#Titanium Ball Valve Manufacturers

Text

Learn About On Titanium Ball Valve Types And Features

Ladhani Metal Corporation is one of the leading Titanium Ball Valve Manufacturers in India. Our company provides these Titanium Ball Valves with high demand due to its features like lightweight, high strength, sturdy design, easy to install, high performance and longer service life.

According to the Titanium Ball Valve Manufacturer that is to be used for radioactive material will have different requirements than one that is to be used for storing or handling gasoline.This titanium ball valve is a type of valve that controls the flow of fluids or gases by using a ball with a hole in the centre. It is mostly constructed of titanium, which is a strong, lightweight, and corrosion-resistant metal.

Types Of Titanium Ball Valve

Titanium One Piece Ball Valve

Titanium Two Piece Ball Valve

Titanium Three Piece Ball Valve

Titanium Top Entry Ball Valve

Titanium Orbit Ball Valve Manufacturer

Titanium Jacketed Ball Valve

Titanium Unibody Ball Valve

Features On Titanium Ball Valve

Titanium ball valves have a number of distinguishing characteristics that make them suited for a wide range of applications. Here are some significant characteristics of titanium ball valves:

Titanium Construction: Titanium ball valves are largely made of titanium, a metal that is strong, lightweight, and corrosion-resistant. Titanium is extremely durable and resistant to corrosion, chemicals, and severe conditions.

Full Bore Design: This design reduces flow constraints, pressure drop, and turbulence, enabling for efficient fluid or gas flow.Titanium ball valves are normally full bore, which means the internal diameter of the valve is the same as the pipe's Diameter.

Two-Way Flow Control: Titanium ball valves provide reversible flow control, which allows fluid or gas to travel through the valve in both directions. This feature allows for greater flexibility in system setups and easy control of flow direction.

Various End Connections: The type of end connection used is determined by the application and installation requirements.Titanium ball valves are offered with a variety of end connectors to accommodate a variety of pipe systems.Threaded, flanged, socket weld, and butt weld connectors are all common forms of end connections.

Wide Temperature and Pressure Range: Titanium ball valves are resistant to a broad variety of temperatures and pressures. They can be used in both low-temperature cryogenic applications and high-temperature procedures, making them adaptable to a wide range of industrial conditions.

In conclusion,Titanium ball valves are a highly dependable and adaptable solution for applications needing corrosion resistance, high strength, and effective flow control. Their distinctive qualities, such as superior corrosion resistance, a high strength-to-weight ratio, and temperature/pressure resistance, make them suitable for a wide range of sectors, including chemical processing, oil and gas, petrochemical, power generation, water treatment, and aerospace.

#Titanium Ball Valve#Titanium Ball Valve Manufacturers#Titanium One Piece Ball Valve#Titanium Two Piece Ball Valve#Titanium Three Piece Ball Valve#Titanium Top Entry Ball Valve#Titanium Orbit Ball Valve#Titanium Jacketed Ball Valve#Titanium Unibody Ball Valve

0 notes

Text

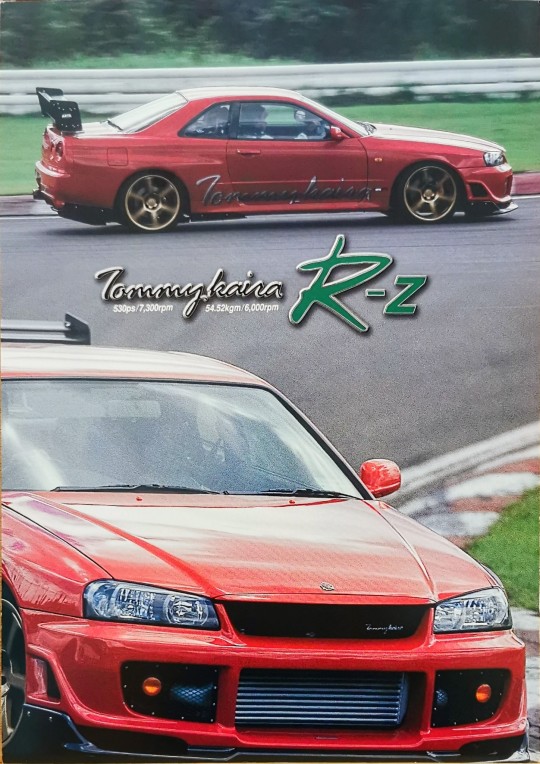

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

17 notes

·

View notes

Text

Pneumatic Actuated Valve Manufacturer in Germany

ValvesOnly Europe is the leading Pneumatic Actuated Valve Manufacturer in Germany. They use compressed air to control the opening and closing of the valve, due to their reliability, ability to handle high pressure and temperature and fast response time these valves are widely used in the industries such as power plants, chemical industry and many others. They have two main components: a valve body and actuator, they receive a signal when compressed air or gas is directed into the actuator chamber and create a pressure and start operating the valve, opening or closing the valve.

Types:

Pneumatic Actuated Ball valve

Pneumatic Actuated Gate valve

Pneumatic Actuated Butterfly valve

Pneumatic Actuated Knife Gate valve

Advantages:

Fast response time

Adjustability to varying conditions

Need low maintenance

Withstand high pressure and temperature fluids

Reliable

Cost effective

Industries:

Oil and Gas Industry

Chemical Industry

Petrochemical Industry

Mining Industry

Marine Industry

Description:

Available Material: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class: 150-2500, PN6-PN450

Ends: Flanged, Socket weld, Butt weld, Lug, Wafer, Threaded.

Operations: Pneumatic Actuated

Configuration of a Pneumatic Actuator:

Torque – 3 – 9000 nm

Operating pressure- 8 Bar

Port Connection-NPT1.4”

Mounting Base-ISO5211

Temperature–20°C – +80°C

0 notes

Text

Valve supplier in Nigeria

African Valve is the top Valve Supplier in Nigeria. African Valve stands as the premier supplier and manufacturer of valves across Africa with a commitment to excellence, we ensure top-notch products and services. We proudly serve clients across Africa, including Nigeria, Kenya, Algeria, Ghana, Tanzania, Sudan, and Ethiopia, ensuring reliable access to top-tier valve solutions continent-wide. As a reputed valve supplier we provide different types of valves available in different sizes and classes made with high standard material quality to meet the needs of various industries.

Choose a premium valve and ensure safety, reliability and durability with African Valve, your trusted industrial Valve Supplier in Nigeria. Here are some major types of valve we manufacture and supply:

Control Valve: It is a type of valve used in various industrial processes to regulate the flow of fluids such as liquids, gases, steam, or slurries

Cryogenic Valve: This type of valve is specifically designed to handle extremely low temperatures encountered in cryogenic applications.

Pressure Reducing Valve: These valves are also known as a pressure regulator, is a type of valve used to control and maintain a lower pressure in a pipeline or system than the pressure of the fluid entering it.

Safety Valve: It is a crucial safety device used in industrial systems to prevent dangerous pressure build-ups.

Check Valve: These valves are also known as a non-return valve or one-way valve, a mechanical device used in piping systems to allow fluid to flow in one direction while preventing reverse flow

Gate Valve: It is a type of valve used to control the flow of fluid within pipes. They consist of a sliding gate or wedge-shaped disc that moves perpendicular to the flow of the fluid.

Butterfly Valve: A butterfly valve is a type of quarter-turn valve that controls the flow of fluid through a pipeline by means of a disc mounted on a rotating shaft.

Globe Valve: It is a type of linear motion valve used for regulating the flow of fluids in pipelines.

Ball Valve: A ball valve is a type of valve used to control the flow of fluids within a piping system. It consists of a spherical closure (the "ball") with a hole or port through the center

Knife Gate Valve: A knife gate valve is a specialized type of gate valve designed for applications involving the flow control of fluids with high concentrations of solids, such as slurries and viscous media.

Foot Valve: A foot valve is a type of check valve commonly used in pumping systems to prevent backflow and maintain prime in suction lines

Electric Actuated Valve: Thay are automated valves that use electric power to control the opening and closing of the valve.

Advantages:

Control and Regulate the flow of fluids

Prevent from leakage of fluids

Quick shut off and quick response in the operation

Pressure regulation

Ensure safety in operations

Easy to operate and install

Versatility comes in different sizes for various industrial applications

Prevention of backflow of fluid

Corrosion Resistance

Industry:

Oil and Gas Industry

Power Generation

Water and Wastewater Treatment

Chemical and Pharmaceutical Industries

Pulp and paper industry

Marine and offshore industry

Petrochemical industries

Textile and Process Industries

Thermal and Nuclear Power industries

Mining and Minerals

HVAC and Plumbing

Food and Beverage

Marine Industry

Irrigation System

Textile industry

Description:

Available materials: Ductile iron, Monel, WCB, WCC, WC6, LCB, LCC, SS304, SS316, CF8, CF8M, CF3, CF3M, Aluminum Bronze, Bronze, Brass, F55, F53, F51, Inconel, Titanium.

Class: 150 to 2500.

Nominal Pressure: PN6 to PN450.

Size: ½” to 80”.

Ends: Flanged, Wafer, Lug, Buttweld, Socket weld, Threaded.

Operations: Lever operated, Gear operated, Electric actuated, Pneumatic actuated.

For more detail visit our website: https://www.africanvalve.com/

0 notes

Text

Exploring the Technological Features of Stainless Steel Flange

The stainless steel flange is easy to make, simple to manufacture, low in cost and widely used, but the rigidity is poor, so it can not be used in the chemical process piping system with the requirement of supply and demand, flammable, explosive and high vacuum degree, and the high and extreme harm situation. The sealing type has a plane and a sudden face.

Stainless Steel Flange Features: Simple structure, small size, light weight, tight and reliable, the current ball valve sealing surface materials widely used plastic, good sealing, in the vacuum system has been widely used, easy to repair, the ball valve structure is simple, sealing ring is generally active, disassembly and replacement is more convenient; in full or closed, the ball and seat sealing surface and media isolation.

Stainless Steel Flange film is not produced corrosion, pitting, corrosion or wear, is the construction of metal materials in one of the highest strength. Because the stainless steel has good corrosion resistance, it can make the structural parts permanently maintain the integrity of the engineering design. Chromium-containing stainless steel flange film also set mechanical strength and high extensibility in a, easy parts of the processing and manufacturing, can be satisfied with architects and structural designers need. All metals react with oxygen in the atmosphere, forming an oxide film on the surface.

In the maintenance of stainless steel flange is necessary to pay attention to some problems: long-time use of stainless steel flange should be scheduled to check, often on the surface of the exposed processing should be kept clean, clean dirt, neatly stored in the room ventilated dry place, is strictly prohibited to heap or open storage. Always keep the stainless steel flange dry and ventilated, keep the clean and tidy, according to the accurate storage method.

Installation, the stainless steel flange can be connected directly to the tube on the road, according to the location used to install. Under normal circumstances, can be installed in the pipeline at any location, but to facilitate the operation of the inspection, pay attention to the cut-off stainless steel flange medium flow should be the vertical disc below the upper, stainless steel flange can only be installed horizontally. Stainless steel flange in the installation should pay attention to the tightness, to prevent leakage phenomenon, affect the normal operation of the pipeline.

In order to prolong the service life of the stainless steel flange tap, to improve the quality of thread processing, we should pay attention to some matters needing attention when processing and production: the surface of the tap thread is coated with titanium nitride, which can remarkably improve the abrasion resistance, heat resistance and lubricity of the tap. But it should be noted, such as the shovel back too large, it is easy to produce the phenomenon that the chip plugs into the back corner of the tap in the retract, and the thread finish of the tapping is not good; enlarge the front corner of the tap properly, but notice that the front corner of the tap is too large, and it is easy to cause the tap to collapse and the tapping of the

Because the stainless steel has good corrosion resistance, it can make the structural parts permanently maintain the integrity of the engineering design. Stainless steel flanges do not produce corrosion, pitting, rust or abrasion. Chromium-containing stainless steel flange is also set mechanical strength and high extensibility in a, easy parts of the processing and manufacturing, can be satisfied with architects and structural designers need. All metals react with oxygen in the atmosphere, forming an oxide film on the surface. If a hole is formed, it can be plated with paint or oxidation-resistant metals to ensure the surface of the carbon steel, but, as is known, this protection is only a thin film.

0 notes

Text

Ball Valve Manufacturer in Italy

Valvesonly Europe is a preeminent Ball Valve Manufacturer in Italy. Ball valve stands tall as a versatile and important player. Ball Valve is a quarter-turn rotary motion valve that uses ball shaped disk to start or stop the flow of gas or liquid. It helps in regulating the flow of liquids or gases through pipeline and piping system, It take 90 degree turn to open or close the flow . When the valve is parallel to the pipeline it allows the flow and when its perpendicular to the pipe it stops the flow. They are used industry where there is a need of fast shut off capability. The ball valves has reliable sealing that prevents any form of leakage. It can withstand high pressure and temperatures and requires low maintenance .

Parts : All internal components of a ball valve are contained inside a casing or housing . It’s made up of hard materials, that protects the internal components of the valve .A ball valve body consists of the following components:

Ball: The ball is a sphere that has a hole in the centre and that centre is called bore. It controls the flow of fluid. The ball being parallel to the system ensures smooth flow, while being cross stops the flow .

Shaft: The shaft connects the ball to the control mechanism that turns it. It has seals to prevent fluid leaks. The shaft can be manually operated or controlled electronically or by pneumatic or hydraulic means.

Bonnet: The bonnet is an extension of the housing, covering the shaft and its seals. It can be welded or bolted to the body and made of hard metal . It provides protection to the shaft .

Seat: Seats are where the ball seals with the body, ensuring no fluid leaks. There's an upstream seat on the inlet side and a downstream seat on the outlet side. They create a tight seal when the valve is closed.

Understanding Ball Valve Types:

Floating Ball Valve: We can picture a freely moving ball adjusting itself to ensure a tight seal, like a perfectly fitting puzzle piece.

Trunnion-Mounted Ball Valve: In this type, the ball remains steady, ideal for situations where stability under high pressure is necessary to maintain flow control

Fully Welded Ball Valve

Top Entry Ball Valve

Jacketed Ball Valve

Double block and bleed ball Valve

Side Inlet Ball Valve

Forged Ball Valve

Cast Iron and Cast Steel Ball Valve

Heavy Duty Investment Casting Ball Valve

Wafer Ball Valve

Industry Applications:

Oil and Gas Industry: They are often employed in pipelines, wellheads, and storage facilities.

Chemical Industry: They find application in chemical processing plants for controlling the flow of acids, bases, and other corrosive chemicals.

Water and Wastewater Treatment: They are also employed in sewage treatment plants for managing the flow of wastewater.

Power Generation: Ball valves play a crucial role in power plants, controlling the flow of water, steam, and other fluids in boilers and cooling systems.

Petrochemical Industry: Ball valves are widely used in petrochemical plants for regulating the flow of various petrochemical products.

Marine Industry: They are utilized in marine applications for controlling the flow of water, fuel, and other fluids on ships and offshore platforms.

Mining Industry: Ball valves are used in mining operations for controlling the flow of water, slurry, and chemicals in various processes.

Description:

Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M , F55, F51, F53, Monel, Ductile Iron.

Available Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: LNG, Cryogenic application, Water, Air, Steam, Oil

Ends: Flanged, Threaded, Buttweld, Socket weld

Operations: Lever Operated, Electric Actuated and Pneumatic Actuated., Gear

Our website visit us : https://www.valvesonlyeurope.com/product-category/top-entry-ball-valve

1 note

·

View note

Text

Valve Manufacturer and Supplier in South America

South American Valve is the largest Valve Manufacturer and Supplier in South America. We supply Gate, Globe, Ball, Butterfly, PRV, Safety valve. South America, with its burgeoning industrial sector, has witnessed a significant surge in demand for high-quality valves that can withstand the rigors of diverse applications. A valve is a mechanical device that controls the flow of fluids (liquids or gases) by opening, closing, or partially obstructing passageways. They are designed to manage the flow rate, pressure, and direction of the fluid within a pipeline or a system.

Valves can be manually operated or actuated using external devices like electric or pneumatic actuators for automated control. The choice of a valve type and its operation method depends on factors such as the intended application, required precision, and the characteristics of the fluid being controlled. Regular maintenance and monitoring are crucial to ensure valves function properly and contribute to the efficiency and safety of industrial processes.

As a Valve Manufacturer and Supplier in South America, we offer a range of precision-engineered valves tailored to diverse industrial needs, ensuring efficient control and regulation of fluid flow.

Different types of valves and their function-

Control Valve: Regulates the flow, pressure, or temperature of a fluid to maintain desired process conditions.

Check Valve: Permits flow in one direction only, preventing backflow and ensuring system integrity.

Safety Valve: Automatically releases excess pressure to prevent system overpressure and potential damage.

Pressure Relief Valve: Protects equipment by relieving excess pressure and maintaining safe operating conditions.

Gate Valve: Provides a straight-line flow path and is suitable for applications requiring full opening or closing.

Ball Valve: Offers quick, quarter-turn operation for on/off control in various applications.

Butterfly Valve: Controls flow with a disc that rotates around a central axis, suitable for large-scale applications.

Globe Valve: Precisely controls flow rate and is ideal for throttling applications.

Advantages of valve-

Flow Control

On/Off Functionality

Pressure Regulation

Directional Control

Emergency Relief

Diverse Applications

Versatility in Fluid Handling

Automated Control

Reliability and Longevity

Minimized Leakage

Customization

Energy Efficiency

Industry of valves-

Oil and Gas

Chemical Processing

Water and Wastewater Treatment

Power Generation

Pulp and Paper

Mining and Minerals

Aerospace

Automotive

Marine and Shipbuilding

Biotechnology

Description-

Available materials: Ductile iron, Monel, WCB, WCC, WC6, LCB, LCC, SS304, SS316, CF8, CF8M, CF3, CF3M, Aluminum Bronze, Bronze, Brass, F55, F53, F51, Inconel, Titanium.

Class: 150 to 2500.

Nominal Pressure: PN6 to PN450.

Size: ½” to 80”.

Ends: Flanged, Wafer, Lug, Buttweld, Socket weld, Threaded.

Operations: Lever operated, Gear operated, Electric actuated, Pneumatic actuated.

Visit our Website: https://www.southamericanvalve.com/

0 notes

Text

Titanium Ball Valve Manufacturers | Samvay Fluid Tekniks Inc

Samvay Fluid Tekniks Inc is the leading titanium ball valve manufacturer, offering superior-quality valves with unmatched durability and reliability. Shop with confidence, knowing that you are getting the best products and services from our experienced team.

titanium ball valve manufacturers

0 notes

Text

Ball Valve Manufacturer in USA

SVR Global is the well-known Ball valve manufacturer in USA. A ball valve is a shut-off valve that rotates a ball with a bore inside it to permit, restrict, and control the flow of liquids, gases, and vapors in a pipe system. The shaft that connects the ball to the operational and controlling mechanism that rotates the ball is mounted against two seats. The fluid is not allowed to pass through the valve when the cross-section of the bore is perpendicular to the area of the flow. The area of the bore that is exposed to the floor determines how much fluid flows through the valve and at what pace. They can be turned manually, with the aid of an actuator, a wrench, or a lever that is manually turned by the operator. To open or close the valve, torque is exerted to move the lever arm by 90 degrees in either a clockwise or counterclockwise direction. The valve is open if the lever arm is perpendicular to the pipe. A closed valve is indicated by the lever arm being perpendicular to the pipe. To meet varied industrial applications, it is available in a variety of designs and characteristics. Depending on the industry in which this valve is used, different norms and specifications apply. Ball valve can be utilized for extremely corrosive or viscous fluids that harden at room temperature. These valves are manufactured in the USA.

Types:

Full port ball valve

Forged Ball Valve

Reduced port ball valve

Floating ball valve

Trunnion ball valve

Top entry ball valve

Multi-port ball valve

V-port ball valve

Three-way ball valve

Industries:

Ball valves are utilized in water treatment plants, wastewater treatment plants, and distribution systems for controlling the flow of water, chemicals, and sludge.

Natural Gas Industries

Manufacturing Sectors

Chemical Storage Industries

Oil & Gas Industries

Textile Industries

Mining Industries

Marine Industries

Applications:

Oil and gas

Chemical processing

Water and wastewater treatment

Power generation

Pulp and paper

Marine and offshore

Aerospace

Advantages:

These valves are made using a forging process that results in a stronger and more durable valve compared to those made using casting or machining methods.

These valves can be made from a range of materials that offer excellent corrosion resistance, including stainless steel, alloy steel, and other exotic alloys.

These valves provide precise flow control by rotating the ball to either block or allow flow through the valve.

These valves are easy to operate and require minimal maintenance, making them a popular choice in a wide range of applications.

Quick opening and closing of valves.

Description:

Body Material: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron.

Class: 150-2500, PN10 to PN450

Size: DN15 TO DN1200

Operations: Lever operated, electric actuated, pneumatic actuated, gear operated

Ends: threaded, socket-weld, flanged, buttweld

0 notes

Text

Aerospace Valves Market Rising Trends and Research Outlook 2022-2030

The latest market report published by Credence Research, Inc. “Global Aerospace Valves Market: Growth, Future Prospects, and Competitive Analysis, 2022 – 2030. Aerospace Valves Market will expand at a compound annual growth rate (CAGR) of 6.50%. From USD 10548.8 million in 2022, the market is projected to be worth USD 17458.2 million by 2030.

Aerospace valves are mechanical devices designed to control the flow of fluids or gases within aircraft, rockets, and satellites. These valves are critical components that manage the circulation of fuel, hydraulic fluids, air, and other essential substances required for the operation of aerospace systems. Aerospace valves must meet stringent standards for performance, durability, and safety to ensure the smooth functioning of aerospace vehicles.

Aerospace Valves Market Top Report Findings provide a comprehensive and illuminating analysis of the current state and future prospects of the aerospace valves market. This report delves into various segments such as valve type, material, aircraft type, end-user, and region to offer valuable insights for industry players and potential investors. The study highlights that there is a rising demand for advanced aerospace valves due to the growing airline industry worldwide. Additionally, it reveals that ball valves are anticipated to witness significant growth in the coming years owing to their ability to control high-pressure fluids effectively. Furthermore, the report identifies titanium as a prominent material choice for aerospace valves due to its superior strength-to-weight ratio and resistance against corrosive environments. It also emphasizes that commercial aircraft will dominate market share due to increasing air passenger traffic across emerging economies. Moreover, military segment expansion is expected due to escalating defense budgets globally.

Significance of Aerospace Valves

Safety: Safety is the foremost concern in aerospace engineering. Aerospace valves play a pivotal role in preventing accidents by controlling the flow of hazardous materials and ensuring the reliability of various systems on board.

Performance: Aerospace valves are designed to withstand extreme conditions such as high temperatures, pressure differentials, and rapid changes in altitude. Their precise control capabilities contribute to the overall performance of aerospace vehicles.

Efficiency: Efficiency is crucial in aerospace operations, where every ounce of weight and drop of fuel counts. Valves help optimize fuel consumption and reduce operational costs.

Key Players in the Aerospace Valves Market

Several companies specialize in manufacturing aerospace valves, each with its unique strengths and areas of expertise. Some of the key players in the aerospace valves market include:

Honeywell International Inc.: Known for its cutting-edge technology, Honeywell produces a wide range of aerospace valves known for their reliability and performance.

Parker Hannifin Corporation: Parker Hannifin is a global leader in motion and control technologies, offering a comprehensive range of aerospace valves and systems.

Eaton Corporation: Eaton is a prominent player in the aerospace valves market, providing solutions for various aerospace applications, from commercial aviation to space exploration.

Crane Co.: Crane Co. specializes in aerospace and defense technologies, including high-performance valves for critical aerospace systems.

Moog Inc.: Moog is renowned for its precision motion control systems and aerospace valves, catering to the unique needs of the aerospace industry.

Future Prospects of the Aerospace Valves Market-

The aerospace valves market is poised for significant growth in the coming years. This growth can be attributed to several factors:

Rising Aerospace Industry: The increasing demand for air travel and space exploration is driving the aerospace industry to expand, creating opportunities for aerospace valve manufacturers.

Technological Advancements: Continuous advancements in materials and manufacturing processes are enhancing the performance and reliability of aerospace valves.

Fuel Efficiency and Environmental Concerns: As environmental concerns grow, the aerospace industry is focusing on developing more fuel-efficient aircraft, creating a demand for innovative valves that contribute to reduced emissions.

Space Exploration: The resurgence of interest in space exploration, including Mars missions and commercial spaceflight, requires robust aerospace valves to ensure mission success.

Browse 245 pages report Aerospace Valves Market By Application (Fuel Systems, Hydraulic Systems, Pneumatic Systems, Environmental Control Systems (ECS), Landing Gear Systems, Fire Protection Systems, Avionics and Electronics Cooling, Others) - Growth, Future Prospects & Competitive Analysis, 2016 – 2030 https://www.credenceresearch.com/report/aerospace-valves-market

List of the prominent players in the Aerospace Valves Market:

Eaton Corporation PLC (Ireland)

Safran SE (France)

Woodward Inc. (U.S.)

Triumph Group (U.S.)

Parker Hannifin Corporation (U.S.)

Moog Inc. (U.S.)

Crissair Inc. (U.S.)

Liebherr (Germany)

Porvair PLC (U.K.)

Conclusion

In the world of aerospace engineering, precision and reliability are non-negotiable. Aerospace valves are unsung heroes that keep aircraft and spacecraft flying safely and efficiently. As the aerospace industry continues to evolve and expand, the aerospace valves market will play an increasingly vital role in shaping the future of aerospace technology. With key players continually innovating and advancing their products, the aerospace valves market is set to soar to new heights in the years to come.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Aerospace Valves Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Aerospace Valves Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major player analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/aerospace-valves-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/aerostat-systems-market

Related Report: https://www.credenceresearch.com/report/high-altitude-platforms-haps-market

Browse Our Blog: https://www.linkedin.com/pulse/aerospace-valves-market-size-analyzing-growth-k9ezc

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Text

Best Quality Titanium Ball Valve Manufacturer in India

Ladhani Metal Corporation is a well-known Titanium Ball Valve Manufacturer in India. Our Titanium Ball Valve is in great demand due to its advantages such as lightweight, high strength, solid construction, ease of installation, excellent performance, and extended service life.

As a supplier, stockiest, and manufacturer, we provide these Titanium Ball Valves in custom-built thicknesses and sizes according to exact requirements of our well-regarded patrons.Titanium Ball Valves come in a variety of diameters and finishes.Titanium Ball Valve is a high-quality product with an ever-increasing demand in the industry.

Types of Titanium Ball Valve Manufacturer & Stockists in India

Titanium One Piece Ball Valve

Titanium Two Piece Ball Valve

Titanium Three Piece Ball Valve

Titanium Top Entry Ball Valve

Titanium Orbit Ball Valve Manufacturer

Titanium Jacketed Ball Valve

Titanium Unibody Ball Valve

Also, We Export Titanium Ball Valves in Various Country Titanium Ball Valve Supplier in Brazil ,Titanium Ball Valve Supplier in Qatar and Titanium Ball Valve Supplier in Singapore

For More Details:

Mail us: [email protected]

Source:Titanium Ball Valve Manufacturer in India

#Titanium Ball Valve Manufacturer#Titanium One Piece Ball Valve#Titanium Two Piece Ball Valve#Titanium Three Piece Ball Valve#Titanium Top Entry Ball Valve#Titanium Orbit Ball Valve Manufacturer#Titanium Jacketed Ball Valve#Titanium Unibody Ball Valve

0 notes

Text

Duplex Ball Valve Supplier in Chile

South American Valve is a premier Duplex Ball Valve Supplier in Chile. A duplex ball valve is a specialized type of valve crafted from duplex stainless steel, a material renowned for its exceptional resistance to corrosion and robust mechanical properties. This valve design revolves around a spherical component with a hollow centre, allowing for precise regulation of fluid flow by rotating this sphere. These valves find extensive applications across diverse industries.

South American Valve is a leading Duplex Ball Valve Supplier in Chile. They are trusted provider of high-quality valves, offering reliable solutions for a wide range of industrial needs in Chile and beyond.

Parts

Body

2. Ball

3. Seat

4. Stem

5. Actuator

Advantages of Duplex Ball Valves:

Corrosion Resistance

2. Mechanical Strength

3. Resistance to Chloride Stress Corrosion Cracking

4. Wide Temperature Range

5. Improved Flow Characteristics

6. Bi-Directional Flow

7. Easy Operation

8. Low Maintenance Requirements

Industries Using Duplex Ball Valves:

Oil and Gas

2. Chemical Processing

3. Petrochemical

4. Water and Wastewater Treatment

5. Marine and Offshore

6. Power Generation

7. Mining and Mineral Processing

Applications of Duplex Ball Valves:

Controlling the flow of corrosive fluids, including hydrocarbons, seawater, and sour gas.

2. Regulating the flow of various aggressive chemicals, acids, solvents, and corrosive gases.

3. Managing high-pressure and high-temperature conditions in processes such as polymer production and chemical synthesis.

4. Managing the flow of water, chemicals, and effluent in water and wastewater treatment plants.

5. Providing corrosion resistance in saltwater environments for marine and offshore applications.

6. Controlling the flow of steam, feedwater, and chemicals in power generation processes.

7. Regulating the flow of slurry and corrosive chemicals in mining and mineral processing.

Description

Body: Duplex 1B, Alloy 20, Super Duplex, Hastelloy C276/B3, Inconel, F347, F44, F317L, F321, Titanium, Monel. Operation: Manual, Pneumatic, Electric Actuated.

2. class 1000PSI,

3. Size- 1", 2", 3/4",

4. End-Threaded or Welded

5. Operation: Manual, Pneumatic, Electric Actuated.

0 notes

Text

Industrial valve Manufacturer in USA

Valvesonly is a premier Industrial Valve Manufacturer in the USA, revered for its exceptional offerings in the field of industrial valves. These indispensable devices serve the critical function of regulating the flow of liquids, gases, and slurries within various applications. Through adept manipulation, they enable the seamless control of fluid dynamics within pipelines and conduits.

Valvesonly is a premier Industrial Valve Manufacturer in the USA, renowned for offering top-tier products of the highest caliber. Our valve offerings are celebrated for their effectiveness, longevity, and cost-effectiveness. Clients frequently endorse our valves due to their peak quality and precisely tailored design.

Diverse categories of Industrial valves include:

Gate Valves: These valves are strategically placed in wider pipe sections to exert precise control over liquid flow. They exhibit versatile designs with options like rising stems or non-rising stems. Gate valves find application across industries such as textiles, power generation, refineries, petrochemical plants, and paper factories.

Ball Valves: Employing a spherical mechanism to manage and navigate fluid flow, ball valves are pivotal in controlling both flow and pressure in gas distribution systems. They also play a crucial role in reducing pressure within gas storage connections.

Butterfly Valves- Characterized by their capacity to regulate flow and provide controlled limitation, butterfly valves serve a multitude of purposes. From water supply and wastewater treatment to fire protection, gas supply, and applications in chemical and oil industries, they hold a significant presence.

Globe Valves: Sporting an S-shaped channel, globe valves excel as control valves, offering precise modulation of fluid flow. They often find use in high-point vents and low-point drains, where accuracy is paramount.

Check Valves: Relying on internal pressure rather than external forces, check valves facilitate the opening and closing of fluid passages. They are essential components in pumps, compressors, steam boilers, chemical plants, and power generation facilities.

Plug Valves- Known for their simplicity, ease of maintenance, and affiliation with the quarter-turn valve family, plug valves are invaluable in gas pipelines, handling slurries, and managing environments with high levels of debris.

Safety Valves: Engineered to respond to excess pressure in vessels or equipment, safety valves are instrumental in averting catastrophic failures. Their role extends to preventing further fluid release once normal conditions are reinstated.

Control Valves: These power-operated devices are instrumental in regulating or manipulating fluid flow across various mediums, including gas, oil, water, and steam.

Description-

Available materials: Ductile iron, Monel, WCB, WCC, WC6, LCB, LCC, SS304, SS316, CF8, CF8M, CF3, CF3M, Aluminum Bronze, Bronze, Brass, F55, F53, F51, Inconel, Titanium

Class: 150 to 2500

Nominal Pressure: PN6 to PN450

Size: ½” to 80”

Ends: Flanged, Wafer, Lug, Buttweld, Socket weld, Threaded

Operations: Lever operated, Gear operated, Electric actuated, Pneumatic actuated

0 notes

Text

Ball Valve Manufacturer in Colombia

South American Valve is the greatest ball valve manufacturer in Colombia. We deliver our products in cities like Argentina, Brazil, Columbia, Peru and Chile. A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of fluid through it. The ball within the valve has a hole, known as the bore, that aligns with the pipe when the valve is in the open position, allowing fluid to pass through.

South American Valve is the best ball valve manufacturer in Colombia. This is also known as quarter-turn valve. They are known for their quick and easy operation, providing a full or nearly full flow path when fully open and a tight shut-off when fully closed. Ball valves offer quick and reliable control over fluid flow and are suitable for a wide range of applications due to their versatility and ease of use. They are versatile and can be found in various sizes, materials, and configurations to suit the specific requirements of different industries and applications. Ball valves designed for cryogenic service are used in industries dealing with extremely low-temperature applications. And also they used in process control systems and laboratories for precise flow control in various analytical and measurement applications.

Type

Floating Ball Valve

Trunnion Ball Valve

Fully Welded Ball Valve

Top Entry Ball Valve

Jacketed Ball Valve

Parts:

Body

Ball

Seats

Stem

Actuator

Applications and Industries:

Mining and slurry

HVAC systems

Water and wastewater treatment plants

Power generation

Marine and shipbuilding

Oil and gas industry

Agriculture and irrigation

Benefits:

Quick and easy operation

Excellent flow control

Reliable shut-off

Low maintenance

Durability and longevity

Bi-directional flow

Description

Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron.

Available Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: LNG, Cryogenic application, Water, Air, Steam, Oil

Ends: Flanged, Threaded, Buttweld, Socket weld

Operations: Lever Operated, Electric Actuated and Pneumatic Actuated., Gear

Visit us: https://www.southamericanvalve.com/product-category/ball-valve/

0 notes

Text

BALL VALVE MANUFACTURER IN GERMANY

BALL VALVE MANUFACTURER IN GERMANY

Valvesonly Europe is well known Ball Valve manufacturer in Germany A ball valve is a type of valve that has a rotatable ball with a bore for controlling the flow of fluid or gas. Ball valves operate by turning the ball a quarter turn so that the medium can either flow through or be inhibited from doing so, additionally utilized as control valves these valves.

Description -

Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M , F55, F51, F53, Monel, Ductile Iron.

½” to 48”

150 to 2500

PN10 to PN450

LNG, Cryogenic application, Water, Air, Steam, Oil

Flanged, Threaded, Buttweld, Socket weld

Lever Operated, Electric Actuated and Pneumatic Actuated., Gear

For more details visit here: https://www.valvesonlyeurope.com/product-category/ball-valve/

0 notes

Text

Specialityvalve is the topmost 1 Piece Ball Valve Manufacturer in India.

Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M , F55, F51, F53, Monel, Ductile Iron.

Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Lever Operated, gear operated, Electric Actuated and Pneumatic Actuated.

End: Connection Flanged, Threaded, Buttweld, Socketweld

Medium LNG, Cryogenic application, Water, Air, Steam

0 notes