#automated sortation conveyor systems

Explore tagged Tumblr posts

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn’t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

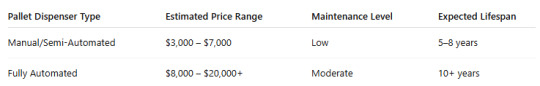

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

Automated Warehouse Systems: Revolutionizing Supply Chain Efficiency

Introduction

In the rapidly evolving world of logistics and supply chain management, automated warehouse systems have emerged as a transformative solution. From streamlining operations to enhancing productivity, automation is redefining how warehouses function. With rising customer expectations and global e-commerce expansion, businesses are increasingly turning to automation to remain competitive and agile.

What Are Automated Warehouse Systems?

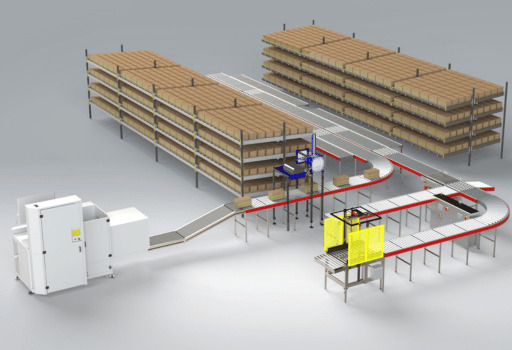

Automated warehouse systems are technology-driven solutions that perform warehousing functions—such as storage, retrieval, sorting, and packaging—with minimal human intervention. These systems integrate hardware like automated storage and retrieval systems (AS/RS), conveyor belts, robotic arms, and automated guided vehicles (AGVs) with intelligent software to manage inventory and workflows efficiently.

Key Components of Warehouse Automation

Automated Storage and Retrieval Systems (AS/RS): Mechanized systems that place and retrieve goods from specific locations in the warehouse, improving storage density and speed.

Robotics and AGVs: Robots and self-driving vehicles transport goods throughout the warehouse, reducing the need for forklifts or manual labor.

Warehouse Management Systems (WMS): Software platforms that coordinate data, monitor inventory, and optimize task assignments in real-time.

Sortation Systems: High-speed sorters classify and direct items to their respective locations, essential for handling thousands of parcels daily.

Conveyor Systems: Automated conveyors streamline movement across packing, picking, and shipping stations.

Benefits of Automated Warehouse Systems

Increased Efficiency: Automation significantly reduces picking and handling time, allowing warehouses to process more orders faster.

Enhanced Accuracy: With advanced sensors and tracking systems, errors in inventory management and order fulfillment drop dramatically.

Lower Operational Costs: While initial investment may be high, automation reduces long-term labor and operational costs.

Scalability: Automated systems can easily adapt to demand fluctuations and business growth.

Improved Safety: By minimizing manual handling and using robots for repetitive or heavy tasks, workplace injuries are reduced.

Challenges in Implementing Automation

High Initial Investment: The upfront cost for equipment, software, and integration can be substantial.

Technical Complexity: Requires skilled professionals for maintenance, troubleshooting, and optimization.

Change Management: Employees may need to be retrained, and workflows must be adapted to new systems.

Real-World Applications

E-commerce Fulfillment Centers: Giants like Amazon and Alibaba use automated warehouses to manage millions of orders daily.

Cold Storage Facilities: Automation ensures fast, efficient handling in temperature-sensitive environments.

Pharmaceutical and Healthcare Logistics: Ensures accuracy, compliance, and timely delivery of sensitive medical supplies.

The Future of Warehouse Automation

The future looks promising with the rise of AI, machine learning, and IoT-enabled devices enhancing automation capabilities. Predictive analytics, real-time data monitoring, and fully autonomous operations are set to become standard in modern warehouse facilities.

Conclusion

Automated warehouse systems are not just a trend—they are the future of efficient, reliable, and scalable logistics. As technology advances and market demands grow, automation will play a critical role in ensuring operational excellence across the supply chain.

0 notes

Text

Warehouse Automation Market Growth Driven by E-commerce Expansion and Smart Logistics Integration Globally

In recent years, warehouse automation has emerged as a critical component of modern supply chain management. With global commerce expanding and customer expectations rising, businesses are under increasing pressure to enhance efficiency, reduce errors, and streamline operations. The warehouse automation market has responded to this demand with innovative technologies that are reshaping the way goods are stored, sorted, picked, and shipped.

The Driving Forces Behind Warehouse Automation

The surge in e-commerce has been one of the most significant catalysts for warehouse automation. Consumers now expect rapid order fulfillment and real-time tracking, which necessitates precise inventory management and faster logistics. Manual processes, while still common in many warehouses, can no longer keep pace with the volume and speed of modern retail. Automation technologies fill this gap by providing scalable, data-driven solutions that improve accuracy and throughput.

Labor shortages have also played a role in accelerating automation adoption. Warehousing jobs often involve repetitive tasks and physically demanding work, leading to high turnover rates and recruitment challenges. Automated systems such as robotic arms, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs) can handle these tasks efficiently while reducing the dependency on human labor.

Moreover, the increasing availability of affordable sensors, AI-driven software, and cloud-based warehouse management systems (WMS) has made automation more accessible to businesses of all sizes. Even small and mid-sized companies are now exploring automation solutions to remain competitive in a rapidly changing marketplace.

Key Technologies Shaping the Market

Several technologies are central to the transformation of warehouse operations:

Robotics: Robotic systems are being widely used for picking, packing, and transporting goods within warehouses. These systems use machine learning and computer vision to navigate and perform tasks with high precision.

Automated Storage and Retrieval Systems (AS/RS): AS/RS use cranes, shuttles, and conveyors to store and retrieve products efficiently. These systems are especially beneficial in high-density storage environments.

Conveyor and Sortation Systems: These enable rapid sorting of packages based on size, weight, destination, or priority, which is essential in high-volume distribution centers.

Warehouse Management Software (WMS): A robust WMS integrates with hardware systems to provide real-time visibility into inventory, order status, and workforce productivity.

Internet of Things (IoT): Sensors and connected devices provide data on equipment performance, warehouse temperature, and stock levels, allowing predictive maintenance and better resource management.

Market Outlook and Growth Trends

According to market analysts, the warehouse automation market is expected to continue its robust growth trajectory over the next decade. Valued at approximately $22 billion in 2024, it is projected to surpass $60 billion by 2030, growing at a compound annual growth rate (CAGR) of over 14%.

Geographically, North America and Europe have been early adopters of warehouse automation, driven by well-established logistics infrastructure and high labor costs. However, Asia-Pacific is rapidly catching up, fueled by booming e-commerce sectors in countries like China and India, as well as a strong push toward industrial modernization.

Industries beyond retail are also embracing automation. Sectors such as pharmaceuticals, food and beverage, and electronics are increasingly investing in warehouse technologies to meet stringent quality standards and ensure traceability throughout the supply chain.

Challenges to Implementation

Despite its benefits, warehouse automation is not without challenges. High upfront investment remains a significant barrier for many companies, particularly in emerging markets. Additionally, the complexity of integrating new technologies into existing systems can lead to downtime and operational disruptions during the transition phase.

There is also the issue of workforce displacement. While automation reduces the need for manual labor, it also necessitates upskilling workers to manage and maintain automated systems. Companies must invest in training and change management to ensure a smooth technological transition.

Cybersecurity is another growing concern. As warehouses become more digitally connected, the risk of cyberattacks increases. Ensuring robust data protection and system security is critical for preventing operational disruptions and safeguarding sensitive information.

The Road Ahead

The warehouse automation market is at a pivotal juncture. As technological capabilities expand and the cost of automation continues to decline, its adoption will become increasingly widespread. Businesses that embrace automation early stand to gain a competitive edge through improved efficiency, reduced operational costs, and enhanced customer satisfaction.

However, success in this space requires more than just investment in hardware and software. It demands a holistic strategy that includes employee training, supply chain integration, and a commitment to continuous innovation. By reimagining warehouse operations through the lens of automation, companies can not only meet today’s demands but also build a more agile and resilient logistics ecosystem for the future.

0 notes

Text

0 notes

Text

0 notes

Text

Warehouse Automation: 2025 Trends, Types, and Best Practices

Warehouse automation, a cornerstone of the fourth industrial revolution, is transforming logistics by enhancing efficiency, accuracy, and scalability. Technologies like robotic pickers, conveyor belts, and AI-driven systems reduce manual labor and streamline operations to meet soaring e-commerce demands. As global retail sales are projected to hit $7.4 trillion by 2025, automation is critical for staying competitive. This 700-word guide explores the benefits, types, trends, and best practices for warehouse automation in 2025.

What is Warehouse Automation?

Warehouse automation leverages advanced technologies—robotics, software, and automated systems—to optimize tasks with minimal human involvement. It replaces repetitive, error-prone manual processes with faster, more accurate solutions. For instance, robotic arms sort goods, while conveyor systems move items seamlessly, saving time, cutting costs, and boosting efficiency in today’s fast-paced logistics landscape.

Benefits of Warehouse Automation

Enhancing Efficiency and Productivity

Automation streamlines workflows, accelerating tasks like storage and retrieval. Automated Storage and Retrieval Systems (AS/RS) maximize space, while robotic pick-and-pack stations enable rapid order fulfillment, supporting services like overnight shipping. Operating 24/7, automated systems reduce bottlenecks and boost productivity.

Reducing Errors and Improving Accuracy

Technologies like barcode readers achieve near-100% data capture, eliminating picking and tracking errors. Real-time monitoring ensures accurate inventory, and precise systems deliver 99.9% picking accuracy, minimizing costly mistakes and enhancing order reliability.

Lowering Operational Costs

Automation reduces labor and material waste, offering significant savings. AS/RS systems provide a 3–5-year payback period and can last 30 years, optimizing resources. By automating repetitive tasks, businesses lower operational expenses and achieve sustainable cost reductions.

Scaling Operations Seamlessly

Automated solutions adapt to seasonal spikes or growth without major overhauls. Scalable systems like Autonomous Mobile Robots (AMRs) integrate new technologies, ensuring warehouses remain agile in dynamic markets.

Types of Warehouse Automation Technologies

Collaborative Robots (Cobots)

Cobots work alongside humans, handling repetitive tasks like sorting or packing. Equipped with safety sensors, they prevent collisions and free workers for complex duties, such as quality checks, improving efficiency and safety.

Autonomous Mobile Robots (AMRs)

AMRs use AI and sensors to navigate warehouses, transporting goods precisely. Integrated with Warehouse Management Systems (WMS), they enhance inventory tracking, reduce labor costs, and operate 24/7 to support peak periods.

Conveyor and Sortation Systems

Conveyor belts and sortation systems use barcode scanners and RFID to move and sort goods efficiently, streamlining picking, packing, and shipping while reducing manual labor.

Automated Storage and Retrieval Systems (AS/RS)

AS/RS use robots or cranes to store and retrieve items, maximizing vertical space and speeding up inventory management. Integrated with WMS, they reduce congestion and boost throughput.

Key Trends in Warehouse Automation for 2025

Advancements in Robotics

Robots now handle picking, packing, and sorting with 99.9% accuracy. AI and machine learning enable them to manage complex tasks, like handling delicate items. The robotic picking market is expected to reach $5.7 billion by 2028.

Growth of AI Applications

AI optimizes restocking and demand forecasting, preventing stockouts and overstocking. AI-driven systems enhance quality control and adapt to customer demands, integral to modern WMS.

Increasing IoT Connectivity

IoT sensors provide real-time data on equipment and inventory, minimizing downtime via predictive maintenance and streamlining workflows for seamless operations.

Adoption of Predictive Analytics

Predictive analytics tools forecast demand, reducing inventory costs (averaging $3.7 million annually). They drive smarter decisions and faster ROI.

Sustainable Automation

Energy-efficient conveyors and AI-driven energy management reduce environmental impact, aligning with green logistics demands.

Steps to Implement Warehouse Automation

Assess Processes: Identify inefficiencies, like slow picking, to prioritize automation’s impact.

Set Goals: Define targets, such as 20% higher order accuracy, aligned with business needs.

Choose Tools: Select scalable solutions like AGVs or robotic arms, balancing cost and ROI.

Pilot Test: Start small in a low-traffic area, measuring metrics like processing time.

Train Workforce: Upskill staff on WMS and robotics for smooth adoption.

Implement in Phases: Begin with simple tasks like barcode scanning, progressing to robotic sorting.

Monitor and Optimize: Track KPIs like order accuracy and adjust workflows to maintain efficiency.

Overcoming Challenges

High Costs: Use financing or grants to offset investments. Solutions like Pio achieve 99.9% accuracy, reducing long-term costs.

Change Resistance: Involve staff, highlight benefits like less physical strain, and share success stories.

Compatibility: Assess systems and test integrations to ensure seamless operation.

Downtime: Schedule implementations during low-demand periods and monitor early stages.

Calculating ROI

Cost Savings: Automation cuts labor and error-related costs, with savings outweighing investments in 2–3 years.

Productivity: Sorting systems process thousands of packages hourly, far surpassing manual labor.

Error Reduction: Accurate systems boost customer retention, as 17% of consumers abandon brands after one error.

Scalability: Dynamic systems handle growth without reinvestment.

Conclusion

Warehouse automation delivers faster, more accurate, and cost-effective operations. Technologies like cobots, AMRs, and AI enable warehouses to meet e-commerce demands and scale efficiently. By starting small, integrating with WMS, and training staff, businesses can maximize ROI and overcome challenges. With the automation market projected to reach $69 billion by 2025, now is the time to invest for sustainable success.

1 note

·

View note

Text

Parcel Sortation Systems: Driving the Future of Automated Logistics

The global parcel sortation system market was valued at USD 2.2 billion in 2023 and is projected to grow to USD 3.1 billion by 2034, representing a compound annual growth rate (CAGR) of 3.1% over the forecast period (2024–2034). Parcel sortation systems are automated solutions designed to detect, sort, and route various types of packages based on predefined criteria such as size, weight, destination, or barcode data. These systems play a critical role in modern logistics, warehousing, e-commerce, and airport operations by optimizing order fulfillment and improving operational efficiency.

According to industry analysts, the steady growth of the parcel sortation system market is driven primarily by the surge in online shopping and the rapid adoption of automated sorting technologies. Leading vendors are increasingly integrating AI-driven analytics, machine learning algorithms, and advanced robotics to fully automate the sortation process. These innovations not only enhance throughput rates but also significantly reduce labor costs and order errors.

Market Drivers & Trends

Surge in Online Shopping: E-commerce giants and retail players are witnessing unprecedented package volumes. For example, Amazon Logistics alone shipped approximately 4.8 billion packages in 2022, averaging over 13 million deliveries per day. This boom in online retail necessitates scalable sortation infrastructures to process high volumes with accuracy and speed.

Adoption of Automated Parcel Sorting Robots: The transition from manual sorting to robotic and AI-powered solutions is accelerating. Automated guided vehicles (AGVs), robotic arms, and crossbelt sorters enhance the flexibility and reliability of warehouse and distribution centers.

Labor Shortages & Cost Reduction: Rising labor costs and workforce scarcity are prompting companies to invest in automation. Automated sortation systems offer long-term operational savings and can be redeployed to perform higher-value tasks.

Integration of AI & Data Analytics: Predictive maintenance, real-time monitoring, and dynamic routing are now feasible thanks to data-driven platforms. These systems help preempt equipment failures and optimize workflow.

Latest Market Trends

Hybrid Sorting Solutions: Combining multiple sorter types (e.g., crossbelt, tilt-tray, and pop-up sorters) in a single system to handle diverse parcel dimensions and fragility levels.

Last-Mile Optimization: Sortation systems integrated with route-planning software to accelerate delivery times and reduce transportation costs.

Cloud-Based Control Platforms: SaaS offerings that allow remote monitoring and performance analytics of sortation assets across multiple sites.

Sustainability Initiatives: Energy-efficient conveyors and recyclable sorter components are gaining traction in response to corporate ESG commitments.

Key Players and Industry Leaders Major vendors in the parcel sortation system market include:

Daifuku Co. Ltd.: Pioneer in automated warehouse solutions, with recent investments in ML-based sortation intelligence.

Dematic: Offers modular sortation lines and turnkey warehouse automation services.

GreyOrange: Known for its AI-driven Butler robotics and Rian sorter systems.

Bastian Solutions, LLC: Specializes in conveyors, sortation, and integration services.

Siemens Logistics GmbH: Provides end-to-end sortation solutions, from barcode scanners to crossbelt sorters.

Beumer Group: Developer of the PSL crossbelt sorter and energy-optimized automated systems.

Honeywell International Inc.: Integrates voice-guided picking with automated sortation for e-commerce fulfillment.

Unlock crucial data and key findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=62082

Recent Developments

January 2024: Viettel Post deployed 160 LiBiao ‘Mini Yellow’ autonomous guided robots at its Hanoi distribution hub, resulting in a 30% increase in sorting throughput and 20% reduction in sorting errors.

February 2024: Daifuku Intralogistics India showcased its fully automated warehouse solutions at LogiMAT India 2024, featuring virtual reality demonstrations of sorting transfer vehicles and AS/RS integration.

August 2023: Falcon Autotech partnered with DTDC Express to automate parcel sorting at DTDC’s 1.7 million sq. ft. super hub in Chennai, deploying high-speed crossbelt sorters capable of processing 25,000 parcels per hour.

Market Opportunities

Expansion in Emerging Economies: Asia Pacific and Latin America present significant growth potential as e-commerce adoption accelerates and infrastructure investments increase.

SME-Oriented Solutions: Scalable, cost-effective sortation modules tailored for small-to-mid-sized logistics providers.

Aftermarket Services: Remote monitoring, predictive maintenance, and training services for optimized system uptime.

Collaboration with Last-Mile Delivery Providers: Integrating sortation systems directly with delivery fleet management platforms to close the logistics loop.

Future Outlook Looking ahead to 2034, the parcel sortation system market is expected to benefit from:

5G-enabled IoT Connectivity: Real-time asset tracking within warehouses and distribution centers.

Autonomous Mobile Robots (AMRs): Flexible sortation workflows that adapt to changing parcel profiles and order mix.

Blockchain for Provenance: Secure, immutable records of parcel movement to meet regulatory requirements, especially in pharmaceuticals.

Augmented Reality (AR) for Maintenance: Technician support through AR overlays to reduce downtime during repairs.

Market Segmentation

By Offering:

Hardware: Conveyors, sensors, scanners, sorters.

Software: Warehouse execution systems, sortation control software.

Services: Implementation, training, maintenance.

By Type:

Case Sorters

Pop-up Sorters

Shipping Carton Sorters

Pivoting Arm Sorters

Pusher Sorters

Tilt Tray Sorters

Crossbelt Sorters

Pouch Sorters

Others

By End-Use:

Logistics

E-commerce

Airports

Pharmaceuticals

Food & Beverages

Others (Healthcare, etc.)

Regional Insights

North America: Leading region with the highest market share in 2023, driven by consumer demand for same-day/next-day delivery and significant automation investments in U.S. and Canada.

Europe: Strong growth owing to high e-commerce penetration (82% of U.K. consumers made online purchases in 2021) and the adoption of AI/ML for sortation optimization.

Asia Pacific: Emerging distribution hubs in China, India, and ASEAN countries are investing in modern fulfillment centers equipped with advanced sortation technologies.

Middle East & Africa: Growing retail infrastructure and government initiatives to enhance supply chain resilience.

South America: Increasing e-commerce activities in Brazil and Argentina creating demand for small-scale sortation solutions.

Why Buy This Report?

Comprehensive Coverage: Detailed quantitative and qualitative analysis including market drivers, restraints, opportunities, and key trends.

Strategic Insights: In-depth profiles of 15+ leading players, including their product portfolios, financial overviews, and recent developments.

Robust Forecasting: Market projections through 2034, with historical data (2020–2022) to contextualize growth trajectories.

Actionable Recommendations: Market entry strategies, investment opportunities, and aftermarket service models.

Customizable Data: Interactive PDFs and Excel workbooks with segment-level data and regional break-downs.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Maximizing Efficiency with Pneumatic Part Feeders in Modern Automation Systems

In the fast-paced world of industrial automation, efficiency and reliability are paramount. One essential component that continues to streamline production lines across industries is the pneumatic part feeder. These systems are designed to deliver parts swiftly and accurately, enabling manufacturers to meet high production demands while minimizing downtime and labor costs.

What Are Pneumatic Part Feeders?

Pneumatic part feeders are automation devices that use compressed air to transport and position parts within a manufacturing or packaging process. Unlike traditional vibratory feeders, pneumatic systems offer quieter operation, precise control, and enhanced flexibility in part orientation and delivery.

They are especially effective in applications where delicate handling is crucial, such as electronics assembly, medical device manufacturing, or any process involving lightweight or small components.

Key Benefits of Pneumatic Part Feeders

1. Precision and Speed: Pneumatic feeders can be finely tuned to deliver parts at exact intervals, ensuring synchronized performance with downstream equipment.

2. Reduced Noise Levels: Operating on air pressure rather than vibration significantly reduces workplace noise, creating a more comfortable and compliant work environment.

3. Low Maintenance: With fewer moving parts than mechanical feeders, pneumatic systems typically require less maintenance, translating to lower operational costs.

4. Versatile Design: Easily integrated into various production lines, these feeders can be customized to handle a wide range of parts and materials.

Applications Across Industries

From automotive and consumer electronics to pharmaceuticals and food packaging, pneumatic part feeders are the backbone of efficient automation. Their adaptability allows for integration into robotic cells, assembly lines, and complex sortation systems, making them a preferred choice for engineers seeking custom-engineered solutions that can scale with production needs.

Why Choose Dillin for Pneumatic Part Feeder Solutions?

At Dillin, we understand the intricacies of modern manufacturing. Our team designs and delivers custom engineered systems that incorporate pneumatic part feeders as part of a larger ecosystem of automation solutions. Whether you're optimizing sortation, conveyor systems, or capping and lid placement, our equipment is built to perform with precision and reliability.

Explore how Dillin's expertise inautomation systems and part handling solutions can elevate your operational efficiency. Let’s build a system tailored to your production goals.

Source Url : - https://listsearch.net/maximizing-efficiency-with-pneumatic-part-feeders-in-modern-automation-systems/

0 notes

Text

Automated Material Handling Equipment Market: Innovations and Technological Advancements Reshaping Industries Worldwide

The Automated Material Handling Equipment (AMHE) market is experiencing significant growth, driven by advancements in technology and an increasing demand for efficient and cost-effective solutions in various industries. These systems are designed to automate processes such as the transportation, storage, and retrieval of materials in warehouses, manufacturing plants, distribution centers, and other industrial settings. AMHE includes a broad range of equipment, such as conveyors, automated guided vehicles (AGVs), cranes, robots, and sortation systems, all of which work together to streamline material flow and improve operational efficiency.

Market Drivers

Several key factors are contributing to the rapid expansion of the Automated Material Handling Equipment market. One of the main drivers is the increasing demand for automation in industries such as manufacturing, logistics, e-commerce, and retail. The need for faster and more accurate material handling solutions, as well as the growing pressure to meet customer demands for quick deliveries, is pushing companies to adopt automation technologies.

The rising labor costs and the shortage of skilled labor are also influencing the market. Many businesses are turning to automated systems to reduce reliance on human labor, thereby lowering operational costs and improving productivity. Additionally, automated systems can work around the clock, ensuring higher efficiency and reducing the chances of human error. This results in enhanced throughput, better utilization of resources, and improved safety.

Technological advancements in robotics, artificial intelligence (AI), and the Internet of Things (IoT) are also playing a crucial role in the growth of the market. AMHE systems are becoming increasingly intelligent and capable of performing complex tasks, such as inventory management, predictive maintenance, and real-time data analysis. These innovations make automation systems more versatile and adaptable to a variety of industries, thus broadening their applications.

Market Segmentation

The Automated Material Handling Equipment market can be segmented based on the type of equipment, end-user industry, and region.

By Type of Equipment:

Conveyors: These are commonly used in manufacturing and distribution centers for transporting goods and materials. Conveyors offer an efficient means of material handling by reducing the need for manual labor and enhancing operational efficiency.

Automated Guided Vehicles (AGVs): AGVs are mobile robots used to transport materials within a facility. They follow pre-programmed paths and are equipped with sensors to avoid obstacles, improving the flow of materials while ensuring safety.

Robotic Systems: Robotic systems, such as robotic arms, are widely used in material handling for tasks such as sorting, picking, and packaging. They are often used in combination with other automated equipment to optimize processes.

Cranes and Hoists: These systems are used for lifting and transporting heavy materials in industrial settings. Cranes and hoists are vital in sectors such as construction and manufacturing.

Sortation Systems: These systems are designed to sort products based on predefined criteria such as size, color, or destination. They are typically used in warehouses and distribution centers for efficient order fulfillment.

By End-User Industry:

E-commerce and Retail: The e-commerce industry is one of the largest adopters of automated material handling systems. With the increase in online shopping, there is a growing need for efficient fulfillment centers that can handle large volumes of orders quickly and accurately.

Manufacturing: In manufacturing, AMHE systems are used to streamline processes such as assembly, packaging, and delivery. The automotive and electronics industries, in particular, rely heavily on automated material handling to improve production efficiency.

Logistics and Warehousing: The logistics industry is also a major consumer of AMHE, as it allows companies to optimize their supply chains, reduce transit times, and improve inventory management.

Food and Beverage: In the food and beverage sector, automated systems are used for tasks such as sorting, packaging, and palletizing. These systems ensure that products are handled hygienically and meet safety standards.

Pharmaceuticals: Automated systems in the pharmaceutical industry are crucial for ensuring the accuracy and safety of products. They help with tasks such as inventory management, sorting, and packaging of sensitive pharmaceutical products.

Regional Insights

The Automated Material Handling Equipment market is experiencing significant growth across various regions, with North America, Europe, and Asia Pacific being key players.

North America: North America, especially the United States, is one of the largest markets for AMHE, driven by the high adoption rate of advanced technologies in industries such as e-commerce, manufacturing, and logistics. The region's strong focus on research and development, along with the presence of several key market players, is also contributing to market growth.

Europe: Europe is another prominent region in the AMHE market, with countries like Germany, the UK, and France leading the way. The European market is characterized by a high demand for automation in manufacturing, logistics, and e-commerce, particularly in countries with strong industrial sectors.

Asia Pacific: The Asia Pacific region is expected to see the highest growth in the Automated Material Handling Equipment market. This can be attributed to the rapid industrialization in countries like China, Japan, and India. The increasing demand for automation in manufacturing and logistics, coupled with the region’s large population and growing e-commerce sector, is driving market expansion.

Challenges

Despite the significant growth potential, the AMHE market faces several challenges. One of the main obstacles is the high initial cost of implementing automated systems, which can be a barrier for small and medium-sized enterprises (SMEs). Additionally, the complexity of integrating new automated systems with existing infrastructure can lead to disruptions in operations.

Moreover, the rapid pace of technological advancements in automation means that businesses must constantly invest in upgrading their systems to remain competitive. This presents a challenge for companies in terms of budget allocation and resource management.

Conclusion

The Automated Material Handling Equipment market is poised for substantial growth, driven by the need for efficiency, cost reduction, and technological advancements. As industries continue to embrace automation to meet the demands of modern supply chains, the market for AMHE is expected to expand significantly in the coming years. However, businesses must carefully consider factors such as initial costs and system integration to ensure successful adoption.

0 notes

Text

Conveyor Roller Systems: The Complete Guide: Effectiveness and Creativity in Material Processing

Conveyor roller systems have revolutionized the material handling industry, offering efficiency, reliability, and cost-effectiveness. Whether in warehouses, manufacturing plants, or distribution centers, these systems play a vital role in streamlining logistics. This guide explores conveyor roller systems in-depth, covering types, benefits, and key considerations when selecting the right system for your needs.

What Are Conveyor Roller Systems?

A conveyor roller system is a mechanical assembly designed to transport materials effortlessly across a defined path. It consists of rollers, frames, and a drive system that work together to move goods efficiently. These systems are commonly used in industries such as logistics, food processing, mining, and e-commerce fulfillment centers.

Types of Conveyor Roller Systems

Conveyor roller systems come in different variations, each designed for specific applications. Understanding their differences helps businesses choose the right solution for their operational needs.

1. Gravity Roller Conveyors

Operate without external power.

Relies on gravity to move items.

Ideal for lightweight packages and manual operations.

2. Powered Roller Conveyors

Uses motors or belt drives to transport materials.

Suitable for high-speed and automated operations.

Offers better control over material movement.

3. Chain-Driven Roller Conveyors

Uses chains to rotate rollers.

Best for heavy-duty applications such as automotive and industrial manufacturing.

Provides robust durability and load capacity.

4. Belt-Driven Roller Conveyors

Features a belt running beneath the rollers for movement.

Great for fragile or irregularly shaped items.

Used in applications requiring precise product handling.

5. Flexible Roller Conveyors

Can expand, contract, and curve as needed.

Excellent for temporary or space-limited workspaces.

Common in retail, e-commerce, and parcel distribution centers.

Key Benefits of Conveyor Roller Systems

Investing in a conveyor roller system provides a range of benefits that enhance operational efficiency.

1. Increased Productivity

Automating material handling reduces manual labor, ensuring faster throughput and increased efficiency in manufacturing and distribution processes.

2. Reduced Labor Costs

By minimizing manual handling, businesses can cut labor expenses while improving workplace safety.

3. Improved Accuracy and Consistency

Conveyor roller systems reduce errors and inconsistencies that often occur in manual handling, leading to better inventory management and order fulfillment.

4. Versatility in Applications

These systems can handle various materials, including boxes, pallets, and bulk materials, making them adaptable for diverse industries.

5. Enhanced Workplace Safety

By automating movement, conveyor systems reduce workplace injuries related to heavy lifting and repetitive strain.

Real-World Applications and Testimonials

Many businesses have successfully integrated conveyor roller systems into their operations, experiencing remarkable improvements in productivity and efficiency.

Case Study: E-commerce Distribution Center

A leading online retailer implemented a powered roller conveyor system to handle high order volumes. The result? A 40% increase in order processing speed and a significant reduction in manual labor costs.

Testimonial: Manufacturing Industry

“After installing a chain-driven roller conveyor, our production line became 30% faster with fewer material handling errors. It has been a game-changer for our efficiency.” – Operations Manager, Automotive Manufacturer

Future Trends in Conveyor Roller Systems

With advancements in automation and AI, conveyor roller systems are evolving to become smarter and more efficient. Here are some future trends to watch:

IoT-Enabled Monitoring – Smart conveyors with sensors provide real-time analytics on system performance and maintenance needs.

AI-Powered Sorting – Artificial intelligence helps improve sorting accuracy and operational efficiency.

Sustainability Improvements – Energy-efficient motors and recyclable materials are making conveyor systems more eco-friendly.

Conclusion

Conveyor roller systems are an indispensable asset in material handling, providing unparalleled efficiency and reliability. Whether for a small warehouse or a large manufacturing plant, choosing the right system can significantly improve operations. By understanding the different types, benefits, and industry applications, businesses can optimize their workflows and stay competitive in a fast-paced market.

0 notes

Text

What Is Automation in Operations? A Deep Dive into Its Impact on Palatine, Illinois Businesses

In recent years, automation in operations has emerged as a powerful force reshaping how businesses across Illinois function. In Palatine—a growing village within the Chicago metropolitan area—industries are rapidly adapting automation technologies to streamline workflows, boost efficiency, and enhance scalability.

Whether it’s a manufacturing plant using automated machinery or a logistics center implementing smart tracking systems, the transformation is visible across sectors. Businesses in Palatine, Illinois, are now recognizing that automation is no longer optional but essential for remaining competitive and agile in today's fast-paced market.

What Does Automation in Operations Actually Mean?

At its core, automation in operations refers to the use of technology—like machines, control systems, and software—to perform tasks that were traditionally done manually. These tasks may involve manufacturing, processing, monitoring, or even decision-making.

By integrating automation into operations, companies in Palatine can:

Reduce human error

Minimize repetitive labor

Increase productivity

Save time and money

Improve customer satisfaction through consistent output

From robotic process automation (RPA) in administrative tasks to programmable logic controllers (PLCs) in assembly lines, automation is making every facet of business more responsive and resilient.

Key Industries in Palatine Benefiting from Automation

Palatine is home to a mix of manufacturing, distribution, healthcare, and tech-based businesses. Automation plays a distinct role in each of these sectors, helping them scale while maintaining quality and cost-efficiency.

Manufacturing and Assembly Palatine’s proximity to industrial hubs in Illinois makes it ideal for manufacturers looking to modernize. With automation, local facilities can now rely on CNC machines, robotic arms, and automated conveyors to handle tasks that once took multiple shifts to complete. These systems also reduce the risk of injury and ensure higher output consistency.

Warehousing and Logistics The demand for faster delivery and real-time tracking has pushed logistics companies in Palatine to invest in warehouse automation. This includes:

Autonomous mobile robots (AMRs) Smart inventory management systems Automated sortation and packaging equipment

With these tools, operations become more efficient, and human workers are freed up for tasks requiring judgment and flexibility.

Healthcare and Medical Devices Palatine’s healthcare facilities and medical device manufacturers are also leveraging automation to handle high-volume processes with precision. From sterile packaging lines to automated diagnostic equipment, these solutions improve both patient safety and operational efficiency.

Food and Beverage Processing Automation ensures consistency in quality, taste, and safety in food production—something that’s critical to food manufacturers operating in and around Palatine. Automated mixers, dispensers, and inspection systems can significantly increase throughput while meeting strict regulatory standards.

Advantages of Adopting Automation in Local Operations

Integrating automation into day-to-day operations offers many advantages that go beyond simple productivity gains. For businesses in Palatine, Illinois these benefits include:

Enhanced Accuracy and Reliability Machines don’t tire, lose focus, or skip steps. By reducing manual intervention, automation ensures greater consistency and accuracy—especially important in industries like pharmaceuticals and electronics.

Cost Savings Over Time Though automation may require a higher upfront investment, it often results in long-term cost reductions by decreasing labor costs, minimizing waste, and reducing downtime.

Scalability and Flexibility Automated systems can easily adapt to different product lines or changing workloads. This scalability allows Palatine businesses to grow without a complete overhaul of their infrastructure.

Improved Data and Decision-Making Many automated systems provide real-time data and analytics, empowering businesses to make informed decisions. This insight is vital for continuous improvement and optimizing resource allocation.

Challenges Faced and How Palatine Businesses Are Overcoming Them

Despite its numerous benefits, automation isn’t without challenges—especially for small to mid-sized enterprises (SMEs). Concerns include:

Initial cost of installation Integration with existing systems Employee resistance to change

However, businesses in Palatine are actively overcoming these hurdles through phased implementation and workforce training. Community colleges and technical institutes in the area also offer courses in automation technology, helping bridge the skills gap and prepare workers for the future of industry.

Automation in Operations and the Human Workforce

One common misconception is that automation replaces human jobs entirely. In reality, it often transforms them.

In Palatine, we’re seeing a shift where routine tasks are automated, allowing workers to focus on more strategic, creative, or safety-critical roles. For example, instead of manually inspecting each unit on an assembly line, workers now oversee quality control systems and use data dashboards to make decisions.

By automating low-value tasks, companies also improve job satisfaction and reduce burnout, creating a healthier work environment.

The Future of Operational Automation in Palatine, Illinois

Looking ahead, the automation trend in Palatine is only expected to grow. With technologies like artificial intelligence, machine learning, and the Internet of Things (IoT) gaining traction, the possibilities for automation are expanding every day.

Imagine predictive maintenance systems that can fix equipment before it fails, or AI-driven scheduling tools that adapt production in real time based on customer demand. These aren’t distant dreams—they’re becoming a reality right here in Palatine.

To fully benefit, businesses must continue to invest in innovation, prioritize workforce development, and collaborate with trusted automation experts.

Start Your Automation Journey Today

If your business in Palatine, Illinois is ready to integrate smarter systems into your daily operations, professional support is key. Partnering with an experienced automation provider ensures smooth planning, installation, and maintenance of your systems.

One such reliable partner is Xtreme Automation LLC. With a focus on engineering excellence, smart control systems, and industrial automation, they serve businesses across Illinois with customized automation solutions built for real-world performance.

0 notes

Text

Optimizing Efficiency: The Benefits of Warehouse Automation Services

In today’s fast-paced logistics and supply chain industry, efficiency and accuracy are critical for businesses aiming to stay competitive. Warehouse automation services have emerged as a game-changer, helping companies streamline operations, reduce costs, and enhance overall productivity. In this blog, we explore the key benefits and applications of warehouse automation services.

What is Warehouse Automation?

Warehouse automation involves the use of technology, robotics, and software systems to manage warehouse tasks with minimal human intervention. It includes automated storage and retrieval systems (AS/RS), robotic picking solutions, conveyor systems, and warehouse management software (WMS). These technologies work together to optimize material handling, inventory management, and order fulfillment.

Key Benefits of Warehouse Automation

1. Increased Efficiency and Productivity

Automated systems perform repetitive tasks at a much faster pace than human workers. With robots and AI-driven solutions handling order picking, packing, and sorting, warehouses can process higher volumes of goods efficiently, reducing labor-intensive operations.

2. Improved Accuracy and Reduced Errors

Automation significantly minimizes human errors in order fulfillment. AI-powered warehouse management systems ensure accurate picking and packing, reducing returns due to incorrect shipments. Barcode scanning and RFID tracking also enhance inventory accuracy.

3. Cost Savings and Labor Optimization

By reducing reliance on manual labor, businesses can lower operational costs. Automation helps redistribute human resources to more strategic roles while mitigating challenges related to labor shortages and workforce fatigue.

4. Better Space Utilization

Automated storage and retrieval systems enable warehouses to optimize vertical space, allowing for higher storage capacity within the same footprint. This maximizes storage efficiency and improves warehouse organization.

5. Enhanced Safety

Warehouse automation reduces the risk of workplace injuries by minimizing the need for employees to perform physically demanding or hazardous tasks. Autonomous robots and conveyor systems transport goods safely, preventing accidents associated with manual handling.

Popular Warehouse Automation Technologies

Autonomous Mobile Robots (AMRs): These self-navigating robots transport goods within the warehouse, improving picking and sorting efficiency.

Automated Guided Vehicles (AGVs): AGVs follow predefined paths to move inventory between locations.

Conveyor and Sortation Systems: Automated conveyor belts and sorting systems accelerate order processing and distribution.

Pick-to-Light and Put-to-Light Systems: These systems use LED lights to guide warehouse workers in picking and placing items, reducing errors and increasing speed.

AI-Powered Warehouse Management Systems (WMS): AI-driven software solutions optimize inventory tracking, demand forecasting, and workflow automation.

Future of Warehouse Automation

The future of warehouse automation is driven by AI, IoT, and machine learning. Smart warehouses are adopting predictive analytics, real-time tracking, and robotic process automation to improve decision-making and operational efficiency. As technology advances, fully autonomous warehouses are becoming a reality, revolutionizing supply chain logistics.

Conclusion

Warehouse automation services are transforming logistics by increasing efficiency, reducing costs, and enhancing accuracy. As businesses continue to invest in automation technologies, they will gain a competitive edge in an ever-evolving market. If you’re looking to optimize your warehouse operations, now is the time to explore automation solutions tailored to your business needs.

Ready to automate your warehouse? Contact us today to learn how our warehouse automation services can elevate your operations.

0 notes

Text

0 notes

Text

Warehouse Optimization: Key Techniques for Maximizing Space and Efficiency

In today’s fast-paced and competitive business environment, efficient warehouse management is crucial for operational success. Warehouses are not just storage spaces; they are dynamic hubs that play a critical role in the supply chain. Optimizing warehouse operations can lead to significant improvements in productivity, cost savings, and customer satisfaction. This blog explores key techniques for maximizing space and efficiency in warehouse management best logistics institute in kochi

The Importance of Warehouse Optimization Warehouse optimization involves the strategic planning and management of warehouse operations to ensure the best use of space, labor, and equipment. Effective warehouse optimization can lead to:

Increased Storage Capacity: By maximizing the use of available space, warehouses can store more inventory without the need for expansion. Improved Efficiency: Streamlined processes and optimized layouts reduce the time and effort required for tasks such as picking, packing, and shipping. Cost Savings: Efficient use of resources reduces operational costs, including labor, energy, and equipment expenses. Enhanced Customer Satisfaction: Faster and more accurate order fulfillment leads to improved customer experiences and loyalty. Key Techniques for Warehouse Optimization Space Utilization Effective space utilization is the foundation of warehouse optimization. Techniques for maximizing space include:

Vertical Storage: Utilizing vertical space with high-rise racking systems and mezzanines can significantly increase storage capacity. This approach allows for more efficient use of floor space and reduces the need for warehouse expansion. Narrow Aisle Shelving: Narrowing aisle widths can free up additional space for storage. Advanced material handling equipment, such as narrow aisle forklifts, can navigate these tighter spaces efficiently. Optimized Layout Design: A well-designed warehouse layout minimizes travel time and enhances workflow. Grouping similar items together, placing high-demand products near shipping areas, and creating clear paths for material handling equipment can improve overall efficiency. Inventory Management Effective inventory management is crucial for warehouse optimization. Key strategies include:

ABC Analysis: Classifying inventory into A, B, and C categories based on demand and value helps prioritize storage and handling. High-demand items (A) should be easily accessible, while lower-demand items (C) can be stored in less accessible areas. Just-in-Time (JIT) Inventory: Implementing JIT inventory practices reduces excess stock and minimizes storage requirements. By receiving goods only as needed, warehouses can maintain lower inventory levels and reduce carrying costs. Automated Inventory Tracking: Utilizing barcode scanning, RFID technology, and inventory management software enhances accuracy and reduces manual errors. Real-time inventory tracking ensures that stock levels are optimized and helps prevent overstocking or stockouts. Warehouse Automation Automation technologies can greatly enhance warehouse efficiency. Key automation solutions include:

Automated Storage and Retrieval Systems (AS/RS): AS/RS technology automates the storage and retrieval of goods, reducing labor costs and improving accuracy. These systems are particularly useful for high-density storage and can operate in tight spaces. Conveyor Systems: Conveyor belts and automated sortation systems streamline the movement of goods within the warehouse. This reduces manual handling, speeds up order processing, and minimizes the risk of damage. Robotics: Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) can perform tasks such as picking, packing, and transportation. These robots enhance efficiency, reduce labor costs, and improve safety by minimizing human intervention in hazardous areas. Efficient Order Picking Order picking is one of the most labor-intensive and time-consuming tasks in a warehouse. Optimizing the order picking process can lead to significant efficiency gains. Key techniques include:

Zone Picking: Dividing the warehouse into zones and assigning workers to specific areas reduces travel time and increases picking speed. Orders are picked in stages as they move through the different zones. Batch Picking: Grouping multiple orders together and picking items in batches reduces the number of trips made by workers. This method is particularly effective for small, high-volume items. Pick-to-Light Systems: Pick-to-light technology uses light indicators to guide workers to the correct picking locations. This reduces errors and speeds up the picking process. Labor Management Efficient labor management is crucial for warehouse optimization. Key strategies include:

Labor Scheduling: Using labor management software to schedule shifts and allocate resources based on demand ensures that the right number of workers are available when needed. This minimizes downtime and maximizes productivity. Training and Cross-Training: Providing comprehensive training and cross-training for employees enhances their skills and flexibility. Cross-trained workers can perform multiple tasks, reducing bottlenecks and improving overall efficiency. Incentive Programs: Implementing performance-based incentive programs motivates employees to work more efficiently and achieve productivity targets. Sustainability Practices Incorporating sustainability practices into warehouse operations can lead to cost savings and environmental benefits. Key techniques include:

Energy-Efficient Lighting: Using LED lighting and motion sensors reduces energy consumption and lowers utility costs. Renewable Energy Sources: Installing solar panels or wind turbines can provide a sustainable source of energy for warehouse operations. Recycling and Waste Reduction: Implementing recycling programs and reducing packaging waste minimizes the environmental impact of warehouse operations.

Warehouse optimization is a critical component of efficient supply chain management. By implementing key techniques such as effective space utilization, inventory management, warehouse automation, efficient order picking, labor management, and sustainability practices, companies can maximize space and efficiency in their warehouse operations. These strategies not only lead to cost savings and improved productivity but also enhance customer satisfaction and support long-term business success. As technology continues to evolve, the future of warehouse optimization will likely see even more innovative solutions that drive efficiency and sustainability in the logistics industry best logistic training in kochi

0 notes

Text

0 notes

Text

Elevate Your Production Line with Custom Engineered Solutions from Dillin

In today’s fast-paced manufacturing environment, optimizing your production line is no longer optional — it’s a necessity. That’s where Dillin comes in. As a leader in designing and delivering custom engineered solutions, we help manufacturers streamline their operations with cutting-edge air conveyor systems, carton accumulation, capping systems, and more.

Whether you’re handling round container sortation or need a reliable conveyor table top solution, our automation expertise ensures smooth, efficient movement from start to finish. Let’s explore how our systems elevate your production line’s efficiency and give you a competitive edge.

Why Choose Air Conveyor Systems for Modern Manufacturing?

Air conveyor systems have revolutionized the way products move through a facility. By utilizing low-pressure air to transport lightweight items like bottles, cans, and cartons, these systems reduce mechanical wear and energy consumption while increasing speed and reliability.

At Dillin, our engineered systems are designed with precision, offering seamless integration with your existing production lines. Our expertise in air conveyor systems ensures gentle handling, reduced downtime, and optimized throughput.

Efficient Carton Accumulation for Continuous Flow

For industries relying on high-speed production lines, carton accumulation systems are essential for maintaining continuous flow. Our accumulation solutions help balance line speeds, reduce bottlenecks, and prevent product damage — ensuring that your operations run smoothly even during peak demand.

With Dillin’s advanced accumulation technology, manufacturers can achieve greater flexibility, accommodating fluctuations in production rates without sacrificing efficiency.

The Power of Table Top and Mat Top Conveyor Systems

A reliable conveyor system is the backbone of any successful manufacturing operation. Dillin offers both table top conveyor systems and mat top conveyors, tailored to meet your specific application needs.

Table top chain conveyors are ideal for precision handling of products in bottling, packaging, and assembly lines. Their durability and smooth operation make them a go-to solution for high-speed environments.

Mat top conveyors offer superior load capacity and product stability, perfect for heavier products or complex sortation requirements.

With our comprehensive design and engineering services, we create custom engineered solutions that keep your line running efficiently and reliably.

Precision Sortation Systems: Lid and Round Container Sortation

Sortation is a critical component of modern manufacturing, and Dillin specializes in bothlid sortation and round container sortation solutions. Our systems are designed to handle high volumes with accuracy, reducing waste and ensuring that each product is exactly where it needs to be.

By incorporating advanced sensors, automation technology, and seamless system integration, we deliver automation systems inc-level performance that exceeds expectations.

Why Partner with Dillin for Custom Engineered Solutions?

At Dillin, we’re more than just a conveyor company — we’re your partners in production line efficiency. Our solutions are built on decades of experience, engineering innovation, and a commitment to helping our clients stay ahead of the curve.

By investing in our conveyor table top, air conveyor systems, and advanced sortation technologies, manufacturers can achieve: ✅ Higher throughput and efficiency ✅ Reduced operational costs ✅ Improved product handling and safety ✅ Seamless integration with existing systems

Let’s Build Your Future Production Line

If you’re looking to optimize your manufacturing process with custom engineered solutions, Dillin is here to help. From carton accumulation to mat top conveyors and everything in between, our team of experts will work with you to design a system that meets your unique needs.

👉 Visit Dillin.net today to learn more about our innovative solutions and discover how we can transform your production line into a model of efficiency and reliability.

Source Url : - https://seowebpromote.com/elevate-your-production-line-with-custom-engineered-solutions-from-dillin/

0 notes