#automation in fmcg industries

Explore tagged Tumblr posts

Text

Automation solutions for FMCG Manufacturing

Automation in FMCG Manufacturing

We offer innovative automation solutions designed to optimize production processes in the FMCG (Fast-Moving Consumer Goods) industry. As consumer demand increases and market competition intensifies, automation has become a key driver in enhancing manufacturing efficiency, reducing costs, and improving product quality. We provide automation systems tailored for a wide range of FMCG sectors, including food and beverages, personal care, household goods, and healthcare products.

Our solutions help manufacturers streamline production lines, improve throughput, reduce waste, and maintain consistent product quality—critical factors in an industry where speed, precision, and flexibility are paramount

Key Automation Solutions for FMCG Manufacturing

1. Automated Production Lines

Our automated production lines are designed to handle the fast-paced environment of FMCG manufacturing, integrating seamlessly with filling, capping, labeling, and packaging machines. We offer automated systems that can handle high volumes, ensuring products are efficiently moved through the production stages, from raw material handling to the final packaged product.

Filling Systems: Automating the filling process ensures accurate and consistent measurement, improving product consistency and reducing waste.

Capping and Sealing: Our automated capping systems provide secure, reliable sealing, reducing contamination risks and ensuring the integrity of your products.

Labeling Systems: Automated labeling systems ensure that all products are correctly labeled with high-speed accuracy, reducing errors and minimizing downtime.

2. Robotics and Material Handling

Robots and automated guided vehicles (AGVs) play an essential role in material handling and assembly within FMCG plants. We design and implement robotic systems that ensure efficient transport, handling, and packaging of goods.

Robotic Palletizing and Depalletizing: Our robots handle the stacking and unstacking of products onto pallets, which can be done at high speeds and with consistent accuracy.

Material Transfer and Sorting: Automated material handling systems move products to different stages of production, improving the speed and efficiency of the supply chain while reducing manual labor.

3. Automated Quality Control and Inspection

In the FMCG industry, product quality and packaging accuracy are critical to maintaining brand reputation. 3DCAD integrates vision inspection systems and automated testing solutions to monitor product quality at every stage of production.

Automated Vision Inspection: Our vision systems check for defects in packaging, labeling, and product condition, ensuring products meet the highest quality standards before leaving the production line.

Inline Testing: Automated testing solutions monitor key product characteristics such as weight, fill levels, temperature, and other parameters to ensure they meet regulatory and brand standards.

4. Packaging and End-of-Line Automation

3DCAD’s automation solutions streamline the packaging process, making it more efficient and accurate. From primary packaging (bottles, cans, pouches) to secondary packaging (cartons, shrink wrapping), our systems improve packaging speed while ensuring that products are correctly sealed and labeled.

Robotic Packaging: Automated systems ensure that products are packaged quickly, securely, and consistently, reducing handling time and the risk of human error.

Case Erecting and Sealing: Automation in case erecting, filling, and sealing ensures that packaging materials are used efficiently, and packaging is done with speed and precision.

5. Real-Time Data and Process Monitoring

Automation helps you gather real-time data on production processes. With smart sensors and monitoring systems, we provide visibility into your operations, enabling you to monitor productivity, track inventory, and identify potential bottlenecks. This data-driven approach improves decision-making and helps with predictive maintenance, reducing unexpected downtime.

Process Monitoring: Our systems track machine performance, production rates, and material usage to ensure the entire line is operating efficiently.

Real-Time Analytics: Data is collected throughout the production process, providing insights that help improve quality, minimize waste, and optimize production flow.

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Note

So, when it comes to investing in stocks there are a few pointers to keep in mind in order to build a decent portfolio.

1-One should make sure to diversify their investment into different industries, for example having a few stock in each sector like banking, energy, FMCG, automobile etc so that you can hedge your risks in this way

2- While making a fundamental analysis of the entire business you should understand the value it is creating and how the business works before going into its numbers.

3- While coming back to numbers one of the factors that I personally check is the percentage of promoter holding (promoter is the person who started the company) and FII( Foreign Institutional Investors). If the promoter holding i.e. their ownership has decreased over the years then it is not a good sign because it might translate into them losing faith in the business, which means chaotic upper management and hence not a very stable business. On the other hand increasing FII ownership over the year shows that big foreign investors have shown interest in the company and they show interest after doing a lot of inside digging which a retail investor i.e the common people can never do. So if they're investing then it's a good sign you should invest too.

4- Next thing you would like to have a stable debt/equity ratio.

5- And you can create SIP i.e Systematic Investment plan which will invest a certain amount into your selected stocks every month/quarter/year whatever you want. Kinda automates and eases the burden of actively investing.

6-Mutual funds are a great option as well because then whatever amount you plan to invest gets invested proportionally by the fund managers into the top 100/50 companies whatever the fund's breakup looks like.

7- One last thing try to divide your investments into shares and bonds, becasue if the stock market is up bonds is down and vice versa. this can protect you from suffering huge losses in future if a crash ever happens.

That was lot but i love sarah's writing too much to miss a blurb opportunity.

For @harryforvogue viewing pleasure

9 notes

·

View notes

Text

Visa-Friendly Trade Shows and Business Events to Attend in 2025

A curated list of major international expos and summits that welcome Indian business travelers

Introduction

In 2025, numerous global trade shows and business summits are intentionally designed with streamlined visa processes to encourage Indian entrepreneurs and professionals to participate. From industry-specific expos to multi-sector summits, these events offer excellent platforms for networking, business partnerships, and market expansion. Below is a comprehensive list of top visa-friendly events that Indian business travelers can plan to attend this year.

1. Hannover Messe (Germany – April 22–26, 2025)

One of the world's leading industrial technology fairs, Hannover Messe showcases automation, robotics, energy, and digital innovations. Germany’s business visa framework is structured to facilitate participation in official trade events, making it an accessible destination for Indian companies seeking manufacturing partnerships and tech collaborations.

2. India Rubber Expo (Italy – May 14–16, 2025)

Held in Milan, this expo focuses on rubber processing, pneumatic systems, and industrial additives. Italy is known for facilitating Schengen business visas for Indian exhibitors and delegates attending recognized fairs. The Expo provides opportunities in machinery sourcing, supplier outreach, and joint development of industrial products.

3. BIO International Convention (USA – June 2–5, 2025)

A premier event in biotechnology and life sciences, this Boston-based convention attracts global biotechs, pharmaceutical firms, and investors. The US offers business visas (B‑1) for participants attending accredited shows, making it a strategic opportunity for Indian biotech startups to showcase innovations, form R&D partnerships, and secure funding.

4. China International Import Expo (China – November 5–10, 2025)

A government-backed initiative in Shanghai designed to welcome foreign businesses. China’s trade show visa process is optimized for participants officially invited by event organizers. Indian FMCG, machinery, and IT services companies can use this platform to penetrate the Chinese market and meet large-scale buyers.

5. Africa Tech Festival (South Africa – October 28–30, 2025)

Hosted in Johannesburg, this festival gathers tech innovators, financiers, and governments to explore digital solutions across the African continent. South Africa issues business visas for attendees of major conferences, offering Indian IT and fintech firms exposure to emerging market opportunities and potential collaborations.

6. Gulf Construction Expo (UAE – September 10–12, 2025)

Situated in Dubai, this expo highlights construction, building materials, and project finance. The UAE offers accessible business visa provisions for official expo delegates. Indian contractors, material suppliers, and engineering consultants can use this platform to secure projects in the rapidly expanding Gulf region.

7. Singapore FinTech Festival (Singapore – November 10–12, 2025)

Recognized as Asia’s leading fintech gathering, this event attracts innovators, regulators, and investors. Singapore’s business entry permit for trade events is straightforward for Indian visitors. Indian fintech startups can engage with global partners, explore sandbox collaborations, and connect with financial institutions.

Planning Tips & Visa Preparation

• Secure an Official Invitation

Most trade events offer formal participation confirmation or invitation letters. This document is crucial for visa applications to demonstrate the purpose of travel.

• Apply Early During Peak Season

Countries like the USA, Germany, and UAE experience visa demand surges around major expos. File 8 to 12 weeks before travel to allow time for interviews and documentation.

• Prepare Business-Focused Documents

Carry a company letter explaining your role and visit intent, along with financial proofs, trade fair registrations, and itinerary details. Highlight the trade event as the purpose of your visit.

• Check COVID‑19 & Health Guidelines

Stay informed on entry regulations, including any vaccination or test requirements. Many events maintain health protocols to ensure safe travel for international attendees.

Conclusion

Visa-friendly trade shows and business events in 2025 provide invaluable pathways for Indian entrepreneurs to expand globally. Whether your focus is technology, biotech, construction, fintech, or industrial manufacturing, these curated events offer structured visa processes that support professional travel and collaboration. Begin planning early by securing invitations and preparing documentation to maximize your international business opportunities this year.

Click Here

1 note

·

View note

Text

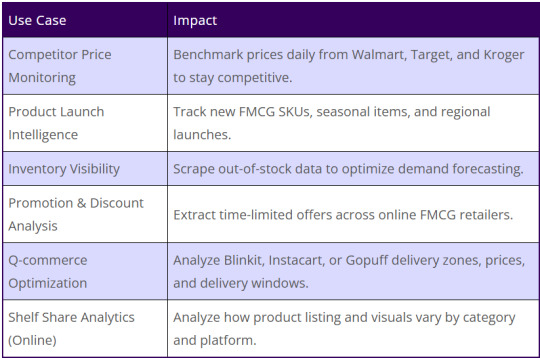

FMCG Data Scraping Services USA - Actowiz Solutions | Retail Insights

Introduction: The Rise of Hyperlocal Intelligence

In the rapidly evolving retail landscape, real-time data is power—especially in the competitive Fast-Moving Consumer Goods (FMCG) sector. From supermarkets and convenience stores to eCommerce platforms and Q-commerce players, businesses rely on dynamic market insights to fine-tune pricing strategies, track competitor moves, monitor inventory, and anticipate consumer preferences.

That’s where FMCG Data Scraping Services come in. For enterprises operating in or targeting the USA FMCG market, partnering with a leader like Actowiz Solutions provides a game-changing edge. With intelligent scraping solutions tailored to the American retail ecosystem, Actowiz helps brands, retailers, and analytics firms extract and act on valuable FMCG data at scale.

What is FMCG Data Scraping?

FMCG data scraping refers to the automated extraction of structured information from websites, mobile apps, online marketplaces, and digital catalogs related to consumer-packaged goods. This includes products like food, beverages, toiletries, cleaning supplies, over-the-counter meds, and more.

Key FMCG data points include:

Product names and SKUs

Brands and manufacturers

Prices and discounts

Package sizes and weight

Availability and stock levels

Consumer reviews and ratings

Shelf placement (for online stores)

Time-sensitive promotions

Why the USA FMCG Market Needs Data Scraping

The USA is one of the largest and most fragmented FMCG markets in the world, with thousands of brands competing across multiple channels—physical retail, D2C platforms, Q-commerce, and marketplaces like Amazon, Walmart, Target, Instacart, and Costco.

Here's why FMCG data scraping is essential for U.S. businesses:

📊 Sample Chart: Daily Price Tracking for Top 5 Beverages (Walmart.com)

Insights:

Frequent mid-week promotions.

Red Bull’s volatility could be linked to promotional campaigns.

Coca-Cola has price stability on weekends.

How Actowiz Solutions Powers FMCG Data Extraction in the USA

Actowiz Solutions is at the forefront of intelligent FMCG data scraping and retail analytics in the United States. Here’s how their services unlock data-driven decisions for brands and retailers:

1. ✅ End-to-End Data Pipeline

Actowiz offers a full pipeline—from web crawling and extraction to cleaning, structuring, and delivering data via API, dashboard, or CSV.

2. 🛍 Platform Coverage

Extract data from major U.S. retailers and platforms:

Retailers: Walmart, Target, Costco, Kroger, CVS, Walgreens

Marketplaces: Amazon, eBay, Instacart, Boxed

Q-commerce: Gopuff, DoorDash, Uber Eats (Grocery)

3. 🔄 Real-Time & Scheduled Crawling

Customizable crawl frequencies (hourly, daily, weekly) help monitor fast-changing prices, stockouts, and discounts.

4. 💡 Intelligent Matching & Product Normalization

Standardizes product naming, packaging sizes, and UPC codes across retailers for precise comparisons.

5. 📦 Category Coverage

Actowiz supports data scraping across categories like:

Beverages

Snacks

Health & Beauty

Home Cleaning

Baby & Personal Care

OTC Healthcare

📈 Infographic: Actowiz FMCG Data Scraping Workflow in the USA

diff

CopyEdit

[Infographic Description]

- Data Source Identification

- Retailer Site Crawling

- Product Data Extraction

- Data Cleaning & Mapping

- Price/Stock Monitoring Setup

- Analytics & Dashboard Delivery

Real-World Use Cases by Industry

🛒 Retailers

Goal: Monitor prices across competitors like Walmart, Target, and Amazon to dynamically adjust pricing strategies.

Actowiz Impact: Retailers saw 12% increase in price-match conversions after implementing scraped competitor price feeds.

🍫 FMCG Brands

Goal: Analyze online shelf visibility, customer reviews, and stock presence across platforms

Actowiz Impact: One major food brand used review sentiment scraped from Amazon and Instacart to improve product formulations.

📦 Supply Chain & Inventory Teams

Goal: Forecast demand by tracking out-of-stock alerts in various regions.

Actowiz Impact: A U.S. distribution company reduced inventory holding costs by 18% using real-time availability data.

📊 Market Research Firms

Goal: Provide accurate retail audits, price benchmarking, and brand share data.

Challenges in FMCG Data Scraping (And How Actowiz Overcomes Them)

Sample Dataset Snapshot (FMCG Beverage Category – Walmart USA)

Benefits of Partnering with Actowiz Solutions

✔ Fast Turnaround

Quick setup and deployment tailored to your SKU and category needs.

✔ Customized Dashboards

Visualize trends in pricing, inventory, reviews, and more with Actowiz’s reporting tools.

✔ Compliance-Focused

Ethical, legally-compliant scraping practices aligned with U.S. data policies.

✔ Scalable Infrastructure

Handles millions of products daily—ideal for nationwide retail tracking.

The Future of FMCG Data Intelligence

As U.S. consumers increasingly shift to online grocery shopping and q-commerce channels, the role of data becomes even more central. FMCG brands that invest in automated market intelligence will lead the pack in innovation, efficiency, and customer satisfaction.

Conclusion

The FMCG sector in the United States is more dynamic and data-driven than ever before. Whether you're a legacy retailer, a startup brand, or a data intelligence company, access to real-time product, pricing, and inventory data is no longer optional—it’s essential.

Actowiz Solutions offers unmatched FMCG data scraping services tailored to the nuances of the U.S. retail environment. With the ability to extract granular, timely, and structured data across major platforms, Actowiz empowers businesses to innovate and scale faster.

Learn More >>

#FMCGDataScrapingServicesInTheUSA#FMCGDataScraping#IntelligentScrapingSolutions#MonitorPricesAcrossCompetitors#ScrapedCompetitorPriceFeeds#ActowizSolutions

0 notes

Text

How the Automated Guided Vehicle Is Driving the Future of Logistics

In the era of automation, one device—the automated guided vehicle, or AGV—is subtly but significantly changing the landscape of manufacturing and warehouse operations. Despite their lack of ostentation, these clever robots are the unsung heroes of effective operations, providing a more intelligent method of moving materials, lowering human error, and streamlining workflows.

What is anautomated guided vehicle, then? Imagine it as an autonomous car that follows predetermined routes in factories, distribution hubs, and warehouses. It's a smart cart with sensors, software, and occasionally lasers to help it safely navigate intricate routes rather than an arm-wielding robot or self-driving automobile. The outcome? Consistent output, fewer accidents, and 24-hour operations.

AGVs are ideal for time-consuming, repetitive jobs like moving products, bins, or pallets from one end of a facility to the other. This is particularly helpful in industries where accuracy and dependability are essential, such as the automotive, food and beverage, FMCG, and pharmaceutical sectors. Additionally, companies can continue operations even during peak hours or night shifts because automated guide vehicles don't require lunch breaks or time off. The versatility of AGVs is what further increases their allure. Routes can be expanded or reprogrammed as activities grow or change without requiring significant alterations or the destruction of floor infrastructure. Additionally, they are scalable, so you can begin with a small fleet and expand it as your company grows. Additionally, cost-effectiveness and safety are crucial in the current competitive environment. By taking over activities involving heavy lifting or the transportation of hazardous materials, AGVs assist reduce workplace injuries and, over time, personnel expenses.

In summary, for any company that is serious about optimizing its warehouse handling equipment, the autonomous guided vehicle is not only a wise investment, but also the next logical step. AGVs are demonstrating that sometimes the best drivers don't have any steering wheels at all, thanks to lean operations and intelligent automation.

0 notes

Text

Expert Shopify Development Services In India – Power Your E-Commerce Success with NRS Infoways

In a rapidly evolving digital marketplace, your online store must do much more than simply “work.” It has to delight, convert, and scale—all while staying secure, lightning-fast, and easy to manage. That’s exactly what you get with Expert Shopify Development Services In India from NRS Infoways. For over a decade, we’ve been the silent engine behind hundreds of thriving Shopify stores, tailoring every pixel and feature to our clients’ unique goals. Whether you’re launching your first product line or migrating a high-volume catalog from another platform, our team transforms vision into revenue-driving reality.

Why Shopify—And Why NRS Infoways?

Shopify offers rock-solid hosting, built-in PCI compliance, and a robust app ecosystem that keeps pace with the latest e-commerce trends. Yet out-of-the-box Shopify rarely meets every nuanced business requirement. That’s where NRS Infoways excels. We combine deep platform expertise with creative problem-solving to craft bespoke storefronts that stand out in crowded niches. From pixel-perfect UX/UI design to advanced back-end customization, our certified Shopify developers ensure seamless integrations with CRMs, ERPs, payment gateways, and third-party logistics providers—so your operations run like clockwork.

Comprehensive Services—From Concept to Continuous Growth

Custom Store Design & Theme Development

We don’t simply tweak pre-made themes; we build immersive, brand-specific experiences that convert casual browsers into loyal customers. Our mobile-first designs load in milliseconds, score high on Core Web Vitals, and foster trust at every click.

App Integration & Custom Functionality

Need subscription billing, product bundling, or headless commerce architecture? Our Expert Shopify Development Services In India include building or integrating custom apps that extend Shopify’s capabilities without compromising speed or security.

Data Migration & Re-Platforming

Migrating from WooCommerce, Magento, or BigCommerce? We manage the entire process—catalog, customer records, order history—ensuring zero data loss, no SEO hit, and minimal downtime.

SEO & Conversion Rate Optimization

A beautiful store means little if no one finds it. Our SEO specialists set up structured data, lightning-fast page loads, and keyword-rich content strategies that rank. Paired with A/B-tested landing pages, watch your conversion rates soar.

Ongoing Maintenance & Growth Marketing

Launch day is just the beginning. We monitor site health, apply security patches, and roll out iterative improvements based on user behavior analytics. Add our growth marketing packages—email automation, social ads, influencer outreach—and you’ve got an end-to-end partner for sustained success.

Proven Process—Transparent, Agile, Results-Focused

At NRS Infoways, we follow a five-step agile methodology:

Discovery & Strategy – Intensive workshops to crystalize goals, audiences, and KPIs.

Design & Prototyping – Interactive wireframes and style guides ensure every stakeholder is aligned.

Development & Integration – Sprint-based coding, rigorous QA, and real-time progress dashboards keep you informed.

Launch & Training – Seamless go-live with staff workshops so your team can manage day-to-day operations confidently.

Optimization & Support – Continuous performance tuning and feature rollouts driven by data insights.

Why Global Brands & Ambitious Start-Ups Trust Us

Certified Shopify Experts: Our developers and designers hold official Shopify Partner and Plus Partner credentials.

Transparent Pricing: Clear milestones, zero hidden fees, and measurable ROI metrics.

Local Advantage: With a base in India, we deliver world-class quality at highly competitive rates, coupled with 24/7 support that matches your time zone.

Cross-Industry Expertise: From fashion and FMCG to B2B wholesale, we’ve mastered niche-specific best practices that shorten your learning curve and accelerate growth.

Ready to Elevate Your Store?

The difference between a good Shopify store and a great one lies in granular details—micro-animations that nudge clicks, one-page checkouts that slash cart abandonment, and analytics loops that inform rapid iteration. NRS Infoways brings those details together under one roof through Expert Shopify Development Services In India that are laser-focused on your bottom line.

Let’s turn your e-commerce aspirations into measurable milestones. Contact NRS Infoways today for a free consultation and discover how our expert team can transform your Shopify storefront into a revenue powerhouse. Empower your business with scalable, conversion-driven, and truly expert Shopify solutions—crafted in India, celebrated worldwide.

0 notes

Text

Image Recognition shelf

In today’s technology-driven world, the shelf image recognition market is gaining significant momentum, transforming various industries. According to Allied Market Research, the global image recognition market was valued at $28.3 billion in 2022 and is projected to reach $126.8 billion by 2032, with a CAGR of 16.5% from 2023 to 2032.

The growing demand for automation is a major driver of this market expansion, as FMCG businesses seek to enhance productivity and efficiency, making automation a core strategic priority. Additionally, advancements in machine learning and computer vision continue to play a crucial role in shaping the industry’s evolution.

Evolution of Shelf Image Recognition

The development of shelf recognition technology began in 2015, following the Gartner Hype Cycle for Computer Vision. Initially, the technology trigger phase sparked high expectations, with many believing image recognition would solve all challenges. By 2017, enthusiasm and investments surged, anticipating flawless solutions.

At the time, recognition accuracy and processing speed were key priorities, expected to optimize operations. However, by 2021, industry challenges led to a trough of disillusionment, prompting adjustments. The focus shifted beyond identification to real-time analytics and finding even more effective methods of technology adoption.

By 2023, shelf image recognition neared the plateau of productivity. It started to not only support field teams but also provide valuable insights, becoming a key data source for a variety of business functions. Even more, with technologies like Augmented Reality, the process of scanning shelves has become as fast as ever before.

Manual Shelf Image Recognition

FMCG companies have been relying on manual image recognition shelf as the primary method for auditing retail shelves for decades. This process involves employees manually examining shelves to verify product placement against planograms, confirm product availability, check assortment, and ensure compliance with merchandising standards.

However, this approach is inherently time-consuming, labor-intensive, and costly. It is also prone to human error, subjective assessments, and incomplete analysis, making it difficult to maintain high-quality retail audit data. By adding subjective factors, FMCG businesses no longer rely on rationality and numbers, which could significantly impact the business.

0 notes

Text

Empowering Field Operations with Field Workforce Management Software by FieldEZ Technologies

In today’s fast-paced, customer-driven market, efficient field operations are vital to business success. Whether it’s delivering services, managing a remote sales team, or ensuring smooth retail operations, having complete visibility and control over your workforce can significantly boost productivity and customer satisfaction. This is where FieldEZ Technologies steps in with its innovative field workforce management software solutions.

What is Field Workforce Management Software?

Field workforce management software is designed to streamline and optimize operations involving remote or on-field employees. It helps businesses manage their workforce effectively by enabling real-time tracking, task allocation, route optimization, attendance monitoring, and performance analytics. With automation and data-driven decision-making, businesses can reduce manual errors, cut operational costs, and deliver better service outcomes.

Why Choose FieldEZ Technologies?

FieldEZ Technologies stands out in the domain of workforce management software by offering a suite of powerful products tailored for various industries. Their solutions are built to enhance the efficiency of field teams and improve organizational agility. With a proven track record across service, sales, and retail domains, FieldEZ delivers measurable results in workforce productivity and customer engagement.

Key Products by FieldEZ:

1. ServiceEZ — ServiceEZ is a comprehensive field service management software designed to simplify service delivery. It automates service scheduling, dispatch, customer feedback, and invoicing. With ServiceEZ, companies can achieve faster response times, real-time status updates, and greater visibility into service operations, ultimately enhancing customer experience.

2. SalesEZ — SalesEZ empowers sales teams with tools that streamline lead management, customer visits, order capturing, and sales reporting. This workforce management software enables businesses to track sales rep performance, optimize customer interactions, and drive revenue growth by equipping field sales staff with the right information at the right time.

3. RetailEZ — RetailEZ is tailored for managing field operations in the retail sector. It supports tasks such as merchandising, audits, stock checks, and promotional activities. With its mobile-first interface, RetailEZ improves execution accuracy and ensures compliance with retail processes while giving supervisors real-time insights into field activities.

Benefits of Using FieldEZ’s Field Workforce Management Software:

Real-Time Monitoring: Keep track of your workforce across multiple locations with GPS-based tracking and instant updates.

Efficient Scheduling: Automatically assign jobs to the right personnel based on availability, location, and skill sets.

Mobile Accessibility: FieldEZ’s applications are mobile-ready, allowing field agents to update task status, collect customer feedback, and access vital data on the go.

Advanced Analytics: Get actionable insights through customized reports and dashboards to make smarter, data-backed decisions.

Scalability and Customization: Whether you’re a small business or a large enterprise, FieldEZ’s solutions are designed to scale and adapt to your specific operational needs.

Industries Benefiting from FieldEZ:

FieldEZ’s field workforce management software caters to a wide range of industries including telecom, BFSI, healthcare, home services, and FMCG. Companies across these sectors rely on FieldEZ to manage their field personnel, enhance service efficiency, and reduce administrative overhead.

Final Thoughts:

In an era where customer satisfaction and operational efficiency go hand in hand, investing in reliable field service management software is no longer optional — it’s essential. FieldEZ Technologies, with its suite of products like ServiceEZ, SalesEZ, and RetailEZ, provides businesses with the tools they need to drive transformation in field operations.

By choosing FieldEZ, organizations gain more than just software — they gain a partner committed to operational excellence and innovation in workforce management.

#fieldez#field service#services#apps#management software#field management#field service software#field force management#field workforce management#workflow automation

0 notes

Text

Automation solutions for FMCG Manufacturing

1. Automated Production Lines

Our automated production lines are designed to handle the fast-paced environment of FMCG manufacturing, integrating seamlessly with filling, capping, labeling, and packaging machines. We offer automated systems that can handle high volumes, ensuring products are efficiently moved through the production stages, from raw material handling to the final packaged product.

Filling Systems: Automating the filling process ensures accurate and consistent measurement, improving product consistency and reducing waste.

Capping and Sealing: Our automated capping systems provide secure, reliable sealing, reducing contamination risks and ensuring the integrity of your products.

Labeling Systems: Automated labeling systems ensure that all products are correctly labeled with high-speed accuracy, reducing errors and minimizing downtime.

2. Robotics and Material Handling

Robots and automated guided vehicles (AGVs) play an essential role in material handling and assembly within FMCG plants. We design and implement robotic systems that ensure efficient transport, handling, and packaging of goods.

Robotic Palletizing and Depalletizing: Our robots handle the stacking and unstacking of products onto pallets, which can be done at high speeds and with consistent accuracy.

Material Transfer and Sorting: Automated material handling systems move products to different stages of production, improving the speed and efficiency of the supply chain while reducing manual labor.

3. Automated Quality Control and Inspection

In the FMCG industry, product quality and packaging accuracy are critical to maintaining brand reputation. 3DCAD integrates vision inspection systems and automated testing solutions to monitor product quality at every stage of production.

Automated Vision Inspection: Our vision systems check for defects in packaging, labeling, and product condition, ensuring products meet the highest quality standards before leaving the production line.

Inline Testing: Automated testing solutions monitor key product characteristics such as weight, fill levels, temperature, and other parameters to ensure they meet regulatory and brand standards.

4. Packaging and End-of-Line Automation

3DCAD’s automation solutions streamline the packaging process, making it more efficient and accurate. From primary packaging (bottles, cans, pouches) to secondary packaging (cartons, shrink wrapping), our systems improve packaging speed while ensuring that products are correctly sealed and labeled.

Robotic Packaging: Automated systems ensure that products are packaged quickly, securely, and consistently, reducing handling time and the risk of human error.

Case Erecting and Sealing: Automation in case erecting, filling, and sealing ensures that packaging materials are used efficiently, and packaging is done with speed and precision.

5. Real-Time Data and Process Monitoring

Automation helps you gather real-time data on production processes. With smart sensors and monitoring systems, we provide visibility into your operations, enabling you to monitor productivity, track inventory, and identify potential bottlenecks. This data-driven approach improves decision-making and helps with predictive maintenance, reducing unexpected downtime.

Process Monitoring: Our systems track machine performance, production rates, and material usage to ensure the entire line is operating efficiently.

Real-Time Analytics: Data is collected throughout the production process, providing insights that help improve quality, minimize waste, and optimize production flow.

#automation solutions for fmcg manufacturing#fmcg manufacturing industries#fmcg industry#fmcgproducts#3dcad india#3dcad#general industries#general industry

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Choosing the Right Pallet Conveyor Manufacturer: Key Factors to Consider

In the world of material handling and logistics, pallet conveyors play a critical role in streamlining operations, improving safety, and boosting efficiency. Whether you're managing a warehouse, distribution center, or manufacturing facility, choosing the right pallet conveyor manufacturer can significantly impact your productivity and ROI.

Here’s what you need to know when selecting a reliable manufacturer for pallet conveyor systems.

Why Pallet Conveyors Matter

Pallet conveyors are designed to transport heavy loads—typically pallets of goods—smoothly across production lines or storage areas. They are widely used in industries like:

Warehousing and logistics

Food and beverage

Pharmaceuticals

Automotive

FMCG and more

By automating material movement, these systems reduce manual handling, enhance safety, and ensure consistent workflow.

What to Look for in a Pallet Conveyor Manufacturer

1. Industry Experience and Expertise

Choose a manufacturer with a strong track record in designing and installing pallet conveyor systems. Years of experience often translate to better product knowledge, problem-solving capabilities, and tailored solutions.

2. Customization Capabilities

No two facilities are the same. A good manufacturer will offer custom conveyor solutions that fit your unique space, load requirements, and workflow.

Ask about:

System layout design

Weight/load capacity

Automation and integration options

Conveyor length and material type

3. Quality of Materials and Engineering

Durability is key. Ensure the manufacturer uses high-grade steel, rollers, motors, and controls that comply with international standards. The build quality will determine the longevity and maintenance needs of your conveyor system.

4. After-Sales Support & Maintenance Services

A good conveyor system is only as good as the support that comes with it. Check if the manufacturer offers:

Installation support

Staff training

Regular maintenance plans

Spare parts availability

Emergency response time

5. Technology Integration

Modern pallet conveyors often come with smart features like:

IoT-enabled tracking

Automated sensors

Integration with warehouse management systems (WMS)

Partner with a manufacturer who stays ahead of the tech curve.

Benefits of Working with a Trusted Manufacturer

Improved workflow efficiency

Reduced downtime and labor costs

Enhanced workplace safety

Scalable systems for future growth

Compliance with industry regulations

Final Thoughts

Investing in a pallet conveyor is a long-term decision. Take the time to research and compare different manufacturers. Look for one that not only delivers high-quality products but also becomes a strategic partner in your material handling journey.

Are you searching for a reliable pallet conveyor manufacturer in the UK or globally? Choose a company that combines engineering excellence with customer-focused service.

0 notes

Text

How to Pick a Cataloguing Service in India

In the highly competitive world of online retail, the presentation of your products is key to attracting and converting customers. That’s where cataloguing services come into play. But with so many providers in the market, how do you choose the right one? In this blog, we’ll walk you through how to pick the right Cataloguing Service Provider in India to elevate your brand presence online.

1. Start With Your Business Needs

Before evaluating cataloguing companies, be clear on what you need:

Are you selling on multiple platforms (Amazon, Flipkart, Shopify)?

Do you have bulk SKUs that need regular updating?

Do you require image editing along with copywriting?

Is your target audience local, national, or global?

Answering these questions helps narrow down cataloguing providers who specialize in your product type, marketplace, and scale.

2. Check for Industry-Specific Experience

Every product category has unique cataloguing requirements. For example:

Apparel needs sizing charts, fabric descriptions, model fit info.

Electronics require specifications, tech compatibility, warranty details.

FMCG may need batch info, expiry, nutritional details.

An experienced Cataloguing Service Provider in India will be familiar with these nuances and ensure your product listings are not just complete but also buyer-friendly.

3. Evaluate Their SEO Expertise

A major benefit of cataloguing is increasing product visibility. A good provider will:

Use the right keywords in titles and descriptions

Write SEO-optimized content without stuffing

Improve your chances of ranking higher on marketplaces and Google search

Ask to see examples of past listings they've worked on and how they contributed to traffic or sales growth.

4. Check Platform Compatibility

Every e-commerce platform has its own listing format. Your cataloguing service should be:

Familiar with seller centers and APIs of Amazon, Flipkart, Myntra, Meesho, and others

Able to upload listings directly or share them in approved formats (CSV, XLS)

Capable of customizing descriptions and metadata per platform without duplication

This ensures smooth uploads and reduces the chance of listing errors or rejections.

5. Assess Content Quality

Effective cataloguing isn't just technical—it’s creative too. The service provider must:

Write clear, engaging, error-free product descriptions

Include bullet points for easy readability

Use consistent tone and brand language

Avoid plagiarism or copied content

Ask for samples across various categories to judge their writing quality and attention to detail.

6. Ensure Strong Image Handling

Images are often the first thing customers see. Your provider should:

Offer high-resolution editing and formatting

Be able to remove or replace backgrounds

Follow specific platform image guidelines (size, margin, file format)

Compress images for fast loading without losing quality

Visual consistency across listings builds brand trust and enhances user experience.

7. Ask About Turnaround Time and Scalability

Time is money in e-commerce. Your cataloguing partner must deliver:

Fast turnaround on bulk uploads or seasonal collections

Clear timelines for each project

Flexibility to ramp up during peak periods or festive sales

Reliable communication to avoid delays

Choose a provider with proven systems and workflows in place to handle scaling.

8. Review Their Quality Control Process

Poor cataloguing can lead to:

Listing rejections

Wrong orders

Poor reviews

Brand reputation loss

A professional Cataloguing Service Provider in India will have strict quality checks—like peer reviews, automated checks, and client approvals—before final uploads.

9. Evaluate Pricing Transparency

Pricing can vary depending on:

Product category

Number of SKUs

Services required (content, images, uploads)

Look for providers with clear pricing models. Avoid those with hidden charges, vague quotes, or inconsistent billing. Some may offer per-SKU, per-hour, or package pricing.

Don’t just choose the cheapest—focus on value.

10. Look for Client Testimonials and Case Studies

Nothing speaks louder than real-world results. Before finalizing:

Ask for references or client success stories

Check reviews on Google, LinkedIn, or marketplace forums

Request a small trial project to judge their performance firsthand

This gives you insight into their reliability, communication, and real impact on business growth.

Final Thoughts

Choosing the right Cataloguing Service Provider in India is a long-term investment in your e-commerce success. Look beyond just data entry—evaluate content quality, SEO strength, technical capabilities, and customer support.

A professional and experienced team like MagicWords can help transform your product listings into high-converting, SEO-friendly digital assets—saving you time and boosting your sales.

Ready to enhance your product catalog? Let MagicWords handle it with precision, creativity, and performance.

0 notes

Text

In the fast-moving consumer goods (FMCG) industry, managing expiry dates, tracking batches, and maintaining regulatory compliance are mission-critical for ensuring product safety and building consumer trust. LOGIC ERP FMCG software offers real-time visibility, automation, and control to help businesses track perishable inventory, streamline recall processes, and stay compliant with government standards.

#fmcg software#fmcg erp software#fmcg retail software#fmcg distribution software#fmcg software solutions

0 notes

Text

How Palletizer Machines Are Transforming Modern Manufacturing

Speed, accuracy, and efficiency are not merely desirable qualities in the dynamic fields of manufacturing and logistics; they are necessary. One unsung hero stands tall (literally) when it comes to simplifying the end-of-line process: the palletizer machine.

The last packing step frequently entails stacking boxes or bags onto pallets, regardless of whether you're making consumer items, packaged meals, beverages, or medications. Doing this by hand? It takes a lot of time, is physically demanding, and is prone to human mistake. The palletizing machine is a technological marvel that has revolutionized the industry by automating a labor-intensive manual process.

What is a Palletizer Machine?

Fundamentally, a palletizer machine is a device that automatically arranges goods on pallets in a predetermined pattern for secure and effective storage or transportation. However, that's only the tip of the iceberg. Palletizers of today are intelligent, nimble, and incredibly configurable. There is a palletizing machine that can perform the task with robotic accuracy, whether it is for shrink-wrapped cartons, cases of soda, or bags of cement.

Palletizers come in a variety of forms, including hybrid, robotic, and conventional models. While robotic palletizers employ articulated robot arms with grippers or suction pads to pick and put things, conventional palletizer uses mechanical arms and conveyors to align products. Hybrid systems offer speed and versatility in one convenient package, combining the best features of both systems.

Why a Palletizer matter more than ever

Manufacturers are under pressure to transport items more quickly and precisely as supply chains get more complicated and demand increases. Palletizers are ideal in this situation. These machines eliminate heavy lifting-related workplace injuries and labor expenses by taking over repetitive stacking operations.

They also make the packaging process more consistent. A palletizing machine never gets bored, fatigued, or distracted. It consistently positions every item just where it should be. This translates into greater utilization of storage space, fewer damaged goods, and more effective warehouse operations.

The Rise of Smart Palletizing

The palletizers of today are not only robust, but also intelligent. These days, a lot of systems have sensors, vision systems, and AI-powered software that enables them to instantly adjust to various product sizes, shapes, and configurations. Because of this, they are quite helpful in businesses whose product lines are constantly changing.

Real-time performance, uptime, and output data can be obtained by integrating smart palletizing machines with enterprise resource planning (ERP) platforms and warehouse management systems (WMS). Better decision-making and more effective resource planning are made possible by this digital connectivity.

Flexibility for Every Industry

The adaptability of contemporary palletizers is one of their main advantages. There is a solution for almost every industry, ranging from high-speed systems for mass production lines to small robotic units made for confined places.

Food and Beverage: In bottling and packaging facilities where efficiency and hygienic conditions are crucial, palletizer machines are an essential component.

Pharmaceuticals: Palletizer is essential for securely stacking delicate medical goods because of the requirement for accuracy and traceability.

FMCG and Retail: Palletizers make it easier to handle the range of shapes and sizes that are frequently used in retail-ready packaging.

Chemicals and Agro-products: Sturdy, dust-resistant palletizing systems are advantageous for bagged items such as fertilizers or powders.

A Green Advantage Too

You might be surprised to learn that palletizing devices can also help achieve sustainability objectives. They contribute to minimizing packaging waste and increasing transportation efficiency by guaranteeing optimal stacking patterns. More goods on a pallet means fewer shipping, which means less fuel and carbon emissions.

Some devices are even made with energy efficiency in mind, reducing the amount of electricity they use by utilizing servo motors and regenerative drives.e.

Choosing the Right Palletizer Machine

Here are some things to think about if you're thinking about purchasing a palletizing equipment for your company:

Type of Product and Packaging: Are you stacking trays, drums, cartons, or bags?

Speed Requirements: How many units must be palletized every minute, hour, or day?

Space Available: Do you require a small robotic device or do you have space for a huge mechanical system?

Budget & ROI: Although initial expenditures may be substantial, they are justified over time by labor savings and less damage.

Integration Capabilities: Is it possible to connect the machine to your current control systems and conveyor lines?

The Future Is Automated

The palletizer will continue to be a vital component of contemporary logistics as automation boosts productivity across many industries. In addition to increasing accuracy and efficiency, these devices empower human workers by relieving them of physically taxing and repetitive jobs.

Palletizer machines are undoubtedly a need for businesses hoping to maintain their competitiveness in the fast-paced world of today, rather than only a choice.

Your packaging line cannot afford to fall behind in a world that is changing at an accelerating rate. You get speed, accuracy, and peace of mind when you have a palletizer machine. Therefore, whether you're opening a new facility or renovating an old one, think about boosting your operations by stacking smarter, not harder.

0 notes