#USB Temperature Data Logger Market

Explore tagged Tumblr posts

Text

USB Temperature Data Logger Market Future Trends: Growth, Innovation, and Emerging Industry Opportunities Worldwide

The USB temperature data logger market is undergoing significant transformation due to technological advancements, increasing demand for real-time monitoring, and regulatory requirements across various industries. These devices play a crucial role in maintaining temperature-sensitive products such as pharmaceuticals, food, and chemicals. With the rising adoption of IoT-enabled solutions and cloud connectivity, the market is set for substantial growth.

Market Growth Drivers1. Rising Demand in Pharmaceutical and Healthcare IndustryThe pharmaceutical and healthcare sectors heavily rely on USB temperature data loggers for maintaining the integrity of vaccines, drugs, and other temperature-sensitive products. The global COVID-19 pandemic has further accelerated the adoption of advanced monitoring devices to ensure proper storage conditions.

Stringent Government RegulationsGovernments and regulatory bodies worldwide have imposed strict guidelines on temperature monitoring to ensure product safety and quality. Compliance with Good Distribution Practice (GDP) and Food Safety Modernization Act (FSMA) is boosting the demand for accurate and reliable data logging solutions.

Advancements in IoT and Cloud IntegrationModern USB temperature data loggers are now integrated with IoT and cloud-based platforms, allowing real-time data monitoring, automatic alerts, and remote access. These technological enhancements improve efficiency and reduce the risk of data loss. Emerging Market Trends1. Wireless and Bluetooth-Enabled Data LoggersThe integration of wireless connectivity features, including Bluetooth and Wi-Fi, is becoming a dominant trend. These loggers enable seamless data transfer and remote monitoring, reducing manual intervention and enhancing operational efficiency.

Increased Adoption in Cold Chain LogisticsCold chain logistics require precise temperature monitoring for the transportation and storage of perishable goods. The expansion of global supply chains, especially in the food and pharmaceutical industries, is driving the demand for USB temperature data loggers with real-time tracking capabilities.

AI and Machine Learning for Predictive AnalyticsArtificial intelligence (AI) and machine learning (ML) are being integrated into data loggers to provide predictive analytics. These smart devices can analyze historical data, predict temperature deviations, and suggest corrective actions, thereby improving decision-making. Challenges in the MarketDespite strong growth potential, the USB temperature data logger market faces several challenges: High Initial Costs: Advanced models with IoT and AI features come at a premium price. Data Security Concerns: Cloud-based systems require robust cybersecurity measures to prevent unauthorized access. Limited Awareness in Developing Markets: Many businesses in emerging economies are still unaware of the benefits of real-time data logging. Future Outlook and OpportunitiesThe future of the USB temperature data logger market looks promising with continued advancements in technology. The introduction of disposable loggers, multi-use devices, and longer battery life solutions will further enhance market penetration. Companies are focusing on providing more user-friendly and cost-effective solutions to attract a wider customer base. Moreover, as the demand for automation and precision increases, businesses will increasingly adopt data loggers with real-time alerts and cloud connectivity. This shift will further streamline operations and ensure compliance with stringent industry standards. Conclusion The USB temperature data logger market is poised for significant growth, driven by innovations in IoT, AI, and cloud computing. As industries emphasize better compliance, efficiency, and real-time monitoring, the demand for these devices will continue to rise. Companies investing in smarter, more connected, and cost-effective solutions will emerge as leaders in the evolving landscape of temperature monitoring technology.

0 notes

Text

What to Look for in Industrial Measurement Equipment for Manufacturing Facilities

In manufacturing, precision is everything. Whether you're producing electronics, automotive components, pharmaceuticals, or food packaging, accuracy in measurement directly impacts quality, safety, and regulatory compliance. That’s why investing in the right industrial measurement equipment is not only a smart decision—it’s a critical one.

But with so many options on the market, how do you choose the right tools for your facility?

At EpicRise Electronics, we help businesses across industries source high-performance tools and IT equipment, including measurement systems, scanners, and wholesale label printers. Here's what to look for when equipping your manufacturing facility with industrial measurement solutions.

1. Accuracy and Reliability

The foremost priority in any measurement equipment is accuracy. Whether you're measuring weight, temperature, humidity, voltage, or dimensional properties, even the smallest margin of error can lead to production defects, wasted materials, and safety issues.

Look for devices that meet or exceed ISO or NIST standards and are tested for industrial-grade precision. It’s also essential that the equipment performs consistently over time without needing frequent recalibration.

Tip: Opt for trusted manufacturers that offer certification or documentation on equipment accuracy. Brands partnered with EpicRise often come with reliability reports and compliance details.

2. Durability and Build Quality

Manufacturing environments are often harsh—subject to heat, moisture, dust, vibration, and continuous operation. Your measurement tools must be built for endurance.

When sourcing items such as laser measurement devices, multimeters, or pressure gauges, choose models specifically designed for industrial environments. Features to consider include:

Rugged casings (shock-proof, waterproof, dustproof)

High-quality connectors and cables

Resistance to chemicals or oil

Durability reduces downtime and repair costs—especially in 24/7 operations.

3. Integration with Existing Systems

Modern manufacturing facilities are increasingly automated and data-driven. Measurement devices should seamlessly integrate with your existing systems, whether that’s SCADA software, ERP platforms, or IoT networks.

Look for equipment with USB, Ethernet, or Bluetooth connectivity, and ensure it's compatible with your current software architecture. This allows real-time data collection and monitoring, improving decision-making and traceability.

Pro Tip: Integration also extends to your labeling and tracking tools. For instance, pairing a Zebra barcode scanner with automated weighing or inspection stations ensures that product IDs and measurement data flow smoothly across systems.

4. Ease of Use and Operator Training

Complex equipment that requires excessive training can slow down operations and increase the likelihood of user error. Choose tools that offer intuitive interfaces, clear displays, and simple calibration procedures.

Many leading brands also offer training resources, online support, and documentation. These are crucial when onboarding new team members or troubleshooting issues on the production floor.

At EpicRise, we prioritize stocking measurement tools with user-friendly design, backed by strong manufacturer support and documentation.

5. Scalability and Upgrade Potential

Your facility’s needs today might not be the same five years from now. The best industrial measurement systems are modular or scalable—allowing you to expand or upgrade without overhauling your entire process.

For example:

Multichannel data loggers can be expanded with additional sensors.

Barcode readers and scanners can be upgraded with advanced software.

Integrated systems can support added devices as your production grows.

When planning for growth, choose flexible solutions that evolve with your operations.

6. Data Logging and Traceability Features

In highly regulated industries—like food, medical devices, or aerospace manufacturing—data traceability is non-negotiable. Measurement tools should offer internal storage, cloud connectivity, or the ability to export logs securely.

This helps meet compliance standards (e.g., FDA, ISO 9001) and supports quality audits, troubleshooting, and continuous improvement initiatives.

Pairing your measurement devices with wholesale label printers also boosts traceability. With every reading, you can instantly generate barcode labels that reflect batch numbers, inspection dates, or critical data points.

7. Brand Reputation and Support

With industrial-grade tools, it pays to choose reputable brands with proven track records. These manufacturers typically offer:

Better warranties

Firmware updates

Technical support

Long-term availability of spare parts

One such example is Zebra Technologies, a leader in tracking and scanning tools. Their Zebra barcode scanner models are known for reliability in industrial environments, offering high-speed scanning, rugged durability, and seamless integration with other factory systems.

EpicRise is proud to offer Zebra products, along with measurement devices and peripherals from top global brands.

8. Cost Efficiency Through Wholesale Channels

Quality measurement equipment can be a major investment, especially if you’re outfitting an entire facility. Buying through a distributor like EpicRise Electronics means you gain access to wholesale pricing, faster shipping, and expert consultation.

Need to bundle tools with scanning devices, power supplies, or network equipment? We make procurement simple and affordable by offering:

Wholesale label printers

Bulk orders of barcode scanners and sensors

Compatible accessories and software

You don’t have to compromise quality for budget—EpicRise delivers both.

Final Thoughts

Investing in the right industrial measurement equipment pays dividends across your manufacturing operation—from better product quality and compliance to increased efficiency and cost savings. But success starts with sourcing smart.

When you work with EpicRise Electronics, you get more than just tools—you get a trusted partner in procurement. From Zebra barcode scanner systems to durable measurement devices and wholesale label printers, we supply the equipment that powers precision manufacturing.Need help choosing the right gear for your facility? Explore our full product range at EpicRiseElectronics.com or contact our support team for a custom quote today.

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Ultimate Guide to Choosing the Right Data Logger for Your Application

Data loggers are indispensable tools in various industries, from environmental monitoring to scientific research and beyond. With a plethora of options available in the market, selecting the Best data logger for your specific application can feel daunting.

Fear not! In this ultimate guide, we'll walk you through everything you need to know to make an informed decision.

Understanding Your Application Needs

Before diving into the world of data loggers, it's crucial to understand the specific requirements of your application. Ask yourself questions such as:

What type of data am I looking to collect?

What environmental conditions will the data logger be exposed to?

How frequently will I need to retrieve or access the data?

By identifying your needs upfront, you'll be better equipped to narrow down your options and find the ideal data logger.

Key Features to Consider

When evaluating data loggers, several key features should be on your radar:

Measurement Parameters: Different data loggers specialise in recording various parameters, including temperature, humidity, pressure, voltage, and more. Ensure the data logger you choose can accurately measure the parameters relevant to your application.

Accuracy and Precision: The accuracy and precision of a data logger can significantly impact the reliability of your data. Look for devices with high-quality sensors and calibration options to ensure precise measurements.

Memory Capacity: Consider the amount of data storage required for your application. Some data loggers offer ample onboard memory, while others may require external storage options like SD cards or cloud-based solutions.

Battery Life and Power Options: For applications in remote or inaccessible locations, battery life is paramount. Evaluate the data logger's power consumption and consider options for battery replacement or alternative power sources.

Durability and Environmental Ratings: Depending on your application environment, you may need a data logger that can withstand harsh conditions such as extreme temperatures, moisture, or dust. Look for devices with robust construction and appropriate environmental ratings.

Choosing the Right Type of Data Logger

Data loggers come in various shapes and sizes, each tailored to specific applications:

Standalone Data Loggers: Standalone data loggers are self-contained devices that operate independently, making them ideal for applications where portability and simplicity are key.

Wireless Data Loggers: Wireless data loggers offer the convenience of remote monitoring and data retrieval via Wi-Fi, Bluetooth, or cellular networks. These are perfect for applications that require real-time data access or monitoring from a distance.

USB Data Loggers: USB data loggers are compact devices that connect directly to a computer or mobile device for data retrieval and analysis. They are suitable for applications where frequent data downloads are necessary.

Budget Considerations

While it's tempting to splurge on the latest and greatest data logger, it's essential to balance your needs with your budget. Consider the long-term costs of ownership, including maintenance, calibration, and support services.

Conclusion

If you're still unsure which data logger is right for your application, don't hesitate to seek advice from experts in the field. Reach out to data logger manufacturers, distributors, or industry professionals who can provide guidance based on their experience and expertise.

With these tips in mind, you're now equipped to navigate the vast landscape of data loggers and choose the perfect solution for your application.

Remember, the right data logger can make all the difference in the accuracy and reliability of your data, so choose wisely!

Source by - Choosing the Right Data Logger for Your Application

0 notes

Text

Testing new environmental dataloggers: Pt. 1

Happy Preservation Week!

My name is Erin Fitterer and I am a third-year student at the Conservation Center at the Institute of Fine Arts, New York University, with a focus on objects and time-based media. Though I am now focusing on other materials, much of my pre-program experience before attending NYU was actually in paper conservation, and I’m excited to be able to work in a library again. This semester, I am working with Jessica Pace on a project involving the dataloggers used by the Barbara Goldsmith Preservation and Conservation Department to monitor collections storage spaces at Bobst Library.

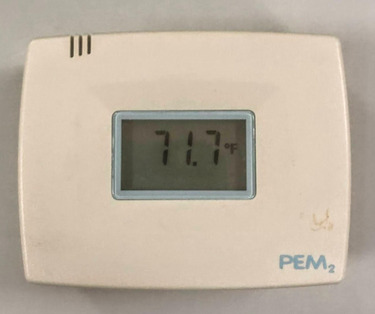

Dataloggers are an important tool when it comes to the care of collections. A datalogger is a device that records data about its surroundings at a regular interval, allowing conservators to monitor the environment of a given room or area over a long period of time. Depending on how they are made, a datalogger can record a wide range of information about a space, including monitoring vibrations and light levels. As conservators, we are most interested in monitoring the temperature and humidity levels in locations where collections are stored. Previously, conservators from the Preservation Department have been using PEM2 dataloggers. These devices monitor both temperature and relative humidity. To access the data, a USB device must be inserted into each logger. Unfortunately, the PEM2 device is no longer being supported by its manufacturer. To ensure continued access to loggers that can be calibrated and updated, we set out to find a replacement.

The first step for replacing PEM2 dataloggers was research. We wanted to find a datalogger that was able to record similar information as the PEM2 devices (namely relative humidity and temperature). Technology has changed since the introduction of the PEM2 to the market. While being able to capture the data from each device with a USB is a straightforward process, newer models enable the data to be accessed via the library’s WiFi network from any computer without needing to go to the location of each datalogger. This would allow our staff to monitor the collection in real-time, without needing to physically access each device.

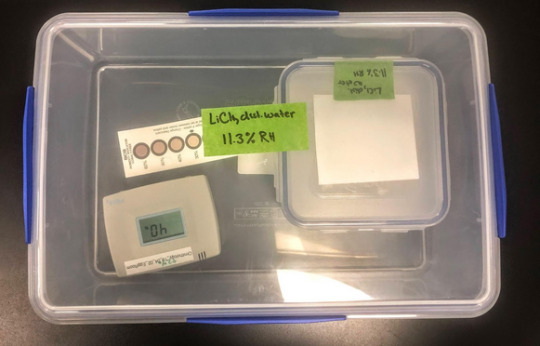

When considering what we wanted in our new dataloggers, we looked for loggers that met several criteria, including: wireless capability, unlimited software storage, visible display, and the ability to send alarms to our computer/phone. Ultimately, we decided to test out: Dickson DWE DicksonOne Display, Lascar High Accuracy Wi-Fi (no picture yet as we are waiting for it to arrive), and WirelessTag. These loggers, with exception of the WirelessTag (which has no display) met all of the criteria that we had listed above. During testing, we will be evaluating the type of power source of the datalogger (whether it needed to be plugged in or not, the average battery life, and so forth), the accuracy of the recorded temperature and relative humidity, and the ease of use of both the loggers and their software.

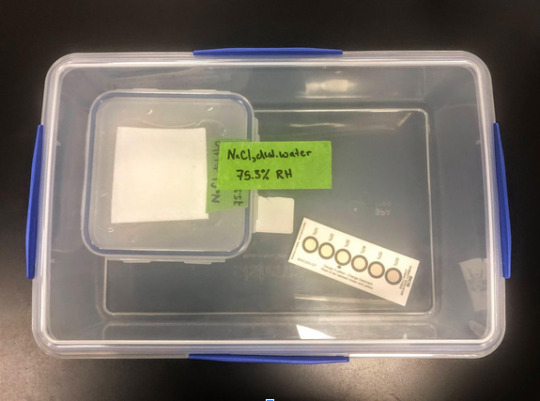

We decided to use saturated salt chambers to test the accuracy of loggers’ ability to detect relative humidity because each type of saturated salt solution has its own relative humidity (you can see a table documenting each relative humidity for its respective salt here). There are a number of recorded relative humidities for saturated salt solutions. We chose three salts for our testing chambers: sodium chloride (NaCl), RH 75.3%; magnesium chloride (MgCl), RH 32.8%; lithium chloride (LiCl), RH 11.3% . These three salts represent a broad range of relative humidities that will allow us to see how the devices perform under a range of conditions. To create the saturated salt solution testing chambers, we followed instructions posted on the Conservation Wiki written by Samantha Alderson and Rachael Perkins Arenstein. The lithium chloride and magnesium chloride were purchased from a chemical supply company. For the sodium chloride, we used Kosher sea salt purchased at a nearby grocery store. To create the chambers, we cut windows into three plastic food storage containers. Over each window, we taped a piece of Gortex.

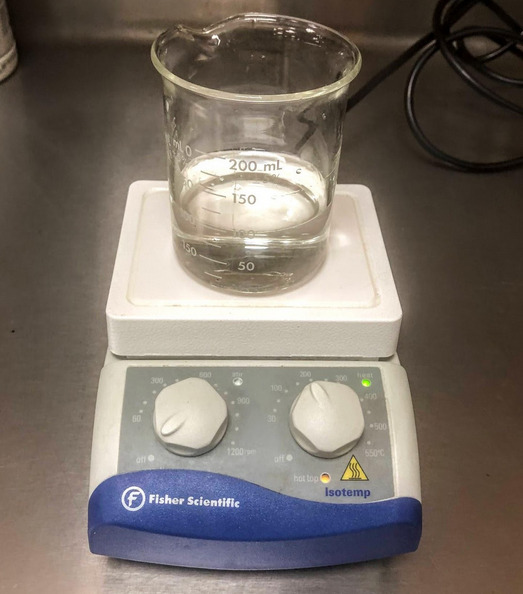

To prepare the salt solutions, we researched how much salt needed to be added to the water in order to create a saturated salt solution. We found a few publications that provided the ratios of water to salt used to achieve a saturated salt solution. Using these publications as a guide, for each salt solution, we measured 100 mL of water into a beaker. This water was heated on a hot plate, though not allowed to boil. For each of the salt solutions, salt was slowly added and allowed to dissolve. Once dissolved, more salt was added to the solution. Once the salt no longer dissolved (that is, it appeared on the bottom of the beaker), the solution was removed from the heat and allowed to cool. The result was a thick slurry mixture that was subsequently poured into the plastic food storage container. Each container and its salt solution were placed in a larger air-tight container. Within these larger containers, the datalogger devices will be placed. We will provide an update once we complete our testing.

5 notes

·

View notes

Text

Latest Research Report on Temperature Data-loggers Market by Application, Industry Share, End User, Opportunity Analysis 2030

The temperature data-loggers market refers to the industry that focuses on the production, distribution, and use of temperature data-loggers. Temperature data-loggers are electronic devices designed to measure and record temperature readings over time. They are commonly used in various industries and applications where monitoring and tracking temperature conditions is crucial.

For Sample Report Click Here:- https://www.globmarketreports.com/request-sample/191625

The market for temperature data-loggers has been growing steadily in recent years, driven by factors such as increasing awareness of temperature-sensitive products, stringent regulations in industries like healthcare and food, and the need for data-driven decision-making. These data-loggers are used in industries such as pharmaceuticals, healthcare, cold chain logistics, food and beverage, environmental monitoring, and manufacturing, among others.

Temperature data-loggers come in various forms, including standalone devices, wireless loggers, USB loggers, and Bluetooth-enabled loggers. They typically have sensors to measure temperature and often feature additional capabilities such as humidity sensing, pressure monitoring, and data connectivity. They can record temperature readings at regular intervals, store the data internally, and provide options for data retrieval and analysis.

Key market players in the temperature data-loggers industry offer a wide range of products with varying features and specifications to cater to different applications. These companies compete in terms of product quality, accuracy, durability, ease of use, data storage capacity, battery life, and connectivity options. Some prominent manufacturers in this market include Vaisala, Omega Engineering, Testo, Onset, Dickson, Rotronic, T&D Corporation, and Elpro-Buchs.

The temperature data-loggers market is expected to continue its growth trajectory in the coming years. Factors such as the increasing demand for temperature-sensitive products, the need for regulatory compliance, and the growing emphasis on quality control and traceability are driving the market. Additionally, advancements in wireless and IoT technologies are enabling real-time monitoring and remote access to temperature data, further fueling market growth.

0 notes

Link

0 notes

Text

0 notes

Link

0 notes

Text

Beelog fine furniture high point

In our tests, the following problems occurred. Sometimes, but it almost never works as well as with scales from A&D. Does the data logger work with scales from other manufacturers? The weight will appear as a number in its own column, ready for further processing. The CSV file created by the AD-1688 can be opened in applications such as Excel by simply double-clicking on it. After weighing, it is connected to a USB port on a computer (just like a flash drive) to access the data: It stores the weight and – if required – a sequential number and the date/time. It is a compact device designed to be connected to scales and balances made by A&D via their RS-232 interface. What is the A&D AD-1688 weighing data logger? Posted on Categories Buying advice Tags beehive scale, Data acquisition, outdoor scale Leave a comment on Beehive scales: List of commercial and open source projects in Europe Does the A&D AD-1688 weighing data logger also work with scales from other manufacturers? We would be happy to receive links to other products and projects in the comments. The Internet of Bees: Adding Sensors to Monitor Hive Health (Make Magazine project from 2015).Penso Bienenstockwägesystem (Emsystech Engineering, in German only).HoneyPi (DIY project based on the Raspberry Pi, partially in English).Hiveeyes (Open source project, active community but mostly in German).Capaz Bienenwaage (CAPAZ GmbH, in German only).BeeSaver (BeeSaver GmbH, in German only).BEEP (Open source project from the Beep Foundation, previous Kickstarter campaign can be found here).Bee Hive Monitoring (Save the bees s.r.o).Dieter Metzler, DIY project, in German only) Websites with descriptions in English and with recent updates were highlighted: The following list contains all beehive scales available in Europe that we currently know of (both commercial and open source / DIY projects). It is therefore unsurprising that no major scale manufacturer offers a hive scale and that commercially available scales from specialized manufacturers can be quite expensive. Must have low power consumption (for off-grid installations).Must be able to transmit weight data (often over long distances).Must support a heavy load over a long period of time while still registering small weight changes.Must weigh accurately under challenging conditions (temperature fluctuations, vibrations caused by wind).Must withstand long-term outdoor use (protection against rain, moisture/dust, very low and high temperatures, possibly theft/vandalism, wild animals etc.).Hive scales for use by beekeepers are a niche market moreover, they must meet a number of special requirements, such as: Define ES module: esCounterModule.js.Making an electronic hive scale can be harder than you think Load entry module and return exports return require( require.s = 0) ( function ( exports, require, module, _filename, _dirname) Define CommonJS module: wrapped commonJSCounterModule.js. In the browser, defining a JavaScript variable is defining a global variable, which causes pollution across all JavaScript files loaded by the current web page: TypeScript module: Transpile to CJS, AMD, ES, System modules.Webpack module: bundle from CJS, AMD, ES modules.ES dynamic module: ECMAScript 2020, or ES11 dynamic module.ES module: ECMAScript 2015, or ES6 module.UMD for both AMD (RequireJS) and CommonJS (Node.js).UMD for both AMD (RequireJS) and native browser.UMD module: Universal Module Definition, or UmdJS module.AMD module: Asynchronous Module Definition, or RequireJS module.CJS module: CommonJS module, or Node.js module.Revealing module: JavaScript revealing module pattern.IIFE: Immediately invoked function expression.This article discusses all mainstream terms, patterns, libraries, syntax, and tools for JavaScript modules. In years, tons of technologies are invented to modularize JavaScript. However, JavaScript language was initially invented for simple form manipulation, with no built-in features like module or namespace. When you build an application with JavaScript, you always want to modularize your code. JavaScript TypeScript Web Webpack Babel CommonJS Node.js AMD UMD

0 notes

Text

Are you running out of water and not getting time for backup?

Water is an essential part of our lives. We rely on it almost every minute, whether it is about daily hygiene or keeping our surrounds neat and clean or even to maintain that beautiful garden in your back yard or more when we talk about usage in industries. Large amount of water is consumed every day. When the consumption is more and water sources are not reliable one needs to arrange for water backup supply which is often obtained by paying a fee. If you have been running out of water and ever wished a way to know the water levels in your storage, then “level logger” is the answer for you.

What is Water Levelogger?

Installing a levelogger to keep a watch on surface water and ground water is an inexpensive solution. Leveloggers collect data of water level, pressure, flow and temperature both using a pressure sensor which is inside the device. This smart device is battery operated and comes with a data logger. There are more than one type of data logger available in the market. As per convenience data loggers can be supported by Bluetooth, USB or can be web-based.

Selecting the right levelogger and sensors

There are few ways to ensure you have selected the right levelogger for yourself. Firstly, you must determine how you wish to connect to the logger, then understand, how many channel logger’s you will need, then check the logger’s accuracy, and software capability and compatibility. All these basic points would help you select the accurate water levelogger and make your work easier and comfortable.

Good leveloggers

Broadly three types of leveloggers are used. One which can record water level and temperature, there is another which record the exact water level and measure temperature at surface water and in shallow waters, then there are leveloggers which are inexpensive but can be good alternative for carrying out the same functionality. Although there are several brands available which are offering similar services but the ones who have spent the maximum time in the markets are the best players.

There are advance sensors and data loggers which can conveninetly used by bluetooth which are accurate and need not be manual turned on or off, such combinations would provide series of short intervelled data to the desired monitoring system. There are leveloggers which can save over 81000 readings and multiple unique recording options, which are fast and accurate. They can be as fast as ten samples per second.

0 notes

Text

Industry 4.0 requires enclosures for smart sensor applications

The fourth industrial revolution, or "Industry 4.0" for short, has already begun, even if many people are not really aware of this. On the one hand, this is due to the fact that most people have already heard of it, but many are struggling with the definition and its real impact on day-to-day working life. In addition, the topical subjects of IoT (Internet of Things) and IIoT (Industrial Internet of Things) are mentioned in the same breath as Industry 4.0. This makes things a little more complex.

IoT in the household

Digitisation and networking can best be used and understood in your own private environment: with your smartphone, which has meanwhile become "man's best friend", you can today control a wide variety of things, no matter where you are. Individual devices such as the smart watch are linked up with other "smart things" and the data is stored in a centralized secure "cloud". All of this is intended to make our everyday life easier for us. In my opinion much of this is absolutely sensible, such as wearable emergency call systems/transmitters in hospitals or social areas. Or also personal tracking systems in occupations with an increased safety risk. An interesting example is the "Capturs" by the French manufacturer of the same name (www.capturs.com). At first glance this GPS tracking system may seem to cater for the fun factor, but a closer look reveals much more: the wearable device makes it possible for friends, family and fans to keep track of routes and thus to be involved live when persons are pursuing their sports activities, regardless of the terminal unit in question. You can export/save the data (route, distance, elevation, duration) and even publish them in social networks. But now the special feature: in the event of crashes or accidents, departure from the predefined route, longer stay at a given location and when the battery is weak, it automatically sends an email or a text message to certain persons. This makes it possible to call for help quickly in case of emergency. The Capturs was installed in the OKW MINITEC series of enclosures and can be used for all outdoor activities: hiking, skiing, climbing, paragliding etc. Other OKW series of enclosures that can be used for wearables are the BODY-CASE and the ERGO-CASE.

Industry 4.0 and IIoT

Let us come back now to the actual topic of "Industry 4.0" and IIoT "Industrial Internet of Things". There is a significant difference between the two concepts – in short, Industry 4.0 is a high-tech strategy for promoting the digitisation of industrial production; IIoT is the concrete use of smart technologies in the manufacturing industry. Many companies are currently discussing the question of how to make internal processes transparent and how to optimise them across different levels/organisations. In IIoT, it is also basically a question of making things smarter by making them communicate with each other. The focus here is on sensors which are embedded in the devices and which constantly gather and centrally deliver data concerning machinery and special application scenarios or data about the user and the entire value-added chain. The main objectives are always the same: providing better quality, optimising processes and streamlining operations, optimising the use of resources, completing orders faster and delivering them faster to the customers. In addition, an important objective is to significantly shorten the market introduction cycle for new products in order to gain a competitive advantage.

Enclosures and IIoT

Even today, many OKW enclosures series are used for the most varied applications in the smart factory. Subsequent use in day-to-day work is highly varied, and the requirements to be met by the enclosures may therefore vary considerably:

Mobile enclosures for the integration of temperature, humidity or presence sensors – ergonomic design for fatigue-free working.

Installed permanently on the wall as gateways – simple, concealed wall mounting, possibly with security functions

In machines/systems with integrated vibration/pressure and status sensors.

In miniature form for wearable applications – on the arm, wrist, around the neck or in the shirt/trouser pocket

Larger sizes in a robust design – if more space is required for installing components/displays.

Use of high-quality materials for the manufacture of the standard enclosures

High IP classes for the protection of the built-in electronic components and sensors.

Options for modifying the tandard products according to individual customer wishes and requirements.

In the following, I have picked out some interesting examples of customer applications from the field of IIoT for you:

Wireless data logger

With the Almemo 470 wireless data logger by Ahlborn Mess- und Regelungstechnik, you can wirelessly measure climate parameters such as temperature or atmospheric humidity. A flexible connection technology for digital sensors allows the adaptation of a large number of different sensors for measuring different variables.

Application wireless data logger

Wireless network access point

At field level, the sWave.NET wireless network by steute Schaltgeräte GmbH & Co. KG facilitates variable communication between wireless switching devices and access points, which function in a similar manner to a router. They receive signals from wireless switching devices, bundle them and then transmit them, e.g. by Ethernet or WiFi, to one or more application servers. The access points are installed across the transmission range and communicate with the wireless switchgear.

Application wireless network access point

Smart TAG

The conbee Smart TAG is based on the Bluetooth 4.x specification with a range of up to 150 m. The fully configurable TAG has an authentication function using out-of-band or SecureSimple pairing, is forgery-proof and has a motion sensor that is capable of detecting manipulation attempts. Status data are transmitted at dynamically adaptable transmission intervals in advertisement packets that provide information about the object to be tracked. The intelligent TAG cyclically reports its identification number, temperature and movement data as well as battery status and optionally also its position.

Application Smart TAG

Robust UHF reader

RF-Embedded GmbH has developed an RFID reader for the passive ultra high frequency (UHF) radio range, which generates an energy field from electromagnetic waves. As soon as a passive UHF transponder enters the energy field, it sends the content of its memory to the relevant RFID reader.

Application robust UHF reader

We have now drawn up a list of all enclosures that are suitable for the use of smart sensors under a separate heading. Now you can find a suitable sensor enclosure even more quickly.

Overview IIoT/Sensor Enclosures >>

To ensure that the standard enclosures also meet individual customer requirements in terms of company colour, visual adaptation to the usage environment, company logo, the electronic components and cables etc., we offer a wide range of services: painting, printing, EMC aluminium vapour plating as protection from stray radiation, cutouts/openings, for example for USB/SPI/I2C/LAN connectors or control buttons. In industrial enclosures with high IP classes, the use of special pressure compensation elements is a big advantage. A partial vacuum may be created inside sealed enclosures if there is a change of temperature. Moisture and dirt particles may be sucked in, damaging the sensitive electronics. These OKW pressure compensation elements can counteract this, since they allow an especially high air flow. At the same time the innovative design provides reliable protection against dirt and, if required, is absolutely waterproof up to a pressure of 6 bar.

#Enclosres#enclosure#plastic enclosure#plastic enclosures#okw#OKW Gehäusesysteme#OKW Gehäuse#OKW Enclosures#OKW Enclosure#IoT#IIot#iiot solution#smart factory#smart fabrics#smart industry#industry 4.0#sensor#sensoric#sensor enclosure#IoT enclosures#sensor enclosures#internet of things#industrial internet of things

2 notes

·

View notes

Text

Global Automotive Data Logger Market measured to be worth US 3.13 bn by 2023 due to enhanced passenger safety features

The automotive data logger is an automobile functionality enhancing system that is utilized for diverse purposes ranging between simple performance evaluation and complex development of the latest applications. Market Research Future (MRFR) has published a research report about the global automotive data logger market that measures boost for this market at 7.2% CAGR (Compound Annual Growth Rate) between 2017 and 2023. By value, the market has been figured to be worth the US $ 3.13 bn by the end of forecast period.

The compelling factor for the global automotive data logger market is increased incorporation of technologically advanced solutions in the automotive industry for monitoring various factors of automobiles. These automobile factors include acceleration, shock, temperature, vibration, and others. Other factors contributing to the market growth include advanced electronic architecture in modern vehicles, enhanced vehicle safety features, enhanced passenger safety features, proliferation in the utilization of electric vehicles, and rise in demand for autonomous vehicle testing. However, some factors that can hinder the market growth include the high cost of data acquisition systems, lack of skilled workforce for installation, and maintenance of data loggers.

Get a FREE Report Sample - https://www.marketresearchfuture.com/sample_request/6676

The global automotive data logger market has been segmented on the basis of application, channels, connection type, and lastly, region. The application-based segmentation segments this market into pre-sales application and post-sales application. The post-sales applications have been sub-segmented into advanced driver-assistance systems (ADAS) & safety, automotive insurance, fleet management, and onboard diagnostics (OBD).

Based on channels, the market has been segmented into controller Area Network (CAN) & CAN FB, Ethernet, FlexRay, and local interconnect network (LIN). By connection type, the market has been segmented into Bluetooth/Wi-Fi, secure digital (SD) card, and universal serial bus (USB).

The regional segmentation of the global automotive data logger market segments the market into the regional markets namely Europe, The Americas (North America & South America), Asia Pacific, and the Middle East & Africa (MEA). The Americas currently holds the largest market share because North America alone has the potential to hold this share due to the established automotive industry in the USA. Status quo is expected during the forecast period. The second factor supporting the market growth in this region covers all technological innovations and their early adoption. Other factors aiding the market growth include rapid inclination witnessed towards the adoption of electric cars and the presence of key players in the significant country-specific markets. After the USA, Canada is the biggest country-specific market, followed by the remaining countries in the Americas. In South America, Argentina and Brazil are two strong economies that can be suitable markets in the future.

Europe is another highly lucrative market that during the forecast period, is expected to emerge as the fastest growing region. This region has adopted electronic architectures for automobiles. In this region, the demand for electric vehicles is rising, and many key players are based in this region. Therefore, the market is growing in this region. The vital country-specific markets in this region are France, Germany, Spain, and the UK, followed by the remaining countries of Europe.

During the forecast period, the Asia Pacific is also expected to grow as a regional market due to the high density of population, growing economies, rising disposable income, and demand for automobiles.In this region, the major country-specific markets are China, India, and Japan, followed by the remaining countries of this region. The MEA region is a small regional market due to poor countries, lack of awareness, lack of education, lack of infrastructure, and lack of technological advancement.

Key Players

The key players in the global automotive data logger market include Continental Automotive GmbH (Germany), Danlaw Technologies India Limited (India), Delphi Technologies (UK), Dewesoft d.o.o. (Slovenia), Harman International (USA), HEM Data Corporation (USA), Influx Technology (UK), Intrepid Control Systems Inc. (USA), Ipetronik GmbH & Co. KG. (Germany), MadgeTech Inc (USA), MEN Micro Inc. (USA), myCarma (Canada), National Instruments (USA), NSM Solutions (India), Racelogic (UK), Robert Bosch GmbH (Germany), Transtron Inc. (Japan), TTTech Computertechnik AG (Austria), Vector Informatik GmbH (Germany), and Xilinx (USA).

Get a FREE Report Sample - https://www.marketresearchfuture.com/sample_request/6676

Key Questions Addressed by the Report

What was the historic market size?

Which segmentation (Product/ Capacity) is driving market?

What will be the growth rate?

How are the key players in this market?

What are the strategies adopted by key players?

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY

2 SCOPE OF THE REPORT

2.1 MARKET DEFINITION

2.2 SCOPE OF THE STUDY

2.2.1 DEFINITION

2.2.2 RESEARCH OBJECTIVE

2.2.3 ASSUMPTIONS

2.2.4 LIMITATIONS

2.3 RESEARCH PROCESS

2.3.1 PRIMARY RESEARCH

2.3.2 SECONDARY RESEARCH

2.4 MARKET SIZE ESTIMATION

2.5 FORECAST MODEL

3 MARKET LANDSCAPE

3.1.1 THREAT OF NEW ENTRANTS

3.1.2 BARGAINING POWER OF BUYERS

3.1.3 THREAT OF SUBSTITUTES

3.1.4 SEGMENT RIVALRY

3.1.5 BARGAINING POWER OF BUYERS

3.2 VALUE CHAIN/SUPPLY CHAIN ANALYSIS

4 MARKET DYNAMICS

4.1 INTRODUCTION

4.2 MARKET DRIVERS

4.3 MARKET RESTRAINTS

4.4 MARKET OPPORTUNITIES

4.5 MARKET TRENDS

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Edibles.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Media Contact Company Name: Market Research Future Contact Person: Abhishek Sawant Email: Send Email Phone: +1 646 845 9312 Address:Market Research Future Office No. 528, Amanora Chambers Magarpatta Road, Hadapsar City: Pune State: Maharashtra Country: India Website: https://www.marketresearchfuture.com

Browse Complete Report - https://www.marketresearchfuture.com/reports/automotive-data-logger-market-6676

0 notes

Text

(COVID-19 Version) Global Temperature Logger Market

The report forecast global Temperature Logger market to grow to reach xxx Million USD in 2019 with a CAGR of xx% during the period 2020-2025 due to coronavirus situation. The report offers detailed coverage of Temperature Logger industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Temperature Logger by geography. The report splits the market size, by volume and value, on the basis of application type and geography. First, this report covers the present status and the future prospects of the global Temperature Logger market for 2015-2024. And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru]. At the same time, we classify Temperature Logger according to the type, application by geography. More importantly, the report includes major countries market based on the type and application. Finally, the report provides detailed profile and data information analysis of leading Temperature Logger company.

Key Content of Chapters as follows (Including and can be customized) : Part 1: Market Overview, Development, and Segment by Type, Application & Region Part 2: Company information, Sales, Cost, Margin etc. Part 3: Global Market by company, Type, Application & Geography Part 4: Asia-Pacific Market by Type, Application & Geography Part 5: Europe Market by Type, Application & Geography Part 6: North America Market by Type, Application & Geography Part 7: South America Market by Type, Application & Geography Part 8: Middle East & Africa Market by Type, Application & Geography Part 9: Market Features Part 10: Investment Opportunity Part 11: Conclusion

Market Segment as follows: By Region Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia] Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland] North America[United States, Canada, Mexico] Middle East & Africa[GCC, North Africa, South Africa] South America[Brazil, Argentina, Columbia, Chile, Peru] Key Companies Tesco Omron OMEGA Onset Vaisala ROTRONIC Hioki Dickson Xylem Cryopak ACR Systems E+E Elektronik Apresys Maxim Amprobe Senonics T&D Corporation Extech Instruments Delta TRAK Sksato Elpro Gemini MadgeTech CENTER Lascar Electronics Monarch Yotta Sense LogTag Recorders Aosong Asmik Market by Type USB Access Type Wireless Access Type Market by Application Pharmaceutical and Food Facility Management Transport and Storage Industry

for sample report please visit: https://www.statzyreports.com/report.php?reportnumber=SR151983&reportnames=COVID-19-Version-Global-Temperature-Logger-Market-Status-2015-2019-and-Forecast-2020-2025-by-Region-C-Product-Type--6-End-Use

Phone Number (IN) - +918484035727

(US) - +1415-871-0483

Email Address Email : [email protected]

Email : [email protected]

0 notes