#Tungsten Carbide Hardfacing

Explore tagged Tumblr posts

Text

🛠 Cut Deeper. Drill Smarter. Stay Steady. SV Series Six-Point Stabilization Tri-Cone Bit — Built for Speed, Engineered for Precision. ⚙️🔥

No more compromises in high-speed directional drilling. The SV Series is your go-to bit for extreme stability, extended tool life, and unmatched borehole quality.

✨ Top Features at a Glance:

🔹 Smart Inserts, Tougher Teeth Upgraded tungsten carbide inserts deliver superior wear resistance and rock-crushing power.

🔹 Triple-Layer Gauge Protection From gauge inserts to hardfaced shirttails, this bit holds diameter like a champ.

🔹 Turbocharged Bearings Silver-plated, friction-resistant, and high-speed ready. Say goodbye to heat seizure.

🔹 Metal-to-Metal Seal Tech Lower torque, longer lifespan — no seal failures, no downtime.

🔹 Six-Point Stabilization Frame Minimizes vibration, shields the cutting structure, and ensures clean, smooth holes every time.

📌 Ideal For: ✔ High-RPM motor applications ✔ Directional & horizontal wells ✔ Rough formations needing steady control

📐 Available Sizes: 8 1/2", 9 1/2", 12 1/4" 🔧 Models: SVT437G → SVT617G

0 notes

Text

Hardfacing Wear Parts

Hardfacing Wear Parts BERAY developed HS 63HRC is mixed with alloy powder with a high density of primary chromium carbides in an iron matrix and non-metallic powders. Hardfacing wear parts by BERAY , a reputable casting and forging company, especially skilled in impression die forging process, are the best cost-effective choice for high wear application compared to Tungsten carbide. Abrasion…

#Bi-Metal Wear Parts#Bucket Chocky Bar#Chocky Bars#Hardfacing Wear Parts#Laminated Wear Bars#Ni-hard Wear Parts#replacement wear parts#Wear Bars & Blocks#Wear Button#Wear Buttons#Wear Parts#Wear Plates

0 notes

Text

Chrome Metal Powder in Aerospace, Automotive, and Coatings: Market Growth & Opportunities

The global chrome metal powder market is experiencing steady growth, driven by its increasing application in aerospace, automotive, metallurgy, electronics, and thermal spray coatings. Chrome metal powder, produced from chromium metal and chromium salts, is widely used in powder metallurgy, welding electrodes, cutting tools, and corrosion-resistant coatings due to its high melting point, hardness, and oxidation resistance.

The Chrome Metal Powder Market CAGR (growth rate) is expected to be around 6.15% during the forecast period (2024 - 2032).

For In depth Information Get Free Sample Copy of this Report@

Chrome Metal Powder Market Companies Are:

Carpenter Technology Corporation, CAMET Alloys and Powders Inc, Pyromet, Hubei Runkang Material Technology Co., Ltd., Baoji Juxing Electromechanical Equipment Co., Ltd., Shanghai Luhong Cemented Carbide Co., Ltd., Sichuan Huanghua New Material Co., Ltd., Zhuzhou Fulun Technology Development Co., Ltd., Ganzhou Tianyuan Tungsten Co., Ltd., Hunan Huayin New Material Co., Ltd., Elkem, ATI (Allegheny Technologies Incorporated), Chongqing Chuandong Special Alloy Co., Ltd., Hunan Jinheng Tungsten Co., Ltd.

With growing industrialization, advancements in additive manufacturing (3D printing), and increased demand for high-performance alloys, the market is expected to expand at a moderate to high CAGR. However, challenges such as environmental concerns related to chromium mining, regulatory restrictions, and price volatility could impact long-term growth.

DROC Analysis

Drivers

Rising Demand in Aerospace and Automotive Sectors – Chrome metal powder is used in high-performance alloys, thermal barrier coatings, and engine components, supporting growth in these industries.

Expanding Applications in Powder Metallurgy and 3D Printing – The increasing adoption of chrome-based powders in additive manufacturing and sintered components is boosting market demand.

Growth in Corrosion-Resistant Coatings – Chrome metal powder is a key material in wear-resistant and anti-corrosion coatings, particularly in marine, energy, and industrial equipment.

Advancements in Welding and Hardfacing Alloys – The use of chrome-based powders in welding electrodes and overlay applications is increasing, enhancing the durability of industrial tools.

Restraints

Stringent Environmental Regulations – Chrome production and processing are subject to strict regulations due to health hazards associated with chromium exposure.

Price Volatility and Supply Chain Risks – The availability and cost of raw chromium ores are impacted by geopolitical factors, mining regulations, and market fluctuations.

Limited Awareness in Emerging Markets – Despite its industrial importance, awareness and adoption of high-purity chrome metal powders remain low in some developing regions.

Opportunities

Increasing Adoption in 3D Printing and Advanced Manufacturing – The growing use of metal powders in additive manufacturing presents new opportunities for high-purity chrome-based powders.

Development of Sustainable and Eco-Friendly Chrome Processing Technologies – Innovations in green metallurgy and cleaner extraction techniques could help address regulatory challenges.

Expansion in High-Performance Ceramics and Electronics – Chrome metal powders are gaining traction in ceramic coatings, superconductors, and electronic applications.

Challenges

Health and Safety Concerns Related to Chromium Exposure – Strict worker safety regulations and handling precautions may limit production efficiency and increase operational costs.

Substitutes and Alternative Coatings – In some applications, ceramic, nickel, and carbide-based coatings may serve as alternatives, affecting market demand for chrome-based powders.

Dependence on Chromium Ore Mining – The market is influenced by supply chain disruptions, regulatory bans on certain mining activities, and resource depletion.

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients.

Contact us: Market Research Future (part of Wantstats Research and Media Private Limited), 99 Hudson Street, 5Th Floor, New York, New York 10013 United States of America +1 628 258 0071

0 notes

Text

Various Types of TIG Filler Wire to Buy Online

Do you want to buy Tungsten Inert Gas filler for your new welding shop? If yes, you may find multiple types to Buy TIG Filler Wire Online based on the composition materials. In this blog post, we have discussed a few common types of TIG filler wires available over the internet:

ER 308L TIG Filler Wire ER 308L TIG Filler Wire is a stainless steel filler wire used for welding 304L and other austenitic stainless steels. With low carbon content, it minimizes carbide precipitation, ensuring better corrosion resistance, particularly in as-welded conditions. It is commonly used in food processing, chemical, and petrochemical industries.

ER312 TIG Filler Wire ER312 TIG Filler Wire is a high-alloy stainless steel filler wire suitable for joining dissimilar steels, like stainless to carbon steel. Its high ferrite content offers exceptional strength and crack resistance, even in severe conditions. These filler wires by Shop Castron Electrode are commonly used in tool steels, hardfacing applications, and welding of difficult-to-weld steels.

ER 4043 TIG Filler Wire ER 4043 is an aluminum-silicon alloy TIG filler wire used for welding aluminum alloys like 6061 and cast aluminum. ER 4043 TIG Filler Wire comes with a high silicon content to reduce cracking and improve flowability during welding. It’s widely used in automotive, aerospace, and general fabrication industries for joining various aluminum components.

ER 4047 TIG Filler Wire ER 4047 is an aluminum-silicon filler wire with a higher silicon content (around 12%) than ER 4043. ER 4047 TIG Filler Wire offers lower melting temperatures and enhanced fluidity, providing excellent gap-filling properties. It is commonly used in automotive and aerospace industries for brazing and welding aluminum alloys.

ER 5356 TIG Filler Wire ER 5356 is an aluminum-magnesium alloy filler wire used primarily for welding 5XXX series aluminum alloys. It provides good strength, corrosion resistance, and ductility, especially in marine and structural applications. ER 5356 TIG Filler Wire is often chosen for boatbuilding, automotive parts, and other applications requiring toughness and durability.

ER 70S G TIG Filler Wire ER 70S-G is a general-purpose carbon steel filler wire with good mechanical properties and weldability. It’s versatile, used for welding a variety of steels, including low-alloy steels. ER 70S G TIG Filler Wire provides excellent arc stability and smooth bead appearance, making it ideal for structural, pipeline, and fabrication work.

H-13 TIG Filler Wire H-13 is a high-carbon, high-chromium steel TIG filler wire used for tool and die repair. It offers excellent hardness, wear resistance, and thermal stability, making it suitable for high-temperature applications. H-13 TIG Filler Wire is widely used in molds, dies, and other components subjected to high thermal and mechanical stresses.

Overall, there are a wide variety of TIG filler wires you may buy online. Make sure to check the properties and analyze your requirements to select the right one for your welding project. To get more information, visit https://shop.castonelectrode.in/2024/07/26/tig-filler-wire/

0 notes

Text

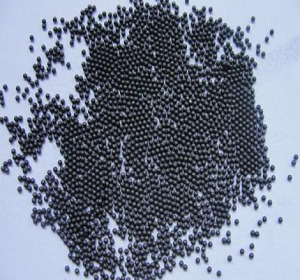

Uses of Tungsten Carbide Hardfacing

What is Hardfacing?

Hardfacing is a process of making the metal even more tough and hard by applying another strong material on its surface. Materials like tungsten carbide work wonderfully in industrial processes that go through extreme conditions like the oil industry. Tungsten carbide hardfacing is hence a highly popular technique offering high levels of wear and abrasion resistance at the required locations.

Uses of tungsten carbide Hardfacing

When tungsten carbide was first considered for hardfacing, the crushed granules that were irregular in shape did not offer the much-needed resistance. Due to their irregular shapes, the granules easily succumbed to extreme conditions of temperature and pressure in various industrial processes. The same gave rise to the invention of the modern process of creating perfectly shaped tungsten carbide grit using its powder along with an organic binder. The grit formed comes with high strength and resistance making it a perfect hardfacing material for the industry.

Tungsten carbide hardfacing in industry are used in applications like hardbanding, drill pipes, drill collars, etc. Tungsten carbide offers protection to the surfaces which is a necessity considering the extreme conditions in the industries. In addition to its applications, tungsten carbide hardfacing process is often used to restore some worn down surfaces of old parts of various machines and equipment in the industries.

It is more cost efficient hardfacing materials, the tungsten carbide ball grain has more impact and wear resistance mixture of WC and spherules with different composition and particle size having very high resistance to abrasion and impact. Non recurring welding with high hardness. Famous corrosion resistance, high cobalt alloy spheres with small friction coefficient can be used to solve the casing wear problem in an affordable way. Tungsten carbide is widely used in surfacing, deposited in a variety of tools and parts surface to form hard layer grinding , with its excellent characteristic it can improve the surface hardness , wear resistance, corrosion resistance significantly , and extend lifespan. In the longer run, it brings good economic effectiveness used in the oil industry and will widely spread to greater benefit.

For more information visit our website.

1 note

·

View note

Photo

The Use of Tungsten Carbide Hardfacing for Oil Industry

Hard facing is a process of making the base metal tougher and harder by applying another stronger material on its surface. Materials like tungsten carbide grit work excellent in industrial processes that undergo extreme conditions like the oil industry. Tungsten carbide hard facing in the oil industry is hence highly popular technique offering high levels of wear and abrasion resistance at the required locations.

0 notes

Link

0 notes

Text

Fixed cutter PDC Hole Opener reamer with hard facing for HDD drilling

Overview of PDC Hole Opener

PDC Hole opener is designed for the enlargement of pilot holes and large hole applications. They are also used for road and river crossing applications.

The hole opener is made of AISI 4145H fully heat-treated alloy steel. All products have carbide grinding teeth and inserting tools. Body and cutters are hard-faced in three different designs with different conditions and rock formations. We also can design of the PDC hole opener blade allows replaced in the field.

We offer innovative drilling technology to mitigate drill string vibration during reaming. GREAT hole opener solution can help you solve your challenges, whether you use a rotary steerable drill combination, a rotary motor drill combination, or a traditional rotary drilling system. Our reaming tools operate at high efficiency, increase equivalent cycle density (ECD), reduce the risk of fractured formations, reduce torque and drag, and overcome drilling challenges.

The Details of PDC Hole Opener

The Advantage of PDC Hole Opener

The body is machined out of a single block of heat-treated AISI 4145H alloy steel.

Compared to the roller hole opener, the PDC hole opener performs better during the drilling process. The post-maintenance process is much simpler, just replace the PDC cutter, which can reduce the production cost later.

Depending on the formation and the customer's special requirements, different sizes of PDC hole openers can be produced.

Application

Hole reamer bit are designed for the enlargement of pilot holes and large hole applications. They are also used for road and river crossing aplications.

Constructure

The hole openers are manufactured from AISI 4 145H fully heat-treated alloy steel. All are available with carbide-milled teeth and insert cutters. Arms and cutters are hardfaced for protection in three iferent designs for varying conditions and rock formations. The design of the hole opener llows for field-changing the cutters.

Cutting stucture

The reamer mainly consists of four or more cones. Cuting Structure with premium tungsten carbide hardfacing or premium tungsten carbide insert of formulas and new techniques is utilized, and increases wear-resistance capability of reamer.

http://www.greatdrillbit.com/product/pdc-hole-opener/

0 notes

Text

The effect of Ta substitution for Nb on the microstructure and wear resistance of an Fe-Cr-C hardfacing alloy

Publication date: 15 September 2017 Source:Surface and Coatings Technology, Volume 324 Author(s): Farzad Sadeghi, Hamidreza Najafi, Alireza Abbasi The effect of Ta substitution for Nb on the microstructure and wear resistance of an Fe-Cr-C hardfacing alloy deposited with gas tungsten arc welding (GTAW) process was investigated. Results showed that the microstructure of the base composition was a hypoeutectic one consisting of primary austenite dendrites and eutectic constituents of γ+M7C3. Addition of Nb did not change the hypoeutectic nature of the microstructure. However, coarse semi-cuboidal NbC was formed in the microstructure. Moreover, compared with the base composition, higher eutectic content and finer austenite dendrites were observed as a result of Nb addition. Ta substitution for Nb has changed the microstructure from hypoeutectic to hypereutectic containing primary hexagonal M7C3 carbides in an eutectic matrix along with coarse semi-cuboidal TaC particles. Hardness test results revealed that the hardness value increased by the addition of Nb or Ta. Maximum hardness value was obtained from Ta-containing coating. Reciprocating wear test results were directly related to the hardness of the hardfacing alloys. Hence, Ta-containing coating exhibited a superior wear resistance mainly due to the formation of primary hexagonal M7C3 carbides and coarse TaC precipitates. As well, Scanning Electron Microscopy (SEM) of the worn surfaces revealed evidences of abrasive and delamination wear mechanisms. Read more from Journal of Safety Research http://ift.tt/2qvlKFa

0 notes

Text

What are the effects of Weldment layer on the Tungsten Carbide hardfacing?

The hardfaced carbon steel blade is used to mix ilmenite ore with sulphuric acid as part of a production process inside a digester tank. With that, the carbon steel blade wear life is improved by applying tungsten carbide hardfacing using shielded metal are welding.

This blog explains the effect of welding layers on the microstructure and distribution of WC hardfaced.

Sample preparation — Carbon steel grade blade acts as the base metal in the hardfacing process. Also, the carbon percentage in the blade determines the grade of the blade. With that, carbon and manganese are the major elements in carbon steel. The electrode is of speed mullers, pump impellers cutter knives, and construction machineries.

Hardfacing method and welding condition — Shielded metal are welding and were assigned for this particular welding condition due to its extensive usage in the industries. The portability of its welding equipment and relative simplicity of SMAW makes it more economical without needing any complex equipment compared to other welding methods.

Micrograph of the WC hardfacing — SEM is used to investigate the microstructure where the carbide distribution pattern is observed from the images.. Please note that that Tungsten Carbide Hardfacing is made up of carbide region, non-carbide, and substrate regions.

Effects on carbide growth — Some studies report that the higher number of weld layers caused more large-sized carbide presence in the coating region compared to a lower number of layers.

Are you looking for Tungsten Carbide Hardfacing? If so, then you are in the right place and for more information, please visit our official website www.globaltungstens.com now!

0 notes

Link

PDC Bit is not widely talked about, which is why there is so little information about there. Its prominent features include blades and cutters. Different types of cutting structures are concentrated along the cone, nose, shoulder, and measure the areas of the top orbit. Moreover, the nozzles or junk slots and fluid courses aid in the removal of cuttings from the bit face. If you are interested to know more about PDC bits, then make sure to visit our official website https://www.globaltungstens.com/ now.

0 notes

Link

If you are looking for Tungsten Carbide Hardfacing products? Arcwel is the best company which provide HardFacing Technologies and Products. Valuable equipment is subject to extreme wear by abrasion corrosion, erosion, friction, heat or impact For more - http://www.arcwel.com/hardfacing/

0 notes

Text

Strength Your Hardfacing Applications Need WEISON’s Composite Rod Welding Provides!

WEISON specializes in surface solutions for use in many industries. With having tremendous comprehensive knowledge of wear and corrosion mechanisms in industrial environments, we have effective solutions customized for each application. To equip our customers with the best solution for their wear control application, we employ processes that include thermal spray, thin film, and hard face welding technologies. Our portfolio of hard face welding products produce overlay solutions that resist extreme wear in the harshest environments.

Applications of Composite Rod Welding Products Offered by WEISON

WEISON’s composite rod welding products produce hard face overlays with excellent wear, impact and corrosion resistance that are compatible with most steel and cast steel substrates. The diverse industries that benefit from WEISON’s composite rod welding products include:

Oil and gas

Tunneling

Foundries

Agricultural

Mining

Construction

Material Handling

Wood Processing

Oxyacetylene Welding Products:

Composite welding rods (rigid and flexible)

Composite welding rods with hard carbide additives

Quality of WEISON’s Composite Rod Welding Products You Can Trust

Reproducible and consistent product quality

Classification and qualification of products to existing hard facing standards as well as customer specifications

Tightly controlled particle size distributions with carbide grain sizes designed for customer specific applications

Quality management system certified in accordance with the aerospace management system

Composite rod welding has been respected throughout mining, oil drilling and construction industry worldwide, even spreading more and more industries and get greater using. The cemented carbide composite rod welding has high wear and cutting properties, weldability and low fuming. It is successfully used like stabilizers, construction drilling, reamers, pipe cutter blades, drill pipe joints, scraper, hydraulic cutter, core bit, twist drill, piling drill, milling and grinding shoes etc.

Tungsten Carbide Composite Rod Welding Specification

YD-9.5 Grade, 9.5mm, 9.5-6.5 Scrap size in mm, dark color green

YD-8 Grade, 8.0mm, 8.0-6.5 Scrap size in mm, Dark blue color

YD-6.5 Grade, 6.5mm, 6.5-5.0 Scrap size in mm, Red color

YD-5 Grade, 5.0mm, 5.0-3.0 Scrap size in mm, Yellow color

YD-3 Grade, 3.0mm, 3.0-2.0 Scrap size in mm, Pink color and more

Large particles are suitable for surfacing of oil pipeline cleaning equipment

The small particle is suitable for surfacing of large mixer blades

Smaller particles are suitable for root tree grinding machine

For full specification details and size guidelines of WEISON’s composite rod welding products; please visit us online!

0 notes