#Wooden Crates Manufacturer

Text

Wooden Box and Crates Manufacturer in Ahmedabad, India

Wooden Box and Crates Manufacturer in Ahmedabad, India

Shivam Packaging is Premier Wooden Box and Crate manufacturer in Ahmedabad, India. Expertly crafting custom-made, durable packaging solutions. Trusted by industries for tailored products, timely delivery, and competitive pricing. Choose reliability and quality for all your wooden packaging needs.

Read More: https://www.epalpalletindia.com/products/wooden-box-crates/

Call : +91 92281 91111 | +91 92285 88888

Mail : [email protected]

1 note

·

View note

Text

nailless boxes manufacturers in india

Newel Packaging is one of the leading Nail less Plywood Boxes Manufacturers, Suppliers in India. Contact us for Nail less Wooden Boxes, Collapsible wood plywood packaging boxes, Nailess Packaging Boxes, Nailess Boxes Manufacturer, Supplier, Exporter

#nailless boxes suppliers in india#nail less boxes in india#nail less packaging boxes in india#wooden crates manufacturers in india

1 note

·

View note

Link

Wooden Packing Crates India Newel Packaging is one of the leading Wooden Crates Manufacturers in India. Our Wooden packaging crates are durable and are perfectly designed. These packing crates come in wooden, plywood and plastic material in standard as well as tailor made variants.

Contact us for Nail less Wooden Boxes, wooden crates , wooden packing crates Wooden Packing Crates India, Crate Manufacturers India, Wooden Crates India, Wooden Crate Manufacturers India, Plywood Crates India, Plywood Crate Manufacturer India, Wooden Crate Supplier India

Address: 203, Vasantdada Industrial Estate, Sangli 416416.

Phone No.: 91023323104 | Email ID: [email protected]

#Wooden Packing Crates India#Crate Manufacturers India#Wooden Crates India#Wooden Crate Manufacturers India#Plywood Crates India#Plywood Crate Manufacturer India#Wooden Crate Supplier India

0 notes

Text

https://orchiddinex.com/product-category/tableware/dinex-woodenware/acacia-wooden-bowls/

You Switch to Wooden Tableware Dinex products

Contrary to popular misconception, wooden serving bowls, plates, and dishes are rather simple to keep. Wooden Salad bowls, wooden risers, and wooden chip & dip platters may all be cleaned with warm water and little soap due to the outside coating. To remove the food scraps, clean the surface with a bristle brush. You may let your dinnerware soak in water for a bit if it seems very sticky.

#wooden chip & dip platters#wooden risers#wooden crates#wooden bowls#wooden cheese boards#wooden serving paddle boards#woodenware serving platters#wooden Salad bowls wholesale#woodenware manufacturers india

0 notes

Note

Hey,

I don't know if you know a lot about cars or not but I've compiled a list of cars of what the senshi would drive and you can tell me what you think.

(If you can look it up if you want)

(This is also going to be a long one lol)

Usagi- Newer Volkswagen Beetle because she thinks it's cute

Ami- Toyota Corolla or Honda Civic. She prefers something reliable and economical.

Makoto- Toyota FJ Cruiser or New Ford Bronco because I see her as an off road driver who enjoys exploring.

Rei- Probably something that runs and drives but I would lean her towards something that is cheap and practical while still enjoying it. Probably a Mitsubishi Lancer Evo or a Subaru Impreza WRX Hatchback.

Minako- Something cool like a BMW M5 F10 (Rip water pump lol) or 2012 Mercedes SL-Class (Rip engine due to trashing the shit out of that car lol)

Michiru- Something fancy yet practical such as a Mercedes E-Class Wagon Diesel or Volkswagen Passat 4Motion.

Haruka- Sport cars obviously lol. I would think a BMW M3 E46 Convertable for daily driver and Volkswagen Golf R to take Hotaru to school while still looking cool lol

Hotaru- Haruka's Golf but Michiru would get her a Toyota Yaris to start but if she doesn't want it, then she's going to get her own car lol.

Setsuna- Anything that runs and drives lol

I love this question! 🌞🚙 (Though I warn I'm not a knowledgeable car person and most of this is based on aesthetics. Also, I'm adding to, not disagreeing with your choices. I like the Yaris!)

Usagi - I agree on the newer Beetle Bug. She needs an automatic, it would be pale yellow with cute glitter decals on the windows and a pink license plate frame. I'd even say she has a pink fuzzy steering wheel cover and some kind of cute pink seat covers. There would be a little crystal hanging from the rearview mirror.

Rei - I feel like I'm being mean to her, but Rei has a faded 1977 Red Gremlin hatchback with the white stripes. It runs (and not much else). And she can shove a dozen people into the hatchback if she really tries. She's no frills with this and also refusing to take anything from her father even though he could have/maybe offered her a nicer vehicle.

Ami - this one was harder. I actually see her on a scooter with a cute little basket on the front. Pale blue with white details and a matching helmet. But, if she were to get a car, it would be a Smart Car. Same pale blue with white details and a little black cat decal on the back window. She's getting her transportation to take her from point A to point B without really thinking of passengers. If it's more than just her going anywhere, the other person is driving. Or alternately, a dark blue Prius.

Makoto - my girl has a small, budget-friendly pick-up truck. Specifically, a Chevy LUV (manufactured by Isuzu). Fading baby blue with a rust spot on the hood and a pink plastic flower hanging from the rearview mirror. She keeps an old wooden crate in the bed to throw stuff in and has a flowered license plate frame. Alternately, she gets a classic Bronco. There's still a wooden crate in the back.

Minako - my party girl gets a party vehicle. A bright sunny yellow VW Bus with polished chrome. It's a bitch to park in Tokyo but she loves it. It has a hippie stoner look but only because Minako loves the aesthetic of all the rainbows and colors and peace sign stickers. There's a blue bird figure glued to the dashboard and she pats its head every time she gets in. Fuzzy dice! Artemis has his very own customized cat seat slung over the front bench (it can be relocated if he wants to get in the back to get away from the commotion of the entire crew on a road trip). She has a custom license plate - SAYLAV

Haruka - like you said, definitely sport cars. And more than one because she married really well. 😁 I definitely see her going with mostly modern cars, like day one off the assembly line. There's a Porsche involved. But there has to be a classic 1965 Shelby Mustang in there somewhere. White with a dark blue racing stripe. She would not besmirch her car with decals. LOL

Michiru - she's going for classy and high end. I had to look some of these up because I'm not familiar with high end 😅, but I could see her in something like a Lexus LFA as her everyday driver. But I'm also giving her a high end modern Jeep for fun, like when they go on trips to the mountains. It is teal. Because she is girly.

Setsuna - she's going for basic use and reliability. Cadillac XTS in dark burgundy.

Hotaru - she'll inherit Michiru's Jeep and have it repainted purple. 😎

#sailor moon#the girls and their rides#sailor mars#sailor mercury#sailor jupiter#sailor venus#sailor uranus#sailor neptune#sailor pluto#sailor saturn

6 notes

·

View notes

Text

Finally...

I was looking for a really good shortwave receiver for at least a decade -an old tube equipped one of course. The problem getting one nowadays is that they were only produced in small numbers half a century (or more) ago, since then most are scrapped, botched, altered or corroded cause of bad storage -or all together. So if you have the chance getting one today you most likely will buy a 'construction site', needing hundreds of working hours for restoring it in a good working condition.

But after a looong search finally i had real luck. A big wooden crate was delivered on a pallet.

In this crate was one of the -for my opinion- ugliest shortwave receivers ever built, but at the same time also one of the best ones: a Rohde + Schwarz EK07.

Built in 1958 this one was a storage unit from the German Army. Well stored, regularly maintained and serviced, not altered, not botched, never used. So it is in nearly mint condition. It wasn't cheap but getting my hands on this was just sheer luck. Without doing anything: it's in perfect working order. No potentiometer, no switch crackles, every tube checks new -of course you can check all the tubes in the radio itself without removing them.

The manufacturer is more known for it's precision Lab-Equipment and less for it's shortwave receivers. This is also because their receivers weren't consumer or amateur gear, this was pro gear by any means. They were used in applications like coast guards or military surveillance and such. Always things where equipment costs doesn't matter -only the outcome. So back in 1958 when this unit was manufactured you could buy at least two brand new cars for the same amount of money. In exchange for this you got a masterpiece of german engineering and craftsmanship -and also an electro-mechanical nightmare if anything fails and you're not absolutely familiar with it's guts.

Fancy? No, there's absolutely nothing fancy on these. These are absolute workhorses, designed for doing an important job 24/7/365 for decades. Just take a look to that bandswich gear in the photo above. How often you have to switch over the bands until this would be worn out? Millions and Millions of times... And nope: this dark residues at that drum on the left and box below isn't mold or such. These are completely silver plated so it's just the darkened silver.

As you may see, most of the structural parts are made of die-cast and aluminum, so from the materials used it's relatively light weight. But all that built-in sturdiness and shielding adds up to staggering 147lbs/67kg. It's only a receiver, not a transmitter or a power amplifier.

Tubes... and more tubes

If you're not familiar with tube radios: your average AM (and shortwave) Radio from the 50's or 60's used 4 tubes (without the rectifier if this was a tube). Your trusty Hammarlund or Yaesu shortwave receiver from that time would have somewhat from 8 to 12 tubes -and these were quite good and sensitive receivers! This Rohde + Schwarz counts 28 tubes.

Some tubes here, some there, all fully shielded. But why the hell that much? The answer is quite simple: stability. On every count. Constant and stable gain over all bands and for a looong service time, stunningly stable VFO frequencies and all that stuff. No, they used no consumer tubes like in your TV or such. All of them are out of the 'commercial'-tube-series with a guaranteed service life of at least 10000 hours like in every aircraft of that time or such. Failing was not an option, this HAD to work.

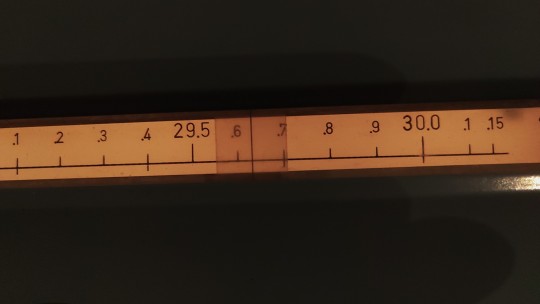

Speaking about stability and accuracy:

this of course isn't digital stuff -it's purely analog. In the pictures below you can see the dials. Just add both frequencies and you know where you are -here on 29.630MHz or 29630kHz.

As you see: your readout is easily accurate down to less than 500Hz. So you can read at least 500Hz out of 29630000Hz. With other words the accuracy of your readout is 0.001687% in this case. Your average modern digital multimeter would be proud if it came only near to this 65 year old contraption.

Of course that large dial in the picture on the left isn't the only one. There are 12 of 'em, mounted on a drum and rotating according to the selected band. Giving you a simple S-Meter like in other shortwave receiver was of course also not possible.

Instead they provided you with a Voltmeter which displays directly the input voltage at the antenna input -and the threshold voltage for the 'Squelch' (if you have set that) which isn't a normal squelch. If activated it doesn't cut your Audio, it reduces the Gain instead with a settable time constant, so it acts more like a active noise cancelling between any signal -also between any dash and dot if you're receiving CW (Morse Code). Besides that you can choose your IF-Passband between 150Hz and 12kHz, have a absolutely stable BFO, a good Envelope Detector for AM-Reception and a perfect Audio Stage - that's all.

Speaking of the Audio Stage: 2W undistorted output power from a single end class-A is more than you need with a good speaker. McIntosh ® would call that circuit 'Unity Coupled', further a E88CC for the Audio-Preamp. We're talking about an Shortwave Radio, not an 'High-End' Audio Amplifier. Wanna take recordings of what you hear? No problem: here's your Line-Output, symmetric, 600 ohms, transformer coupled and with +10dBm (if you want) and in accordance to all Studio-Standarts. Sound quality for AM Broadcasts? With a passband switchable up to max. 12kHz for the IF better than the majority of stations can provide.

Precise?

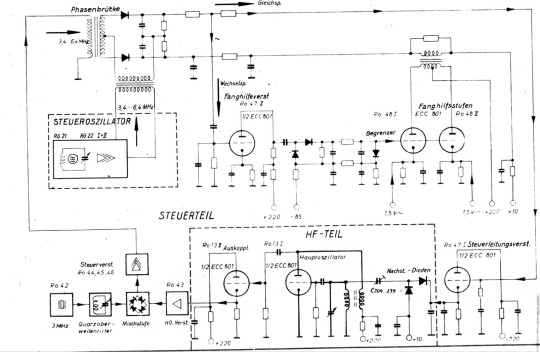

So far so good, but what's about the heart of every shortwave receiver: the Oscillator or VFO? How stable and precisely does it beat after 65 years?

In your trusty -and quite good- Hammarlund or Yaesu amateur Radio from these days the VFO usually is equipped with two tubes: the Oscillator itself and the buffer amplifier -both sometimes also united in one bulb. If i hadn't lost track here they used 12 -and tons of other stuff. So that frickin VFO has a component count which is easily about the order of a complete shortwave receiver.

What the hell is all that stuff about -and wtf they had for breakfast back then? The answer is again simple: precision and stability.

As i said: this thing is 65 years old and i touched nothing. Of course I checked how much it's 'off' in terms of the frequency. After warming up for 20 Minutes i checked it every 1000kHz from the bottom to the top of its range. It was a bit different between all points, at some less than 50Hz and about 1kHz worst case.

My Lab-Equipment is quite good and precise, but for these low errors the tolerances of the measuring equipment has absolutely taken into account. So i made a separate measurement only for 10MHz -with the aid of a frequency standard sourced from an atomic clock. So this was 'the real thing'. After warming up for an hour i measured for 15 Minutes. The deviaton was between -717 to -722Hz. Including the error of the dial. This means frickin' 71.7...72.2ppm. PPM -parts per million! 65 years after manufacturing.... Just absolutely stunning -and with what freaking kind of equipment they had calibrated this back then??? Just have in mind: this is pure analog goodness, not a modern PLL. How the f***k they got there? Here's the clear link between a manufacturer of high-grade Lab Equipment and a shortwave receiver. I'm just stunned over the knowledge of the engineers who designed that circuit back then and the precision this was built.

All without doing anything and all it's original capacitors. Yap, i could realign that but tbh it's just wayyy to less been worth the effort. So it will stay as it is.

Nope,

you're not provided with that fancy stuff your new digital or SDR may have on board. There's no notch filter, no panoramic display -not even SSB! Why the hell they just 'forgot' all these things? The answer is easy: it's modular. The EK07 is just the 'mainframe', everything else you wanted to have can be added as external components you had to buy separately -also for tons of money of course.

Wanting SSB? Just add this:

35kg/77lbs and 18 Tubes more -to mention it's also a synchronous detector for AM is not worth the effort. Panoramic display, digital frequency counter, Teletype Adaptor, a remote control for controlling that beast over a telephone line? FM? Diversity reception?? No problem, you had just buy it. Everything of course with the same standards for precision and build quality.

The outcome...

Yea, i spent a good amount of money getting this -but in my opinion it was worth every dime. I wanted a good tube receiver and i got a really good one. Compared to upper class modern Radios it's still a very good radio. So the only thing I have to add is an external SSB/AM-Synchronous Detector. The originals are nearly impossible to get today, so i decided to build one. It's on the way and i will give you the results later. So stay tuned...

2 notes

·

View notes

Note

(ravensroleplays, FNAF RP, Adventures in Babysitting Verse) How many times now had one of the kids ended up somewhere they weren't supposed to be?!?! Four times?! Five?! Fifty?!

Well, at least there was a good excuse this time, apparently, this location had wanted to borrow 'Foxy' for a few days. So here he was. It was still a good while before midnight, so the ghostly boy took the opportunity to leave his proxy body and do a little exploring. Eyes wide and alert as he took in his surroundings.

The malfunction was one of the worst in a long time.

Perhaps not 'Bite' bad.

But still.

Even so, the animatronics were always expected to have quirks. They were complex machines, a small problem every now and then was considered to be quite normal, manageable. Just a quick trip to Parts and Service. However, what had happened at Pirate's Cove was not little, it was big. The spotlight shined bright, the children were all watching in their eager excitement for the reveal of the fox...and boy, did he.

When those purple-star patterned curtains opened up what greeted the crowd wasn't the usual energetic Foxy, ready to spin a tale of the seas or shout of sharks, treasure, and if Freddy could actually beat him at a sword fight. Instead, the animatronic stood in one firm spot on the small stage twitching, eyes dark and powered off, jaw agape so much that it almost looked like his bottom jaw was going to fall right off. It didn't matter how many times Freddy attempted to prompt the pirate mascot from the main stage, in hopes to snap him out of whatever hit his system-the fox was absolutely busted. The show came to a grinding halt as an announcement sounded off, claiming Foxy wasn't feeling 'well'.

The management was utterly displeased. Parents came to complain of their children getting scared by the sight of Foxy's malfunction, birthdays were cancelled and a whole lot of free merchandise was promised. Not to mention the discount pizza vouchers. What was even worse was the mechanics came to the conclusion that they couldn't fix Foxy, he'd have to be sent back to the manufacturer to be repaired there. So, early the next morning Foxy was wheeled out the back door, placed in a wooden crate, loaded into an unmarked truck and off it went to Fazbear Entertainment Inc.

Freddy had been sworn to by one of the mechanics that Foxy would be back-their Foxy, of course. He just needed some extra care that only the experts on the assembly lines could tend to. But whether the bear truly believed that?

No. No, he didn't.

However, Freddy, Chica and Bonnie all passed their calibration tests, movement tests, dialogue tests and were cleared to do shows.

It had hardly been a week when Foxy-a Foxy-made a reappearance. Being wheeled in just before closing, employees placing the fox back behind the curtains then promptly removing the 'OUT OF ORDER' sign. Then the place was cleaned, stock accounted for, doors locked, leaving the pizzeria to the animal characters until the arrival of the night-guard at midnight.

Freddy was suspicious right off the bat and strictly forbid his bandmates from going near Pirate's Cove until he did his own investigation. And so, it seemed the fox was destined to be alone for the night.

It wasn't long before the crew of bear, bunny and chicken split off. Freddy was geared to the Parts and Service room, his mind set on breaking into the mechanics' desk for any information on the pirate fox, or where his actual friend was, where this...replacement even came from. Bonnie had sat himself down on the edge of the mainstage, guitar in his paws as he plucked at it before giving a rather impressive jam session-one he couldn't dare play during a programmed show. Finally, Chica was already across the dining hall, beelineing for the kitchen, her cupcake perched on her shoulder as she went.

But, like clockwork, the three would meet up on stage an hour or so before twelve for the 'game-plan' against the guard.

...

Foxy's Cove was simple enough for a side stage character, the stage itself being fashioned like the front of a pirate ship. On one of the inner walls was a plethora of children's drawings all depicting the fox, hanging off a rusty nail was a weathered navy blue captain's jacket and on a stool sat a pirate hat with a feather. There were also scratches in the walls from that of a sharp tip of a hook, some deeper than others.

// @ravensroleplays

#thanks for popping in!#Request Taken (posted)#Pizza By The Pound! (pre sanctuary - fnaf 1)#Freddy Fazbear#FiveNightsAtFreddy's#fnaf#five nights at freddys rp#fnaf rp#ravensroleplays

6 notes

·

View notes

Text

Why Drop Tester Are Crucial for Your Packaging Integrity

Introduction

In the realm of packaging, ensuring that products can withstand the rigors of transport is crucial for maintaining quality and customer satisfaction. This is where Drop Tester come into play. These devices are essential for assessing the durability and impact resistance of packaging materials, ensuring that they can protect contents against common handling and shipping stresses.

What is a Drop Tester?

A Drop Tester is a specialized piece of equipment used in the packaging industry to simulate the impacts that packages may endure during shipping and handling. By mimicking real-world conditions through controlled drop tests, manufacturers can assess the effectiveness of packaging in protecting its contents.

How Does a Drop Tester Work?

The core functionality of a Drop Tester involves a platform where the test package is placed. This platform is then elevated to a predetermined height—typically up to a few meters—depending on the test requirements. Upon release, the package undergoes a free fall and impacts a solid surface, which mimics the real-world impacts that occur during transportation. The effects of this impact are then analyzed to determine the package's durability and the protection it offers to the contents inside.

Key Features of Drop Tester

Drop Tester are designed with several key features that make them indispensable in the testing process:

Adjustable Drop Heights: Allows for testing under various conditions to simulate different real-world scenarios.

Precision Controls: Ensures that each test is reproducible, providing consistent and reliable results.

Versatile Testing Capabilities: Suitable for testing a wide range of packaging materials, including cardboard, plastic, and wooden crates.

The Importance of Using Drop Tester

Compliance with Safety Standards: Many industries are required to meet specific packaging standards set by regulatory bodies. Drop Tester help ensure compliance with these standards, such as those from the International Safe Transit Association (ISTA) and American Society for Testing and Materials (ASTM).

Improving Product Safety: By understanding how packaging reacts under stress, companies can innovate safer and more effective packaging solutions that reduce the risk of product damage during transit.

Cost Reduction: Effective drop testing helps in optimizing packaging by identifying over-engineered or underperforming design elements, which can lead to significant savings in material costs and reduce waste.

Applications in Different Industries

Drop Tester are used across various sectors, including:

Electronics: Ensuring that devices such as smartphones, laptops, and TVs are protected when shipped.

Pharmaceuticals: Testing packaging for medical equipment and supplies, where protection from impact is crucial.

Food and Beverage: Assessing the resilience of glass bottles, cans, and plastic containers to prevent spillage and contamination.

What standards do Drop Tester help meet?

Drop Tester help meet standards set by organizations such as:

International Safe Transit Association (ISTA): Offers protocols specific to different product types and shipping scenarios.

American Society for Testing and Materials (ASTM): Provides standardized methods for testing the physical and mechanical properties of packaging materials.

How often should testing be performed?

Testing frequency can vary based on several factors, such as:

Product Changes: Any change in product design or packaging material should prompt re-testing.

Incidence of Damage: If there's an increase in product damage during shipping, re-evaluating the packaging through drop testing is advisable.

Regulatory Requirements: Some standards may require periodic testing to ensure ongoing compliance.

FAQ

What is a Drop Tester?

A Drop Tester is a specialized device that simulates the impact a package undergoes during shipping by dropping it from a controlled height.

How does a Drop Tester work?

It securely holds a package, elevates it to a set height, and releases it to fall freely and impact a hard surface, testing the packaging's resilience.

Why is drop testing important?

Drop testing ensures that packaging can protect its contents effectively, helping to comply with safety standards and reduce damage-related costs.

What types of packages can be tested?

Drop Tester can assess a variety of packaging materials, including cardboard, plastic, and wood, accommodating different package sizes and weights.

Can Drop Tester simulate different types of falls?

Yes, they can simulate various fall scenarios such as corner, edge, and flat drops to provide comprehensive testing results.

What standards do Drop Tester help meet?

They help meet international standards like ISTA (International Safe Transit Association) and ASTM (American Society for Testing and Materials) for packaging.

How often should testing be performed?

Testing frequency should be based on new packaging introductions, changes in packaging materials, or after noticing an increase in transit damage.

What are some tips for conducting effective drop tests?

Ensure accurate simulation of shipping conditions, use controls for comparison, and thoroughly document all test results for consistent improvements.

For more insights into using Drop Tester effectively, visit Pacorr.com

Conclusion

A Drop Impact Tester is a crucial investment for any manufacturer prioritizing product quality, safety, and durability. By simulating real-world impact conditions, it allows for the identification and rectification of potential weaknesses in product design. When selecting a Drop Tester, it's essential to consider your specific testing requirements, the versatility of the equipment, and the depth of analysis you need.

0 notes

Text

The Evolution of Commercial Van Shelving

Commercial van shelving has undergone a remarkable evolution, transforming from simple storage solutions to sophisticated organizational systems tailored to the diverse needs of businesses. This evolution reflects advancements in technology, changes in industry demands, and a growing emphasis on efficiency and safety in transportation operations.

Early Beginnings:

The history of commercial van shelving can be traced back to the early days of commercial transportation when businesses relied on rudimentary storage solutions to transport goods and equipment. Wooden crates, basic shelving units, and improvised storage compartments were common fixtures in commercial vans, providing minimal organization and protection for cargo.

Industrial Revolution:

The advent of the Industrial Revolution marked a significant turning point in the evolution of commercial van shelving. As manufacturing and trade expanded, businesses sought more efficient ways to transport goods and materials. This led to innovations in storage and transportation technologies, including the development of metal shelving systems designed specifically for commercial vehicles.

The Rise of Customization:

With the rise of customization in the automotive industry, commercial van shelving became increasingly tailored to the unique needs of businesses across various sectors. Customization options allowed businesses to optimize their storage solutions according to the size, shape, and nature of their cargo, maximizing space utilization and improving workflow efficiency.

Innovations in Materials and Design:

Advancements in materials science and engineering led to the introduction of lightweight yet durable materials for commercial van shelving. Aluminum, steel, and composite materials replaced traditional wood and heavy metal shelving, offering improved strength-to-weight ratios and corrosion resistance. Innovative design features, such as adjustable shelves, modular components, and ergonomic layouts, further enhanced the versatility and functionality of commercial van shelving.

Integration of Technology:

The integration of technology into commercial van shelving systems revolutionized the way businesses manage their transportation operations. GPS tracking, inventory management software, and telematics solutions became standard features in modern commercial vans, allowing businesses to track and monitor their cargo in real time, optimize route planning, and improve overall efficiency.

Emphasis on Safety and Compliance:

In recent years, there has been a growing emphasis on safety and compliance in the transportation industry, driving innovations in commercial van shelving designed to enhance driver and cargo safety. Features such as crash-tested shelving units, load-rated tie-down points, and integrated cargo barriers help minimize the risk of accidents and ensure compliance with safety regulations.

Environmental Considerations:

Environmental sustainability has also become a key consideration in the evolution of commercial van shelving. Manufacturers are increasingly focused on reducing the environmental impact of their products by using recyclable materials, optimizing production processes, and designing energy-efficient solutions. Eco-friendly shelving options help businesses minimize their carbon footprint while maximizing efficiency and productivity.

The Future of Commercial Van Shelving:

Looking ahead, the future of commercial van shelving is characterized by continued innovation and adaptation to emerging trends and technologies. Integrated connectivity features, automation, and smart storage solutions are expected to play a more prominent role, enabling businesses to streamline their operations, reduce costs, and stay competitive in an ever-evolving marketplace.

In conclusion, the evolution of commercial van shelving has been marked by advancements in materials, design, and technology, reflecting a growing emphasis on efficiency, safety, and sustainability. With customizable options, including shelves for van, businesses can optimize their transportation operations and adapt to evolving industry demands.

0 notes

Text

Top Benefits of Using Pallets in the USA

Are you tired of loss and damage to your goods during their shipping well these damages can increase your expenses and make your business suffer. Pallets could be a perfect choice for your business. They can make your goods safe while their shipping and storing. The pallets could provide your business with multiple benefits ranging from safety to security. You must get your pallets designed by an expert manufacturer In this blog, we will guide you bout the potential benefits of using pallets in the US.

Potential Benefits Of Using Pallets In The USA

These days a lot of businesses are using USA pallets for storage and shipping of goods. You can also avail the below-mentioned advantages if you make use of shipping pallets for shipping and other tasks:

Space Optimization

If you want your business warehouse to look well-maintained and organized then space optimization is the perfect solution for you. The pallets can store a large amount of goods in them and give your storage house a better look. A well-maintained warehouse with properly arranged and managed goods can have a good impression on the visitor visiting your place. Even if you have a small or medium-sized warehouse then using pallets you can store more goods in there and in an organized manner.

Product Protection

As a business, you need to take care of the safety of your goods during transit. pallets give a defensive base to merchandise during dealing with, stockpiling, and travel. They raise items off the ground, decreasing the gamble of harm from dampness, soil, and vermin. Additionally, palletized loads are more stable and secure, making it less likely that the product will shift or tip over during transport, which is critical for items that are delicate or sensitive.

Ability to handle different product type

No matter whatever business you are undertaking pallets can easily occupy all types of goods ranging from heavyweight to lightweight goods. These pallets for sale can safeguard the goods from environmental and other kinds of damage. They are suitable for retail, manufacturing, agriculture, and pharmaceuticals because they can handle a wide range of product sizes, shapes, and weights.

Recyclability and Sustainability

Through recycling and reusing, pallets support efforts to preserve the environment. A lot of pallets are made of sustainable materials like wood from forests that have been properly managed. By repairing, remanufacturing, and upcycling pallets, pallet recycling programs also promote circular economy principles by extending their lifespans and minimizing waste and environmental impact. The pallet recycling is an innovative way to reuse the old and discarded pallets and give them a new and interesting for

Conclusion

The above-mentioned advantages of shipping pallets can make them the perfect choice Make sure you choose the right kind of pallets for your business. The pallets can fulfill your storage and shipping needs in the best manner. Explore the available pallet collection and pick the one that is perfect, for your business. You must study the quality, features, and functionality of the pallets and ensure that they can fulfill your goods storage needs.

Are you planning to buy new pallets for your business? Well, the USA Pallets and Warehousing is the right destination for all your pallets shopping and wood waste recycling. They have the best quality and exclusive shipping pallet collection with them. From recycled to wooden and customized pallets they have everything your business needs.USA Pallet & Warehousing Inc. is proud to offer a wide range of new and recycled wood shipping containers, crates, and pallet warehousing. Start your pallets shopping with them today.

#wood waste recycling#usa pallet#wooden pallets for sale#pallets for sale#custom wood pallets#pallets usa#wood pallets#pallets#pallet dimensions

0 notes

Text

#wooden chip & dip platters#wooden risers#wooden crates#wooden bowls#wooden cheese boards#wooden serving paddle boards#woodenware serving platters#wooden Salad bowls wholesale#woodenware manufacturers india

0 notes

Text

5 Reasons Why Corrugated Shipping Boxes are Ideal for Shipping

Corrugated shipping boxes are widely favored for shipping due to several reasons:

Durability: Corrugated boxes are made of sturdy, rigid materials designed to withstand the rigors of transportation. The corrugated structure, with its fluted inner layer sandwiched between two outer layers, provides excellent strength and cushioning, protecting the contents from damage caused by impacts, stacking, and rough handling during transit.

Versatility: Corrugated boxes come in various shapes, sizes, and strengths, making them suitable for shipping a wide range of products, from lightweight items like clothing and books to heavier goods like electronics and machinery. They can also be customized with inserts, partitions, and padding to securely hold and protect specific items during shipment.

Lightweight: Despite their robustness, corrugated boxes are relatively lightweight compared to alternative shipping materials like wooden crates or metal containers. This lightweight nature helps reduce shipping costs, as carriers typically charge based on weight and size.

Eco-friendly: Corrugated boxes are made from recyclable materials, primarily paperboard sourced from sustainable forestry practices. Additionally, many corrugated boxes are manufactured using recycled content, further reducing their environmental impact. After use, corrugated boxes can be recycled to make new packaging materials, contributing to a circular economy and minimizing waste.

Cost-effectiveness: Corrugated boxes are cost-effective packaging solutions for shipping due to their affordability and efficiency. They are readily available in the market at competitive prices, and their lightweight nature helps minimize shipping expenses. Moreover, their durability reduces the likelihood of product damage during transit, decreasing the need for costly replacements or returns.

In summary, Corrugated Shipping Boxes offer durability, versatility, lightweight construction, eco-friendliness, and cost-effectiveness, making them an ideal choice for shipping a wide variety of products safely and efficiently.

#cube boxes#wholesale boxes#wholesale packaging material#stock boxes#poly bags packaging#carton sealing tape#hand stretch wrap#wholesale tape

0 notes

Text

Console Table Market Insights: Key Players, Strategies, and Opportunities

Console Table Market Poised to Grow at Highest Pace owing to Increasing Demand for Modern Home Decor

Console tables are rectangular or oval shaped tables meant to be placed against the wall in an entryway, living room, or dining area. They provide extra surface space and storage. Console tables come in different styles from traditional to contemporary and are made of various materials like wood, glass, metal and stone. The growing demand for modern home decor and organizing clutter in home interiors have propelled the sales of console tables.

The global console table market is estimated to be valued at US$ 6.70 billion in 2024 and is expected to exhibit a CAGR of 5.4% over the forecast period of 2023 to 2030.

Key Takeaways

Key players operating in the console table market are IKEA, Ashley Furniture Industries, La-Z-Boy, Ethan Allen, Restoration Hardware (RH), Crate & Barrel, Pottery Barn, Wayfair, West Elm, and Bernhardt. Key players are focusing on developing sustainable and low-cost console tables to tap the growing demand.

Technological advancements like compact folding and adjustable console tables have provided more options to consumers. Companies are coming up with innovative designs, materials and finishes to make console tables more versatile and functional.

Market Trends

Modern and minimalist designs are gaining popularity in the console table market. Manufacturers are focusing on sleek, versatile and space-saving designs made of materials like wood, glass and metal to match contemporary interiors.

Sustainable and eco-friendly materials like recycled wood, bamboo and recycled plastics are being used widely to develop green console tables catering to the increasing demand for sustainable furniture.

Market Opportunities

The rising trend of blended home and work spaces due to hybrid work models has opened new growth avenues for versatile, foldable and movable console tables. Manufacturers can capitalize on it by developing multi-functional tables.

Impact of COVID-19 on Console Table Market growth

The COVID-19 pandemic has negatively impacted the global console table market. During the peak of lockdowns in 2020-21, furnishing stores were closed for several months restricting sales. Factory shutdowns disrupted production and supply chains leading to delays in fulfilling existing orders. Consumer spending also reduced dramatically as job losses increased and economic uncertainty grew.

However, with people spending more time at home due to work from home and social distancing norms, home furnishings gained increased importance. This augured well for some sections of the console table market especially in the affordable range. Online sales helped mitigate declines to some extent as e-commerce offered contactless shopping options.

Post pandemic, the console table market is expected to grow steadily underpinning economic recovery and continuity of hybrid work models. While headwinds of high inflation and rising interest rates pose downside risks, growing investments in real estate refurbishing and renovation offer new prospects.

Europe region currently dominates console table market in terms of value

Europe currently accounts for the largest share in the global console table market in terms of value. Countries like the UK, Germany, France and Italy have long traditions of wooden furniture making and hence a well-established console table industry. The region is dominated by prominent manufacturers like IKEA, Ashley Furniture Industries and La-Z-Boy.

#Concrete Bonding Agents Market Growth#Concrete Bonding Agents Market Trends#cConcrete Bonding Agents Market Size

0 notes

Text

Crating and Packing in Miami

Crating and packing is not just a service but an art that can only be manifested by the most professional companies, such as Axis Logistics Services. Driven by commitment and known by its experience, the company offers services such as crating and packing in Miami, furniture crating in Miami, and custom crating in Miami. Today, we shall take a good look at how packing and custom crating are done and what materials and objects are used to make sure that your goods are reaching their destination safely.

Crating and Packing in Miami: Visit Here

Use of protection layers for crating and packing in Miami

The use of many layers of protection is necessary in order to guarantee that your things will arrive at their destination in the same condition in which they were transported.

There are several cases in which a sturdy wooden crate serves as the initial layer. The majority of the time, this is a wooden crate that has been manufactured to order and is intended to provide the highest possible level of security for the items that are being transported. There is also the possibility of using skids and pallets made of wood that have been customised.

Other options for furniture pricing in Miami

Nevertheless, this is only the beginning. When it comes to the steps that are taken within a container to prevent objects from moving around while they are being transported, packaging experts are also quite clever.

In the field of specialty shipping, what exactly are the terms "blocking" and "bracing"?

Customers frequently inquire, "What exactly is blocking and bracing?" The use of blocking and bracing offers an additional degree of security for assets that are being shipped. When it comes to ensuring that things, particularly those that are large and/or heavy, do not shift or move within their container while they are being transported, it requires the utilization of a variety of different methods.

Typically, it is not sufficient to just cover the area surrounding a crated object with loose material in order to eliminate the possibility of the item moving around. The object should be placed in its box or on a wooden pallet, and then it should be immobilised using wood blocks or cradles that are fastened together to create a protective framework. This is a more effective method.

All about custom crating in Miami

An object or gadget that is equipped with casters, for instance, could have blocks encircling the front and rear to prevent sliding, wood bracing to restrict movement from side to side, and straps that are connected to the wood foundation to offer even more support.

It is possible to successfully secure any item, regardless of its shape or size, by employing blocking and bracing procedures that have been meticulously designed. Everything from massive pieces of industrial equipment to one-of-a-kind works of art is included in this category.

What kinds of product-specific packaging options are there to choose from?

The assets that are going to be carried provide a third layer of protection, and there are various different forms of packaging that can provide this protection. In accordance with the characteristics of the objects, these materials are chosen, and they may include the following:

Pillows with specialized padding. When transporting certain assets, it is essential to not only reduce the amount of vibration that occurs but also to make certain that the objects do not come into contact with one another or with the walls of the container. Personalized cushioning is a viable option for accomplishing this goal. Polyurethane foam is frequently used for components that are on the lighter side and more sensitive. The use of polyethylene foam is often a great choice for the protection of heavier assets. There are other materials, such as felt, that may be utilized to assist in protecting the surface finish of the units that are being crated. In many cases, it is of the utmost importance to safeguard sensitive gadgets from the frequency of vibrations and potential impacts that are encountered in transportation contexts. One frequent solution to this problem is the installation of a floating platform that has been created specifically for the crate deck and is secured to it using polyethylene foam and spring fasteners.

When it comes to designing an efficient solution, the engineering staff at Axis Logistics Services is able to deal with any frequency vibration specifications that are offered.

Material that is anti-static. Damage to sensitive electrical devices can be caused by electrostatic discharge. However, there are a variety of anti-static packing materials that may be utilized to circumvent this issue. The anti-static stretch wrap, buttle wrap, foam, and barriers are all included in this category.

Contact Us at:

Website: www.axislogisticservices.com

Contact us link: https://www.axislogisticservices.com/contact/

Address: 16295 NW 13th Ave bay c-2, Miami, FL 33169

Email: [email protected]

Phone: 3057534011

#crating miami#packing miami#logistics#logistics services#furniture delivery#logistics company#packing#logistics us#united states#furniture installation in miami

0 notes

Text

ISPM 15 Certified Crates Available Economically

Even the largest and the most fragile products will be easy to handle with high-quality crates offered by this manufacturer. They have packaging options in the form of wooden boxes and crates that come with fully enclosed and open-faced options and are made from timber sourced from sustainable forests. The wooden boxes and crates are heat treated and ISPM 15 certified. You can get them customised to ensure that the products are transported safely and securely.

0 notes

Text

Are custom rigid boxes more environmentally friendly compared to other packaging options?

Custom rigid boxes, often made from materials such as cardboard, paperboard, or other forms of dense paper-like materials, can be compared to other packaging options in terms of environmental friendliness using the context of the wood packaging industry and the wood pallet manufacturing process.

Pallet Foundation: Pallets, particularly wooden pallets, are a foundational element in the wood packaging industry. They are widely used for transporting goods of various kinds. The sustainability of wooden pallets can be linked to the fact that wood is a renewable resource. However, the environmental impact of wooden pallets includes the energy and resources used in harvesting, manufacturing, and transporting the wood. The treatment of wood to ensure durability and pest resistance also contributes to environmental considerations.

Wood Packaging Industry: This industry encompasses a variety of products including pallets, crates, and boxes. The wood packaging industry relies heavily on the availability and sustainability of timber resources. While wood is biodegradable and recyclable, the environmental footprint of this industry also includes the impact of logging, processing, and the potential use of chemicals for wood preservation.

Wood Pallet Manufacturing Process: This process involves cutting, shaping, and assembling wood into pallets. The energy used in the manufacturing process, along with waste generated from wood offcuts and sawdust, contribute to its environmental footprint. However, advancements in technology and practices such as recycling and repurposing can mitigate some of these impacts.

In comparison, custom rigid boxes made from paper-based materials may have a different environmental profile. These are often produced using recycled materials and can be more easily recycled after use, reducing their overall environmental impact. The manufacturing process of these boxes, depending on the practices and materials used, might also be less resource-intensive than that of wood pallet manufacturing.

In summary, custom rigid boxes could be more environmentally friendly compared to wood-based packaging options like pallets, depending on factors such as the source of their materials, the manufacturing process, and their end-of-life recyclability. However, it's also important to consider the entire lifecycle of the packaging, including production, usage, and disposal, to make a comprehensive assessment of its environmental friendliness.

0 notes