#TE temperature sensor

Explore tagged Tumblr posts

Text

TE temperature sensor

TE Connectivity (TE) introduces the MS5525DSO, a new generation of digital small outline integrated circuit pressure sensors that measure pressure and temperature for applications such as CPAP (continuous positive airway pressure) and ventilators. This sensor module includes a pressure sensor and an ultra-low power 24-bit ?S ADC with internal factory calibrated coefficients. It provides a 24-bit digital pressure and temperature value, and different operation modes that allow the user to optimize for conversion speed and current consumption. The Industrial Mini I/O connector system is a small, compact, latching, wire-to-board I/O interface is suitable for the stringent demands of an industrial device.

0 notes

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Unlock the Power of Electronics Design in Cooking Robot Hygiene

Table of Contents

Why Hygiene Matters in a Cooking Robot

How Electronics Design Improves Cooking Robot Hygiene

Sensor Integration for Real-Time Hygiene Monitoring

Sealed PCB Design for Wash-Down Protection

Built-In Cleaning Automation

Touchless Control Systems

Real-World Scenario: Electronics Design Enabling Hygiene

Meeting Global Food Safety Standards

What’s Next: Future of Hygiene in Cooking Robots

Key Takeaways

Conclusion

Smart electronics design plays a critical role in maintaining hygiene in a cooking robot. From precision control to built-in sanitation systems, advanced electronics ensure that cooking robots meet the highest cleanliness and food safety standards. Whether it’s managing temperature, automating cleaning, or preventing contamination, the secret to hygienic food automation lies in how the electronics are designed.

If you’re exploring how modern cooking robots stay clean, safe, and food-ready, the answer begins with smart, reliable electronics design. Let’s break down how this works — and why it matters.

Why Hygiene Matters in a Cooking Robot

In commercial kitchens, food factories, or even smart homes, a cooking robot handles critical tasks like chopping, frying, stirring, or mixing. Because they come into direct contact with food, hygiene isn’t just about cleanliness — it’s vital for health, compliance, and preventing cross-contamination.

Contamination risks may include:

Leftover food residues

Cross-contact between raw and cooked items

Improper temperature management

Bacteria buildup in hard-to-clean areas

How Electronics Design Improves Cooking Robot Hygiene

1. Sensor Integration for Real-Time Hygiene Monitoring

Smart sensors integrated into the cooking robot help monitor:

Surface cleanliness

Sanitization temperatures

Moisture levels that signal bacterial growth

These sensors help the robot take action — whether it’s sounding alerts or starting cleaning cycles — making electronics design a key part of hygiene management.

2. Sealed PCB Design for Wash-Down Protection

In hygiene-sensitive environments, the electronics design includes:

Waterproof PCB coatings

Isolated high-voltage components

IP67+ enclosures for safe wash-downs

This allows the cooking robot to be cleaned externally without damaging the electronics, maintaining both hygiene and reliability.

3. Built-In Cleaning Automation

Electronics power intelligent hygiene functions like:

Pre-programmed cleaning schedules

Motor control for rotating brushes and sprayers

Hot water and detergent dispensers

These automated systems reduce manual intervention and improve hygiene consistency across every cooking cycle.

4. Touchless Control Systems

Modern cooking robots feature touchless controls to avoid surface contamination. These include:

Gesture or voice recognition

Infrared sensors for non-contact operation

Capacitive proximity-based interfaces

Such innovations are only possible through thoughtful electronics design that enhances hygiene while improving user experience.

Real-World Scenario: Electronics Design Enabling Hygiene

Imagine a robotic kitchen unit preparing soups:

Sensors detect residue inside the container

A cleaning cycle is triggered automatically

Electronics control nozzles, heat, and drainage

Sealed circuits protect the system during cleaning

Here, hygiene, automation, and electronics design work together to ensure safe and sanitary operation.

Meeting Global Food Safety Standards

HACCP guidelines

FDA and EU food-grade equipment regulations

NSF/ANSI safety standards

A strong electronics design not only automates hygiene but helps manufacturers log cleaning activity and prove compliance with regulations.

What’s Next: Future of Hygiene in Cooking Robots

Emerging electronics design trends are pushing hygiene even further:

AI-Powered Hygiene Monitoring: Adaptive cleaning schedules and anomaly detection

IoT for Hygiene Reports: Remote access to logs, diagnostics, and alerts

Self-Cleaning Tech: UV light modules and antimicrobial surfaces managed by electronics

These innovations promise a future where cooking robot hygiene becomes smarter, faster, and more autonomous.

Key Takeaways

Hygiene is a critical factor in every cooking robot application

Smart electronics design enables better hygiene through sensors, automation, and protective enclosures

Sealed systems, real-time detection, and automated cleaning are only possible through modern electronics

Investing in better design reduces contamination risk and ensures compliance with food safety standards

Conclusion

A cooking robot is only as clean as its electronics allow it to be. By integrating cutting-edge sensors, sealed PCBs, and automated cleaning capabilities, electronics design plays a central role in ensuring hygiene in robotic kitchens. As the demand for automation in food preparation rises, smarter electronics will remain the backbone of safe, hygienic cooking technologies.

Hygiene isn’t optional — it’s a core feature that defines the success of any cooking robot. And it starts with smarter electronics design.

Whether you’re building the next generation of kitchen robotics or optimizing hygiene in automated food systems, the right design partner helps you move from idea to market with precision and safety built-in.

Discover how advanced electronics design can elevate hygiene in cooking robots. 🔗 Learn more at www.auckam.com

0 notes

Text

Xanadu Achieves Scalable Gottesman–Kitaev–Preskill States

States Gottesman–Kitaev–Preskill

Xanadu leads photonic quantum computing with their development of a scalable building block for fault-tolerant quantum computers. The achievement involves on-chip Gottesman–Kitaev–Preskill state production and was initially reported in January 2025 by Nature and summarised in June 2025. “First-of-its-kind achievement” and “key step towards scalable fault-tolerant quantum computing” describe this work.

Understanding GKP States' Importance

GKP states are error-tolerant photonic qubits. These complex quantum states consist of photons stacked in specific ways. Due to its unique structure, quantum error correcting methods may identify and fix phase shifts and photon loss. Zachary Vernon, CTO of Xanadu, calls GKP states “the optimal photonic qubit” because they enable quantum logic operations and error correction “at room temperature and using relatively straightforward, deterministic operations.” It has always been challenging to construct high-quality Gottesman–Kitaev–Preskill States on an integrated platform. This discovery advances continuous-variable quantum computing architectures by overcoming that obstacle.

GKP states provide fault-tolerant computing by using linear optics and measurement algorithms, unlike probabilistic entanglement methods that require repeated trials and complex feed-forward control. They fit well with hybrid systems because they generate quantum networks that link chips or modules or create larger cluster states for measurement-based computation.

Quantum systems' interoperability with optical fibre makes scaling easy, allowing them to be distributed among system components or data centres. This demonstration changed photonic quantum computing by taking a different approach from superconducting and trapped-ion platforms and bringing these systems closer to utility-scale quantum machine error thresholds.

Aurora: Photonic Quantum Computing Architectur

The “sub-performant scale model of a quantum computer” “Aurora” represents Xanadu's work. This system uses scalable, rack-deployed modules connected by fibre optics to incorporate all basic components. With 35 photonic devices, 84 squeezers, and 36 photon-number-resolving (PNR) detectors, Aurora provides 12 physical qubit modes each clock cycle. All system components except the cryogenic PNR detection array are operated by a single server computer and fit into four server racks.

Aurora's key technologies and their functions:

Silicon nitride waveguides feature minimal optical losses. This waveguide uses 300 mm wafers, which are common in semiconductor production. Newer chips based on Ligentec SA's 200-mm silicon-nitride waveguide architecture show potential for better squeezing and lower chip-fiber coupling losses.

The efficiency of photon-number-resolving (PNR) detectors is above 99%. In 12-mK dilution coolers, 36 transition edge sensor (TES) arrays form its base. These TES detectors cycle at 1 MHz and detect up to seven photon counts with little miscategorization error. Despite being highly effective, PNR detection efficiencies of over 99% are needed to meet the architecture's strict P1 path loss constraints.

Loss-optimized optical packaging—including accurate alignment, chip mounting, and fibre connections—was emphasised. This protects critical quantum information during routing and measurement.

The refinery array has six photonic integrated circuits (PICs) on a thin-film lithium-niobate substrate. Each refinery's two binary trees of electro-optic Mach-Zehnder modulator switches dynamically select the best output state based on PNR detection system feedforward instructions. Even though current Aurora refinery chips use probability-boosting multiplexing and Bell pair synthesis, future generations will use homodyne detectors to complete the adaptive breeding method.

Interconnects: Phase- and polarization-stabilized fiber-optical delay lines connect the refinery to QPU and refinery modules. These delays allow temporal entanglement and buffer information heralding in the cluster state.

Experiments and Results

Two large trials benchmarked Aurora's main features.

To generate a 12 × N-mode Gaussian cluster state, the system was set to send squeezed states to the QPU array. Data was collected at 1 MHz for two hours to synthesise and measure a macronode cluster state with 86.4 billion modes. Despite substantial optical losses (approximately 14 dB), the nullifier variances remained below the vacuum noise threshold, proving squeezing and cluster state entanglement.

Detecting Repetition Code Errors: This experiment showed the system's feedforward and non-Gaussian-state synthesis using low-quality GKP states. In real time, the QPU decoder assessed the system's two (foliated) repetition code checks. The decoder calculated bit values and phase error probabilities to change the measurement basis for the next time step.

Limitations and Prospects

Despite these notable examples, the “component performance gap” between existing capabilities and fault tolerance needs remains large. The main limiter of quantum state purity and coherence is optical loss. Ideal designs for fault-tolerant operation require loss budgets of about 1%, whereas the Aurora system lost 56% for heralding pathways (P1) and nearly 95% for heralded optical paths (P1 and P2).

Xanadu's future projects include:

Hardware improvements: Chip fabrication, waveguide geometry, and packaging are optimised to improve fidelity and reduce optical loss. The photonic components' insertion loss must be improved by 20-30 times (on a decibel scale).

Architectural Refinements: Testing cutting-edge hardware-level photon generation and detection rates and error mitigation measures to reduce loss and imperfection.

Integration and Scaling: combining the new GKP generation methods with Aurora's networking, error correcting protocols, and logic gates. The company believes scalable, semiconductor-compatible platforms can mass-produce, modify, and monitor error-correcting components for modular quantum computing.

Even though quantum hardware across all platforms is currently in the noisy intermediate-scale quantum (NISQ) period, Xanadu's work shows how to scale photonic quantum computers to address real applications. Fiber-optical networking, classical control electronics, and photonic-chip fabrication can scale and modularise a realistic photonic architecture. We must continuously improve optical GKP-based architectures to find the most hardware-efficient and imperfection-tolerant systems.

#GottesmanKitaevPreskillState#GKPstates#physicalqubit#QuantumProcessingUnit#Xanadu#quantumcomputing#News#Technews#Technology#Technologynews#Technologytrends#Govindhtech

0 notes

Text

Global Fluid Sensors Market Set to Grow at 9.5% CAGR Through 2031

The global fluid sensors market stood at US$ 12.5 Bn in 2022 and is projected to reach US$ 19.4 Bn by 2031, growing at a robust CAGR of 9.5% from 2023 to 2031. The growing need for precise monitoring, detection, and measurement of fluids across various industries such as food & beverages, petrochemicals, power generation, and water treatment is significantly boosting the demand for advanced fluid sensing technologies.

Market Overview: Fluid sensors play a critical role in detecting, monitoring, and controlling the properties of fluids such as flow rate, pressure, temperature, and level—across industrial applications. The integration of IoT, microelectromechanical systems (MEMS), and microfluidic technology has further expanded the scope of these sensors, particularly in industries demanding high efficiency, safety, and hygiene.

These sensors are especially vital in sectors such as food & beverages, where safe and sustainable production depends on real-time monitoring of liquid levels and temperature, and in petrochemical plants, where they help reduce spillage and monitor corrosive or hazardous substances.

Market Drivers & Trends

Several drivers are propelling the growth of the fluid sensors market:

Surge in demand for real-time monitoring of liquid and gas parameters in complex industrial processes.

Stringent government regulations on industrial safety and environmental protection, especially in oil & gas and chemical sectors.

Rapid automation and digitization in manufacturing and utilities, demanding advanced sensor integration.

Increased emphasis on hygienic production in food & beverage processing plants, boosting demand for contactless fluid sensors.

One of the key market trends is the integration of fluid sensors with AI and IoT platforms, enabling remote monitoring, predictive maintenance, and automated control systems. Additionally, miniaturization and combination of microfluidic tech with MEMS are driving the adoption of fluid sensors in healthcare and automotive applications.

Latest Market Trends

Adoption in medical devices: Fluid sensors, particularly air flow sensors, are being extensively deployed in medical devices to monitor gas flow for accurate patient care.

Automotive applications: Automotive OEMs like BMW and Audi are using fluid sensors to assess stopping mechanism fluid levels and cooling systems.

Flexible sensor materials: Advancements in sensor material science are enabling sensors to be embedded in soft robotics and wearable health monitoring devices.

Key Players and Industry Leaders

The competitive landscape of the fluid sensors market is characterized by innovation, partnerships, and strategic expansion. Leading players include:

SICK AG

Omron Corporation

Schneider Electric SE

Lord Sensing Stellar Technology

Honeywell International Inc.

NXP Semiconductors N.V.

Bosch Sensortec

TE Connectivity

Infineon Technologies AG

Gems Sensors, Inc.

Sensata Technologies Holding N.V.

STMicroelectronics

Futek Advance Sensor Technologies

Sensirion AG

Yokogawa Electric Corporation

General Electric Company

These players are investing in IoT-enabled sensors, MEMS-based solutions, and multi-functional sensing platforms to expand their product portfolios and gain a competitive edge.

Recent Developments

STMicroelectronics, in July 2023, introduced its FlightSense multi-zone sensors, capable of 3D scene mapping and distance measurement from multiple objects. This innovation strengthens the use of fluid sensors in robotics and industrial automation.

Key manufacturers are collaborating with tech providers to integrate AI-based analytics into their sensor platforms, enabling smarter fluid monitoring systems for industries like utilities and pharmaceuticals.

Discover essential conclusions and data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=37271

Market Opportunities

Several growth opportunities are emerging in the fluid sensors space:

Expansion in emerging economies: Rapid industrialization in Asia-Pacific and Latin America offers lucrative prospects for fluid sensor deployment.

Smart water and wastewater treatment: Increasing investments in smart water infrastructure present a major opportunity for non-contact, high-precision fluid sensors.

Oil & gas exploration: Increasing offshore and deep-water drilling activities will drive the need for advanced fluid sensing technologies to manage pressure and fluid levels.

Future Outlook

The global fluid sensors market is expected to experience sustained growth, driven by:

Rising industrial automation

Demand for safety and quality in processing industries

Integration of next-gen technologies like 5G, AI, and machine learning in sensor systems

By 2031, manufacturers are likely to focus more on energy-efficient, remote-controllable, and miniaturized sensor solutions, customized for specific industrial needs.

Market Segmentation

By Product Type:

Pressure Sensor

Temperature Sensor

Flow Sensor

Level Sensor

By Detection Medium:

Liquid

Gas

Plasma

By Measurement Type:

Contact

Non-contact

By End-use Industry:

Oil & Gas

Chemical

Power Generation

Food & Beverages

Water & Wastewater Treatment

Others

Regional Insights

North America held the largest market share in 2022, thanks to stringent safety regulations and high adoption of smart fluid sensing technologies, especially in the oil & gas industry.

Asia Pacific is anticipated to witness the fastest growth during the forecast period, driven by:

Integration of AI and IoT in water management systems in China, India, and Singapore.

Growth in manufacturing and utility sectors demanding real-time fluid monitoring.

Rising awareness about environmental sustainability and efficient resource management.

Europe and MEA are also expected to witness notable adoption of fluid sensors due to advancements in industrial automation and renewable energy sectors.

Why Buy This Report?

In-depth market sizing and forecasts from 2023 to 2031

Detailed competitive landscape analysis

Comprehensive segmentation and regional breakdown

Key market drivers, restraints, and opportunities

Profiles of top players, including strategies and product portfolios

Insights on recent innovations and developments

Analysis of emerging technologies and investment trends

Access to historical data (2017–2021) for context and benchmarking

Frequently Asked Questions

1. What is the projected market size of the fluid sensors industry by 2031? The global fluid sensors market is expected to reach US$ 19.4 Bn by 2031.

2. What is driving growth in the fluid sensors market? Growth is driven by rising demand in food & beverage, petrochemical, and wastewater sectors, along with increasing integration of IoT and AI technologies.

3. Which region is expected to dominate the fluid sensors market during the forecast period? North America currently leads the market, while Asia Pacific is projected to grow at the fastest rate.

4. Who are the key players in the global fluid sensors market? Major players include Honeywell, Omron, SICK AG, STMicroelectronics, and Bosch Sensortec.

5. What are some recent innovations in fluid sensors? Key innovations include multi-zone 3D mapping sensors, AI-integrated sensing platforms, and MEMS-based miniature sensors for automotive and medical applications.

Explore Latest Research Reports by Transparency Market Research:

Commercial Security Systems Market: https://www.transparencymarketresearch.com/commercial-security-systems-market.html

High Resistivity Silicon Wafers Market: https://www.transparencymarketresearch.com/high-resistivity-silicon-wafers-market.html

Semiconductor Metrology Equipment Market: https://www.transparencymarketresearch.com/semiconductor-metrology-equipment-market.html

Tactile Switches Market: https://www.transparencymarketresearch.com/tactile-switches-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Keep Your Cool with Professional Refrigerator Repairing Service in Chennai

In this blog, we’ll walk through the benefits of hiring professional fridge repair services, common problems people face, and why local support in Chennai can save your time and money.

Why Is Timely Refrigerator Repair Important?

A fridge that’s not working properly can lead to:

Food spoilage and wastage

Unpleasant smells

Increased electricity bills due to poor performance

Complete breakdown leading to expensive replacements

Addressing small issues early can prevent major failures. Whether your fridge is not cooling, over-freezing, leaking water, or making noise, professional refrigerator repairing services can diagnose and fix the problem quickly.

Common Refrigerator Problems and Fixes

Here are the most common issues that professionals handle:

1. Fridge Not Cooling Properly

This could be due to a dirty condenser coil, faulty thermostat, or low refrigerant. Technicians check the system thoroughly to restore the right temperature.

2. Excessive Frost in the Freezer

If you notice frost build-up, it might be a problem with the defrost system, heater, or door seal. Prompt repair prevents further damage and saves electricity.

3. Water Leaks

Leaking water may come from a clogged defrost drain or a broken water supply line. A quick inspection and fix can prevent floor damage and hygiene issues.

4. Strange Noises

Buzzing, clicking, or rattling sounds often indicate problems with the compressor, fan motor, or other internal parts. A technician can identify the noise source and replace damaged components.

5. Fridge Runs Constantly

If your fridge doesn’t turn off, it could mean your thermostat or temperature sensor is faulty. Repairing it helps reduce your energy bill.

Why Choose a Professional Refrigerator Repairing Service in Chennai?

When your fridge breaks down, it’s tempting to try and fix it yourself or call a local handyman. However, working with a certified technician ensures:

1. Accurate Diagnosis

Trained professionals can identify the root cause quickly and provide the right solution without guesswork.

2. Genuine Spare Parts

Authorized service providers use original parts that extend your appliance’s life.

3. Time and Cost Savings

Quick repairs save you from the cost of food spoilage and the hassle of replacing the entire unit.

4. Warranty on Service

Most professional services offer a warranty on repairs and replaced parts.

5. Safety First

Fridges operate using electrical systems and gas-based cooling mechanisms. Professional handling ensures safety for you and your family.

Benefits of Local Service in Chennai

Getting a refrigerator repairing service in Chennai comes with its own advantages:

Quick response time: Local services can reach your home on the same day or next day.

Familiar with local brands and models: Chennai households use a variety of Indian and international fridge brands. Local experts are trained to handle models from LG, Samsung, Whirlpool, Haier, Godrej, and more.

Affordable pricing: Being close to your area reduces travel and service charges.

Emergency services: Some providers offer urgent or weekend support for breakdowns during hot weather or festivals.

What to Expect from a Reliable Fridge Repair Technician

A professional refrigerator repair technician in Chennai will:

Inspect the fridge and identify the problem

Explain the issue clearly and provide a quote

Use proper tools and parts for repair

Offer service warranty (typically 30 to 90 days)

Ensure the appliance is cleaned and tested before leaving

They may also share tips to help you maintain your fridge better and avoid future problems.

Tips to Maintain Your Refrigerator for Long Life

Don’t overload — Give space for air circulation inside.

Clean coils regularly — Dusty condenser coils make the fridge work harder.

Check door seals — Ensure the rubber seals are tight to maintain cooling.

Avoid frequent opening — It allows warm air in and reduces cooling efficiency.

Set the right temperature — Keep your fridge between 2°C and 5°C.

Routine maintenance and early repairs go a long way in avoiding costly replacements.

Final Thoughts

Refrigerators are essential in every home, especially in a warm city like Chennai where food spoils faster. When your fridge starts showing signs of trouble, don’t ignore them. Trust an expert refrigerator repairing service in Chennai to get your appliance running like new.

With trained technicians, fast response, and quality service, you can avoid the stress of malfunctioning appliances and enjoy peace of mind. Always choose experienced professionals who offer reliable, safe, and affordable repair solutions.

Whether it’s a cooling issue or a broken part, timely action ensures your fridge stays efficient and lasts longer. Keep your cool — literally and financially — by choosing the right service today.

0 notes

Text

Blockchain in Agriculture and Food Supply Chain Industry Forecast 2032: Market Size, Scope, and Growth Trends

The Blockchain in Agriculture and Food Supply Chain Market Size was valued at USD 299.1 Million in 2023 and is expected to reach USD 7035.7 Million by 2032, growing at a CAGR of 42.1% over the forecast period 2024-2032.

Blockchain technology is rapidly transforming the agriculture and food supply chain industry by offering a transparent, secure, and immutable digital ledger for tracking the journey of agricultural products from farm to fork. As consumers demand greater traceability, safety, and sustainability in their food, blockchain presents a revolutionary way to ensure accountability across the supply chain. The integration of this technology is helping stakeholders overcome critical challenges such as fraud, data manipulation, food contamination, and inefficiencies in logistics.

Blockchain in the Agriculture and Food Supply Chain Market is emerging as a powerful enabler of trust and operational efficiency. By decentralizing record-keeping and enabling real-time data sharing among farmers, suppliers, retailers, and consumers, blockchain is reshaping how agricultural goods are produced, transported, and consumed. The technology is gaining traction globally as governments, agribusinesses, and startups increasingly invest in blockchain-based solutions to modernize food systems and meet evolving regulatory and consumer demands.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/4792

Market Keyplayers:

IBM (IBM Food Trust, IBM Blockchain Platform)

Microsoft (Azure Blockchain Workbench, Azure IoT)

SAP (SAP Blockchain, SAP Leonardo)

ChainPoint (ChainPoint Platform, ChainPoint Data)

TE-FOOD (TE-FOOD Platform, TE-FOOD Blockchain)

Provenance (Provenance Platform, Provenance Ledger)

Ripe.io (RipeChain, Ripe.io Traceability)

Ambrosus (AMB-NET, AMB-DATA)

AgriLedger (AgriLedger App, AgriLedger Platform)

Everledger (Everledger Wine Platform, Everledger Supply Chain)

Market Trends

Several key trends are driving the adoption and growth of blockchain in agriculture and food supply chains:

Rising Demand for Food Traceability: With growing concerns over food safety and quality, blockchain is enabling end-to-end traceability by recording each step in the supply chain. Consumers can now scan QR codes on products to access detailed information about origin, handling, and quality certifications.

Integration with IoT and Smart Sensors: Blockchain is being paired with IoT (Internet of Things) devices and sensors to provide real-time updates on temperature, humidity, and location during storage and transit. This helps reduce spoilage, ensure compliance with safety standards, and optimize logistics.

Sustainable and Ethical Sourcing: Consumers and brands alike are prioritizing ethical farming practices and sustainable sourcing. Blockchain ensures that product claims—such as organic, fair trade, or pesticide-free—are verifiable and backed by transparent data.

Government and Regulatory Support: Regulatory bodies in regions like Europe, the U.S., and Asia are beginning to support blockchain initiatives for agricultural monitoring and food compliance, fostering innovation and boosting industry credibility.

Enquiry of This Report: https://www.snsinsider.com/enquiry/4792

Market Segmentation:

By type

Public

Private

Hybrid/Consortium

By stakeholders

Growers

Food manufacturers/processors

Retailers

By providers

Application providers

Middleware providers

Infrastructure providers

By Enterprise size

Small and medium-sized enterprises

Large enterprises

By application

Product traceability, tracking, and visibility

Payment and settlement

Smart contract

Governance, risk, and compliance management

Market Analysis

The technology is particularly beneficial in sectors like dairy, seafood, coffee, and organic produce, where provenance and authenticity are crucial.

Asia-Pacific and North America are currently leading the adoption curve, with Europe following closely. Developing regions are also showing increasing interest as blockchain proves its value in improving supply chain efficiency, reducing waste, and ensuring fair trade practices for smallholder farmers.

Future Prospects

The future of blockchain in the agriculture and food supply chain market looks promising, with several innovations and advancements expected to shape the sector:

Wider Use of Smart Contracts: Automated agreements between producers, distributors, and retailers will reduce paperwork, increase trust, and ensure timely payments based on predefined conditions.

Blockchain-Based Marketplaces: Decentralized platforms will empower farmers by connecting them directly with buyers, removing middlemen and increasing profit margins.

Blockchain for Carbon Credits and Sustainability Tracking: Blockchain will play a vital role in helping agribusinesses and food companies track carbon footprints, water usage, and other sustainability metrics to meet ESG (Environmental, Social, and Governance) goals.

Interoperability and Standardization: As adoption increases, the focus will shift toward creating industry-wide standards and cross-platform compatibility to enable a more cohesive global supply chain system.

Access Complete Report: https://www.snsinsider.com/reports/blockchain-in-agriculture-and-food-supply-chain-market-4792

Conclusion

Blockchain in the agriculture and food supply chain market is revolutionizing the way the world grows, processes, and consumes food. By offering transparency, traceability, and trust, blockchain empowers consumers, protects producers, and strengthens supply chains against disruptions and fraud. While challenges such as scalability, digital literacy, and infrastructure gaps remain, ongoing innovation and investment are paving the way for widespread adoption.

As the global food industry faces increasing scrutiny and complexity, blockchain stands out as a powerful tool for building resilient, secure, and sustainable food systems. The technology is not just a trend—it's becoming a foundational layer for the future of agriculture and food logistics.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

0 notes

Text

On-the-Go Fixes: Revolutionizing Windscreen Solutions

Introduction to a New Era of Convenience

In a world where time is as precious as safety, the way we handle vehicle repairs is undergoing a remarkable shift. Gone are the days of lengthy garage visits for a cracked windscreen; today, innovation brings the solution right to your doorstep. Mobile windscreen replacement and traditional windshield replacement are at the heart of this evolution, offering drivers options that blend convenience with quality. This article explores the captivating rise of these services, delving into their benefits, differences, and how they’re reshaping the automotive landscape one clear view at a time.

The Rise of Mobile Windscreen Replacement

The concept of mobile windscreen replacement is a game-changer, turning a once-tedious task into a seamless experience. Imagine a busy parent juggling work and family, only to discover a spiderweb of cracks across their car’s windscreen. Instead of carving out hours to visit a shop, a technician arrives at their home or office, tools in tow, ready to restore clarity on the spot. This service is built on the idea that repairs should fit into your life, not disrupt it.

What makes this approach so compelling is its flexibility. Technicians equipped with portable workstations can tackle replacements in parking lots, driveways, or even roadside emergencies, weather permitting. Advances in adhesive technology and lightweight tools have made it possible to achieve the same precision as a fixed location, all while saving drivers time and hassle. Mobile windscreen replacement isn’t just a repair—it’s a lifeline for those who can’t afford to pause their day, blending modern ingenuity with old-fashioned customer care.

Windshield Replacement: The Traditional Backbone

While mobile services steal the spotlight, windshield replacement in its classic form remains a cornerstone of automotive repair. This method typically unfolds in a controlled shop environment, where skilled hands and specialized equipment ensure a flawless fit. Picture a driver with a shattered windscreen pulling into a garage, entrusting their vehicle to experts who meticulously remove the old glass, prep the frame, and install a new pane with surgical accuracy. It’s a process steeped in reliability, honed over decades.

The strength of traditional windshield replacement lies in its consistency. Shops offer a stable setting where temperature, dust, and moisture—factors that can affect adhesive curing—are tightly managed. For complex cases, like vehicles with advanced sensors or unique glass shapes, this controlled approach ensures every detail is addressed. It’s the gold standard for those who prioritize precision and have the flexibility to leave their car for a few hours, proving that sometimes the tried-and-true method still holds its own.

Comparing Convenience and Craftsmanship

The interplay between mobile windscreen replacement and windshield replacement highlights a fascinating balance of convenience and craftsmanship. Mobile services excel in speed and adaptability, arriving where and when you need them. A commuter stranded with a cracked windscreen can get back on the road without detouring to a shop, thanks to a technician who performs the swap in under an hour. It’s a tailored solution for the on-the-go lifestyle, prioritizing accessibility without skimping on quality.

Conversely, traditional windshield replacement offers a depth of expertise that shines in intricate scenarios. A vehicle with a heads-up display or rain-sensing wipers might benefit from the shop’s diagnostic tools and controlled conditions, ensuring every system recalibrates perfectly. While it requires a trip and some downtime, the meticulous process delivers peace of mind for drivers who value a factory-like finish. Together, these options cater to diverse needs, letting drivers choose based on urgency, complexity, and personal preference.

The Future of Windscreen Solutions

As technology accelerates, both mobile windscreen replacement and windshield replacement' are poised for exciting advancements. Mobile services could soon leverage drones or augmented reality to assist technicians in remote fixes, pushing the boundaries of what’s possible on the fly. Meanwhile, shop-based replacements might integrate robotics for even greater precision, especially as cars become more tech-laden with autonomous features. The line between these approaches may blur, with hybrid models emerging to combine the best of both worlds.

This evolution reflects a broader shift in how we view vehicle upkeep—less as a chore, more as a service that adapts to us. Whether it’s a mobile unit rolling up to a worksite or a shop restoring a windscreen to perfection, the focus is on safety and clarity without compromise. As road travel remains a lifeline for millions, these innovations ensure that a clear view ahead is always within reach, no matter where life takes you.

0 notes

Text

Fluoropolymer Tubing Market Analysis: Key Players and Competitive Landscape

Expanding Applications in Healthcare, Electronics, and Industrial Sectors Drive Growth in the Fluoropolymer Tubing Market.

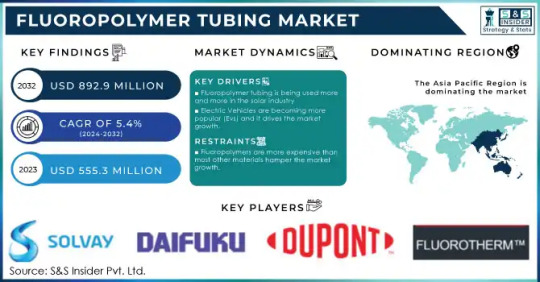

The Fluoropolymer Tubing Market Size was USD 555.3 Million in 2023 and is expected to reach USD 892.9 Million by 2032 and grow at a CAGR of 5.4% over the forecast period of 2024-2032.

The Fluoropolymer Tubing Market is witnessing significant growth due to increasing demand for high-performance tubing solutions in industries such as pharmaceuticals, chemicals, automotive, aerospace, and electronics. Fluoropolymer tubing is known for its exceptional chemical resistance, high-temperature stability, non-stick properties, and biocompatibility, making it an ideal choice for harsh and demanding environments. The rising adoption of fluoropolymer tubing in medical devices, fluid handling systems, and semiconductor manufacturing is further propelling market expansion.

Key Players

Daikin Industries Ltd.

Solvay SA

Fluorotherm

Saint-Gobain

Optinova

TE Connectivity

3M Company

Honeywell International Inc.

Parker Hannifin

Ametek

Future Scope

The Fluoropolymer Tubing Market is expected to grow steadily due to rising applications in biopharmaceuticals, industrial processing, and high-tech manufacturing. The expansion of semiconductor fabrication, medical equipment production, and chemical processing industries is increasing the demand for durable and corrosion-resistant tubing solutions. Innovations in extrusion technology and the development of custom-engineered fluoropolymer tubing are set to drive market advancements. The shift toward miniaturized, high-performance medical and electronic components will further create opportunities for precision-engineered tubing solutions.

Emerging Trends

The market is evolving with the introduction of next-generation fluoropolymer materials, such as modified PTFE, PFA, and FEP, which offer improved performance in extreme environments. The demand for biocompatible and medical-grade fluoropolymer tubing is rising, particularly in catheters, drug delivery systems, and diagnostic equipment. Additionally, sustainability initiatives are driving the development of recyclable and environmentally friendly fluoropolymer solutions. The integration of smart tubing technologies, such as tubing with embedded sensors for real-time monitoring, is expected to revolutionize industrial applications.

Key Points

Growing demand for fluoropolymer tubing in pharmaceuticals, electronics, and industrial processing.

Advancements in material science leading to enhanced chemical and temperature resistance.

Increased adoption of biocompatible and medical-grade fluoropolymer tubing.

Development of recyclable and eco-friendly fluoropolymer tubing solutions.

Rising use of embedded sensor technology for real-time monitoring in industrial applications.

Conclusion

The Fluoropolymer Tubing Market is set for continued expansion, driven by technological advancements, increasing industrial applications, and the demand for high-performance materials. As industries push for more durable, chemically resistant, and sustainable solutions, fluoropolymer tubing will play a crucial role in critical applications. With ongoing research in smart tubing and eco-friendly materials, the market is expected to evolve, offering enhanced performance and efficiency across multiple sectors.

Read Full Report: https://www.snsinsider.com/reports/fluoropolymer-tubing-market-1978

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Fluoropolymer Tubing Market#Fluoropolymer Tubing Market Size#Fluoropolymer Tubing Market Share#Fluoropolymer Tubing Market Report#Fluoropolymer Tubing Market Forecast

0 notes

Text

Coolant temperature sensor

My studies over the past few months have been about understanding TE Connectivity, 5499922-6, Pin and Socket Connectors, Headers Connectors, Wire-to-wire headers and coolant temperature sensor.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] The real water separation, highly sensitive built-in leakage protection, anti-dry design to ensure there is water, electricity, high pressure waterproof design, safe care. Suitable for household water, wash dishes, vegetables, bathing and other uses 3 seconds speed heating, instant hot. Support and well-being of dual-use electric faucet, while heated, the water, the lower the temperature whereas the smaller the flow, the higher the temperature. Tankless Design: With a compact and tankless design, it saves space and is suitable for kitchens and bathrooms. : Cute shape design with beautiful colours, nice for home kitchen decoration, your kids will love it and like to wash their food and hands proactively Handy flexible sprayer is 6" long and provides a 360 range of motion.with tap, easy to turn up or turn down the water.Instant tankless water heater with temperature sensor screen allows you to provide hot water to summer cottages, garages, and guest houses. The way of the water heater is under the influent. Don't need to store heating water. Our instant tankless water heater heated the water when it turned on. It can be used directly on the faucet without special equipment. The hot water temperature is 30 to 40 degrees in winter and 30 to 60 degrees in summer. Heat up quickly in 3 seconds, no need to wait in cold winter. water Open the handle of the hot water zone. The more boiled the water is, the faster the water will flow and the cooler it will be water Innovative water and electricity separation technology, waterproof, anti-electricity, safe and reliable, completely isolated from current and water flow. water 𝐑𝐚𝐩𝐢𝐝 𝐇𝐞𝐚𝐭𝐢𝐧𝐠 𝐟𝐨𝐫 𝐈𝐦𝐦𝐞𝐝𝐢𝐚𝐭𝐞 𝐇𝐨𝐭 𝐖𝐚𝐭𝐞R Experience the luxury of hot water in just seconds with this powerful 3000W electric heater. Designed to heat water almost instantly, it provides hot water within 3 seconds of activation, ensuring you never have to wait. Whether for washing dishes in the kitchen or taking a quick shower, this heater’s rapid response time enhances convenience and efficiency, making it an indispensable part of your daily routine. 𝐂𝐨𝐦𝐩𝐚𝐜𝐭 𝐒𝐢𝐳𝐞 𝐰𝐢𝐭𝐡 𝐑𝐨𝐭𝐚𝐭𝐚𝐛𝐥𝐞 𝐅𝐚𝐮𝐜𝐞𝐭 Measuring 48x16x25cm, this water heater is compact enough to fit into tight spaces without compromising functionality. The faucet’s rotatable design adds to its flexibility, allowing you to direct the water flow wherever you need it. This space-saving, adjustable feature makes it ideal for both small and large areas, offering practical use and easy integration into any room layout. Support and well-being of dual-use electric faucet, while heated, the water, the lower the temperature, whereas the smaller the flow, the higher the temperature. Quick Electric Hot Water Tap Heating tube: high-purity copper liner heating element Rated voltage: 220V/50HZ Rated Power: 3000W Power unified are the 3000-watt, 5 seconds fast heat! Your hands won't feel cold when washing dishes or doing the laundry or washing vegetables. Of course, washing face and brushing teeth with warm water every morning are great enjoyments. When you receive Dr Water tankless instant electric tap water heater, please do not test it in your hands, you need install it well and then test, or it will be dangerous. Please operate it according to the instructions. Your hands won't feel cold when washing dishes or doing the laundry. Of course,washing face and brushing teeth with warm water every morning are great enjoyments. When you receive the water heater, please do not test it in your hands, you need install it well and then test, or it will be dangerous. Please operate it according to the instructions. [ad_2]

0 notes

Text

TE Connectivity offers a wide range of connector cables designed for various industries, including industrial automation, transportation, consumer electronics, medical devices, and renewable energy. These cables, paired with TE’s connectors, provide reliable, high-performance solutions for power, data, and signal transmission in demanding environments.

Applications of TE Connector Cables

1. Industrial Automation

Sensor and Actuator Connections: TE cables are used to link sensors and actuators to control systems, ensuring precise data and power transfer.

Robotics: Facilitate signal and power connections in robotic arms, motion control systems, and vision systems.

Distributed Control Systems (DCS): Provide robust and reliable connections between distributed I/O devices and controllers.

2. Automotive and Transportation

Vehicle Electronics: TE connector cables are used for in-vehicle networking, connecting ECUs (Electronic Control Units), sensors, and actuators.

Electric Vehicles (EVs): Provide connections for battery management systems (BMS), charging ports, and high-voltage power systems.

Railways and Aerospace: Rugged cables ensure reliability under high-vibration and extreme environmental conditions.

3. Medical Equipment

Patient Monitoring Devices: Deliver accurate signal transmission in diagnostic and monitoring devices.

Imaging Systems: Provide high-speed data transmission for devices like MRI and CT scanners.

Wearable Medical Devices: Offer lightweight and compact connections for portable and wearable technologies.

4. Consumer Electronics

Home Appliances: TE cables connect sensors, motors, and controllers in smart home devices and appliances.

Computing and Communication: Used in high-speed data connections for networking equipment, laptops, and mobile devices.

5. Renewable Energy

Solar Power: Provide durable connections for photovoltaic (PV) panels, inverters, and monitoring systems.

Wind Energy: Ensure reliable power and data connections in wind turbine control systems and monitoring sensors.

6. Data Centers and Telecommunications

High-Speed Networking: TE’s connector cables support high-speed Ethernet, fiber optics, and other data transmission technologies in servers and communication infrastructure.

Power Distribution: Deliver efficient power connections in data centers.

7. Harsh Environment Applications

Oil and Gas: Resistant to high temperatures, chemicals, and corrosive environments.

Military and Defense: Rugged cables provide reliable connections in critical applications like communication systems and unmanned vehicles.

Key Features of TE Connector Cables

Durability: Withstand mechanical stress, temperature extremes, and environmental factors like moisture and dust.

High-Speed Data Transfer: Support modern communication protocols and IoT applications.

Compact and Modular Design: Ideal for space-constrained applications.

Wide Range of Options: Available in various lengths, materials, and connector types to meet specific requirements.

Environmental Protection: IP-rated options ensure performance in harsh environments.

Popular TE Connector Cable Types

M8/M12 Connector Cables: Widely used in industrial automation for compact and reliable connections.

Circular Connector Cables: For robust connections in outdoor and industrial applications.

Rectangular Connector Cables: Used in power and signal connections for modular equipment.

Fiber Optic Cables: For high-speed data transmission in telecommunications and data centers.

Power and Signal Cables: Designed for high-current and mixed signal applications in EVs and industrial systems.

Conclusion

TE connector cables are designed to deliver reliable, high-performance connections across a diverse range of industries. Their robustness, versatility, and compatibility with modern technologies make them a preferred choice for applications demanding durability, precision, and efficiency.

1 note

·

View note

Text

Johnson Controls TE-68NP-1N00S 1K Nickel Sensor With Modular jack Warm Cool | PartsHnC

Manufacturer Name: Johnson Controls Product Number: TE-68NP-1N00S OEM Part Number: TE-68NP-1N00S Product Description: 1K Nicksens W/Modjck/Warm/Cool Weight:0.33lbs/149.69g

The Johnson Controls TE-68NP-1N00S is a temperature sensor mounted on the wall for controlling the room temperature in HVAC systems. This nickel-plated sensor accurately determines the temperature of the air.

0 notes

Text

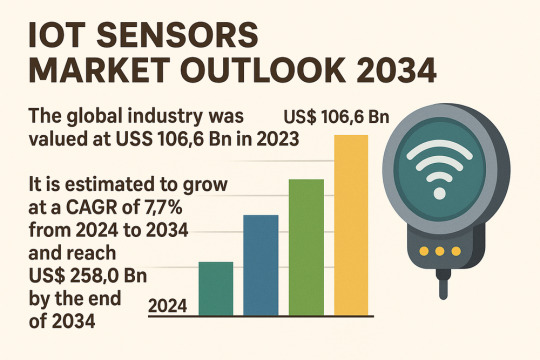

Internet of Things (IoT) Sensors Market to Hit US$ 258 Billion by 2034

The global Internet of Things (IoT) sensors market was valued at US$ 106.6 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 7.7% between 2024 and 2034, reaching US$ 258.0 billion by the end of the forecast period. IoT sensors, which convert physical parameters such as temperature, pressure, humidity, and motion into electrical signals, are key enablers of real-time data analytics across consumer electronics, healthcare, automotive, agriculture, transportation, and industrial sectors.

Market Drivers & Trends

Surge in Demand for Smart Sensors

Smart sensors provide digital data ready for immediate transmission, reducing latency in performance monitoring.

Adoption of automated predictive maintenance in smart factories is accelerating the shift toward intelligent sensor networks to prolong asset life and prevent unplanned downtime.

Rise in Investment in Industry 4.0

Industrial IoT (IIoT) sensors aggregate data centrally and feed it back to optimize processes, critical for factory automation and digital twin implementations.

Growth in collaborative robotics and autonomous guided vehicles has driven demand for Inertial Measurement Units (IMUs) comprising accelerometers, gyroscopes, and magnetometers to enable precise motion control.

Shift Toward Wireless Connectivity

Wireless IoT sensors are rapidly gaining traction due to simpler installation, scalability, and elimination of wiring constraints, essential for real-time asset tracking via GPS and network connectivity.

Latest Market Trends

Industrial IoT (IIoT) Proliferation: Manufacturing companies, post-pandemic, are heavily investing in digital and supply-chain technologies, fueling growth in IIoT sensor deployments for condition monitoring and quality control.

Industry 5.0 Foundations: Emerging trends see humans collaborating with robots, underscoring the need for sensors with embedded AI capabilities to interpret nuanced environmental cues and support safe, efficient cooperation.

Edge Computing Integration: Key players are developing edge-based network architectures that process sensor data locally, minimizing latency and bandwidth usage, and empowering real-time decision-making.

Key Players and Industry Leaders

The competitive landscape is marked by strategic investments and product innovations from leading semiconductor and sensor manufacturers:

Analog Devices, Inc.: Investing €630 million in its Limerick, Ireland facility for advanced semiconductor research in industrial and automotive sensors.

Bosch Sensortec GmbH: Unveiled the BHI380 Smart Connected Sensors platform at CES 2024, enhancing motion-tracking applications with ready-to-use hardware and software reference designs.

Honeywell International Inc.: Expanding its wireless sensor portfolio for building automation and aerospace applications.

Infineon Technologies AG: Focusing on low-power gas and environmental sensors for consumer electronics and healthcare monitoring devices.

Texas Instruments, Murata Manufacturing, STMicroelectronics, and TE Connectivity: Continuously broadening their IoT sensor lines across temperature, pressure, flow, and proximity sensing.

Recent Developments

January 2024: Bosch Sensortec launched the BHI380 platform, addressing wearable and motion-tracking needs with integrated AI support.

2023: ABB Ltd. entered a strategic partnership with Pratexo to co-develop edge-computing solutions for decentralized IoT networks.

2023: Siemens announced a US$ 150 million smart factory in Dallas–Fort Worth, leveraging Siemens-made IoT and AI tools for digital twin and factory automation.

2023: Momenta, backed by the European Commission, launched a US$ 100 million Industry 5.0 fund to support human-robot collaboration technologies.

Market Opportunities

Smart Factory Deployments: As Industry 4.0 adoption deepens, demand for temperature, vibration, and level sensors is set to accelerate, particularly in process-driven verticals like pharmaceuticals and petrochemicals.

Healthcare Monitoring: Wearable IoT sensors for continuous patient vitals tracking present a high-growth avenue amid digital health initiatives.

Agricultural IoT: Precision farming technologies, utilizing soil moisture and ambient condition sensors, offer substantial potential in optimizing crop yields and resource utilization.

Smart Buildings and Cities: Growth in building-management systems and urban infrastructure monitoring will escalate demand for environmental and occupancy sensors.

Future Outlook

Looking ahead to 2034, the IoT sensors market is poised for transformative growth driven by:

Advancements in AI-Embedded Sensors: On-sensor analytics will enable localized anomaly detection and autonomous decision-making.

Expansion of 5G and Beyond: Ultra-low latency networks will unlock new applications, from autonomous vehicles to remote surgery, demanding robust sensor ecosystems.

Sustainability Focus: Energy-harvesting and self-powered sensor technologies will reduce maintenance costs and environmental impact, aligning with corporate ESG objectives.

Market Segmentation

Segment

Sub-Segments

By Type

Temperature, Pressure, Humidity, Flow, Level, Image, Smoke, Hall Effect, Accelerometer, Vibration, Magnetometer, Gyroscope, Light, Gas, Others (Motion, Occupancy)

By Technology

Wired, Wireless

By End-Use Industry

Consumer Electronics, Healthcare, Automotive, Industrial, Building & Construction, Retail, Others (Agriculture, Transportation)

Regional Insights

Asia Pacific: Led the market in 2023, driven by accelerated technology investments in manufacturing. Indian manufacturers allocated 35% of operating budgets to tech investments above global averages to bolster IoT, automation, and AI integration.

North America: Strong uptake in smart building projects and automotive sensor applications, supported by major OEMs and tech giants.

Europe: Growing emphasis on sustainable manufacturing and Industrial Internet Consortium initiatives has catalyzed sensor adoption in Germany, France, and the U.K.

Latin America & MEA: Emerging infrastructure modernization and smart agriculture projects are creating greenfield opportunities for sensor deployment.

Why Buy This Report?

Comprehensive Analysis: Deep-dive quantitative and qualitative assessment covering 2020–2022 historical data and 2024–2034 forecast.

Actionable Insights: Detailed coverage of market drivers, restraints, opportunities, and Porter’s Five Forces to guide strategic decision-making.

Competitive Benchmarking: Profiles of 16 leading companies, including product portfolios, financial metrics, strategic initiatives, and recent developments.

Segmentation & Regional Breakdowns: Granular market sizing across types, technologies, end-use industries, and five key regions plus 12 major countries.

Customizable Format: Delivered in PDF and Excel formats with interactive data dashboards for further analysis.