#Thermoplastic Polyester Elastomer Market

Text

Thermoplastic Polyester Elastomer Market – Forecast (2021-2026)

Thermoplastic Polyester Elastomer Market size is forecast to reach US$1.22 billion by 2026, after growing at a CAGR of 3.8% during 2021-2026. Thermoplastic Polyester Elastomers, (TPE-E) combines the properties of high-performance elastomers and flexible polymers. These high-strength materials, also known as thermoplastic rubbers, are known for their ability to withstand multiple flex cycles and their resistance to a variety of solvents and lubricants. TPE-Es have a strong impact strength even at low temperatures and can withstand temperatures up to 300°F. PET resin is one of the most frequently used thermoplastics, especially in the packaging industry. In outdoor conditions, thermoplastic elastomers (TPE) and ethylene propylene diene monomer (EPDM) rubber both provide sealing and insulation. They can be molded into specific shapes or produced from sponge or solid material sheets and extrusions. Polyester (polyethylene terephthalate (PET)) is the most common fiber used in automobile textile production. The growing use of TPE-Es in suspension bushings for automotive performance applications because of its greater resistance to deformation when compared to regular rubber bushings is expected to drive the market in the forecast period.

COVID-19 Impact

Currently, due to the COVID-19 pandemic, the Plastic and the rubber industry were affected in multiple ways. There was a supply disruption of raw materials. A delay in farming activities and latex collection further exacerbated the problem. Critical inputs like plastic, carbon black, and rubber compounds were in short supply due to global economic turmoil and import restrictions. For a sector dominated by MSMEs that do not often have solid business continuity planning, the delay in farming activities also resulted in liquidity and working capital concerns. They rely on consistent cash flows to cover their working capital needs and pay their employees. The industry's prospects were further harmed by worldwide market volatility. During the pandemic, however, the market is steadily rebounding due to the growth of TPE (Thermo Plastic Elastomer) in the medical, as well as food and beverage packaging industries.

Thermoplastic Polyester Elastomer Market Report Coverage

The report: “Thermoplastic Polyester Elastomer– Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Thermoplastic Polyester Elastomer market.

By Application: Rubber seals, Belting, Tubing, Bushing and Gears, Conveyer, Geophysical, Industrial, Material Handling, Wire and Cable, Others.

By End-Use Industry: Aerospace, Automotive (Passenger Vehicles (PV), Light Commercial Vehicles (LCV), Heavy Commercial Vehicles (HCV)),Electrical and Electronics (Medical Devices, Smart Phones, Computer Electronics, Home Appliances, and Others), Marine,Sports and Leisure, Energy (Wind Energy, Solar Energy, and Others), and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Key Takeaways

The Thermoplastic Polyester Elastomer (TPE-E) market in Asia-Pacific is dominated by the region's rising use in a variety of applications in the automotive, medical, construction, and other industrial markets.

The varieties of TPE-Es and their modification options provide the foundation for a wide range of material qualities, allowing for cost-effective processing in a wide range of industries.

TPE-E is easy to mold or extrude onto rigid thermoplastic materials, making it ideal for product soft-touch grips. TPE-Es can also be used to make bottle cap liners and seal rings. It's also good for vehicle parts, wire and cable insulation, HVAC systems, and home appliances.

The biggest opportunity for this market in practically every key industry is increasing need for TPE-Es in densely populated nations like China and India, where demand is growing every day.

Request Sample

Thermoplastic Polyester Elastomer Market Segment Analysis – By Application

Belting segment held the largest share in Thermoplastic Polyester Elastomers Market in 2020 and is growing at a CAGR 4.5% during 2021-2026. Drive Belts, Conveyor Belts, Weighing Belts, Process Belts, Vacuum Belts, Vacuum Timing Belts, Thermo Belts, Food Processing Belts, ATM-Bill Ejector Belts, and Credit Card Transfer Belts are all made with Hytrel, a thermoplastic polyester elastomer with great durability and flexibility. A metal and x-ray detecting conveyor belt is being developed using DuPont Hytrel TPC-ET thermoplastic elastomer. DuPont Performance Materials teamed up with Esbelt, a conveyor belt manufacturer, to develop a unique, effective polymer that allows for food contamination detection. The new conveyor belt improves food makers' capacity to demonstrate due diligence by controlling the quality of the product on the belt using metal and x-ray detection. Based on the special properties of TPO and TPEE coatings, Habasit P line belts were designed specifically for the tobacco industry. Belt surfaces are critical in tobacco processing because they must serve a variety of functions while enduring harsh environmental conditions such as humidity, sand or dirt, and mechanical impacts. As a result, the increased use of TPEEs across a variety of core sectors is expected to boost the market in the next years.

Thermoplastic Polyester Elastomer Market Segment Analysis – By End-Use Industry

Automotive segment held the largest share in the Thermoplastic Polyester Elastomer market in 2020 and is growing at a CAGR of 6.2% during 2021-2026. Polyester (polyethylene terephthalate (PET)) is the most common fibre used in automobile textile production. According to the SVOA Materials Science & Technology Journal, global TPEEs manufacturing capacity surpassed 150,000 tons per year in 2019, while market demand surpassed 120,000 tons. TPE-E (thermoplastic polyester elastomer) is a thermoplastic polyester elastomer (TPE-E) that is utilized in fabric designs for car seating. Arnitel's TPEEs resin has been utilized on numerous Ford vehicles, including the Mondeo, S-Max, Galaxy, and Focus, and Arnitel's TPEEs have recently been selected as the vacuum brake tube material for Fiesta cars. Thus the growing use of TPEEs in Automotive is evidently going to flourish the market in the forecast period.

Thermoplastic Polyester Elastomer Market Segment Analysis – By Geography

Asia-Pacific region held the largest share in the Thermoplastic Polyester Elastomer Market in 2020 up to 43%, owing to the accelerating automotive industries in the region. According to the International Organization of Motor Vehicle Manufacturers, China produced 25.2 million automobiles in 2020, while India produced 3.9 million, with 25.7 million and 3.8 million automobiles sold in China and India, respectively. China remains the world's largest vehicle market, with the Chinese government projecting that car production will hit 30 million units by 2020 and 35 million by 2025. In 2018, nearly 27 million automobiles were sold in China, according to the China Association of Automobile Manufacturers. The Made in China 2025 program, which aims to transition the country's industry from low-cost mass production to higher-value-added advanced manufacturing, includes automobiles, including new Energy Vehicles (NEVs). The government's target for NEVs is to create 1 million electric and plug-in hybrid cars in China by 2020, with local production accounting for at least 70% of the market. Chinaese government is making a huge investment in the automotive industry which can lead to Thermoplastic Polyester Elastomer Market growth in the forecast period.

Inquiry Before Buying

Thermoplastic Polyester Elastomer Market Drivers

Increasing Automotive Production

Thermoplastic Polyester Elastomers are increasingly being used to replace their equivalents in the production of the inside and exterior of automobiles due to their specific strength and modulus. Thermoplastic Polyester Elastomers are becoming more popular in the vehicle industry due to their superior strength-to-weight ratio and are used in a range of applications in the industry, including automotive hoses, seats, gears, and brake systems, among others. China is the world's largest automobile market, with the Chinese government projecting that car production will reach 30 million units in 2020 and 35 million by 2025. As a result, increased automation will necessitate more automotive components, which will drive the Thermoplastic Polyester Elastomers market during the forecast period.

Use of Thermoplastics in Commodity Sector

Commodity The term thermoplastic refers to the least priced thermoplastics, such as polypropylene and certain grades of polyethylenes, that account for the majority of total plastic production. Elastomeric polymers have a high degree of elasticity, which makes them less prone to breaking or cracking. In fact, depending on the substance, elastomers can reversibly extend up to 700 percent. Wires and cables, photographic and magnetic tape, apparel, reusable bags, medical trays, and seeding trays are all examples of commodity products that can benefit from the high tensile strength and tear resistance of elastomers. period. As a result of the diverse uses of commodities in everyday life, the plastics market is predicted to grow, which would favorably impact the Thermoplastic Polyester Elastomers market over the forecast period.

Thermoplastic Polyester Elastomer Market Challenges

Higher Price of raw materials:

Extrusion and injection molding are the two most common TPE manufacturing processes. Injection molding allows for incredibly quick and cost-effective fabrication. The TPE-raw E's material costs are substantially greater. The reason for this is its high production cost; while producing TPE-E, the apparatus and equipments used are more expensive, and they also demand a lot of maintenance. As a result of this feature, the product has a greater price than its alternative materials, which tends to limit the market's growth.

Buy Now

Thermoplastic Polyester Elastomer Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Thermoplastic Polyester Elastomer Market. Thermoplastic Polyester Elastomer Market top companies include:

1) A. Schulman, Inc.

2) BASF SE

3) Celanese Corporation

4) Chang Chun Group

5) Covestro AG

6) DuPont

7) Entec Polymers

8) LG Chem

9) Mitsui Chemicals Inc

10) PolyOne Corporation and others.

Relevant Reports

Thermoplastic Elastomers Market

Report Code: CMR 0098

Thermoplastic Elastomer (TPE) Gaskets Market

Report Code: CMR 1056

For more Chemicals and Materials Market reports, please click here

#Thermoplastic Polyester Elastomer Market#Thermoplastic Polyester Elastomer Market Size#Thermoplastic Polyester Elastomer Market Share

0 notes

Text

Thermoplastic Polyester Elastomer Market 2022, Sales Volume, Cost, Status and Future Forecast

The Thermoplastic Polyester Elastomer (TPEE) Market report is latest report published by Fusion Market Research which provides comprehensive information, overview of the demands and describe Impact of Covid-19 on the market during the forecast period 2022–2030.

At the beginning of a recently published report on the global Thermoplastic Polyester Elastomer (TPEE) Market, extensive analysis of the industry has been done with an insightful explanation. The overview has explained the potential of the market and the role of key players that have been portrayed in the information that revealed the applications and manufacturing technology required for the growth of the global Thermoplastic Polyester Elastomer (TPEE) Market.

Request Free Sample Report @ https://www.fusionmarketresearch.com/sample_request/(COVID-19-Version)-Global-Thermoplastic-Polyester-Elastomer-(TPEE)-Market/2146

The report offers detailed coverage of Thermoplastic Polyester Elastomer (TPEE) industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Thermoplastic Polyester Elastomer (TPEE) by geography. The report splits the market size, by volume and value, on the basis of application type and geography.

First, this report covers the present status and the future prospects of the global Thermoplastic Polyester Elastomer (TPEE) market for 2016-2025.

And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru].

At the same time, we classify Thermoplastic Polyester Elastomer (TPEE) according to the type, application by geography. More importantly, the report includes major countries market based on the type and application.

Finally, the report provides detailed profile and data information analysis of leading Thermoplastic Polyester Elastomer (TPEE) company.

Leading players of Thermoplastic Polyester Elastomer (TPEE) including:

DuPont

DSM

Toyobo

Taiwan Changchun

Jiangyin Hetron

Celanese

SK Chemicals

LG Chem

SABIC

Mitsubishi Chemical

RadiciGroup

Kelong

Eastman

Sichuan Sunplas

Thermoplastic Polyester Elastomer (TPEE) Market split by Type, can be divided into:

Injection Molding Grade

Extrusion Grade

Blow Molding Grade

Others

Thermoplastic Polyester Elastomer (TPEE) Market split by Application, can be divided into:

Automotive Industry

Industrial Products

Consumer Products

Others

Thermoplastic Polyester Elastomer (TPEE) Market Report Scope

Report AttributeDetails

Base year of estimation2021

Historical data2017 – 2020

Forecast period2022 – 2030

Quantitative unitsRevenue in USD million/billion and CAGR from 2022 to 2030

Segmentation

By Type

By Application

By Region/Country

By Type Injection Molding Grade, Extrusion Grade, Blow Molding Grade, Others

By Application Automotive Industry, Industrial Products, Consumer Products, Others

Report coverageRevenue forecast, company market share, competitive landscape, growth factors, and trends

Key companies profiledDuPont, DSM, Toyobo, Taiwan Changchun, Jiangyin Hetron, Celanese, SK Chemicals, LG Chem, SABIC, Mitsubishi Chemical, RadiciGroup, Kelong, Eastman, Sichuan Sunplas

Regional scope

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Spain etc.)

Asia-Pacific (China, Japan, Korea, India, Australia and Southeast Asia etc.)

South America (Brazil, Argentina and Colombia etc.)

Middle East & Africa (South Africa, UAE and Saudi Arabia etc.)

Ask Queries @ https://www.fusionmarketresearch.com/enquiry.php/(COVID-19-Version)-Global-Thermoplastic-Polyester-Elastomer-(TPEE)-Market/2146

What our report offers:

– Market share assessments for the regional and country-level segments

– Strategic recommendations for the new entrants

– Covers Market data for the years 2020, 2021, 2022, 2025, and 2030

– Market Trends (Drivers, Constraints, Opportunities, Threats, Challenges, Investment Opportunities, and recommendations)

– Strategic recommendations in key business segments based on the market estimations

– Competitive landscaping mapping the key common trends

– Company profiling with detailed strategies, financials, and recent developments

– Supply chain trends mapping the latest technological advancements

Free Customization Offerings:

All the customers of this report will be entitled to receive one of the following free customization options:

• Company Profiling

o Comprehensive profiling of additional market players (up to 3)

o SWOT Analysis of key players (up to 3)

• Regional Segmentation

o Market estimations, Forecasts and CAGR of any prominent country as per the client’s interest (Note: Depends on feasibility check)

• Competitive Benchmarking

o Benchmarking of key players based on product portfolio, geographical presence, and strategic alliances

Continue

0 notes

Text

Polycaprolactone Market to Grow at a CAGR of 9.5% during the 2023 to 2031

The global polycaprolactone market stood at US$ 500 million in 2023 and is projected to reach US$ 1.1 billion in 2031. The global polycaprolactone market is anticipated to expand at a CAGR of 9.5% between 2023 and 2031.

Polycaprolactone (PCL) is a partially crystalline biodegradable polyester produced either by polycondensation of carboxylic acid or ring-opening polymerization using catalysts such as stannous octoate. Biodegradable polyesters help address environmental concerns associated with plastic pollution. PCL is used to make thermoplastic polyurethane, which, in turn, is employed as an elastomer, adhesive, and coating in various end-users including automobiles, paints & coatings, and construction. Polycaprolactone resin has a low melting point, making it easy to process and shape.

Polyurethane-based materials are gaining in the construction sector due to their elasticity and flexibility. R&D of novel polyurethane adhesives is projected to offer lucrative opportunities to vendors in the global polycaprolactone industry. Vendors are developing sustainable products for use in the production of transient and biodegradable electronics. They are also specializing in the production of biodegradable polycaprolactone for medical devices.

Download PDF Brochure: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=35069

Market Segmentation

The Polycaprolactone market can be segmented by service type, sourcing type, application, industry vertical, and region.

By Service Type:

PCL Pellets

PCL Nanoparticles

PCL Microspheres

By Sourcing Type:

Petroleum-Based

Renewable Sources

By Application:

Biomedical (tissue engineering, drug delivery systems, sutures)

Packaging (films, bags)

Additive Manufacturing (3D printing filaments)

Others (coatings, adhesives)

By Industry Vertical:

Healthcare

Packaging

Manufacturing

Consumer Goods

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America: Dominates the market due to high investment in research and development, advanced healthcare infrastructure, and increasing demand for biodegradable polymers.

Europe: Significant growth is anticipated due to stringent environmental regulations and a strong focus on sustainability.

Asia-Pacific: Expected to be the fastest-growing region, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of biodegradable materials.

Latin America and Middle East & Africa: Emerging markets with potential growth opportunities due to rising environmental awareness and regulatory changes.

Market Drivers and Challenges

Drivers:

Increasing demand for biodegradable and sustainable materials.

Technological advancements in biomedical applications.

Government regulations and policies promoting the use of eco-friendly materials.

Challenges:

High production costs compared to conventional plastics.

Limited availability of raw materials from renewable sources.

Technical limitations in specific applications.

Market Trends

Innovation in Biomedical Applications: Continuous research leading to new medical uses of PCL, such as advanced drug delivery systems and tissue engineering.

Growth in Additive Manufacturing: Increased adoption of PCL in 3D printing for various applications.

Sustainability Initiatives: Rising trend of using renewable sources for PCL production to enhance sustainability.

Future Outlook

The future of the Polycaprolactone market looks promising with advancements in technology and growing environmental awareness. Innovations in biomedical applications and additive manufacturing are expected to open new avenues for market growth. Additionally, the shift towards renewable sources for PCL production will further drive the market forward.

Key Market Study Points

Market size and forecast from 2023 to 2031.

Detailed segmentation and regional analysis.

Identification of key drivers, challenges, and trends.

Competitive landscape analysis.

Recent developments and innovations in the market.

Competitive Landscape

The Polycaprolactone market is competitive with several key players striving to enhance their market position through innovation and strategic partnerships. Major players include:

Perstorp Holding AB

BASF SE

Sigma-Aldrich Corporation

Daicel Corporation

Corbion N.V.

These companies are focusing on expanding their product portfolio, investing in research and development, and exploring new applications for PCL to maintain a competitive edge.

Place an Order Copy of Polycaprolactone Market Report at: https://www.transparencymarketresearch.com/checkout.php?rep_id=35069<ype=S

Recent Developments

Innovation in PCL-based medical devices: Companies are developing advanced medical devices using PCL due to its biocompatibility.

Partnerships and Collaborations: Strategic alliances between companies to enhance research capabilities and product offerings.

Sustainability Initiatives: Increased focus on producing PCL from renewable resources to meet regulatory requirements and consumer demand for sustainable products.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Global Top 12 Companies Accounted for 77% of total Thermoplastic Polyester Elastomer (TPEE) market (QYResearch, 2021)

Thermoplastic Polyester Elastomer (TPEE) is a block copolymer who contains a hard segment of polyester and a soft segment of polyether; wherein the amorphous is formed from the soft segment of polyether and the uncrystallized polyester. Micro-crystals play a role as physical crosslinking points formed from the hard segment of the polyester. Thermoplastic polyester elastomer has the rubber elasticity and strength of engineering plastics. Soft segment gives it flexibility to make it like rubber; hard segment assigns the processing properties which makes it like plastic. Compared with rubber, it has a better processing performance and longer life; and the same high strength characteristics compared to plastic, while the flexibility and dynamic mechanical properties is better.

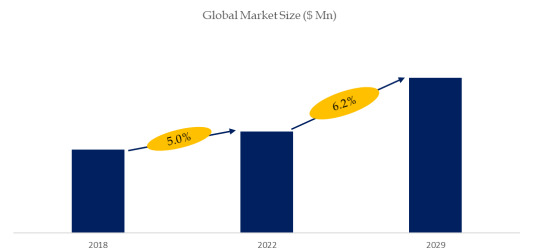

According to the new market research report “Global Thermoplastic Polyester Elastomer (TPEE) Market Report 2023-2029”, published by QYResearch, the global Thermoplastic Polyester Elastomer (TPEE) market size is projected to reach USD 1.94 billion by 2029, at a CAGR of 6.2% during the forecast period.

Figure. Global Thermoplastic Polyester Elastomer (TPEE) Market Size (US$ Million), 2018-2029

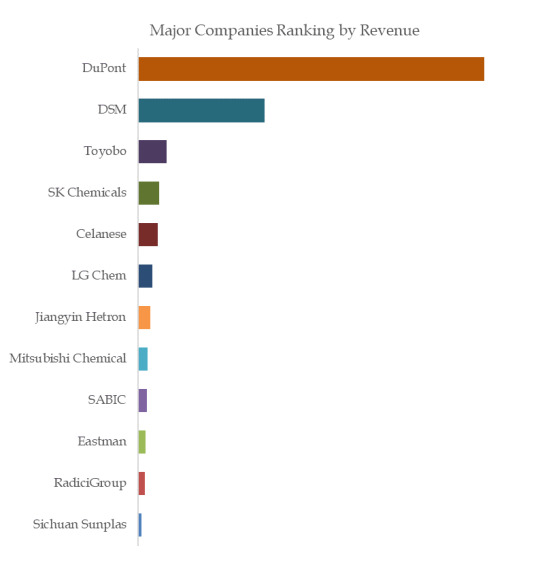

Figure. Global Thermoplastic Polyester Elastomer (TPEE) Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Thermoplastic Polyester Elastomer (TPEE) include DuPont, DSM, Toyobo, SK Chemicals, Celanese, LG Chem, Jiangyin Hetron, Mitsubishi Chemical, SABIC, Eastman, etc. In 2022, the global top five players had a share approximately 77.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

0 notes

Text

"Diving Deep into the Specialty Polymers Market: Trends, Innovations, and Strategic Insights

Specialty Polymers: Harnessing the Power of Specialty Macromolecules for Next-Generation Technologies

Specialty Polymers Overview

Specialty macromolecules, also known as engineering macromolecules, are a class of macromolecules that are specially engineered to have targeted physical and chemical properties that make them suitable for advanced applications. Though they only represent a small fraction of the total macromolecules market, specialty macromolecules command a significant revenue share due to their higher value and more niche end uses.

Types of Specialty Macromolecules

There are several main types of specialty macromolecules classified based on their monomer makeup and resultant properties. Some of the major types include:

Polyamides (Nylons)

Polyamides, best known by the brand name Nylon, are a class of thermoplastic macromolecules containing amide linkages along their polymer chains. They are known for their high strength, toughness, and relative durability compared to other plastics. Engineering polyamides such as Nylon 46 and Nylon 610 can withstand higher temperatures than commodity nylons.

Fluoromacromolecules

Fluoromacromolecules contain strong carbon-fluorine covalent bonds which give them unique oil, chemical, heat and weather resistance properties. Popular fluoromacromolecules include polytetrafluoroethylene (PTFE or Teflon), fluorinated ethylene propylene (FEP), and polyvinylidene fluoride (PVDF). They are used in applications requiring non-stick, low friction surfaces.

Polyesters

Engineering polyesters such as liquid crystal macromolecules (LCP), polybutylene terephthalate (PBT), and polyethyleneterephthalate (PET) can be formulated with enhanced heat resistance, strength and rigidity over traditional polyesters. They are employed in automotive, electrical/electronic and consumer goods.

Liquid Silicone Rubbers

Liquid silicone rubbers (LSRs) are two-part addition-cure silicone elastomers that vulcanize at room temperature. Their biocompatibility, stability and flexibility make them well-suited for medical, food and microfluidic device applications. Low compression set LSRs retain shape over time.

Polyketones

Polyketones are a family of thermoplastics with high strength, heat resistance and chemical resistance derived from their ketone groups in the polymer backbone. They include comacromolecules like polyetheretherketone (PEEK) used in demanding mechanical and electrical end uses.

Markets and Applications

Specialty macromolecules are developing across diverse markets driven by the need for advanced material performance. Some of the major application areas include:

Automotive

In automotive, specialty macromolecules enable lightweighting through replacement of traditional metals. Nylons, PBT, polycarbonate and liquid silicone aid composites in vehicles. Use in engine components require heat resistance of PEEK and liquid crystal macromolecules.

Electronics

Electronics rely on specialty macromolecules for miniaturization and reliability. PTFE, FEP, PET and PVDF bring dielectric, insulating properties. PBT molding aids housings. Semiconductor uses benefit from high heat resistance of PEKK and LCP.

Medical

Biocompatible and non-leaching properties of silicones, nylons and PEEK suits medical industry. Implants, catheters, sensors and drug delivery use these. PEKK aids orthopedic devices. Silicones serve prosthetics, wound care and contact lenses.

Infrastructure

Resistance to chemical, heat and environmental stress qualifies many macromolecules for infrastructure. PVDF and silicones protect coatings and paints. Dams, tunnels utilize durability of PTFE and polyketones lining.

Other Developments

New technologies foster demand for high performance plastics. Renewable energy harvest requires specialty macromolecules in wind turbines, solar cells. Aerospace gravitates toward sturdy yet lightweight materials like PEKK, PEEK. Microfabrication leverages specialty silicones and fluoromacromolecules. As applications diversify, advanced macromolecules enable novel solutions.

Future Prospects

The specialty macromolecules market is forecast to sustain strong growth over the medium term supported by their rising penetration across major end-use industries. Polyketones, liquid silicone rubbers and high-temperature polyamides will be key winning product types. The Asia Pacific region is expected to lead future demand growth driven by its large manufacturing industries. Robust R&D focus on bio-based and high-tech specialty macromolecules will further fuel new product innovations and market opportunities going forward.

In Summary, specialty polymers represent a fascinating realm of materials science, offering tailored properties and applications beyond traditional macromolecules. These advanced materials are engineered to meet specific performance requirements, such as enhanced durability, conductivity, or biocompatibility. From aerospace components to medical devices, specialty macromolecules play a crucial role in a wide range of industries, driving innovation and pushing the boundaries of what's possible.

0 notes

Text

Impact of COVID-19 on the Polyurethane Prepolymer Market: Strategies for Resilience

Polyurethane Prepolymers: An Essential Raw Material for Manufacturing Industries

What are Polyurethane Prepolymers?

Polyurethane prepolymers, also known as isocyanate terminated prepolymers, are polyols that have been reacted with diisocyanates but terminated with residual isocyanate groups. They are highly viscous resins synthesized by reacting a polyol such as polyether polyol or polyester polyol with a diisocyanate like MDI or TDI in a 1:1 or 1:2 stoichiometric ratio resulting in an isocyanate functional prepolymer.

Applications of Polyurethane Prepolymers

Polyurethane prepolymers find wide applications due to their versatile chemical and physical properties. Some key applications include:

Coatings - Prepolymers are used as binders, crosslinkers and intermediates in manufacturing coatings for wood, concrete, leather and various industrial applications. Their excellent adhesion, chemical resistance and flexibility makes them ideal for coatings.

Adhesives and Sealants - The film forming and adhesive properties of prepolymers are leveraged to produce structural and high-performance adhesives as well as sealants for construction and automotive applications.

Elastomers - Prepolymers impart flexibility, elasticity and high strength to elastomers used in hoses, gaskets, rollers and various flexible molded articles. They aid in processability and enhance mechanical properties.

Footwear - The mechanical strength and flexibility imparted by prepolymers in polyurethane enables their use in manufacturing shoe soles, heels and sport shoe midsoles providing comfort and durability.

Types of Polyurethane Prepolymers

Based on the polyol/diisocyanate ratio and reactants used, prepolymers can be categorized as:

- MDI based: Formed from reaction of MDI with polyester polyols or polyether polyols. Offer high strength, hardness and chemical resistance. Widely used.

- TDI based: React TDI with polyols. Provide flexibility and high elongation. Used in elastomers, sealants and adhesives.

- Polyester based: Have good hydrolytic stability and strength. Used in coatings.

Manufacturing Process of Polyurethane Prepolymers

The manufacturing process involves the following key steps:

1. Reaction of Polyol and Diisocyanate: Polyether polyol or polyester polyol is charged into the reactor and heated to the required temperature. Diisocyanate like MDI or TDI is added slowly with agitation.

2. Controlled Polyaddition Reaction: The exothermic polyaddition reaction between hydroxyl groups of polyol and isocyanate groups proceeds. Process parameters like temperature, catalysts are controlled.

3. Termination Reaction: Once the pre-set NCO index is reached, the prepolymer is terminated by residual isocyanate groups and deactivated by adding catalyst kill.

4. Filtration and Packaging: The viscous prepolymer solution is filtered to remove impurities and filled in drums, IBCs or bulk tankers.

Applications determine the suitable type of prepolymer and optimization of process parameters like reaction temperature, reaction time and NCO index yields prepolymers with desired physical and chemical qualities. Strict quality control during manufacturing is vital.

Outlook for Polyurethane Prepolymers Market

The global polyurethane prepolymers market is forecast to grow at over 5% CAGR through 2030 driven by increasing usage in coatings, adhesives, sealants, thermoplastic polyurethanes and various consumer and industrial applications. Rapid growth of key end use industries like footwear, construction, automotive, packaging and furniture will boost demand.

Moreover, continuous product innovation to develop new grades catering to changing industry and regulatory trends along with expansion into emerging markets in Asia Pacific and Middle East regions are factors expected to fuel the prepolymer market in the coming years. However, volatility in raw material prices remain a key challenge. Overall, polyurethane prepolymers market outlook looks positive owing to their excellent performance attributes and versatile usage profile.

#Polyurethane Prepolymer Market Growth#Polyurethane Prepolymer Market Trends#Polyurethane Prepolymer Market

0 notes

Text

0 notes

Text

Specialty Polymers Market - Forecast (2023 - 2028)

Specialty Polymers Market size is estimated to reach US$248.1 billion by 2027, after growing at a CAGR of 6.5% during the forecast period 2022-2027. Specialty polymers are derived from natural polymers, semisynthetic polymers and synthetic macromolecule polymers. Specialty polymers have advantageous characteristics, such as improved gas barrier performance, flame resistance and heat stability. They are thus frequently used in a variety of applications, including polymers, resins, monomers, intermediates and more. The booming transportation industry is the primary factor driving the growth of the specialty polymers market. According to the Organisation Internationale des Constructeurs d'Automobiles, in 2020, the global automotive production was 77,711,725 units and in 2021, it was 80,145,988 - an increase of 3%. Also, the growth in construction activities worldwide would fuel the demand for specialty polymers. The COVID-19 pandemic, on the other hand, hampered the growth of the specialty polymers industry. This was due to the halt in industrial activities associated with automotive, building & construction and more in 2020. Nonetheless, the increase in industrial production activities in 2021 fueled the growth of the Specialty Polymers industry.

Report Coverage

The "Specialty Polymers Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Specialty Polymers Market.

By Source: Natural, Semisynthetic and Synthetic.

By Form: Solid and Liquid.

By Type: Specialty Elastomers (Fluoroelastomers, Fluorosilicone Rubber, Liquid Silicone Rubber, Natural Rubber and Others), Specialty Thermoplastics (Polyolefins, Polyimides, Vinylic Polymer, Polyphenyles and Others), Specialty Thermosets (Epoxy, Polyester, Vinyl Ester, Polyimides and Others), Biodegradable Polymers, Conducting Polymers, Liquid Crystal Polymers and Others.

By End-use Industry: Building & Construction (Residential, Commercial, Industrial and Infrastructure), Transport [Automotive {Passenger Vehicles (PV), Light Commercial Vehicles (LCV) and Heavy Commercial Vehicles (HCV)}, Aerospace (Commercial, Military and Others), Marine (Passenger, Cargo and Others) and Locomotive], Textile, Food & Beverages (Fruits & Vegetables, Meat, Confectionery, Bakery Products, Dairy Products, Alcoholic Beverages, Non-alcoholic Beverages and Others), Electrical & Electronics (Computers, Smartphones, Semiconductors, Wires and Others), Cosmetics & Personal Care (Hair Care, Skin Care, Perfumes & Fragrance and Others) and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World [the Middle East (Saudi Arabia, the UAE, Israel and the Rest of Middle East) and Africa (South Africa, Nigeria and the Rest of Africa)].

Key Takeaways

Asia-Pacific dominated the Specialty Polymers Market, owing to the growth of the automotive industry in the region. According to the Society of Indian Automobile Manufacturers (SIAM), in 2020, the total automobile production in India was 22,655,609 units and in 2021, it was 22,933,230 units - an increase of 1.2%.

The increasing research & development associated with Specialty Polymers would create an opportunity for market growth during the projected forecast period.

Moreover, the surging application of Specialty Polymers as resins, monomers and intermediates in the textile and cosmetics & personal care industries is driving the market growth.

However, the higher price of Specialty Polymers may confine the growth of the Specialty Polymers industry in the upcoming years.

#Specialty Polymers Market#Specialty Polymers Market size#Specialty Polymers Market trends#Specialty Polymers Market forecast#Specialty Polymers Market report#Specialty Polymers Market research

0 notes

Text

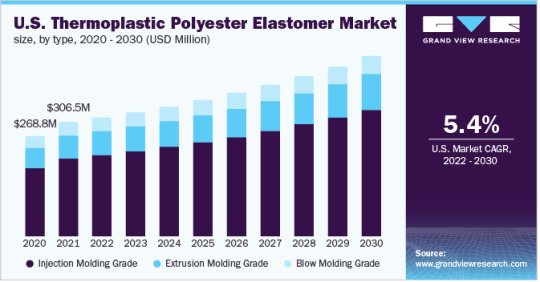

Flexibility and Resilience: Thermoplastic Polyester Elastomer Market Targets $2.3 Billion by 2030

Thermoplastic Polyester Elastomer Market Growth & Trends

The global thermoplastic polyester elastomer market size is expected to reach USD 2.3 billion by 2030, according to a new report by Grand View Research, Inc. It is projected to expand at a CAGR of 5.2% from 2022 to 2030. The thermoplastic polyester elastomer market is expected to witness significant growth over the forecast period owing to…

View On WordPress

0 notes

Text

N95 Grade Medical Protective Masks Market to Witness Excellent Revenue Growth Owing to Rapid Increase in Demand

Advance Market Analytics released a new market study on Global N95 Grade Medical Protective Masks Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global N95 Grade Medical Protective Masks Forecast till 2027*.

N95 Grade is approved by many governments agency as the best Antibacterial mask or virus-proof mask. These masks are the respirators and surgical masks (face masks) that act as personal protective equipment and protect the wearer from airborne particles and from liquid contaminating the face. For example Centers for Disease Control and Prevention (CDC) National Institute for Occupational Safety and Health (NIOSH) and Occupational Safety and Health Administration (OSHA) also regulate N95 respirators masks. With the rising outbreak of the virus (Covid- 19), people are indeed buying these masks as their PPE. This market has consumed a huge amount of market share, due to the owing spread of disease namely novel coronavirus. With an upsurge of these diseases across the world, the market of these N95 masks has been flourish in such a way that the mask markers have to produce masks in numerous numbers and enhance their market position.

Key Players included in the Research Coverage of N95 Grade Medical Protective Masks Market are 3M (United States),Honeywell (United States),Kimberly-Clark Professional (United States),Vogmask (United States),Shanghai Dasheng (China),Totobobo (Singapore),Cambridge Mask Co. (United Kingdom),Ellessco LLC (United States)

What's Trending in Market: Adoption of Different Kinds of Filters in these N95 Masks

Adoption of Light-weighted Mask

Challenges: The rising concern of counterfeit of products by the manufactures. As the end side demand is so much due to growing coronavirus, that the manufacturers are producing counterfeit products in order to fulfill the current demand of consumers.

Opportunities: With The Rising Number of Affected Humans across the Globe Majorly In China

Growing Demand for Full Cure of Coronavirus Disease

Market Growth Drivers: Increases Number of People in China Infected By the New Coronavirus Surpasses

Rising Inclination of Human Being towards their Unhygienic Pets

The Global N95 Grade Medical Protective Masks Market segments and Market Data Break Down by Type (Disposable Masks, Reusable Masks), Application (Industrial, Individual, Hospital & Clinic), Distribution Channel (Online, Offline), Material (Thermoplastic Elastomer, Aluminum, Polyurethane, Polypropylene, Polyester)

To comprehend Global N95 Grade Medical Protective Masks market dynamics in the world mainly, the worldwide N95 Grade Medical Protective Masks market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

Presented By

AMA Research & Media LLP

0 notes

Text

Thermoplastic Elastomers Market | Global Industry Size, Share, Analysis Report, 2030 | ChemAnalyst

According to ChemAnalyst report, “Global Thermoplastic Elastomers Market: Plant Capacity, Production, Operating Efficiency, Demand & Supply, Technology, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030”, global Thermoplastic Elastomers market has shown promising growth in the past five years and is anticipated to achieve a CAGR of 4.55% during the forecast period owing to its high demand in automotive industry coupled with its eco-friendly and easy to recycle nature. Thermoplastic elastomers are the superior polymers that has properties of both thermoplastic and elastomers, also known as Thermoplastic rubbers because of their rubbery property. The rubbery property is present due to one of the components of the copolymer. There are various types of thermoplastic elastomers including styrene block copolymers, thermoplastic olefin, elastomeric alloy, thermoplastic polyurethane, thermoplastic co-polyester, thermoplastic polyamide. Among all styrene block copolymers holds the major share for the total volume consumed. Thermoplastic Elastomers offer high performance attributes in compared to thermoset rubbers, metals, and other conventional materials.

Read Full Report Here: https://www.chemanalyst.com/industry-report/thermoplastic-elastomers-market-567

Due to their versatile properties like high strength, flexibility and light weight, Thermoplastic Elastomers find application in automotive and transportation, building and construction, footwear, electrical and electronics, medical, household appliances, adhesive, sealant and coating. Growing demand from the automotive industry coupled with the rising demand from other application areas such as building and construction, footwear etc. is expected to drive the demand of thermoplastic elastomers during the forecast period. Moreover, growing demand for bio based Thermoplastic Elastomers is going to push the demand further during the forecast period. It is expected that Thermoplastic Elastomers are going to replace the market for PVC in the upcoming years.

In 2020, the spread of COVID-19 in major global economies caused nationwide lockdowns which had an impact on a numerous industry. Automotive and construction were among the most affected industries during the pandemic. This had an impact on the demand of thermoplastic elastomers for the first half of 2020. However, a rise in the demand for Thermoplastic Elastomers has been witnessed since there is relaxation in the lockdown due to its high demand from various end use industries. Additionally, the government policies to support electric vehicles for the clean environment consequently endorses the growth of the thermoplastic elastomers market.

Region wise, Asia pacific region holds the major share of global demand for thermoplastic elastomers due to the expansion of Automobile industry in the region, rapid industrialization as well as the increasing construction activities specially in China and India. Moreover, there is heavy demand for Thermoplastic Elastomers from various other end use industries like electronics, consumer goods, Packaging etc. which further will drive its market in the forecast period.

Sample Request Report: Thermoplastic Elastomers Market

North America and Europe are also expected to show a prominent growth in the demand for Thermoplastic Elastomers during the forecasted period owing to the presence of various end use Industries and their focus in using environment friendly and biodegradable materials.

According to ChemAnalyst report, Global Thermoplastic Elastomers Market: Plant Capacity, Production, Operating Efficiency, Demand & Supply, Technology, Application, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030, Major players for thermoplastic elastomers globally include BASF SE, Dow industries, A. Schulman Inc., Huntsman International LLC, Arkema Group, DSM Corporation, DuPont Inc., Evonik Industries AG, SABIC Co., Exxon Mobil Corporation, LG Chem, LANXESS Industries, Sinopec Group, LyondellBasell Industries Holdings B.V., Mitsubishi Chemical Corporation, Sumitomo Chemicals Co. Ltd,

“Being linked to the automotive and construction sectors, the global Thermoplastic Elastomers industry has shown a robust growth. China and India are the hub of Automobile industries and in Asia Pacific which fuels the demand for Thermoplastic Elastomers in the region. Additionally, Government regulations concerning the use of Biodegradable, recyclable and ecofriendly material are driving the market for Thermoplastic Elastomers across the globe. Additionally, it is also safe to use in sectors like Medical and Food Packaging that will create lucrative market growth opportunities for Thermoplastic Elastomers in the forecasted period. With new competitors emerging across the Asia Pacific Thermoplastic Elastomers market, players anticipate that there will be sufficient supply demand gaps in future. At this, it is extremely important to keep an eye which region will grab the biggest market share in the upcoming years.” said Mr. Karan Chechi, Research Director with TechSci Research, a research based global management consulting firm promoting ChemAnalyst.

About Us:

ChemAnalyst is a subsidiary of Techsci Research, which was established in 2008, and has been providing exceptional management consulting to its clients across the globe for over a decade now. For the past four years, ChemAnalyst has been a prominent provider of Chemical commodity prices in more than 15 countries. We are a team of more than 100 Chemical Analysts who are committed to provide in-depth market insights and real-time price movement for 300+ chemical and petrochemical products. ChemAnalyst has reverberated as a preferred pricing supplier among Procurement managers and Strategy professionals worldwide. On our platform, we provide an algorithm-based subscription where users can track and compare years of historical data and prices based on grades and incoterms (CIF, CFR, FOB, & EX-Works) in just one go.

The ChemAnalyst team also assists clients with Market Analysis for over 1200 chemicals including assessing demand & supply gaps, locating verified suppliers, choosing whether to trade or manufacture, developing Procurement Strategies, monitoring imports and exports of Chemicals, and much more. The users will not only be able to analyze historical data for past years but will also get to inspect detailed forecasts for the upcoming years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

ChemAnalyst is your one-stop solution for all data-related needs. We at ChemAnalyst are dedicated to accommodate all of our world-class clients with their data and insights needs via our comprehensive online platform.

Contact Us:

ChemAnalyst

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523990

Mob: +91-8882805349

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

0 notes

Text

0 notes

Link

0 notes