#WeldedStructures

Explore tagged Tumblr posts

Text

The forge KB Schmiedetechnik��is located in Hagen, Westphalia, with just under 100 employees. It is situated between the historic 'blade and metal' region of Solingen and 'soccer city' Dortmund, near the hilly landscape of the Sauerland.

KB specializes in the small series production of safety-critical closed-die forgings, ranging from 200 g to 130 kg in unit weight, using all steel grades, including duplex stainless steels, nickel-based superalloys, and even titanium.

Depth of Manufacturing

All production processes are carried out in-house, including CAD design, tool construction, closed-die forging, heat treatment, hardening, CNC machining, as well as testing and surface inspection in our own lab.

We process all types of steel, including carbon, alloyed, duplex, as well as nickel-based alloys and titanium.

For 20 years, we have been helping our customers optimize forgings through material flow simulation. We advise on transitioning from assemblies, such as welded structures or cast parts, to forged components with enhanced grain flow. Additionally, material flow simulation facilitates the reduction of excess material, such as flash, allowing for completely flash-free forging (depending on the geometry), which saves both material and energy.

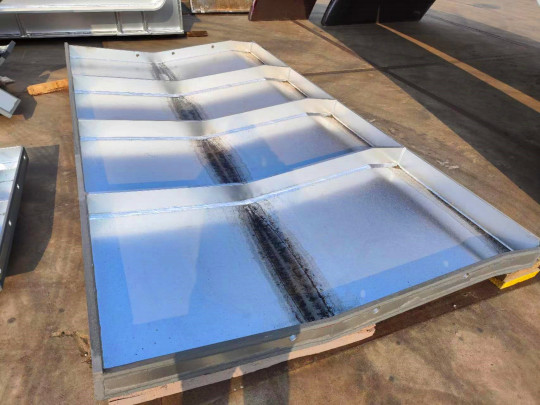

Forged components are often not only more robust and visually appealing (picture above), but also more cost-effective to produce. We assist in transitioning from assemblies, such as welded structures (right) or cast parts, to forged components (left) with enhanced grain flow.

Materials and Case Studies

Nickel (Ni) is used as an alloying element in steels to improve their toughness and ductility at low temperatures. From a nickel content of 9%, steels are considered cold-resistant and free from embrittlement. Besides steel, there are also other alloys with such properties (e.g., superalloys). Examples:

F316x – The standard chromium, nickel, and molybdenum stainless steel for cutlery, power plants, and cryogenics (10-13% Ni). Many sub-varieties with specific properties, such as: 1.4404, 1.4435, 1.4571 exist.

Monel®400 – A nickel-copper superalloy highly resistant to corrosion, particularly suitable for chemical applications, seawater, and high-temperature environments such as rocket engines (63% Ni)

Nitronic®, 1.3964, Alloy 50 – A non-magnetic chromium-nickel alloy (12.5% Ni) specifically for offshore and marine areas.

KB Schmiedetechnik GmbH holds certifications for both ISO_9001 and ISO_14001, along with various additional certifications for demanding sectors such as pressure equipment, nuclear power plants, and even five shipbuilding supplier certifications such as ABS, BV Marine & Offshore, ClassNK, DNV, and LR. Relevant documents can be downloaded from the company's website in the 'Quality' section.

At a glance

Pressure equipment and nuclear power (valves, boilers, piping):

PED 2014/68/EU, AD 2000-W0, ASME, KTA, RCC-M

Shipbuilding and ocean engineering

American Bureau of Shipping (ABS)

Bureau Veritas Marine & Offshore

Det Norske Veritas (DNV)

Lloyds Register (LR)

Nippon Kaiji Kyōkai (ClassNK)

An articles by me on the stability of forged parts of steel (it is the grain flow):

https://www.openpr.com/news/3670898/grain-flow-optimised-forgings-for-maximum-stability-in-critical

0 notes

Text

Sharing a splendid moment with the welder is concentrating on his welding work, skilled welders are the one of key factors in the success of a fabrication project, especially the high-quality requirements project like lifting equipment, mining equipment, etc

0 notes

Text

An excellent manufacturer is not only capable to produce high-quality products but also capable to do the job in a fast way. quality is important, and schedule is important too, we can do both

#customsteelfabrication#steelstructures#steelfabrication#weldedstructures#fabricationinchina#equipmentfabrication#mechanicalsteelwork#hansalgroup#quality#metalfabrication#aluminum structures

1 note

·

View note

Photo

The quiet manufacturing base during the Chinese New Year holiday, this year very special, we welcomed our client`s visit during the holiday, and the Italian client took a detailed look at our facilities, lifting capacity, and fabrication quality on the completed components. he was impressed to our well-organized workshop and looked forward to working with us on some projects together, the next step will be working closely to come out with quotation documents asap, really a good sign in the new year. As a China bridge equipment and custom steel manufacturer, we are expected to work with clients from all over the world. our products and services include: #bridgebuildingequipment,#customsteelfabrication and #steeltowerfabrrication. if any of our products and services can be helpful to your business, welcome to contact for inquiry, thanks. Email: [email protected], WhatsApp: +86 186 3853 0916 for more information,welcome to visit our pages:custom steel fabrication and bridge construction equipment #steelfabrication #steelstructures #machinefabrication #industrialequipmentfabriation #mechanicalequipmentsteelwork #mechanicalconstruction #weldedstructures #chinasteelmanufacturer #chinasteeltowermanufacturer #quality #manufacturing #projects

0 notes