#Waterproof Adhesives and Sealants Market Growth

Text

Innovations and Trends in the Wetroom Waterproofing Solutions Market

Introduction: Wetrooms have become increasingly popular in modern construction due to their sleek design, functionality, and accessibility. However, ensuring the waterproofing integrity of these spaces is paramount to prevent water damage and structural issues. This has led to a burgeoning market for wetroom waterproofing solutions, characterized by constant innovation and evolving trends. This comprehensive content explores the latest innovations, emerging trends, and market dynamics within the wetroom waterproofing solutions industry.

Market Overview: The global wetroom waterproofing solutions market has witnessed significant growth in recent years, driven by the booming construction industry, particularly in urban areas. Rapid urbanization, coupled with increasing disposable incomes and changing lifestyles, has fueled the demand for residential and commercial properties with modern amenities, including wetrooms. This has created a favorable environment for manufacturers and suppliers of wetroom waterproofing solutions to expand their market presence and introduce innovative products.

Innovations in Wetroom Waterproofing Solutions:

Advanced Membrane Systems: Manufacturers are developing high-performance membrane systems that offer superior waterproofing properties while being easy to install. These membranes provide a barrier against water infiltration, preventing leaks and moisture damage in wetroom environments.

Hybrid Waterproofing Technologies: Hybrid waterproofing solutions combine different materials and technologies to enhance durability and performance. These solutions often integrate elements such as liquid-applied membranes, self-adhesive tapes, and sealants to create a comprehensive waterproofing system.

Eco-Friendly Solutions: With growing environmental consciousness, there is a rising demand for eco-friendly wetroom waterproofing solutions. Manufacturers are developing products made from sustainable materials or incorporating recycled components to minimize the environmental impact of construction projects.

Smart Waterproofing Systems: Integration of smart technologies in waterproofing systems allows for real-time monitoring of moisture levels and early detection of leaks. These systems enable proactive maintenance and minimize the risk of water damage, enhancing the longevity of wetroom installations.

Emerging Trends:

Prefabricated Wetroom Modules: Prefabricated wetroom modules are gaining traction as a cost-effective and time-saving solution for construction projects. These modules come with integrated waterproofing systems, reducing on-site labor and installation time.

Customization and Design Flexibility: Consumers are increasingly seeking customizable wetroom solutions that cater to their specific design preferences and space requirements. Manufacturers are offering a wide range of colors, textures, and finishes to meet the diverse needs of customers.

Integration with Smart Home Systems: Wetroom waterproofing solutions are being integrated with smart home systems, allowing for seamless control and automation of water-related functions. This integration enhances convenience and enables remote monitoring and management of wetroom environments.

Market Dynamics:

Increasing Demand for Renovation and Remodeling: The growing trend of renovation and remodeling projects, particularly in the residential sector, is driving the demand for wetroom waterproofing solutions. Homeowners are upgrading their bathrooms to incorporate modern wetroom designs, creating opportunities for market players.

Stringent Building Regulations and Standards: Stringent building codes and regulations pertaining to waterproofing in wet areas are influencing product development and market dynamics. Manufacturers are required to adhere to these standards to ensure the safety and durability of wetroom installations.

Competition and Consolidation: The wetroom waterproofing solutions market is highly competitive, with numerous players competing based on product quality, innovation, and pricing. Consolidation activities such as mergers and acquisitions are prevalent as companies strive to strengthen their market position and expand their product portfolios.

Conclusion: The wetroom waterproofing solutions market is witnessing robust growth driven by factors such as urbanization, construction activities, and consumer preferences for modern amenities. Innovations such as advanced membrane systems, hybrid technologies, and eco-friendly solutions are reshaping the industry landscape. Emerging trends such as prefabricated modules and smart integration are providing new opportunities for market players. However, compliance with building regulations and standards remains crucial for ensuring the quality and safety of wetroom installations. Overall, the future outlook for the wetroom waterproofing solutions market is promising, fueled by ongoing advancements and evolving consumer demands.

#wetroomwaterproofing#waterproofingsolutions#constructionindustry#buildingmaterials#innovation#trends#marketanalysis

0 notes

Text

Construction Chemicals Market 2023-2031: Driving Innovation in Building Materials

The global construction chemicals market is set to witness substantial growth from 2023 to 2031, fueled by the booming construction industry, increasing infrastructure projects, and the demand for advanced building materials. Construction chemicals play a vital role in enhancing the performance, durability, and sustainability of construction materials, contributing to the development of resilient and high-quality structures. With technological advancements and sustainability concerns at the forefront, the construction chemicals market is experiencing dynamic shifts and innovations, shaping the future of the construction industry worldwide.

The construction chemicals market is experiencing steady growth globally, driven by the need for specialized chemicals and additives to improve the properties of concrete, mortar, waterproofing materials, adhesives, and sealants used in construction projects. Construction chemicals enhance the workability, strength, durability, and performance of building materials, ensuring the longevity and sustainability of structures.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3123

Market Segmentation:

By Service Type: Includes product sales, installation services, consulting services, and technical support.

By Sourcing Type: Comprises admixtures, waterproofing chemicals, adhesives and sealants, protective coatings, and others.

By Application: Covers residential, commercial, industrial, and infrastructure construction projects.

By Industry Vertical: Encompasses building & construction, infrastructure, transportation, and industrial manufacturing.

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa.

Regional Analysis:

Asia Pacific is anticipated to dominate the construction chemicals market, driven by rapid urbanization, infrastructure development, and investments in emerging economies such as China, India, and Southeast Asian countries.

North America and Europe are expected to witness steady growth, supported by stringent building codes, sustainability initiatives, and investments in green building projects.

Latin America, Middle East & Africa regions are projected to experience moderate growth, fueled by construction activities and infrastructure development projects.

Market Drivers and Challenges:

Drivers:

Increasing construction activities, infrastructure development projects, urbanization trends, and the need for high-performance and sustainable building materials.

Challenges: Fluctuating raw material prices, regulatory compliance requirements, technical challenges in product formulation, and environmental concerns related to chemical usage.

Market Trends:

Rising adoption of eco-friendly and low-VOC (volatile organic compounds) construction chemicals.

Development of smart and self-healing construction materials for enhanced durability.

Integration of nanotechnology and advanced polymers in construction chemical formulations.

Future Outlook:

The future outlook for the construction chemicals market is promising, with increasing demand for innovative and sustainable solutions driving market growth. Technological advancements, regulatory requirements, and shifts towards green building practices are expected to shape the future landscape of the construction chemicals industry.

Key Market Study Points:

Analysis of market dynamics and regulatory frameworks influencing the construction chemicals market.

Evaluation of key technological advancements and innovations in construction chemical formulations.

Assessment of market opportunities and challenges in different industry verticals and regions.

Identification of emerging trends and growth drivers driving market expansion.

Competitive Landscape:

The construction chemicals market is characterized by intense competition among key players such as BASF SE, Sika AG, Dow Inc., RPM International Inc., and MAPEI Corporation. These companies are focusing on product innovation, strategic partnerships, and investments in research and development to maintain a competitive edge in the market.

Recent Developments:

Introduction of advanced construction chemical products with improved performance characteristics and sustainability credentials.

Strategic collaborations and partnerships to expand product portfolios and global market presence.

Investments in research and development initiatives to develop next-generation construction chemical solutions.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=3123<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Polyurethane Sealants, Global Market Size Forecast, Top 10 Players Rank and Market Share

Polyurethane Sealants Market Summary

According to the new market research report “Global Polyurethane Sealants Market Report 2023-2029”, published by QYResearch, the global Polyurethane Sealants market size is projected to reach USD 3.92 billion by 2029, at a CAGR of 4.2% during the forecast period.

Figure. Global Polyurethane Sealants Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Polyurethane Sealants Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

Figure. Global Polyurethane Sealants Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Polyurethane Sealants Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Polyurethane Sealants include Henkel, H.B. Fuller, Sika, Arkema, Soudal, 3M, ITW Polymer Sealants, BASF, Splendor Industry, Asian Paints, etc. In 2022, the global top 10 players had a share approximately 42.0% in terms of revenue.

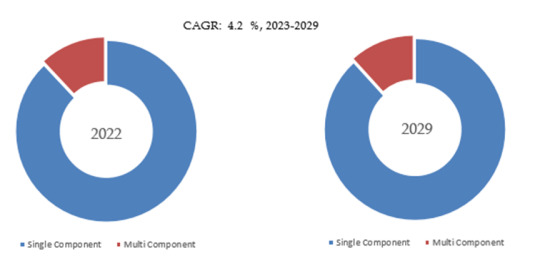

Figure. Polyurethane Sealants, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Polyurethane Sealants Market Report 2023-2029.

In terms of product type, currently Single Component is the largest segment, hold a share of 88.0%.

Figure. Polyurethane Sealants, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Polyurethane Sealants Market Report 2023-2029.

In terms of product application, currently Building & Construction is the largest segment, hold a share of 63.4%.

Figure. Polyurethane Sealants, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Polyurethane Sealants Market Report 2023-2029.

Market Drivers:

The polyurethane sealants market is driven by several key factors. Firstly, the continuous growth of the construction industry globally acts as a major driver. Polyurethane sealants find extensive use in construction applications such as joint sealing, waterproofing, and bonding due to their excellent properties including high durability, adhesion, and flexibility. Secondly, the automotive industry's expansion contributes significantly to market growth as polyurethane sealants are utilized in automotive assembly processes for bonding and sealing various components, providing structural integrity and resistance to environmental factors.

Restraint:

A significant restraint for the polyurethane sealants market is the volatility in raw material prices, particularly those derived from crude oil and petrochemicals. Fluctuations in raw material costs can impact production expenses, leading to challenges in maintaining profit margins and pricing strategies for manufacturers. This volatility poses a constraint on market growth as manufacturers need to adapt to changing cost structures and market conditions.

Opportunity:

One of the key opportunities for the polyurethane sealants market lies in the growing demand for sustainable and eco-friendly sealant solutions. With increasing environmental awareness and stringent regulations regarding emissions and sustainability, there is a rising demand for sealants with low VOC (volatile organic compound) emissions and renewable or recycled content. Manufacturers have the opportunity to capitalize on this trend by developing innovative green sealant formulations to meet market demand and regulatory requirements, thereby expanding their market share and enhancing their competitiveness.

About The Authors

Yang Min - Lead Author

Email: [email protected]

Yang Min is a market senior analyst specializing in chemical materials. Yangmin has 8 years’ experience in chemical materials market analysis, and focuses on chemical materials and API. He engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Styrene Block Copolymer (SBC) Market Assessment: Current Status and Outlook

Styrene Block Copolymers (SBCs) have established themselves as versatile materials in the realm of polymers, offering a unique combination of properties that cater to diverse applications across industries. This blog delves into the dynamics of the global Styrene Block Copolymer market, exploring its demand drivers, applications, emerging trends, and future prospects.

Understanding Styrene Block Copolymers (SBCs):

Styrene Block Copolymers thermoplastic elastomers composed of styrene and diene monomers arranged in a block structure. This distinctive molecular arrangement imparts SBCs with characteristics of both thermoplastics and elastomers, including flexibility, resilience, and processability, making them ideal for various applications.

Demand Drivers:

Adhesive and Sealant Industry: SBCs serve as key ingredients in adhesive and sealant formulations, offering excellent adhesion, tackiness, and cohesion properties, driving demand in the construction, automotive, and packaging sectors.

Footwear and Textiles: The footwear industry extensively utilizes SBCs in the production of shoe soles and components due to their cushioning, durability, and abrasion resistance. Additionally, SBCs find applications in textile coatings, providing waterproofing and abrasion resistance.

Medical and Healthcare: SBCs are increasingly used in medical and healthcare applications, including medical adhesives, wound dressings, and drug delivery systems, benefiting from their biocompatibility and flexibility.

Consumer Goods Manufacturing: SBCs are integral in the manufacturing of consumer goods such as toys, sporting goods, and household products, owing to their versatility, durability, and aesthetic appeal.

Applications Across Industries:

Adhesives and Sealants: Construction, automotive, packaging.

Footwear and Textiles: Shoe soles, textile coatings.

Medical and Healthcare: Medical adhesives, wound dressings, drug delivery.

Consumer Goods: Toys, sporting goods, household products.

Market Trends:

Focus on Sustainability: The SBC market is witnessing a shift towards sustainable solutions, with an increasing demand for bio-based and recyclable SBCs to meet environmental concerns and regulatory requirements.

Customization and Specialty Grades: Manufacturers are offering specialized SBC formulations tailored to specific industry needs, incorporating additives and modifiers to enhance performance characteristics and address niche applications.

Technological Advancements: Ongoing research and development efforts focus on improving SBC processing techniques, exploring novel applications, and enhancing product performance to meet evolving market demands.

Future Prospects:

The global Styrene Block Copolymer market is poised for significant growth, driven by its versatility, adaptability, and increasing demand across industries. As industries continue to prioritize performance, sustainability, and innovation, SBCs are well-positioned to meet the evolving needs of diverse applications.

Conclusion:

Styrene Block Copolymers have emerged as indispensable materials in various industries, offering a unique blend of properties that address a wide range of application requirements. Navigating the global SBC market requires a deep understanding of market dynamics, emerging trends, and the evolving needs of industries. With a promising future shaped by sustainability initiatives and technological advancements, SBCs stand as versatile solutions paving the path for innovation in polymer applications worldwide.

#MarketResearch#SustainableMaterials#MarketTrends#AutomotiveApplications#PackagingMaterials#ChemicalIndustry#PolymerIndustry#StyreneBlockCopolymer

0 notes

Text

The Ultimate Guide to Choosing Waterproofing Suppliers in Qatar!

In the heart of the Arabian Peninsula lies Qatar, a country known for its towering skyscrapers, luxurious lifestyle, and, importantly, its extreme climate conditions. With temperatures that can soar above 40°C in the summer and occasional heavy rains in the winter, the need for robust waterproofing solutions cannot be overstated. Whether it’s a new construction project or a renovation, ensuring that your building is protected against water damage is paramount. This comprehensive guide aims to navigate you through the process of selecting the best waterproofing suppliers in Qatar, ensuring your project's longevity and integrity.

Understanding the Importance of Waterproofing in Qatar

Waterproofing is not just an optional addition; it’s a fundamental aspect of construction that safeguards the structural integrity of buildings. In Qatar’s harsh climate, the risk of damage caused by water ingress is significantly high. This can lead to a plethora of issues, including mold growth, structural damage, and deterioration of building materials. The right waterproofing strategy can protect your investment, extend the lifespan of your building, and ensure the safety and comfort of its occupants.

The Waterproofing Market in Qatar

The Qatari market is bustling with waterproofing suppliers and companies, each promising unparalleled products and services. However, the challenge lies in distinguishing the truly reliable and high-quality suppliers from the rest. The key is to look for companies that not only offer superior waterproofing solutions but also bring a wealth of experience, technical support, and after-sales service to the table.

Key Factors to Consider When Choosing a Waterproofing Supplier

Product Range: A reputable supplier should offer a comprehensive range of waterproofing products, from membranes and coatings to sealants and adhesives. This variety ensures that you can find all necessary solutions under one roof, tailored to different parts of your project.

Quality and Certification: Quality should never be compromised when it comes to waterproofing. Look for suppliers whose products meet international standards and come with quality certifications. This is a testament to their commitment to providing durable and effective waterproofing solutions.

Technical Expertise: The best waterproofing companies in Qatar are those that provide not just products but also valuable advice and technical support. Their expertise can guide you in selecting the right products and methods for your specific project needs.

Project Portfolio: A supplier’s past projects can offer insights into their capabilities and reliability. Companies that have supplied reputable projects in Qatar are more likely to provide quality solutions and services.

After-Sales Support: The relationship with your supplier shouldn’t end at purchase. After-sales support, including technical assistance during application and addressing any post-application issues, is crucial.

Waterproofing Solutions for Qatar’s Climate

Selecting the right waterproofing solution is critical, given Qatar's unique environmental challenges. Here are some solutions well-suited for the region:

Membrane Waterproofing: Ideal for roofs, basements, and under-tile areas, membrane waterproofing provides a robust barrier against water ingress.

Liquid Waterproofing: This versatile solution can be applied to a wide range of surfaces, offering flexibility and strong waterproofing protection.

Cementitious Waterproofing: Especially suitable for areas in direct contact with water, such as swimming pools and water tanks, cementitious waterproofing provides a durable and seamless barrier.

Navigating the Selection Process

With numerous waterproofing suppliers in Qatar, making the right choice can seem daunting. Start by conducting thorough research, both online and through industry contacts. Recommendations and reviews can provide valuable insights into a supplier’s reliability and the quality of their products and services.

Once you have shortlisted potential suppliers, engage with them directly to discuss your project requirements. This interaction can offer a deeper understanding of their expertise, customer service, and commitment to quality. Don’t hesitate to ask for product samples, technical data sheets, and case studies of previous projects.

Choosing the right waterproofing supplier in Qatar is a critical decision that can significantly impact the success and longevity of your construction project. By prioritizing quality, technical support, and a comprehensive product range, you can ensure that your building is well-protected against the harsh Qatari climate. Remember, the best waterproofing companies in Qatar are those that understand the local challenges and offer solutions tailored to meet these specific needs.

waterproofing is an investment in your building’s future. Take the time to select a supplier that not only provides high-quality products but also stands by your side throughout the project lifecycle. With the right partner, you can achieve a waterproofing solution that ensures the durability, safety, and comfort of your construction project for years to come.

0 notes

Text

Customized Formulations: Tailoring Chemicals to Diverse Construction Applications

The Gulf Cooperation Council (GCC) countries are renowned for their ambitious construction projects, vibrant urban landscapes, and dynamic infrastructure development. Behind the scenes of these architectural marvels lies a crucial element: construction chemicals. These specialized chemicals play a vital role in enhancing the durability, strength, and sustainability of construction materials, contributing to the longevity and performance of buildings and infrastructure. As we step into 2024, the GCC Construction Chemical Market is poised for significant growth, driven by factors such as rapid urbanization, infrastructure investments, and the adoption of advanced construction technologies. This article delves into the key trends, market dynamics, and factors shaping the GCC Construction Chemical Market in the coming years.

Market Overview:

The GCC Construction Chemical Market is experiencing robust growth, with a projected Compound Annual Growth Rate (CAGR) exceeding 7% from 2022 to 2024. This growth is fueled by factors such as increasing construction activities, government investments in infrastructure, and the demand for high-performance construction materials across the GCC region.

Key Factors Driving Growth:

Rapid Urbanization and Infrastructure Development: The GCC countries are undergoing rapid urbanization, with significant investments in infrastructure projects such as roads, bridges, airports, and smart cities. Construction chemicals play a vital role in improving the durability, performance, and longevity of these structures, driving demand for a wide range of products such as concrete admixtures, waterproofing agents, and sealants.

Focus on Sustainable Construction Practices: There is a growing emphasis on sustainability in the construction industry, driven by factors such as environmental regulations, green building certifications, and consumer preferences for eco-friendly materials. Construction chemicals that enable energy efficiency, water conservation, and waste reduction, such as low-VOC (volatile organic compound) adhesives and eco-friendly sealants, are in high demand.

Technological Advancements and Product Innovation: Manufacturers of construction chemicals are investing in research and development to introduce innovative products that address the evolving needs of the construction industry. Advanced formulations, nanotechnology-based solutions, and self-healing materials are among the innovations driving growth in the GCC Construction Chemical Market.

Infrastructure Investments and Mega Projects: Governments in the GCC region are investing heavily in infrastructure projects, including transportation networks, utilities, and mega developments such as stadiums, hotels, and commercial complexes. These projects require specialized construction chemicals for applications such as concrete repair, protective coatings, and corrosion inhibition.

Challenges and Opportunities:

While the GCC Construction Chemical Market presents significant growth opportunities, challenges such as fluctuating raw material prices, regulatory compliance, and competition from unorganized sectors remain. However, these challenges also create opportunities for innovation, collaboration, and the development of customized solutions to meet the diverse needs of construction projects in the region.

For More Info@ https://www.gmiresearch.com/report/gcc-construction-chemical-market/

Conclusion:

In 2024, the GCC Construction Chemical Market stands as a critical enabler of the region's infrastructure development, urbanization, and economic growth. As construction activities continue to expand across the GCC countries, the market's growth is not just about chemicals; it is about building stronger, more resilient communities and shaping the built environment for generations to come. The GCC Construction Chemical Market is not merely a segment of the construction industry; it is a cornerstone of progress, sustainability, and innovation in the region. In embracing the opportunities presented by rapid urbanization, sustainability goals, and technological advancements, the GCC Construction Chemical Market is not just supplying chemicals; it is laying the foundation for a brighter, more sustainable future for the GCC region and beyond.

0 notes

Text

Chlorinated Polyethylene (CPE) Market| Market Size, Analysis, Growth and Forecast, 2024 – 2028

Originally published on Technavio: Chlorinated Polyethylene (CPE) Market Analysis APAC, North America, Europe, Middle East and Africa, South America - US, China, Japan, South Korea, Germany - Size and Forecast 2024-2028

The Chlorinated Polyethylene (CPE) Market is poised for significant growth across multiple regions including APAC, North America, Europe, the Middle East and Africa, and South America during the forecast period from 2024 to 2028. The market outlook is influenced by various factors such as increasing demand from end-use industries, technological advancements, and growing applications of CPE in various sectors.

In APAC, countries like China, Japan, and South Korea are expected to be key contributors to the growth of the CPE market. Rapid industrialization, urbanization, and infrastructure development projects in these regions are driving the demand for CPE in applications such as wires and cables, hoses and tubing, automotive parts, and construction materials. Additionally, favorable government policies and investments in the manufacturing sector further stimulate market growth.

North America and Europe are mature markets for CPE, characterized by established manufacturing industries and stringent regulations regarding product quality and environmental standards. However, continued investments in research and development, along with advancements in production technologies, are expected to fuel market growth in these regions. The US and Germany are among the leading countries driving innovation and market expansion in the CPE sector.

In the Middle East and Africa region, increasing construction activities, especially in the Gulf Cooperation Council (GCC) countries, are driving the demand for CPE-based products such as waterproofing membranes, adhesives, and sealants. South America, particularly Brazil, Argentina, and Chile, is witnessing growth in the automotive and construction sectors, driving demand for CPE-based materials for various applications.

Market analysis reveals a growing trend towards the development of eco-friendly and sustainable CPE formulations, in response to increasing environmental concerns and regulations. Manufacturers are focusing on producing bio-based and recyclable CPE materials to meet the evolving demands of environmentally-conscious consumers and comply with regulatory standards.

Key applications of CPE include impact modifiers, flame retardants, and processing aids in industries such as automotive, construction, electrical, and consumer goods. The versatility of CPE makes it a preferred choice for enhancing the performance and durability of various products and materials.

Market segmentation by product type includes CPE grades such as impact-modified, wire and cable, and thermoplastic elastomers, catering to diverse industry requirements and specifications. Additionally, distribution channels encompass direct sales, distributors, and online platforms, providing accessibility and convenience to customers.

To Learn deeper into this report , View Sample PDF

Overall, the Chlorinated Polyethylene (CPE) Market presents lucrative opportunities for manufacturers, suppliers, and stakeholders across the globe, driven by increasing industrialization, infrastructure development, and technological advancements. By understanding regional dynamics, consumer preferences, and industry trends, market players can capitalize on the growing demand for CPE and expand their market presence in the forecast period.

For more information please contact.

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email: [email protected]

Website: www.technavio.com/

0 notes

Text

Epoxy Flooring Dubai: Enhancing Durability and Protection

Introduction:

The United Arab Emirates (UAE) is known for its iconic skyscrapers, luxurious hotels, and stunning architectural marvels. However, the region's extreme climate, characterized by scorching temperatures and sporadic rainfall, poses unique challenges for construction projects. Waterproofing is a critical aspect of building maintenance and infrastructure development in the UAE, ensuring the longevity and durability of structures against water damage and moisture infiltration. In this comprehensive guide, we'll delve into the importance of waterproofing, explore the top Epoxy Flooring Dubai, and highlight key considerations for selecting the right waterproofing solutions.

Understanding the Importance of Waterproofing:

Waterproofing is the process of making a structure resistant to the ingress of water and moisture. In the UAE, where extreme weather conditions and high humidity levels are prevalent, waterproofing is essential for protecting buildings, infrastructure, and assets from water-related damage. Here are some key reasons why

waterproofing is crucial in the UAE:

Prevents Structural Damage: Water infiltration can weaken building materials, corrode steel reinforcements, and compromise the structural integrity of a building. Waterproofing systems create a barrier that prevents water from seeping into the structure, minimizing the risk of cracks, leaks, and structural damage.

Protects Against Mold and Mildew: Moisture buildup and humidity provide an ideal environment for mold and mildew growth. Waterproofing solutions inhibit the growth of mold and mildew, safeguarding indoor air quality and preventing health hazards associated with respiratory problems and allergies.

Preserves Aesthetic Appeal: Water stains, discoloration, and efflorescence can mar the appearance of buildings and infrastructure. Waterproofing coatings and sealants maintain the aesthetic appeal of surfaces, preserving their beauty and architectural integrity.

Extends Lifespan of Assets: Waterproofing extends the lifespan of buildings, infrastructure, and assets by shielding them from water-related deterioration and degradation. By investing in waterproofing solutions, property owners can avoid costly repairs and replacements in the long run.

Top Waterproofing Companies in the UAE:

The UAE boasts a robust construction industry and a plethora of waterproofing companies offering innovative solutions tailored to the region's unique climate and architectural requirements. Here are some of the top waterproofing companies in the UAE:

Drymix: Drymix is a leading provider of waterproofing solutions in the UAE, offering a comprehensive range of products and services for residential, commercial, and industrial projects. Their portfolio includes waterproofing membranes, coatings, sealants, and admixtures designed to withstand the harsh climatic conditions of the region.

Sika: Sika is a global leader in specialty chemicals and construction materials, with a strong presence in the UAE market. Their waterproofing solutions encompass a wide range of products, including liquid-applied membranes, cementitious coatings, and injection systems, catering to various waterproofing needs and applications.

BASF: BASF is a multinational chemical company that offers innovative solutions for construction, including waterproofing systems and building materials. Their portfolio includes high-performance waterproofing membranes, sealants, and additives designed to enhance durability and protect structures from water damage.

Alchimica: Alchimica is a renowned manufacturer of polyurethane waterproofing systems, with a focus on sustainable and environmentally friendly solutions. Their products range from liquid-applied membranes and coatings to polyurethane injection systems, providing reliable waterproofing solutions for roofs, basements, and foundations.

Henkel: Henkel is a global leader in adhesive technologies and construction chemicals, offering a wide range of waterproofing products under its renowned brands such as Loctite and Thomsit. Their portfolio includes waterproofing membranes, sealants, and adhesives that deliver superior performance and durability in the UAE's challenging climate.

Key Considerations for Selecting Waterproofing Solutions:

When choosing waterproofing solutions for projects in the UAE, several factors should be taken into account to ensure optimal performance and longevity:

Climate Compatibility: Select waterproofing products that are specifically designed to withstand the extreme temperatures, high humidity, and occasional heavy rainfall typical of the UAE's climate. Ensure that the products offer UV resistance, thermal stability, and flexibility to accommodate temperature fluctuations.

Substrate Compatibility: Consider the type of substrate and surface conditions when selecting waterproofing solutions. Whether it's concrete, masonry, metal, or wood, choose products that adhere well to the substrate and provide seamless protection against water ingress.

Durability and Longevity: Invest in waterproofing systems that offer long-term durability and require minimal maintenance. Look for products with proven track records of performance in similar applications and environments, backed by warranties and technical support from reputable manufacturers.

Application Method: Evaluate the ease of application and compatibility with existing construction methods and techniques. Choose waterproofing systems that can be applied efficiently and effectively by skilled labor, minimizing downtime and labor costs during installation.

Environmental Impact: Consider the environmental sustainability of waterproofing products and their impact on indoor air quality, occupant health, and ecological balance. Opt for eco-friendly formulations that are low in VOCs (volatile organic compounds) and comply with green building standards and regulations.

Conclusion:

Waterproofing is a critical aspect of construction and infrastructure development in the UAE, where extreme weather conditions and high humidity levels pose significant challenges. By investing in high-quality waterproofing solutions from reputable companies, property owners and developers can protect their assets, enhance durability, and ensure long-term structural integrity. Whether it's residential buildings, commercial complexes, or industrial facilities, waterproofing plays a vital role in safeguarding structures against water-related damage and preserving their value for years to come. With the expertise of top waterproofing companies and innovative solutions tailored to the UAE's unique climate, builders and developers can achieve superior waterproofing performance and peace of mind in their projects.

0 notes

Text

Innovations in the Roofing Chemicals Market: Key Players and Emerging Technologies

The Roofing Chemicals Market encompasses a wide array of substances and materials used in the construction and maintenance of roofs. These chemicals play a crucial role in enhancing the durability, weather resistance, and overall performance of roofing systems. They are employed in various roofing applications, such as residential, commercial, and industrial, to protect structures from environmental elements like rain, UV radiation, and temperature fluctuations.

In terms of market overview and scope, the roofing chemicals industry has witnessed substantial growth in recent years. This growth can be attributed to the increasing awareness of the importance of high-quality roofing materials in ensuring structural integrity and energy efficiency. Roofing chemicals cover a broad spectrum, including sealants, adhesives, waterproofing materials, coatings, and insulation products. Their applications extend from traditional shingle and tile roofs to advanced roofing systems like green roofs and solar installations.

Roofing chemicals market growth has been driven by a variety of factors. One of the primary drivers is the global construction industry's expansion, especially in emerging economies. Increased urbanization, population growth, and a rising demand for energy-efficient buildings have further fueled the need for advanced roofing solutions. Additionally, growing concerns about climate change and sustainability have encouraged the adoption of eco-friendly roofing chemicals, contributing to market expansion.

The roofing chemicals industry is characterized by a constant evolution of materials and technologies. Manufacturers are continuously innovating to meet the demands for enhanced performance, longer lifespan, and reduced environmental impact. Trends in the market include the development of cool roofing materials that reflect sunlight and reduce heat absorption, as well as the integration of smart and self-healing materials into roofing systems for better longevity and efficiency. Moreover, there is a growing trend towards green and sustainable roofing chemicals that minimize the carbon footprint of construction projects.

In conclusion, the roofing chemicals market is a dynamic and evolving sector that plays a vital role in the construction industry. It offers a wide range of materials and solutions to meet the diverse needs of modern construction, with an increasing focus on sustainability and energy efficiency. As the construction industry continues to grow and adapt to changing environmental and economic conditions, the roofing chemicals market is expected to remain a key component of this ever-expanding sector.

0 notes

Text

U.S. Mortar and Admixtures In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

The U.S. mortar and admixtures market size was valued at $5,683.9 million in 2020 and is projected to reach $11,798.7 million by 2032, registering a CAGR of 4.3% from 2023 to 2032. Mortar and admixtures, both are construction materials widely used for construction as well as the repair or rehabilitation of masonry, concrete, natural stone, and wood structure. Mortar is made by mixing binding agents such as cement or lime, and fine aggregates such as sand, sawdust, fibers, and others. This bonding agent is used for bonding bricks, blocks, stones, and wood, and also for plastering & rendering walls, grouting, and other such applications. Furthermore, epoxy mortar, resin, thixotropic mortar, flowable mortar, 3D mortars, dehumidifying mortar, and strengthening mortars, are also a few types of mortars used in the construction and repair of the structure. Moreover, admixtures are chemicals mixed in mortar or cement to alter their properties as per the need, which includes adhesion improvers, waterproofing admixtures, quick set admixtures, and others.

The U.S. mortar and admixtures market is anticipated to witness growth at a considerable CAGR in the coming decade, however, the market is negatively impacted by the inflation triggered by the war in Ukraine and the impact of the coronavirus pandemic. The high prices of raw materials and the continued rise in the cost of energy have severe impacts on the U.S. construction sector; thereby, limiting the U.S. mortar and admixtures market growth.

The U.S. mortar and admixtures market is divided into residential, commercial, industrial, infrastructural, and others. The infrastructural segment accounted for the highest market share in 2022, owing to the growing population and urbanization, which drives the demand for infrastructure such as roads, tunnels and bridges. Such large scale undertaking is anticipated to drive tremendous demand for grouts, epoxy resin, road overlay, structure strengthening materials, shotcrete, and various other mortar and related admixtures. However, the residential segment is anticipated to register a higher growth rate during the forecast period. The residential construction in the U.S. is witnessing a steady growth owing to a gradual population rise. This is expected to drive the demand for tile grouts, wood repair mortar, board sealants, epoxy resins, strengthening materials, and other mortars and admixtures. Moreover, the house improvement sector is also experiencing growth, which is also expected to drive the demand.

Competition Analysis

Competitive analysis and profiles of the major players in the U.S. mortar and admixtures market are provided in the report. Major companies in the report include BASF, Fritz-Pak Corporation, LATICRETE International, Inc., Mapei S.P.A., Pidilite Industries Limited, Saint-Gobain Group, Sika AG, RPM International (The Euclid Chemical Company), W.R. Meadows, Inc., Master Builders Solutions, and Xypex Chemical Corporation.

Major players to remain competitive adopt development strategies such as product launches. For example, Sika USA launched its new ready-to-use grout at Coverings 2022 in Las Vegas. In addition, in February 2021, MAPEI launched Planibond SBA two-component, epoxy bonding adhesives made for application in segmental bridges. Similarly, in December 2021, LafargeHolcim launched TerCem™, an ultra-low carbon footprint cement offering up to 65% CO2 reduction.

Full Report With TOC:-https://www.alliedmarketresearch.com/u-s-mortar-and-admixtures-market-A191631

0 notes

Text

Super Seal PS (Pour Grade) Market Overview, Size, Share, Trend, Growth and Outlook

Polysulphide sealant, specifically pour grade polysulphide sealant, is a type of sealant commonly used in construction and civil engineering applications. It is a two-component sealant that cures to form a flexible, durable, and watertight seal. The two components typically consist of a liquid polymer base and a curing agent.

Read more@ https://supremebituchem.com/

Here are some key features and properties of polysulphide sealants:

Flexibility: Polysulphide sealants exhibit excellent flexibility, allowing them to accommodate joint movements and vibrations without cracking or losing their seal.

Chemical Resistance: They have good resistance to various chemicals, including fuels, oils, and some solvents, making them suitable for applications where exposure to such substances is expected.

Waterproofing: Polysulphide sealants provide effective waterproofing properties, making them commonly used for sealing joints in concrete structures, such as expansion joints in buildings, bridges, and dams.

Adhesion: They have good adhesion to a wide range of substrates, including concrete, metal, glass, and many plastics, ensuring a strong bond between the sealant and the surface.

Weather Resistance: Polysulphide sealants exhibit good resistance to weathering, including UV radiation, temperature extremes, and aging, which helps maintain the integrity of the seal over time.

Pour Grade: The term "pour grade" refers to the consistency of the sealant, which allows it to be poured or dispensed easily into horizontal joints or cracks. This makes it suitable for filling larger voids or sealing expansion joints in concrete pavements or other flat surfaces.

Cure Time: The curing time for polysulphide sealants can vary depending on the specific product and environmental conditions. Generally, they cure through a chemical reaction that takes place over several hours or days, forming a resilient rubber-like material.

It's important to follow the manufacturer's instructions and guidelines when using polysulphide sealants to ensure proper application and achieve the desired results. Additionally, safety precautions, such as wearing protective gloves and ensuring adequate ventilation, should be observed during handling and application.

0 notes

Text

Silanes Market Future Trends, Industry Size and Forecast to 2032

Silanes, a versatile group of chemical compounds composed of silicon and hydrogen, are making significant strides in transforming industries and driving innovation. The Silanes Market plays a crucial role in providing a wide range of solutions across various sectors, revolutionizing materials, coatings, adhesives, and more.

Silanes are known for their unique properties and functionalities, making them indispensable in numerous applications. These compounds possess the ability to form strong covalent bonds with both organic and inorganic materials, enabling effective adhesion, surface modification, and compatibility enhancement. They offer exceptional water repellency, weather resistance, and corrosion protection, making them valuable components in coatings, sealants, and protective finishes.

In the construction industry, silanes are widely used for their ability to enhance the durability and performance of materials. They are utilized in concrete sealants, waterproofing agents, and protective coatings, providing long-lasting protection against moisture, UV radiation, and environmental degradation. Silanes play a vital role in increasing the lifespan of infrastructure and reducing maintenance costs.

Furthermore, the automotive industry relies on silanes for a wide range of applications. Silane-based adhesion promoters are used in tire manufacturing, enhancing the bonding between rubber and metal reinforcements. They also improve the adhesion of paints and coatings to automotive surfaces, ensuring long-term durability and resistance to harsh conditions. Silanes are integral in manufacturing lightweight composites, improving mechanical properties and fuel efficiency in vehicles.

Silanes also find applications in the electronics industry, where they are utilized for surface treatment, adhesion enhancement, and moisture protection. They enable better adhesion between materials in printed circuit boards, improving performance and reliability. Silane coatings are employed in electronic displays, enabling clear visibility and protection against moisture and contaminants.

The energy sector benefits from silanes as well. Silane-based coatings are used in solar panels, providing enhanced light transmission, reducing surface reflectivity, and protecting against moisture and environmental damage. Silanes also play a role in energy storage systems, such as lithium-ion batteries, improving performance and stability.

The Silanes Market is characterized by continuous research and development efforts to expand the range of available silanes and optimize their properties. Manufacturers are investing in innovative synthesis methods and exploring new applications, driving the market forward. Additionally, the focus on sustainability and environmental regulations is driving the development of eco-friendly silane solutions with reduced toxicity and improved performance.

For More Info@ https://www.persistencemarketresearch.com/market-research/Silanes-Market.asp

As industries continue to seek solutions that enhance performance, durability, and sustainability, the Silanes Market is poised for substantial growth. With their versatile properties and wide-ranging applications, silanes are empowering innovative solutions across industries. The ongoing advancements in silane technology and the increasing demand for high-performance materials ensure that the Silanes Market will remain at the forefront of transformative advancements, driving progress in diverse sectors and shaping the future of materials science.

0 notes

Text

Silicone Resins Market Analysis by Growth: 2023, Business Dynamics, Product Segments and Regional Overview 2030

Silicone resins are a group of synthetic resins that are formed by the polymerization of siloxane monomers. These resins are characterized by their high thermal stability, weather resistance, and excellent electrical properties, making them useful in a wide range of applications. Silicone resins are often used as coatings, adhesives, and sealants due to their ability to withstand high temperatures and harsh environments. They can also be used as additives in other materials to improve their performance properties.

One of the most common applications of silicone resins is as a binder in high-temperature coatings, such as those used on automotive exhaust systems, industrial equipment, and aerospace components. These coatings provide excellent corrosion and chemical resistance and can withstand temperatures up to 600°C (1112°F). In addition to their high-temperature resistance, silicone resins also exhibit excellent electrical insulation properties, making them ideal for use in electronic components, such as potting compounds, encapsulants, and conformal coatings.

The global silicone resins market has been growing steadily over the past few years and is expected to continue to do so in the coming years. The market is primarily driven by the increasing demand for silicone resins in various end-use industries, such as automotive, construction, and electronics.

The automotive industry is a significant consumer of silicone resins, with increasing demand for high-temperature-resistant coatings and adhesives in exhaust systems, engine parts, and other components. The construction industry also accounts for a significant share of the market, with demand for silicone resins in coatings, sealants, and waterproofing applications.

The electronics industry is another major consumer of silicone resins, with increasing demand for high-performance electronic components that require excellent electrical insulation and thermal stability properties.

Geographically, Asia-Pacific is the largest market for silicone resins, driven by the growth of the automotive and electronics industries in countries such as China, Japan, and South Korea. North America and Europe are also significant markets, with increasing demand for silicone resins in various industrial applications.

Key players operating in the global silicone resins market include, Wacker Chemie AGThe Dow Chemical Company, Shin-etsu Chemical Co. Ltd., Evonik Tego Chemie, GmbH, Bluestar Silicones, Kaneka Corporations, Momentive performance materials holdings Inc., Adhis S.A.S, BRB International BV, and Siltech Corportion.

The global silicone resins market is expected to experience steady growth in the coming years, driven by several factors.

Firstly, the increasing demand for silicone resins in various end-use industries such as automotive, construction, and electronics is expected to drive market growth. The automotive industry, in particular, is a significant consumer of silicone resins due to the high-temperature resistance and excellent electrical properties of these materials.

Secondly, the growing demand for sustainable and eco-friendly products is expected to drive the development of new and innovative silicone resins with improved performance properties and reduced environmental impact.

Thirdly, the Asia-Pacific region is expected to continue to be the largest market for silicone resins due to the growth of the automotive and electronics industries in countries such as China, Japan, and South Korea. North America and Europe are also expected to experience steady growth due to increasing demand in various industrial applications.

The silicone resins market has a wide range of applications in various industries, including automotive, construction, electronics, and others. Some of the common applications of silicone resins are:

Coatings: Silicone resins are used as binders in high-temperature-resistant coatings that provide excellent corrosion resistance and durability. These coatings are used in various industries, including automotive, aerospace, and industrial equipment.

Adhesives and Sealants: Silicone resins are used as adhesives and sealants due to their excellent adhesion and weatherability properties. These are widely used in the automotive and construction industries for bonding and sealing various components.

Potting Compounds: Silicone resins are used in potting compounds, which are used to encapsulate and protect electronic components from harsh environments. These compounds provide excellent electrical insulation and thermal stability properties.

Encapsulants: Silicone resins are used as encapsulants to protect electronic components from moisture, dust, and other contaminants. These materials provide excellent protection against environmental factors and help improve the performance and reliability of electronic devices.

Waterproofing: Silicone resins are used in the construction industry for waterproofing applications, such as roofs, walls, and foundations. These materials provide excellent weatherability and durability, making them ideal for use in harsh environments.

Release Agents: Silicone resins are used as release agents in various industries, including the automotive and manufacturing industries. These agents help in the easy release of components from molds, preventing damage to the parts and molds.

The silicone resins market offers several benefits to various end-use industries, including automotive, construction, electronics, and others. Some of the key benefits of silicone resins are:

High-temperature resistance: Silicone resins offer excellent high-temperature resistance, making them ideal for use in high-temperature environments. This property is particularly important in the automotive and aerospace industries, where components operate at high temperatures.

Excellent electrical insulation: Silicone resins offer excellent electrical insulation properties, making them ideal for use in electronic components, where electrical insulation is critical.

Weatherability: Silicone resins are highly resistant to weathering, UV radiation, and moisture, making them ideal for use in outdoor applications.

Durability: Silicone resins offer excellent durability and can withstand harsh environments, making them ideal for use in various industrial applications.

Chemical resistance: Silicone resins are highly resistant to chemicals, including acids, bases, and solvents, making them ideal for use in various industrial applications.

Sustainability: Silicone resins are eco-friendly and can be recycled and reused, making them ideal for use in sustainable and green applications.

Overall, the silicone resins market offers several benefits to various industries, including high-temperature resistance, excellent electrical insulation, weatherability, durability, chemical resistance, and sustainability. These properties make them ideal for use in various industrial applications, where performance and reliability are critical.

0 notes

Text

Specialty Methacrylate Market Worth $2.91 Billion by 2028

Meticulous Research®– a leading global market research company published a research report titled “Specialty Methacrylate Market By Derivative (Lauryl Methacrylate, 1,4 Butylene Glycol Dimethacrylate), Application (Paint & Coating, Special Plastic, Construction, Additives), and End User (Automotive, Plastic & Chemical) – Global Forecasts to 2028”.

Download Sample Report : https://www.meticulousresearch.com/download-sample-report/cp_id=5027

According to this latest publication from Meticulous Research®, the global specialty methacrylate market is expected to reach $2.91 billion by 2028, at a CAGR of 4.1% during the forecast period of 2021 to 2028. The growth of this market is mainly attributed to the rising demand for lightweight vehicle parts & low carbon-emitting vehicles; increasing R&D into specialty methacrylates for various applications; increasing demand for specialty methacrylates in the construction, packaging, and paper industries; and growing focus on sustainable low-VOC products.

The market is segmented on the basis of derivative, application, end-use industry, and geography. The study also evaluates industry competitors and analyzes the market at the country level.

Based on derivative, the overall specialty methacrylate market is segmented into 1,4 Butylene Glycol Dimethacrylates, Benzyl Methacrylates, Methoxy Peg (350 to 5000) Methacrylates, Lauryl Methacrylates, Tridecyl Methacrylates, Methacrylic Ester 13.0, Triethyleneglycol Dimethacrylates, Polyethylene Glycol Dimethacrylates, Diethylene Glycol Dimethacrylates, Isodecil Methacrylates, Ethylene Glycol Dimethacrylates, 1,3 Butylene Glycol Dimethacrylates, Trimethylolpropane Trimethacrylates, Cyclohexyl Methacrylates, 2-Ethylhexyl Methacrylates, Stearyl Methacrylates, Tetrahydroforfuryl Methacrylates, Isobornyl Methacrylates, Neopentyl Glycol Dimethacrylates, BPA(Eo)N DI Methacrylates, 1,6-Hexandiol Dimethacrylates, 3,3,5 Trimethyl Cyclohexyl Methacrylates, Tetraethylene Glycol Dimethacrylates, and other derivatives. In 2021, the lauryl methacrylate segment is estimated to account for the largest share of the overall specialty methacrylates market. The large share of this segment is mainly attributed to its widening applications in floor waxes, textiles, coating, adhesives, & sealants and their rising demand from the growing construction, textile, automotive, paper & packaging, and consumer goods industries.

Based on application, the specialty methacrylate market is majorly segmented into paints & coating, adhesives & sealants, waterproofing membranes, special plastics, electrical insulation, water treatment, construction, paper & packaging, health & personal care, oil & gas, additive, textile auxiliaries, electronics, and other applications. in 2021, the paints & coatings segment is estimated to account for the largest share of the specialty methacrylates market. However, the paper & packaging application is expected to grow at a rapid pace over the forecast period, mainly due to rising health & hygiene awareness among consumers, new regulatory requirements on packaging recycling, and rising demand for packaging from growing food & beverages, pharmaceuticals, and chemicals sectors.

Based on geography, the overall market is predominantly divided into five major regions, namely, North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The Asia-Pacific is expected to command the largest share of the overall specialty methacrylate market in 2021. However, the Latin America is expected to grow at the highest CAGR during the forecast period. The fast growth of the region is mainly due to the increasing investment in infrastructural developments and the growing automotive & electronics industry.

Key Players :

Some of the key players operating in the specialty methacrylate market are Evonik Industries AG (Germany), BASF SE (Germany), Mitsubishi Chemical Holdings Corporation (Japan), Nippon Shokubai Co. Ltd. (Japan), Arkema Group (France), Showa Denko Materials Co., Ltd. (Japan), Merck KGaA (Germany), Miwon Specialty Chemical Co., Ltd. (South Korea), Fushun Donglian Anxin Chemical Co., Ltd. (China), Kyoeisha Chemical Co., Ltd. (Japan), Shin Nakamura Chemical Co., Ltd. (Japan), and CPS Performance Materials Corp. (U.S.).

Speak to our Analysts to Understand the Impact of COVID-19 on Your Business:https://www.meticulousresearch.com/speak-to-analyst/cp_id=5027

Scope of the Report

Specialty Methacrylate Market, by Derivative

Lauryl Methacrylates

1,4 Butylene Glycol Dimethacrylates

Methoxy PEG Methacrylates

Methoxy PEG 550 Methacrylate

Methoxy PEG 350 Methacrylates

Other Methoxy-PEG-Methacrylates

Benzyl Methacrylates

Tridecyl Methacrylates

Methacrylic Ester 13.0

Triethyleneglycol Dimethacrylates

Polyethylene Glycol Dimethacrylates

Polyethylene Glycol 200 Dimethacrylates (PEGDMA 200)

Polyethylene Glycol 400 Dimethacrylates (PEGDMA 400)

Polyethylene Glycol 600 Dimethacrylates (PEGDMA 600)

Other Polyethylene Glycol Dimethacrylate Derivatives

Diethylene Glycol Dimethacrylates

Isodecyl Methacrylates

Ethylene Glycol Dimethacrylates

1,3 Butylene Glycol Dimethacrylates

Trimethylolpropane Trimethacrylates

Cyclohexyl Methacrylates

2-Ethylhexyl Methacrylates

Stearyl Methacrylates

Tetrahydroforfuryl Methacrylates

Isobornyl Methacrylates

Neopentyl Glycol Dimethacrylate

BPA(EO)N Di Methacrylate

1,6-Hexandiol Dimethacrylates

3,3,5 Trimethyl Cyclohexyl Methacrylate

Tetraethylene Glycol Dimethacrylate

Other Derivatives

Specialty Methacrylate Market, by Application

Paints & Coatings

Adhesives & Sealants

Waterproofing Membranes

Special Plastics

Composites

Artificial Stones

Resin/Aggregate Flooring

PMMA Sheets

Rubber Modification

Other Special Plastics

Electrical Insulation

Water Treatment

Construction

Paper & Packaging

Health & Personal Care

Oil & Gas

Additives

Textile Auxiliaries

Electronics

Other Applications

Specialty Methacrylate Market, by End User

Paint, Coatings, and Adhesives Industry

Architecture and Construction Industry

Chemical and Plastics Industry

Packaging and Paper Industry

Automotive & Transportation Industry

Advertisement & Communication Industry

Electronics Industry

Other End Users

Here are the Top Suppliers of the Specialty Methacrylate Market

0 notes

Text

Securing Success: How Adhesives & Sealants Enhance Performance Across Industries in GCC in 2024

In the diverse landscape of construction, manufacturing, and automotive industries, adhesives and sealants play an indispensable role in bonding materials, enhancing durability, and ensuring product integrity. Across the Gulf Cooperation Council (GCC) region, comprising countries such as Saudi Arabia, the United Arab Emirates (UAE), Qatar, Oman, Bahrain, and Kuwait, the demand for adhesives and sealants continues to grow steadily. As we enter 2024, the GCC Adhesives & Sealants Market is poised for significant expansion, driven by factors such as infrastructure projects, industrial growth, and technological advancements. This article delves into the key trends, market dynamics, and factors shaping the GCC Adhesives & Sealants Market in the coming years.

Market Overview:

The GCC Adhesives & Sealants Market is experiencing robust growth, with a projected Compound Annual Growth Rate (CAGR) exceeding 5% from 2022 to 2024. This growth is fueled by factors such as the region's expanding construction and manufacturing sectors, infrastructure development projects, and the increasing adoption of advanced bonding solutions in various applications.

Key Factors Driving Growth:

Infrastructure Development: The GCC countries are investing heavily in infrastructure projects, including transportation, energy, and construction of smart cities. Adhesives and sealants are essential components in infrastructure development, used in applications such as road construction, building insulation, and waterproofing.

Industrial Growth: The industrial sector in the GCC region is witnessing significant expansion, driven by investments in petrochemicals, manufacturing, and automotive industries. Adhesives and sealants play a vital role in assembly, fabrication, and maintenance processes, contributing to the growth of the industrial adhesives market.

Technological Advancements: Technological advancements in adhesive formulations, curing technologies, and application methods are driving improvements in product performance, durability, and efficiency. Innovations such as low-VOC (volatile organic compound) formulations, UV-curable adhesives, and hybrid sealants are gaining traction in the GCC market.

Shift towards Sustainable Solutions: There is a growing emphasis on sustainability and environmental stewardship in the GCC region, leading to the adoption of eco-friendly adhesives and sealants with reduced environmental impact. Bio-based adhesives, recycled content sealants, and solvent-free formulations are becoming increasingly popular among manufacturers and end-users.

Challenges and Opportunities:

While the GCC Adhesives & Sealants Market presents significant growth opportunities, challenges such as fluctuating raw material prices, regulatory constraints, and competition from imported products remain. However, these challenges also create opportunities for industry players to innovate, invest in research and development, and collaborate on sustainable solutions to address market demands.

For More Info@ https://www.gmiresearch.com/report/gcc-adhesives-sealants-market-2019-2026/

Conclusion:

In 2024, the GCC Adhesives & Sealants Market stands as a cornerstone of industrial progress and infrastructure development in the region. As the GCC countries continue their journey towards economic diversification and sustainable growth, the market's expansion is not just about bonding materials; it is about bonding communities, industries, and aspirations for a brighter future. The GCC Adhesives & Sealants Market is not merely a segment of the chemical industry; it is a catalyst for innovation, efficiency, and progress in the Gulf Cooperation Council. In embracing infrastructure projects, industrial growth, and sustainability initiatives, the GCC Adhesives & Sealants Market is not just bonding materials; it is bonding the future of the GCC region.

0 notes

Text

Construction Chemicals Market 2022: Top Manufacturers, Production Analysis and Growth Rate Through 2030

Construction Chemicals Market is projected to be worth USD 37.55 billion by 2030, registering a CAGR of 8.60% during the forecast period 2021 - 2030

The growth of the global demand for building chemicals is powered mainly by growing investment in infrastructure development and residential construction activities worldwide. These chemicals are rapidly being used to enhance concrete performance, along with growing industry knowledge of the consistency of concrete, cement, asphalt, and other building materials. Growing urbanization and rapid population development worldwide push the development of residential projects and houses, and construction activity in both new construction and renovation and refurbishment is projected to increase over the forecast period. This, in fact, is expected to raise demand for building chemicals over the projected period.

Development is also driven by expanded spending in the Sector of Infrastructure. In addition, the government is spending heavily in infrastructure construction across the developed world to accelerate economic growth. The growing adoption of ready-mix concrete is expected to further propel the demand for construction chemicals, especially in the commercial and infrastructure sectors.

The absence of customer knowledge of chemical and building aids and lower profit margins are the factors that are projected to hinder the development of the global chemical construction market.

Market Segmentation

The global construction chemicals market, by product type, has been segmented into concrete admixtures, waterproof chemicals, flooring compounds, adhesives and sealants, and others.

By end-use, the global demand for building chemicals was segmented into domestic, commercial, manufacturing, and utilities. Owing to the growing population and urbanization, infrastructure will be the first choice for potential applicants, which would fuel the need for sustainable infrastructure and environmentally friendly goods. The residential sector is the second most lucrative category for new entrants in the demand for construction chemicals. In 2021, this sector was the biggest sales producer, representing almost half of the global industry. Leading to the rising in demand for houses and residences in urban areas, construction chemicals are commonly used in residential infrastructure.

Regional Overview

Asia-Pacific is projected to be the region's biggest and most profitable building chemicals market. Growing developments in urban construction accelerated industrialization and the rising amount of new residential building ventures are due to the fast growth of the regional sector. China is projected to be Asia-Pacific's largest market while India, led by ASEAN countries, is projected to be the fastest-growing market over the forecast period. To satisfy the rising demand for building chemicals in the country, the leading players are investing in rising their production capacity in the country.

Another prominent market for construction chemicals is expected to be in North America. Growth in the region is supported by the rebuilding of the US construction industry. As rapidly increasing urbanization needs the development of residential towers, North America has an enormous capacity for construction products, and buildings are in high demand in response to perennial urbanization worldwide. In order to offer increased structural stability and durability, building companies undertake relatively greater numbers of residential developments using high-grade construction materials.

During the review period, the European market is expected to see steady expansion. Due to economic growth and increased spending in infrastructure production, Latin America and the Near East & Africa are projected to have substantial demand for construction chemicals during the forecast period.

Access Full Report: https://www.marketresearchfuture.com/reports/construction-chemicals-market-1960

Competitive Dashboard

Some of the eminent players operating in the global construction chemicals market are LATICRETE International, Inc (US), BASF SE (Germany), Pidilite Industries Ltd (India), Tata Chemicals (India), Sika AG (Switzerland), Fosroc, Inc. (India), Henkel AG (Germany), Apple Chemie India Pvt. Ltd (India), Croda International Plc (UK), W. R. Grace & Company (US), RPM International, Inc (US), Evonik Industries AG (Germany), Huntsman International LLC (US), Dow (US), and Chemax Chemical (India).

Contact:

Market Research Future®

99 Hudson Street,5Th Floor

New York, New York 10013

United States of America

Phone:

+1 628 258 0071(US)

+44 2035 002 764(UK)

Email: [email protected]

Website: https://www.marketresearchfuture.com

#Construction Chemical Industry research#Construction Chemical Market Size#Construction Chemical Market Share#Construction Chemical Market Regional Analysis

0 notes