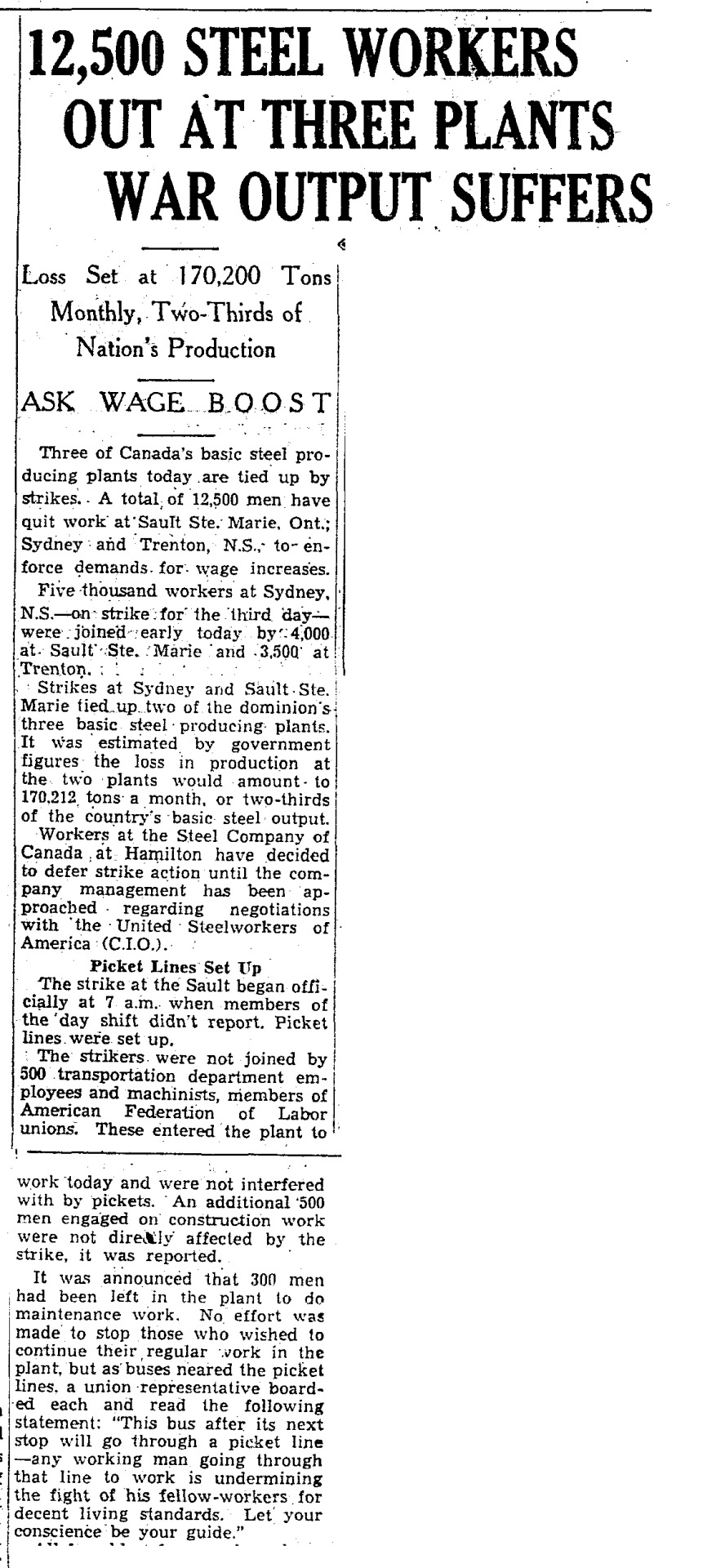

"12,500 STEEL WORKERS OUT AT THREE PLANTS; WAR OUTPUT SUFFERS," Toronto Star. January 14, 1943. Page 1.

----

Loss Set at 170,200 Tons Monthly, Two-Thirds of Nation's Production

----

ASK WAGE BOOST

----

Three of Canada's basic steel producing plants today are tied up by strikes. A total of 12,500 men have quit work at Sault Ste. Marie, Ont.; Sydney and Trenton, N.S., to enforce demands for wage increases.

Five thousand workers at Sydney, N.S. - on strike for the third day - were joined early today by 4,000 at Sault Ste. Marie and 3,500 at Trenton.

Strikes at Sydney and Sault Ste. Marie tied up two of the dominion's three basic steel producing plants. It was estimated by government figures the loss in production at the two plants would amount to; 170,212 tons a month, or two-thirds of the country's basic steel output.

Workers at the Steel Company of Canada at Hamilton have decided to defer strike action until the company management has been approached regarding negotiations with the United Steelworkers of America (C.I.O.).

Picket Lines Set Up

The strike at the Sault began officially at 7 a.m. when members of the day shift didn't report. Picket lines were set up.

The strikers were not joined by 500 transportation department employees and machinists, members of American Federation of Labor unions. These entered the plant to work today and were not interfered with by pickets. An additional 500 men engaged on construction work were not direly affected by the strike, it was reported.

It was announced that 300 men had been left in the plant to do maintenance work. No effort was made to stop those who wished to continue their regular work in the plant, but as buses neared the picket lines, a union representative boarded each and read the following statement: "This bus after its next stop will go through a picket line - any working man going through that line to work is undermining the fight of his fellow-workers for decent living standards. Let your conscience be your guide."

#sault ste. marie#sydney nova scotia#trenton#strike#picket line#picketing#steel workers#steel plant#steel industry#algoma steel#dominion steel#united steel workers of america#central industrial organization#hamilton#wage demands#wage increase#wage freeze#price controls#canada during world war 2#working class struggle

9 notes

·

View notes

Text

Premier Source for pipe for Fire-Fighting works - tubetrading

Discover top-quality pipes for fire-fighting works in Vadodara at Tube Trading. Safeguard your property with our reliable, durable, and certified pipes. Your safety is our priority! With a wide range of sizes and materials, we've got the perfect solution for all your fire safety needs. Trust Tube Trading for unmatched quality and peace of mind. Count on us for expert advice and prompt delivery to ensure your fire-fighting systems are always ready for action.

Your safety, our commitment! Choose Tube Trading for unrivaled fire-fighting expertise, 100% customer satisfaction, and competitive prices that will not compromise your safety.

#Pipe for fire fighting works in Vadodara#Pipe for fire fighting works#Jindal pipes#steel industry#steel companies#seamless pipes#piping material#construction structure#tubetrading

7 notes

·

View notes

Text

1952..when steel was still hot in the US..before the silicon chips

4 notes

·

View notes

Text

Freight Cost in Steel Industry

A Detailed Analysis of Increase in Freight Cost in Steel Industry

Are you searching for efficient ways to reduce freight costs in steel industry logistics operations? Companies with Freight as a crucial part of their business must deal with the continuous rise in transportation of steel industry logistics as a whole.

This is why finding best ways to transport steel to ensure freight cost optimization is becoming critical. It eventually improves the supply chain procedures and saves money for businesses.

Strategies for logistics cost control can range from streamlining inventory levels, revising smarter shipping networks, providing better processes, improving relationships between suppliers and third parties, etc.

Before looking for the best ways to transport steel cost-efficiently, it is critical to understand the reasons that lead to the rise in Freight logistics costs in the steel industry.

This blog post highlights the reasons behind the ongoing rising Freight costs in the steel industry and ways to reduce freight costs.

#software#logistics#fretron#tms#transportation management software#logistics software#steel industry#Freight Cost

2 notes

·

View notes

Text

POWERPLANT F

Every blast furnace company also has a power station. The gases generated during the blast furnace's smelting process were converted into electricity here, which was then used to power the rest of the company.

This power station was part of a blast furnace that was demolished back in 2016. Despite years of inactivity, the power plant has been beautifully preserved. This is probably due to the fact that all possible entrances on the ground floor were firmly closed. Getting in here required some climbing. Since the rest of the site has mostly been demolished, it will only be a matter of time before this beautiful piece of industrial heritage will undergo the same destiny.

#urban exploration#urbex#abandoned#abandoned places#ue#urbexworld#urbexpeople#photography#belgium#urban relics#industrial#steel industry#urbanexploration#urbanexploringphotography

159 notes

·

View notes

Text

Esch-Alzette. Metzeschmelz. 1889

#esch-sur-alzette#esch-alzette#grand duchy of luxembourg#metzeschmelz#1880s#1889#trains#steel industry

2 notes

·

View notes

Text

As a native of Gary, Indiana, and a former "summer employee" at U.S. Steel (to pay for my college education), I'm obviously invested in what happens to the Gary Works of U.S. Steel. This story answers several of my questions, and puts me on the "no" side of this proposal. Excerpt from this story from Grist:

U.S. Steel, once the world’s largest company of any kind, can take substantial credit for the growth of American industrial power in the 20th century. But in recent decades, it’s been shuttering mills and shedding workers. Now, the iconic Pittsburgh-based manufacturer is set to be acquired by a Japanese steelmaker, Nippon Steel — if the federal government allows the deal to proceed.

Earlier this month, reports emerged that the Biden administration is preparing to block the nearly $15 billion merger on the grounds that it presents a threat to America’s national security interests. The United Steelworkers union opposes it, fearing future layoffs and weaker labor protections under new ownership. So do both major candidates for president, who are vying for votes in the Rust Belt. Supporters of the deal, like the Washington Post editorial board and the nonpartisan think tank The Atlantic Council, have cast the politicians’ opposition as election-season pandering, and argued that the national security rationale on which Biden may block it is flimsy. But one area, in which the question of whether the merger goes through could be particularly consequential, has gone largely unremarked upon in the conversation: what it means for the climate.

Some environmentalists say the deal could slow the crucial progress that the steel industry must make in order to decarbonize. Their argument stems from the fact that both U.S. Steel and Nippon Steel have been slow, compared to industry peers, to adopt the most impactful decarbonization technologies, even with federal funding available in the U.S. to do so.

The most common process by which primary steel is produced is massively carbon-intensive. The reasons for this lie in chemistry. Steel is made from iron, but the form in which iron ore occurs in the Earth’s crust is mostly iron oxide (similar to rust). In order to get usable iron from it, one needs to remove the oxygen. For centuries, iron-makers have accomplished this by using coke, a fuel made from coal, which is heated alongside iron ore in a blast furnace at such high temperatures that the iron melts into a liquid while the oxygen bonds with the carbon in the coke and produces carbon dioxide.

Blast furnaces are responsible for the lion’s share of carbon emissions from steelmaking, and the inextricability of carbon emissions from the ironmaking process is a large part of the reason why, overall, steelmaking is responsible for 7 percent of global carbon emissions, and a quarter of industrial carbon emissions. These percentages will likely grow as other sectors of the economy are decarbonized. In the U.S., demand for steel is also expected to grow dramatically over the next decade to provide the raw material of the industrial growth sparked by the Inflation Reduction Act and the planned buildout of clean energy infrastructure and transmission lines. For these reasons, the task of decarbonizing steel is as urgent as it is difficult and expensive.

Fortunately, there is a solution on offer that has recently become viable due to new technological advances — and one that the Biden administration has sought to heavily subsidize: replacing blast furnaces with a process called direct reduction, and using hydrogen as a reducing agent in place of carbon, ultimately discharging water rather than carbon dioxide. “The chemistry is sound, it’s being built, it’s been piloted and demonstrated,” said Yong Kwon, a senior advisor with the Sierra Club’s Industrial Transformation Campaign. “The question is now: Will industries adopt it?”

There are eight operating steel mills in the United States that make “primary” steel (newly created steel, rather than the generally lower-quality “secondary” steel produced from scrap metal). Three are owned by U.S. Steel. Cleveland-Cliffs, the owner of the other five, has also made an offer to buy U.S. Steel and has been much more proactive in making the shift to greener production. “The Department of Energy has made available a great deal of money to do partnerships with industry to demonstrate the value of decarbonized projects,” said Todd Tucker, director of the industrial policy and trade program at the Roosevelt Institute. Both Cleveland-Cliffs and U.S. Steel have availed themselves of such funding to embark on decarbonization programs. U.S. Steel has partnered with the Department of Energy on carbon capture projects at several of their steel mills, and funded research and development of hydrogen-based ironmaking technology. The company also plans to install a carbon capture program at a blast furnace at its steel mill in Gary, Indiana, which it says will turn up to 50,000 metric tons of carbon dioxide annually into limestone — a tiny fraction of that facility’s overall emissions. But critics note that U.S. Steel has yet to take a step as ambitious as its rival by actually replacing one of its blast furnaces with direct reduction of iron.

The stakes of the potential U.S. Steel-Nippon Steel merger are perhaps best illustrated in the city of Gary, Indiana, which was built in 1906 by U.S. Steel to house workers at its Gary Works steel mill. That mill is home to the country’s largest and most carbon-emitting blast furnace — and it’s nearing the end of its lifespan. This situation hypothetically presents the furnace’s owner with an ideal opportunity to switch to a cleaner technology, with federal funding on the table to do so. But in August, Nippon Steel announced its prospective plans for Gary Works, which include a $300 million investment in relining the furnace to extend its lifespan for another 20 years. With this announcement, Kwon said, “Not only have they back in Japan not pursued solutions that we feel are responsible; they’ve now explicitly come out and said that they’re not going to pursue the solution that is on the table for reducing the climate change and public health harms that are currently produced by the iron-making process.”

4 notes

·

View notes

Text

Stainless Steel Seamless 316 Pipe

M- PIPE & FITTING SOLUTION INC. is a Leading Pipes &Tubes Manufacturer, Sheets & Plates Manufacturer, Buttweld Fittings Manufacturer, Forged Fittings Manufacturer, Flanges Manufacturer, Fasteners Manufacturer, Round Bars Manufacturer, in Mumbai, India.

2 notes

·

View notes

Text

Leading TMT Bar Suppliers In India - Suman Industries

Indian brand with flexibility, strength and endurance all together is found only in products by Suman Industries

#industrial steel#iron & steel#steel industry#rolled plates#ms pipes#ms square pipes#tmt bars#square bars

2 notes

·

View notes

Text

Made a new handle for one of Grandad's old tools. Really proud of how snugly it fitted in, just needed a little hammering into the last few millimetres. Handle is perfectly sized for my smallish hands.

The mark says E.S.L. (possibly C), CYCLOPS, Sheffield K, with a V & camel logo.

My mum's family worked in steel and cutlery factories in Sheffield throughout the 20th century. I did a bit of research and found out about the Cyclops steel works built by the Cammell company, later known as Cammell Laird, the famous ship builders.

youtube

Eventually, Cammell Laird and Vickers formed the English Steel Corporation. And that's where the file is from.

Anyway, I'm hoping to get to show my grandma what I made because I know she had family working making cutlery handles and we can chat about it all.

#woodworking#sheffield#local history#industrial history#steel industry#cammell laird#vickers#Youtube#wood carving

3 notes

·

View notes