#aludecor

Text

Tech-Driven Elevations: The Future of Commercial Building Design

In today’s rapidly evolving architectural landscape, commercial buildings embrace technology to transform their elevations into visually striking, sustainable, and smart facades. Elevations, being the face of the building, play a crucial role in creating first impressions. The integration of advanced technologies such as smart glass, photovoltaic (PV) facades, interactive LED displays, and advanced materials like Aluminium Composite Panels (ACP) is redefining the design of modern commercial buildings, enhancing both aesthetics and functionality.

Smart Glass and Dynamic Glazing: A New Era in Facade Design

Smart glass and dynamic glazing are revolutionizing commercial building elevations by merging aesthetics with advanced functionality. These innovative materials respond to environmental changes, allowing precise control over light and heat entering the building. This adaptability not only enhances energy efficiency but also adds a sleek, modern look to the facade. Smart glass allows users to adjust transparency with a switch, offering privacy on demand while maintaining a bright, airy atmosphere.

By integrating smart glass into elevation designs, architects can create responsive facades that align with the growing demand for sustainable and energy-efficient buildings. This forward-thinking approach combines visual appeal with performance, making smart glass a preferred choice in contemporary architecture.

Photovoltaic Facades: Sustainable Energy Solutions

Photovoltaic (PV) facades are setting new standards in sustainable elevation design by integrating energy-generating solar panels directly into the building’s exterior. This innovative approach transforms the building into a power generator, reducing reliance on external energy sources and lowering operational costs. PV facades not only support eco-friendly practices but also offer aesthetic flexibility, seamlessly blending with various architectural styles.

For businesses focused on sustainability, PV facades provide a dual benefit: enhancing the visual appeal of their buildings while contributing to environmental goals. As more companies prioritize energy efficiency, these facades are becoming a popular choice in commercial building design.

Interactive LED Facades: Elevating Visual Communication

Interactive LED facades are redefining commercial building elevations by turning them into dynamic communication platforms. Capable of displaying advertisements, art, or real-time updates, these facades engage the public in a unique and memorable way. This technology is especially valuable in urban environments, where visibility and engagement are crucial for brands looking to make a bold statement.

By incorporating LED technology into their facades, businesses can create an interactive experience that captivates audiences, enhancing their brand presence and making their buildings stand out in crowded cityscapes.

Advanced Materials: Redefining Modern Elevation Design

The evolution of building materials is driving innovation in commercial elevations. Aluminium Composite Panels (ACP) have become a cornerstone in modern design due to their lightweight, durable, and versatile nature. Available in various finishes and textures, ACPs offer architects the flexibility to create visually stunning facades that are both functional and low-maintenance.

Lightweight metals such as aluminium, zinc, and copper also contribute to contemporary designs, providing durability, corrosion resistance, and ease of installation. These advanced materials empower architects to push design boundaries, merging form and function to meet the demands of modern architecture.

Digital Tools and Automation: The Future of Elevation Design

Digital and parametric design tools are revolutionizing elevation design by enabling architects to explore complex geometries and innovative structures. These tools offer unparalleled flexibility, allowing for precise manipulation of shapes and forms that enhance both aesthetics and building performance.

Additionally, integrating IoT and building automation systems into elevation design enhances the functionality of commercial buildings, allowing real-time control over lighting, climate, and other systems for optimal performance and sustainability.

Transform Your Designs with Aludecor

Aludecor offers innovative solutions for your design needs. Explore our e-catalogues and contact our sales team at 1800 102 0407 (Toll-free) for a consultation. Let us help you redefine the future of commercial building elevations.

1 note

·

View note

Text

Transforming Architecture: The Role of Fabrication Work and ACP Sheet Design Catalogues

In the evolving world of construction and interior design, Aluminium Composite Panels (ACP) play a pivotal role due to their versatility, durability, and aesthetic appeal. These panels are not only easy to install but also offer endless design possibilities. This article explores the significance of fabrication work in the use of ACP sheets and the value of consulting an ACP sheet design catalogue for achieving outstanding architectural results.

The Importance of Fabrication Work in ACP Installation

Cutting, bending, and assembling ACP sheets to meet precise design specifications are all part of the fabrication process. This procedure is essential for a number of reasons:

Precision and Accuracy: Proper fabrication ensures that ACP sheets are cut and shaped with precision, allowing for seamless integration into various architectural elements. This accuracy is essential for achieving a clean and professional finish.

Customization: Fabrication work allows for the customization of ACP sheets to match unique design specifications. Whether it’s creating intricate patterns, custom shapes, or specific sizes, fabrication makes it possible to tailor ACP sheets to any project.

Structural Integrity: Skilled fabrication ensures that ACP sheets are securely installed, maintaining the structural integrity of the building. This is particularly important for exterior cladding, where the panels must withstand environmental factors such as wind and rain.

Aesthetic Appeal: Through expert fabrication, ACP sheets can be used to create visually stunning designs. From sleek modern facades to intricate interior details, the possibilities are endless when fabrication work is done right.

Utilizing an ACP Sheet Design Catalogue

An ACP sheet design catalogue is an invaluable resource for architects, designers, and builders. Here’s why consulting a catalogue is beneficial:

Diverse Design Options: ACP sheet design catalogues offer a wide range of colors, textures, and finishes. This diversity allows designers to find the perfect match for their aesthetic vision, whether it’s a metallic sheen, a wood grain finish, or a bold solid color.

Inspiration and Ideas: Browsing through a design catalogue can provide inspiration and new ideas for incorporating ACP sheets into various projects. Seeing the available options can spark creativity and help designers envision how different designs will look in real-world applications.

Specification Details: Catalogues provide detailed information about each ACP sheet, including dimensions, thickness, and material properties. This information is crucial for ensuring that the selected sheets meet the technical requirements of the project.

Ease of Selection: With all options presented in one place, an ACP sheet design catalogue simplifies the selection process. Designers can compare different designs side by side, making it easier to make informed decisions.

Leading ACP Sheet Design Catalogues

Several leading ACP manufacturers provide comprehensive design catalogues, showcasing their product offerings and inspiring creative use of ACP sheets. Notable examples include:

Aludecor Design Catalogue: Known for its extensive range of designs and finishes, Aludecor’s catalogue is a go-to resource for innovative ACP sheet options.

Eurobond Design Catalogue: Eurobond offers a diverse selection of ACP sheets, with detailed specifications and design inspirations to guide users.

Viva Composite Panels Catalogue: Viva’s design catalogue features a variety of textures and colors, highlighting the versatility and aesthetic potential of their ACP sheets.

Alstone Design Catalogue: Alstone provides a comprehensive catalogue that includes a wide array of finishes and designs, perfect for both interior and exterior applications.

To know more visit our website:-https://timexbond.com/acp-projects

0 notes

Text

🤩Alu Bending by Hand👍3D Led Decor👍#alu #aludecor 👍 #3dquangcao #3d #led ...

0 notes

Text

Leading the Way: Sandwich Panel Manufacturers in India

India's construction and industrial sectors are booming, and sandwich panels have emerged as a game-changer in creating energy-efficient and versatile structures. In this article, we'll explore the top sandwich panel manufacturers in India who are driving innovation, sustainability, and excellence in the industry.

The Role of Sandwich Panels in Modern Construction:

1. Efficient Insulation:

Sandwich panel manufacturers in india with their core insulation material, provide excellent thermal resistance, making them crucial for maintaining comfortable indoor temperatures and reducing energy consumption.

2. Versatility:

- These panels are incredibly versatile, suitable for various applications, including roofing, wall cladding, cold storage, clean rooms, and more.

3. Sustainability:

- Sandwich panels contribute to sustainable building practices by enhancing energy efficiency, reducing construction waste, and supporting green building certifications.

Top Sandwich Panel Manufacturers in India:

1. Tata Steel:

- Tata Steel is a leading manufacturer of steel-based sandwich panels in India. They offer a range of innovative products for industrial, commercial, and residential construction projects.

2. Jindal Mectec:

- Jindal Mectec is known for its high-quality insulated panels. They provide customized solutions for diverse applications, including cold rooms, warehouses, and modular buildings.

3. Sintex-BAPL Limited:

- Sintex-BAPL specializes in manufacturing insulated sandwich panels that find applications in industrial construction, warehouses, and clean rooms.

4. Everest Industries:

- Everest Industries is a well-established name in the construction sector. They offer a range of PUF (Polyurethane Foam) and EPS (Expanded Polystyrene) sandwich panels.

5. Kingspan Jindal:

- A collaboration between Kingspan Group and Jindal Mectec, this manufacturer produces high-performance insulated panels designed for energy-efficient buildings.

6. Aludecor Lamination Pvt. Ltd.:

- Aludecor offers a range of aluminum composite panels, including sandwich panels, suitable for modern architectural designs.

Why Choose Indian Sandwich Panel Manufacturers?:

1. Quality Assurance:

- Indian manufacturers adhere to international quality standards, ensuring that their products meet or exceed industry benchmarks.

2. Customization:

- Manufacturers offer tailored solutions to meet specific project requirements, allowing for versatility in design and application.

3. Cost-Effective Solutions:

- Indian manufacturers provide competitive pricing without compromising on quality, making sandwich panels an economically viable choice.

4. Sustainability Commitment:

- Many Indian manufacturers prioritize sustainable practices, contributing to eco-friendly construction initiatives.

Conclusion:

Sandwich panel manufacturers in India are at the forefront of providing innovative and sustainable solutions for the construction industry. Their commitment to quality, versatility, and energy efficiency has made sandwich panels an integral part of modern building projects across India. Whether you're constructing a cold storage facility, a commercial complex, or a residential building, these manufacturers offer a wide range of options to meet your specific needs and contribute to a greener, more energy-efficient future.

For more info. visit us:

Sandwich roof sheets

Roofing accessories

Colour coated roofing sheets supplier in bangalore

Best quality roofing sheets

0 notes

Video

undefined

tumblr

Aludecor uses PVDF resin of Kynar 500/ Heyner 5000 in a 70:30 PVDF and Acrylic Resin ratio. PVDF ACP Panels comprises two layers of aluminium skin sandwiching a PE core in a continuous extrusion process. This safeguards you and your family against carcinogenic lead paint dangers, such as increased risks of nervous system damage and renal failure.

0 notes

Text

Aludecor Inaugurates its Third Manufacturing Unit in Haridwar

Aludecor Inaugurates its Third Manufacturing Unit in Haridwar

Becomes First Indian ACP Player to establish Three Aluminium Coil Coating Lines

NEW DELHI, Oct. 10, 2022 /PRNewswire/ — India’s leading Aluminium Composite Panel brand, Aludecor inaugurates its third manufacturing unit in Haridwar today by elevating itself as country’s highest ACP producer. With all three manufacturing units in Haridwar spreading over 35000 Sq. Mt., Aludecor is now equipped with…

View On WordPress

0 notes

Text

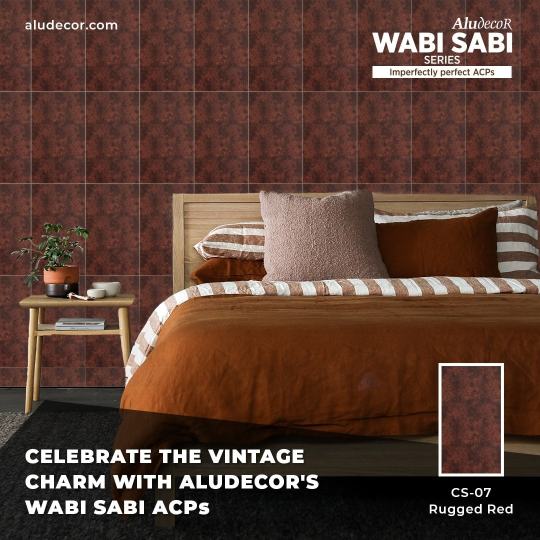

Aludecor's Wabi Sabi series of ACPs has been curated with Zen artistry, celebrating its timeless beauty that is vintage and rustic. The shade CS-07 Rugged Red instills a sense of comfort in this bedroom. Our Wabi Sabi series of ACPs brings a touch of imperfectly perfect beauty to your dream spaces!

To know more, enquire here:

https://www.aludecor.com/enquiry

2 notes

·

View notes

Photo

Aludecor

With Design Assist-the Digital Fabrication Preview service of Aludecor, one can now explore the previews of appearances that a building can boast featuring the usage of Aludecor’s Metal Composite Panels in different shades, textures and finishes. From guiding the Influencers about the best-suited colours for a particular structure to offering honest technical handholding- Aludecor’s Deign Assist service stands out as the best.

1 note

·

View note

Text

Transforming Architecture: The Role of Fabrication Work and ACP Sheet Design Catalogues

In the evolving world of construction and interior design, Aluminium Composite Panels (ACP) play a pivotal role due to their versatility, durability, and aesthetic appeal. These panels are not only easy to install but also offer endless design possibilities. This article explores the significance of fabrication work in the use of ACP sheets and the value of consulting an ACP sheet design catalogue for achieving outstanding architectural results.

The Importance of Fabrication Work in ACP Installation

Cutting, bending, and assembling ACP sheets to meet precise design specifications are all part of the fabrication process. This procedure is essential for a number of reasons:

Precision and Accuracy: Proper fabrication ensures that ACP sheets are cut and shaped with precision, allowing for seamless integration into various architectural elements. This accuracy is essential for achieving a clean and professional finish.

Customization: Fabrication work allows for the customization of ACP sheets to match unique design specifications. Whether it’s creating intricate patterns, custom shapes, or specific sizes, fabrication makes it possible to tailor ACP sheets to any project.

Structural Integrity: Skilled fabrication ensures that ACP sheets are securely installed, maintaining the structural integrity of the building. This is particularly important for exterior cladding, where the panels must withstand environmental factors such as wind and rain.

Aesthetic Appeal: Through expert fabrication, ACP sheets can be used to create visually stunning designs. From sleek modern facades to intricate interior details, the possibilities are endless when fabrication work is done right.

Utilizing an ACP Sheet Design Catalogue

An ACP sheet design catalogue is an invaluable resource for architects, designers, and builders. Here’s why consulting a catalogue is beneficial:

Diverse Design Options: ACP sheet design catalogues offer a wide range of colors, textures, and finishes. This diversity allows designers to find the perfect match for their aesthetic vision, whether it’s a metallic sheen, a wood grain finish, or a bold solid color.

Inspiration and Ideas: Browsing through a design catalogue can provide inspiration and new ideas for incorporating ACP sheets into various projects. Seeing the available options can spark creativity and help designers envision how different designs will look in real-world applications.

Specification Details: Catalogues provide detailed information about each ACP sheet, including dimensions, thickness, and material properties. This information is crucial for ensuring that the selected sheets meet the technical requirements of the project.

Ease of Selection: With all options presented in one place, an ACP sheet design catalogue simplifies the selection process. Designers can compare different designs side by side, making it easier to make informed decisions.

Leading ACP Sheet Design Catalogues

Several leading ACP manufacturers provide comprehensive design catalogues, showcasing their product offerings and inspiring creative use of ACP sheets. Notable examples include:

Aludecor Design Catalogue: Known for its extensive range of designs and finishes, Aludecor’s catalogue is a go-to resource for innovative ACP sheet options.

Eurobond Design Catalogue: Eurobond offers a diverse selection of ACP sheets, with detailed specifications and design inspirations to guide users.

Viva Composite Panels Catalogue: Viva’s design catalogue features a variety of textures and colors, highlighting the versatility and aesthetic potential of their ACP sheets.

Alstone Design Catalogue: Alstone provides a comprehensive catalogue that includes a wide array of finishes and designs, perfect for both interior and exterior applications.

To know more visit our website:-https://timexbond.com/acp-projects

0 notes

Text

India’s Top Best ACP Sheets Brands

Aluminium composite panels are being increasingly used on the facade of buildings. These are commonly called sandwich ACP sheets which comprise aluminium sheets at both ends bonded to a polyethene core. This product gives the liberty to be bent, moulded and designed in any way possible. Being eco-friendly and sustainable, it is gaining popularity even in residential places. Innovative aluminium sheets are used for cladding in both interior and exterior construction. The anti-scratch and anti-fade technology have made it durable and look new over the years.

Its increasing demand has made many new manufacturers and suppliers come up with their ACP. It has become difficult for customers to choose the best quality sheets among many competitors. After understanding the needs of the clients and deep research about the market, we are here with the top 10 ACP manufacturers in India.

1. Aludecor: Aludecor is a premium manufacturer for introducing the first 3D finish ACP in India. Having a presence in over 250 cities, the company is supported by a retail network of 500 stores. For 20 years, it has set benchmarks for others by introducing breakthrough products. They have two production units spread over 25,000 sq m at Haridwar and are equipped with the latest technology and testing facilities. The stringent quality control system helps it maintain the best quality in each sheet. Aludecor is the only Indian ACP company that produces mineral core for fire retardant materials. These sheets are the first preference for architecture over a long period for their excellence in both design and excellence.

2. Viva: Viva, which was started in 2003 in Maharashtra, is now an established ACP manufacturer across India. It is the first Indian ACP company to introduce FR class A2 to ensure fire safety. Their large network is understandable by these figures, 18 warehouses across India and 500+ dealers and distributors. They are working on six production lines with a 7 million square per annum production capacity with the manufacturing plant in Gujarat. To protect their aesthetic look for a longer duration, they have been given ACPs anti-dust and anti-scratch properties. Their ACP sheets are ideal for improving the aesthetics and appearance of old and new buildings because of their unmatched quality, unparalleled designs and exhilarating shades and textures.

3. Alutech: Alutech is a leading manufacturer of “Aluminium Composite Panels & HPL Sheets”, having manufacturing units in Southern (Hindupur, Andhra Pradesh) & Northern (Kala Amb, Himachal Pradesh) India. Our products make us stand out from competitors in terms of being Robust, Eco-friendly, Maintenance-free, Quality driven & can be customised as per demand for both modern/innovative interiors & exteriors, well appreciated in both residential commercial sectors vice versa. We have proven to be an established player in the industry renowned for producing impeccable quality panels. Having a variety of best ACP designs/colours/shades helps them meet individual tastes and preferences. With every single project, we try to do something innovative and valuable in architecture. We aim to give every site an extraordinary and attractive element with their exclusive quality products.

4. E3 Panels: E3 Panels is the first company to establish an ACP manufacturing Plant in South India. E3 Group never compromises on quality, similarly, ACP sheets are innovated after several quality tests. Their versatile E3 ACP is designed with superior anti-fade and anti-scratch technologies and is 90 degrees bendable inside our enduring dedication to quality. Their production capacity is 4 million sq. mt. /annum. These sheets' seamless finish imparts a very/ contemporary look to the buildings, available in thickness from 2 MM to 6 MM max. Their ACP is easy to handle since it can be cut, bent, folded, drilled, and punched easily.

5. Virgo: Founded in 1993, the Virgo group has come a long way from introducing ply boards to entering various market categories. They’ve created ACP sheets under Virgo ALFA’s brand name, which guarantee excellent construction quality and come in a wide range of colours and surface options. These ACPs passed a 10-year accelerated ageing test, indicating extreme resistance to infections and environmental factors. They are recognised for their high-quality products and ideals such as honesty and dependability. Their sheets are resistant to solvents, heat and scratch because of the special PVDF coating on their surface. Common applications of their panels are architecturally designed, attractive, and eye-catching green facades to make the buildings stand out from the crowd.

6. Alstone: Alstrong is another popular company for ACP sheets across India. Since its inception in 2001, it has gained customers’ trust for durability and performance. They employ Korean and Japanese technology across 5 ACP lines to create products which set industry standards. Having headquarters in Delhi, their current ACP production capacity is 50 million sq. ft. per year, with various production lines in place. The range of ACP designs they offer is above 1000. Only industry-certified and reputable sources are used to get basic materials. Their quality control specialists guarantee that the raw materials are of the highest possible quality before purchase.

7. Eurobond: Eurobond is a Mumbai-based brand which was established 19 years ago. Its manufacturing unit is equipped with top-class machinery and state-of-the-art equipment, making them stand amongst others. It has a production capacity of 20,000 sq m of ACP per day in Umbergaon and regularly serves the global clientele. Their differentiation point is that every ACP they produce is of the highest quality. They select high-quality raw materials and use cutting-edge technology to create products that meet or exceed worldwide industry standards. Significant companies like Hyundai, Adani, Mahindra, K Raheja Corp, Indian Oil Corp. Ltd. and Bharat Petroleum, amongst others, have trusted them.

8. Wonder Aluboard: Wonder Aluboard is a Delhi-based company and a leading manufacturer of ACP. The capacity of their manufacturing unit is 16 million square feet per annum spread over 50,000 square feet area—pioneers in Panel Sandwiching facilities to produce Aluminum Composite panels up to 1550mm. Wonder ACP is available in 62 colours to choose from. The company manufactures flawless panels in the best manufacturing facility managed and monitored by the best professionals in the industry, not only in India but also internationally. The applications of these panels range from panelling and wall cladding to interior decoration. Their ACP has numerous salient features like colour uniformity, sound and thermal insulation and weather durability.

9. Alex Panels: Alex Aluminium Composite Panels, an ISO 9001&14001 and OHSAS 18001 certified company is an emerging manufacturer of ACP sheets based in Dehradun(Uttrakhand). The name black cobra knows as this company. Their USP is the usage of Kynar 500/PVdF resins in exterior grade panels. Their product is eco-friendly and contains around 70 per cent of resins. The vision of this company is to scale panels to great heights in both the nascent Indian and overseas markets. Their ACP is widely used because it gives resistance to extreme weather and temperature. Excellent UV resistant characteristics help to retain colour after even long exposure, thus, making it durable.

10. Alucobond: Alucobond composite panels are ACP sheets bonded by thin aluminium sheets to thermoplastic polythene core. It has been in the market since 1969 and has its head office in Mumbai. These sheets are extensively used in building front elevation (facades), panelling, signage, modular kitchen and cladding and partition. You don’t need to worry about the variety, it is available in a wide range of colours and textures like wood, stone etc. This material is famous for its leverage in easy bending, moulding, and shaping. It doesn’t matter if you are looking for it for your home or office. The superb properties of this material boost one’s inspiration and offer architecture a whole new range of solutions.

1 note

·

View note

Text

Difference between Non-Combustible and Combustible Facades

Facades are a common sight in any metropolitan setting, and urban environments are known to be densely populated. Fires remain a significant threat to the cityscape because of the high number of residential and business areas spread across such a system.

When a fire breaks out within a structure, it frequently flashes over to the facade and spreads through broken glass windows. Meanwhile, a strong breeze can aid the spread of a fire from its source to the building's facade. The fate of the damage caused by the fire is now determined by the type of the facade, which is either combustible or non-combustible.

A flammable facade, such as non-fire rated materials, instantly catches fire and consumes the entire structure. Significant levels of hazardous gases and smoke also enhance the risk of casualties and block escape routes. A flammable facade adds fuel to the fire and puts large regions and large numbers of people in peril.

As the temperature rises, the facade melts away, leaving behind hot molten substances that can scald and severely burn anyone who comes into contact with them.

On the other hand, if the facade is composed of fire-resistant, non-combustible materials, it will not contribute fuel to an already burning structure. Even if the fire reaches the facade and begins to consume it, the non-combustible facade will be able to contain the fire and halt its development.

The people would have enough time to leave the building this way. Even the Fire Department would have a lot more time on their hands to get to the scene and put out the fire.

There is also no risk of hazardous gases because Aludecor FireWall and FireWall A2 ACPs' mineral core burns to ashes while producing water droplets to cool the flames. Whatever occurs, Aludecor's FireWall ACP sheets ensure that the fire does not spread.

To learn more about Aludecor FireWall and FireWall A2 ACPs' remarkable fire-retardant properties, join our #BeatTheFire Movement. Call us at 1800 102 0407 or visit aludecor.com today to fireproof your building!

0 notes

Text

Top 10 ACP Sheets Manufacturer in India

The ACP Sheet (Aluminium Composite Panel) is a new-age material used for architectural building exteriors, interiors, and signage applications. ACP has a comparatively long life due to unbreakable material, UV Resistant, and resistance to stain. It comes with exclusive features such as Light Weight, Easy to Install, Eco Friendly, Weather Resistance, Termite Proof, Durability, UV Resistant, Incredible variety, Fully Recyclable & Swelling or Shrinkage Free. Here is the top ACP sheets manufacturer.

1) E3 Panels - Aluminium Composite Panel or ACP Sheets is a new age material used for architectural building exteriors, interiors, and signage applications. E3 Group is the first company to establish an ACP manufacturing Plant in South India. Aluminum Panels are readily available in a wide range of colors and finishes like wood, stone, sparkle, gloss, pebbles, and more, E3 ACP Sheet offers the flexibility and character you need. This user-friendly material can be bent, folded, and turned into shapes that can’t be achieved by any other material. E3 Group never compromises on quality, similarly, ACP sheets are innovated after several quality tests.

2) Alutechpanels - Alutech is a leading manufacturer of "Aluminium Composite Panels & HPL Sheets", having manufacturing units in Southern (Hindupur, Andhra Pradesh) & Northern (Kala Amb, Himachal Pradesh) India. Our products make us stand out from our competitors in terms of being Robust, Eco-friendly, Maintenance-free, Quality driven & can be customized as per demand for both modern/innovative interiors & exteriors, well appreciated in both residential/commercial sectors vice versa.

3) Alexpanels - is a Dehradun-based totally organization with ISO 9001 & OHSAS 18001 certified. it's miles a subsidiary of Punjab Plywood Industries, a well-known pillar of the Indian plywood industry known for its high quality.

4) Viva - is a Mumbai-based totally firm referred to as a great and famed logo in ACP sheets in India. ACP’s ACP texture is smooth and durable as nicely, and the alternative capabilities of top-pleasant merchandise have led to us being Viva, an enterprise chief.

5) WONDER ALU BOARD OVERSEAS - is a brand new Delhi-based totally company this is the most important producer and distributor of Aluminium Composite Panels in India. The manufacturing facility in Rajasthan covers an area of 50,000 square feet and is accompanied by many groups of experts and professors.

6) Eurobond - is a Bombay-primarily based enterprise called an early adopter of Aluminium Composite panels. The enterprise is underneath the umbrella this is Euro Panel merchandise Pvt. Ltd. is a market leader in providing ACPs for various enterprise sectors.

7) ALUCOBOND - is another well-known company in India known for its premium ACP panels. The organization is located in Bombay and was based in 1969, and the manufacturing plant is positioned in Maharashtra.

8) Aludecor - is a Kolkata-based business and is taken into consideration as one of the pioneers inside the ACP sheets for enterprise markets. The company was founded in 2004 and operated with a constant flow of confidence and trust from the customers.

9) Citybond - CityBond, the brand under the flagship of Unistone Panels Pvt. Ltd has taken the Indian ACP industry with the aid of typhoon in a very short span of 6 years seeing that its release.

10) Alstoneindia - Alstone is a leading manufacturer of High-Pressure Laminate (HPL) & Aluminum Composite Panel (ACP) in India, established in 12 months 2004 with its production unit located close to Dehradun, spanning over a 20,000 sq Meter Factory Area.

1 note

·

View note

Text

ACP cladding is a type of metal panel that is used for exterior walls and roofs. Aludecor is a company that manufactures acp cladding. They have become one of the leading manufacturers in this field. Aludecor provides a wide array of products, including roofing panels, wall panels, and so on. All their products are made from quality materials and come with a warranty to ensure their durability. To know more, visit https://www.aludecor.com/.

0 notes

Photo

FEATURE WALL

The theme of the design for the office space was set to revolve around lucid, industrial yet charmingly inviting.

0 notes