#aac blocks

Text

Hublex block

Hablex block is considered one of the best insulating blocks in construction, which has many advantages.

Among these advantages, we can mention light weight, sound insulation, fire insulation, high resistance to earthquakes, moisture resistance, reduction of transportation, etc.

In this video, you can see the resistance of Hablex blocks against earthquakes.

Hablex light block is available in various dimensions in the building materials market.

Hablex block size

60*25*20

60*25*15

60*25*10

60*25*8

60*20*20

Also, this light block is available in different brands such as Hablex, Siporex, etc.

source: siporex.ir

instagram: siporex.ir

telegram: siporexblock

2 notes

·

View notes

Text

Revolutionize Construction: Introducing Magicrete Eco-Friendly Solutions

Discover the Future of Construction with Magicrete - India's Leading AAC Products,

Construction Chemicals & Precast Construction Solutions Provider.

At Magicrete, we're not just building structures but shaping a revolution in the construction

industry. Established in 2008 by a dynamic team of visionaries from prestigious institutions like

IIT Kharagpur, IIT Delhi, and IIM Lucknow, we've pioneered a new era of green building

materials and innovative construction technologies.

Our Vision: Empowering Homebuilders for a Better, Cheaper, and Faster Tomorrow.

Setting the Benchmark: Magicrete has become a beacon of modern construction technology

over the last decade. Our solutions have transformed the lives of over a million individuals,

gracing more than 500,000 homes nationwide.

Awards and Accolades: Our dedication to excellence has earned us numerous prestigious

awards, including the "Most Promising Brand Award 2019" for building materials by the Global

Real Estate Congress, "Most Preferred Brand 2018" for blocks/bricks by ET Now, and

nominations such as "Start-up of the Year 2015" by Forbes and "Entrepreneur of the Year 2015"

by Tiecon.

Championing Innovation: Magicrete's recent victory in the Global Housing Technology

Challenge, organized by the Ministry of Housing & Urban Affairs, speaks volumes about our

commitment to innovation. We successfully constructed 1000 houses in Ranchi within a year

using our groundbreaking 3D Modular Technology.

Driving the 'Housing for All' Mission: As we forge ahead, Magicrete is proud to play a pivotal

role in advancing the 'Housing for All' initiative. Our products are now integral to affordable housing projects nationwide, promising a brighter future for urban and rural homeowners in

India.

Discover the Magicrete advantage today and be a part of the revolution shaping the

construction's future.

For more information, visit our website or contact us at [email protected]

2 notes

·

View notes

Text

AAC blocks, also known as Autoclaved Aerated Concrete blocks, are lightweight, precast building materials used in construction. These blocks are made from a mixture of sand, fly ash (a waste product from coal combustion), cement, lime, and water. The mixture is poured into molds and then cured under pressure using an autoclaving process, which involves steam curing.

#aac blocks#aac bricks#aac blocks manufacturers#aac panels#bricks suppliers#aac block manufacturers#modcrete aac blocks#modcrete aac blox#aac block#aac

3 notes

·

View notes

Text

നിങ്ങളുടെ സ്വപ്നഭവനനിർമാണത്തിനായി തയ്യാറെടുക്കുകയാണോ നിങ്ങൾ? എങ്കിൽ കൂടുതൽ കരുത്തോടെ നീണ്ടുനിൽക്കാൻ ഞങ്ങളുടെ AAC Blocks തിരഞ്ഞെടുക്കൂ. ഞങ്ങളുടെ AAC ബ്ലോക്കുകൾ ലോകത്തിലെ ഏറ്റവും ശക്തമായ നിർമ്മാണ ബ്ലോക്കുകളാണ്. നിങ്ങൾക്ക് ശക്തമായ ഒരു വീട് നൽകുന്നതിനോടൊപ്പം നിങ്ങളുടെ സമയവും പണവും ലാഭിക്കുന്നതിന് അവ നിങ്ങളെ സഹായിക്കുന്നു.

✅️Save Up to 20-30% on the cost

✅️Good insulation properties

✅️Lightweight

✅️Excellent dimension properties

For enquiries :

🌐www.invictusbuilders.com

☎️8590387842, 9074758651

2 notes

·

View notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

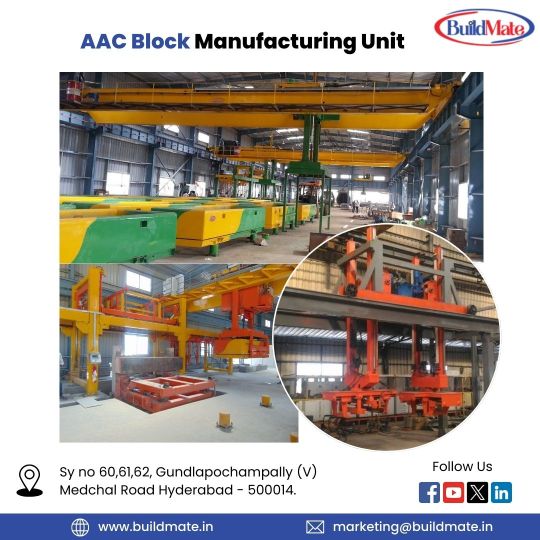

BuildMate is a strong technology oriented, high-tech engineering project and execution company providing technology and supply of machinery and equipment for Building Material projects. If you are looking for top-tier AAC block plant machinery manufacturers in Hyderabad, India, then look no further. Buildmate is the best AAC block manufacturing unit suppliers in India that are committed to delivering premium quality AAC block plants at competitive prices. If you are worried about the AAC block manufacturing plant cost, these manufacturers provide customized solutions that cater to the specific needs of the customer.

#AAC Blocks#AAC Block Machinery#AAC Machine#AAC Block Plants#AAC Plant Suppliers#AAC Plant Machinery#aac blocks#AAC plants#aac block plants#AAC Plant Machine#Small AAC block#AAC block plant cost#AAC Plant in hyderabad#AAC Blocks in India#Small AAC block plant#AAC Block Plant Cost

2 notes

·

View notes

Text

Shreesha Building is a leading AAC blocks dealer in Coimbatore, providing blocks from some of the top producers including Birla Aerocon and Meghalite. We provide a wide range of AAC blocks in various sizes, qualities, and types to meet the needs of our customers. Our products are of the highest quality, providing long-term durability, fire-resistance, and insulation.

Dealer of AAC Blocks such as

Birla Aerocon AAC Blocks

MeghaLite aac blocks

Siporex AAC Blocks

#aacblocks#aac blocks#aacblock#aac#aerocon#meghalite#building solution#construction#lightweight#aac panel#coimbatore

2 notes

·

View notes

Text

Buy ACC Green AAC Blocks (For B2B segment)

ACC Green AAC Blocks are Lightweight and high-strength blocks with an excellent surface finish that offers faster construction with higher durability.

2 notes

·

View notes

Text

Manufactured using a non polluting and highly energy efficient process, AAC Brikolite blocks ensure a reduction in Carbon footprints by utilising fly ash as its resource.

3 notes

·

View notes

Text

WHY BUILD ECO AAC BLOCKS ARE THE BEST CHOICE FOR YOUR CONSTRUCTION PROJECTS?

When it comes to building your dream project, every material choice counts. That's why our AAC blocks stand out as the ultimate choice for your construction endeavors. Crafted with top-grade quality raw materials, our AAC blocks offer unparalleled strength, durability, and versatility.

What sets our AAC blocks apart from the rest? It's simple – we start with A-grade quality raw materials. We understand that the strength and durability of any construction project lie in the foundation, and that's why we spare no expense in sourcing the finest materials available.

Our AAC blocks are engineered to perfection, ensuring unparalleled structural integrity and longevity. Whether you're building a residential complex, commercial space, or industrial facility, our AAC blocks provide the ideal solution for all your construction needs.

But that's not all. Beyond their superior quality, our AAC blocks offer a myriad of benefits that make them the preferred choice for builders and developers alike. From their lightweight design for easy handling and installation to their excellent thermal insulation properties, our AAC blocks tick all the boxes for modern construction requirements.

Moreover, by opting for our AAC blocks, you're not just investing in a product – you're investing in peace of mind. Our commitment to sustainability means that our blocks are eco-friendly and contribute to a greener future for generations to come.

In conclusion, when it comes to choosing the best for your construction projects, look no further than our AAC blocks. With top-notch quality, unmatched performance, and a dedication to sustainability, we're confident that our AAC blocks will exceed your expectations and stand the test of time. Unlock the potential of your projects with BUILD ECO AAC BLOCKS – where excellence meets innovation.

#aac blocks#aac bricks#autoclaved aerated concrete block#flyash bricks#lightweight aac blocks#concrete blocks#concrete bricks#lightweight bricks#builders#lightweight blocks#civil engineering#contractors#construction

0 notes

Text

0 notes

Text

AAC block (heblex-siporex)

AAC block is considered the best insulating block in construction.

Advantages of light block:

low weight

Reducing the dead load of the building

sound insulation

fire insulation

High resistance to moisture

Earthquake Resistant

low cost

...

source: siporex.ir

4 notes

·

View notes

Text

The Power of Wall Putty, Cement, AAC & Cover Blocks in Construction

The foundation and success of every construction project hinges upon the quality of materials used, a crucial aspect sought after by every investor who seeks to get the best value out of money. Each project is evaluated based on the quality levels promised and delivered. The selection of materials holds a significant role in this evaluation process.

Top-quality materials are ideal for constructing durable and resilient structures capable of withstanding environmental challenges. From wall putty, cement, and AAC blocks to cover blocks, each component counts in ensuring the longevity and integrity of the construction. High-quality materials not only guarantee long-lasting structures but also provide an ideal environment for various aspects of construction, such as drainage, insulation, and electrical components.

Let’s understand the use of premium building materials and their importance in construction projects, making quality a non-negotiable factor in the construction industry.

Use of Wall Putty, Cement, AAC Blocks, and Cover Blocks in Construction

Some of the most crucial uses and applications of these construction materials, like wall putty, cement, AAC blocks, and cover blocks, include:

Wall Putty

Wall Putty is used to fill up the fine poles, ceiling, and walls, and it also provides a smooth and even surface for flawless painting. Wall Putty also acts as a barrier against flaking and assures even-looking walls for several years. It is applied on room walls, the external face of the building, parapet walls, and the ceilings of rooms.

Cement

Cement acts as a binder and is used for setting, hardening, and adhering to other materials, as well as binding them together. Hence, it is useful for producing several structures, including roads, runways, buildings, bridges, and harbours. It can also be used for decorative features and facades on buildings.

AAC Blocks

Autoclaved Aerated Concrete (AAC) blocks are precast and low-maintenance building materials that come with excellent durability and thermal insulation. Due to their heat-insulating properties, they are installed outside to keep the building cooler and prevent the entrance of heat. They are basically installed on roofs, floors and walls of the buildings.

Cover Blocks

Cover Blocks are used to maintain spaces between the steel’s reinforcement and the surface of the concrete. Cover blocks also prevent concrete cracking and increase the structural strength of the building’s framework.

Importance of Wall Putty, Cement, AAC Blocks, and Cover Blocks in Construction

Wall putty, cement, AAC blocks, and cover blocks are extremely important materials in construction, so they must be purchased and used only by some of the best and most well-recognised brands. To acknowledge the major benefits and importance of these building materials, read the points listed below:

Wall Putty

Wall putty creates an even and smooth surface.

It fixes the holes and cracks in the walls.

Wall putty creates a waterproof barrier on the walls, preventing the peeling and chipping of paint from the wall.

By applying wall putty, the water does not seep into the walls and avoids damaging the walls.

Cement

It is used to build several structures, including bridges, buildings, and roads.

It is used to bind multiple materials together to create a sticky mass and also provides strength after hardening.

AAC Blocks

These blocks are extremely lightweight as compared to the traditional bricks. Hence, it can be easily installed.

They come with amazing flexibility, which allows them to be cut and shaped very easily.

They integrate high-level strength into the production process and are very durable.

As they have fewer joints, they can be laid easily and speed up the construction process.

Cover Blocks

Cover blocks maintain a certain distance between the shuttering and the rebar.

Cover blocks also act as protection to the steel reinforcement bars and prevent corrosion from environmental effects.

Cover blocks also offer thermal insulation, protecting the reinforcement bars from fire.

Conclusion

Using top-quality construction materials helps craft buildings that are durable, reliable, long-lasting, good-looking, and protective. Moreover, for the protection and safety of residents living in particular buildings or visiting a commercial or industrial building, it is essential to build durable buildings with the best building materials. Hence, designers and engineers must ensure that building elements such as cement, AAC blocks, cover blocks, wall putty, etc., are purchased from trustworthy and reputable brands like LnTSufin present in the market.

0 notes

Text

In the realm of modern construction, innovative building materials have revolutionized the way we construct sustainable and energy-efficient structures. One such groundbreaking material is Autoclaved Aerated Concrete (AAC) blocks. AAC blocks have garnered significant attention and adoption in recent years due to their remarkable properties and environmental benefits. This blog aims to delve into the world of AAC blocks, exploring their composition, advantages, and the positive impact they have on the construction industry and the environment.

#aac blocks#aac bricks#aac blocks manufacturers#aac panels#bricks suppliers#aac block manufacturers#modcrete aac blocks#modcrete aac blox#aac block

2 notes

·

View notes

Text

Building your dream house just got easier with Brikolite AAC Blocks! Say goodbye to the hassle of heavy and time-consuming construction. Our lightweight, efficient, and durable blocks are the perfect solution for your construction needs. Experience a smooth and stress-free building process with Brikolite AAC Blocks.

0 notes