#Vertical Lift Module

Explore tagged Tumblr posts

Text

Friday, June 20, 2025, Kaleigh Harrison

Peru’s largest solar installation—the 300 MWdc San Martín plant—has officially entered commercial operation in Arequipa’s La Joya district. Developed by Zelestra and completed in under 18 months, the plant delivers power to Kallpa Generación through a long-term PPA. Its projected annual output of 830 GWh is expected to power approximately 440,000 homes and prevent more than 166,000 tons of CO₂ emissions each year.

The utility-scale project includes 450,000 solar modules and was delivered by Zelestra’s internal EPC division. This approach enabled the team to stay on schedule and within budget, showcasing a controlled, vertically integrated execution model that minimized delays and avoided cost overruns. Employment during peak construction reached 900 workers, offering a temporary economic lift to the region.

Latin America Expansion Gains Momentum as San Martín Sets Benchmark

The launch of San Martín marks a key step in Zelestra’s broader regional strategy. The company is currently advancing over 7 GW of solar and battery storage projects across Peru, Chile, and Colombia, with 1.7 GW under contract. As more countries in Latin America pursue decarbonization targets, San Martín serves as a model for how clean energy can scale rapidly under the right development framework.

#peru#solar power#south america#latin america#solar energy#decarbonization#good news#environmentalism#science#environment#climate change#climate crisis#green energy

14 notes

·

View notes

Text

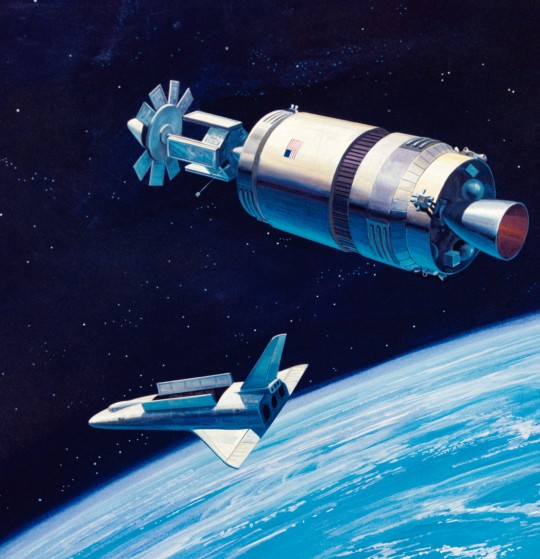

Space Shuttle Development, Phase B: North American Rockwell and General Dynamics B9U/NAR-161-B

North American and General Dynamics B9U / NAR-161-B proposed their final Phase B shuttle proposal on June 25, 1971.

"The fully reusable 'B9U / NAR-161-B' configuration would now weigh 2,290t at liftoff vs. the Phase-A limit of 1,587t and the total estimated cost of the development project had doubled, to almost $10 billion. The thrust of the space shuttle main engines had to be increased from 1,850KN to 2,450KN. Part of the problem was the shuttle now would have to be a much more versatile and capable vehicle than originally anticipated, since the space station and the manned lunar/planetary program evaporated in 1970. Critics in Congress contended that it was 'a project searching for a mission.' As a result, the new space transportation system was instead increasingly being promoted as a low-cost 'space truck' for unmanned NASA & USAF satellites."

"The North American Rockwell 'NAR-161-B' orbiter was designed for carrying a crew of two plus up to ten passengers in the forward crew module. Note the four deployable landing jet engines on top of the vehicle; NASA was planning to use modified F-15 or B-1B aircraft jet engines on some missions and for ferry flights from test sites or alternative landing fields. But the jets would be omitted for heavy-lift missions since the additional weight greatly reduced the shuttle's payload capability. The thermal protection system was based on silica tiles. The blended wing/body design was chosen for uniform load distribution. It would have produced a 2300-kilometer crossrange capability to satisfy USAF reentry requirements; North American also decided to replace the wingtip fins with a single vertical tail. The 2,450KN main engine thrust upgrade was motivated in part by the need to have a single engine-out abort capability. Analysis showed that the orbiter still would be able to return to the launch site after a single orbit in case one of its two main engines failed during ascent, but only if the engines were powerful enough. Unlike McDonnell-Douglas (who proposed to use RL-10s), North American favored a brand new oxygen/hydrogen 45KN-thrust orbital maneuvering system (OMS) engines. Three OMS engines would have been carried for orbit insertion, orbital changes and the de-orbit burn."

"General Dynamics' final 'B9U' booster design differed considerably from the earlier straight-wing 'B8D' concept. The landing jets were moved from the nose back to the delta wing in order to reduce the launch drag & heating effects and to minimize the jet engine exhaust effects on stability, control and drag. General Dynamics felt the delta wing would provide better stability & control over the entire flight regime than the B8's straight wing. It would also create more room for the main landing gear and jet engine installation. The gross liftoff mass was 1,886.2t including a jet fuel load of 62.2t for the 850km flight back to the launch site. The high staging velocity (3300m/s) and altitude (73.8km) created some problems since the booster would have to be very large, require a relatively advanced thermal protection system and carry lots of jet fuel for the return flight. The contractors also examined downrange landing sites or in-flight propellant transfer in order to reduce the amount of booster jet fuel. NASA also seriously considered a proposal to use gaseous hydrogen rather than jet fuel since it would have saved thousands of kilograms, but decided against the idea in the end since it would have increased the technical risk."

North American Rockwell Phase-B shuttle orbiter docks with modular space station.

"Payload capability (without landing jets): 29,484kg into a 185km 28.5 deg. Orbit; 18,144kg into a 185km 90 deg. polar orbit; 11,340kg into a 500km 55 deg. orbit with landing jets installed on orbiter and 20,411kg without landing engines.

Cost per mission: $100-200/lb. [1970 rates] or $950-$1900/kg in 1999. 75 missions/year max. Space station rescue mission capability within 48 hours of emergency call.

Liftoff Thrust: 2,606,810 kgf. Total Mass: 2,188,488 kg. Core Diameter: 10.4 m. Total Length: 98.0 m.

Stage Number: 1. 1 x Shuttle R134C-1 Gross Mass: 1,886,200 kg. Empty Mass: 290,000 kg. Thrust: 29,370-32,233.575 KN. Isp: 442 sec. Burn time: 209 sec. Isp(sl): 392 sec. Diameter: 10.4 m. Span: 43.9 m. Length: 82 m. Propellants: Lox/LH2 No Engines: 12. SSME Study

Stage Number: 2. 1 x Shuttle R134C-2 Gross Mass: 383,260 kg. Empty Mass: 121,560 kg. Thrust (vac): 5,624.8 KN. Isp: 459 sec. Burn time: 264 sec. Isp(sl): 359 sec. Diameter: 4.6 m. Span: 32.6 m. Length: 62.8 m. Propellants: Lox/LH2 No Engines: 2. SSME Study

- information from "INTRODUCTION TO FUTURE LAUNCH VEHICLE PLANS [1963-2001]" by Marcus Lindroos: link

SDASM Archives: 08_00941, 08_00943, 08_00944

Mike Acs's Collection: link, link

Posted on Flickr by Numbers Station: link, link, link, link, link

source

Boeing image: 71SV13043

#Space Shuttle Development#Phase B#North American Rockwell General Dynamics B9U/NAR-161-B#North American RockwellNAR-161-B#NAR-160-B#General Dynamics B9U#concept art#Space Shuttle Phase B#Space Shuttle#Orbiter#NASA#Space Shuttle Program#June#1971#B9U#my post

58 notes

·

View notes

Text

January 13, 1921 — Space engineer Philip Bono is born in Brooklyn, New York

While employed by Douglas Huntington Beach in the 1960s, Bono designed advanced heavy-lift, reusable, and single-stage-to-orbit space launch vehicles. For example, the Reusable Orbital Module-Booster & Utility Shuttle (ROMBUS) wan SSTO vertical takeoff and landing heavy-lift recoverable launch vehicle pitched as a low-cost follow-on to the Apollo program. Ithacus, an adaptation of ROMBUS, would've been used as an intercontinental military troop transport.

Read more about some of Bono's vehicle concepts here!

image credit: painted by Don Charles via Flickr

4 notes

·

View notes

Text

Warehouse automation Company in Canada and US

At Greenspace Industrial, we are at the forefront of revolutionizing the warehousing industry through our state-of-the-art Automated Storage and Retrieval Systems (ASRS) and Vertical Lift Module (VLM). As a leading Warehouse Automation Company in Canada, we pride ourselves on offering cutting-edge technologies that optimize efficiency, streamline operations, and boost productivity for businesses across Canada.

Looking to optimize your warehouse space and operations?

At Greenspace Industrial, we specialize in Automated Storage and Retrieval Systems (ASRS), Vertical Lift Modules (VLM), and advanced warehouse automation solutions. Our systems help businesses across Canada and the USA improve efficiency, reduce labor costs, and increase storage capacity.

Smart Storage Solutions Vertical Lift Modules ASRS Systems Custom Automation Setups Serving Industrial & Commercial Warehouses

📞 Contact us today for a consultation! 🌐 Visit: https://greenspaceind.com 📧 Email: [email protected]

0 notes

Text

IPAF Training: A Key to Safer Work at Height Operations

In industries where working at height is part of the daily routine, it becomes essential to be extra cautious. Safety is a priority for jobs performed in construction, facilities management, warehousing and more. When it comes to performing tasks at heights, Mobile Elevated Work Platforms (MEWPs), such as scissor lifts and cherry pickers make it easier for professionals to perform these elevated tasks. Having said this, these professionals require proper training as these machines can pose serious risks. This is where IPAF training plays a crucial role in protecting lives and promoting safer work environments.

What is IPAF Training?

The International Powered Access Federation (IPAF) is a globally recognized authority for training individuals who operate, supervise, or manage the use of MEWPs. Those opting for IPAF training courses and successfully completing them are able to safely operate various access platforms, inspect equipment before use, and respond correctly to potential hazards.

The Link Between Training and Safety

Workplace accidents involving MEWPs often occur due to:

Lack of operator awareness

Incorrect machine selection

Poor pre-use inspections

Inadequate understanding of ground conditions and surroundings

IPAF training addresses all of these areas through a structured mix of theory and practical sessions.

Key safety benefits of IPAF training

Proper equipment handling

Trained operators understand the limitations and capabilities of different MEWP types—whether it’s a static boom (1B), mobile vertical (3A), or mobile boom (3B). So, when professionals learn through these courses, they are able to use the machines correctly and in the right environment.

Accident prevention through risk awareness

IPAF courses teach hazard identification and safe planning techniques. Operators learn to assess their surroundings for power lines, unstable ground, overhead obstructions, and other potential dangers.

Harness use and fall protection

Courses like the Harness Awareness and User modules ensure that those using MEWPs understand how to properly wear and inspect fall protection gear, minimizing fall-related injuries.

Safe loading and transport

For companies that move access platforms between sites, the IPAF Load & Unload course ensures that equipment is transported safely, reducing the risk of accidents before and after MEWP use.

All in all, IPAF training is more than just a certification—it’s a critical step toward reducing workplace accidents, protecting workers, and ensuring operations run smoothly and safely. If you wish to learn these courses or want to have more information about these, you can visit our website - https://www.kentectraining.co.uk/our-courses/category/ipaf

#uk#kentectraining#constructiontraining#certificationcourse#cherry picker training#ipaf training courses#Ipaf Courses#Ipaf Training Kent

0 notes

Text

0 notes

Text

Warehouse Mezzanines: The Future of Scalable Warehouse Design

As an integrated part of the latest logistics and supply chain industry, warehouse mezzanines are no longer just an option, they are critical for easier retrieval and functioning of activities. Here at Decora Point, intelligent design means more than making space; it is about creating an environment that works efficiently. If you are setting up a new building or shifting to a new one, warehouse mezzanines are cost-effective options that enhance your space without construction.

What Is a Warehouse Mezzanine?

A warehouse mezzanine refers to an elevated platform that is constructed within a building with additional floor levels. These systems “grow up” instead of “out,” which multiplies the usable square footage by leveraging vertical space.

Unlike traditional racking systems that restrict implementation of automation technologies and shift to different operational requirements, mezzanines are customizable, dynamic, and adaptiv,e supporting workflows.

The Importance of Warehouse Mezzanines in Today's World

As the costs associated with owning and operating warehouse real estate continue to skyrocket, it is becoming harder to obtain strip malls, retail stores, and warehouses. This makes the mezzanine solution practical because it assists in addressing spatial constraints easily. Along with the e-commerce boom, companies are expected to process more orders for faster fulfillment, with little to no additional space for storage. This places immense pressure on organizations.

Vertical grippers, such as warehouse mezzanines, enable businesses to:

Enhance storage and picking locations

Increase fulfillment speed and order accuracy

Minimize off-site storage costs or expensive facility relocation

Strategic Married Design: Ground Up Efficiency.

More than simply a structure, Decora Point perceives a mezzanine as a strategic advantage. Completing design work means taking a broader perspective towards labor flow, inventory escalation, security during work hours, adaptability and future safety.

Key elements regarding design work include:

SKU Slotting: Important demand products need to be placed for simple and fast access. They should be placed at 90-degree turns and towards the end of hallways.

Labor Distribution: The Floor must be set for optimization of the workload, which is especially true for high-output environments.

Aisle Widths & Flow Paths: Proper layout increases workers' productivity.

Mezzanines and Automation Integration

The gap that exists between automation and a mezzanine is more than just a gap, it's a revolution in the warehousing industry. Robotics, like AMRs (autonomous mobile robots), vertical lifts, and smart conveyor,s can all be added to the mezzanine framework, allowing for the smooth transfer of inventory between different floors.

Apart from these innovations, robotic charging stations, pick towers, and AI-driven slotting system tools also fuel productivity and allow businesses to grow without interference.

The Importance of AI In A Mezzanine System

With the introduction of AI as well as machine learning, the whole concept of a mezzanine system has been reinvented. Analyzing the demand patterns and volatility within the stock AI assists:

Dynamic re-slotting of items and prediction of SKU movement

Workforce allocation in accordance with the real-time data and by floors

Prevention of bottlenecks

The predicted approach towards managing the warehouse turns into the need of the hour. Having such structured systems makes scaling up operations easier while allowing for multi-level investment protection.

Safety, Versatility, and Return on Investment

In all our mezzanine designs, safety and flexibility are prioritized at Decora Point. Reinforced handrails, pre-marked floors, and subdivided zones also enable better navigation and compliance with safety regulations. Moreover, greater aisle widths and adjustable racking modules simplify and reduce costs for future design and layout changes.

Some of the benefits gained from properly integrated mezzanines include:

Improved space utilization

Decreased operating expenses

Increased speed of order processing

Reduced servicing costs through more efficient overhead management

Future-Proof Your Facility with Decora Point

Investing in a warehouse mezzanine adds to the footprint but does not mechanically inflate the measurement—it allows building better, faster, and more strategically adaptable facilities. At Decora Point, we design tailored perimeter interfaces that help you with your objectives, spatially integrate within your automation systems, and utilize all available resource in the warehouse.

Want to take full advantage of your warehouse operations?

Get in touch with Decora Point now for designing a custom mezzanine solution tailored towards your present requirements and your future plans.

1 note

·

View note

Text

How Automated Storage and Retrieval Systems (ASRS) Are Redefining Modern Warehousing

In today’s high-speed, high-demand world, traditional warehousing methods are struggling to keep up. Businesses are looking for smarter ways to store, manage, and move goods with greater efficiency. Enter the automated storage and retrieval system (ASRS), one of the most transformative technologies revolutionizing supply chain operations today.

Whether you’re managing a sprawling distribution center or a compact urban warehouse, ASRS systems offer a way to streamline operations, maximize space, and drive serious productivity gains. But what exactly are automated storage systems, and why are they becoming an industry standard? Let’s dive in.

What is an Automated Storage and Retrieval System?

An automated storage and retrieval system is a type of technology that uses robotics, conveyor belts, and computerized controls to store and retrieve goods automatically. Instead of relying on workers to locate and transport items manually, ASRS systems handle the heavy lifting, literally and figuratively.

These systems are made up of several key components: storage racks, retrieval machines, conveyors, and a sophisticated software platform that manages inventory and movement. Depending on the design, automated storage systems can handle pallets, totes, cartons, or even individual items with incredible precision.

Key Benefits of ASRS Systems

1. Space Optimization Traditional warehouses leave a lot of vertical and horizontal space unused. ASRS systems are engineered to maximize every inch. By building upwards and minimizing the need for wide aisles, companies can dramatically increase their storage capacity without expanding their physical footprint.

2. Speed and Efficiency Speed is the name of the game in modern logistics. With automated storage and retrieval system, goods are located, retrieved, and delivered in a fraction of the time it would take manually. Faster picking and storage times mean quicker order fulfillment and happier customers.

3. Improved Accuracy Human error is one of the biggest challenges in warehousing. Misplaced items, wrong picks, and inventory inaccuracies can cost businesses time and money. Automated storage systems offer near-perfect precision, reducing errors and ensuring that inventory records are always up-to-date.

4. Labor Savings While ASRS doesn't eliminate the need for human workers, it does shift them away from repetitive, labor-intensive tasks. This not only reduces labor costs but also allows employees to focus on more value-added activities like quality control, inventory management, and customer service.

5. Enhanced Safety Warehouses can be dangerous environments. ASRS systems reduce the need for forklifts, ladders, and manual handling of heavy goods, leading to fewer accidents and a safer working environment.

Different Types of Automated Storage Systems

There isn’t a one-size-fits-all solution when it comes to automated storage systems. Depending on your needs, you might choose from several types of ASRS setups:

Unit Load ASRS: Designed for handling large pallets or heavy loads, commonly used in manufacturing and large distribution centers.

Mini Load ASRS: Ideal for small items stored in bins or totes, often used in e-commerce or retail operations.

Vertical Lift Modules (VLMs): Space-saving systems that store items in vertical columns and automatically bring trays to an operator at an ergonomic height.

Horizontal Carousels: Great for high-speed picking of small items, often used in pharmaceutical or parts distribution.

Each type of automated storage and retrieval system can be customized to fit a specific workflow, making ASRS highly adaptable across industries.

Is ASRS the Right Choice for Every Warehouse?

While ASRS systems offer incredible advantages, they are a significant investment. Factors like warehouse size, inventory type, order volume, and business goals all play a role in determining whether an automated storage system is the right fit.

Small warehouses with low SKU counts might not benefit as much from a full-scale ASRS as a high-volume fulfillment center would. However, with modular solutions like VLMs or mini load systems, even smaller businesses can tap into the power of automation.

Future Trends: Where Are Automated Storage Systems Heading?

The future of automated storage systems looks even more promising with advancements in artificial intelligence, machine learning, and IoT integration. Modern ASRS platforms are becoming smarter, capable of predictive maintenance, dynamic inventory optimization, and even autonomous decision-making based on real-time data.

Additionally, as e-commerce continues to skyrocket, the demand for flexible, scalable, and high-speed automated storage and retrieval systems will only grow. Warehouses of the future will rely heavily on ASRS, not just for storage, but as intelligent hubs that drive overall supply chain performance.

Investing in an automated storage and retrieval system is more than just a move toward efficiency, it’s a strategic decision that future-proofs your operations. Whether you’re looking to optimize space, boost accuracy, cut costs, or enhance safety, ASRS systems offer a proven path to better, smarter warehousing.

As supply chains become more complex and customer expectations rise, companies that embrace automated storage systems will be better positioned to compete, and win, in the marketplace. The future of warehousing isn’t just automated; it’s intelligent, scalable, and powered by innovation. Are you ready to make the move?

0 notes

Text

Four basic links of outdoor full-color LED advertising screen installation

Imagine a huge outdoor full-color LED advertising screen standing on the bustling streets, playing eye-catching advertising films, bringing a rush of customers to merchants. Behind this shocking visual effect is the hard work and rigorous process of the installation team. The installation of outdoor full-color LED advertising screens is not a simple "building blocks". They involve multiple key links, each link is crucial, and directly affects the final effect and service life of the display. Today, I will analyze in detail the four basic links of outdoor full-color LED advertising screen installation, and let you understand how this gorgeous picture is implemented step by step.

The first part: meticulous and thoughtful preliminary preparations - "Sharpening the knife will not delay the chopping of wood"

Just as detailed drawings and foundation surveys are required before building a house, the installation of outdoor full-color LED advertising screens also requires sufficient preliminary preparations. This link is crucial and determines the smooth progress of subsequent installation and the final display effect. It mainly includes the following aspects:

On-site survey and solution design: First, professional engineers are required to go to the installation site for detailed surveys to understand the actual situation of the installation environment, such as the structure of the installation wall or column, load-bearing capacity, the light conditions of the surrounding environment, the viewing distance, and the access point of the power supply and signal. Develop detailed installation plans based on the on-site situation and customer needs, including the display screen size, model, installation method, steel structure design, power load calculation, signal transmission plan, etc. Let you learn about LED rental screens vs fixed installation screens.

Approval and filing: The installation of outdoor advertising screens usually involves approval and filing by government departments. You need to understand the relevant local laws and policies in advance, prepare relevant application materials, and then install them after approval.

Steel structure production and foundation treatment: According to the design plan, the steel structure frame for the display screen is made. The stability of the steel structure is the key to ensuring the safe operation of the display screen. For floor-standing displays, foundation treatment is also required to ensure the load-bearing capacity and stability of the foundation. The corrosion protection treatment of steel structures is also crucial and can extend its service life.

Equipment inspection and preparation: Before the equipment enters the site, comprehensive quality inspection of the modules, power supplies, control systems, wires, etc. of the LED display screen is required to ensure that all equipment is intact. At the same time, prepare the various tools, equipment and safety protective supplies you need to install. Let you learn about the LED display soft module in 5 minutes.

The second link: Stable and reliable steel structure installation-"Solid skeleton is the key"

The steel structure is the "skeleton" of the LED display screen. It carries the weight of the entire display screen and resists the influence of various natural factors, such as wind and rain. Therefore, the installation of the steel structure must be stable and reliable. This link mainly includes:

Component lifting and splicing: According to the design drawings of the steel structure, each component is transported to the installation site through lifting, etc., and splicing and assembled in a predetermined order. During the splicing process, it is necessary to strictly control the size of the components and the firmness of the connection to ensure the verticality and horizontality of the overall structure.

Welding and reinforcement: The connection between steel structural components is usually done by welding. The welding quality is directly related to the strength and stability of the steel structure. Professional welders are required to operate and conduct quality inspection of welds. If necessary, reinforcement treatment is also required to improve the overall strength of the steel structure.

Anti-corrosion treatment: After the steel structure is installed, comprehensive anti-corrosion treatment is required. Usually spraying anti-rust paint and other methods are used to prevent the steel structure from being corroded and extend its service life.

Review of embedded parts: For wall-mounted or suspended display screens, it is necessary to check the position and firmness of the embedded parts to ensure that they can reliably carry the weight of the display screen.

The third part: Precision display body installation-"Pixel-level meticulous crafting"

The installation of the display screen body is the process of accurately installing LED modules onto the steel structure frame, which directly determines the final display effect. This link requires meticulousness and patience:

Module installation: Install the LED modules one by one on the steel structure frame according to the arrangement of the design drawings. During the installation process, you need to pay attention to the flatness and uniformity of the gaps between the modules to ensure the flatness and consistency of the entire screen.

Cable connection and finishing: Connect the power cord and signal cord between each module. The connection of cables must be firm and reliable, and properly cabling and sorting to avoid cable tangling and loosening, and ensure stable transmission of signals and power.

Power and Control System Installation: Install the power and control system of the display and make correct wiring. The power of the power supply must meet the needs of the display screen, and the settings of the control system must match the model and size of the display screen. Here are the size and aspect ratios of the 3x3 LED video wall.

Preliminary debugging: After the display screen is installed, a preliminary power-on test is carried out to check whether there are any modules that are not lit or display abnormalities.

Section 4: meticulous debugging and improvement—“Put the finishing touch and strive for excellence”

The installation of the display screen does not mean that the work is completed. It also requires careful debugging and improvement to present the best display effect. This link includes:

Software debugging: Install and configure the display control software to adjust brightness, color, contrast and other parameters to ensure the clarity of the picture and the accuracy of the color.

Signal debugging: Connect the signal source, test the playback effect of videos, pictures, etc., and check whether there are any problems such as screen, flashing or out-of-sync.

Protection treatment: Sealing the edges of the display screen, cable connections, etc., improve the waterproof, dustproof and lightning protection performance of the display screen to ensure its stable operation in an outdoor environment. Are LED billboards expensive? How high is the operating cost?

Whole-screen testing and acceptance: Perform a long-term full-screen testing to observe the operating status of the display to ensure there are no abnormalities. Finally, customers are invited to conduct acceptance and provide relevant technical training and after-sales service.

Conclusion

The installation of outdoor full-color LED advertising screens is a complex and meticulous process. Each link is linked together, and a professional team and rigorous operation are required to ensure the ultimate perfect presentation. From the careful preparation in the early stage, to the stable steel structure construction, to the precise screen installation and final careful debugging, every step embodies technology and experience. I hope that through the analysis of these four basic links, you can have a clearer understanding of the installation of outdoor LED advertising screens and better understand the hardships and wisdom behind the gorgeous pictures.

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: What aspects should be paid attention to when choosing a full-color LED display correctly? Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send?phone=+8613510652873&text=Hello

0 notes

Text

How to Optimize Space Utilization in Warehouse Management

Efficient warehouse management is crucial for businesses aiming to streamline operations and reduce costs. One of the most significant challenges in Warehouse Management in Dubai is optimizing space utilization to accommodate increasing inventory demands while maintaining smooth workflow operations. Proper space optimization can enhance productivity, improve inventory control, and ultimately boost profitability. This blog explores key strategies for maximizing space utilization in warehouse management.

1. Analyze and Plan Your Warehouse Layout

The first step to optimizing warehouse space is evaluating the current layout. Conducting a thorough analysis of space usage can help identify inefficiencies and bottlenecks. Use warehouse management software (WMS) to generate heat maps and track inventory flow. Based on this data, reconfigure storage areas to minimize travel time, streamline processes, and ensure smooth inventory movement.

2. Implement Vertical Storage Solutions

Maximizing vertical space is an effective way to optimize warehouse storage. Instead of expanding floor space, consider using high-rise shelving, mezzanine floors, and stackable storage systems. Investing in automated vertical lift modules (VLMs) can further improve efficiency by reducing manual labor and retrieving items quickly from elevated storage locations.

3. Adopt Smart Inventory Management Techniques

An effective inventory management system can significantly enhance space utilization. Consider adopting the following techniques:

ABC Analysis: Categorize inventory based on demand and storage priority.

Just-in-Time (JIT) Inventory: Maintain minimal stock levels to avoid overstocking.

FIFO and LIFO Methods: Organize inventory based on expiration or usage trends to reduce wasted space. By implementing these strategies, businesses can ensure a more efficient and organized storage system.

4. Utilize Multi-Depth Storage Systems

Traditional shelving often results in wasted space due to single-depth storage. Instead, use multi-depth storage systems like double-deep racking or drive-in racking. These solutions allow for higher storage density while maintaining accessibility to inventory.

5. Leverage Automated Warehouse Systems

Automation can greatly improve space optimization by reducing the need for wide aisles and manual handling. Some automated solutions include:

Automated Guided Vehicles (AGVs): For efficient material handling and reduced congestion.

Conveyor Systems: To streamline inventory movement and maximize space.

Robotic Picking Systems: Which can reduce aisle space while improving picking accuracy and speed.

6. Optimize Aisle Width and Rack Configuration

Standardizing aisle widths and rack configurations can create more storage space. Narrow aisle racking and mobile shelving units can significantly increase storage capacity. Using specialized forklifts designed for narrow aisles can further improve efficiency in limited spaces.

7. Implement Cross-Docking Strategies

Cross-docking minimizes storage time by transferring goods directly from inbound to outbound shipments. This reduces the need for excessive storage space and enhances warehouse efficiency. Cross-docking is particularly useful for fast-moving consumer goods (FMCG) and perishable items.

8. Regularly Audit and Optimize Space Utilization

Periodic space audits ensure that storage strategies remain effective. Warehouse managers should conduct routine checks to eliminate unused or inefficiently used areas. Removing obsolete inventory and reallocating space based on changing demand patterns can help maintain optimal warehouse efficiency.

Conclusion

Optimizing space utilization is a critical aspect of Warehouse Management in Dubai, where real estate costs are high and efficiency is paramount. By implementing smart storage solutions, leveraging automation, and regularly auditing space usage, businesses can significantly improve their warehouse operations. A well-organized and space-efficient warehouse not only enhances productivity but also contributes to long-term cost savings and business growth.

0 notes

Text

Automated Storage & Retrieval Systems Market

Research suggests Automated Storage and Retrieval Systems (ASRS) are computer-controlled systems that automate storage and retrieval in warehouses, with projections showing significant market growth.

It seems likely that key types include unit-load, mini-load, vertical lift modules, and carousels, each suited for different load sizes and applications.

The evidence leans toward ASRS improving efficiency, accuracy, and space utilization, with unexpected innovations like robotic models with limbs for advanced handling since the 2010s.

What Are ASRS?

Automated Storage and Retrieval Systems (ASRS) are technology-driven solutions that use computers and robotics to automatically store and retrieve items in warehouses or storage facilities. They are designed to enhance efficiency, reduce labor costs, and optimize space, making them essential for modern supply chain management.

Types and Applications

ASRS come in various forms, such as unit-load systems for heavy pallets, mini-load systems for smaller items, and vertical lift modules for high-density storage. They are used in industries like manufacturing, distribution, and retail to streamline operations and meet high demand.

Benefits and Innovations

Research indicates ASRS can increase space utilization by up to 90%, productivity by 90%, and accuracy to 99.9%, with throughput up to 750 lines per hour per operator. An unexpected detail is the use of robotic models with limbs, radar, and computer vision since the 2010s, enabling advanced tasks like loading from trucks or picking orders.

Survey Note: Detailed Analysis of Automated Storage and Retrieval Systems (ASRS)

The Automated Storage and Retrieval Systems (ASRS) market, focusing on technology-driven solutions for automated storage and retrieval in warehouses and storage facilities, is experiencing significant growth and transformation. This note provides a comprehensive analysis of what ASRS are, their types, applications, benefits, and recent innovations, tailored for investors and business leaders seeking to understand opportunities in this dynamic sector as of March 3, 2025. The analysis is based on recent market research, industry developments, and technological advancements, with a focus on clarity and actionable insights.

Market Definition and Scope

Automated Storage and Retrieval Systems (ASRS), also known as AS/RS, are computer-controlled systems that automatically place and retrieve loads from defined storage locations in a facility. These systems integrate various technologies, such as robotics, conveyors, and inventory management software, to handle, store, and retrieve materials on demand. They are used in applications where high volume loads must be moved rapidly and accurately, and are critical for industries like manufacturing, distribution, retail, wholesale, and institutions, including libraries and self-storage facilities.

#ASRS#Automation#WarehouseAutomation#LogisticsAutomation#MaterialHandling#SupplyChain#Intralogistics#Robotics#Warehousing#ECommerce#Industry40

0 notes

Text

Material handling systems

The Ultimate Guide to Material Handling Systems: Revolutionizing the Future of Industries

In today’s fast-paced world, efficient operations are paramount for businesses across various industries. One of the key components that have led to significant improvements in operational efficiency is material handling systems. These systems are designed to move, store, and manage materials throughout the manufacturing process, warehouses, and distribution centers. In this comprehensive guide, we’ll dive deep into the different types of material handling systems, their importance, and how they’re reshaping industries globally.

What Are Material Handling Systems?

A material handling system refers to a mechanical equipment and technology designed to handle, transport, and store materials in manufacturing, warehousing, and logistics environments. These systems are crucial for streamlining processes, improving safety, reducing operational costs, and enhancing productivity. Whether it’s a conveyor system that transports goods across a factory floor or a robotic system that automates the picking and sorting of products in a warehouse, material handling systems are at the core of modern industrial operations.

Types of Material Handling Systems

The world of material handling systems is vast, with different solutions designed for various operational needs. Let's take a look at the most common types:

Conveyors: Conveyors are among the most common and widely used material handling systems. These systems allow the easy transportation of materials from one location to another, reducing the need for manual labor and improving speed and efficiency in the process.

Automated Guided Vehicles (AGVs): These are mobile robots used to move materials around a facility without human intervention. AGVs are designed to work alongside other systems in a warehouse or manufacturing plant, offering flexibility and scalability to operations.

Robotic Arms: Robotic arms are often used for tasks such as picking, packing, sorting, and palletizing goods. They’re highly efficient, accurate, and can work continuously without the need for breaks.

Crane Systems: Cranes are ideal for lifting and moving heavy or large materials, especially in industries like construction, manufacturing, and logistics. They can be designed for both indoor and outdoor environments, ensuring maximum flexibility.

Pallet Racking Systems: These are storage systems that allow businesses to store materials on pallets. They come in various configurations, such as drive-in racks, push-back racks, and selective racks, depending on the needs of the warehouse or distribution center.

Vertical Lift Modules (VLMs): These systems are used to store materials vertically, maximizing space efficiency in smaller warehouses. VLMs are perfect for industries dealing with high-density storage needs.

Why Are Material Handling Systems Important?

Material handling systems play a critical role in the operational efficiency of any industry. Below are a few reasons why these systems are indispensable:

Improved Efficiency: By automating the movement and storage of materials, businesses can significantly reduce manual labor, minimize errors, and increase throughput. Systems like conveyors and AGVs enable seamless, continuous operations that improve overall productivity.

Enhanced Safety: Material handling systems reduce the risk of workplace injuries by taking over tasks that could otherwise be hazardous for workers. Automated systems ensure that materials are handled with care, reducing accidents and injuries.

Cost Savings: Automation and material handling systems reduce the need for manual labor, which in turn cuts down on labor costs. Additionally, the increased efficiency leads to lower operational costs over time.

Space Optimization: With advanced material handling systems, companies can better utilize their space. For instance, vertical lift modules and pallet racking systems allow businesses to store more goods in a smaller footprint, reducing the need for costly expansions.

Scalability and Flexibility: As businesses grow, they can scale their material handling systems to meet new demands. Whether it’s adding more conveyors, installing robotic arms, or expanding warehouse space, the systems can evolve to meet the business’s ever-changing needs.

How Material Handling Systems Impact Different Industries

Different industries have different material handling needs. Here’s how material handling systems are used across various sectors:

Manufacturing: In manufacturing, material handling systems are used to move raw materials to production lines, transport finished goods, and even store inventory. Automated systems such as conveyors and robotic arms ensure high efficiency and consistency.

Warehousing & Distribution: For warehouses, material handling systems are essential for storing, retrieving, and sorting products. With the rise of e-commerce, systems like automated storage/retrieval systems (AS/RS) and automated guided vehicles (AGVs) have become commonplace in warehouses, ensuring quick and accurate order fulfillment.

Retail: Retailers use material handling systems for inventory management and order fulfillment. Automated systems allow for quick stocking, sorting, and even picking orders for delivery, improving customer satisfaction.

Pharmaceuticals: In the pharmaceutical industry, precise and accurate handling of materials is crucial. Material handling systems are designed to ensure that products are moved and stored in controlled conditions, maintaining the integrity and safety of the goods.

Challenges in Implementing Material Handling Systems

Despite the benefits, businesses can face challenges when integrating material handling systems into their operations:

High Initial Investment: Setting up material handling systems can require significant capital. Whether it's for conveyors, robotic arms, or other automation technologies, the upfront costs can be substantial, though the long-term savings often justify the investment.

Complexity: Implementing and maintaining automated systems requires a high level of technical expertise. Businesses need to ensure they have trained personnel to manage and troubleshoot these systems.

Integration with Existing Systems: Integrating new material handling systems into existing infrastructure can be a complex process. Companies need to ensure that new systems work seamlessly with their current operations to avoid disruptions.

FAQs on Material Handling Systems

Q1: What is the role of conveyors in material handling systems?

Conveyors are integral to material handling systems as they allow for the efficient and continuous movement of materials across a facility. Whether it’s moving raw materials to production lines or transporting finished goods to packaging areas, conveyors are versatile and essential.

Q2: How do automated guided vehicles (AGVs) improve efficiency in warehouses?

AGVs automate the process of moving materials around a warehouse, reducing the need for human intervention. They follow predetermined paths, ensuring smooth and efficient material transport, increasing the speed of order fulfillment while reducing the risk of human errors.

Q3: Can material handling systems reduce workplace injuries?

Yes, by automating tasks that are physically demanding or dangerous, material handling systems reduce the risk of injuries. For instance, robotic arms can handle hazardous materials, and conveyors can move heavy items without putting workers at risk.

Q4: Are material handling systems scalable for small businesses?

Absolutely! Many material handling systems are scalable, which makes them suitable for businesses of all sizes. Small businesses can start with a basic system and expand as they grow, ensuring that the system meets the changing needs of their operations.

Q5: What factors should be considered when choosing a material handling system?

When selecting a material handling system, businesses need to consider factors such as the size of the operation, types of materials being handled, budget, scalability, and the complexity of the system. Consulting with a material handling expert can help determine the best solution.

Conclusion

The importance of material handling systems in modern industries cannot be overstated. These systems streamline operations, reduce costs, and enhance productivity, making them crucial for businesses striving to remain competitive in today’s fast-paced world. Whether it’s for manufacturing, warehousing, or logistics, implementing the right material handling system can revolutionize your business operations.

0 notes

Text

Innovations in Fitting Solutions for Efficient Warehouse Management

Effective warehouse management is essential in logistics and supply chain operations. Optimising space, improving processes, and adapting to shifting demands are vital for efficient warehouse functioning. Recent advancements in shopfitting and warehouse fitting solutions have significantly boosted warehouse management efficiency. This article explores key innovations in this sector and their impact on warehouse operations.

Intelligent Shelving Solutions

A major advancement in warehouse fitting is the advent of intelligent shelving solutions. These systems are designed to enhance space usage and improve inventory tracking. Equipped with sensors and automation technology, smart shelving allows real-time inventory monitoring, reducing time spent on manual checks and mitigating the risks of stock shortages or surpluses.

These intelligent shelving units can be tailored to the specific requirements of a warehouse, ensuring optimal space utilisation. For instance, adjustable shelving can accommodate various item sizes, while automated vertical lift modules utilise often overlooked vertical space.

Flexible Racking Systems

Flexible racking systems have transformed the organisation and storage of goods in warehouses. These systems offer flexibility and scalability, enabling warehouses to quickly adjust to inventory and storage needs changes. Flexible racking can be easily assembled, disassembled, and reconfigured, making them ideal for warehouses that frequently experience changes in product types and volumes.

One key benefit of flexible racking systems is their ability to optimise space. Using modular components, warehouses can create customised storage solutions that maximise available space, whether in small warehouses with limited floor space or large facilities with extensive storage requirements.

Automated Storage and Retrieval Systems (AS/RS)

Automated storage and retrieval systems (AS/RS) represent some of the most advanced innovations in warehouse fitting solutions. AS/RS technology utilises computer-controlled systems to automatically place and retrieve loads from defined storage locations, enhancing efficiency by reducing manual labour and minimising errors in the storage and retrieval process.

AS/RS can significantly improve the speed and accuracy of warehouse operations, especially in high-density storage environments where space is limited, and quick access to items is crucial. Automating the storage and retrieval process allows warehouses to increase throughput, reduce labour costs, and improve overall efficiency.

Intermediate Floors (Mezzanine Floors)

Intermediate floors offer a practical solution for expanding storage capacity without needing additional floor space. These floors can be installed within an existing warehouse structure, providing extra storage space above the ground level. Intermediate floors are versatile and customisable to suit specific warehouse needs, whether for storage, office space, or production areas.

Installing intermediate floors is a cost-effective way to increase storage capacity and improve warehouse layout. Utilising vertical space allows warehouses to optimise their storage solutions and create more efficient workflows. Intermediate floors are also durable and can support heavy loads, making them suitable for various industrial applications.

Dynamic Storage Options

Dynamic storage options, such as flow racks and push-back racks, enhance warehouse operations by facilitating easy access to stored items. Flow racks use gravity to move items from the back to the front, ensuring products are always readily accessible. This system is ideal for warehouses handling high-turnover items, minimising search time and reducing inventory obsolescence risk.

Push-back racks, on the other hand, allow for deep lane storage, making them suitable for warehouses with limited floor space. These racks use nested carts that move along inclined rails, enabling multiple pallets to be stored in a single lane. Push-back racks maximise storage density and improve warehouse efficiency by reducing aisle needs and increasing space utilisation.

Integration of IoT and AI Technologies

The integration of Internet of Things (IoT) and Artificial Intelligence (AI) technologies into warehouse and shop fitting solutions is another significant innovation transforming the industry. IoT devices, such as sensors and RFID tags, enable real-time monitoring of inventory levels, environmental conditions, and equipment performance. This data can be analysed using AI algorithms to optimise operations, predict maintenance needs, and improve decision-making.

AI-powered warehouse management systems enhance inventory management by predicting demand patterns and optimising stock levels. Analysing historical data and identifying trends helps warehouses make more informed inventory replenishment decisions, reducing stockout and overstocking risks.

Eco-friendly Shopfitting Solutions

Sustainability is increasingly important in warehouse management, and innovations in shopfitting solutions reflect this trend. Eco-friendly shopfitting solutions focus on reducing the environmental impact of operations by using sustainable materials, energy-efficient lighting, and renewable energy sources.

For instance, many warehouses now incorporate LED lighting systems, which consume less energy and have a longer lifespan than traditional lighting. Additionally, using recycled materials in the construction of shelving and racking systems helps reduce the carbon footprint of warehouse operations.

Conclusion

Innovations in warehouse and shop fitting solutions are crucial in enhancing the efficiency and sustainability of warehouse management. From intelligent shelving and flexible racking to automated storage and retrieval systems, these advancements help warehouses optimise space usage, improve inventory management, and reduce operational costs. As technology continues to progress, we can expect even more innovative solutions that will further revolutionise warehouse operations, ensuring they remain efficient, adaptable, and sustainable in an ever-changing market.

#shopfitting solutions#warehouse fitting#warehouse fittings solutions#warehouse fitting manufacturer#warehouse fitting equipment manufacturer#shopfitting warehouse shelves#shop fitting equipment#shopfitting suppliers#custom fitting solutions#retail display manufacturers#inventory shelving systems#shop display equipment#merchandising solutions#shelving systems#display shelving systems#retail shelving display

0 notes