#Using A Vinyl Plotter

Explore tagged Tumblr posts

Text

i mean the truth is that we do not need and should not have all this stupid plastic clutter in or houses. no one should be producing or selling this shit. everyone make your own merchandise and charge a living hourly wage to sell it 🤷 sorry to be so simplistic about this but it's one of the results of the lack of class unity specifically in the means of production-owning creative class, who is not mentioned or dealt with by the core Marxist texts as far as I know (i asked about this earlier on here, did marx ever address in his analysis people like, for example, a professional photographer who owns a camera ans prints his own dagguereotypes? or a portrait painter or idk, independent milliner or seamstress? these people all own the means of production and do not employ anyone, and the answer from better educated people than I was that no, Marx didn't mention them), I'm not well read on this at all, there is just a big void where leftist analysis of what modern economists call "the creative class"

I'm getting off topic. my point is make your own keychains in your kitchen. it's actually not hard. you can even mass produce (on a small scale) little plastic crap if you want, with resin and a UV lamp, or a 3d printer, or a laser cutter and acrylic sheets (or just use balsa wood damn, at least its biodegradable and less tacky).

all this stuff is available to little creators AND there are hundreds of people who already own these machines who will take work for you and produce your designs. you just have to actually find them and know them and email them. that's what I mean about the class unity issue with creatives. we have no large scale union, we have no large scale class consciousness, and we're all sending our orders for little plastic crap to sweatshops instead of emailing a guy with a laser cutter in his garage and saying "hey Keith can I get uhhhhhhhhhhh 50 laser cut keychains of this twerking Diggler design I made, like how much would that cost" and he's like sure here's the work and materials cost and tbh it's always always less than i think it's going to be. you just have to do some basic arithmetic and then order shipping, and I hate order fulfillment with my life but you can actually pay or barter with someone to do that for you too. learn to delegate and then factor that into your unit cost. this is basic shit every commercial creator needs to know. they should teach you this in art school but they dont

don't give me crap about "I can't afford a laser cutter" either because I just told you to email Keith. and all these machines get sold secondhand when a manufacturer or hobbyist needs to upgrade. i got a color laser printer perfect for making zines and wheatpastes and shipping labels from a retired lesbian on capital hill for $75 and it was still full of ink. my friend gave me her 20 year old canon dslr because she just didn't need it and didn't want to bother selling it. it works fine because I spent the time finding the right drivers and shit for my computer. and card readers exist. Craigslist. Facebook marketplace. nextdoor sales section. eBay. everyone always forgets eBay. eBay lets you save searches and will email you when it finds a guy selling his vinyl plotter in your city with local pickup. I'm serious

#long post#pro doom strats#leather embossing is another one#risograph prints#woodblock prints#rubber prints#etchings even#silicon molds for sculpey or resin or clay#local pottery studios#local photography studios#professional art printers with giclee printers!#ive used all these techniques to make merch#none of them are difficult or out of reach its just EASIER and adverised more to order shit from china#oh my god i forgot button presses#ALSO WE NEED A UNION AND STANDARDIZED HOURLY WAGES BTW#TIRED OF THIS BICKERING ABOUT PRICE UNDERCUTTING

406 notes

·

View notes

Text

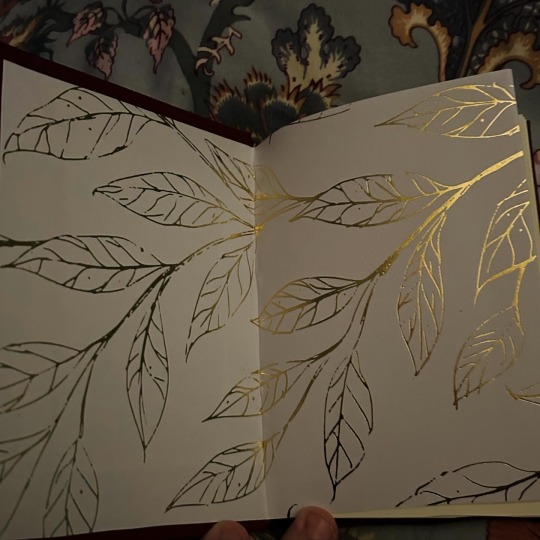

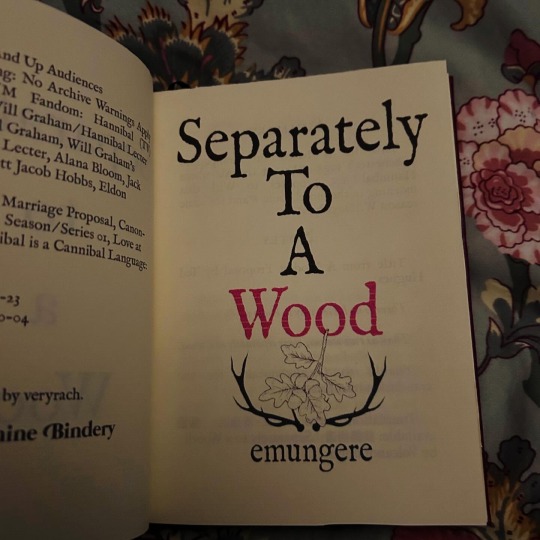

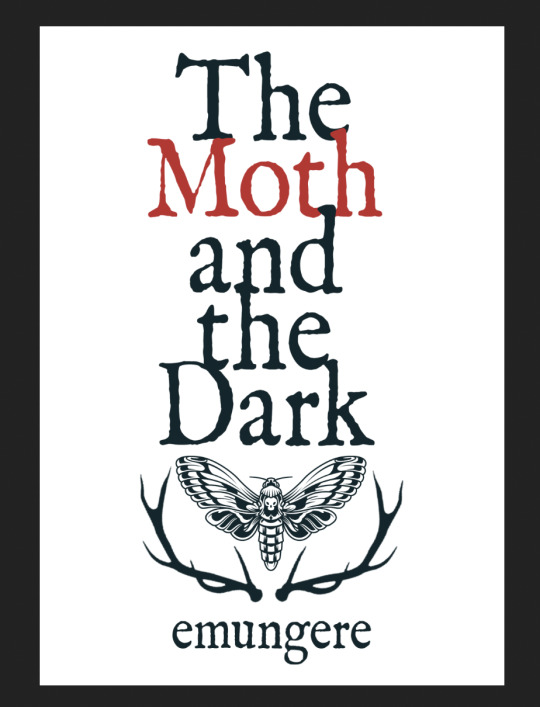

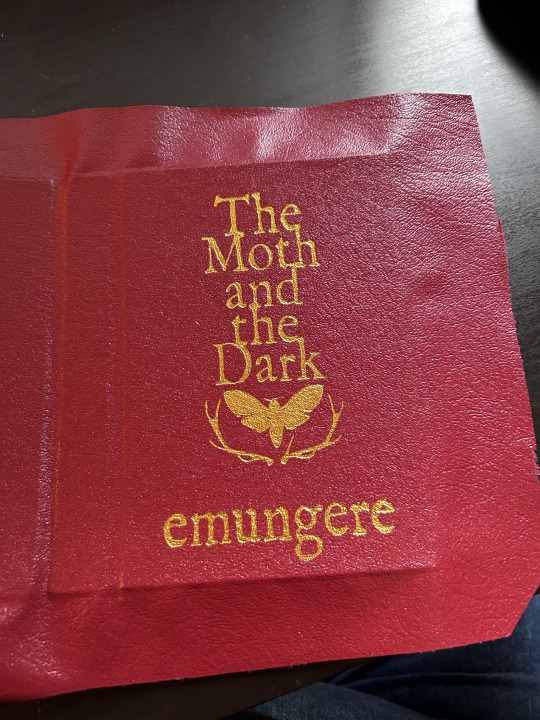

Book No. 13

A tête-bêche quarto of two Hannibal fics by emungere, bound for @springkitten, which were exactly the right length to make this a satisfyingly chunky little book to hold.

I have to confess I'm only passing familiar with Hannibal, so I had to take a wild stab at the vibes (as Hannibal does at people, perhaps?), but they assure me that these were acceptable.

This was my first time typesetting from start to finish in Affinity Publisher, and I'm now at that stage where it's not so frustrating to use that I can't appreciate how powerful a tool it is, which is great.

I also trialled a new method of hot foiling, using a handheld foil pen with a plotter-cut vinyl stencil. I'm really pleased with the results here, which is largely due to the faux-leather bookcloth (also a first for me). It took the foiling beautifully, as well as taking creases nicely and generally being very fun to work with.

64 notes

·

View notes

Text

Book Progress 03: The thing about this build is that it requires A Lot of thinking about the order of doing. The construction feels closer to building Ikea chairs (a thing I adore) than painting. Flat tho it may be, it's 3D enough to be an asshole.

It's time for me, in this build, to work on Some of the heat transfer vinyl. As I said, I have a plotter but the stuff can be cut by hand, no sweat.

If you fucking remember to invert your text. Holy shit. Ugh.

All the same. Heat vinyl is fun and pretty cheap for its uses. 8' for 9 bucks on Amazon. A good deal since all one needs is a clothes iron and something that needs ruined. After it comes out of the cutter, one gets to do a thing called weeding and it's the best ever. I recommend vinyl just to weed. It's scab-pickers gone to therapy. Brilliant. This to this.

I really need you to ignore why I already had dental tools.

And does it work all the time? No, it fucking does not. Here my iron was too hot and the vinyl fused to the transfer paper while leaving a glue ghost on the cloth. Irritating but I re-cut and re-afixed. There's still some ghosting- and it's slightly off center, both of which I hate- But Frailties.

Oh, yeah. Before the vinyl, I cut and wrapped the coffin shape. How's that for order of doing? Just immediately chronologically wrong. Nice. Wrapping irregular voids like such is surprisingly straightforward as long as you go slow and don't cut right up to the edge of the board. One must leave enough cloth to poke, stab, and jam into the corners with my dearest heart, BONE FOLDER. Ask me how I know.

2 notes

·

View notes

Note

Hey, can i ask about how you do the detais in your books (like the title and the things that go on the cape)? I wish to start but dont now the name (is vinil adesivo or some thing like that?) ? Do you desing yourself (where?)? I am sorry to bother you, is that i plan to start fanbinding but i dont feel like i have all the knowledable about it

heya! it's called a Heat transferring vinyl (or short HTV ) :)

it's basically vinyl product that you iron onto your book case/ book cloth

I personally design them myself using clip studio paint, but there are bunch of other free-softwares you can use to design covers. Canva is a very popular option, because it comes with a huge library of assets that you can use

In order to transfer the design on to your htv, you'll need a cutter machine (plotter?). Popular brands are Silhoutte america or Cricut, but the are a wee bit on the expensive side, but there are many many many other cheaper alternatives to get your design on the book case

I'm still very new to fanbinding and still learning, the people over at @renegadepublishing helped me out immensely with any questions I had. I recommend checking them out, they also have a discord server where you can ask questions or see what other people have done

Another good place to start is also DAS bookbinding youtube channel

Hope this all helps!

11 notes

·

View notes

Text

From Precision to Production: How Vinyl Cutters and Plotters Are Powering the Creative Industry

In today’s fast-paced world of design, signage, fashion, and crafting, vinyl cutters and plotters have emerged as indispensable tools. Whether you're a small business owner creating custom t-shirts or a professional sign maker producing intricate graphics, these machines offer a perfect balance of speed, accuracy, and versatility. But what exactly are they, how do they differ, and why are they becoming more popular than ever in 2025?

Understanding Vinyl Cutters and Plotters

At their core, both vinyl cutters and plotters are machines designed to cut or draw on materials such as vinyl, paper, or heat transfer film. A vinyl cutter uses a sharp blade to precisely slice through the surface of thin materials, primarily used for cutting decals, signs, labels, and heat transfers for apparel. A plotter, in contrast, is a more general term and may refer to devices that draw vector graphics with a pen or cut materials, depending on the model.

The distinction is narrowing in recent years as modern machines often serve dual functions, capable of both plotting and cutting with interchangeable tools.

The Rise in Popularity

One major factor behind the growth of vinyl cutters and plotters is the explosion of small businesses and DIY entrepreneurship. Platforms like Etsy, Amazon Handmade, and Shopify have enabled creators to sell custom products globally, fueling demand for tools that can produce professional-grade items at home or in small studios.

Additionally, affordability and accessibility have improved. Where once vinyl cutting machines were limited to industrial use, today’s models come in compact sizes, with user-friendly software, and are priced for hobbyists as well as professionals.

Applications Across Industries

The applications for vinyl cutters and plotters span numerous industries:

Signage and Advertising: From storefront lettering to car decals, vinyl cutters are a staple for creating clean, weather-resistant graphics.

Fashion and Apparel: Heat transfer vinyl (HTV) can be cut and applied to garments for custom clothing, uniforms, or branded merchandise.

Crafting and DIY: Crafters use these machines for scrapbooking, home décor, and gift-making.

Education: Schools and colleges are integrating vinyl cutters into design and technology programs, giving students hands-on experience with digital fabrication tools.

Features That Matter

Modern vinyl cutters and plotters come equipped with advanced features such as:

Bluetooth and Wi-Fi Connectivity for wireless design transfer.

Precision Cutting with optical sensors for alignment.

Dual Tool Capability, allowing for cutting and sketching in one go.

Cloud-Based Design Software with thousands of templates and font options.

These features make the machines both powerful and user-friendly, even for beginners.

The Future of Creative Production

As customization becomes the new standard in product design, tools like vinyl cutters and plotters are shaping the future of creative production. Businesses can now prototype, personalize, and produce with speed and precision—without needing massive equipment or large production runs.

In conclusion, vinyl cutters and plotters have transcended their original roles as niche tools. They are now central to a growing movement of makers, artists, and entrepreneurs who value quality, creativity, and control. Whether you’re producing one item or a thousand, these machines are proving that the future of design is both digital and personal.

1 note

·

View note

Text

Vinyl Cutting Plotter Machine – your new creative companion! 💥 Whether you're running a business or just love crafting, this machine + premium vinyl wholesale supply = game changer! 💡 ✅ High precision cutting ✅ User-friendly design ✅ BEST price in India 🇮🇳 ✅ Bulk vinyl available at unbeatable rates

🔥 Don’t miss out – CLICK LINK IN BIO to grab yours now! 💯 💬 DM us for inquiries or bulk orders. Let's make magic together! ✨

👇Tag a friend who needs this in their life!👇 🔗👉 https://dittoboss.com/ 🌐 📞 +91 9891579158 🌟

DittoBoss #VinylCuttingMachine #VinylPlotter #CraftMachine #VinylWholesale #CraftSuppliesIndia #DIYIndia #CricutIndia #SilhouetteIndia #CraftBusiness #StickerMaking

0 notes

Text

Digital Knife Cutter

IGOLDENCNC oscillating knife cutter relies on advanced technology and keeps up with the trend of industrial intelligent development in the world. The main products include digital flatbed cutter table, CNC knife cutte, CNC leather cutting machine, car interior cutting machine, automatic fabric cutting machine, floor mat cutting machine, cardboard cutting machine, composite material cutting machine, gasket cutting machine, laser cutting machine, etc. Digital cutter idely used in clothing, luggage, automotive interiors, fabric, shoes, textiles, advertising, packaging, metal and other industries. What Is Automatic Digital Cutting Machine (CNC Knife Cutter)? Automatic digital cutting machine (also known as CNC knife cutter) is a type of automated precision cutting system with CNC (Computer Number Controlled) controller which is used for high-precision cuts of heavier flexible and semi-rigid materials. It works with the multi-tool blades consisting of vibration knife, oblique knife, circular knife, punching knife, milling knife, punch roller, or marking pen. CCD camera and projector are optional for more precise cuts.

A automatic digital cutter is also known as digital cutting table, automatic flatbed cutter, cutting plotter, dieless cutter, flash cutter, CNC knife cutter, CNC drag knife, CNC tangential knife, CNC oscillating knife, automatic precision cutter, and CNC blade cutting table.

A CNC knife cutting machine is a professional automated digital cutting system that uses the up and down high-frequency vibration of the blade to cut flexible materials.

It can high-speed, single-layer and multi-layer cut material such as fabric, cloth, textile, clothing, leather, vinyl, cardboard, carton board, corrugated board, honeycomb board, gray board, paper, plastic, EVA, EPE foam, PVC foam, polyethylene foam,Non-asbestos gasket, silicone gasket, tangled pattern gasket, rubber gasket, cork gasket, PTFE, PTFE,display stand, printed PVC board, KT board, acrylic, paper, EVA, foam, vinyl sticker, reflective material, outdoor advertising, sign, etc.

A automatic digital cutter is also known as digital cutting table, automatic flatbed cutter, cutting plotter, dieless cutter, flash cutter, CNC knife cutter, CNC drag knife, CNC tangential knife, CNC oscillating knife, automatic precision cutter, and CNC blade cutting table. In recent years, oscillating knife cutting technology has been more and more widely used in the processing industry of non-metallic materials.

CNC OSCILLATING KNIFE

Automatic Knife Cutting Machine

CNC OSCILLATING KNIFE

Double Head Oscillating Knife Cutting Machine

CNC OSCILLATING KNIFE

Industrial Apparel Textile Digital Cutting Table

CNC OSCILLATING KNIFE

Automatic Digital Die Cutting Machine

CNC OSCILLATING KNIFE

Automatic Digital Knife Multi-layer Fabric Cutting Machine

CNC OSCILLATING KNIFE

Automatic Leather Pattern Punching Machine

CNC OSCILLATING KNIFE

Best Flatbed Vinyl Cutter | Digital Flatbed Plotter

CNC DIGITAL KNIFE CUTTERAutomatic CNC Gasket Cutting Machine with Oscillating Knife Cutter for Sale

CNC DIGITAL KNIFE CUTTERCNC Oscillating Tangential Knife Cutting Machine

CNC DIGITAL KNIFE CUTTERMulti Layer Fabric Cutting Machine

CNC DIGITAL KNIFE CUTTERAutomatic Cloth Cutting Machine for Textile Fabric

CNC DIGITAL KNIFE CUTTERBest Drag Knife CNC Router & Digital Cutter for Sale

CNC DIGITAL KNIFE CUTTEROscillating Cutter for Cardboard Craft Paper Fabric Die

CNC DIGITAL KNIFE CUTTERDouble Head Digital Die Cutter_Vibration Knife Cutter

READ MOREQUICK VIEWCNC DIGITAL KNIFE CUTTERProjecttion Visual Vibrating Knife Cutting Machine

CNC OSCILLATING KNIFE

Fabric Digital Oscillating Knife Cutting Machine

0 notes

Text

✂️ Silhouette CURIO-2: The Ultimate Crafting & Cutting Machine! ✂️ With high-precision flatbed cutting, the Silhouette CURIO-2 offers superior accuracy for engraving, embossing, and cutting across multiple materials. Whether you’re crafting custom designs, branding materials, or DIY décor, this machine gets the job done!

📞 Call Us: +91-7701993306, 011-41563389 🌐 Website: www.ambitiongifts.com

Silhouette Cutting Plotter, DIY Cutting Machine, Crafting Vinyl Cutter, Electronic Cutting Tools, High-Precision Cutting Machine

A powerful Silhouette CURIO-2 cutting machine, demonstrating its ability to cut and engrave intricate designs on different materials.

0 notes

Text

Glitter Heat Transfer Vinyl: Add Sparkle To Your Designs

In the world of garment customisation, glitter heat transfer vinyl (HTV) has become a popular choice for creating eye-catching and stylish designs. This special type of HTV allows designers to add a shimmering, textured effect to their prints, making apparel stand out with vibrant sparkle. Whether you are designing for fashion, promotional wear, or personalised gifts, glitter HTV offers a unique way to enhance your creations. In this article, let’s explore what glitter heat transfer vinyl is, its benefits, and how to use it effectively.

What is Glitter Heat Transfer Vinyl? Glitter HTV is a type of heat transfer vinyl that contains embedded glitter particles, providing a sparkly and textured appearance when applied to fabrics. It is designed to be cut into various shapes, letters, or intricate designs and then heat-pressed onto garments or accessories. Glitter HTV is available in a variety of colors, allowing for endless creative possibilities.

How Does Glitter HTV Work?

The process of using glitter HTV involves the following steps:

Designing and Cutting: Use a vinyl cutter or plotter to cut your design from the glitter HTV sheet.

Weeding: Remove the excess vinyl, leaving only the desired design on the carrier sheet.

Heat Press Application: Place the design onto the fabric and apply heat using a heat press at the recommended temperature and time.

Peeling: After pressing, remove the carrier sheet to reveal the final sparkling design.

Benefits of Glitter Heat Transfer Vinyl

Eye-Catching Sparkle: Adds a bold and glittery effect to garments, making designs stand out.

Durable and Long-Lasting: High-quality glitter HTV is resistant to washing and fading, ensuring long-lasting designs.

Versatile Application: Works on various fabrics, including cotton, polyester, blends, and more.

No Messy Glitter Fallout: Unlike loose glitter, the embedded particles stay in place, preventing unwanted glitter shedding.

Great for Fashion and Branding: Popular in custom T-shirts, dancewear, sports jerseys, and promotional apparel.

Glitter HTV vs. Other Heat Transfer Media

Glitter HTV vs. Standard HTV: Standard HTV has a smooth finish, while glitter HTV provides a textured and shiny effect.

Glitter HTV vs. Screen Printing: Screen printing requires high setup costs and is less effective for metallic or textured designs.

Glitter HTV vs. Sublimation: Sublimation printing works best on light polyester fabrics, whereas glitter HTV can be applied to a wider range of materials.

Tips for Using Glitter HTV Effectively

Use a sharp blade for cutting to ensure clean and precise edges.

Apply firm and even pressure during heat pressing to ensure strong adhesion.

Follow the manufacturer’s heat and time settings for optimal results.

Wash garments inside out and avoid high heat drying to prolong the design’s lifespan.

Conclusion

Glitter heat transfer vinyl is a fantastic way to add sparkle and personality to custom apparel. Its durability, versatility, and striking appearance make it a favorite among designers and businesses alike. Whether you're creating personalised gifts, stylish fashion pieces or promotional wear, glitter HTV ensures your designs shine bright with long-lasting glamour.

0 notes

Note

Can I ask what cutter/plotter you use? I'm hoping to invest in one but don't know what's the best option (everyone I know who binds uses cricut) I absolutely love the effects you create so would love to get your opinion on it!

OH HI I LOVE YOUR SWIMMING BEAR PLATES THEY ARE SO CUTE

I use a cricut Explorer 3! I originally got a SIlhouette portrait, because several people complained about cricut being overpriced and just not working as it should and switched over to Silhouette.

I had to send my Silhouette back because the pressure of the arm (where the needle is attached and slides back and right to cut) was not working?? It couldn't even cut through normal copy paper.

Got a Cricut then and never looked back since. I also find the Cricut Design space much easier navigate and to use than Silhouette Studio :)

I got mine brand new on Amazon, but I was told if you check your facebook marketplace, people resell theirs for quite a good price

also also, the htv vinyl also plays into how it cuts! some are softer and some are harder. I find gold htv vinyl hardest to work with, because the material seems to be very soft and keep curling up after being cut before I even weed it;;

4 notes

·

View notes

Text

Kongsberg PCS at Media Expo New Delhi

Visitors to this month’s MediaExpo in New Delhi event will discover first-hand how the Kongsberg X Series of digital cutting tables can enable businesses to boost their productivity and creativity. From 12-14 September, the Kongsberg Precision Cutting Systems (Kongsberg PCS) team will be at stand C26 of the Pragati Maidan in New Delhi, showcasing how its X24 cutting system and range of advanced tooling combine to help sign and display converters meet increasing demand and drive throughput.

“With a noticeable shift towards more eco-friendly materials, the versatility of finishing equipment becomes crucial,” said Rafiq Shaikh, sales and service leader at Kongsberg PCS. “The Kongsberg machine stands out in this regard, offering cutting and routing capabilities that allow it to efficiently process a wide range of materials with minimal setup time.

“This single machine can surpass the production speeds of traditional routers, lasers, and plotters, leading to significant savings on labor and floor space,” he said. “By integrating a Kongsberg machine into their operations, businesses can streamline production while staying aligned with the growing demand for sustainable solutions. At Media Expo New Delhi, we’ll highlight how the Kongsberg X24 Edge delivers the flexibility needed to address these current and future challenges, protecting a business's investment and equipping it for what's ahead.”

Kongsberg digital cutting tables are engineered for continuous 24/7 operation, ensuring they meet high production demands with flawless finish and precision. With a minimal learning curve, the machines do not require highly sophisticated knowledge or skills to operate, making them accessible and easy to use. Additionally, the operating costs are kept low thanks to their efficient power consumption and minimal need for consumables. This combination of reliability, ease of use, and cost-effectiveness makes Kongsberg machines an excellent investment for businesses looking to optimize their production processes.

“The Kongsberg X24 Edge can easily handle the full spectrum of display, signage and packaging materials from kiss-cutting vinyl through to heavy-duty milling,” said Rafiq. “There is no sacrifice on machine configuration with all the X-Series options available, and perhaps most importantly the X24 Edge can evolve to keep pace with the changing demands of a business, and those of their customers.

“At Kongsberg PCS, we are harnessing the latest technology in solutions that meet the challenge of delivering the creative freedom demanded by consumers,” added Rafiq. “Throughout this event, we will demonstrate how the wide range of specialty tools ensures the cutting system can easily handle a wide range of applications to bring the most creative designs to life without compromising on quality.

“Over the three days, we’ll demonstrate the routing, cutting, creasing and notching capabilities of the versatile table on a range of creative displays,” he said. “What’s more, we’ll do this using a whole range of materials - everything from acrylic, foam board and MDF through to PVC, polycarbonate and vinyl.”

Rafiq said these demonstrations would highlight the versatility of the Kongsberg X24 Edge, cutting more materials with fewer - but specialist - tools, which helps reduce stop time for greater efficiency and productivity and also reduce wastage.

“Incorporating the X24 Edge into an existing production not only enables a business to boost its throughput but also gives them the ability to accept any size order run and even expand their offering to drive overall sales,” he said. “This is particularly beneficial for those converters considering a move into packaging, with the Kongsberg X24 Edge having the versatility to switch from sign and display jobs to packaging in next to no time.

“Not only this, but the modular table can also easily be upgraded with additional tooling, speed and even acceleration to ensure it keeps up with your business demands,” he said.

To see demos of the versatile Kongsberg X24 Edge in action or to discuss your digital cutting needs, visit the Kongsberg PCS team at Stand #C26 at Media Expo New Delhi from 12-14 September 2024.

0 notes

Text

Raster To Vector Conversions

Vector Conversions is a vectorization and image editing service. Vector conversions specialize in converting bitmap images to vector ordination. Vector files are compatible with peculiarity printers and spot color hiatus, chopped-up art for vinyl signs, engravings, plotters, and site on and off. We can also generate the construction of vector lines from rough sketches.

Vector's illustration makes your business look more professional. With a clear logo and image as the face of your business, people are going to think more about you. You have invested in the right services to make your business look better. They see that you care for your image and that you want to look good for your customers.

Raster to vector conversion can help you to attract more attention and profits by giving your image a boost.

The most significant thing is that you need a vector file if you need to enlarge something like a logo or a graphic design. A raster image cannot get you the high resolution as a vector image in the case of enlargement. Our vectorization service can allow vector tracing to build any size for your image.

In photography, vectorization is using specialized software to convert an image into a vector. This process ensures that images retain their shape and structural integrity even when blown up to any size. Sharpening the edges and making the colors pop out gives images a clear and crisp quality.

Some vector programs can create single-shape color gradients, but these are raster effects. A vector graphic with gradients contains both vector and raster elements and is not suitable for a process requiring 100% vector or true vector art.

For further details

Visit: www.embexpert.net

Email: [email protected].

Phone: 843-353-4577

1 note

·

View note

Text

PixMax 72cm Vinyl Cutter, SignCut Pro

Keep your vinyl cutting neat and gorgeous by using every tool at your disposal, and that definitely means this vinyl cutter plotter from PixMax. It’s beautifully designed and powerful, but extremely easy to use when you’re vinyl cutting. With this deal you’ll get: PixMax 28″ / 720mm Vinyl Cutter plotter complete with optical eye, Windows drivers and USB cable A choice of two cutting programs;…

0 notes

Text

Industrial Automatic Cloth,Carpet Cutting Machine

In the textile and garment industry, precision cutting of fabrics is a critical step in the manufacturing process. Traditional manual cutting methods are time-consuming, labor-intensive, and prone to errors. However, with the advent of industrial automatic fabric cutting machines, these challenges are being overcome.

Industrial automatic Cloth cutting machines are advanced cutting systems designed specifically for the textile industry. These machines utilize cutting-edge technology to automate the fabric cutting process, increasing efficiency, accuracy, and productivity. They employ various cutting methods, such as rotary blade cutting, laser cutting, or ultrasonic cutting, to achieve precise and clean cuts on different types of fabrics.

Carpet Cutting Machine

Cloth Digital Cutter

The Cloth Digital Cutter is a versatile cutting solution suitable for a wide range of materials, including wide range of soft and hard materials. Some examples include foam, rubber, leather, fabrics, composites, plastics, cork, paper, and even wood.. It offers high-speed cutting, exceptional precision, and a modular design that allows for customization and future upgrades. The Digital Cutter incorporates advanced cutting tools, intelligent software, and automated material handling systems, ensuring efficient and accurate fabric cutting.

A cloth digital cutter, also known as a computerized cutting machine or plotter cutter, is a device that combines the power of computer technology with precision cutting mechanisms. These machines are equipped with cutting tools, such as blades or lasers, and are controlled by specialized software that allows for precise and automated cutting of various materials. Digital cutters can handle a wide range of materials, including paper, vinyl, fabric, foam, leather, and more.

Our machine adopts advanced and mature rolling table design, the cutting width of your material can be customized according to your request, the theoretical cutting length is unlimited, with vacuum suction design (small sample adsorption is no longer difficult) and automatic camera positioning function , it can automatically finish the positioning and cutting of printing materials, and the contour can be cut without manual positioning.

The configuration of oscillating knife, drag knife strokes, tools and optional half knife, cutter, slotted knife, knife, cutter, indentation knife and other tools, can achieve the office of line drawing, cutting, cutting, dotted half cut off all the cutting and milling cutter cutting, various materials, V-CUT slot milling, pressing wheel, indentation size the utility function and so on scratch hard materials.

Benefits of cloth Digital Cutters

1. Precision and Accuracy

One of the primary advantages of digital cutters is their ability to deliver precise and accurate cuts. The advanced software used in these machines allows for intricate designs and complex cutting patterns to be executed with exceptional precision. This level of accuracy is crucial in industries where precise cutting is essential, such as graphic design and packaging.

2. Increased Efficiency and Productivity

Digital cloth cutter significantly improve efficiency and productivity by automating the cutting process. These machines can quickly and accurately cut multiple pieces in a fraction of the time it would take using manual methods. This increased efficiency allows businesses to meet tight deadlines, handle larger volumes of work, and reduce labor costs.

3. Versatility in Material Handling

Digital cutter is designed to handle a wide range of materials, making them highly versatile machines. Whether it’s cutting paper for intricate designs, vinyl for signage, or fabric for apparel production, digital cutters can adapt to different materials with ease. This versatility makes them valuable assets in industries that require diverse cutting capabilities.

4. Waste Reduction

By utilizing precise cutting patterns and nesting algorithms, digital cutters help minimize material waste. The software used in these machines optimizes the placement of designs on materials, ensuring maximum utilization and reducing unnecessary waste. This not only saves costs but also contributes to sustainable and eco-friendly practices.

5. Design Flexibility

Digital cutters offer unparalleled design flexibility, allowing businesses to create intricate and complex designs without limitations. The software used in these machines enables designers to translate their creative visions into reality, opening up a world of possibilities for customization and personalization. This flexibility is particularly valuable in industries such as signage, packaging, and apparel, where unique and eye-catching designs are essential.

Applications of Industrial Automatic Fabric Cutting Machines

Industrial automatic Carpet cutting machine find applications ina variety of industries and sectors. Some of the key applications include:

Apparel and Fashion Industry: Industrial automatic fabric cutting machines are extensively used in the apparel and fashion industry for cutting fabrics for garments, accessories, and other textile products. These machines enable precise and efficient cutting of various fabric types, helping manufacturers meet the demands of fast-paced fashion trends.

Upholstery and Furniture Manufacturing: Fabric cutting machines play a crucial role in the upholstery and furniture manufacturing industry. They ensure accurate and clean cuts of upholstery fabrics, leather, and other materials used in furniture production. The machines’ ability to handle different fabric thicknesses and textures makes them ideal for creating customized and high-quality furniture pieces.

Automotive and Aerospace Industries: Industrial automatic fabric cutting machines are also utilized in the automotive and aerospace sectors. These machines can cut fabrics used for car interiors, seat covers, headliners, and aircraft interiors. The precision cutting capabilities of these machines ensure that the fabrics fit perfectly and meet the stringent quality standards of these industries.

Technical Textiles and Industrial Applications: Technical textiles, such as those used in protective clothing, medical textiles, and industrial applications, require precise cutting to meet specific requirements. Industrial automatic fabric cutting machines can handle technical textiles with ease, ensuring accurate and clean cuts for applications such as protective gear, filtration materials, and industrial components.

Home Furnishings and Interior Design: From curtains and drapes to bedding and upholstery, industrial automatic fabric cutting machines are essential for the home furnishings and interior design industry. These machines enable manufacturers to cut fabrics in bulk, ensuring consistency and precision in the production of home textiles. They also help reduce material waste, making them cost-effective and sustainable solutions.

Fabric Cutters FAQ (Frequently Asked Questions)

1. What types of materials can be cut with a digital cutter?

Fabric Digital cutters can handle a wide range of materials, including paper, vinyl, fabric, foam, leather, cardboard, corrugated board, acrylic, and wood.

2. How precise are digital cutters?

Digital cutters offer exceptional precision and accuracy, allowing for intricate designs and complex cutting patterns. The advanced software used in these machines ensures precise cuts, minimizing errors and wastage.

3. Can digital cutters handle large volumes of work?

Yes, Fabric digital cutter are designed to handle large volumes of work efficiently. These machines automate the cutting process, significantly improving productivity and reducing production time.

4. Are digital cutters user-friendly?

Most digital cutters come with user-friendly interfaces and intuitive software, making them accessible to users with varying levels of expertise. Manufacturers often provide training and support to ensure users can maximize the capabilities of the machines.

5. How do digital cutters contribute to sustainability?

Digital cutter help reduce material waste by optimizing cutting patterns and nesting algorithms. This minimizes unnecessary waste and promotes sustainable practices. Additionally, the automation and efficiency of digital cutters reduce energy consumption and carbon footprint.

CNC DIGITAL KNIFE CUTTERProjecttion Visual Vibrating Knife Cutting Machine

CNC DIGITAL KNIFE CUTTERPP Foam | PE Foam | PVC Foam | EVA Foam Cutting Machine

CNC DIGITAL KNIFE CUTTEROscillating Cutting Machine with Automatic Feeding Device

CNC DIGITAL KNIFE CUTTEROscillating Cutter for Cardboard Craft Paper Fabric Die

CNC DIGITAL KNIFE CUTTERMulti Layer Fabric Cutting Machine

CNC DIGITAL KNIFE CUTTERIndustrial Automatic Cloth Cutting Machine

How Many Types of Automatic Digital Cutters?

Digital cutting machines are divided into digital gasket cutter, carpet cutter, fabric cutter, leather cutting tool, cardboard cutter, foam cutting system, paper cutter, film cutting tool, vinyl cutter and fiberglass cutting system.

What Are CNC Digital Knife Cutting Machines Used For?

CNC digital knife cutters are used for the cuts of special-shaped graphics made of non-metallic flexible materials. It can quickly complete various processes such as full-cut, half-cut, milling, perforate, crease and mark, solving the problems of special-shaped picture cuts, improving production efficiency, and reducing labor cost. It can reduce the defect rate caused by manual tool errors, help users complete high-quality cuts faster, more stable, and more accurately at low cost, improve user market competitiveness, and seize more market shares. Digital flatbed cutters are used in advertising packaging, clothing and footwear, automotive interiors, luggage, composite materials and other industries.

Graphics Industry

Applications: Outdoor advertising, displays, traffic signs, fleet graphics, exhibits, illuminated signage, store décor, decals, floor graphics, etc.

References: 3M, Airbus, Avery Dennison, Christinger, Fair-play, Fastsigns, Graphics Gallery, Imaba, Lufthansa, netService, PlotFactory, Quarmby Colour Studio, Sin Fung Advertisement, Stylographics, Supersine Duramark, Zebra Graphics, etc.

Packaging Industry

Applications: Printed or unprinted packaging, POP/POS displays, foam inserts, dies making.

References: Beiersdorf, Chesapeake, Edelmann, Hasbro Toys, Heidelberg, International Paper, Long Chen Paper, Mauro Benedetti, Mondi, Packaging Cooperation of America (PCA), Panther Packaging, Philip Morris, sanovi aventis, SCA,Seda, Smurfit Kappa, STI, TetraPack, Thimm Verpackung, Triwall, etc.

Leather Industry

Applications: Shoes, garments, upholstery, handbags, briefcases, car and airplane seats, etc.

References: Adidas, Akris, Bally, Cavallo, Clarks, Ecco, Gabor, Geox, Gucci, Louis Vuitton, Nike, Prada, Puma, Recaro, Rolf Benz, Samsonite, de Sede, Sergio Rossi, Timberland, etc.

Textile Industry

Applications: Garments, upholstery, airbags, flags, sun shades/umbrellas, car and airplane seats, etc.

References: BMW, Diesel, Ford, Hugo Boss, Interstuhl, Jil Sander, Joop, Levi Strauss, Mercedes, Triumph, Volkswagen, Zodiac, etc.

Composite Industry

Applications: Defense, functional textiles, rotor blades for wind wheels and helicopters, aircraft and automotive parts, etc.

References: 3C-Carbon Composite Company, ACE, Airbus, Audi, Bell Helicopter, BMW, Carbo Tech, DLR, Dyneema, Eurocopter, FACC, Ferrari, McLaren, Pilatus, Red Bull Racing, Scuderia Toro Rosso, SGL Group, ThyssenKrupp, etc.

Techtex Industry

Applications: Truck tarpaulin, carpets, awnings, hot-air balloons, sails, outdoor equipment, inflatable boats, etc.

References: Badertscher, Barrisol, Bieri, Daedler, de Sede, Eschenbach Zeltbau, Estrella Betten, Höcker HTS Structures, interstuhl, Kusch+Co, Quelli In Luce, Ruckstuhl, Sachsen Fahnen, W.Schillig, etc.

0 notes

Text

Vinyl for T-Shirt Printing with cutting plotter 🔥 Looking to elevate your t-shirt game? Discover the best Heat Transfer Vinyl for T-Shirt Printing, perfect for plotter use! 👕✨ Get the best price in India from Ditto Boss! 🇮🇳 Don't miss out on this amazing deal! 🌟

🔹 Brand: Ditto Boss 🔹 🔗👉 https://dittoboss.com/ 🌐 📞 +91 9891579158 🌟

👉 CLICK LINK IN BIO to grab yours now!

TShirtPrinting #HeatTransferVinyl #BestPrice #DittoBoss #IndiaDeals #CraftingSupplies #DIYFashion #CustomTees #VinylCutting #PlotterVinyl #CreativeDesigns #CraftingCommunity #HeatPress #VinylAddict #CraftyLife #HTV #FashionDesign #CraftingMaterials #DIYProjects #CustomApparel #TShirtDesign #CraftingIdeas #VinylProjects #HeatTransfer #BestDeals

0 notes

Text

How to Apply Easyweed Heat Transfer Vinyl?

Heat Transfer Vinyl is a fantastic tool to add to your crafting abilities. HTV will go from clothes and hats to coffee mugs and picture frames on several surfaces. Using easy weed heat transfer vinyl is a simple way to add t-shirts to lettering, photographs, and decorations. The process is fast and easy — as long as you have some simple materials and a hot iron, you can turn any shirt into a unique piece of art.

Creating Your Design :

This is the fun part, as when making your template, Easyweed heat transfer vinyl provides plenty of artistic opportunities. Bear in mind that you need to use your editing program to flip the image before printing. If you do not, the conversion would be the mirror image of what you wanted: if you are printing snowflakes, not a significant deal, but a nightmare if you have placed letters in your template. So remember always to flip the image or reverse it before printing.

Preparing the easy weed heat transfer vinyl and the Shirt :

Prewash every shirt you will be using for vinyl transfers. If you do not, when washed, the finished shirt can shrink, pulling at the edges of the vinyl and producing an unsightly look-and an uncomfortable shirt!

As for the progress, you must cut out the design using a craft knife or cutting tool until your artwork is ready to go and your clothing is washed. Realistically, your best bet is to invest in a plotter which is used to cut vinyl. Using a plotter simplifies the process rather than using a knife, as it is challenging to achieve adequate pressure and precision to cut your template effectively.

If you are using a plotter, be sure to refer to the plotter's cutting settings and the instructions given by your vinyl manufacturer. This is necessary and will save you many headaches throughout the whole process.

When you have finished cutting out the artwork using either a knife or a plotter, do not be scared if you cannot see the cuts through the translucent back paper while turning the vinyl transfer over. The vinyl material is relatively thin, so the scratches are still there but are not very noticeable.

Ironing the Vinyl Transfer :

Most easyweed heat transfers need a scorching iron environment to stick to the vinyl, so be sure to read the heat transfer vinyl's directions before ironing. Make sure to iron the shirt first to remove any wrinkles and prepare the fabric before applying your shirt's picture.

First, put the vinyl on the shirt facing down with the vinyl and face the black paper. Cover the vinyl with a towel or a handkerchief, or even better if you have a sheet of Teflon or a parchment paper. Place the iron over the towel or parchment paper that covers the vinyl and leave it in the manufacturer's instructions for the amount of time prescribed.

Finally, remove the iron and let the transfer cool down for about 30 seconds before carefully peeling the back paper off. When you peel, this will prevent smooth areas from pulling up with the backing paper.

0 notes