#Textile Processing Machine Price

Explore tagged Tumblr posts

Text

If you’re UK based and love knitting/yarn/rare heritage breeds, there’s a London City Farms Kickstarter out there right run by a sustainable textiles creator now that have pooled together something like 16 rare breeds across the city farms and turned it into a machine and hand knitting yarn. Most of these fleeces were going to waste because, as we all know, fleeces are priced so lowly that it’s usually not worth the cost of the cleaning, processing and industrial spinning. You can buy a skein, cone, or an item made solely from the natural colours that the blended sheep breeds produce.

462 notes

·

View notes

Text

AI turns Amazon coders into Amazon warehouse workers

HEY SEATTLE! I'm appearing at the Cascade PBS Ideas Festival NEXT SATURDAY (May 31) with the folks from NPR's On The Media!

On a recent This Machine Kills episode, guest Hagen Blix described the ultimate form of "AI therapy" with a "human in the loop":

https://soundcloud.com/thismachinekillspod/405-ai-is-the-demon-god-of-capital-ft-hagen-blix

One actual therapist is just having ten chat GPT windows open where they just like have five seconds to interrupt the chatGPT. They have to scan them all and see if it says something really inappropriate. That's your job, to stop it.

Blix admits that's not where therapy is at…yet, but he references Laura Preston's 2023 N Plus One essay, "HUMAN_FALLBACK," which describes her as a backstop to a real-estate "virtual assistant," that masqueraded as a human handling the queries that confused it, in a bid to keep the customers from figuring out that they were engaging with a chatbot:

https://www.nplusonemag.com/issue-44/essays/human_fallback/

This is what makes investors and bosses slobber so hard for AI – a "productivity" boost that arises from taking away the bargaining power of workers so that they can be made to labor under worse conditions for less money. The efficiency gains of automation aren't just about using fewer workers to achieve the same output – it's about the fact that the workers you fire in this process can be used as a threat against the remaining workers: "Do your job and shut up or I'll fire you and give your job to one of your former colleagues who's now on the breadline."

This has been at the heart of labor fights over automation since the Industrial Revolution, when skilled textile workers took up the Luddite cause because their bosses wanted to fire them and replace them with child workers snatched from Napoleonic War orphanages:

https://pluralistic.net/2023/09/26/enochs-hammer/#thats-fronkonsteen

Textile automation wasn't just about producing more cloth – it was about producing cheaper, worse cloth. The new machines were so easy a child could use them, because that's who was using them – kidnapped war orphans. The adult textile workers the machines displaced weren't afraid of technology. Far from it! Weavers used the most advanced machinery of the day, and apprenticed for seven years to learn how to operate it. Luddites had the equivalent of a Masters in Engineering from MIT.

Weavers' guilds presented two problems for their bosses: first, they had enormous power, thanks to the extensive training required to operate their looms; and second, they used that power to regulate the quality of the goods they made. Even before the Industrial Revolution, weavers could have produced more cloth at lower prices by skimping on quality, but they refused, out of principle, because their work mattered to them.

Now, of course weavers also appreciated the value of their products, and understood that innovations that would allow them to increase their productivity and make more fabric at lower prices would be good for the world. They weren't snobs who thought that only the wealthy should go clothed. Weavers had continuously adopted numerous innovations, each of which increased the productivity and the quality of their wares.

Long before the Luddite uprising, weavers had petitioned factory owners and Parliament under the laws that guaranteed the guilds the right to oversee textile automation to ensure that it didn't come at the price of worker power or the quality of the textiles the machines produced. But the factory owners and their investors had captured Parliament, which ignored its own laws and did nothing as the "dark, Satanic mills" proliferated. Luddites only turned to property destruction after the system failed them.

Now, it's true that eventually, the machines improved and the fabric they turned out matched and exceeded the quality of the fabric that preceded the Industrial Revolution. But there's nothing about the way the Industrial Revolution unfolded – increasing the power of capital to pay workers less and treat them worse while flooding the market with inferior products – that was necessary or beneficial to that progress. Every other innovation in textile production up until that time had been undertaken with the cooperation of the guilds, who'd ensured that "progress" meant better lives for workers, better products for consumers, and lower prices. If the Luddites' demands for co-determination in the Industrial Revolution had been met, we might have gotten to the same world of superior products at lower costs, but without the immiseration of generations of workers, mass killings to suppress worker uprisings, and decades of defective products being foisted on the public.

So there are two stories about automation and labor: in the dominant narrative, workers are afraid of the automation that delivers benefits to all of us, stand in the way of progress, and get steamrollered for their own good, as well as ours. In the other narrative, workers are glad to have boring and dangerous parts of their work automated away and happy to produce more high-quality goods and services, and stand ready to assess and plan the rollout of new tools, and when workers object to automation, it's because they see automation being used to crush them and worsen the outputs they care about, at the expense of the customers they care for.

In modern automation/labor theory, this debate is framed in terms of "centaurs" (humans who are assisted by technology) and "reverse-centaurs" (humans who are conscripted to assist technology):

https://pluralistic.net/2023/04/12/algorithmic-wage-discrimination/#fishers-of-men

There are plenty of workers who are excited at the thought of using AI tools to relieve them of some drudgework. To the extent that these workers have power over their bosses and their working conditions, that excitement might well be justified. I hear a lot from programmers who work on their own projects about how nice it is to have a kind of hypertrophied macro system that can generate and tweak little automated tools on the fly so the humans can focus on the real, chewy challenges. Those workers are the centaurs, and it's no wonder that they're excited about improved tooling.

But the reverse-centaur version is a lot darker. The reverse-centaur coder is an assistant to the AI, charged with being a "human in the loop" who reviews the material that the AI produces. This is a pretty terrible job to have.

For starters, the kinds of mistakes that AI coders make are the hardest mistakes for human reviewers to catch. That's because LLMs are statistical prediction machines, spicy autocomplete that works by ingesting and analyzing a vast corpus of written materials and then producing outputs that represent a series of plausible guesses about which words should follow one another. To the extent that the reality the AI is participating in is statistically smooth and predictable, AI can often make eerily good guesses at words that turn into sentences or code that slot well into that reality.

But where reality is lumpy and irregular, AI stumbles. AI is intrinsically conservative. As a statistically informed guessing program, it wants the future to be like the past:

https://reallifemag.com/the-apophenic-machine/

This means that AI coders stumble wherever the world contains rough patches and snags. Take "slopsquatting." For the most part, software libraries follow regular naming conventions. For example, there might be a series of text-handling libraries with names like "text.parsing.docx," "text.parsing.xml," and "text.parsing.markdown." But for some reason – maybe two different projects were merged, or maybe someone was just inattentive – there's also a library called "text.txt.parsing" (instead of "text.parsing.txt").

AI coders are doing inference based on statistical analysis, and anyone inferring what the .txt parsing library is called would guess, based on the other libraries, that it was "text.parsing.txt." And that's what the AI guesses, and so it tries to import that library to its software projects.

This creates a new security vulnerability, "slopsquatting," in which a malicious actor creates a library with the expected name, which replicates the functionality of the real library, but also contains malicious code:

https://www.theregister.com/2025/04/12/ai_code_suggestions_sabotage_supply_chain/

Note that slopsquatting errors are extremely hard to spot. As is typical with AI coding errors, these are errors that are based on continuing a historical pattern, which is the sort of thing our own brains do all the time (think of trying to go up a step that isn't there after climbing to the top of a staircase). Notably, these are very different from the errors that a beginning programmer whose work is being reviewed by a more senior coder might make. These are the very hardest errors for humans to spot, and these are the errors that AIs make the most, and they do so at machine speed:

https://pluralistic.net/2024/04/23/maximal-plausibility/#reverse-centaurs

To be a human in the loop for an AI coder, a programmer must engage in sustained, careful, line-by-line and command-by-command scrutiny of the code. This is the hardest kind of code to review, and maintaining robotic vigilance over long periods at high speeds is something humans are very bad at. Indeed, it's the kind of task we try very hard to automate, since machines are much better at being machineline than humans are. This is the essence of reverse-centaurism: when a human is expected to act like a machine in order to help the machine do something it can't do.

Humans routinely fail at spotting these errors, unsurprisingly. If the purpose of automation is to make superior goods at lower prices, then this would be a real concern, since a reverse-centaur coding arrangement is bound to produce code with lurking, pernicious, especially hard-to-spot bugs that present serious risks to users. But if the purpose of automation is to discipline labor – to force coders to accept worse conditions and pay – irrespective of the impact on quality, then AI is the perfect tool for the job. The point of the human isn't to catch the AI's errors so much as it is to catch the blame for the AI's errors – to be what Madeleine Clare Elish calls a "moral crumple zone":

https://estsjournal.org/index.php/ests/article/view/260

As has been the case since the Industrial Revolution, the project of automation isn't just about increasing productivity, it's about weakening labor power as a prelude to lowering quality. Take what's happened to the news industry, where mass layoffs are being offset by AI tools. At Hearst's King Features Syndicates, a single writer was charged with producing over 30 summer guides, the entire package:

https://www.404media.co/viral-ai-generated-summer-guide-printed-by-chicago-sun-times-was-made-by-magazine-giant-hearst/

That is an impossible task, which is why the writer turned to AI to do his homework, and then, infamously, published a "summer reading guide" that was full of nonexistent books that were hallucinated by a chatbot:

https://www.404media.co/chicago-sun-times-prints-ai-generated-summer-reading-list-with-books-that-dont-exist/

Most people reacted to this story as a consumer issue: they were outraged that the world was having a defective product foisted upon it. But the consumer issue here is downstream from the labor issue: when the writers at King Features Syndicate are turned into reverse-centaurs, they will inevitably produce defective outputs. The point of the worker – the "human in the loop" – isn't to supervise the AI, it's to take the blame for the AI. That's just what happened, as this poor schmuck absorbed an internet-sized rasher of shit flung his way by outraged social media users. After all, it was his byline on the story, not the chatbot's. He's the moral crumple-zone.

The implication of this is that consumers and workers are class allies in the automation wars. The point of using automation to weaken labor isn't just cheaper products – it's cheaper, defective products, inflicted on the unsuspecting and defenseless public who are no longer protected by workers' professionalism and pride in their jobs.

That's what's going on at Duolingo, where CEO Luis von Ahn created a firestorm by announcing mass firings of human language instructors, who would be replaced by AI. The "AI first" announcement pissed off Duolingo's workers, of course, but what caught von Ahn off-guard was how much this pissed off Duolingo's users:

https://tech.slashdot.org/story/25/05/25/0347239/duolingo-faces-massive-social-media-backlash-after-ai-first-comments

But of course, this makes perfect sense. After all, language-learners are literally incapable of spotting errors in the AI instruction they receive. If you spoke the language well enough to spot the AI's mistakes, you wouldn't need Duolingo! I don't doubt that there are countless ways in which AIs could benefit both language learners and the Duolingo workers who develop instructional materials, but for that to happen, workers' and learners' needs will have to be the focus of AI integration. Centaurs could produce great language learning materials with AI – but reverse-centaurs can only produce slop.

Unsurprisingly, many of the most successful AI products are "bossware" tools that let employers monitor and discipline workers who've been reverse-centaurized. Both blue-collar and white-collar workplaces have filled up with "electronic whips" that monitor and evaluate performance:

https://pluralistic.net/2024/08/02/despotism-on-demand/#virtual-whips

AI can give bosses "dashboards" that tell them which Amazon delivery drivers operate their vehicles with their mouths open (Amazon doesn't let its drivers sing on the job). Meanwhile, a German company called Celonis will sell your boss a kind of AI phrenology tool that assesses your "emotional quality" by spying on you while you work:

https://crackedlabs.org/en/data-work/publications/processmining-algomanage

Tech firms were among the first and most aggressive adopters of AI-based electronic whips. But these whips weren't used on coders – they were reserved for tech's vast blue-collar and contractor workforce: clickworkers, gig workers, warehouse workers, AI data-labelers and delivery drivers.

Tech bosses tormented these workers but pampered their coders. That wasn't out of any sentimental attachment to tech workers. Rather, tech bosses were afraid of tech workers, because tech workers possess a rare set of skills that can be harnessed by tech firms to produce gigantic returns. Tech workers have historically been princes of labor, able to command high salaries and deferential treatment from their bosses (think of the amazing tech "campus" perks), because their scarcity gave them power.

It's easy to predict how tech bosses would treat tech workers if they could get away with it – just look how they treat workers they aren't afraid of. Just like the textile mill owners of the Industrial Revolution, the thing that excites tech bosses about AI is the possibility of cutting off a group of powerful workers at the knees. After all, it took more than a century for strong labor unions to match the power that the pre-Industrial Revolution guilds had. If AI can crush the power of tech workers, it might buy tech bosses a century of free rein to shift value from their workforce to their investors, while also doing away with pesky Tron-pilled workers who believe they have a moral obligation to "fight for the user."

William Gibson famously wrote, "The future is here, it's just not evenly distributed." The workers that tech bosses don't fear are living in the future of the workers that tech bosses can't easily replace.

This week, the New York Times's veteran Amazon labor report Noam Scheiber published a deeply reported piece about the experience of coders at Amazon in the age of AI:

https://www.nytimes.com/2025/05/25/business/amazon-ai-coders.html

Amazon CEO Andy Jassy is palpably horny for AI coders, evidenced by investor memos boasting of AI's returns in "productivity and cost avoidance" and pronouncements about AI saving "the equivalent of 4,500 developer-years":

https://www.linkedin.com/posts/andy-jassy-8b1615_one-of-the-most-tedious-but-critical-tasks-activity-7232374162185461760-AdSz/

Amazon is among the most notorious abusers of blue-collar labor, the workplace where everyone who doesn't have a bullshit laptop job is expected to piss in a bottle and spend an unpaid hour before and after work going through a bag- and body-search. Amazon's blue-collar workers are under continuous, totalizing, judging AI scrutiny that scores them based on whether their eyeballs are correctly oriented, whether they take too long to pick up an object, whether they pee too often. Amazon warehouse workers are injured at three times national average. Amazon AIs scan social media for disgruntled workers talking about unions, and Amazon has another AI tool that predicts which shops and departments are most likely to want to unionize.

Scheiber's piece describes what it's like to be an Amazon tech worker who's getting the reverse-centaur treatment that has heretofore been reserved for warehouse workers and drivers. They describe "speedups" in which they are moved from writing code to reviewing AI code, their jobs transformed from solving chewy intellectual puzzles to racing to spot hard-to-find AI coding errors as a clock ticks down. Amazon bosses haven't ordered their tech workers to use AI, just raised their quotas to a level that can't be attained without getting an AI to do most of the work – just like the Chicago Sun-Times writer who was expected to write all 30 articles in the summer guide package on his own. No one made him use AI, but he wasn't going to produce 30 articles on deadline without a chatbot.

Amazon insists that it is treating AI as an assistant for its coders, but the actual working conditions make it clear that this is a reverse-centaur transformation. Scheiber discusses a dissident internal group at Amazon called Amazon Employees for Climate Justice, who link the company's use of AI to its carbon footprint. Beyond those climate concerns, these workers are treating AI as a labor issue.

Amazon's coders have been making tentative gestures of solidarity towards its blue-collar workforce since the pandemic broke out, walking out in support of striking warehouse workers (and getting fired for doing so):

https://pluralistic.net/2020/04/14/abolish-silicon-valley/#hang-together-hang-separately

But those firings haven't deterred Amazon's tech workers from making common cause with their comrades on the shop floor:

https://pluralistic.net/2021/01/19/deastroturfing/#real-power

When techies describe their experience of AI, it sometimes sounds like they're describing two completely different realities – and that's because they are. For workers with power and control, automation turns them into centaurs, who get to use AI tools to improve their work-lives. For workers whose power is waning, AI is a tool for reverse-centaurism, an electronic whip that pushes them to work at superhuman speeds. And when they fail, these workers become "moral crumple zones," absorbing the blame for the defective products their bosses pushed out in order to goose profits.

As ever, what a technology does pales in comparison to who it does it for and who it does it to.

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2025/05/27/rancid-vibe-coding/#class-war

Image: Cryteria (modified) https://commons.wikimedia.org/wiki/File:HAL9000.svg

CC BY 3.0 https://creativecommons.org/licenses/by/3.0/deed.en

349 notes

·

View notes

Text

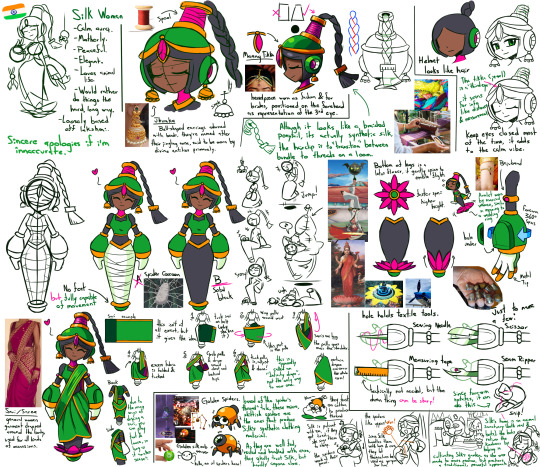

Introducing: Silk Woman.

A Robot Master from India, developed for the intent of crafting and mass producing clothes of the finest quality and prettiest design to the higest bidder.

Loosely based off Lakshmi, this gal was built to embody beauty, feminity and fortune, the last of which would come as a result of her work being made of the best genuine silk her patron corporation could acquire.

However, given her personality being that of a saint and her enormous compassion, once she learned of the process that went into adquiring real silk as fast as possible, she rebelled against the corporation that built her, and a robot that wasn't gonna comply would no longer be useful, so she was quickly discarded soon after.

Abandoned at the scrapyard, she was at a loss of what to do since she was stripped of the silk that had given her name and had no real method of getting out in the world on her own.

Fortune would soon smile upon her, however, as she soon discovered a tiny insect scuttering about on the scrapyard and saved it from nearly getting crushed by the rubble of the place, as it would have it, this little insect was a tiny mechanical golden spider.

As it happens, these golden spiders were companions to hobbyist in the textile arts, made to produce synthetic thread in various colors as long as they were provided the materials for it. However, these models were easily disposable if the hobbyist ran out of materials or merely didn't want to continue their lost passion.

This little spider was thankful for the kindness Silk had shown, and as if it could talk, it led her to more of its kind, who had various amounts of left-over silk within them.

With the help of the spiders, she was led out of the scrapyard and safely escaped a grim demise at the hands of crushers or trash melters. Though she had little to her name, she did had the skills to sew, and the thankful spiders would gladly provide what they had.

The group would soon find a place where they could prepare and sell their wares, though given the mass produced tools she had the people did not trust her as she was seen as a machine and not as a crafter, soon would she decide to switch her methods and learn the trade once more on her own, with no tricks to speed up the process.

It was a hard time, and the thread of the spiders was running out (and not a dime to feed them as they needed to be), it seemed to be over for the seamstress… until fortune shone on her once more.

A young couple this time, poor but deeply in love, they came in looking for wares they could use for their wedding and the other stablishements had rejected them for they couldn't pay the higher price. Feeling pity on them, Silk lended them her finest wares for almost free (the couple insisted on paying back what they could, and the spiders hungered for the flowers they needed to produce once more).

It took some days and Silk didn't had much time to keep her business afloat, but soon did she hear that the wedding was filled with love and amazement, with the wife presuming and praising the clothes she had acquired. Soon did word of mouth spread and little by little Silk acquired more and more clientelle who were happy with her wares.

Over time, Silk acquired a fortune and fame for the clothes she and the spiders produced, using her money not in frivolous jewels but in creating a lush garden, where she could grow flowers and trees that would help feed the spiders. This garden attracted lost animals -both of the robotic and living kinds- and were invited to stay as long as they pleased, some even providing help to tend to the flowers of the garden.

Today, Silk's business has grown to be recognized across various countries. Although slow to produce as she's a single woman doing the work, her textile works now fetch a good amount of money, though even today she freely donates her most elegant wares to couples soon to be married if their love rings true in their hearts.

-----

Silk here is a creation to go along with the rest of the robots that I have created thus far, by sheer accident I have been doing a worldwide theme with the end result being almost an echo of MegaMan 6 as each one of my robots would match a country seen in that game (or, well, almost. I have to represent my homeland of México, you know, close enough to Brazil).

Out of the ones I needed to make, the middle east was the one I needed to represent at this point, so I landed on making one based off the idea of the textile works of India as well as loosely basing her off Lakshmi and other various middle eastern themes. Hope I got her right and sincere apologies if I got something wrong.

Thus, I now have 9 robots, one for each country in MegaMan 6!

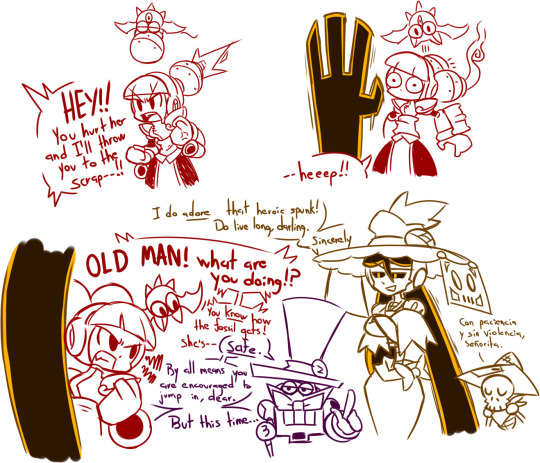

…Though one of them may not be exactly happy about it.

...Don't worry, Cave isn't getting demoted or replaced, its all just for show! He's just as valued as the others.

#Art#Open Commissions#Robot Master#Mega Man#Rock Man#OC#Original Character#Comic#Character Design#Pixel Art

31 notes

·

View notes

Text

The more I read economics literature about automation trends and globalization trends (the actual economics term, not the rabid racist term) and their economic impacts on developed economies, the more I realize that the fundamental picture we have been sold these things is a lie.

The general picture of automation revolutions is that they present some way of doing work more efficiently and/or to create a better product, and so market forces simply demand it. And we have to figure out how to deal with all of the lost jobs which are resulting from this. Because even in a socialist utopia, surely it would be absurd to continue forcing people to use old and outdated technology to do work less efficiently just so they could have work to do, right? Maybe the socialist utopia will take care of people displaced by this work better, but the displacement will still happen.

Except then I start reading about the actual history in the actual economics of automation revolutions (I recommend Blood In The Machine for a history of the Luddites and the automated textile revolution in Britain). And that's not what happens even a single time. These automated revolutions increase the cost per unit to create a good! They make the quality worse! And the existing workers get displaced, and replaced with oppressed or even outright enslaved labors who make nothing in worse conditions! They didn't even actually reduce the amount of labor involved significantly, they just started working orphan slaves 80-90 hours a week rather than artisan workers doing 30-35, to "reduce" the labor involved by reducing the number of laborers. It seems like no one benefits from this. So why is it happening!?

Well the answer is simple. The machine looms were less efficient, created lower quality products, and were worse for every single person in every sector of the economy ... except insofar as that they enabled a more unequal economy. The textile industry itself made less profit. The world itself had worse and less textiles. But the machine loom owners specifically made more money, because machine rooms enabled more control over workers in ways which could be used to relegate them to an even smaller share of the smaller profits. And they didn't outcompete others by being better, they did it through regulatory capture, illegal business practices, outright fraud, and by having a pre-existing place of power in their society.

The same applies to the classic story of Ford and his great automobile factory model. Sure it produced a lot of cars at low prices, but what the history doesn't tell you is that a bunch of other automobile companies which weren't using the factory model were putting out their own cars similar cost. Sure they weren't scaling up as fast, but everyone involved was making good money and the market kept on producing more companies to fill the gap. Ford made the decision to sell to a new lower cost car market sure, but he did not make a better profit margin per dollar of car purchases than his competitors did. He made significantly worse actually because he had such hideous turnover at his factories, and his cars were of lower quality than non-factory line cars aimed at the same market could be.

So why the hell did the entire automobile industry follow in his wake? Well, because he personally was making an insane amount of money. The factory line model let him simplify the production chain in a way which cut out a lot of people who previously been making good salaries, and it let him replace well paid laborers with dirt cheap labor. (Despite the hubbub about how good Ford's factory jobs paid, they only paid well relative to other no skill no training work available. They paid much worse than the skilled laborers he fired had made.)

And the people who controlled how the car manufacturing process worked were the people who would stand to make money by switching over.

The same is true for globalization. When a berry monopoly which controls 60% of all berry sales in the US does so by importing berries from South America, from varieties optimized for durability rather than flavor, that isn't cheaper than growing them at home. Not even with the higher cost of labor in the US. Not even if you actually paid farm hands a good wage rather than by abusing undocumented workers who can't fight back as effectively. The transport costs are too high.

All across the US food sector we have examples of food monopolies exporting produce production overseas in ways that make the final product more expensive for the customer, and lower quality at the same time. Why!?

Well because it allows them to access even more vulnerable labor markets. So even though the whole pie shrinks, the company owners get a bigger enough cut of the pie to make up for it.

The lie of automation and globalization of work and the damage it does to developed economies is just that, a lie. It is not economically predestined for this stuff to happen. Alternatives are not predestined to be competed out of the market. Unless, of course, ownership of profits is concentrated in only a few hands. Unless what's being competed for isn't net profit or net service provided or net quality of goods, but how much profit you can localize in capital owners.

If that's the actual competition, and of course it is because the people making decisions for companies also own those companies, only then does job automation and the presence of exploitable overseas labor devastate economies.

If laborers actually owned their places of business piecemeal, the motivation for these kinds of economic shocks would largely dry up. Like, sure, labor saving devices get invented sometimes and you need less people to do the same work. And sure, sometimes work can be done overseas for cheaper because standards of living at lower or because there's some comparative economic advantage. But that is not actually what is happening most of the time this stuff occurs.

If there's one thing I've learned studying this stuff, it's that genuine examples of net gain automation are less common than we think, and tend to be implemented on fairly slower timelines. Same for globalization of work. What is very common is ways in which already unequal systems of ownership and decision making and profit can be made more unequal. And the only fix I can imagine is fundamentally changing and democratizing how businesses operate, and how we handle concepts of ownership.

#also I know this can read as dismissive of the impacts#of this stuff on the labor forces most exploited by it#especially in South America#it's just that I'm trying to come at this from the perspective of#the justification of the existing system uses#which do not care about that kind of suffering#and trying to point out how they don't even do the things they claim to do

37 notes

·

View notes

Text

lrb this is kind of only tangentially related to their broader point about money within the concert scene and more relevant to the caveats discussed at the front end of the post. and also everything discussed here is through a usamerican lens because that is where i live ♥️. but i firmly believe every person with the ability to do so should try to partake in some form of garment fabrication—whether thats spinning yarn, weaving fabric, knitting/crocheting, designing, or sewing—to get a better idea of what an insanely labor intensive process it is and how much goes into it for clothes to be produced Ethically. granted yes automation takes care of some of that (economies of scale and etc) but like for a simple graphic tee i would say even $40 is fucking low for me to be reassured that the people

harvesting the raw fibers

transporting the fibers

processing the material into cloth

transporting the cloth

designing the garment

sewing the prototypes

programming and maintaining the machines that cut and sew

harvesting the raw material to create the ink/paint/logo material (i think what this is will vary)

transporting the logo raw material

processing the raw material into ink/paint/whatever

designing the logo/design on the shirt

maintaining the machines that print the logo/design onto the shirt

transporting the finished shirts to warehouses and points of sale

are all being compensated fairly and treated well by their employer. and that is all Before considering that posts main point about all the artists and road crew and etc that need to be able to sell that shirt at enough of a profit to not be literally destitute. and this is Also entirely not considering (again this was mentioned in the post) the money that would be required to mitigate the environmental ramifications of

the land being used as a monoculture to produce fibers (im aware synthetic textiles exist but i do not think the mass production of non-biodegradable junk counts as ethical per se)

the fossil fuel usage of the transport at every step of the way

the electricity usage of the machines/facilities producing the shirts

whatever the fuck they have to do to make the paint or ink or whatever that makes the logo/design

the disposal of the fabric scrap waste

like. idk im preaching to the choir i think most people on here are already fully aware that overconsumption is bad. and im not moralizing buying cheap/expensive clothes because i think it just distracts from the main problem to go around attacking people who buy cheap clothes because the structure of our society does not enable them to earn enough to buy anything else. ADDITIONALLY. price is a completely legitimate criticism to make about products when it's obvious that moneys going into some rich fuckers pocket instead of towards compensating the workers involved in making the products. but ☝️my thesis statement so to speak is that along with op of that last post, i think the criticism should not be "why is this product so expensive", it should be "why am i not paid enough to afford this" and "why are you charging that much and then all but enslaving people in impoverished countries to make this product" and "why is it all but impossible to participate in broader usamerican society without funding systems that treat people as disposable". this post got long as fuck if youre somehow still reading this Haiiiii :3

2 notes

·

View notes

Text

Pet Bottle Scrap Plastic Washing and Recycling Plant in Vijayawada

R Mech Machines LLP is a leading provider of advanced Pet Bottle Scrap Plastic Washing and Recycling Plants in Vijayawada. Our Manufacturing Unit is located in Ahmedabad, Gujarat, India. R Mech Machines LLP PET washing and recycling plants utilize advanced technology to ensure high efficiency in processing plastic waste. The process involves cleaning, sorting, and transforming PET bottles into high-quality, reusable plastic flakes. The recycled plastic flakes produced through our washing and recycling process are of the highest quality, suitable for reuse in the manufacturing of new bottles, packaging, textiles, and other products. R Mech Machines LLP provide tailored solutions based on your capacity, requirements, and budget, ensuring maximum efficiency and profitability. We design our plants to be energy-efficient and cost-effective, helping businesses reduce operational costs while improving production efficiency and output. Why R Mech Machines LLP is Your Ideal Partner in Vijayawada: Proven Expertise: R Mech Machines LLP is committed to providing the best solutions for your PET recycling needs. Our engineers and technical team bring vast expertise to each project. Comprehensive Support: We offer full support from plant design, installation, training, to after-sales service, ensuring smooth operations and long-term success for your business. Affordable Solutions: We price our Pet Bottle Scrap Plastic Washing and Recycling Plants competitively, offering high returns on investment while reducing operational costs. Application: Packaging Industry Textile Industry Construction Consumer Goods R Mech Machines LLP Offers Pet Bottle Scrap Plastic Washing and Recycling Plant in Vijayawada, Andhra Pradesh and including locations Visakhapatnam, Vijayawada, Guntur, Nellore, Kurnool, Kakinada, Rajamahendravaram, Kadapa, Mangalagiri-Tadepalli, Tirupati, Anantapuram, Ongole, Vizianagaram, Eluru, Proddatur, Nandyal, Adoni, Madanapalle, Machilipatnam, Tenali, Chittoor, Hindupur, Srikakulam, Bhimavaram, Tadepalligudem, Guntakal, Dharmavaram, Gudivada, Narasaraopet, Kadiri, Tadipatri, Chilakaluripet. Contact us today for more information or to request a quote. View Product: Click Here Read the full article

#Ahmedabad#AndhraPradesh#Exporter#ExporterofPETBottleScrapPlasticWashingandRecyclingPlant#Gujarat#India#Manufacturer#ManufacturerofPetBottleScrapPlasticWashingandRecyclingPlant#PetBottleScrapPlasticWashing#PetBottleScrapPlasticWashingandRecyclingPlant#PetBottleScrapPlasticWashingandRecyclingPlantExporter#PetBottleScrapPlasticWashingandRecyclingPlantin#PetBottleScrapPlasticWashingandRecyclingPlantinAhmedabad#PetBottleScrapPlasticWashingandRecyclingPlantinGujarat#PetBottleScrapPlasticWashingandRecyclingPlantinIndia#PetBottleScrapPlasticWashingandRecyclingPlantinVijayawada#PetBottleScrapPlasticWashingandRecyclingPlantManufacturer#PetBottleScrapPlasticWashingandRecyclingPlantSupplier#RMechMachinesLLP#RecyclingPlantinVijayawada#Supplier#SupplierofPetBottleScrapPlasticWashingandRecyclingPlant#Vijayawada

2 notes

·

View notes

Note

I'm pretty clueless to fashion production; is there no way you can produce a "decent" facsimile of that camo by taking a digital pattern and sort of printing it onto a similar match of fabrics? I actually have some stake in something like this existing, because there's a lot of discontinued aloha shirt patterns I wanna claim for myself.

you can, technically, and for reproductions that’s usually the easiest solution. if you look up “michell pattern camo for sale” you’ll find a variety of shops selling cheap dropshipped commodities, usually outsourced, in every pattern under the sun from the emblematic, like M81 woodland, to the esoteric, like 1945 German Leibermuster. all of these are polyester shein-esque clothes tho, with all the quality of a halloween costume and made at the cheapest price possible. to truly recreate a pattern as authentic to the originals as possible, one not only needs quality fabrics to print on but a similar machine to those that existed in the factories 40, 60, or 80+ years ago, and to replicate the printing process. camouflage is typically printed in layers, similar to silkscreening though at an industrial scale, and to a discerning eye this can produce distinctions in the final product. as one might expect, none of these factories still exist, their tooling has disappeared into time, and the manufacture process was likely either never recorded or kept secret. that said, some modern companies do seek out old tools, of which Buzz Rickson’s became famous with their bomber jacket repros, and it’s not like it’s impossible to make something that looks nice with new methods. however, even if a cunning tailor finds a solution or negotiates with a textile mill to produce a pattern, such manufacturing steps are often time consuming and expensive, and the commodity itself is only appealing to a very niche market. thus, old camo patterns are either not worth it to businesses to try and recreate, or have a dizzying price tag when they do.

Aloha shirts are actually a very apt comparison, not only are the patterns themselves somewhat of a civilian equivalent of camouflage, but the trends in production and reproduction are similar. Companies like Sugar Cane are well renowned for their Hawaiian shirts, but, like with military apparel, because the tooling doesn’t exist anymore many of the best new-made garments are made with vintage dead-stock fabric.

all that said tho, i’m not an expert on such things so all of the above is more or less what i’ve learned or intuited through exposure, there are likely more erudite articles on the subject.

6 notes

·

View notes

Text

The main event, the wool market, starts in the gymnasium of the Floccesy school, spilling out into the halls and even behind the building. Vendors from all over have come to sell their textile wares or handicraft goods. There is a constant flow of people coming in, with patrons stopping to shop or watch craftsmen work at their booths.

Gymnasium Vendors:

The main area for textile vendors. They have sections roped off for various displays to educate potential customers about the processes involved with their wares.

Fleece Dyer: They have set up a stand with their dye pots to show the process. While the rovings used in the display are not for sale, they have a rainbow of pre-dyed rovings to purchase.

Plush vendor: A vendor who has crocheted a whole pokedex has them on display in national dex order and quite a few shiny variants.

Fluff Station: Various tables of freshly cleaned fluff from Pokemon. The fluff rolls are arranged by the typings of Pokemon it came from. Staff are at each table to explain how the fluff is gathered and what are various uses for it.

Spinning: The station with the most action. The worker is using a machine to spin fluff into yarn. Their daughter is using yarn to make kumihimo braids when she is not manning the cash register. The braids she does finish are being sold as “friendship bracelets”. If people ask, the girl can show them how to make twist braids for quick custom bracelets.

Hallway Vendors:

These vendors have various handicraft goods. As the halls are more cramped than the gymnasium, the vendors have smaller stands and are not able to make custom goods on the spot. Some are willing to make custom orders that would be mailed.

Painter: A local artist has set up their table of paintings and advertisements for their studio. Browsing their works, you see that they have been all over Unova, getting paintings of the Relic Castle, the Pokemon League, and Skyarrow Bridge. They have framed paintings, full size prints, and miniature canvases on sale.

Stained Glass: A glass artisan has various sun catchers of various designs hanging on the wall. They have a form for making custom pieces, with price ranges for various sizes and complexities.

Pokeball Painter: A custom Pokeball painter. There are balls for sale with designs according to types, some painted to look like Pokemon, and others are painted to mimic other pokeballs. There are a couple that look like the masterball. Despite the lack of space, the artist has their station set up to paint simple designs on Pokeballs on the spot.

Custom jewelry: Different racks of jewelry section off the space this seller occupies, all crowded with different charms, pendants, and earrings. The majority of the charms that make the jewelry have Unovan sports team logos or semi-precious stones. The children’s racks have plastic cartoon characters on them.

Face painter: The most popular booth for kids! Two painters are set up with their kits and a book of designs to pick from. Many kids are just hopping up onto the provided stools and asking for something without looking.

Outside:

The area in the back is noisy, with a roped off path that leads the crowd around a petting zoo.

Duck Slide: recently hatched duckletts are hopping down a slide! They waddle back up on ramps on both sides of the slide. There’s a quaxly mixed in with them for some reason.

Skiddo feeding station: For a small fee, visitors can buy a handful of feed for skiddo. The grass types are raised by local children to be shown in the summer fairs later.

Wooloo pen: A pen of freshly shaved wooloo. These Pokemon will headbutt the fencing to try to get pets from visitors.

Yamper run: Yampers are chasing a Boltund who is teaching them how to herd. The smaller yampers will run to the fencing to beg for treats or pets.

Buneary Den: Several buneary are let out to hop around freely. A farmhand is nearby to help show off the tricks the buneary learned! They even have treats for people to feed the pokemon.

Wool Market Starters here!

4 notes

·

View notes

Text

Export Import Products List

Exporting and importing products is a major part of the global economy. In 2022, the value of global merchandise trade was over $28 trillion. This means that businesses and consumers all over the world are exchanging goods and services on a massive scale.

There are a wide variety of products that are exported and imported, but some of the most common include:

Agricultural products: This category includes food crops, such as wheat, rice, and corn, as well as livestock and animal products, such as meat, dairy, and eggs.

Chemicals: This category includes a wide range of products, such as petrochemicals, pharmaceuticals, and fertilizers.

Electrical machinery and equipment: This category includes products such as generators, motors, and computers.

Food and beverages: This category includes processed foods and drinks, as well as fresh produce.

Machinery and equipment: This category includes products such as machine tools, engines, and construction equipment.

Manufactured goods: This category includes a wide range of products, such as textiles, clothing, and electronics.

Minerals and fuels: This category includes products such as crude oil, natural gas, and coal.

Other goods: This category includes products that do not fall into any of the other categories, such as furniture and toys.

Textiles and clothing: This category includes products such as yarn, fabric, and garments.

Transport equipment: This category includes products such as cars, trucks, and airplanes.

The specific products that are exported and imported vary from country to country. For example, the United States is a major exporter of agricultural products, machinery, and equipment, while China is a major exporter of manufactured goods and electronics.

Factors to Consider When Choosing Export Import Products

There are a number of factors that businesses should consider when choosing which products to export or import. These factors include:

Demand: Is there a strong demand for the product in the target market?

Competition: How much competition is there for the product in the target market?

Profitability: Is the product profitable to export or import?

Regulations: Are there any regulations that restrict the export or import of the product?

Logistics: How will the product be transported to and from the target market?

Benefits of Exporting and Importing Products

There are a number of benefits to exporting and importing products. For businesses, exporting can help to increase sales and profits, and it can also help to diversify the business's customer base. Importing can help businesses to access products that are not available domestically, and it can also help businesses to reduce costs.

For consumers, exporting and importing can help to lower prices and increase the availability of goods. For example, consumers in the United States can buy fresh produce from all over the world, and they can also buy electronics and other manufactured goods at lower prices because of imports.

Conclusion

Exporting and importing products is a vital part of the global economy. It helps businesses to grow and consumers to save money. If you are considering starting an export import business, there are a number of resources available to help you get started.

#Export Import Products List#export import products#export import data#exporter#bussiness#export#import#importers

2 notes

·

View notes

Text

Pillow block bearing - Ball Units at Best Price | Jayco Engineering

Pillow Block Bearings stand out as an essential component across industries. At Jayco Engineering, a trusted name in the world of Industrial Bearings, we specialize in offering High Quality Pillow Block Bearings that deliver outstanding performance even in the most demanding environments.

As a leading Pillow Block Bearing Manufacturer and Pillow Block Bearing Supplier in India, we are proud to present a wide selection of Heavy Duty Pillow Block Bearings designed for maximum durability, reliability, and ease of installation. Whether you are in need of a Custom Pillow Block Bearing for a specialized application or want to Buy Pillow Block Bearings Online for your existing equipment, Jayco Engineering is your go-to source.

What is a Pillow Block Bearing?

A Pillow Block Bearing (also called a plummer block) is a type of mounted bearing that consists of a housing and an insert bearing. The housing is typically made of cast iron, cast steel, or stainless steel, while the insert can be a deep groove ball bearing or other type, depending on the application.

These bearings are used to provide stable support for rotating shafts while reducing friction and wear. The housing allows for easy mounting and alignment, making Pillow Block Bearings ideal for machinery in sectors such as manufacturing, packaging, food processing, agriculture, mining, and more.

As an experienced Bearing Manufacturer in India, Jayco Engineering offers Pillow Block Bearings in a wide range of sizes, materials, and configurations to meet the specific needs of different industries.

Why Choose Heavy Duty Pillow Block Bearings?

For applications where equipment is subjected to high loads, extreme speeds, or harsh operating conditions, Heavy Duty Pillow Block Bearings are a must. These bearings are engineered to handle demanding environments and provide extended service life, reducing downtime and maintenance costs.

At Jayco Engineering, our Heavy Duty Pillow Block Bearings are precision-engineered with superior materials and advanced manufacturing techniques. We understand the critical role that these bearings play in your operations, which is why we ensure:

Enhanced load-carrying capacity

Superior resistance to wear and corrosion

Accurate shaft alignment

Ease of installation and maintenance

Vibration and shock resistance

If you are looking to Buy Pillow Block Bearings Online, you can trust Jayco Engineering to supply High Quality Pillow Block Bearings that exceed expectations.

Custom Pillow Block Bearings for Specialized Needs

Not all equipment is built the same, which is why Jayco Engineering offers Custom Pillow Block Bearings tailored to your unique requirements. Whether you need a non-standard size, special housing material, or a specific type of bearing insert, we can design and manufacture the perfect solution for your application.

Our in-house engineering team collaborates closely with clients to understand their machinery and operational challenges. This enables us to create Custom Pillow Block Bearings that deliver optimal performance, longevity, and value.

By choosing Jayco Engineering as your Pillow Block Bearing Manufacturer and Pillow Block Bearing Supplier, you benefit from decades of industry experience, precision craftsmanship, and a commitment to customer satisfaction.

Industries We Serve

As a trusted Bearing Manufacturer in India, Jayco Engineering supplies Industrial Bearings to a diverse range of industries, including:

Agriculture: Equipment such as harvesters, tractors, and irrigation systems

Mining & Construction: Crushers, conveyors, screening equipment

Food & Beverage: Conveyor belts, filling machines, packaging systems

Textile Machinery: Spinning machines, weaving looms, fabric processing

Paper & Pulp Industry: Rollers, printing machines

Automotive: Assembly lines, testing equipment

General Manufacturing: Pumps, compressors, gearboxes, fans

Whether you need Heavy Duty Pillow Block Bearings for high-load industrial applications or Custom Pillow Block Bearings for specialized machinery, Jayco Engineering has the expertise and product range to meet your demands.

Contact us Today to discuss your requirements and experience the difference of working with one of India’s top Pillow Block Bearing specialists!

Advantages of Jayco Engineering’s Pillow Block Bearings

When you choose Jayco Engineering to Buy Pillow Block Bearings Online, you can count on receiving products that are:

High-Quality Materials: Our bearings are made with premium-grade metals and components, ensuring superior performance, corrosion resistance, and long life.

Precision Engineering: We manufacture to exacting tolerances, resulting in better shaft fit, alignment, and overall efficiency.

Competitive Pricing: As a top Pillow Block Bearing Exporter and Bearing Manufacturer in India, we offer unbeatable value for your investment.

Wide Product Range: From Heavy Duty Pillow Block Bearings to Custom Pillow Block Bearings, we provide solutions for virtually every application.

Fast, Reliable Delivery: With our robust supply chain and global distribution network, we ensure timely delivery of your bearings—whether locally or internationally.

Global Reach – Your Trusted Pillow Block Bearing Exporter

Jayco Engineering is not just a local Pillow Block Bearing Supplier—we are a trusted Pillow Block Bearing Exporter serving clients around the world. Our commitment to quality, innovation, and customer service has made us a preferred partner for businesses in the Middle East, Europe, Africa, North America, and beyond.

We understand the logistics and compliance requirements involved in international trade and ensure seamless export services to help clients get the High Quality Pillow Block Bearings they need—on time and on budget.

The Ease of Buying Pillow Block Bearings Online

In today’s fast-paced industrial world, time is money. That’s why Jayco Engineering makes it easy to Buy Pillow Block Bearings Online through our user-friendly website and e-commerce channels. You can browse our product catalog, request quotes, and place orders with just a few clicks—saving time and effort.

Our expert team is always available to provide technical assistance, help with product selection, and ensure that you get the perfect bearing for your application.

Choose Jayco Engineering for High Quality Pillow Block Bearings

Whether you are a large manufacturing plant, a small workshop, or an OEM looking for a reliable partner, Jayco Engineering is the name you can trust for Industrial Bearings of unmatched quality. As a leading Pillow Block Bearing Manufacturer, Pillow Block Bearing Supplier, and Pillow Block Bearing Exporter, we are committed to delivering products that perform, last, and exceed expectations.

For Heavy Duty Pillow Block Bearings, Custom Pillow Block Bearings, or to Buy Pillow Block Bearings Online, choose Jayco Engineering—your reliable Bearing Manufacturer in India.

For more info: https://www.jaycohousing.com/

Email ID: [email protected]

Call us: 9512244473

Location: Plot No. 18,19,20, Dharti Industrial Park, P.O. Mirjapur, Ahmedabad-Indore Highway, Ahmedabad, Gujarat, INDIA.

#Pillow Block Bearing#Heavy Duty Pillow Block Bearing#Pillow Block Bearing Manufacturer#Pillow Block Bearing Supplier#Custom Pillow Block Bearing#Industrial Bearings#Bearing Manufacturer in India#Buy Pillow Block Bearing Online#High Quality Pillow Block Bearing#Pillow Block Bearing Exporter

0 notes

Text

Get the Best Gear Hobbing Machine in Coimbatore – Trusted Quality, Precision Engineering

The manufacturing industry is the backbone of Coimbatore, a city proudly known as the “Manchester of South India.” As industrial growth continues to rise, the demand for gear hobbing machines in Coimbatore is increasing rapidly. If you are looking for high-performance gear-cutting solutions for your factory, then investing in a quality gear hobbing machine in Coimbatore is the best decision you can make.

At Gear Hobbing Solutions, we specialize in offering top-quality, affordable, and precision-engineered machines that meet global standards. Whether you are a small business or a large enterprise, we deliver machines that suit your exact production needs with excellent support.

✅ What Is a Gear Hobbing Machine?

A gear hobbing machine is a specialized machine tool used to cut gears. It uses a rotating tool called a hob to slice teeth into a gear blank. Gear hobbing is a highly efficient process used to produce spur gears, helical gears, and worm gears.

Using a gear hobbing machine in Coimbatore gives local manufacturers the ability to:

Produce gears with excellent accuracy

Increase manufacturing speed

Reduce manual effort

Improve gear life and performance

Modern gear hobbing machines also support automation, allowing consistent production with minimal human error.

🔧 Why Choose Gear Hobbing Solutions?

When searching for a gear hobbing machine in Coimbatore, you want a supplier that understands your business and provides quality machines with reliable support. Here’s why Gear Hobbing Solutions is the right partner for your gear manufacturing needs:

1. Local Expertise

We have in-depth knowledge of the local industrial ecosystem in Coimbatore. Our machines are built to serve industries like automotive, agriculture, textile, and engineering, which are the backbone of this region.

2. Precision Machines

We offer high-accuracy gear hobbing machines that deliver fine finishes and consistent gear tooth cutting. Precision matters when it comes to gears—and we deliver it every time.

3. Affordable Prices

While we offer international-grade machinery, we keep our pricing competitive. Our goal is to make world-class machines accessible to every factory in Coimbatore.

4. After-Sales Support

From installation and training to maintenance and spare parts, we are with you every step of the way. Our local support ensures minimal downtime.

5. Wide Range of Machines

We supply vertical gear hobbing machines, horizontal hobbing machines, CNC hobbing machines, and semi-automatic models, depending on your specific requirement.

🏭 Why Coimbatore Is a Growing Hub for Gear Manufacturing

Coimbatore is a well-known industrial city with thousands of small and large-scale factories involved in precision engineering. Industries in and around Coimbatore increasingly need reliable gear hobbing machines to meet the growing demand for gear-driven equipment.

From textile machinery and pump sets to electric motors and auto parts, gears are everywhere in Coimbatore’s industrial space. That’s why investing in a durable gear hobbing machine in Coimbatore helps local manufacturers meet rising demand without compromising on quality.

🛠️ Types of Gear Hobbing Machines We Offer

We provide a wide range of gear hobbing machines in Coimbatore to suit various industries:

➤ CNC Gear Hobbing Machines

Ideal for high-volume production with extreme precision. Fully programmable and highly efficient.

➤ Vertical Gear Hobbing Machines

Best suited for smaller components and offers excellent visibility and operator access.

➤ Horizontal Gear Hobbing Machines

Perfect for large and heavy gear blanks. Provides stable cutting and support.

➤ Semi-Automatic Gear Hobbing Machines

Combines manual setup with automatic hobbing—ideal for small batch production.

Each machine is carefully built with top-quality materials and advanced technology to ensure durability, accuracy, and efficiency.

📈 Applications of Gear Hobbing Machines in Coimbatore

The demand for a quality gear hobbing machine in Coimbatore is strong across industries:

Automobile Industry – For cutting transmission, steering, and gear shaft components.

Agriculture Equipment – Used in tractors and farming tools.

Electric Motor Manufacturing – Gears are critical for smooth functioning.

Textile Industry – Gear-driven machines are used in looms and spinning machines.

General Engineering – Used for various machine components and automation systems.

No matter your industry, a robust gear hobbing machine is essential to maintain quality and productivity.

🔍 How to Choose the Right Gear Hobbing Machine in Coimbatore

Here are a few tips to help you choose the right machine:

Check Capacity: Match the machine’s gear size and material capabilities with your production needs.

Automation Level: Choose CNC or semi-automatic depending on your production scale.

Build Quality: Ensure the machine is made with durable materials for long-term use.

Support: Choose a company like Gear Hobbing Solutions that offers strong after-sales support.

Customization: Ask if the machine can be tailored to your specific application.

With our expert guidance, you can select the perfect gear hobbing machine in Coimbatore without hassle.

⚙️ Maintenance Tips for Gear Hobbing Machines

To get the most out of your investment, regular maintenance is important. Follow these tips:

Keep the machine clean to avoid dust build-up.

Lubricate moving parts regularly to reduce wear.

Use quality hobs to maintain gear finish.

Inspect electronics and wiring periodically.

Keep the CNC software updated if applicable.

We also offer annual maintenance contracts and technical training for your staff.

📢 What Our Clients Say

"We were looking for a reliable gear hobbing machine in Coimbatore and found Gear Hobbing Solutions. The team provided excellent guidance, and the machine is performing beyond expectations." — Precision Auto Components, Coimbatore

"Thanks to Gear Hobbing Solutions, our production capacity has doubled in just six months. Their support team is always ready to help. Highly recommended!" — Engineering Firm, Tamil Nadu

Our clients are our biggest advocates, and their success stories are proof of our commitment to quality and customer satisfaction.

🌟 Why Now Is the Best Time to Invest

The industrial landscape in Coimbatore is growing rapidly. The demand for locally manufactured gears is on the rise. By investing in a high-performance gear hobbing machine in Coimbatore, you can:

Boost productivity

Improve gear quality

Reduce production costs

Meet customer deadlines faster

Stay ahead of competitors

Let Gear Hobbing Solutions help you take your manufacturing business to the next level.

📞 Contact Us Today

If you are ready to invest in a quality gear hobbing machine in Coimbatore, look no further than Gear Hobbing Solutions. We’re here to understand your business, guide your decisions, and deliver the right machine at the right price.

Our team is always available for site visits, demonstrations, and consultations. Let’s power your business with precision!

0 notes

Text

Auto Catalysts Market Growth Analysis, Market Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2031

The global Auto Catalysts market was valued at USD 11,154.62 million in 2023 and is estimated to decrease to USD 8,135.97 million in 2024. However, it is expected to reach USD 8,780.56 million by the end of 2030, growing at a CAGR of 1.28% between 2024 and 2030. Auto catalysts, also known as automotive catalytic converters, are emission control devices that are installed in automobiles to reduce the emissions of harmful gases, such as carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HCs).

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/440/auto-catalysts-market-research

North America market for Auto Catalysts is estimated to increase from USD 3,057.14 million in 2023 to reach USD 2,192.51 million by 2030, at a CAGR of -0.47% during the forecast period of 2024 through 2030.

Europe market for Auto Catalysts is estimated to increase from USD 4,299.62 million in 2023 to reach USD 3,427.31 million by 2030, at a CAGR of 1.24% during the forecast period of 2024 through 2030.

China market for Auto Catalysts is estimated to increase from USD 1,928.22 million in 2023 to reach USD 1,408.02 million by 2030, at a CAGR of 1.07% during the forecast period of 2024 through 2030.

The major global manufacturers of Auto Catalysts include BASF, Johnson Matthey, Umicore, Cataler, Tokyo Roki, N.E. Chemcat, Sinocat, Wuxi Weifu Environmental Catalysts, and Sino-Platinum, etc. In 2023, the world's top four vendors accounted for approximately 77.23 % of the revenue.

Report Scope

This report aims to provide a comprehensive presentation of the global market for Auto Catalysts, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Auto Catalysts.

The Auto Catalysts market size, estimations, and forecasts are provided in terms of output/shipments (K Liter) and revenue ($ millions), considering 2023 as the base year, with history and forecast data for the period from 2019 to 2030. This report segments the global Auto Catalysts market comprehensively. Regional market sizes, concerning products by Type, by Application, and by players, are also provided.

For a more in-depth understanding of the market, the report provides profiles of the competitive landscape, key competitors, and their respective market ranks. The report also discusses technological trends and new product developments.

The report will help the Auto Catalysts manufacturers, new entrants, and industry chain related companies in this market with information on the revenues, production, and average price for the overall market and the sub-segments across the different segments, by company, by Type, by Application, and by regions.

Market Segmentation

By Company

BASF

Johnson Matthey

Umicore

Cataler

Sino-Platinum

N.E. Chemcat

Wuxi Weifu Environmental Catalysts

Tokyo Roki

Sinocat

by Type

Gasoline Catalyst

Diesel Catalyst

Natural Gas Catalyst

by Application

Passenger Cars

Commercial Vehicles

Production by Region

North America

Europe

China

Japan

Consumption by Region

North America

U.S.

Canada

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Europe

Germany

France

U.K.

Italy

Spain

Latin America

Mexico

Brazil

Rest of Latin America

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/440/auto-catalysts-market-research

0 notes

Text

Common Contaminants in PET Bottle Flakes and How to Eliminate Them

If you’re in the recycling or plastic manufacturing game, you already know how important PET bottle flakes are. These small plastic shards serve as the building blocks for numerous recycled products, ranging from textiles to packaging. But here’s the catch: if your PET bottle flakes are full of junk, they are useless. Clean flakes ensure better products, better profits, and a healthier planet.

The Dirty Truth: Common Contaminants in Pet Bottle Flakes

Before PET bottles become flakes, they go through all kinds of rough handling, including trash bins, food residue, and mixed waste. That’s where contamination comes in. Here are the usual suspects:

1. Labels and glue

Labels made from PVC or other non-PET materials

Sticky adhesives that don’t wash off easily

2. Liquids and organic residue

Leftover soda, juice, or milk inside bottles

Mold or fermentation during storage

3. Other plastics

Caps and rings made of HDPE or PP

Shrink sleeves and wrappers that melt differently

4. Dirt, sand, and dust

Collected from storage yards or open transportation

It affects flake clarity and increases processing costs

5. Metal or inorganic waste

Small screws, staples, or even parts of labels

Dangerous for machinery and quality output

Why Contaminants Are a Big Deal?

You might be thinking, “What’s a little dirt?” But contamination in PET bottle flakes can:

Damage recycling machinery

Reduce the purity and strength of the end product

Increase processing and cleaning costs

Cause product rejections or low market value

Contamination kills the value of your flakes.

How to Eliminate Contaminants from PET Bottle Flakes

Cleaning up your PET flakes is easier than you think if you follow the right process. Here’s a simple breakdown:

1. Pre-sorting is a must

Remove non-PET items before shredding

Separate by colour, material, and size manually or using optical sorters

2. Hot washing works wonders

A hot caustic wash removes labels, adhesives, and organic grime

Ideal temperature: 80–85°C for best results

3. Use a float-sink tank

PET sinks, but most other plastics float

A great way to separate HDPE, PP, and PVC easily

4. Magnetic and metal detection

Install metal detectors or magnets before processing

Prevents machine damage and ensures clean output

5. Rinse and dry properly

A final cold rinse ensures zero residue

Drying eliminates moisture, which can mess up the extrusion process

Pro Tips for Maintaining Clean PET Bottle Flakes

Always source bottles from trusted collection points

Store flakes in clean, dry conditions after processing

Schedule regular maintenance of your washing and sorting equipment

Keep staff trained on identifying and handling

Conclusion

In the world of plastic recycling, quality is everything. Clean PET bottle flakes ensure better prices, perform more efficiently in manufacturing and contribute to a cleaner environment. By knowing what contaminants to look out for and how to get rid of them, you’re not just improving your product; you’re also boosting your business’s revenue.

0 notes

Text

How to Choose the Right Spur Gear Manufacturer for Industrial Applications

Spur gears are essential in the fields of machinery and power transmission. From heavy-duty industrial machines to precision-driven mechanical tools, spur gears are the unsung heroes behind smooth motion and efficiency. However, when it comes to sourcing these crucial components, choosing the right spur gear manufacturer can make all the difference in product quality, performance, and lifespan.

Whether you’re a procurement officer, a mechanical engineer, or an industrial project manager, understanding what to look for in a gear manufacturer is essential to avoid costly downtime and ensure long-term reliability. This blog will guide you through what makes a great manufacturer and why choosing a specialized industrial gear supplier matters.

Why Spur Gears Are So Important in Industry

Spur gears are the most common type of gear used in mechanical applications. Their simplicity, efficiency, and ability to transmit large amounts of power at constant speed make them indispensable in sectors like:

Automotive

Packaging

Printing

Food processing

Textile machinery

Conveyor systems

These gears are typically manufactured with high precision to meet demanding operational standards. That’s why selecting the right spur gear manufacturer who understands technical tolerances and application-specific demands is crucial.

Key Qualities of a Reliable Spur Gear Manufacturer

1. Experience and Industry Reputation

Always seek out an Indian gear manufacturer with a solid track record of producing precise spur gears and shown competence. Companies with a wide client base and years of production experience are more likely to deliver consistent quality.

2. Material Versatility

The raw material is frequently where a spur gear's quality starts. A professional manufacturer should offer options such as:

Carbon Steel

EN Materials (EN8, EN9, EN19, EN31, EN353)

Alloy Steel

20MNCR5 (CR Material)

Bronze and Phosphor Bronze

Delrin Plastic & Cast Nylon

Cast Iron

Stainless Steel

Every material has unique qualities that make it perfect for a certain use. For instance, Bronze is excellent for anti-friction applications, while EN31 is used for high wear resistance.

3. Customization Capabilities

A great spur gear exporter doesn’t just sell off-the-shelf components. They should offer custom spur gears tailored to your design and performance requirements. This includes tooth profile modifications, gear ratios, and shaft sizes.

4. Modern Manufacturing and Testing Facilities

With the advent of CNC machines and advanced gear hobbing technology, today’s gear production demands high-end infrastructure. A reliable manufacturer should have in-house quality testing, material hardness checks, and runout inspections to ensure consistent product integrity.

Don’t Forget Related Components

While spur gears are critical, many industrial systems also rely on components like the Timing Belt Pulley and V pulley for smooth motion and torque transmission. A manufacturer offering a complete range of power transmission components becomes a one-stop solution for all your mechanical needs. This ensures compatibility and ease of integration in your machinery.

Why Choosing the Right Supplier Saves You Money

Partnering with a reliable industrial gear supplier doesn’t just ensure better products—it reduces lead times, improves maintenance cycles, and minimizes the risk of operational failure. When you buy from a top spur gear manufacturer, you're not just buying a product; you're investing in peace of mind and operational efficiency.

Additionally, buying from a known gear manufacturer in India also gives you better local support, faster turnaround, and better customization at cost-effective pricing compared to imported alternatives.

Look No Further Than the Experts

If you’re in search of a trusted gear partner who can deliver everything from custom spur gears to timing belt pulleys and v pulleys, explore Rajendra Pulley Pedestal Centre. They specialize in manufacturing high-quality gears with diverse material options and precision tolerances, serving clients across industries for decades.

Conclusion

Choosing the right spur gear manufacturer for industrial applications involves more than comparing price lists. It requires evaluating technical capability, material selection, product range, and service reliability. With the right partner, you can ensure smooth machinery performance, reduced downtime, and long-term value.

Partner with a manufacturer who understands your industry and delivers uncompromised quality. Email: [email protected] or Call+91-958-682-3032. Let our gear experts help you find the perfect solution for your mechanical system!

#spur gear manufacturer#custom spur gears#industrial gear supplier#precision spur gears#spur gear exporter#gear manufacturer in India#Rajendra pulley gears#durable spur gears#gear solutions for machines#spur gear supplier

0 notes

Text

How Cotton Scrap Buyers in Madurai Ensure Sustainable and Transformative Waste Management Practices in India

The Growing Need for Cotton Scrap Buyers in Madurai and Their Role in Clean India In today's fast-developing India, there's a significant surge in demand for eco-conscious waste solutions. Cotton scrap buyers in Madurai are now playing a vital role in this movement by handling cotton waste responsibly and systematically. From handloom mills to garment exporters, Madurai's textile hubs generate massive volumes of cotton scrap daily. Rather than letting these pile up in landfills or incinerators, cotton scrap buyers in Madurai collect, sort, and channel this waste into recycling industries. These cotton scrap buyers in Madurai operate with local tailors, mills, boutiques, and even households, helping them earn income by selling offcut cotton fabrics. The cotton scrap is processed and repurposed into insulation, industrial cleaning cloths, paper pulp, and more. The sustainability goals of India are amplified by these quiet yet powerful efforts of cotton scrap buyers in Madurai. What separates BN Royal Traders is their swift service and ethical recycling network. With modern sorting infrastructure and extensive pickup services, this cotton scrap buyer in Madurai ensures that textile waste doesn’t go to waste.