#UPVC Welding Machine

Explore tagged Tumblr posts

Text

UPVC Welding Machine Company in India?

UPVC Welding Machines are essential for producing high-quality, durable UPVC windows and doors, and Segatech Machinery stands at the forefront of this industry in India. As a leading manufacturer, Segatech Machinery is renowned for its commitment to innovation, quality, and customer satisfaction. Their UPVC welding machines are designed with advanced technology to ensure precise welding, superior strength, and seamless finishes.

Segatech Machinery offers a diverse range of UPVC welding machines, including single-head, double-head, and four-head welding machines, catering to various production needs. These machines are equipped with features like digital control panels, automatic temperature control, and high-efficiency heating elements, ensuring consistent performance and energy efficiency.

The company's dedication to quality is evident in the robust construction of its machines, using high-grade materials and components to ensure long-lasting durability and minimal maintenance. Moreover, Segatech Machinery provides comprehensive after-sales support, including installation, training, and maintenance services, ensuring that clients can maximize the potential of their investment.

By continuously adopting the latest technological advancements and adhering to stringent quality standards, Segatech Machinery has established itself as a trusted name in the UPVC welding machine manufacturing sector in India, committed to delivering excellence and value to its customers.

For more information :-

Contact us :- +91-9258712127

Email id :- [email protected]

Address :- 572/01 SADDIK NAGAR, OPP. DELHI PUBLIC SCHOOL, SIHANI ROAD, Ghaziabad-201003, Uttar Pradesh, India

#UPVC Welding Machine#UPVC Welding Machines#UPVC Welding Machine Manufacturers#UPVC Welding Machine Manufacturer in India#UPVC Welding Machine Supplier in India

0 notes

Text

Top UPVC Welding Machine Manufacturers

If you are looking for high-quality of UPVC Welding Machine at best valuable price then must contact Atlas Machine which has many years of experience in this field. We are counted top UPVC Welding Machine Manufacturers and suppliers in Ghaziabad, India. UPVC welding machines are extensively used in plumbing and drainage systems for connecting UPVC pipes and fittings. These systems are widely used in residential, commercial, and industrial buildings for conveying water, sewage, and other fluids.

0 notes

Text

UPVC Profile Welding and Cleaning Machines | Contact LGF Sysmac

Experience precision and perfection with LGF Sysmac’s UPVC Profile Welding and Cleaning Machines. Designed to enhance your production capacity, they deliver clean edges and solid welds with minimal human intervention. Choose LGF Sysmac for seamless fabrication every time.

#sliding windows#sliding doors#architectural hardware#lgfsysmac#UPVC Profile Welding and Cleaning Machines

0 notes

Text

Top uPVC Fabrication Machines Supplier in Meerut

Act Interior – Top uPVC Fabrication Machines Supplier in Meerut

Looking for high-performance, precision-engineered uPVC fabrication machines? Act Interior proudly stands as the Top uPVC Fabrication Machines Supplier in Meerut, delivering cutting-edge solutions for manufacturers who prioritize quality, efficiency, and sustainability.

Established in 2018 and based in Ghaziabad, Act Interior is a trusted name in the uPVC industry. Our mission is simple—to create eco-conscious, human-friendly living spaces through innovative, durable, and energy-efficient solutions. Alongside our premium uPVC windows and doors, we also offer advanced fabrication machines that help businesses produce top-quality uPVC products with ease and accuracy.

Why Choose Our uPVC Fabrication Machines?

Our uPVC fabrication machines are built with precision technology to ensure smooth, consistent, and reliable operations. They are ideal for businesses looking to scale their production capabilities without compromising on quality. From cutting to welding and corner cleaning, our machinery delivers unmatched performance and long-term durability.

What Sets Act Interior Apart?

✔ Top-Grade Machinery – Built to perform under high-demand environments ✔ Customizable Setups – Tailored solutions for your specific fabrication needs ✔ Energy-Efficient Technology – Supporting eco-friendly production ✔ Easy Maintenance & Support – Backed by expert technical guidance ✔ Trusted by Manufacturers – Recognized as a reliable partner in Meerut and beyond

As the Top uPVC Fabrication Machines Supplier in Meerut, Act Interior empowers local businesses with state-of-the-art tools to achieve precision in every product. Our commitment to innovation, sustainability, and customer satisfaction makes us the preferred choice in the fabrication industry.

📞 Let’s Build Better Together

Upgrade your uPVC production with our high-performance machines. ✅ Call: 9717511265, 9897014156 ✅ Visit: www.actinterior.in

0 notes

Text

Understanding the Technology Behind uPVC Windows and Doors

uPVC doors and windows have become popular among builders and architects as they offer numerous advantages. uPVC (unplasticized polyvinyl chloride) has several unique properties including high thermal insulation, durability, enhanced aesthetics, and superior weather resistance. So, it has become a preferred alternative to traditional materials like wood and aluminium.

Aparna Venster is among the leading uPVC doors and windows suppliers and uses world-class technology in fabrication. This ensures greater reliability, precision, and accuracy of the uPVC solutions. Read the blog to understand the technological aspects of the process that we follow in uPVC windows and doors manufacturing.

Manufacturing process for uPVC windows and doors

The manufacturing of the uPVC windows and doors happens in different phases. The operations involved and resources required at various stages in the manufacturing process are listed below:

1. Raw material preparation

The quality of the raw materials and the preparation process determine the functionality and durability of the uPVC windows and doors. At Venster, we handpick the raw materials and process them with utmost care. The windows and doors made from low-quality materials are prone to cracks and lack robustness. So, we pay close attention to ensuring raw materials quality in the manufacturing process.

While manufacturing uPVC windows and doors, the primary ingredient is PVC resin. It is blended with stabilizers, impact modifiers, UV absorbers are also added to the mixture. An extensive raw material preparatory phase promotes colour stability, UV resistance, and longevity of the windows and doors.

2. Extrusion of the compound

Extrusion is a crucial phase of the uPVC windows and doors manufacturing process. The mixture is then melted at very high temperatures and fed into extrusion moulds to finally create long, hollow uPVC profiles. They serve as the key component in manufacturing and shaping up the windows and doors.

A large mixing equipment is used to mix the compound and then cast it into a die. By pulling and stretching the extruded mould, the uPVC profile can be shaped appropriately.

3. Reinforced profiles

The hollow uPVC profiles must be strengthened to bear the heavy loads and adverse weather conditions. The galvanized steel is the best form of reinforcements and they are pushed into the hollow profiles. This enhances their resilience against high temperatures, heavy loads, and poor weather conditions.

4. Welding and cutting

While the extruded profiles are put into a shape, they are cooled down completely. Using advanced machines, they are cut to the desired size and welded together into frames. At Venster, we use world-class robotic welding equipment to ensure accuracy. This helps ensure tightness and minimise the problem of water seepage/ leakage.

5. Glazing

After the profiles are cut and welded into desired frames, they are fitted with glass panels. The panels can be single, double, or triple-glazed. Adding multiple layers of glass helps improve the acoustics, insulate against outside noise, and prevent heat transfer. The barriers elevate energy efficiency and depending on your desired needs between single, double, or triple-glazed windows.

6. Final assembly

Locks, handles, gaskets, etc. are added to finish the assembly and get a complete product. At each step of the process, our team invests in a strenuous effort to ensure that the output meets the desired quality standards.

Key technologies in uPVC windows and doors manufacturing:

While we described the entire manufacturing process in the previous section, here we take a deeper look at some of the essential technologies involved in manufacturing uPVC windows and doors.

1. UV resistance

In the preparatory phase, uPVC profiles must be enhanced with UV stabilisers. This helps prevent discolouration when exposed to sunlight. The UV stabilisers ensure that the windows and doors do not fade away and remain new and fresh for a long time. The structural integrity also improves and minimises the need for maintenance and repairs.

2. Steel reinforcements for durability

Steel reinforcements are crucial for improving the strength and longevity of uPVC windows and doors, enabling them to withstand strong wind loads and harsh weather conditions. These reinforcements offer structural stability, guaranteeing that the windows stay stable and secure, even in difficult conditions. Aparna Venster uPVC systems merge exceptional strength with elegant design by incorporating premium steel reinforcements, providing an ideal harmony of safety and visual appeal. This renders them a perfect option for residences in tall buildings or regions susceptible to severe weather.

3. Resilience against adverse weather

The windows and door frames are integrated with high-quality, watertight seals. This prevents seepage of water, dust, etc. while enhancing their durability and functionality.

4. Innovative mechanisms

uPVC windows and doors suppliers, ie, Aparna Venster, are exploring innovative mechanisms to provide greater convenience to the residents. We also look for ways to improve energy efficiency, lighting, air circulation, etc. For instance, the tilt and turn mechanism in uPVC windows is an innovative opening method for windows that allows the window to be tilted for ventilation or cleaning purposes.

uPVC sliding doors help improve space utilization inside the building. They can be moved horizontally along the track. This reduces the extra space needed for opening and closing the windows. Similarly, slide and fold doors add a minimal yet modern appeal and bring you close to nature. The uPVC casement windows can be open inwards or outwards on hinges. This ensures water tightness and greater energy efficiency.

Looking for a reliable uPVC window and door supplier?

Aparna Venster is the leading uPVC windows and doors manufacturers in India. It has production facilities in Hyderabad & fabrication unit in Bangalore and holds a remarkable achievement of delivering 3 million+ windows and doors .. Our production facilities are equipped with top-notch machinery from Germany.

The uPVC windows and doors manufactured at Aparna Venster conform to stringent European quality standards. Equipped with world-class technology, we ensure precision and accuracy in all our products. Our laboratory equipment used for testing is certified by NABL (National Accreditation Board for Testing and Calibration Laboratories). Additionally, our uPVC windows and doors adhere to RoHS (Restriction of Hazardous Substances) standards, guaranteeing that they are free from harmful substances like lead, making them safe for both your home and the environment.

At Venster, we provide a greater degree of customisation, in terms of colour, size, glazing, energy efficiency, and so on. Our uPVC windows and doors have unique properties.

If you are looking for a high-quality uPVC windows and doors manufacturer, Aparna Venster is your go-to choice. Check our products at https://aparnavenster.com/.

FAQs

What is the average uPVC windows price?

At Venster, we offer high-quality windows at economical rates. However, the exact price of the uPVC windows depends on several aspects like size, glazing options, open type, etc. To know the exact price, book a free consultation with us.

Why choose Aparna Venster for uPVC windows and doors?

At Aparna Venster, we are committed to delivering the highest quality when it comes to uPVC windows and doors. Our products meet the most stringent European standards and this stands as a testament to our quality commitment. With rich experience in the field, we help customise the size, type, and appeal of the windows and doors to match your specific requirements.

0 notes

Text

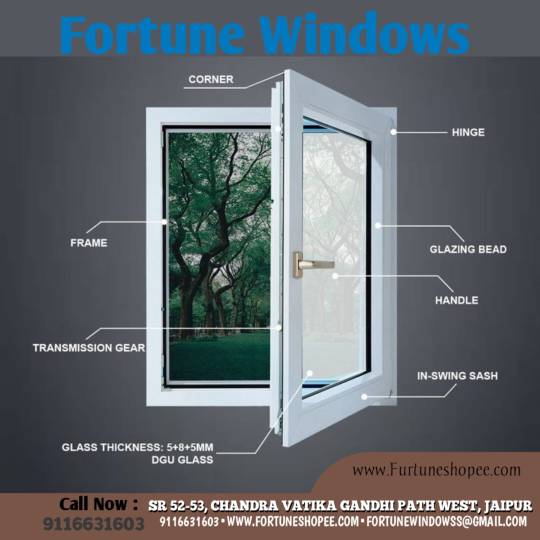

What happens when weld blocks are not used in uPVC window fabrication machines?

What happens when weld blocks are not used in uPVC window Fabrication Machines?

Weld blocks are typically used in UPVC window fabrication machines to hold the frame components in place during the welding process. If weld blocks are not used or are improperly positioned, several issues can occur:

Misalignment: Without weld blocks, the frame components may not align correctly during welding. This can result in uneven or crooked joints, affecting the window’s aesthetics and functionality.

Weak Joints: Inadequate support from weld blocks can lead to weak and unreliable weld joints. Weak joints may compromise the window’s structural integrity, reducing its durability and resistance to environmental factors.

Welding Defects: The absence of weld blocks can cause welding defects such as gaps, voids, or incomplete welds. These defects can create air or water leaks in the finished window, reducing its efficiency and performance.

Increased Scrap: Improper welding due to the absence of weld blocks can result in a higher rate of rejected or scrapped window frames, increasing production costs.

In summary, using weld blocks is essential in uPVC window fabrication to ensure precise alignment, strong weld joints, and high-quality finished products. Failure to use them can lead to various issues in window construction.

Does Fortune Windows sell welding blocks?

Yes we have ready stock of high quality & delivered instantly based on location.

For more information about our products and services, please visit our website at

contact us at : 091166 31603 Message Fortune on WhatsApp.

#frenchswingdoorinstallation #bifolddoorinstallation #residentialdoorreplacement #weathershieldwindows #floridawindows #roofing #windowcompany #nonimpactwindows #hurricanewindows #glass #home #residentialwindows #homerenovations #daytonabeach #doorsandwindows #design #siding #madeintheuk #framefast #manufacturer #framefastderby

0 notes

Text

Best UPVC Profile Welding and Cleaning Machines - LGFSysmac

Lgfsysmac provides best in class UPVC profile welding and cleaning machines at very affordable costing. You can compare this product in the market and after a good analysis on it once visit at the online website of Lgfsysmac you will definitely get a better deal on it.

#UPVC profile welding and cleaning machines#lgf sysmac#best architectural hardware companies in india#top upvc casement windows manufacturers#architectural hardware manufacturers

0 notes

Photo

Atlas Machine is offering high-quality UPVC Welding Machine Manufacturers in India, which is designed by premium quality materials and the latest techniques. Our machine is highly appreciated in the market due to its best features like User friendly interface, Easy to operate, Trouble free performance, etc. And also available in various specification as per our client’s need.

0 notes

Text

Best UPVC window profile machine Manufacturer in Delhi

HPMC is top growing UPVC window profile machine Manufacturer in India It was established in 1973 and also has an ISO 9001:2008 certfied manufacturer, exporter and supplier of plastic processing machine .

The irrigation pipe plant manufacturer is an effective and innovatively crafted unit that is designed well by skilled engineers. UPVC (unplasticized polyvinyl chloride) doors and windows have emerged because of the popular choice among urban Indian homes and builder apartments over conventional materials like wood or aluminium. Our team behind the walls works day and night to make our customer happy

UPVC window profile machine manufacturer: 1 Popular machinery type 2 Can use to form angel welding between various angles. 3 Solid machinery base and structure 4 Profile fixture to use various height profiles

Address- Hindustan Plastic & Machine Corporation 5, Category II, DSIDC Industrial Area Nangloi, Delhi-110041 Phone : 011-25473361,25471114, (M)+91 9891061200, 9899074169, 9312645101 E-mail : [email protected]

Website https://www.hpmcindia.com/upvc-window-profile-machine.html

380 notes

·

View notes

Text

What is an UPVC welding machine?

Segatech Machinery is looking into the thriving market of UPVC welding machine manufacturers in India. UPVC (Unplasticized Polyvinyl Chloride) welding machines are essential for the construction and plumbing industries, facilitating the precise and durable joining of UPVC pipes and fittings.

In India, several reputable manufacturers specialize in UPVC welding machines, catering to diverse industrial needs. These manufacturers offer a range of machines, including manual, semi-automatic, and fully automatic models, ensuring efficient and reliable welding operations. Prominent companies like DRTS, Wegener Welding, and CEMSA International provide high-quality UPVC welding solutions, known for their robust performance and advanced technology.

Indian manufacturers focus on innovation, incorporating features such as digital controls, temperature regulation, and user-friendly interfaces. These machines are designed to deliver consistent weld quality, minimizing defects and ensuring long-lasting joints. Additionally, the emphasis on energy efficiency and cost-effectiveness makes them an attractive choice for businesses aiming to enhance productivity and reduce operational costs.

For Segatech Machinery, partnering with these established manufacturers can lead to significant advantages, including access to cutting-edge technology, superior product quality, and comprehensive customer support. By leveraging the expertise of these manufacturers, Segatech Machinery can offer top-notch UPVC welding solutions, meeting the demands of the growing construction and plumbing sectors in India.

For more information

Contact us :- +91-9258712127

Email id :- [email protected]

Address :- 572/01 SADDIK NAGAR, OPP. DELHI PUBLIC SCHOOL, SIHANI ROAD, Ghaziabad-201003, Uttar Pradesh, India

0 notes

Photo

Four Head Seamless Welding Machine is Suitable for white and colored profile welding. It could weld and clean the up and bootom surface at one time.

0 notes

Text

UPVC Fabrication Machinery | Get Quote at LGF Sysmac

LGF Sysmac provides world-class UPVC Fabrication Machinery for modern manufacturers. Designed for heavy-duty performance and minimal maintenance, our machines support high-speed production and consistent quality. Join thousands of professionals who trust LGF Sysmac for their UPVC fabrication needs.

0 notes

Link

Mozart Turkey, offering its wide range of windows and doors and partitions etc. made up of uPVC (Un-Plasticized Polyvinyl Chloride)which will not only protects one’s home from dust, noise, insects, leakages, etc. but also contributes to the environment.

#upvc doors manufacturer#upvc window manufacturers#upvc door and windows in delhi#upvc Windows#windows and doors price#upvc door frame#sliding french doors#upvc sliding window#sliding glass window#upvc casement door#Casement windows#upvc welding machine price

0 notes

Text

Which is the leading UPVC window profile machine Manufacturer?

HMPC India is the leading UPVC window profile machine Manufacturer is specifically created to create premium quality UPVC windows. This machine is used mainly for welding PVC windows and doors. It highlighted a 24V electromagnetic valve, solid clamp, four layers of heightening board, etc.

This machine can do welding at multiple angles. UPVC window profile machine manufacturer highlights consecutive machinery support and structure that assures long-lasting service life with long dimension efficiency.

Uses of UPVC window profile machine manufacturer:

· Modern machinery type

· Can use to create angle welding within several aspects.

· Reliable machinery support and structure

· Contour switch to using different length forms

· Fast and straightforward changing profile fixture

· Standard compact welding machine

· Welding cleansing line

Read more - https://www.hpmcindia.com/upvc-window-profile-machine.html

For Further Information-

Please Contact

Hindustan Plastic & Machine Corporation

5, Category II, DSIDC Industrial Area Nangloi, Delhi-110041 011-25473361, 25471114, 9891061200, 9899074169, 9312645101 [email protected]

1 note

·

View note

Text

Best upvc dealers in bangalore With ’Providers of Quality Solutions’.

upvc windows in bangalore With ’Providers of Quality Solutions’ as a commitment and collaborating with uPVC giants- SIMTAastrix makes it foray into the Karnataka market tO cater the exact requirements of Residential and Commercial consumers,A state-of-the-art and highly advanced fabrication facility in Bangalore, Compounded by latest machineries that include Double Head Welding ,CNC corner Cleaning, Double Head Glazing Bead Saw, various types of Copy Milling Machine for Slots, Double Head Saws, for profile cutting and many other Pneumatic Machines, empowers bangalore upvc windows with faster and better production.With the distinction of housing the longest completely automatic CNC Machine in India, which helps produce over 100 windows every day. bangalore upvc windows is geared up to meet highest standard set by Consultants and Corporate Houses. Vast experience and extensive expertise, being the core quality, bangalore upvc windows.employs the best talent in the industries in every department from Designing to Fabrication to Installation. In addition, the company is fur- ther boosted with their partner’s technical know-how and In-House Designing that spans over 24 years. The exclusive R&D Department provides true-to life insights on the Indian Weather and market preferences, enabling the company to provide highest quality of windows that match the exact requisites, besides making tl1em economical. upvc windows in bangalore, Best upvc windows manufacturers, Sliding, Flymesh.

#upvc windows near me#upvc windows manufactures near me#upvc door manufactures near me#upvc mesh door manufacturers#best upvc dealers in bangalore#lowest price upvc dealers in bangalore#india make color upvc dealers in bangalore#Aluminum window &door dealers in bangalore#upvc door & window suppliers#upvc sound proof windows dealers

1 note

·

View note

Text

How uPVC Windows & Doors are manufactured in a factory ?

Introduction:

In the dynamic world of construction and home design, uPVC (Unplasticized polyvinyl chloride) windows and doors have emerged as a preferred choice, blending durability, energy efficiency, and aesthetic appeal. FortuneWindows, a brand synonymous with innovation and quality, takes us behind the scenes to unveil the meticulous process of manufacturing their uPVC windows and doors.

Material Selection:

The journey begins with the careful selection of raw materials. FortuneWindows sources high-quality uPVC, known for its durability, resistance to weathering, and low maintenance. The raw material undergoes a rigorous testing process to ensure it meets the brand’s stringent quality standards.

Extrusion Process:

Once the raw material is approved, it’s time for the extrusion process. The uPVC is heated and forced through a precision-designed die, taking the shape of the window or door profile. FortuneWindows’s state-of-the-art extrusion machinery ensures uniformity and consistency in every profile, setting the foundation for a product that stands the test of time.

Reinforcement Insertion:

To enhance structural strength, FortuneWindows integrates galvanized steel reinforcement within the uPVC profiles. This step ensures that the windows and doors not only maintain their shape but also provide the necessary support for hardware and operational components.

Cutting and Welding:

Precision is paramount in crafting FortuneWindows uPVC windows and doors. Computer-guided cutting machines accurately cut the profiles to the required dimensions. The pieces are then welded together using advanced welding technology, creating seamless joints that contribute to both the aesthetic appeal and structural integrity of the final product.

Glazing Installation:

FortuneWindows places a strong emphasis on energy efficiency. The next step involves the installation of high-performance glazing, which includes double or triple-pane glass with low emissivity coatings. This not only enhances insulation but also contributes to noise reduction and UV protection.

Hardware Integration:

The windows and doors are then equipped with top-of-the-line hardware, sourced from reputable suppliers. FortuneWindows ensures that all components, from handles to locking mechanisms, meet the brand’s standards for functionality, security, and longevity.

Quality Control Inspections:

At every stage of the manufacturing process, FortuneWindows conducts rigorous quality control inspections. From profile dimensions to welding integrity, each component undergoes scrutiny to ensure that the finished product aligns with the brand’s commitment to excellence.

Finishing Touches:

Once the uPVC windows and doors have passed the quality checks, they undergo any necessary finishing touches. This may include adding decorative elements, textures, or colour finishes to meet the design preferences of customers.

Packaging and Delivery:

FortuneWindows understands the importance of ensuring that their products reach customers in pristine condition. The carefully crafted uPVC windows and doors are securely packaged and prepared for delivery to construction sites or distribution centres, ready to adorn homes and buildings with functionality and style.

Conclusion:

The manufacturing process of FortuneWindows uPVC windows and doors is a testament to the brand’s commitment to precision, quality, and innovation. From material selection to the final touches, each step reflects the brand’s dedication to crafting products that not only meet but exceed the expectations of homeowners and architects alike. As FortuneWindows continues to shape the future of uPVC solutions, it is evident that excellence is not just a goal – it’s a standard.

Phone: 091166 31603 Message Fortune on WhatsApp.

#window #italy #interiordesign #clouds #homedecor #streetphotography #city #view #light #street #world #interior #garden #house #bnw #wood #building #reflection #kitchen #construction

0 notes