#atc cnc router

Explore tagged Tumblr posts

Text

💥ATC CNC Router with Straight Tool Magazine

🔰In field of woodworking machinery for over 15 years, valuable team of designing and developing machines. Attending Germany LIGNA, USA Atlanda, Australia lWSA, Russia Woodex etc. exhibitions over 60 international dealers choose us as their trust partner. Professional solutions for each furniture manufacturers. Highly specialized services are offered by SAMACH team.

👉Visit our website: https://www.samach.cn/collections/cnc-router and discover the perfect machineries solutions for you.

1 note

·

View note

Video

youtube

1328 Automatic loading unloading ATC Cnc Router Machine for Panel Furnit...

0 notes

Video

youtube

4 axis waving head ATC Foam Carving CNC Router machine with rotary#foamm...

0 notes

Text

MÁY CNC ROUTER 4D THAY DAO TỰ ĐỘNG – KW 1325 ATC 4D Đặc điểm nổi bật của máy phay cnc router 4D thay dao tự động

Có khả năng xoay gia công nhiều góc (±90°), giúp gia công các sản phẩm có biên dạng phức tạp.

Máy có chứa 10 ổ dao tự động thay đổi dao, giảm thiểu thời gian gia công.

Giao diện điều khiển thân thiện, dễ dàng sử dụng.

Khung máy chắc chắn không bị biến dạng và có khả năng chịu lực tốt, bền bỉ.

Bàn làm việc chia thành 4 vùng hút chân không giúp giữ chặt vật liệu trong quá trình gia công. Nguồn: https://kingwoodmac.com/may-cnc-router-4d-thay-dao-tu-dong/ Số điện thoại: 0708 990 113

0 notes

Video

youtube

HONZHAN HZ-ATC1325L Linear Auto Tool Changer Magazine ATC CNC Router machine

1 note

·

View note

Video

youtube

The Newest Custom 5x10 ATC CNC Router Woodworking Machine with C Axis Ag...

1 note

·

View note

Text

Introduction to CNC Spindle Motors and their Importance in CNC Machines

CNC (Computer Numerical Control) spindle motors are crucial components in CNC machines, playing a vital role in the cutting, shaping, and machining of various materials. These motors provide the rotational motion needed to spin the cutting tools or workpieces, enabling precise and efficient fabrication processes.

CNC spindle motors come in various types, including water-cooled, air-cooled, and ATC (Automatic Tool Change) spindle motors. Each type has its own distinct features and advantages, catering to different CNC applications.

Importance of CNC Spindle Motors:

Rotation and Control: CNC spindle motors drive the rotation of cutting tools, allowing for precise and controlled material removal. Their speed and torque can be precisely adjusted, enabling efficient and accurate machining operations.

Versatility: CNC machines are used in a wide range of industries, such as metalworking, woodworking, and automotive. Spindle motors provide the versatility required to handle different materials and machining processes.

Productivity and Efficiency: CNC spindle motors are designed to deliver high-speed rotation and torque, facilitating faster material removal and reducing production time. This leads to increased productivity and enhanced efficiency.

Precision and Accuracy: CNC machines are known for their ability to achieve highly precise and accurate cuts. Spindle motors play a crucial role in maintaining the required precision during machining processes, ensuring dimensional accuracy in the final product.

Tool Change Capability: Some CNC machines feature ATC spindle motors, which allow for automatic tool changes. This feature eliminates the need for manual tool swapping, saving time and improving workflow efficiency.

Types of CNC Spindle Motors:

Water-Cooled Spindle Motors: Water-cooled spindle motors use water as a coolant to dissipate heat generated during operation. These motors are highly efficient and provide excellent temperature control, making them suitable for prolonged heavy-duty machining. Triquench India specializes in the production and supply of high-quality CNC router water-cooled spindles, catering specifically to CNC milling, drilling, and engraving operations. Our motorized spindle motors are meticulously designed to achieve accuracy levels of less than 3 microns, making them a preferred choice in various CNC machine spindles.

The water-cooled spindle motors offered by Triquench India are renowned in the industry for their exceptional durability and performance. As a leading spindle manufacturer, exporter, and supplier, we excel in providing top-notch solutions in all categories related to spindle technology.

Our CNC router water-cooled spindles are equipped with an efficient water cooling system, making them the best choice for CNC machines. Whether you are engaged in woodworking or metal machining, our water-cooled spindles are designed to meet the diverse needs of your CNC projects

Air-Cooled Spindle Motors: Air-cooled spindle motors rely on airflow to cool down during operation. They are simpler in design and maintenance compared to water-cooled motors, making them cost-effective for lighter machining applications. TriQuench India specializes in the production and supply of MTC Air-Cooled Spindle Motors, meticulously designed to meet the specific needs of our customers. These motorized spindle motors are particularly well-suited for various applications, including wood carving, PCB drilling, aluminum processing, and bangle making. Renowned for their efficiency and reliable performance, our CNC spindle motors have earned the trust and acclaim of our customers, consistently delivering desired outcomes.

Our MTC Air-Cooled Motorized Spindles are available in two distinct portfolios: Round Body and Square Body, providing customers with versatile options to suit their preferences and application requirements.

As a leading spindle manufacturer, exporter, and supplier, TriQuench India excels in delivering top-notch solutions across all categories related to spindle technology. Our commitment to quality and proficiency is reflected in the positive feedback and satisfaction expressed by our valued customer

ATC Spindle Motors: ATC spindle motors are designed to accommodate automatic tool changes within a CNC machine. These motors are equipped with a tool holder mechanism that allows for quick and seamless tool swaps, increasing operational efficiency. TriQuench India's Automatic Tool Changer (ATC) Spindle Motors offer a comprehensive range, renowned for delivering heightened precision and exceptional performance in machining operations.

These ATC Spindle Motors are engineered to provide superior accuracy, with performances characterized by elevated stability and compactness. This makes them well-suited for applications where automatic tool changing, featuring a high frequency of tool changes, is essential.

Our complete portfolio of ATC Spindle Motors spans a broad range from 12,000 rpm to 60,000 rpm, incorporating high-precision spindle bearings such as ceramic and steel bearings. The ATC Spindle Motors seamlessly facilitate the automatic use of different tools without requiring human intervention.

With applications extending across various industries, including PCB Drilling Machines, Die Mold Machines, Jewelry Making Machines, Wood Carving Machines, Stone Carving Machines, CNC Machining Centers, and Denture Making Machines, our ATC Spindle Motors cater to diverse machining needs.

TriQuench India takes pride in its commitment to providing superior service, backed by a team of experienced individuals with diverse expertise. We aim to create a unique and seamless experience in the realm of Motorized Spindle Motors.

Our ATC Spindle Motors stand out for their innovative design, ensuring optimal performance in machining processes. With a focus on precision, stability, and versatility, we strive to meet the dynamic demands of modern machining applications. TriQuench India looks forward to continuing to set industry benchmarks and delivering unparalleled spindle motor solutions.

In conclusion, CNC spindle motors are integral components of CNC machines, providing the necessary rotational motion and control for precise and efficient machining operations. The choice of a specific type of spindle motor, whether water-cooled, air-cooled, or ATC, depends on the specific requirements of the CNC application, including the material being machined, the desired speed and torque, and the automation capabilities needed.

0 notes

Video

youtube

3D Router CNC 600*900 Small CNC Milling Mini carousel ATC CNC Router 6090 More details or free tutorials ,please contact on whatsapp :008618053182392/ [email protected], Our website : jxautocnc.com

0 notes

Text

ATC CNC Router for Wood Cutting and Engraving

Woodworking ATC (automatic tool changer) CNC router is a type of machine that is used to automate woodworking processes and increase efficiency. This type of router is equipped with an automatic tool changer, which allows for the rapid and precise changing of cutting tools during the routing process.

ATC Wood CNC Router

In the world of woodworking, precision, efficiency, and versatility are paramount. Enter the Automatic Tool Change (ATC) Wood CNC Router – a cutting-edge solution that revolutionizes woodworking processes. This comprehensive guide is your key to understanding the capabilities and benefits of ATC Wood CNC routers. From exploring the fundamentals of ATC technology to uncovering its diverse applications in woodworking, this guide equips you with the knowledge to optimize your woodworking operations and unleash your creativity.

It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

An Automatic Tool Change (ATC) Wood CNC Router is a sophisticated machining tool equipped with a tool magazine and a mechanism for automatically changing cutting tools during the machining process. Unlike manual tool changes, which require operator intervention and downtime, ATC routers streamline production by seamlessly switching between different tools as needed, enhancing efficiency and productivity.

Product Recommend

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

Atc CNC Router Wood Carving Machine with Pinch Roller

ATC Linear CNC Wood Machine for Sale

3 Axis Swing Head ATC CNC Router Woodworking Machine

Linear ATC CNC Router Woodworking Machine

Atc CNC Router With Automatci Tool Changer

ATC CNC Router With Automatic Tool Changer

Step into a world of limitless possibilities with our state-of-the-art Woodworking ATC CNC Router with Tool Changer. Designed to revolutionize your woodworking experience, this cutting-edge machine combines precision, efficiency, and versatility to bring your creative visions to life like never before.

Unparalleled Precision

Experience woodworking at its finest with the Woodworking ATC CNC Router’s exceptional precision. Equipped with advanced technology and high-precision components, this machine ensures every intricate detail of your designs is flawlessly executed. From intricate carvings to intricate joinery, achieve perfection with ease.

Automatic Tool Changer

Say goodbye to time-consuming manual tool changes. Our Woodworking ATC CNC Router comes with an Automatic Tool Changer (ATC) that allows seamless and efficient transitions between different cutting, carving, and shaping tools. This feature not only saves you valuable time but also enables uninterrupted workflow, maximizing productivity.

Versatility Redefined

With the Woodworking ATC CNC Router’s tool-changing capabilities, you can explore a wide range of woodworking applications. Whether you’re crafting fine furniture, intricate cabinetry, decorative moldings, or even intricate wood engravings, this machine empowers you to push the boundaries of your creativity with ease.

Efficient Workflow

Boost your efficiency and optimize your workflow with the Woodworking ATC CNC Router. Its user-friendly interface and intuitive controls make operation effortless, allowing you to focus on unleashing your creativity. The machine’s rapid cutting speed, coupled with the automatic tool changer, ensures quick turnarounds and seamless production.

Enhanced Material Compatibility

The Woodworking ATC CNC Router is designed to accommodate a variety of materials, expanding your woodworking capabilities. From hardwoods to softwoods, plywood to MDF, this machine delivers exceptional results on various materials, enabling you to tackle diverse woodworking projects with confidence.

Reliable and Durable

Invest in a woodworking machine that stands the test of time. Our Woodworking ATC CNC Router is built with durability and reliability in mind. The robust construction and high-quality components ensure consistent performance, minimizing downtime and maximizing your return on investment.

Unmatched Customer Support:

We are committed to providing exceptional customer support throughout your woodworking journey. Our team of experts is available to assist you with any queries, technical support, or training needs, ensuring a smooth and seamless experience with our Woodworking ATC CNC Router.

Applications of ATC CNC Router Machine

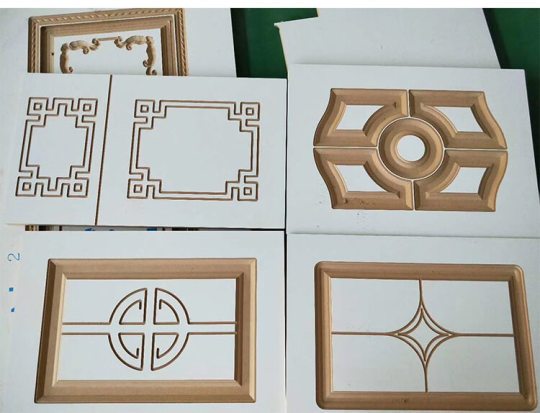

The applications of ATC Wood CNC routers span a wide range of woodworking disciplines and industries. In furniture manufacturing, ATC routers excel at producing custom cabinetry, decorative panels, intricate carvings, and complex joinery with precision and efficiency.

Artistic woodworking thrives with ATC routers, allowing craftsmen to explore creative designs, sculptures, and intricate patterns with ease and precision.

ATC Wood CNC routers offer a multitude of benefits for woodworking professionals and businesses. Firstly, they significantly reduce setup times and tool changeovers, maximizing uptime and throughput. This results in faster production cycles and shorter lead times, ultimately increasing profitability and competitiveness in the market.

Moreover, ATC routers enhance versatility by enabling the use of a wide range of cutting tools, including end mills, drills, saw blades, and specialty tools. This versatility allows woodworkers to tackle diverse projects with varying requirements, from intricate carving and engraving to precision cutting and shaping.

Furthermore, ATC technology improves accuracy and consistency by eliminating human error associated with manual tool changes. This ensures uniformity in finished products and minimizes waste, leading to higher quality and customer satisfaction.

Key Considerations when Choosing an ATC Wood CNC Router

Selecting the right ATC Wood CNC Router is vital to ensure optimal performance and productivity. Here are some essential factors to consider:

a. Machine Size and Work Area: Assess your workspace and determine the appropriate machine size and work area to accommodate your woodworking projects.

b. Spindle Power and Speed: Consider the type of wood materials and cutting requirements you will be working with. Choose a machine with an adequate spindle power and speed range to achieve desired results efficiently.

c. Tool Magazine Capacity: Evaluate the tool magazine capacity of the ATC Wood CNC Router. Ensure that it can accommodate the range and quantity of cutting tools you typically use for your projects.

d. Control System and Software: Look for a machine with a user-friendly control system and compatible software. The software should support your design needs and provide ease of use for programming and toolpath generation. e.Continuation:

e. Machine Durability and Build Quality: Consider the durability and build quality of the ATC Wood CNC Router. Look for machines constructed with robust materials and components that can withstand the demands of continuous use.

f. Support and Training: Ensure that the manufacturer or supplier provides comprehensive support and training for the machine. This will help you maximize the capabilities of the ATC Wood CNC Router and troubleshoot any issues efficiently.

g. Budget and Return on Investment (ROI): Determine your budget and evaluate the potential return on investment. While ATC Wood CNC Routers may require a significant initial investment, their efficiency and productivity gains can lead to long-term cost savings and improved profitability.

ATC Wood CNC Routers offer a multitude of benefits and applications for woodworkers and manufacturers in the woodworking industry. Their automatic tool changing capability, versatility, precision, and efficiency make them indispensable tools for creating intricate designs, producing custom woodworking projects, and streamlining production processes. By considering key factors when choosing a machine and implementing proper maintenance, woodworkers can harness the full potential of an ATC Wood CNC Router to achieve exceptional results and stay at the forefront of the woodworking industry.

0 notes

Video

youtube

China 1325 ATC Cnc Router for Woodworking

0 notes

Text

Mightymill - Build log #4 -professional diy CNC router

The Mightymill is the name I gave my professional DIY cnc router build that I’m working on. It features, BT30 ATC CNC spindle, Durfill polymer concrete filling and more. My build has finally begun and in this post I will take you on the building journey. Make sure you have read part 1 here , part 2 here , part 3 here Lifting it up in the shed It’s been some time since my last update. The…

View On WordPress

1 note

·

View note

Video

youtube

HONZHAN HZ-ATC1325L Linear Auto Tool Changer Magazine ATC CNC Router Machine

0 notes

Text

Atc CNC Router Machine Price CNC Router With ATC For Sale

This atc cnc router machine price Linear auto tool change design, no need to change tool manually. It can help to finish different work quickly. with DSP control system is used for decorations, musical instruments, wood crafts, wood furnitures, wood door making, cabinet making, windows,

Atc cnc router machine price Application

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Whats the atc cnc router machine price advantage?

1.Function: Pop-up pins are used to position the materials,improve the processing accuracy,improve the qualified products percentage and working efficiency.

Advantage of CNC Router with ATC for sale

Firstly all the installing surface are processed by five axis machining center,this can make the accuracy high enough. Secondly the pop-up pins are equipped with aluminum slots along Y axis,when the machine used the pushing function the slots will rise up as a tank on the table surface so that the positioning surface is big enough to stop smalls pieces falling off the machine. All pop-up pins are installed with adjustable air pipe connectors,so all cylinders rise up or fall down at same time,this design wont break the cylinders due to over air pressure and non-working because of short of air pressure

Benefits: save your materials,high accuracy,time efficiency.

Features of CNC Router with ATC for sale

With 9kw air-cooled spindle, the spindle speed is fast, make machine working with high precision and long time service and stable movement.

The ATC CNC Router is equipped with a separate control cabinet, more convenient in terms of operation and maintenance;

Vacuum working table, match one vacuum pump, can fix the material more stable.

Linear Automatic Tool Changer 6Tools moving with beams, high efficiency and low cost

2 notes

·

View notes

Video

youtube

Heavy Duty 4*9ft Wood Router Furniture Cabinet ATC Making Cnc Router Carving Machine

0 notes