#Wire and Cable Insulation and Jacketing Market Factors

Explore tagged Tumblr posts

Text

Leading Data Cable Manufacturers in India

Data cable manufacturers in India | Data cable manufacturers | Data cable manufacturers in Noida

In today's digital era, smooth communication is critical, and the foundation of every connection is a dependable data cable. Data connections are essential for charging, connecting, and sending information between mobile phones and industrial systems. When it comes to quality and creativity, Data cable manufacturers in India are gaining worldwide recognition for delivering high-performance solutions that fulfill the needs of both domestic and international customers.

Why Choose Indian Data Cable Manufacturers?

India has developed as an important hub for cable manufacture due to its mix of low-cost production, a competent workforce, and adherence to international quality standards. The country is home to various well-established businesses that provide USB cables, mobile charging cables, and diverse data transfer solutions. Leading Data cable manufacturers in India use innovative technology, high-quality raw materials such as pure copper conductors, and extensive quality testing techniques to guarantee that their products are not only dependable but also highly efficient and long-lasting.

NexTik: A Trusted Name Among Data Cable Manufacturers in India

One of the most innovative and fast-growing names in the industry is NexTik, a Noida-based brand dedicated to producing high-quality copper mobile cables. NexTik offers a diverse range of mobile charging and data cables that are designed to meet the evolving needs of today's consumers and businesses.

What sets NexTik apart is its commitment to performance, design, and durability. Every cable is built using pure copper conductors for superior signal transmission and fast charging. NexTik also focuses on enhanced shielding, advanced PVC insulation, and ergonomic design, ensuring maximum safety and efficiency in daily use.

Product Range

NexTik’s catalog includes a wide selection of mobile data cables such as:

USB Type-C to Type-C Cable: Engineered for ultra-fast data transfer and rapid charging, ideal for newer Android and smart devices.

USB to Type-C Cable: Widely compatible with smartphones, tablets, and accessories.

USB to Micro USB (Type V8) Cable: Designed for legacy Android devices, Bluetooth speakers, and older gadgets.

Type-C to Lightning Cable: Compatible with Apple devices, offering fast charging and stable connectivity.

3-in-1 Data Cable: A versatile option that supports Micro USB, Type-C, and Lightning ports in one cable, reducing clutter and increasing convenience.

Each NexTik cable is designed for strength and longevity, featuring tangle-free materials, reinforced joints, and over 10,000 bend lifespan.

What to Look for in Data Cable Manufacturers

When choosing from among the many data cable manufacturers in India, it’s important to consider a few critical factors to ensure product quality and long-term value:

1. Material Quality

Top manufacturers use high-purity copper wires and durable insulation to ensure better conductivity and performance. Pure copper ensures faster data transmission and efficient power flow, reducing charging time and improving synchronization.

2. Compatibility

With the diversity of devices in the market, data cable manufacturers must offer solutions compatible with various standards like USB-A, USB-C, Micro USB, and Apple’s Lightning connectors. NexTik, for example, designs cables for both Android and iOS platforms, making them universally suitable.

3. Durability

Quality cables should endure daily wear and tear. Look for features such as reinforced connectors, braided or thermoplastic elastomer (TPE) jackets, and heat-resistant materials. These help prevent fraying, breakage, or internal wire damage.

4. Safety Standards

Certified manufacturing processes ensure product safety. Trustworthy Indian manufacturers conduct rigorous testing, including short circuit, high-voltage, and thermal tests. NexTik, for instance, follows industry best practices to offer secure and reliable performance.

5. Aesthetic and Design

Modern consumers look for style as well as substance. Many Indian manufacturers provide sleek and colorful options that align with current design trends while retaining functionality.

India’s Competitive Edge in Data Cable Manufacturing

India’s cable manufacturing sector is not just driven by cost advantage but also by a commitment to quality, R&D, and innovation. The country has several well-established cable makers who supply to telecom operators, electronics companies, OEMs, and global brands.

Leading Indian cable brands are now expanding their product portfolios to include:

Fast-charging USB cables

Fiber optic cables

HDMI and LAN cables

Custom industrial-grade data cables

This diversity and adaptability make data cable manufacturers in India the preferred partners for global businesses looking for reliable sourcing.

Benefits of Choosing Indian-Made Data Cables

Cost-Effectiveness: Competitive pricing without compromising on quality.

Customization: Flexibility to create OEM/ODM designs based on customer needs.

Scalability: Ability to meet both small and large volume orders efficiently.

Logistics Advantage: Strategic geographical location and robust supply chain systems for domestic and export markets.

Industries Served

Indian data cable manufacturers cater to a wide array of sectors, including:

Consumer Electronics

Telecommunications

Automotive

Industrial Automation

Healthcare Equipment

Education & IT Infrastructure

With the rapid digitization and increasing mobile penetration, the demand for reliable and high-performance data cables continues to surge. Indian manufacturers are rising to the occasion, delivering not only standard solutions but also innovative designs tailored for smart devices and IoT applications.

Conclusion

The growing number of Data cable manufacturers in India reflects the country’s expanding presence in the global electronics supply chain. Leading brands like NexTik are setting industry benchmarks through advanced manufacturing techniques, rigorous quality control, and an unwavering commitment to customer satisfaction. Whether you are a business sourcing bulk quantities or a consumer seeking a reliable charging cable, Indian manufacturers deliver an exceptional balance of affordability, quality, and product variety. Contact us

0 notes

Text

How Do You Ensure the Quality of Your Cables and Accessories During Production?

Production processes that ensure quality and safety during cable manufacturing are essential to meeting industry standards, meeting end user safety requirements, and meeting reliability expectations. Manufacturers must abide by stringent processes, utilize top quality materials, and test each stage of production meticulously - this article details several strategies employed by electrical cable manufacturers in Jaipur and accessory producers in order to guarantee product excellence and safeguard its end-users.

1. Selection of High-Quality Raw Materials

Producing safe and reliable cables and accessories starts with quality raw materials. High-grade conductors such as copper or aluminum ensure optimal conductivity and strength; PVC, polyethylene or cross-linked polyethylene (XLPE) insulation materials must also meet specific standards to guarantee durability and safety for production of electrical cable manufacturers.

Manufacturers typically enlist trusted suppliers to ensure that the materials comply with international standards, testing each raw material's resistance to heat, chemical exposure, and electrical conductivity prior to production. This allows manufacturers to reduce any risks associated with poor-quality materials that could compromise the final product's performance or safety.

2. Adherence to Industry Standards and Regulations

Electrical cables and accessories must meet various industry standards and regulations, such as those set forth by the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and British Standards Institution (BSI). Doing so ensures they meet safety, reliability, environmental criteria, as well as being capable of withstanding various environments or electrical loads.

Manufacturers collaborate closely with industry bodies and regulatory agencies to ensure that their production processes and products adhere to industry standards. Certifications such as the UL or CE mark guarantee that cables meet stringent performance, fire resistance and safety criteria - essential factors for building trust in the market and earning recognition among buyers.

3. Advanced Manufacturing Processes

To ensure high-quality and safe electrical cables, manufacturers employ advanced manufacturing processes. The production process involves multiple stages, from drawing the wire to applying insulation, shielding, and jacketing.

Wire Drawing: The raw metal conductors, typically copper or aluminum, are drawn through dies to create wires of specific thicknesses. This process needs to be precise, as a thinner or uneven wire could result in poor conductivity and eventual overheating or failure.

Insulation Application: After the wire is drawn, a layer of insulation is applied. The insulation material must be applied uniformly and without defects to protect the conductor and prevent short circuits. During this phase, strict checks are made to ensure that the insulation adheres properly to the wire and provides adequate protection against electrical faults, moisture, and extreme temperatures.

Extrusion Process: The insulation and jacketing are applied via an extrusion process, which ensures uniformity in thickness and consistency in quality. The extruder must maintain the right temperatures and pressures to achieve the desired qualities in the final product.

Shielding and Armoring: For some cables, an additional layer of shielding or armoring is applied to provide mechanical protection. This is especially important in harsh environments where cables are exposed to physical stress. The shielding material must be carefully selected to resist external mechanical damage, such as cuts or abrasions, while maintaining the cable’s electrical properties.

Throughout these processes, manufacturers use automated systems that ensure consistent product quality. Automated equipment helps minimize human error and ensures that every cable or accessory is produced with uniform specifications.

Conclusion

To successfully ensure the quality and safety of electrical cables and accessories during production requires an arsenal of ingredients: high-grade raw materials, strict compliance to industry standards, advanced manufacturing processes and rigorous testing. Employing these methods ensures their products perform reliably for intended uses while contributing to overall system integrity - plus electrical accessories manufacturers in Jaipur can maintain high levels of quality through constant testing, refining and refinement throughout their product's lifecycle.

0 notes

Text

Ethylene Tetrafluoroethylene (ETFE) Market[R1] Size by Research Nester Reveals the Market to Grow with a CAGR of ~7% During 2024-2036

Research Nester’s recent market research analysis on “Ethylene Tetrafluoroethylene (ETFE) Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global ethylene tetrafluoroethylene (ETFE) market in terms of market segmentation by technology, product type, application, end-use industry, and by region.

Prospering Architectural Sector to Promote Global Market Share of Ethylene Tetrafluoroethylene (ETFE)

The growing employment prospects in the field may attest to the boom in the architecture industry. For instance, the U.S. Bureau of Labour Statistics (BLS) projects that employment opportunities for architects and designers will increase by 3% between 2022 and 2030. As a result of its affordability and durability, ETFE is increasingly being used in contemporary architectural projects to construct stadiums, polytunnels, and other similar structures, which is expected to drive the worldwide ethylene tetrafluoroethylene market in the years to come. For instance, research has shown that ETFE has tremendous strength and can support 400 times its own weight in weight.

Request Report Sample@

Some of the major growth factors and challenges that are associated with the growth of the global ethylene tetrafluoroethylene (ETFE) market are:

Growth Drivers:

Increasing Investment in Clean Energy

Growing Demand from the Aviation and Aerospace Industries

Challenges:

ETFE claimed, due to the fact that its widespread use has been doubted and hindered market growth, "natural" building materials are actually plastic. The demand for ETFE is expected to decrease over the forecast period, as pollution of plastics becomes one of the world's major threats.

By product type, the global ethylene tetrafluoroethylene (ETFE) market is segmented into granule, powder and others. Granule segment is expected to garner a significant share of around ~45% in the year 2036. In addition, the increasing demand for corrosion resistant parts, insulation components, wire and cable housings, insulated steel jackets, construction films, valve casing etc. is also a factor that contributes to segment growth in global electronics as well as building industry. In fact, the US construction sector was estimated to contribute around 4 % of United States GDP in 2021.

By region, the Asia Pacific ethylene tetrafluoroethylene (ETFE) market is to generate the highest revenue by the end of 2036. The market share of ethylene tetrafluoroethylene in Asia Pacific is projected to be the largest with a share of about 36% by the end of 2036. The increase in demand for fluoropolymers which include PVDF, PTFE, ETFB, and others from the car industry due to their widespread use in lithium-ion batteries, brake systems as well as braking wear sensors is a major factor driving market growth. According to these findings, the main consumer of fluoropolymers worldwide was mainland China in 2022, accounting for 37% of PTFE consumption and around 48% of others. Thus, the market for ethylene tetrafluoroethylene is expected to also grow with other types of fluoropolymers as giant car manufacturers expand their presence in the region and vehicle production increases.

This report also provides the existing competitive scenario of some of the key players of the global thylene tetrafluoroethylene (ETFE) market which includes company profiling of Daikin Industries, Ltd., Saint-Gobain S.A., DuPont Teijin Films, Chemours Company, Foiltec, Taiyo Kogyo Co., Ltd., AGC Inc., Nitto Denko Corporation, Nippon Electric Glass Co., Ltd., Daikin Industries Ltd, MakMax Group and others.

0 notes

Text

Wire and Cable Insulation and Jacketing Market - Global Industry Outlook Research Report 2021-2026 Added By DecisionDatabases

The global Wire and Cable Insulation and Jacketing Market report offers a comprehensive assessment of the market for the forecast years. The report contains several segments and an analysis of the market trends and growth factors that are playing a vital role in the market. These factors encompass the drivers, restraints, and opportunities. This globe industry offers an outlook on the strategic development of the market in terms of revenue profits over the forecast period 2021-2026.

The key market players for the global Wire and Cable Insulation and Jacketing market are listed below:

DowDuPont

Borealis

BASF SE

Mexichem

ECC

Hitachi-cable

Shell Chemicals

SUMITOMO

Fujikura

ExxonMobil Corp

Dewei Advanced Materials

Zhonglian

CGN-DELTA

Yadong

Others

Click here to get a FREE Sample Copy of the Wire and Cable Insulation and Jacketing Market Research Report @ https://www.decisiondatabases.com/contact/download-sample-27241

The Global Wire and Cable Insulation and Jacketing Market Report is equipped with market data from 2016 to 2026. The report gives a market overview covering key drivers and risk factors. The report is bifurcated by top global manufactures mentioning sales, revenue, and prices as applicable. It also evaluates the competitive scenario of the leading players. The report expands to cover regional market data along with type and application. The report forecasts sales and revenue from 2021 to 2026. The detailed sales channel is also covered in the study.

COVID-19 Impact Analysis on Wire and Cable Insulation and Jacketing Market

The global pandemic COVID-19 has affected the Wire and Cable Insulation and Jacketing market directly or indirectly. This study covers a separate section giving an explicitly clear understanding of the aftereffects of this pandemic. The detailed study highlights the probable outcomes of this global crisis on the Wire and Cable Insulation and Jacketing industry. The impact study on production, supply-demand, and sales provides a holistic approach to the future.

Do You Have Any Query Or Report Customization? Ask Our Market Expert @ https://www.decisiondatabases.com/contact/ask-questions-27241

Why Purchase this Report?

A robust research methodology has been followed to collect data for the report. Data, thus collected passes through multiple quality checks to ensure the best quality is served.

The report gives a holistic view of the competitive scenario of the Wire and Cable Insulation and Jacketing market

The latest product launches along with technological changes and development are covered in the report.

The data analysis in the report helps in understanding the anticipated Wire and Cable Insulation and Jacketing market dynamics from 2021 to 2026.

DecisionDatabases has a vast repository of data, therefore, we can accommodate customized requirements also.

The graphs, tables and pie charts, and info-graphics covered in the report will help in a better understanding of the report.

The market drivers, restraints, upcoming opportunities, and anticipated restraints cited in the report will assist in making an informed decision.

To better understand the market scenario, the Wire and Cable Insulation and Jacketing market is segmented as below:

By Types:

PVC

Polyolefins

Polyamides

Fluoropolymers

Others

By Applications:

Jacket

Insulation

By Regions:

North America (U.S., Canada, Mexico)

Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe, CIS)

Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

Latin America (Brazil, Rest of L.A.)

The Middle East and Africa (Turkey, GCC, Rest of Middle East)

The content of the study subjects includes a total of 14 chapters:

Chapter 1: To describe Wire and Cable Insulation and Jacketing product scope, market overview, market opportunities, market driving force, and market risks. Chapter 2: To profile the top manufacturers of Wire and Cable Insulation and Jacketing, with price, sales, revenue, and global market share of Wire and Cable Insulation and Jacketing in 2018 and 2019. Chapter 3: The Wire and Cable Insulation and Jacketing competitive situation, sales, revenue, and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4: The Wire and Cable Insulation and Jacketing breakdown data are shown at the regional level, to show the sales, revenue, and growth by region, from 2015 to 2020. Chapter 5 and 6: To segment the sales by type and application, with sales market share and growth rate by type, application, from 2015 to 2020. Chapter 7, 8, 9, 10 & 11: To break the sales data at the country level, with sales, revenue, and market share for key countries in the world, from 2016 to 2021 and Wire and Cable Insulation and Jacketing market forecast, by regions, type, and application, with sales and revenue, from 2021 to 2026. Chapter 12, 13 & 14: To describe Wire and Cable Insulation and Jacketing sales channel, distributors, customers, research findings and conclusion, appendix, and data source.

Directly Purchase the Complete Global Wire and Cable Insulation and Jacketing Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-27241

About Us:

DecisionDatabases.com is a global business research report provider, enriching decision-makers, and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research reports, customized research reports, company profiles, and industry databases across multiple domains. Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise, and meaningful data at a lightning speed.

For more details: DecisionDatabases.com E-Mail: [email protected] Phone: +91 90 28 057900 Web: https://www.decisiondatabases.com/

Referral Source – https://view.publitas.com/decisiondatabases-com-_vzxge7jabyb/wire-and-cable-insulation-and-jacketing-market-research-report-from-2021-to-2026/

#Wire and Cable Insulation and Jacketing Market#Wire and Cable Insulation and Jacketing Market Size#Wire and Cable Insulation and Jacketing Market Share#Wire and Cable Insulation and Jacketing Market Trends#Wire and Cable Insulation and Jacketing Market Forecast#Wire and Cable Insulation and Jacketing Market Analysis#Wire and Cable Insulation and Jacketing Market Factors#Wire and Cable Insulation and Jacketing Market Demand

0 notes

Text

Common Mistakes to Avoid in Cable Assembly Design and Production

Extensive engineering on multiconductor cables

In the USA, the Multiconductor cable assembly options on the market are practically limitless. It can be difficult for your engineering team to determine which temperature ratings, flex ratings, shielding options, and outer jacket materials they require. On the other hand, it is common to encounter designs that reuse part numbers across assemblies. This is typically the result of using readily available components to construct in-house prototypes.

In either case, this can result in overspecified multiconductor cable, a significant cost factor.

How to avoid it?

If the high-rated multiconductor cable you were planning to use is optional to the operation of your product, you can get away with a less expensive one.

Aspects and tolerances that are excessively precise without rational reason.

When the tolerances are increased, wire-cutting machines become less efficient, the level of precision increases, the application of heat shrinks, and labels become more time-consuming. Assembly workers spend less time overall per unit of output. It is necessary to ensure that the tolerance's benefits are weighed against the amount of time and effort required to accommodate such precise dimensions.

The price of an assembly may increase as a result of dimensions that are at irregular intervals. Use safe bets such as half an inch or a quarter of an inch, which are simple fractions to grasp. Because only some people are familiar with the decimal conversion for 5/32 inches, production has slowed down. This is the core cause of the problem.

How to avoid it?

To find a solution to this issue, a good rule of thumb is that larger tolerances are preferable when precision is required. Additionally, only round, easily measured standard units of measurement should be used. At such short lengths, 1/8 inch is the smallest dimension that can be accommodated without requiring more dynamic calibration of the available tooling options. Skipping a measurement that requires extreme accuracy, if unnecessary, also can help increase productivity.

A mismatch between the gauge of the wire and the size of the terminal

In the USA, Each terminal type is compatible with a specific range of wire gauges (such as AWG 16-18 or AWG 18-22). Before continuing with the process, ensure that they are consistent with each other.

On the other hand, we occasionally encounter designs in which the terminal and wire do not fit together, despite being technically within the acceptable range.

This is because the sizes of the insulation do not correspond. UL 1015 wire, for example, has a higher voltage rating and, as a result, a larger insulation diameter. The reason for this is the larger diameter. Even though the wire may be on the larger end of the gauge range supported by the terminal, the increased thickness of the insulation diameter may render the UL 1015 wire unsuitable for use with the terminal. The gauge appears compatible on paper, but this differs from the practice case.

How to avoid it?

Things are usually different from what they appear when it comes to wire gauge ratings. You should request that your cable assembly partner double-check the pairings of your wires and terminals to ensure that there are no size incompatibilities resulting from insulation or other changes in diameter.

0 notes

Text

What is the difference between the control cable and the power cable and the introduction of the control cable?

What is a control cable? Control Cable Wire are designed for automation control, for signaling control equipment, and for measurement and adjustment. Due to the nature of the environment in which they are used, these cables must be flexible or bent.

Control cables are used in automation systems, transportation, construction, construction, mining and industry. These are multi-conductor cables. They are more commonly copper conductors due to their excellent electrical conductivity.

Control & Instrumentation & Signaling The terms control, instrumentation and signaling refer to cables that are not used to transmit electrical power. However, there are subtle differences between these terms.

Signal cables include coaxial cables, twisted pair cables, and fiber optic cables. Control wires are similar to signal cables in that both carry signals. However, signal cables carry data. Therefore, they require shielding to prevent electromagnetic interference. Conventional control cables do not always have shielding.

Another term commonly associated with control cables is instrumentation cables. Cables that fall under this definition also need to be protected against crosstalk and EMI. Sometimes the terms "control" and "instrument" are used interchangeably to refer to the same cable. Instrumentation and controls are related functions.

Type of control cable According to the primary classification VDE standard, control cables are divided into three types: CY, YY and SY. YY is a normal unshielded cable.

CY is a flexible cable that prevents EMI. It is either shielded individually or has an overall shield. SY cables have a steel wire braid for control applications that require additional mechanical protection.

The standard control cables in the market are SEOW control cables, sprinkler control cables, pallet control cables, marine control cables, etc.

The difference between power cord and control cord Both power cables and control cables are used in industrial, residential and commercial applications. Aside from their general purpose, power and control cables differ in many ways.

On the one hand, they differ in voltage. The voltage of power cables is usually 0.6/1kV or more higher than control wires. Control cables work at 300/450/600/750V.

Because power cables are used in active environments and transmit large amounts of energy, they require excellent sheathing. In power cords, the sheath is durable and resistant to a variety of external factors, including corrosion and temperature. Control wires do not require the same jacket and usually have regular PVC insulation.

Power cables require thicker insulation and jackets than control cables when used in the same environment as industry.

Control cables often have complex color coding, while power cables are usually black and white.

0 notes

Text

LV Cable and Their Applications for Home Wiring

When it comes to an understanding the cable, we begin to know the details depending on their purpose. Ribbon Electric Cables, Shielded Cables, Coaxial cable, Twisted Pair Cables and Fibre Optic Cables and whatnot. Approximately 20 different types of cables are available in the market today, designed based on their applications such as transmission to heavy industrial use. However, we tend to know all of these only when we are in need of such cables, especially when choosing them for our homes.

What kind of cables do World Wire Cables use?

World Wire Cables offers low voltage cables that are usually of 6.6kV to 33kV compacted copper material. They are generally HDPE sheathed and PVC made, which is the most preferred material for home wiring.

Polyvinyl chloride (PVC) wire is a single or multi-core PVC insulated wire. In most instances, the wire has no jacket except when it has more than one core. PVC is a thermoplastic material that softens with heat, a factor that eases wire production and allows manufacturers to extrude the PVC cable insulation.

At home, all we need is the feeder electric cable that is moisture and heavy abrasion resistance. High-density polyethylene (HDPE) protects the house's electric power and telecommunications cables. They are chemically resistant and flexible, durable and long; thereby; reducing the installation time. So, is the reason such HDPE cables or LV cables are suitable for indoors, outdoors, underground and in dry/damp areas. Such LV cables do not consume much of an electric current, the consumption might vary from 7KA/s to 10kA/s. At the same time, PVC wiring on HDPE is an add-on advantage. This does suffice all the accountability needed for home cable wiring.

Now, when you look out for cables that would be appropriate for your home, then use World Wire Cables. For more information, call us on 1800 008 799 or visit our website https://www.wwcables.com.au/products/low-voltage-cables.html

0 notes

Text

Global Wire and Cable Insulation Market to Witness Robust Expansion Throughout the Forecast Period 2021- 2027

Research reports on the 'Global Wire and Cable Insulation Market' provide a complete study of broad market share, market segmentation and global market participants. This report was created with the help of primary and secondary research methods. This report provides an in-depth study of qualitative and quantitative analysis of supply chain, consumer requirements and consumer demand.

Increased competition between the organizational and non-organization sectors and high raw material costs are expected to curb future market growth. The growing interest in segment products and demand generation in developing countries will further accelerate market growth during the forecast period. This report covers all aspects of the Wire and Cable Insulation industry, including market sales, technical thinking, and business profiles.

Key Players Mentioned:

DowDuPont,Mexichem,Hitachi-cable,BASF SE,Fujikura,SUMITOMO,ECC,Borealis,ExxonMobil Corp,Shell Chemicals,Dewei Advanced Materials,CGN-DELTA,Yadong,Zhonglian

For Right Perspective & Competitive Insights, Request a Sample @: https://imrmarketreports.com/request/14160

This report provides a thorough overview of the competitive landscape of global Wire and Cable Insulation Market and a detailed business profile of notable players in the market. Using industry standard tools like Porter's five force analysis and SWOT analysis, analysts in the report measure threats and weaknesses in key companies. The market report covers all key parameters such as product innovation, market strategy for leading companies, market share, revenue generation, the latest research and development and market expert perspectives.

Product Segment Analysis:

PVC

Polyoefins

Polyamides

Fluoropolymers

Others

Application Segment Analysis:

Insulation,Jacketing

Regional Segment Analysis: USA, Europe, Japan, China, India, South East Asia

The Global Wire and Cable Insulation Market Report was produced through extensive primary and secondary studies. The report also focuses on qualitative and quantitative assessments by analyzing data collected from industry analysts and market participants across key points in the industry's value chain, growth aspects, utilization and manufacturing capabilities.

Get Your Copy at a Discounted Rate!!! Limited Time Offer!!!: https://imrmarketreports.com/discount/14160

This report analyzes the factors affecting the Wire and Cable Insulation Market in terms of supply and demand and further assesses the market dynamics affecting the market during the forecast period e.g. drivers, restraints, opportunities and future trends. The report also provides Porter's five forces analysis of global scenarios.

The Report allows you to:

- Formulate significant competitor information, analysis and insights to improve your R&D strategy.

- Identify potentially strong product portfolios emerging players and create effective response strategies to gain a competitive edge.

- Identify and understand important and diverse types of Wire and Cable Insulation under development

- Develop market entry and market expansion strategies

- Identify the main players with the most promising pipeline to effectively plan mergers and acquisitions.

- In-depth analysis of the product's current development phase, area, and expected release date.

Key Points covered in the Wire and Cable Insulation Market Report Coverage:

1 Market share study of the top manufacturing players

2 Market share debts for the regional and country level segments

3 Premeditated references for the new competitors

4 Competitive landscaping planning the key common trends

5 Tactical endorsements in key business segments based on the market estimations

6 Market Trends (Constraints, Drivers, Opportunities, Threats, Challenges, recommendations and Investment Opportunities)

7 Company profiling with detailed strategies, financial and latest developments

8 Supply chain trends mapping the latest technological advancements

About Us:

IMR Market Reports is a visionary market research company who is ready to assist their clients to grow their business by offering strategies through our market research reports for gaining success. We have a well experienced team, who work efficiently and provides complete excellent research data in a complete sync to provide overall coverage and accurate market insights on various industries.

Contact Us:

Aditya Patil

Business Development Executive

Office Address: Office No 15, Vrundavan Commercial Complex, DP Road, Kothrud, Pune, India - 411038

Contact No:

USA: +1 (773)-382-1047

APAC: +91-818-009-6367

0 notes

Text

Several Factors Influencing the Price of Fiber Optic Patch Cords

Today's fiber optic patch cord markets are very complex. The price of a conventional 1 meter SC single core patch cord ranges from $ 0.3 to more than $ 2. What are the reasons for such a big price difference of fiber optic patch cords? Below are the various factors which influence the price of fiber optic patch cords.

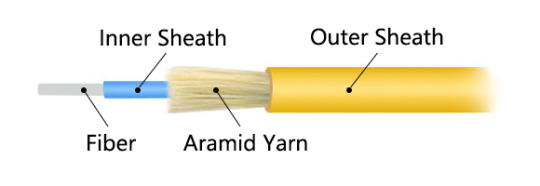

1. Different Quality of Raw Materials Fiber optic patch cord is composed of optical cable in the middle and connectors at both ends. The optical cable is made up of four parts from the inside to the outside: fiber, inner sheath, aramid yarn and outer sheath.

(1) Optical Fiber Optical fiber is the core raw material in fiber optic cables. Formal manufacturers generally use grade A fiber cores. Low-cost and inferior cables are often made from grade C or D fiber cores. Sometimes there are cases where OM3-300 fiber is used to pretend to be OM4 fiber. Small factories lack the necessary test equipment for judgment on the quality of optical fiber. Because such optical fibers cannot be identified by the naked eye, problems often encountered during construction are that excessive loss leads to short transmission distance and uneven core diameter leads to the difficulty to butt with pigtails or large loss after butting.

(2) Aramid Yarn Aramid is a new type of high-tech synthetic fiber with super high strength, high-temperature resistance and acid & alkali resistance. Its strength is 5-6 times that of steel wire, and it does not melt or be decomposed at a temperature of 560 degrees. Aramid also has good insulation and anti-aging properties. The invention of aramid is considered to be a very important historical process in the material industry. The main material of current bulletproof vests and military helmets is generally aramid. The purpose of using aramid in indoor fiber optic cables is to protect tight buffer fiber from mechanical tension.

Aramid yarn is roughly divided into Kevlar, imported aramid yarn, domestic aramid yarn and polyester yarn according to the difference of its material. Kevlar is the patented trade name of para-aramid developed by DuPont in the United States, and its price is high. In addition to DuPont, the major foreign aramid yarn manufacturers include Teijin in Japan and Kolon in South Korea. Their prices are lower than DuPont's. As the performance of aramid yarn made in China tends to stabilize, the price is relatively low. Chinese aramid yarn manufacturers mainly include Yantai Tayho, Suzhou Zhaoda, Sinopec Yizheng and Bluestar Chengrand.

Aramid yarn is one of the main cost components of indoor fiber optic cables. Due to the high cost of aramid yarn, inferior indoor cables may be made from fewer strands of aramid yarn or from polyester yarn which is similar in appearance to aramid yarn instead to save costs. The price of polyester yarn is less than one-tenth of that of imported aramid yarn. But polyester yarn can hardly bear any tension so that the optical fiber is easily broken or damaged when laying. Moreover, polyester yarn is not resistant to high temperature and not flame retardant. Based on these characteristics, the way to distinguish aramid yarn and polyester yarn is very simple -- just burn it with fire. The following are burning test videos of aramid yarn and polyester yarn.

Aramid Yarn Burning Test

Polyester Yarn Burning Test

(3) Sheath The outer sheath materials of indoor fiber optic cables are mainly polyvinyl chloride (PVC), flame-retardant PVC, low smoke zero halogen (LSZH) or flame-retardant LSZH. LSZH cable jacket is composed of thermoplastic or thermoset compounds that emit limited smoke and no halogen when exposed to high sources of heat. The price of LSZH is higher than that of PVC. The price of flame-retardant sheath is different according to the flame-retardant grade. The high quality outer sheath should be easy to be peeled off and its appearance should be smooth, bright and elastic. Inferior cable jacket has poor surface roughness, what’s more, it is easy to stick with tight buffer fiber and aramid yarn.

(4) Ferrule

Ferrule is the core component which affects the performance of fiber optic connector. The quality of ferrule directly affects the precise center connection of the two optical fibers. Ferrule is made of ceramic, metal or plastic. Ceramic ferrule is widely used. There are two situations where the quality of connectors is not good due to the ceramic ferrule. ① Using ferrules with a concentricity of 1.5 um instead of 1.0 um for production. Rotating connector to adjust the position of cores during the test in order to make loss value appear to enter qualified range. ② Using recycled ferrules. Since second-hand ferrules have already undergone a grinding process when they are first made into connectors, the exposed length of the ferrules may be too short which will cause large access loss when they are used again.

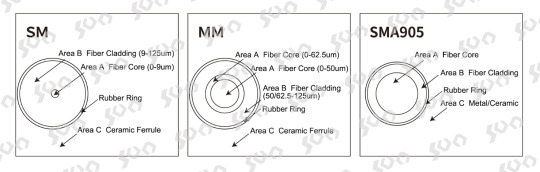

2. Different Technical Standards (1) Fiber End Face As shown in the figure below, the fiber end face is divided into three areas ABC. There must be no spots, scratches or other defects in the fiber core area A and the fiber cladding area B on the high-quality end face. Otherwise, they will cause obstacles to optical signal transmission and affect the values of insertion loss and return loss.

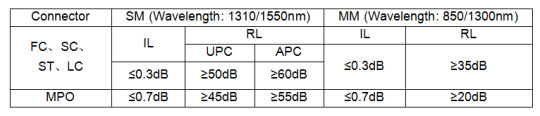

(2) Insertion Loss & Return Loss The optical performance of fiber optic connectors is mainly measured by two basic parameters, insertion loss and return loss. Insertion Loss (IL) refers to the optical power loss caused by the connection. It describes the optical loss between two fixed points in the fiber, usually generated by the horizontal deviation between two fibers, the vertical gap between two connectors or end face quality. The unit is expressed in decibels (dB). And the value of IL is generally required to be less than or equal to 0.3dB. Return Loss (RL) refers to the parameter of signal reflection performance which describes the power loss of optical signal return or reflection. The unit is also expressed in decibels (dB). The typical RL value of a general APC connector is about 60dB, and for a UPC connector, it is about 50dB. During the IL and RL test of Sun Telecom's fiber optic connector, each end is continuously measured 3 times. Each measurement value meets the following requirements, and the insertion loss change is less than 0.2dB. The average value of 3 times will be recorded if it is necessary to record the actual value.

(3) Plug Stability According to the IEC 61753-1 standard, the plugging durability of fiber optic connectors should be greater than or equal to 500 times, and the change in insertion loss should be less than or equal to 0.2dB. The attenuation of inferior connectors will increase after repeated plugging and unplugging many times. Therefore, plugging durability is usually considered to be one of the most important indicators reflecting the stability of fiber optic connectors.

3. Different Strengths of Manufacturers The production steps of fiber optic patch cords can be divided into three parts: an assembly of cables and connectors, end face polishing, inspection and testing. The production of high-quality fiber optic patch cords has high requirements for many aspects. There are many factors that affect the quality and price of patch cords, such as the efficiency of production scale, the automation of the production equipment, the completeness and accuracy of test instruments, the proficiency of operators, the quality control ability and the lean production site management ability, etc. All in all, when choosing a fiber optic patch cord supplier, you should consider the cost performance and the supplier's product quality, technical strength and service quality, not just the cheapest price. As a professional fiber optic solutions provider, Sun Telecom not only provides cost-effective fiber optic patch cords, but also offers turnkey solutions for helping build an integrated or sectional patch cord production line based on more than 30 years of experience.

0 notes

Text

Cable Market Latest News, Cost Profit Structure and Market Share Till 2027

Cable Market for Automotive - Overview

A cable contains two or more insulated wires packed in one jacket. Generally, cables are denoted or marked with letters and numbers to identify cables number and insulation types. A modern vehicle contains numerous electronic applications that provide better driving experience along with fuel efficiency and safety features. In an electric car, nearly 70 kg of wiring is present to due to an increase in the adoption of new technologies, such as parking sensors, lighting, Bluetooth, and navigation. Various types of automotive cables, such as round sheathed cables, flat sheathed cables, and hybrid sheathed cables, are used in automotive applications depending on the requirement and functions these types.

Cable Market for Automotive - Drivers and Restraints

Increase in demand for efficiency and lower energy consumption in modern vehicles along with compact design is likely to raise the temperature in the engine compartment. Automotive cables not only withstand high temperatures in the engine compartment but also offer resistance against fuels, battery acid, and cleaning agents. Consequently, the demand for automotive cables is likely to increase during the forecast period. New challenge of distribution of electrical energy in electric and hybrid vehicle is likely to offer significant business opportunities for the automotive cable in the near future. Rise in consumption of electric vehicles due to stringent emission norms and green transportation initiatives by regulatory bodies is likely to boost the demand for electric vehicles during the forecast period. This, in turn, is anticipated to propel the cable market for automotive during the forecast period.

Request A Sample Copy Of The Report https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=59988

Cable Market for Automotive - Segmentation

The cable market for automotive can be segmented based on application, cable type, vehicle type, and region. Based on application, the cable market for automotive can be classified into engine compartment and gear box, ABS system, battery, and others. Numerous sensors are used in the engine compartment and gear box in order to enhance the efficiency of the vehicle and for the ease of shifting of gears. Operating temperature in the engine compartment is higher as compare to that in the other compartments. High quality cable is required in order to supply voltage, transmit data, and comply with stringent requirements. Rising adoption of electric components in the engine and gear box compartment is projected to boost the demand for automotive cable during the forecast period.

Based on cables type, the market can be bifurcated into single core and multi core. Multi-core cables are widely utilized in the automotive industry and all types of road vehicles, as these cables require high voltage carrying capacity in order to power the electric instruments and the engine. Moreover, high resistance to mineral oil, fuels, and engine liquids is anticipated to propel the demand for multi-core cables during the forecast period.

In terms of vehicle type, the cable market for automotive can be segregated into passenger vehicle, electric vehicle, and commercial vehicle. Large consumption of electrical components and adoption of new technologies in electric vehicles are estimated to boost the demand for automotive cables during the forecast period.

In terms of region, the cable market for automotive can be classified into North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. The presence of several large automotive hubs in Asia Pacific and high production of passenger vehicles coupled with rise in adoption of electric vehicles due to stringent emission norms in the region are anticipated to drive the cable market for automotive in the region during the forecast period.

Cable Market for Automotive - Key Players

Key players operating in the cable market for automotive are Coroplast Fritz Müller GmbH & Co. KG, LEONI AG, General Cable Technologies Corporation, SALCAVI S.p.A., and HUBER+SUHNER.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

The study is a source of reliable data on:

Market segments and sub-segments

Market trends and dynamics

Supply and demand

Market size

Current trends/opportunities/challenges

Competitive landscape

Technological breakthroughs

Value chain and stakeholder analysis

The regional analysis covers:

North America (U.S. and Canada)

Latin America (Mexico, Brazil, Peru, Chile, and others)

Western Europe (Germany, U.K., France, Spain, Italy, Nordic countries, Belgium, Netherlands, and Luxembourg)

Eastern Europe (Poland and Russia)

Asia Pacific (China, India, Japan, ASEAN, Australia, and New Zealand)

Middle East and Africa (GCC, Southern Africa, and North Africa)

The report has been compiled through extensive primary research (through interviews, surveys, and observations of seasoned analysts) and secondary research (which entails reputable paid sources, trade journals, and industry body databases). The report also features a complete qualitative and quantitative assessment by analyzing data gathered from industry analysts and market participants across key points in the industry’s value chain.

Request For Covid19 Impact Analysis https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=59988

A separate analysis of prevailing trends in the parent market, macro- and micro-economic indicators, and regulations and mandates is included under the purview of the study. By doing so, the report projects the attractiveness of each major segment over the forecast period.

Highlights of the report:

A complete backdrop analysis, which includes an assessment of the parent market

Important changes in market dynamics

Market segmentation up to the second or third level

Historical, current, and projected size of the market from the standpoint of both value and volume

Reporting and evaluation of recent industry developments

Market shares and strategies of key players

Emerging niche segments and regional markets

An objective assessment of the trajectory of the market

Recommendations to companies for strengthening their foothold in the market

Note: Although care has been taken to maintain the highest levels of accuracy in TMR’s reports, recent market/vendor-specific changes may take time to reflect in the analysis.

This study by TMR is all-encompassing framework of the dynamics of the market. It mainly comprises critical assessment of consumers' or customers' journeys, current and emerging avenues, and strategic framework to enable CXOs take effective decisions.

Our key underpinning is the 4-Quadrant Framework EIRS that offers detailed visualization of four elements:

Customer Experience Maps

Insights and Tools based on data-driven research

Actionable Results to meet all the business priorities

Strategic Frameworks to boost the growth journey

The study strives to evaluate the current and future growth prospects, untapped avenues, factors shaping their revenue potential, and demand and consumption patterns in the global market by breaking it into region-wise assessment.

The following regional segments are covered comprehensively:

North America

Asia Pacific

Europe

Latin America

The Middle East and Africa

The EIRS quadrant framework in the report sums up our wide spectrum of data-driven research and advisory for CXOs to help them make better decisions for their businesses and stay as leaders.

Below is a snapshot of these quadrants.

1. Customer Experience Map

The study offers an in-depth assessment of various customers’ journeys pertinent to the market and its segments. It offers various customer impressions about the products and service use. The analysis takes a closer look at their pain points and fears across various customer touchpoints. The consultation and business intelligence solutions will help interested stakeholders, including CXOs, define customer experience maps tailored to their needs. This will help them aim at boosting customer engagement with their brands.

2. Insights and Tools

The various insights in the study are based on elaborate cycles of primary and secondary research the analysts engage with during the course of research. The analysts and expert advisors at TMR adopt industry-wide, quantitative customer insights tools and market projection methodologies to arrive at results, which makes them reliable. The study not just offers estimations and projections, but also an uncluttered evaluation of these figures on the market dynamics. These insights merge data-driven research framework with qualitative consultations for business owners, CXOs, policy makers, and investors. The insights will also help their customers overcome their fears.

3. Actionable Results

The findings presented in this study by TMR are an indispensable guide for meeting all business priorities, including mission-critical ones. The results when implemented have shown tangible benefits to business stakeholders and industry entities to boost their performance. The results are tailored to fit the individual strategic framework. The study also illustrates some of the recent case studies on solving various problems by companies they faced in their consolidation journey.

4. Strategic Frameworks

The study equips businesses and anyone interested in the market to frame broad strategic frameworks. This has become more important than ever, given the current uncertainty due to COVID-19. The study deliberates on consultations to overcome various such past disruptions and foresees new ones to boost the preparedness. The frameworks help businesses plan their strategic alignments for recovery from such disruptive trends. Further, analysts at TMR helps you break down the complex scenario and bring resiliency in uncertain times.

You May Also Like PRNewswire on https://www.prnewswire.com/news-releases/sake-brewery-industry-to-play-a-positive-role-in-cubitainers-market-growth-from-2020-to-2028-transparency-market-research-301104740.html

You May Also Like PRNewswire on https://www.prnewswire.com/news-releases/penetration-of-advanced-technologies-to-bring-a-paradigm-shift-in-growth-of-warranty-management-system-market-north-america-to-add-numerous-feathers-of-growth-opines-tmr-301110185.html

The report sheds light on various aspects and answers pertinent questions on the market. Some of the important ones are:

1. What can be the best investment choices for venturing into new product and service lines?

2. What value propositions should businesses aim at while making new research and development funding?

3. Which regulations will be most helpful for stakeholders to boost their supply chain network?

4. Which regions might see the demand maturing in certain segments in near future?

5. What are the some of the best cost optimization strategies with vendors that some well-entrenched players have gained success with?

6. Which are the key perspectives that the C-suite are leveraging to move businesses to new growth trajectory?

7. Which government regulations might challenge the status of key regional markets?

8. How will the emerging political and economic scenario affect opportunities in key growth areas?

9. What are some of the value-grab opportunities in various segments?

10. What will be the barrier to entry for new players in the market?

0 notes

Text

Fine Hydrate Market- Insights on Scope 2025

Fine alumina trihydrate, also known as alumina hydrate as well as aluminium hydroxide, is a fine white powder derived from bauxite ore through Bayer’s process. The average particle size of fine alumina hydrate, as defined and considered within the scope of the report, ranges from 0–2μm.Fine alumina hydrate is an environment-friendly, mineral-based flame retardant and smoke-suppressant, used in variety of polyolefin resins.Fine alumina hydrate are primarily utilized in the insulation layer and manufacturing of jacketing compounds for wires and cable with various voltage requirements.

Request For Report sample @ https://www.trendsmarketresearch.com/report/sample/3294

A rapid rise in the use of flame retardant products is driving revenue growth of global fine hydrate market

Increasing growth of plastics in transportation and automotive industry and rising adoption of fine hydrate as substitute for titanium dioxide pigments are some of the factors driving the growth of global fine hydrate market. Moreover, growing preference for non-halogenated flame retardants and government’s support and stringency regarding the use of fine hydrate are anticipated to boost the demand of fine hydrate over the coming years. However, factors such as low suitability for high temperature applications and growing prominence of alternative additives in developed economies are predicted to provide significant challenge to the fine hydrate market growth.

The cable compounds application segment of the global fine hydrate market is anticipated to grow at a faster rate due to growing wires and cable industry

Based on the application, the global fine hydrate market can be segmented into cable compounds, sheet moulding compounds, bulk moulding compounds, and others. Cable compounds segment accounted for XX.X% volume share in 2017. The segment is growing at a faster rate as the fine hydrate is more used in the manufacturing of cable sheaths. Others application segment is expected to represent a total incremental opportunity of US$ XXX.x Mn between 2018 and 2025.

Request For Discounts @ https://www.trendsmarketresearch.com/report/discount/3294

On the basis of geography, the global fine hydrate market is segmented into North America, Latin America, Western Europe, Eastern Europe, Asia Pacific excluding Japan and China (APEJC), Middle East & Africa (MEA), Japan AND china. Significant market potential exists in the growing market of India, South Korea and China. With Chinaemerging as a key supplier in the global fine hydrates market, global players are involved to reduce their overall material cost to compete with Chinese players.

The Western Europe fine hydrate market accounted for a value share of XX.X% in 2017. The China fine hydrate market is expected to represent significantly high incremental opportunity between 2018 and 2025, while the APEJC fine hydrate market is projected to expand at a healthy CAGR in terms of value over the forecast period. Sales of fine hydrate in Japan is expected to represent a total incremental opportunity of US$ X.X Mn between 2018 and 2025.

Leading market players dominating the global fine hydrates market

Some of the leading market players in the global fine hydrate market include Huber Engineered Materials, Nabaltec AG, Hindalco Industries Limited, Aluminium Corporation of China Limited, Sumitomo Chemical Co. Ltd., Jinan ChenxuChemical CO., LTD., Henan Kingway Chemicals Co., Ltd., Alumina Castables and Chemicals Private Limited.

Make an Inquiry before Buying@ https://www.trendsmarketresearch.com/checkout/3294/Single

0 notes

Text

Wiring Duct Market Intelligence Report by Regions, Type and Application, With Sales and Revenue 2027

It is expected to witness expansion at a CAGR of 4.6% during the years 2019 and 2027. The market will be effected by a range of macroeconomic factors throughout the forecast period. As per recent report by Transparency Market Research, the global wiring duct market is expected to reach the value of US$524.3 Mn by the year 2027.

With the advancement of technologies, the applications of industrial automation is expanding rapidly. This is resulting in emergence of sophisticated but complicated technologies. This contributes to the increase in complexity during the interconnection of system components between sensors and top-level controllers. Hence, in order to combat the complexity, wire ducts are used to properly route as well as conceal cables and wire bundles in the control panel. Consequently, this will augment the size of the wiring duct market globally during the forecast period.

At the same time, proper disposal of ducts and recycling is a major challenge interfering with the expansion of the wiring duct market. Polyvinyl chloride cable is the commonly used duct material. It is also used for jacketing or insulating metal wires. The chemical is neither bio-degradable nor eco-friendly. Also, burning of PVC releases dioxins, which is highly toxic. The toxic byproduct enters into human food chain by contaminating water and land.

Request a Sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=63096

Wide Range of Industrial Application Bolster Revenue Generation

On the basis of application, the commercial segment is expected to majorly contribute in the expansion of global wiring duct market in the given forecast period. There is a high demand for cabling and wiring ducts in the telecom industry, network cabling systems, retail complexes, and hospitals for organization of bundles of cables and separate them in an electric enclosure. At present, numbers of telecom industry, IT hubs, and data centers are increasing in huge numbers. This, in result, is expected to augment the production of wiring ducts in the course of the forecast period.

Moreover, industrial application of the wiring duct has come as another driving factor in the wiring duct market. Demand of wiring ducts in oil and gas industries, grain elevators, and chemical plants is expected to boost the global duct market in the course of the forecast period.

Request For Covid19 Impact Analysis Across Industries And Markets – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=63096

Modernization of Industrial Processes in Emerging Economics Expands Growth Avenue

On geographical segment, the wiring market is witnessing diverse phases. The opportunities in the wiring duct market are saturated in North America and Europe due to presence of both industrial and commercial sectors on large scale. On the other side, Asia Pacific, Middle East and Asia are expected to witness surge in the demand for wiring ducts. Modernization and upgrade in the industrial processes are the main reasons behind the demands.

The companies are focusing on the expansion of the business through strategic acquisitions and partnership with various end-users. Some of the key players in the wiring duct market are Hua Wei Industrial Co., Hager Group, Phoenix Contact GmbH & Co. KG, ABB Ltd, Hammond Manufacturing and OMEGA Engineering.

The study presented here is based on a report by Transparency Market Research (TMR) titled “Wiring Duct Market (Product Type – Slotted Wire Duct (Wide-slotted Wire Duct, Narrow – slotted Wire Duct, Round hole Wire Duct), Solid wall Wire Duct, Flexible Wire Duct; Application – Commercial, Industrial) – Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2019 – 2027”

Customization of the Report: This report can be customized as per your needs for additional data or countries. – https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=63096

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with aims of various industries. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through adhoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key to help enterprises reach right decision.”

Contact

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada

Email: [email protected]

Website: https://www.transparencymarketresearch.com/

0 notes

Text

The Meaning of Cable Producer

Here's What I Know About Cable Producer

The cable employs the most advanced and advanced technology on earth for data transmission. Modern HV cables have a very simple design composed of few components. Abhar Wire and Cable can supply the customer with a complete scope of accessories together with cables, offering a comprehensive system package. Make certain that the conclusion of the cable is correctly seated and doesn't pop loose. The conventional ribbon cable doesn't allow for high speed operation. One might be the armoured cable and the other one is unarmoured. Be aware the government tends to use the expression flat cable rather than ribbon cable.

When it has to do with network cabling, in regards to network cabinets, everybody is familiar. Some cables might have a lead or aluminium jacket in combination with XLPE insulation to permit for fiber optics. Put simply, it's possible to quite possibly locate a cable or many cables made by I Sheng in your residence. High-temperature superconducting energy cables are prepared for commercialization.

New Ideas Into Cable Producer Never Before Revealed

Silver is easily the most conductive metal. To start with, copper needs to be specified properly for the application. It may check out fine at the time of manufacture, but the oxidation seed may already be planted. It's nearly not possible to ascertain when the bare copper will get unacceptable. When there is foil in addition to wire braid, you will likely have to cut or tear a few of that away.

You might even see new growth because of the fact your workouts are becoming harder. The markets where the group operates remain stable. In order to construct the mental capability you should explode on demand you want to incorporate certain drills into your MMA workouts to train yourself. The power supply ought to be connected near the female connector.

The business applies all basic technologies for the creation of electrical cables and wires. It should have a strong logistic team capable enough to deliver consistently as per the requirement. It is by far the most important supplier of cables to Iran's hydrocarbon industry in addition to catering to a large number of other projects. It has been supplying the domestic and global market with a wide range of products of indisputable quality. At group level it identifies three main operating segments. Along with wire and cable, it manufactures casters, hospital equipment, medical products, consumer products, railway products and water treatment products. Today, it has more than 300 employees for serving the customers in the best possible way and meeting the growing demands of the business.

The Number One Question You Must Ask for Cable Producer

The lines are just like the chaotic group. Examine the label on the patch panel whenever you are overhauling, and after that locate the line along the line. Before soldering it's far better tape the 2 cables side by side. The gained shielding factors are very significant. With a few tests it's even feasible to find the place of the defect in the insulation before failure. The use of the jumper is also about the sort of jumper.

Manufactured correctly, it can improve performance and decrease total price tag. The creation of cables is meant for essential products. The Clutch cable producer must completely have all elements of the character 7.

0 notes

Text

Wire and Cable Insulation and Jacketing Market Regional Data Analysis 2020-2027

This report provides a comprehensive 360-degree perspective on the demand for Wire and Cable Insulation and Jacketing Market, putting out perspectives that can help investors recognize both opportunities and challenges. It monitors the global market for Wire and Cable Insulation and Jacketing through key markets, offering in-depth analysis and detailed statistical insights. The study also includes incisive competitive analysis of the landscape and provides Wire and Cable Insulation and Jacketing market players with key recommendations on winning imperatives and successful strategies.

In this study, the growth aspects that will drive the information of the forecast Wire and Cable Insulation and Jacketing are elaborated. This report presents comprehensive information on regional statistics on Wire and Cable Insulation and Jacketing in the industry, development trends, SWOT analysis.

For In-depth Information Get Free Sample Copy of this Report@ https://www.researchkraft.com/request-sample/1066676

Major Players included in this report are as follows –

DowDuPont, Mexichem, Hitachi-cable, BASF SE, Fujikura, SUMITOMO, ECC, Borealis, ExxonMobil Corp, Shell Chemicals, Dewei Advanced Materials, CGN-DELTA, Yadong, Zhonglian

Differentiation of the market based on types of product:

PVC

Polyoefins

Polyamides

Fluoropolymers

Others

Differentiation of the market based on types of its application:

Jacket

Insulation

Click here to get discount@ https://www.researchkraft.com/check-discount/1066676

Wire and Cable Insulation and Jacketing Major Geographical First Level Segmentation:

North America (U.S., Canada, Mexico) Europe (Germany, U.K., France, Italy, Russia, Spain, etc.) Asia-Pacific (China, India, Japan, Southeast Asia, etc.) South America (Brazil, Argentina, etc.) Middle East & Africa (South Africa, Saudi Arabia, etc.)

The report provides detailed and up-to-date statistical analysis on the global Wire and Cable Insulation and Jacketing market. The report presents a variety of factors such as import-export details, sales, regional presence, manufacturer analysis, latest trends, and competitive structure. Crucial information is defined, such as the chain structure of Wire and Cable Insulation and Jacketing , upstream and downstream customers, market volume and sales revenue.

Key Highlights of This Report:

Provide strategic profiles of Wire and Cable Insulation and Jacketing key market players, evaluate their core competencies comprehensively, and create a competitive market landscape.

To evaluate the market for Wire and Cable Insulation and Jacketing on the basis of various factors-price analysis, supply chain analysis.

To provide comprehensive market structure analysis along with forecasts of the various segments and sub-segments of the global market for Wire and Cable Insulation and Jacketing .

To track and evaluate competitive trends in the global market for Wire and Cable Insulation and Jacketing such as joint ventures, strategic alliances, new product launches, and research and development.

To provide Wire and Cable Insulation and Jacketing market analysis at the country level regarding the current size of the market and future prospects.

To analyze competitive developments in the Wire and Cable Insulation and Jacketing market such as expansions, agreements, new product launches and acquisitions.

For More Information On This Report, Please Visit @ https://www.researchkraft.com/send-an-enquiry/1066676

0 notes

Text

Feeder Cable Market Sales and Revenue Share by Countries

Feeder cable refer to the collection of the similar or distinct wires combined together as a single cable. Feeder cables are used to transmit signals from one point to another. Different types of feeder cables are used in different applications. The feeder cable is made up of different element, when these elements combined together they carry the radio signals having low level loss from one point to another. The typical feeder cable consists of center conductor, insulating dielectric, outer conductor, and outer protecting jacket or sheath. All the elements are built up in a concentric layer. The center conductor is made up of copper and it may be a single conductor or it might have several strands. The outer conductor and the center conductor are separated by the insulating dielectric. This insulating dielectric makes sure that both the conductors remain separate and prohibiting the occurrence of any loss. This insulating dielectric may be in the solid form or in the semi air spaced form. The outer conductor is made up of copper braid, to enable the feeder to be flexible. To improve the screening, the double or triple screen feeder cables are used. Due to use of additional screening the stray pickup and radiation level are reduced. The outer jacket or sheath along with covering layer serves as electrical function, however it prevents earth loop forming. This outer jacket also provides a protection needed to prevent from moisture and dirt attack and prevent the feeder cable from damage by other mechanical shocks.

Looking for exclusive market insights from business experts? Request a Sample Report

Feeder cables makes use of advanced processing technology that provides a low cost with higher performance suitable for wireless applications. Major factor that drives the feeder cable market are its performance, lower weight as compared to ordinary cables, and flexibility. However, the use of flexible feeder cables in difficult areas without any change in its attenuation characteristics, further drives the growth of the feeder cable market. One of the major restraining factor that restricts the growth of the feeder cable market is that the failure in one cable will results in the breakdown of the entire network. This is due to the use of single cable used in signal transmission. Also due to installation cost for longer distances compared to other type of cables restricts the growth of the feeder cable market. However due to its wide application at high frequency (>50 MHz), drives the further growth of the feeder cable market.

0 notes

Text

Chloro-sulfonated Polyethylene Market to Set Phenomenal Growth by 2027

Chloro-sulfonated Polyethylene Market: Introduction

Chloro-sulfonated polyethylene, also referred to as CSPE, is a family of chlorinated elastomers. Chloro-sulfonated polyethylene is manufactured by the reaction of polyethylene with chlorine and sulfur dioxide. The reaction changes thermoplastic polyethylene into a synthetic elastomer that can be compounded and vulcanized.

Basic polyethylene has properties such as chemical inertness, resistance to damage caused by moisture, and good dielectric strength. However, when a chlorine molecule is inserted in the polymer, its resistance to fire (self-extinguishing), oil, and the action of microorganisms increases. Also, it exhibits good adhesion to various surfaces.

Chloro-sulfonated polyethylene compounds offer excellent resistance to ozone, oxidation, sunlight (color degradation), and weather. They are also capable of providing excellent resistance to alkalis and acids.

Are you a start-up willing to make it big in the business? Grab an exclusive PDF sample of this report

Applications of Chloro-sulfonated Polyethylene

In terms of application, the global chloro-sulfonated polyethylene market can be divided into construction, automotive, wires & cables, coatings, rubber, industrial products, and others. Other uses of chloro-sulfonated polyethylene include manufacture of tubes, tank linings, rubber gaskets, and protective layers, which are acid resistant and resistant to ozone. Well-known consumer products include shoe soles and garden hoses.

Chloro-sulfonated polyethylene vulcanizates have excellent ozone resistance and weatherability, owing to their unique molecular structure. In addition, properly formulated chloro-sulfonated polyethylene vulcanizates have excellent resistance to heat, oil, chemicals, and aging.

Chloro-sulfonated polyethylene is primarily applied in insulating sheathes and jackets of cables, as it is grease proof, deformation proof, and acid proof and it has anti-breaking and anti-abrasion properties

Chloro-sulfonated polyethylene is primarily used in coatings of ebonite compounds, in addition to anti-corrosion coatings of the inside and outside walls of plants and equipment under acidic and alkali conditions, due to anti-weather and aging characteristics and acid-proof, alkali-proof and solvent-proof properties of chloro-sulfonated polyethylene

Chloro-sulfonated polyethylene is used in power steering and oil cooler hoses for automobiles and industrial hydraulic hoses, wherein impulse testing is performed at temperatures of up to 150°C. Chloro-sulfonated polyethylene is also widely used for fuel hose covers and in various vacuum and emission tubing applications.

Drivers of Global Chloro-sulfonated Polyethylene Market

Chloro-sulfonated polyethylene elastomers are made with the help of eco-friendly technologies. They have excellent resistance to heat, oil, fuel, ozone, and UV rays. Properly formulated compounds have good dynamic properties and they offer strong adhesion to various substrates.

Good electric properties, exceptional toughness and abrasion resistance, and a flexible cure mechanism make chlorosulfonated polyethylene suitable for use in specialty wire and cable applications

Good dynamic properties and outstanding adhesion to substrates such as fabrics and brass-coated steel make chlorosulfonated polyethylene a unique choice for use in hoses and belting

Expanding operations in future? To get the perfect launch ask for a custom report

Asia Pacific to Hold a Major Share of Global Chloro-sulfonated Polyethylene Market

In terms of region, the global chloro-sulfonated polyethylene market can be divided into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa

Low manufacturing costs, increasing disposable incomes, and rising construction activities in Asia Pacific drive the market for chloro-sulfonated polyethylene in the region. China held a leading share of the market in the region in 2018, owing to presence of promising construction industry in the country. China, India, Vietnam, and Indonesia are key countries of the chloro-sulfonated polyethylene market in Asia Pacific.

Increasing construction activities and rising exports are factors responsible for high production of chloro-sulfonated polyethylene in Europe