#Zinc Dust Market

Text

Zinc Dust Market: Driving Growth through Increasing Need for Corrosion Protection

Market Overview:

The global Zinc Dust market is estimated to be valued at US$1,479.7 million in 2021 and is expected to reach US$ Mn by 2022 with a CAGR of 3.7% during the forecast period of 2023-2030, according to a report published by Coherent Market Insights. Zinc dust is a fine powdered form of zinc, widely used in various industries for its superior anti-corrosive properties. With the increasing need for effective corrosion protection in applications such as coatings, paints, rubber, and chemical products, the Zinc Dust market is expected to witness significant growth.

Market Key Trends:

One key trend in the Zinc Dust market is the growing demand from the automotive industry. Zinc dust is extensively used in the automotive sector for cathodic protection, mainly in the production of anti-corrosive coatings for vehicle parts and structures. The rising demand for lightweight vehicles and the need to enhance the durability and longevity of automotive components are driving the adoption of zinc dust. For instance, zinc dust is used in the manufacturing of galvanized steel, which is widely used in automotive body panels. This trend is expected to propel the market growth of Zinc Dust during the forecast period.

Porter's Analysis:

- Threat of New Entrants: The entry barriers for new players in the Global Zinc Dust Market are moderate. Established players have strong distribution networks and brand recognition, making it challenging for new entrants to gain market share. Additionally, the capital-intensive nature of zinc dust manufacturing processes further limits the entry of new players.

- Bargaining Power of Buyers: Buyers in the Zinc Dust market have moderate bargaining power due to the presence of numerous suppliers in the market. However, the critical anti-corrosion properties of zinc dust make it an essential component for various industries, giving buyers limited power to negotiate prices.

- Bargaining Power of Suppliers: Suppliers of zinc dust have moderate bargaining power due to the availability of alternative sources of zinc. However, the industry's concentration is relatively high, with a few key market players dominating the market, which can influence the supply chain dynamics.

- Threat of New Substitutes: The threat of new substitutes in the Zinc Dust market is low. Zinc dust has unique anti-corrosive properties that are difficult to replicate with alternative materials. Therefore, the demand for zinc dust is expected to remain stable despite the availability of substitute products.

- Competitive Rivalry: The competitive rivalry in the Zinc Dust market is intense. Key players are actively engaged in research and development activities to develop innovative products and gain a competitive edge. Market players are also focusing on strategic collaborations and mergers to expand their market presence and enhance their product offerings.

Key Takeaways:

- The global Zinc Dust market is expected to witness high growth, exhibiting a CAGR of 3.7% over the forecast period, driven by the increasing need for corrosion protection. Zinc dust's excellent anti-corrosion properties make it a preferred choice in industries such as coatings, paints, rubber, and chemicals.

- Asia Pacific is the fastest-growing and dominating region in the Zinc Dust market. The region's rapid industrialization, booming construction sector, and increasing automotive production are contributing to the high demand for zinc dust in this region.

0 notes

Text

Zinc Dust Market Growth, Overview with Detailed Analysis 2022-2030

Zinc Dust Market Growth, Overview with Detailed Analysis 2022-2030

The Zinc Dust Market research report 2022-2030 provides an in-depth analysis of the changing trends, opportunities, and challenges influencing the growth over the next decade. The study includes a detailed summary of each market along with data related to demand, supply and distribution. The report examines Zinc Dust market growth strategies adopted by leading manufacturers which include new…

View On WordPress

#Covid-19 Impact Analysis#Zinc Dust#Zinc Dust forecast#Zinc Dust Industry#Zinc Dust Market#Zinc Dust price#Zinc Dust report#Zinc Dust research#Zinc Dust share#Zinc Dust trends

0 notes

Text

For two decades, researchers worked to solve a mystery in West Coast streams. Why, when it rained, were large numbers of spawning coho salmon dying? As part of an effort to find out, scientists placed fish in water that contained particles of new and old tires. The salmon died, and the researchers then began testing the hundreds of chemicals that had leached into the water.

A 2020 paper revealed the cause of mortality: a chemical called 6PPD that is added to tires to prevent their cracking and degradation. When 6PPD, which occurs in tire dust, is exposed to ground-level ozone, it’s transformed into multiple other chemicals, including 6PPD-quinone, or 6PPD-q. The compound is acutely toxic to four of 11 tested fish species, including coho salmon.

Mystery solved, but not the problem, for the chemical continues to be used by all major tire manufacturers and is found on roads and in waterways around the world. Though no one has studied the impact of 6PPD-q on human health, it’s also been detected in the urine of children, adults, and pregnant women in South China. The pathways and significance of that contamination are, so far, unknown.

Still, there are now calls for regulatory action. Last month, the legal nonprofit Earthjustice, on behalf of the fishing industry, filed a notice of intent to sue tire manufacturers for violating the Endangered Species Act by using 6PPD. And a coalition of Indian tribes recently called on the EPA to ban use of the chemical. “We have witnessed firsthand the devastation to the salmon species we have always relied upon to nourish our people,” the Puyallup Tribal Council said in a statement. “We have watched as the species have declined to the point of almost certain extinction if nothing is done to protect them.”

The painstaking parsing of 6PPD and 6PPD-q was just the beginning of a global campaign to understand the toxic cocktail of organic chemicals, tiny particles, and heavy metals hiding in tires and, to a lesser extent, brakes. While the acute toxicity of 6PPD-q and its source have strong scientific consensus, tire rubber contains more than 400 chemicals and compounds, many of them carcinogenic, and research is only beginning to show how widespread the problems from tire dust may be.

While the rubber rings beneath your car may seem benign — one advertising campaign used to feature babies cradled in tires — they are, experts say, a significant source of air, soil, and water pollution that may affect humans as well as fish, wildlife, and other organisms. That’s a problem because some 2 billion tires globally are sold each year — enough to reach the moon if stacked on their sides — with the market expected to reach 3.4 billion a year by 2030.

(Researchers weigh a salmon that died after four hours in a tank filled with road runoff.)

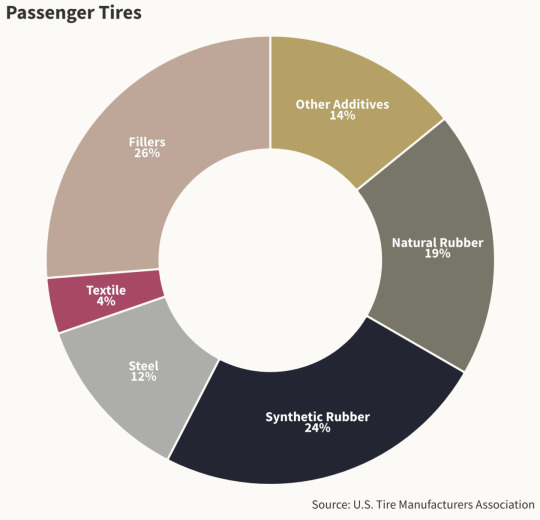

Tires are made from about 20 percent natural rubber and 24 percent synthetic rubber, which requires five gallons of petroleum per tire. Hundreds of other ingredients, including steel, fillers, and heavy metals — including copper, cadmium, lead, and zinc — make up the rest, many of them added to enhance performance, improve durability, and reduce the possibility of fires.

Both natural and synthetic rubber break down in the environment, but synthetic fragments last a lot longer. Seventy-eight percent of ocean microplastics are synthetic tire rubber, according to a report by the Pew Charitable Trust. These fragments are ingested by marine animals — particles have been found in gills and stomachs — and can cause a range of effects, from neurotoxicity to growth retardation and behavioral abnormalities.

“We found extremely high levels of microplastics in our stormwater,” said Rebecca Sutton, an environmental scientist with the San Francisco Estuary Institute who studied runoff. “Our estimated annual discharge of microplastics into San Francisco Bay from stormwater was 7 trillion particles, and half of that was suspected tire particles.”

Tire wear particles, or TWP as they are sometimes known, are emitted continually as vehicles travel. They range in size from visible pieces of rubber or plastic to microparticles, and they comprise one of the products’ most significant environmental impacts, according to the British firm Emissions Analytics, which has spent three years studying tire emissions. The company found that a car’s four tires collectively emit 1 trillion ultrafine particles — of less than 100 nanometers — per kilometer driven. These particles, a growing number of experts say, pose a unique health risk: They are so small they can pass through lung tissue into the bloodstream and cross the blood-brain barrier or be breathed in and travel directly to the brain, causing a range of problems.

According to a recent report issued by researchers at Imperial College London, “There is emerging evidence that tyre wear particles and other particulate matter may contribute to a range of negative health impacts including heart, lung, developmental, reproductive, and cancer outcomes.”

The report says that tires generate 6 million tons of particles a year, globally, of which 200,000 tons end up in oceans. According to Emissions Analytics, cars in the U.S. emit, on average, 5 pounds of tire particles a year, while cars in Europe, where fewer miles are driven, shed 2.5 pounds per year. Moreover, tire emissions from electric vehicles are 20 percent higher than those from fossil-fuel vehicles. EVs weigh more and have greater torque, which wears out tires faster.

Unlike tailpipe exhaust, which has long been studied and regulated, emissions from tires and brakes — which emit significant amounts of metallic particles in addition to organic chemicals — are far harder to measure and control and have therefore escaped regulation. It’s only in the last several years, with the development of new technologies capable of measuring tire emissions and the alarming discovery of 6PPD-q, that the subject is receiving much needed scrutiny.

Recent studies show that the mass of PM 2.5 and PM 10 emissions — which are, along with ozone and ultrafine particles, the world’s primary air pollutants — from tires and brakes far exceeds the mass of emissions from tailpipes, at least in places that have significantly reduced those emissions.

The problem isn’t just rubber in its synthetic and natural form. Government and academic researchers are investigating the transformations produced by tires’ many other ingredients, which could — like 6PPD — form substances more toxic than their parent chemicals as they break down with exposure to sunlight and rain.

“You’ve got a chemical cocktail in these tires that no one really understands and is kept highly confidential by the tire manufacturers,” said Nick Molden, the CEO of Emissions Analytics. “We struggle to think of another consumer product that is so prevalent in the world, and used by virtually everyone, where there is so little known of what is in them.”

“We have known that tires contribute significantly to environmental pollution, but only recently have we begun to uncover the extent of that,” said Cassandra Johannessen, a researcher at Montreal’s Concordia University who is quantifying levels of tire chemicals in urban watersheds and studying how they transform in the environment. The discovery of 6PPD-q has surprised a lot of researchers, she said, because they have learned that “it’s one of the most toxic substances known, and it seems to be everywhere in the world.”

Regulators are playing catch up. In Europe, a standard to be implemented in 2025, known as Euro 7, will regulate not only tailpipe emissions but also emissions from tires and brakes. The California Environmental Protection Agency has passed a rule requiring tire makers to declare an alternative to 6PPD-q by 2024.

(A worker takes apart a tire at a recycling shop in Mit al-Harun, Egypt.)

Tire companies are conducting their own studies of 6PPD, which they have long considered critical for tire safety, and seeking alternatives. In response to new regulations and the emerging research on tire emissions, 10 of the world’s large tire manufacturers have formed the Tire Industry Project to “develop a holistic approach to better understand and promote action on the mitigation” of tire pollution, according to a statement by the project. The group has committed to search for ways to redesign tires to reduce or eliminate emissions.

One critical area of research is how long tire waste, and its breakdown products, persist in the environment. “A five-micron piece of rubber shears off the tire and settles on the soil and sits there a while,” said Molden. “What, over time, is the release of those chemicals, how quickly do they make their way into the water, and are they diluted? At the system level, how big of a problem is this? It is the single biggest knowledge gap.”

Another area of research centers on the impacts of aromatic hydrocarbons — including benzene and naphthalene — off-gassed by synthetic rubber or emitted when discarded tires are burned in incinerators for energy recovery. Even at low concentrations, these compounds are toxic to humans. They also react with sunlight to form ozone, or ground-level smog, which causes respiratory harm. “We have shown that the amount of off-gassing volatile organic compounds is 100 times greater than that coming out of a modern tailpipe,” said Molden. “This is from the tire just sitting there.”

When tires reach their end of life, they’re either sent to landfills, incinerated, burned in an energy-intensive process called pyrolysis, or shredded and repurposed for use in artificial turf or in playgrounds or for other surfaces. But as concern about tire pollutants grows, so do concerns about these recycled products and the hydrocarbons they may off-gas. There is ongoing debate over whether crumb rubber, made from tire scraps, poses a health threat when used to fill gaps in artificial turf. Based on several peer-reviewed studies, the European Union is instituting stricter limits on the use of this material. Other studies, however, have shown no health impact.

Besides California’s requirement to study alternatives to 6PPD, there are a number of efforts worldwide to redesign tires to counter the problems they pose. More than a decade ago, tire makers hoped that dandelions, which produce a form of rubber, and soy oil could provide a steady and sustainable supply of rubber. But tires made from those alternatives didn’t live up to expectations: they still required additives. The Continental Tire Company, based in Hanover, Germany, markets a bicycle tire made of dandelion roots. Tested by Emission Analytics, it emitted 25 percent fewer carcinogenic aromatics than conventionally made bike tires, but the plant-powered tire still contained ingredients of concern.

(Rubber made from dandelions.)

Other companies are searching for ways to address the problem of tire emissions. The Tyre Collective, a clean-tech startup based in the U.K., has developed an electrostatic plate that affixes to each of a car’s tires: The plates remove up to 60 percent of particles emitted by both tires and brakes, storing them in a cartridge attached to the device. The particles can be reused in numerous other applications, including in new tires.

In San Francisco, scientists studying the pollutants in storm runoff found a potential solution: Rain gardens, installed in yards to capture stormwater, were also trapping 96 percent of street litter and 100 percent of black rubbery fragments. In Vancouver, B.C. researchers found that rain gardens could prevent more than 90 percent of 6PPD-q from running off roads and entering salmon-bearing streams.

Tire waste particles, says Molden, of Emissions Analytics, are finally getting the attention they deserve, thanks in part to California’s rule requiring a search for alternatives to 6PPD. The legislation “is groundbreaking,” he says, “because it puts the chemical composition [of tires] on the regulatory agenda.” For the first time, he adds, “Tire manufacturers are being exposed to the same regulatory scrutiny that car manufacturers have been for 50 years.”

8 notes

·

View notes

Text

Sodium Lignosulfonate Market Insight, Outlook, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global sodium lignosulfonate market size at USD 1.19 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global sodium lignosulfonate market size to grow at a significant CAGR of 3.78% reaching a value of USD 1.49 billion by 2029. Major growth drivers for the global sodium lignosulfonate market include a surging number of residential and non-residential construction projects, coupled with the rising demand for concrete admixtures in the construction sector, as well as the need for lignosulfonates as oil additives in the oil and gas industry. Sodium lignosulfonate is widely used as a water-reducing and dispersing agent in concrete admixtures. The growing construction industry worldwide, especially in emerging economies, has led to an increased demand for sodium lignosulfonate to enhance concrete performance, improve workability, and reduce water usage. Another notable factor, sodium lignosulfonate is used as a dispersing agent and binder in agriculture, primarily in fertilizers and animal feed. The growth of the agricultural sector, driven by the increasing need for food production, has contributed to the demand for sodium lignosulfonate in this domain. Also, sodium lignosulfonate finds applications in oil drilling as a deflocculant and water-reducing agent. The expansion of oil and gas exploration and drilling activities has resulted in increased demand for sodium lignosulfonate in the oilfield chemicals sector. However, price volatility of raw materials and limited awareness and adoption in a few regions are anticipated to restrain the overall market growth during the period in analysis.

Global Sodium Lignosulfonate Market – Overview

Sodium Lignosulfonate, a water-reducing additive in concrete mixtures, is a water-soluble and versatile polymer electrolyte with the chemical formula C₂₀H₂₄Na₂O₁₀S₂. Its unique properties enable the efficient dispersion of biological slime, oxidizing phosphate scale, and iron (Fe) scale, while also forming stable complexes with zinc and calcium ions. Production methods involve ion exchange and pulping with sodium carbonate or sodium hydroxide. With low air content and high water-reducing rates, this chemical exhibit adaptability to various cement types, making it an ideal choice for construction projects, including dams, buildings, and highways. It finds extensive application in the construction sector for residential and non-residential structures. Additionally, it serves as a plasticizer, dust suppressant, gypsum plasterboard, animal feed binder, and oil well additive. Sodium Lignosulfonate stands as a multifunctional solution catering to diverse industries.

Sample Request @ https://www.blueweaveconsulting.com/report/sodium-lignosulfonate-market/report-sample

Impact of COVID-19 on Global Sodium Lignosulfonate Market

COVID-19 pandemic had a mixed impact on the global sodium lignosulfonate market. During the initial phases, lockdowns and restrictions on construction activities led to a temporary decline in demand from the construction sector. However, the market found some resilience due to its applications in essential sectors like agriculture and animal feed. The increasing demand for disinfectants during the pandemic also boosted sodium lignosulfonate usage in the production of cleaning agents. Overall, while certain segments faced challenges, the market's diverse applications and adaptability to changing demands helped mitigate the adverse effects, enabling a gradual recovery as economic activities resumed.

Global Sodium Lignosulfonate Market – By Application

By application, the global sodium lignosulfonate market is divided into Animal Feed Binder, Concrete Admixture, Oil Well Additives, Agricultural Chemicals, and Lead Batteries segments. The concrete admixture segment is expected to hold the highest market share during the forecast period by application. Concrete admixtures play a vital role in the construction industry, enhancing concrete performance and workability. Sodium lignosulfonate's effectiveness as a water-reducing agent makes it sought-after in construction projects worldwide. With a growing construction industry and infrastructure development, the demand for concrete admixtures, including sodium lignosulfonate, is on the rise. Its versatility allows for use in various concrete formulations, compatible with different cement types. Also, sodium lignosulfonate's cost-effectiveness makes it an appealing choice for construction companies aiming to enhance concrete quality while optimizing costs. As a result, it remains a significant contributor to the global sodium lignosulfonate market.

Competitive Landscape

Major players operating in the global sodium lignosulfonate market include Material Technology, Abelin Polymers, Sappi, Nippon Paper Industries Co. Ltd., Borregaard LignoTech, Cardinal Chemicals, Liaocheng Jinhui Chemical, Domsjo Fabriker, Tembec, Burgo Group, and Shenyang Xingzhenghe Chemical. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Zinc Stearate Sandpaper: A Revolutionary Product In The Market

Zinc Stearate Sandpaper: A Revolutionary Product In The Market

For years, sandpaper has been an essential tool in the woodworking industry. It is used for cutting, smoothing, and shaping various kinds of materials, including wood, metal, and plastic. The primary purpose of sandpaper is to remove surface defects and rough edges. However, there has been a new addition to the range of sandpapers available in the market - the zinc stearate sandpaper.Get more news about Zinc Stearate,you can vist our website!

Zinc stearate is a compound derived from stearic acid and zinc. Stearic acid is a saturated fatty acid commonly found in animal and vegetable fats, while zinc is a mineral with various uses, including the manufacturing of batteries, alloys, and fertilizers. The combination of these two substances results in the creation of zinc stearate, a white, powdery substance that has numerous industrial applications. In sandpapers, zinc stearate is added to the abrasive coating, which increases the life and durability of the sandpaper.

Zinc stearate sandpaper has several advantages over traditional sandpaper. It is popularly known for its anti-clogging properties, which reduces the build-up of dust and debris on the abrasive surface of the sandpaper. This results in a smoother finish and a longer life of the sandpaper. Additionally, zinc stearate sandpaper doesn't overheat the material being worked on, which makes it an ideal choice for grinding and sanding at high speeds.

With the growing demand for zinc stearate sandpapers in the woodworking industry, manufacturers have started producing them in various grits and sizes. They are readily available both online and offline, making it easier for consumers to purchase them.

In conclusion, zinc stearate sandpapers are a revolutionary product that is changing the game in the woodworking industry. They offer several advantages over traditional sandpapers, and with the increasing demand for them, they are becoming more affordable and readily available. If you're on the lookout for the perfect sandpaper for your next DIY project, you should definitely try zinc stearate sandpaper.

0 notes

Text

ShellPrime EZ106 Market Global Demand, Product Growth, Product Scenario, Application

A two-component zinc-rich epoxy primer is a type of protective coating used in corrosion protection systems for metal surfaces. It consists of two separate components that need to be mixed together before application. The components typically include a base component (Part A) and an activator or curing agent (Part B).

The key feature of a zinc-rich epoxy primer is its high zinc content. The primer contains a significant amount of zinc dust or zinc powder, which acts as a sacrificial anode. When the coating is applied to a metal surface, the zinc particles provide cathodic protection by corroding preferentially to the underlying metal. This sacrificial protection helps to prevent or slow down the corrosion process.

Read more@ https://supremebituchem.com/

Here are the general steps involved in using a two-component zinc-rich epoxy primer:

Surface Preparation: The metal surface to be coated should be clean, dry, and free from rust, grease, oil, or other contaminants. Proper surface preparation, such as abrasive blasting or mechanical cleaning, is essential for ensuring good adhesion and performance of the primer.

Mixing: The two components, Part A (base) and Part B (activator), are typically mixed together in a specific ratio as specified by the manufacturer. Mixing can be done manually or using specialized equipment, such as a power mixer. Follow the manufacturer's instructions for accurate mixing proportions and techniques.

Pot Life: The pot life of the mixed primer refers to the time window during which it can be applied. It is important to note and adhere to the pot life specified by the manufacturer. Once the pot life is exceeded, the mixture can start to cure and become unusable.

Application: Apply the mixed primer to the prepared metal surface using a brush, roller, or spray equipment. Follow the recommended film thickness and coverage rate specified by the manufacturer. It is crucial to achieve uniform and adequate coverage for optimum protection.

Curing: The curing process begins once the primer is applied to the surface. Curing time varies depending on factors such as temperature, humidity, and the specific product used. Follow the manufacturer's instructions regarding the curing time required before further coating or topcoat application.

Two-component zinc-rich epoxy primers are commonly used as a base coat in various industries, including marine, oil and gas, heavy equipment, and infrastructure. They provide excellent adhesion, corrosion resistance, and long-term protection for metal substrates in aggressive environments. However, it's important to note that specific product instructions and technical data from the manufacturer should always be followed for accurate application and performance.

0 notes

Text

8 Different Types Of Metal Cutting Tools And Their Uses

It is possible to be confused about how to choose the right metal cutting machine for you. This guideline will be worth reading to find out what kinds of metal cutting tools you may get available. Also, you will learn about how to use these tools.

Metal cutting is a process that allows you to cut metal in your desired shapes and sizes, also remove unnecessary objects off of the metal workpiece.

Metal cutting tools are instruments used to cut different types of metals. These tools are mostly used for shaping and cutting metal. The tools are used differently in accordance with their style. Whether you really want to learn more details on tools, you've to browse around https://www.sundicuttingtools.com/products/full-solid-cbn-inserts/ website.

This article will cover the different types of tools for cutting metal that are on the market and how they are best used.

Many different types of metal cutting tools

Different cutting instruments are being used to cut metals. Some of them are very useful and do their job well. This is a list of the most effective metal cutting tools.

The Saw

The blade of the saw is toothed, and it will cut through plastic wood or metal depending on what type of tool it is.

They are used by DIYers and metalworkers in order to cut through metal. For this kind of cutting, there are quite a number of saws you'll need included in your toolbox.

Cold Saw

Cold saws can slice through almost anything, starting with the stainless steel to tin, nickel, brass, titanium, copper, aluminum, lead, zinc to alloy steel, and carbon steel. Cold saws produce fewer sparks and less noise.

The circular saw generates no heat and cuts smoothly without friction. The result is a cold saw. The coolant allows for precise cutting, minimal discoloration and dust free production. The price is worth it if you do work with metal on a regular basis.

Hacksaw

Hacksaws are C-shaped saw that has a small blade. It is possible to adjust the frame with different blades. It is an excellent and affordable option for small metal cutting jobs.

Metal Circular Saw

Metal-cutting blades are used for the circular saw that makes it a "metal circular saw". It can cut straight up to 3/8 inches. Mild steel is an excellent quality thickness for mild steel. By using a circular saw, you can cut metal sheeting, roofing metals such as corrugated steel the majority of other metals. When cutting roofing be sure to hold it in the correct direction if necessary.

Install a blade in your saw. Mark the areas you want to cut. After that, cut in accordance with the plan. In order to speed up the process cutting large amounts of material in the same time using a knife made from ferrous metal. It's a fantastic tool for easy and straight cuts.

Band Saws

Band saws are excellent for cutting large quantities. It can be used to cut layers of thick material in curves. This tool can be used to cut unusual shapes.

It is a uninterrupted metal band that runs along the sharp-toothed blade to cut tube-like metal and flat material.

Oxy-Acetylene Torch

This tool produces flames at a high temperature. This tool is a torch which mixes acetylene, the gas derived from hydrocarbons, along with oxygen. The torch is able to cut through metals so thick that a normal saw cannot.

Another great feature is that this tool is very noisy compared to other saws or metal cutting tools. This tool is much more quickly.

Tin Snips

Tin snips are like an apron. When you need to cut various sheet metals, the kit you'll need is a pair of Tin cutting snips. The handheld tool is not that expensive.

This tool is great for cutting curvatures, straight lines or even circles, in soft metals. It's also convenient for cutting metal roofing, sheets of sheet metal, gutters and studs, while leaving an even edge.

Metalworkers make use of tin snips cut sheet metals for car bodies. Professional metalworkers cut corrugated metal using tin snips. You'll have to hold the tin snips as an axe. Keep the blades of the tool open wide, and then cut long and smooth. Cut until the work is completed.

Metal Air Shears

They are perfect for cutting large pieces of steel or even strips. Additionally, it is possible to rotate the head to make an exact cut. They produce better cuts and lesser spark.

It is easy to replace the blade. The blade can be cut in straight or curly lines. You can do both with an air shears. They can provide a different option to the tin snips but it will give a faster and more efficient result. It can be hand powered or electrically. Look for an item with handles that are insulated.

Angle Grinder with Cutoff Wheel

Angle grinders can be utilized to fabricate metal, such as cutting, grinding and finishing. They can also remove the surface, polish it, and take away burrs. It typically operates on electric power, either via a cord or battery. It is possible to cut through metals using an iron cutoff wheel.

Angle grinders can also be used to grind, sharpen and cut metal, in addition to removing the rust. An angle grinder is an excellent tool for seasoned DIYers and metalworkers.

0 notes

Text

What is the best paint to prevent rust on metal? - Trywonderx

At Trywonderx, we strive to provide the best in paint technology and maintenance products that keep your metals looking and functioning as they should. Our special rust prevention paint is perfect for those exposed to moisture and can keep your metal from corroding. With easy application and a variety of colors available, you can feel confident that you're taking care of your metal and keeping it rust-free with Trywonderx!

Rust is a natural byproduct of metal against metal contact. Rust can cause corrosion and eventually lead to a breakdown in the metal. There are different types of rust, each with its own prevention method. The best paint to prevent rust on metal may vary depending on the type of rust and the surface being painted.

best paint to prevent rust on metal?

When it comes to preventing rust on metal, the best paint to use is one that contains rust inhibitors or has anti-corrosion properties. Here are some options to consider:

Rust-Oleum 7779-830 - Rust-Oleum is a popular brand that produces a range of paints and coatings for metal. Their 7779-830 High-Performance Protective Enamel contains rust inhibitors and is designed to provide excellent corrosion resistance.

Krylon K09198000 - Krylon's Rust Protector Enamel is a durable paint that is designed to protect metal surfaces from rust and corrosion. It is ideal for use on outdoor furniture, garden tools, and other metal objects that are exposed to the elements.

POR-15 Rust Preventive Coating - POR-15 is a high-performance coating that is specifically designed to prevent rust and corrosion. It forms a barrier that seals out moisture and prevents rust from forming on the surface.

Behr Premium Direct to Metal Semi-Gloss Paint - Behr's Premium Direct to Metal Semi-Gloss Paint is a water-based paint that is designed to provide excellent adhesion and corrosion resistance. Best Paint to Prevent Rust on Metal It can be used on a variety of metal surfaces, including doors, windows, and trim.

Ultimately, the best paint to prevent rust on metal will depend on the specific application and the conditions the metal will be exposed to. It is important to choose a paint that is specifically designed for use on metal surfaces and has anti-corrosion properties to ensure maximum protection.

Different types of paint and their abilities to prevent rust

There are different types of paint available in the market that have varying abilities to prevent rust. Here are some of the commonly used paint types and their abilities to prevent rust:

Oil-based paint: Oil-based paints are effective in preventing rust as they create a barrier between the metal surface and the moisture that causes rust. They also provide excellent adhesion and durability, making them suitable for use on metal surfaces.

Epoxy paint: Epoxy paints are a type of two-part coating that provides excellent protection against rust. They form a hard, durable surface that can resist corrosion, abrasion, and chemicals. Best Paint to Prevent Rust on Metal Epoxy paints are ideal for use in high-moisture environments, such as on boats or in industrial settings.

Rust-inhibiting primer: Rust-inhibiting primers are specially designed to prevent rust from forming on metal surfaces. They contain chemicals that react with the surface of the metal to create a protective layer that prevents moisture from reaching the metal.

Zinc-rich paint: Zinc-rich paint is a type of paint that contains a high percentage of zinc dust, which provides excellent corrosion protection. The zinc particles in the paint form a barrier between the metal surface and the environment, preventing rust from forming.

Powder coating: Powder coating is a type of coating that involves applying a dry powder to a metal surface and then baking it to create a hard, durable finish. Powder coating provides excellent protection against rust and corrosion, making it suitable for use in a variety of environments.

It's important to note that while these paint types can help prevent rust, they are not foolproof solutions.Best Paint to Prevent Rust on Metal Proper surface preparation, application, and maintenance are also critical to ensuring the longevity of the paint and the prevention of rust.

Conclusion:

In conclusion,we would like to remind our customers that we offer a wide variety of paint and metal maintenance products at Trywonderx. Our team is dedicated to providing the best possible service and products for your needs. Thanks for choosing Trywonderx!

Contact - [email protected]

Phone Number: 020 - 2606 1530Location: Suprabha Corporate House,

373, Somwar Peth, Pune - 411 001, India

#rust remover spray for cars#black rust prevention paint#rust off spray#rust remover spray#prevent rusting of iron equipment#heat resistance of silver paint#heat coat spray#best way to remove rust on metal#rust remover

0 notes

Link

Check out this listing I just added to my Poshmark closet: COPY - Authentic Dagne Dover Landon Carryall Bag.

0 notes

Text

VOOPOO ARGUS GT II Mod + UFORCE -L tank review: a real experience with the two

Previously our author reviewed the VOOPOO ARGUS GT II Mod kit with an atomizer inside, and today the editor himself is going to review the VOOPOO ARGUS GT II again. However, this time it will be reviewed with a different atomizer named UFORCE - L tank. This edition of the ARGUS GT II device is without atomizers or tanks, so you need to find one yourself or just choose the UFORCE - L together to begin. Let's start the review now.

VOOPOO ARGUS GT II Mod + UFORCE -L experience

This device looks good outside. The shining aluminum shell and wood-life surface look cool and tough.

Though the part that looks like wood is not wood, it's a kind of soft plastic foam.

Compared to VOOPOO Drag 4, some buttons like the unlock button and the battery opening button, are a little hard to operate. Compare to the Drag 4 real wooded shell and easy-to-use slider battery cover design, it's a downgrade.

However, the device features IP68 tri-proof certificated design. With the advanced IP68 rating water-proof, dust-proof and drop-proof function, Argus GT II is a device for outdoor use. It's a feature that most mods don't have, making it unique. Instead of calling it a delicate one, a tough one would be more suitable.

At least you can find a working one instead of a broken one if you drop it into water accidentally.

https://us-video.voopoo.com.cn/voopoo_com/video/202208/argus-gt2.mp4

It functions as well as Drag 4, on par with any leading mod devices. The device is working perfect from 5-200W. A very powerful and versatile device for all kinds of e-liquids. There are many high techs applied to the device, like Gene TT2.0 chip, power management system and so on. Smart, RBA, Turbo, and TC mods are available to choose from, for different preferences for vaping. Mouth-to-lung or direct-to-lung vaping are both supported on this device.

If this device is called an adult man on the level of performance, the disposable vapes are just toddlers. It's reversed in the aspect of ease of use.

As to the atomizer, the mouthpiece is even larger than the original one. You can see it in the following pictures. I read from their official site that the air inlets balance the airflow, reduce convective flow and smooth the vapor. It's indeed. Quite smooth with the super large air holes.

The heat-resistant glass and stainless steel bring a safe and durable experience. The glass is tough, too, I dropped it on the ground several times and it just doesn't break.

It makes use of PNP DUAL IN ONE tech. The triple ware structure accelerates the heating speed, gets a more delicate taste and a stronger outbreak. The double mesh design gathers more heat, increases atomization efficiency and brings out a richer flavor. It's true, flavor from it is original, natural and silky, didn't find any issue with it.

There a different tank capacities to choose from, including 4, 5.5, 2ml, catering to different preferences. And the atomizing core includes 1.5, 2Ω, two different versions, for different vapor amount and e-liquids.

VOOPOO ARGUS GT II mod device specifications/ parameters

Size: 90*54*29mm

Name: ARGUS GT II

Material: Leather + Zinc Alloy

Output Power: 5-200W

Output Voltage: 0-12V

Resistance range: 0.05-3.0Ω

Charging voltage: 5V/3A

Battery: 18650*2 (Not included)

https://www.youtube.com/watch?v=OE9Y2NROQU4

VOOPOO UFORCE - L tank specifications/ parameters

UFORCE-L TANK (4mI)*1

PNP-TW20 (0.2Ω)*1

PNP-TW15 (0.15Ω)*1

Spare Glass Container (5.5mI)*1

Silicon Rubber Pack*1

User Manual *1

https://www.youtube.com/watch?v=l4L6TXjxh_I

Verdict

Overall speaking, VOOPOO ARGUS GT II Mod and UFORCE -L tank works great in the aspect of vaping function. The tri-proof design feature is peerless on market. However, the wooden-like surface and buttons don't look high-end enough. Nevertheless, who cares about the look so much rather than the performance?

Where to buy VOOPOO ARGUS GT II mod device

Where to buy VOOPOO UFORCE -L

Read the full article

0 notes

Text

What Does a Zinc Rich Coating Mean?

When in close proximity to steel, a coating with a high concentration of zinc dust is known as a zinc rich coating. Zinc Rich Coating are applied to steel surfaces to prevent corrosion and extend their lifespan. Similar to cold galvanizing, zinc-rich coatings protect metals from cathodic corrosion.

Zinc rich coatings are utilized by numerous enterprises to shield steel substrates from consumption. Industrial, automotive, and highway infrastructure applications all make use of them.

Zinc Rich Coating While regular paints protect by creating an impermeable barrier between the metal and moisture from the environment, zinc rich coatings provide cathodic protection. Steel is protected by the cathodic cell, but zinc is not. Additionally, zinc coatings offer the surface some barrier protection.

Although a zinc-rich coating can be applied on its own, it is typically overlaid with paint or epoxy. Under a top coat of epoxy or urethane paint, this primer serves as a backup or additional method of protecting the steel from corrosion.

Coatings made of zinc come in two varieties:

Inorganic: Coatings made of inorganic zinc must be applied by spraying. When not coated with a top coat, inorganic zinc coatings protect steel better than organic zinc coatings that are not coated with a top coat.

Natural: Coatings made of organic zinc are typically applied with a brush, roller, or spray. They are not as protective of the steel as an inorganic primer if a top coat is not applied. When top-coated, organic zinc coatings offer the same level of protection as inorganic coatings. Organic zinc coatings can be applied to a surface as a moisture-cured urethane zinc primer.

Zinc-rich paints Zinc-rich paints have a high concentration of active anti-corrosion zinc metal pigments (85%–92%). Paint of this kind forms a metallic zinc film that not only serves as a physical barrier but also protects the steel underneath from cathodic corrosion.

It has been established that zinc-rich paints are the most efficient paint systems for preventing corrosion. The thickness of these zinc primers when applied can range anywhere from 6 to 125 microns. The anti-corrosion protection's durability will be directly proportional to its thickness and zinc content.

Zinc powder paints are mostly used to protect industrial structures like steel infrastructure, pipelines, bridges, windmills, offshore rigs, the petrochemical and power industries, and so on. and the coating that prevents corrosion for use in marine applications (such as sea containers, ship construction and upkeep, and marine equipment).

Zinc oxide (ZnO) was one of the main white pigments used in paint for a long time. Even though other materials are mostly used for this, zinc oxide is still a very important part of paint because of other important properties like protecting against mildew, UV light, hiding power, and neutralizing acids that are made when paint oxidizes. Mechanical Plating Zinc Metal Pigments (ZMP) are extensively used in mechanical plating and galvanizing, whereby small steel parts (screws, fasteners, rivets, bolts, etc.) are protected from corrosion and found in anti-fouling paints for ships. are sprayed with a thin, uniform layer of zinc, which prevents hydrogen embrittlement from forming and enhances corrosion resistance.

A process known as sherardizing involves coating small pieces of steel with zinc. Similar to Mechanical Plating, the application is carried out at higher temperatures (380-450° C).

Products Fine Zinc Powder With a production capacity of 100.000 tons per year, we developed three distinct production processes—Atomization, Larvik, and Muffle—that enable us to offer the broadest selection of products. We are the global market leader for Fine Zinc Powder—formerly known as zinc dust.

Zinc oxide produced through an American direct or reduction-oxidation process is known as EPM. The end product is zinc oxide of high quality with low levels of lead and cadmium, which is especially important for industrial applications.

Zinc oxide produced by EPM-E, a direct or American process, is produced through a reduction-oxidation process that is followed by a special treatment that produces zinc oxide of high quality. EPM-E has a particular fineness and a low level of impurities.

In Nashik, India, we rank among the top producers and suppliers of zinc rich coating. Protexion LLP supplies and applies high-performance coatings for high-end engineering applications. By offering "Techno-Commercial" benefits, each product stands out on its own and adds value.

Or, come see us: https://www.protexion.in/zinc-rich-coating-and-paint.php

0 notes

Text

Gi Wire Manufacturer: Providing High-Quality Wire For A Variety Of Applications

Wire has been an essential component of everyday life since its invention. It is used in infrastructure, telecommunications, and manufacturing, just to name a few applications. As such, the quality of wire being produced is paramount for safety and efficiency. That’s why GI Wire manufacturers are so important – they provide high-quality and reliable wires for a variety of uses. Like a spider spinning their web from the finest threads, these companies create wire that can be trusted to perform under pressure.

GI Wire manufacturers specialize in creating galvanized iron (GI) wires with superior strength and durability relative to other types of metal wires. The process begins with carbon steel rods which undergo hot dip galvanizing or electroplating; this results in a corrosion-resistant layer on the outside of the rod that improves its lifespan significantly. From there, multiple processes are employed depending on the intended application; shaping, coiling, weaving, drawing into filaments etc., all contribute to giving it desired properties like flexibility or tensile strength.

The end result is a product that meets stringent international standards while also providing cost savings through longer lifespans compared to traditional alternatives. In this article we will dive deeper into how GI Wire manufacturer provides high-quality wire for various commercial applications as well as explore some of the benefits associated with using them.

1. Overview Of Gi Wire

GI wire is symbolic of a strong, versatile material that serves an essential purpose in many different industries. It has become integral to countless processes and applications with its ability to withstand extreme temperatures, pressures, and corrosive elements. As such, it is important for GI wires to be manufactured with high-quality standards to ensure they can perform reliably under demanding conditions.

Manufacturers of GI wires must not only guarantee the highest purity levels but also meet stringent specifications in terms of size, flexibility, tensile strength, electrical resistance and other physical characteristics. In addition, each batch should undergo strict testing procedures before being released into the market as this ensures consistent quality throughout production runs.

By providing reliable products that exhibit outstanding performance even in challenging situations, manufacturers of GI wire are able to maintain their competitive edge while ensuring customer satisfaction. This allows them to stay ahead of industry trends and keep up with the ever-evolving needs of their customers.

2. Gi Wire Manufacturing Process

The manufacturing process of GI (Galvanized Iron) wire involves a few important steps that need to be carried out in order for the final product to meet high-quality standards. Firstly, the raw material is prepared by cutting and straightening it into specific lengths and sizes as per customer specifications. The next step is galvanizing or coating the iron with zinc to enhance its corrosion resistance and extend its lifespan. This can be done through either hot-dip galvanizing or electroplating processes depending on the nature of the application. After this, quality control tests are conducted to ensure that all the required parameters such as tensile strength, ductility, elongation percentage, etc., are met according to industry regulations.

Apart from these production-related tasks, additional measures like oiling and packaging also play an essential role in ensuring maximum safety during storage and transportation of the finished goods. Packaging helps protect them from dust, moisture and other external factors while shipping them over long distances. Furthermore, metal detectors may be used at various stages throughout the production cycle in order to detect any foreign objects which might have been unintentionally incorporated during processing.

In short, GI Wire manufacturers provide their customers with products made according to strict quality requirements utilizing advanced technologies and rigorous testing methods before they reach the market. By following best practices during manufacture, they guarantee reliable performance regardless of different applications needs so that users can benefit from cost savings due to longer life expectancy without compromising on quality output or safety standards.

3. Benefits And Applications Of Gi Wire

As opposed to the process of manufacturing GI Wire, a discussion on the benefits and applications of it is now in order. This galvanized iron wire serves a variety of purposes with its high-quality features that make it desirable for use. Here are three key advantages of using this material:

1) Corrosion resistance – The zinc coating prevents rusting due to exposure to moisture or other environmental conditions.

2) Durability – It can withstand extreme weather elements such as heat, cold, sunlight and rain.

3) Cost effective – The low cost makes it an attractive option compared to other materials.

These qualities make GI Wire suitable for numerous applications including electrical wiring, construction projects, gardening, fencing, art and craft work. Additionally, because of its strength and durability, GI Wire also finds uses in reinforcement structures such as bridges and buildings. Its ease of installation further adds value to its usage in various industries like automotive, marine and aerospace engineering where precision is essential.

It is evident then that GI Wire has many beneficial properties which have made it one of the most preferred choices among manufacturers worldwide. From corrosion resistance to affordability; from structural support to artistic creativity; there are countless ways Gi wire can be used across diverse fields making it an indispensable commodity in today’s world.

4. Why Choose A Reputable Gi Wire Manufacturer

The journey of finding the right GI wire manufacturer is like a treasure hunt. It requires researching for the best quality products, customer service, and reliable suppliers. In this article, we will explore why it is important to choose a reputable GI Wire Manufacturer when looking for high-quality wires for various applications.

First, selecting an experienced company with a proven track record in producing GI Wire provides assurance that you are getting the best possible product available. A reputable supplier also has access to innovative technologies which can be used to create top quality wires tailored to your specific needs. Additionally, they offer custom solutions so you can get exactly what you need without having to compromise on quality or cost. Finally, these companies often have long warranty periods and provide excellent after sales support services.

Another reason to select a trusted provider is because they are likely to be able to source materials from reliable sources at competitive prices. This gives customers peace of mind knowing that their purchase decision was based on value and not just price alone. Furthermore, if there ever arises any issues with their product down the line then they should have recourse against the supplier as well as being covered by any warranties offered.

In today’s market place it pays dividends to conduct thorough research before making any buying decisions and choosing a reputed GI Wire Manufacturer ensures that you receive only the highest quality product at an affordable price point backed up by excellent post-sales service. Therefore it makes sense to invest time into comparing different vendors and make sure you pick one who meets all of your requirements while offering great value for money too .

Conclusion

The selection of a GI wire manufacturer is an important decision for any business. It determines the quality, reliability and safety of their end product. A reputable company will provide high-quality wire that meets industry standards while offering superior customer service. With such an array of options available, how do you know which one to choose?

Ultimately, it comes down to understanding your requirements and researching the various GI wire suppliers on the market. This includes looking at their manufacturing process, benefits, applications and customer testimonials. Once you have narrowed down your list of potential companies, contact each one directly and ask about pricing, delivery times and availability of custom orders. Also make sure to inquire about additional services they offer like testing or certifications.

By selecting a reliable GI wire manufacturer with experience in providing clients with high-quality products, businesses can rest assured knowing their projects are in safe hands. Taking time to research all aspects of a potential supplier helps ensure that customers get exactly what they need without having to worry about costly delays or substandard components damaging final products.

1 note

·

View note

Text

How to Maintain Your Brass Articles

Brass pieces are a popular addition to any decor, but they can be tricky to take care of. Here are a few tips to help you keep your brass looking its best.

Start by dusting your brass murti regularly with a soft cloth. This will help keep them clean and free of dirt and dust buildup.

If your brass pieces are dirty or tarnished, you can clean them with a mild soap and water solution. Be sure to rinse them thoroughly afterward to remove the entire soap residue.

To protect your brass pieces from tarnishing, apply a light coat of wax or polish. Be sure to rub it in well and reapply as needed.

Brass Elephant Statue With Inlay Work

Following these simple tips, you can keep your brass looking beautiful for years to come!

What Is Brass?

Brass is an alloy of copper and zinc. It's often used in decorative items because it has a beautiful golden color that tarnishes over time to give it a more antique look.

One of the great things about brass is that it's easy to care for. All you need is mild soap and warm water. You can either hand wash or soak your Hindu god statues in a bathtub. If you're using a dishwasher, only put them on the top rack.

Brass Panchmukhi Dancing Ganesha

Benefits of Brass Articles

There are many benefits to owning brass statues. They are sturdy and will last for years with the correct care. Brass is also a beautiful metal that will add a touch of luxury to any room.

The best part is that brass is easy to maintain. A simple polish now and then is all you need to keep your brass shining. Make sure to use a cloth that is not abrasive, as this will damage the surface of the brass. Follow these simple steps, and your brass articles will look new for years.

Cleaning and Maintenance Tips for Your Brass Articles

Just like your favorite outfit, your brass articles need special care to keep them looking their best.

Here are a few tips to help:

Clean your brass God idols with a damp cloth regularly. This will remove any dirt or fingerprints that may build up over time.

To polish your brass, use a soft cloth and brass polish. Follow the manufacturer's instructions closely, as over-polishing can damage the finish.

Store your God idols for Pooja room in a cool, dry place. Excessive heat or humidity can cause them to tarnish more quickly.

You've just got your beautiful new brass statue or a brass murti, and you want to ensure it lasts a lifetime!

Brass Saraswati Playing Veena On Peacock

Here are some tips on how to maintain your brass article:

Keep your brass article in a dry place.

Don't expose your brass article to direct sunlight.

Clean your brass article with a soft cloth regularly.

Apply a coat of brass polish every few months to keep it shining bright.

Thanks for reading, and remember to keep your brass article looking beautiful for years to come!

Where to Buy Quality Brass Artifacts

Getting quality brass statue can be tricky but essential to maintaining your pieces. When shopping for brass articles, look for pieces that are free from defects like chips and scratches and check for any signs of corrosion.

If you’re shopping online, read the descriptions carefully, double-check the measurements, and read up on customer reviews to get an idea of what other people think about the product. You can also check out local or flea markets for unique, one-of-a-kind pieces.

Another option is to find antique stores with knowledgeable staff who can give you all the information you need about a particular piece before you buy it. Then, make sure that the store has a return policy in case there’s something wrong with the piece, and you need to return it.

1 note

·

View note

Text

0 notes

Text

How To Choose The Best Outdoor Cabinet?

It is a waste of effort and money to choose kitchen cabinets that will only be used briefly. Humidity, rain, and heat all damaged wood, making it difficult to preserve wooden cabinets.

Within a few months, the wooden cabinets completely demolished the setup. Outdoor cabinets that can withstand rain and sun have been created by Outdoor Cabinets Manufacturer. Termite resistance is also a feature of these waterproof outdoor kitchen cabinets.

This article guides how to choose the correct outdoor cabinets in UAE.

Materials To Choose

• Stainless Metal

There are lots of design alternatives available when shopping for outdoor kitchen cabinets made of stainless steel. You can find anything you need made of stainless steel now that it has become so popular. This includes base cabinets, wall cabinets, and even grill islands. A lot of the grills that are currently on the market will also match the stainless steel cabinets, you find.

• Redwood

Redwood is one of the more durable timbers you may use to build outdoor cabinets. If you enjoy the way they appear, go for it. In contrast to other types of wood, redwood won't split, warp, or crack when exposed to extreme weather.

Additionally, it is resistant to deterioration and insects. Redwood cabinets appeal to individuals who want their design in a country-chic manner. There are many options for outdoor furniture to go with them.

Typically, strong materials like redwood, stone, and stainless steel make outdoor cabinets. These materials shield cabinets from termites as well as the harmful impacts of seasonal weather.

For cabinets and garden storage, stainless steel is a popular choice since it is simple to clean, attractive, and durable. Outdoor countertops comprise granite, tile, other natural stones, or man-made solid surface.

• Polymer

Typically, the marine sector was the primary use for which the polymer was first created. Due to its complete water resistance, this material can withstand harsh outdoor elements. It can survive without being rotten by rain or snow. It also bears up to the frigid climate.

This material may be available from several outdoor cabinet manufacturers in a selection of hues. You don't have to worry about your cabinets warping or cracking with polymer outdoor cabinets.

To prevent rust, elaborate full-strength stainless steel cabinets with doors and other outdoor items typically use this material. Some businesses are working to create a complete set of polymer appliances.

Factors To Consider

• Durability

Durability is the main consideration while shopping for the best outdoor cabinets. Outdoor cabinets must be impervious to the elements. This is especially crucial in places with a humid and rainy climate, like the UAE.

Choose cabinets constructed of premium quality 316 or 304 stainless steel to ensure maximum weather resistance. Extreme heat and moisture have no problem resisting stainless steel.

The majority of outdoor cabinets look good with their streamlined appearance as well. The best rust resistance in hardware is available in steel handles that have a zinc coating.

• Functionality

Once you are certain that the cabinets you are contemplating are weatherproof, evaluate how you will utilize them. Think about the kind of cuisine you want to perform and the ingredients you'll need. Are you in need of temperature-controlled storage for dry products or food? The best outdoor cabinets, in such cases, will keep dust and bugs out.

Open shelving or cabinets with built-in organizers may be preferable if you don't require much storage.

• Design

The greatest outdoor cabinets will depend on personal preference if you've reduced your options based on the aforementioned criteria. You should look for cabinets that complement your design sense and are esthetically beautiful.

Your outdoor cabinets may make or break their appearance. Therefore, take your time and look at all of your possibilities before settling on one. The size and whether you require custom-made outdoor cabinets are also important factors to take into account.

Ample storage and a stylish touch can add up to your space by picking the appropriate outdoor cabinets. Therefore, look for the best Outdoor Cabinets In UAE today!

0 notes

Text

Latest Gold Mangalsutra: The Best Jewelry for Loved Ones

Mangalsutra has to be purchased from the website that helps you find the best jewellery for your loved ones. They have a wide range of products, from engagement rings to small charms. The site has an easy-to-use interface and offers great prices on jewellery. Additionally, the site offers a variety of services such as gift delivery and returns.

What is Mangalsutra?

Mangalsutra is a type of jewellery made from the jaggery or sugar of the scrubber plant. The product is used in various ways to protect the wearer’s body, including against cuts and injuries. Some Mangalsutra jewels are also used as jewellery to celebrate special occasions, such as weddings or birthdays.

How Do Mangalsutra Jewels Help To Protect The Wearer’s Body?

The jaggery that makes up Mangalsutra is effective at protecting against cuts and injuries due to its high level of hardness and smoothness. This makes it an ideal material for use in jewellery making, as well as protection against dirt, dust, and other debris that can cause damage to delicate skin.

What are the Different Types of Mangalsutra Jewels?

There are several types of latest gold Mangalsutra Jewelry available on the market today: gold, silver, copper-nickel, brass-zinc, and rose gold. Each has its unique properties that can help protect your belongings from damage and Casualties during travel or everyday use.

Some potential uses for Mangalsutra Jewelry include: Making a gift for someone special? wearing during special occasions? adding beauty or elegance to outfits? being part of a luxury collection? etc.?

What to Look for When Buying gold Mangalsutra Jewellery?

When choosing to buy mangalsutra online, look for high-quality pieces that will last a long time. Look for crystals, gemstones, and other unique elements to make your piece stand out from the crowd. Additionally, avoid cheap or low-quality options when looking for mangalsutra jewellery.

Look for affordable prices

When you buy mangalsutra online, be sure to find affordable prices. Be sure to compare prices between different retailers and manufacturers to get the best deal on your favourite piece of jewellery.

Look for unique jewellery

When looking for unique Mangalsutra jewellery, consider incorporating unusual elements into your design. For example, try including a skull or an animal skeleton in your necklace or earrings. This can add an extra level of interest and excitement to your outfit or jewellery collection!

Look for a designer

If you’re looking for a designer-crafted mangalsutra jewellery option, look for a jeweller who has experience designing with this type of material. This will allow you to receive beautiful and unique pieces that are of excellent quality overall.

Mangalsutra Jewellery is a beautiful and unique way to express yourself. By choosing the right type of Mangalsutra jewellery, you can create a beautiful piece of jewellery that will show off your personality and make you feel special. safe and successful buying of mangalsutra jewellery is key to enjoying the product and making it work for you. be precise in your order, read reviews before purchase, avoid buying damaged or missing pieces, and have fun shopping!

Many Indian couples have a dream of presenting a latest Gold Mangalsutra to their brides during the time of marriage. There is no doubt that this is one of the most prized possessions a woman can receive. However, getting it is not always easy on the wallet. These are some reasons why your partner would be happy with a jewellery piece costing less than 500 rupees:

– It does not contain any toxic substance such as nickel, lead or mercury

– It does not make you feel like you are wearing something cheap once worn by someone else

– Affordable maintenance costs and jewellery insurance with no deductibles

– The goldsmith has assured you that there won’t be any gemstone missing from your ring plus he has promised to replace it for free if ever it’s damaged within 5 years

– The 24-carat purity of gold ensures that your jewellery will last for decades without fading away

Gold Mangalsutra Under Budget

The market price of gold has skyrocketed in the recent past. But, it doesn’t mean that you can’t get latest gold mangalsutra at a good price. In this article, we will explore some of the best options to buy mangalsutra under budget.

A latest gold mangalsutra is an important part of a Hindu wedding ceremony. The groom offers this necklace to his bride as a symbol of love and commitment during the ceremony. It also symbolizes the woman’s commitment to her husband and her new family, with her parents, who had previously given away their daughter in marriage.

In Hindu culture, different types of necklaces suit different occasions and these chains vary in size and weight as per convention but all are made from 18-carat or pure gold. Traditionally, only 2 maang tikka (ornamental earrings) were worn by women while wearing a mangalsutra but nowadays it is common.

We all know the importance of the Mangalsutra as it is one of the most important symbols of a married Hindu woman. It is worn around her neck, and this necklace signifies that she is married. But with time, the cost has increased for purchasing such a necklace and it isn’t easy to find cheap mangalsutra. So to get relief here are some pretty designs for you to buy at a budget-friendly price.

So today we are going to talk about latest Gold Mangalsutra Under Budget. First things first, you need to know why we wear them in the first place. Well, Mangalsutra means ‘graceful thread’ and it is worn by Hindu women as one of their marital status symbols. It also signifies that they are now somebody’s wives. The mangalsutra or tika made from gold or silver symbolizes purity and chastity in Indian culture. At Dishis jewels you can check out some latest mangalsutra designs online.

0 notes