#automaticflyashbrickmakingmachine

Explore tagged Tumblr posts

Text

Top Brick Making Machine Manufacturer | Fly Ash & Automatic Machines in India

Explore premium brick making machines by Revomac – trusted manufacturers of fly ash brick making machines, automatic models, and cost-effective solutions. Get the best brick making machine price in India.

#brickmakingmachineManufacturer#flyashbrickmakingmachinemanufacturers#automaticbrickmakingmachine#Automaticflyashbrickmakingmachine#brickmakingmachine#brickmakingmachineprice#brickmakingmachinepriceinindia#flyashbrickmakingmachine#flyashbrickmakingmachineprice

2 notes

·

View notes

Text

7 Insider Secrets: How Are Cement Bricks & Blocks Manufactured for Superior Construction?

How are cement bricks and blocks manufactured?

Cement bricks and blocks form the backbone of modern construction, and understanding their manufacturing process can provide invaluable insights for contractors, engineers, and investors alike. In today’s competitive market, knowing what goes behind creating these essential building components not only improves decision-making but also instills confidence in the durability and quality of construction materials. In this article, we uncover the secrets behind the manufacturing process, address frequently asked questions, and highlight key statistics that underline the importance of precision in production.

Introduction

The construction industry relies heavily on the consistent quality of building materials. Cement bricks and blocks, known for their strength and longevity, are manufactured through a systematic, multi-step process that transforms raw materials into essential components for modern infrastructure. This blog post will walk you through the manufacturing process, answer common queries, and reveal industry insights that every professional and enthusiast should know. Whether you’re a seasoned builder or new to the industry, these insider secrets will elevate your understanding and guide your next project.

The Manufacturing Process Uncovered

1. Raw Materials: The Foundation of Quality

The journey begins with sourcing high-quality raw materials. The primary ingredients include cement, aggregates (like sand and gravel), water, and sometimes additives to enhance performance. Each component plays a crucial role:

Cement: Provides binding strength.

Aggregates: Offer structural stability.

Water: Initiates the hydration process.

Additives: Enhance durability and workability.

Ensuring the correct proportions is essential. For example, maintaining a water-to-cement ratio between 0.4 and 0.6 is critical for achieving optimal strength and durability. Industry statistics indicate that up to 80% of the final product’s quality is determined during this initial stage.

2. Mixing: Precision in Every Batch

Once raw materials are selected, the next step is mixing. Modern facilities employ high-speed mixers that blend the materials to a uniform consistency. This stage is crucial because even a minor imbalance in the mix can result in compromised strength or an inconsistent texture.

Mixing involves:

Batching: Precise measurement of each component.

Blending: Combining materials uniformly to ensure consistent distribution.

Monitoring: Continuous quality checks to ensure the mix adheres to industry standards.

Transitioning to the next phase, advanced monitoring systems now utilize sensors and automation to fine-tune the process, reducing human error and enhancing quality control.

3. Molding and Shaping: Crafting the Perfect Form

After mixing, the homogeneous material is transferred to molds to create bricks or blocks. The manufacturing process here can vary:

Cement Bricks: Typically, the mixture is compressed in a mold using a hydraulic press. The pressure applied can reach up to 10,000 psi, ensuring that the bricks are dense and robust.

Cement Blocks: Larger in size, these blocks are often cast using automated machines. The molds are designed to produce uniform shapes, which is critical for ensuring ease of installation and structural consistency.

Storytelling element: Imagine the precision of an orchestra playing in perfect harmony; every press and cast is a note contributing to the grand symphony of construction excellence.

4. Curing: Transforming Fresh Casts into Durable Structures

Curing is perhaps the most critical phase in the manufacturing process. Once molded, the bricks or blocks must cure—essentially, they undergo a controlled hardening process. This is achieved through:

Moisture Retention: Maintaining adequate moisture levels to allow the chemical reactions in cement to complete.

Temperature Control: Ensuring that environmental conditions support optimal hydration.

Time: Curing can take anywhere from 7 to 28 days depending on the product specifications and environmental conditions.

Statistics show that proper curing can improve the strength of cement bricks and blocks by up to 50% compared to those that are not cured under controlled conditions.

5. Quality Assurance: The Final Seal of Approval

Before cement bricks and blocks reach the market, they undergo rigorous quality assurance tests. These tests include:

Compression Strength Tests: Verifying that each unit can withstand heavy loads.

Dimensional Checks: Ensuring uniformity in size and shape.

Surface Inspections: Checking for any defects that could impact the performance or aesthetics of the final product.

Quality assurance protocols are not just about meeting regulatory standards—they provide peace of mind to builders and investors, ensuring that every brick or block contributes to a safe and sustainable construction.

Frequently Asked Questions

How are cement bricks different from cement blocks?

Cement bricks are usually smaller and are often used for walls and smaller constructions, whereas cement blocks are larger, offering enhanced structural stability for load-bearing walls. Their manufacturing process is similar, but the molding and curing processes may differ slightly to accommodate size differences.

What are the key factors that affect the quality of cement bricks and blocks?

The quality of these products largely depends on the quality of raw materials, the precision of the mixing process, the effectiveness of the molding and pressing systems, and the rigor of the curing and quality assurance processes. Maintaining the optimal water-to-cement ratio and ensuring a controlled curing environment are paramount.

How long does it take to manufacture cement bricks and blocks?

The manufacturing process itself is relatively quick, with mixing and molding taking just a few hours. However, the curing phase can take anywhere from 7 to 28 days, which is essential to achieve the desired strength and durability.

Can the manufacturing process be automated?

Yes, automation plays a significant role in modern production facilities. Automated mixers, robotic molding systems, and digital monitoring for curing are now common, increasing both efficiency and product consistency.

What are the environmental impacts of manufacturing cement bricks and blocks?

While the production process does involve energy consumption and carbon emissions, many manufacturers are adopting eco-friendly practices. Innovations like using recycled materials, optimizing energy usage, and exploring alternative fuels are gradually reducing the environmental footprint.

#BrickAndBlockManufacturers#InterlockingBlockMakingMachine#AutomaticInterlockingBlockMakingMachine#ManualFlyAshBrickMakingMachine#AutomaticFlyAshBrickMakingMachine#FullyAutomaticFlyAshBrickMakingMachine#AutomaticSolidBlockMakingMachine#AutomaticPaverBlockMakingMachine#PanMixerMachine#ConcretePanMixerMachine#RollerPanMixerMachine#PipeBendingMachineManufacturers#HydraulicShearingMachineManufacturers#ArecaLeafPlatesMakingMachine

2 notes

·

View notes

Text

#AutomaticFlyashBrickMakingMachine#BatchingPlantSystem#AutoPalletStackerSystem#Automaticrobo2020MultiBrickMachine#MultiBlockAutoStackerPalletSystem#HollowSolidConcreteBlockMachine#PanMixer#ReadymixConcreteSilos

0 notes

Text

How Does a Concrete Pan Mixer Work and Why Should You Use One

Let’s be honest—concrete mixing isn’t glamorous, but it’s the heart of just about every construction project. You could have the best materials and crew in the world, but if the mix isn’t right, the end result is going to suffer.

That’s why more and more builders, block manufacturers, and contractors are turning to a machine that doesn’t always get the spotlight: the Concrete Pan Mixer Machine.

It’s not huge. It’s not flashy. But it delivers a consistently solid mix—and that’s what really matters on-site.

So, What’s a Concrete Pan Mixer, Anyway? Think of it like a big steel bowl—kind of like a giant kitchen mixer, only tougher. It’s round, flat on the bottom, and fitted with rotating blades that churn everything together��cement, sand, gravel, water, additives—you name it.

The pan either stays still while the blades rotate, or in some models, both the pan and the blades rotate in opposite directions. The idea is to keep everything moving so every bit of the mix is touched, turned, and blended.

What comes out? A smooth, even concrete mix that’s ready for blocks, tiles, flooring, or whatever else you’re working on.

How Does It Work? Here’s the process in plain terms:

Load It Toss your materials in—cement, sand, aggregates, water. If you’re using fibers, colors, or chemicals, now’s the time to add them.

Fire It Up You switch on the machine and the paddles start spinning. Some mixers have fixed pans; others rotate the whole pan while the paddles turn inside. Either way, the mix gets pulled, scraped, and folded thoroughly.

Mix Until It’s Right Most batches are done in about 2 to 5 minutes. You’ll know when it’s ready—the mix looks uniform and the consistency is right for your job.

Discharge There’s usually a trap door or chute at the bottom. Open it, and your concrete flows out into a trolley, bucket, or mold.

No dead corners. No unmixed pockets. Just a clean, reliable batch.

Why Builders Like Using Pan Mixers Here’s the thing: not every job needs a concrete truck or a big drum mixer. And when you’re doing work that needs precision—like making fly ash bricks or casting colored concrete—pan mixers are the way to go.

More Control You’re in charge of the batch size and the exact mix. No guessing. No waste.

Better Mix Quality The blades scrape the sides and base of the pan, so nothing gets left out. That means a smoother, more consistent mix—especially important for decorative or structural work.

Smaller Batches, Less Waste You don’t need to mix a ton of concrete if you’re doing a small run of blocks or prepping for a flooring job. Pan mixers let you make exactly what you need.

Easy to Clean Anyone who’s cleaned a drum mixer knows the struggle. Pan mixers are easier to rinse and scrape down between batches, saving time and effort.

Different Types of Pan Mixers Out There Depending on your site and your work, you’ve got a few options:

Stationary Pan Mixers Great for block plants or small factories where the mixer stays in one place. Built for volume and consistency.

Portable Pan Mixers These come with wheels and can be moved around the site. Handy if you need to shift between work zones.

Electric vs. Diesel Electric models are quieter and good for indoor or city-based work.

Diesel models are better suited for rugged, off-grid jobs with no reliable power source.

What Should You Look for in a Pan Mixer? Buying a pan mixer? Here’s what to consider before handing over your money:

Capacity: Small batches or high-volume work? Get the right size for your needs.

Power Source: Will you have electricity where you’re working, or do you need the independence of diesel?

Build Quality: Heavy steel body, good motor, strong paddles—no compromises here.

Discharge System: Bottom discharge is ideal for quick emptying without leaving material behind.

Ease of Maintenance: Fewer moving parts = fewer breakdowns. Check how accessible the pan and paddles are for cleaning.

Manufacturers like Lino Sella and Shuanglong have been around for years, and they’ve got solid reputations in the industry. Go with a name that’s trusted.

Where Do You Actually Use One? You’ll find concrete pan mixers in all kinds of places:

Fly ash brick and solid block production

Paver and tile plants

Plaster and mortar mixing

Precast concrete units

Lab testing for concrete strength

Decorative or colored concrete mixing

Flooring and renovation work

Basically, if you’re doing work where mix quality matters, a pan mixer belongs on-site.

Wrapping It Up: Is It Worth the Investment? If you’re still mixing by hand or using an old drum mixer that leaves half the cement stuck to the walls—yes, it��s absolutely worth it.

The Concrete Pan Mixer Machine is one of those pieces of equipment that just makes sense: easy to use, reliable, and built to handle real job site conditions.

You save time, reduce waste, and get a better-quality product. Whether you're running a small production unit or working on custom construction projects, this machine will quickly become one of your go-to tools.

FAQs – No-Nonsense Answers About Pan Mixers Q1: Is a pan mixer better than a drum mixer? For smaller, precision jobs—yes. It gives you a more consistent mix and is easier to clean.

Q2: Can it be used for mortar or plaster? Definitely. In fact, many people use them specifically for mortar, plaster, and colored mixes.

Q3: How long does a batch take to mix? Usually about 3–5 minutes, depending on the machine and material.

Q4: Are they hard to clean? Nope. Most models are open and easy to rinse or scrape down.

Q5: Will it work for large-scale jobs? If you're doing massive pours all day long, you might want a bigger mixer. But for most small and medium-scale jobs, a pan mixer is ideal.

#arecaleafplatesmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#automaticflyashbrickmakingmachine#interlockingblockmakingmachine#hydraulicshearingmachinemanufacturers#automaticsolidblockmakingmachine#brickandblockmanufacturers#fullyautomaticflyashbrickmakingmachine#concretepanmixermachine

0 notes

Text

The Automatic Solid Block Making Machine is a high-efficiency machine designed to produce dense and durable solid concrete blocks with minimal manual effort. Fully automated, it streamlines the entire block manufacturing process—from raw material mixing and molding to block shaping and curing—ensuring consistent quality and uniform size. Ideal for large-scale construction and industrial projects, this machine enhances productivity while reducing labor costs. Built with robust components and advanced control systems, it delivers strong, eco-friendly solid blocks suitable for foundations, walls, and other structural applications.

#arecaleafplatesmakingmachine#automaticflyashbrickmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#hydraulicshearingmachinemanufacturers#brickandblockmanufacturers#automaticsolidblockmakingmachine#fullyautomaticflyashbrickmakingmachine#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

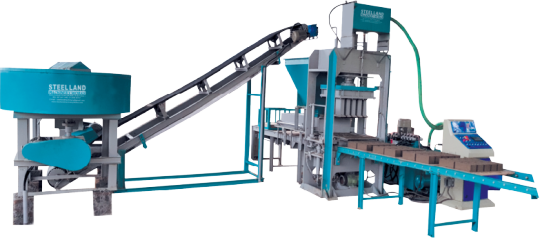

The Automatic Fly Ash Brick Making Machine is a high-performance, fully automated system engineered for the mass production of fly ash bricks with precision and speed. Utilizing advanced hydraulic technology and PLC control systems, it ensures consistent brick quality, high strength, and dimensional accuracy. This machine efficiently combines fly ash, cement, sand, and water to produce eco-friendly and cost-effective bricks, reducing reliance on traditional clay bricks. Ideal for medium to large-scale production units, it minimizes labor requirements and maximizes output, making it a smart investment for modern construction and infrastructure projects.

#arecaleafplatesmakingmachine#automaticflyashbrickmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#brickandblockmanufacturers#concretepanmixermachine#hydraulicshearingmachinemanufacturers#automaticsolidblockmakingmachine#fullyautomaticflyashbrickmakingmachine#interlockingblockmakingmachine

0 notes

Text

The Manual Fly Ash Brick Making Machine is a cost-effective and easy-to-operate solution for producing high-quality fly ash bricks. Designed for small-scale production and startups, this machine allows users to manually compress a mix of fly ash, cement, and aggregates into strong, uniform bricks. Its sturdy construction and simple mechanism ensure durability and low maintenance. Ideal for rural and semi-urban areas, this machine helps reduce construction costs while promoting eco-friendly building practices by utilizing industrial waste materials.

#arecaleafplatesmakingmachine#automaticflyashbrickmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#automaticsolidblockmakingmachine#brickandblockmanufacturers#hydraulicshearingmachinemanufacturers#fullyautomaticflyashbrickmakingmachine#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

The Pan Mixer Machine is a versatile and efficient mixing equipment designed for blending concrete, mortar, and other construction materials uniformly. Featuring a circular pan with rotating blades, it ensures thorough mixing and homogeneity of materials in a short time. Widely used in construction sites, block manufacturing, and precast industries, the pan mixer enhances productivity by delivering consistent mix quality. Known for its durability, easy operation, and low maintenance, this machine is essential for producing high-strength construction materials.

#automaticflyashbrickmakingmachine#automaticpaverblockmakingmachine#automaticinterlockingblockmakingmachine#hydraulicshearingmachinemanufacturers#fullyautomaticflyashbrickmakingmachine#automaticsolidblockmakingmachine#arecaleafplatesmakingmachine#brickandblockmanufacturers#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

The Automatic Fly Ash Brick Making Machine is a high-performance, fully automated system engineered for the mass production of fly ash bricks with precision and speed. Utilizing advanced hydraulic technology and PLC control systems, it ensures consistent brick quality, high strength, and dimensional accuracy. This machine efficiently combines fly ash, cement, sand, and water to produce eco-friendly and cost-effective bricks, reducing reliance on traditional clay bricks. Ideal for medium to large-scale production units, it minimizes labor requirements and maximizes output, making it a smart investment for modern construction and infrastructure projects.

#arecaleafplatesmakingmachine#automaticflyashbrickmakingmachine#automaticinterlockingblockmakingmachine#fullyautomaticflyashbrickmakingmachine#automaticsolidblockmakingmachine#brickandblockmanufacturers#automaticpaverblockmakingmachine#hydraulicshearingmachinemanufacturers#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

What Makes a High-Quality Brick or Concrete Block

Walk past any construction site, and you’ll see bricks and blocks quietly doing their job—forming the backbone of homes, offices, and everything in between. But behind every sturdy wall is a story of precision, consistency, and a whole lot of quality control.

For brick and block manufacturers, ensuring product quality isn't just about meeting a checklist—it's about building trust, structure by structure. So how do they make sure that every single unit lives up to the mark? Let’s dig in.

Why Quality Is More Than Just a Buzzword

When a builder chooses bricks or blocks, they’re not just picking a material—they’re investing in safety, longevity, and peace of mind. Poor-quality bricks can lead to cracks, water damage, or even structural failure down the line. That’s a big deal.

So for manufacturers, quality isn't optional. It’s the foundation of everything they do—literally and figuratively.

It All Starts With the Right Ingredients

Choosing Raw Materials Wisely Just like a good dish starts with good ingredients, quality bricks and blocks begin with top-notch raw materials. For clay bricks, that means clean, plastic clay with the right mineral balance. For concrete blocks, it’s about using high-quality cement, sand, fly ash, and aggregates.

Testing, Testing, Testing

Before these materials even make it into production, manufacturers run several tests:

Moisture content checks (too much water = weak bricks)

Sieve analysis for aggregates (ensures the right size distribution)

Chemical composition of additives (especially fly ash and lime)

All of this helps eliminate surprises later in the process.

Precision in Every Step of Production

Mixing It Just Right

Getting the proportions right is absolutely crucial. Whether it's the cement-to-sand ratio in concrete or the clay-sand mix for traditional bricks, everything has to be consistent. Many manufacturers now rely on automatic batching systems that remove the guesswork entirely.

Molding: Where Form Meets Function After mixing, the material is shaped into bricks or blocks. This could happen through extrusion, hydraulic pressing, or mold casting. The pressure and technique used here impact the final strength and density of the product.

Automatic machines are the norm for most serious manufacturers—they guarantee uniform size, clean edges, and consistent compaction.

Curing: The Secret Ingredient This is where strength is developed. For clay bricks, it means high-temperature kiln firing—up to 1100°C. For concrete blocks, it's usually a 14–28 day curing process with controlled humidity and temperature.

Skipping or rushing this step? That’s a recipe for brittle products.

Quality Checks: Before, During, and After In-Process Monitoring Throughout production, technicians perform ongoing checks. This includes measuring moisture levels, checking machine calibration, and random sampling of the output.

If anything looks off—even slightly—the batch is rechecked or held back. No compromises.

Post-Production Testing Once the bricks or blocks are ready, several tests ensure they’re fit for the real world:

Compressive Strength: Can it handle the load?

Water Absorption: Will it stand up to rain or moisture?

Efflorescence: Any risk of white stains from salts?

Size & Shape Consistency: Uniformity matters in construction

If a unit doesn’t pass, it doesn’t ship. Simple as that.

Technology Is Raising the Bar

Smart Manufacturing Tools

Modern manufacturers are leaning into tech to do things better and faster. Sensors, real-time analytics, and even AI are helping catch inconsistencies early—sometimes before they’re visible to the naked eye.

Some plants use IoT sensors to monitor kiln temperature or curing chamber humidity 24/7. Others use image recognition to flag shape defects in blocks before they leave the conveyor belt.

Full Traceability

Many manufacturers now tag batches with production dates, raw material sources, and machine settings. That means if a problem ever comes up later, they can trace it back in seconds and figure out exactly what went wrong.

Sustainability Meets Quality

Interestingly, many of today’s top-quality bricks and blocks are also eco-friendly. By incorporating materials like fly ash (a by-product of coal power plants), manufacturers not only reduce their carbon footprint but often end up with stronger, more durable blocks.

Recycling cracked or damaged products back into production is also becoming more common. It’s smart, efficient, and good for the planet.

Wrapping It Up: Why It All Matters

Behind every high-quality brick or block is a series of choices, tests, and processes that most people never see. For brick and block manufacturers, it’s not just about production—it’s about responsibility. Responsibility to builders, homeowners, and entire communities.

When you buy from a manufacturer who takes quality seriously, you’re not just getting better materials. You’re getting peace of mind.

FAQ: Common Questions About Brick and Block Quality

What’s the biggest factor that affects brick or block quality? It’s hard to pick just one, but curing is often where quality is made or broken. Without proper curing, even the best materials can underperform.

Do all manufacturers follow the same standards? No. The best ones follow national or international standards like IS, ASTM, or ISO. Always check for certifications—it’s a great sign of consistency.

Can eco-friendly blocks be as strong as regular ones? Absolutely. Fly ash and recycled aggregates can actually improve performance when used correctly.

How can builders spot a high-quality brick or block? Look for uniformity in size, a solid sound when tapped, and no visible cracks. Ask the supplier for test reports—good manufacturers won’t hesitate to share them.

Are handmade bricks still a thing? In some regions, yes. But for most modern construction, machine-made bricks and blocks offer better consistency and performance.

#arecaleafplatesmakingmachine#automaticflyashbrickmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#brickandblockmanufacturers#automaticsolidblockmakingmachine#fullyautomaticflyashbrickmakingmachine#hydraulicshearingmachinemanufacturers#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

Automatic Interlocking Block Making Machine is an advanced, fully-automated system designed for the efficient production of interlocking blocks used in eco-friendly and cost-effective construction. Engineered for high output and precision, this machine automates the processes of feeding, mixing, molding, and pressing, delivering consistent block quality with minimal labor. Ideal for large-scale projects and commercial block manufacturing units, it supports a variety of block designs and sizes. With durable construction, low maintenance, and energy-efficient performance, it's a smart investment for sustainable building solutions.

#automaticflyashbrickmakingmachine#brickandblockmanufacturers#fullyautomaticflyashbrickmakingmachine#automaticpaverblockmakingmachine#hydraulicshearingmachinemanufacturers#interlockingblockmakingmachine#automaticinterlockingblockmakingmachine#arecaleafplatesmakingmachine#automaticsolidblockmakingmachine#concretepanmixermachine

0 notes

Text

A Pan Mixer Machine is a robust mixing device used to blend materials like concrete, mortar, and other construction mixtures. It consists of a circular pan with rotating mixing blades that ensure thorough and uniform mixing. Widely used in construction, paving block manufacturing, and precast industries, the pan mixer is valued for its durability, efficiency, and ability to produce high-quality mixes with minimal labor.

#arecaleafplatesmakingmachine#automaticinterlockingblockmakingmachine#automaticsolidblockmakingmachine#automaticflyashbrickmakingmachine#hydraulicshearingmachinemanufacturers#brickandblockmanufacturers#automaticpaverblockmakingmachine#fullyautomaticflyashbrickmakingmachine#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

Fully Automatic Fly Ash Brick Making Machine is a high-end, industrial-grade machine designed for large-scale production of fly ash bricks. It automates every stage of the process—including material feeding, mixing, molding, and stacking—ensuring maximum efficiency, uniform quality, and minimal human intervention. This machine is ideal for commercial brick manufacturers looking for speed, consistency, and environmentally friendly production using fly ash and other raw materials.

#automaticflyashbrickmakingmachine#automaticsolidblockmakingmachine#brickandblockmanufacturers#automaticpaverblockmakingmachine#automaticinterlockingblockmakingmachine#arecaleafplatesmakingmachine#interlockingblockmakingmachine#fullyautomaticflyashbrickmakingmachine#hydraulicshearingmachinemanufacturers#concretepanmixermachine

0 notes

Text

Automatic Interlocking Block Making Machine is an advanced machine designed to produce interlocking blocks with minimal manual intervention. It automates the processes of mixing, compressing, and shaping raw materials like cement, sand, and soil into uniform, high-strength blocks. These machines increase production efficiency, ensure consistent quality, and are ideal for large-scale construction or commercial block manufacturing.

#arecaleafplatesmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#brickandblockmanufacturers#hydraulicshearingmachinemanufacturers#fullyautomaticflyashbrickmakingmachine#automaticsolidblockmakingmachine#automaticflyashbrickmakingmachine#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

How to Select the Perfect Blocks for Your Building Project

Starting a construction project is exciting — but it can also feel overwhelming, especially when you have to make so many decisions early on. One of the biggest choices? Picking the right blocks. Whether you're building your dream home, a commercial building, or even just a small extension, the blocks you choose will have a huge impact on everything from the structure’s strength to its energy efficiency.

Let’s walk through how to choose the best blocks for your project — the kinds available, what matters most, and why working with reputable brick and block manufacturers makes all the difference.

Different Types of Construction Blocks: What Are Your Options?

First things first: not all blocks are created equal. Understanding the options helps you make a more informed choice.

Concrete Blocks

These are the classic workhorses of construction — made from cement, sand, and aggregates. Concrete blocks are tough, reliable, and widely used for both structural walls and partitions.

What’s great: They’re strong and fire-resistant, plus they can help with insulation if done right. What to keep in mind: They can be heavy and sometimes absorb water if not sealed properly.

Fly Ash Blocks

Fly ash blocks are a bit more eco-friendly, made from a byproduct of coal burning. They're lighter than concrete blocks and offer decent insulation, making them popular in sustainable building.

Perks: Lighter, good for insulation, and help recycle industrial waste. Challenges: You might need to find a specialized supplier, and quality can vary.

Clay Bricks

A timeless choice, clay bricks have been around for centuries. Fired in kilns, they bring not only strength but also a warm, natural look.

Why choose them: They’re durable, weather-resistant, and visually appealing. What to consider: They can be pricier and more labor-intensive to lay than blocks.

AAC (Autoclaved Aerated Concrete) Blocks

AAC blocks are lightweight and airy, made by mixing concrete with foaming agents. They’re easy to cut and great for insulation.

Good for: Reducing building weight and improving energy efficiency. Watch out: They’re less strong than traditional concrete blocks and need proper waterproofing.

What Should You Consider When Picking Blocks?

Choosing the right block isn’t just about picking the first type you see. There are some key factors to think through:

How Strong Do Your Blocks Need to Be?

If you’re building load-bearing walls — basically walls that hold up the building — you’ll need blocks with high strength, like concrete blocks or clay bricks. For non-load-bearing walls (think internal partitions), lighter blocks like AAC might do the job.

Insulation: Keeping Your Space Cozy (or Cool)

Blocks that offer good thermal insulation can make your building more energy-efficient. Fly ash and AAC blocks generally perform better in this department, helping you save on heating and cooling.

Will Your Blocks Stand Up to Moisture?

If your building is in a humid or rainy area, moisture resistance is crucial to avoid problems like mold or crumbling walls. Properly sealed concrete blocks and clay bricks usually handle moisture better.

What Do You Want It to Look Like?

Sometimes, the look of your blocks matters, especially for exposed walls or facades. Clay bricks give a classic, warm appearance, while concrete blocks might need plaster or paint for a finished look.

Budget and Availability

Your budget and what’s readily available locally are practical considerations. Sustainable blocks might cost more upfront but could save money long-term with energy savings. Also, working with nearby brick and block manufacturers can cut delivery times and costs.

Why It Pays to Work with Trusted Brick and Block Manufacturers

Once you’ve narrowed down the type of block you want, sourcing them from reliable manufacturers is key.

Quality You Can Count On

Good manufacturers stick to standards. This means consistent size, strength, and performance — so you’re not left with blocks that crack or crumble.

Customized Options

Sometimes you need specific sizes, colors, or mixes. Reputable manufacturers can tailor their products to your project’s needs.

Steady Supply, No Surprises

Construction schedules can’t afford delays. Trusted suppliers usually have stock ready and deliver on time.

Environmentally Responsible Choices

Many modern brick and block manufacturers focus on sustainability, using recycled materials or greener production processes, which can align with your project goals.

Handy Tips for Choosing and Using Blocks

Here are some practical pointers before you place your order:

Ask for Samples: Seeing and testing blocks before buying helps you avoid surprises.

Get Professional Advice: An architect or engineer can guide you on what blocks suit your structure best.

Think About Your Climate: Different blocks handle weather conditions differently.

Plan Finishes Early: Decide if you want to paint, plaster, or leave blocks exposed, as this influences block choice.

Check Labor Expertise: Some blocks require special handling, so make sure your construction crew knows what they’re doing.

Wrapping Up: Building Strong from the Ground Up

Picking the right blocks might not be the most glamorous part of building, but it’s absolutely foundational. From strength and insulation to looks and budget, your choice will ripple through every stage of construction and beyond.

Take your time, do your homework, and connect with experienced brick and block manufacturers who can support you every step of the way. When you get the blocks right, you’re setting your whole project up to last strong and look great for years to come.

FAQ: Common Questions About Brick and Block Manufacturers and Block Selection

Q1: How do I figure out which blocks are right for my building? A: It depends on your building’s purpose, design, location, and budget. Talking with a structural engineer or architect usually clears things up quickly.

Q2: Can I mix block types in one project? A: Yes, that’s common. For example, using heavy concrete blocks for load-bearing walls and lighter AAC blocks for partitions can work well — just get expert advice.

Q3: Why should I buy from well-known brick and block manufacturers? A: Because quality varies. Established manufacturers provide reliable blocks that meet standards, helping avoid costly problems down the line.

Q4: Are eco-friendly blocks more expensive? A: Often they cost a bit more upfront, but they can reduce energy bills and environmental impact — so they might save you money in the long run.

Q5: What kind of maintenance do block walls need? A: It depends on the type of block and finishing, but generally, sealing and occasional repairs keep block walls in good shape.

#automaticpaverblockmakingmachine#automaticsolidblockmakingmachine#automaticinterlockingblockmakingmachine#brickandblockmanufacturers#fullyautomaticflyashbrickmakingmachine#automaticflyashbrickmakingmachine#concretepanmixermachine#arecaleafplatesmakingmachine#hydraulicshearingmachinemanufacturers#interlockingblockmakingmachine

0 notes

Text

Brick and Block Manufacturers are companies or businesses that produce construction materials such as bricks and concrete blocks. These materials are commonly used in building foundations, walls, and other structural elements. Manufacturers typically use materials like clay, cement, sand, and aggregates, and may offer various sizes, shapes, and finishes to meet different construction needs.

#automaticinterlockingblockmakingmachine#brickandblockmanufacturers#automaticsolidblockmakingmachine#automaticflyashbrickmakingmachine#fullyautomaticflyashbrickmakingmachine#automaticpaverblockmakingmachine#arecaleafplatesmakingmachine#hydraulicshearingmachinemanufacturers#interlockingblockmakingmachine

0 notes