#automotive masking tape

Text

Unveiling the Hidden Hero: The Advantages of Automotive Masking Tape

In the realm of automotive maintenance and repair, precision is paramount. From painting to detailing, every task demands meticulous attention to detail to achieve flawless results. Amidst the array of tools and supplies, one unsung hero stands out – Automotive Masking Tape. This seemingly simple product plays a crucial role in ensuring precision and perfection in various automotive applications. Let's delve into its benefits and why it's a staple in every automotive enthusiast's toolkit.

Precision Protection:

One of the primary purposes of automotive masking tape is to protect surfaces during painting or detailing. Its adhesive properties allow it to adhere firmly to surfaces without leaving behind any residue or damaging the underlying paint or finish. Whether it's masking off intricate designs or delicate trim pieces, automotive masking tape provides a clean and precise barrier, preventing overspray and ensuring crisp lines.

Versatile Application:

The versatility of automotive masking tape knows no bounds. It serves as a versatile tool in various automotive applications, from painting to detailing. Whether you're painting a vehicle's exterior, touching up minor imperfections, or detailing the interior, automotive masking tape is indispensable. Its ability to conform to different shapes and contours makes it suitable for masking off curves, edges, and irregular surfaces with ease.

Time and Effort Savings:

In the automotive industry, time is money. Automotive masking tape helps streamline workflows and expedite tasks by ensuring efficiency and accuracy. By providing a precise masking solution, it eliminates the need for time-consuming touch-ups and rework, saving valuable time and effort. Whether you're a professional auto body technician or a DIY enthusiast, automotive masking tape accelerates the process, allowing you to achieve professional results in less time.

Quality Finishes:

The key to a flawless automotive finish lies in the details. Automotive masking tape plays a crucial role in achieving impeccable results by ensuring clean and sharp lines. Whether you're painting stripes, graphics, or intricate designs, precise masking is essential for a professional-quality finish. Automotive masking tape provides the precision needed to achieve seamless transitions and crisp edges, elevating the aesthetics of any automotive project.

Residue-Free Removal:

After completing a painting or detailing job, the last thing you want is to deal with stubborn adhesive residue. Automotive masking tape offers hassle-free removal, leaving behind a clean surface without any residue or damage. Its advanced adhesive technology ensures easy removal, saving you time and effort while preserving the integrity of the underlying surface.

In the world of automotive maintenance and repair, precision is paramount, and automotive masking tape is the unsung hero that ensures perfection. From safeguarding surfaces to streamlining workflows, its benefits are undeniable. With its versatility, efficiency, and ability to deliver flawless results, automotive masking tape has rightfully earned its place as a staple in every automotive enthusiast's toolkit.

0 notes

Text

Save Time – Automotive masking solution, Tube Tape saves 20, even 30 minutes per car.

Tube Tape is a new, time-saving automotive masking tape that can help you save time and money on your next painting project. This unique tape is made from a flexible foam core that can be shaped to fit any gap or opening. This makes it perfect for masking off areas that are difficult to reach with traditional masking tape.

Here are just a few of the ways that Tube Tape can save you time:

Pops right in (or on): Tube Tape is pre-shaped and ready to use. No need to cut or shape the tape to fit.

Flexes to fit all shape gaps without adjustment – even sharp corners: Tube Tape's flexible foam core makes it easy to get a perfect fit around any curve or corner.

Goes on in just one step: No need to "wet down" the glue. Tube Tape is pressure-sensitive and will stick to any surface.

Sticks until you remove it: Tube Tape is made from a high-quality adhesive that will hold up to the toughest conditions.

No special removal technique required: Tube Tape comes off easily and without leaving any residue behind.

Sticks to all surfaces – metal, glass, rubber, plastic, EPDM rubber moldings: Tube Tape can be used on a variety of surfaces, including metal, glass, rubber, plastic, and EPDM rubber moldings.

Repositions in seconds; no need to start over: Tube Tape can be repositioned as needed without leaving any residue behind. This means that you can make adjustments without having to start over.

Fits any size gap: Tube Tape comes in two sizes, and doubles up for wide gaps, foam core slides out for narrow ones. This means that Tube Tape can be used to mask off any size gap.

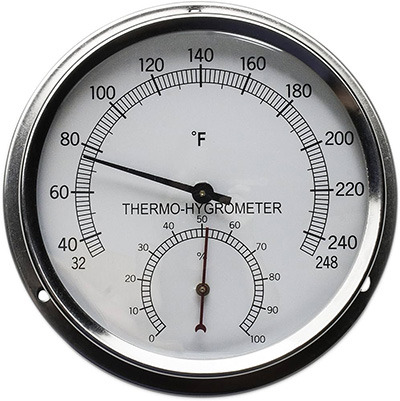

No rubbery, baked-on oven residue to scrape away – heat-resistant up to 250º for up to 30 minutes: Tube Tape is heat-resistant up to 250º for up to 30 minutes. This means that you can use Tube Tape in the oven without worrying about it leaving any residue behind.

Comes off as easily as it goes on: Tube Tape comes off easily and without leaving any residue behind.

No adhesive residue to clean off: Tube Tape is made from a high-quality adhesive that will not leave any residue behind. This means that you can clean up quickly and easily.

Round shape naturally feathers edges, so you can touch up missed spots without having to repaint whole panels: Tube Tape's round shape helps to feather the edges of the paint, so you can touch up missed spots without having to repaint whole panels.

No release paper to wrestle with: Tube Tape comes with a release paper that is easy to remove. This means that you can get started quickly and easily.

Conclusion

Tube Tape is a revolutionary new automotive masking tape that can help you save time and money on your next painting project. This unique tape is easy to use, sticks to any surface, and comes off easily without leaving any residue behind.

For more info:

Please visit the Tube Tape website: https://www.tubetape.works/what-it-is

0 notes

Link

Automotive tapes are an essential part of the automotive industry as they serve multiple purposes in car repair, customization, and maintenance. They are used for attaching exterior trim parts, holding wires and hoses in place, and masking off areas during paint jobs. The need for automotive tapes arises due to their ability to withstand harsh automotive environments such as exposure to extreme temperatures, water, and UV rays. They also provide a strong and reliable bond that can last for a long time and can be easily removed without damaging the surface. From bonding parts together to covering surfaces and protecting paint, tapes play a vital role in keeping vehicles in top condition.

0 notes

Text

Automotive refinish masking tape is typically equipped with a strong adhesive that provides secure adhesion to various surfaces, including metal, plastic, glass, and rubber. The adhesive ensures that the tape sticks firmly in place during painting, preventing paint bleed-through and ensuring clean lines.

The tape’s crepe paper backing is flexible and conformable, allowing it to follow the contours and curves of a vehicle’s body without lifting or wrinkling. This flexibility ensures that the tape can be applied smoothly and tightly around edges and curves, resulting in precise masking lines.

No.414 is UV resistant, which means they can withstand prolonged exposure to sunlight without deteriorating or losing their adhesive properties. UV resistance is particularly important when the vehicle needs to be parked outside or exposed to sunlight during the drying or curing process.

1 note

·

View note

Text

Automotive Tapes Market Growing Popularity and Emerging Trends in the Industry

Latest released the research study on Global Automotive Tapes Market, offers a detailed overview of the factors influencing the global business scope. Automotive Tapes Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Automotive Tapes The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Tesa SE,3M Company,Arkema S.A.,Nitto Denko Corporation,Avery Dennison Corporation,Sika AG,Saint-Gobain,LINTEC Corporation,Scapa,Henkel AG,Others}

Free Sample Report + All Related Graphs & Charts @: https://marketresearchforecast.com/report/automotive-tapes-market-1644/enquiry-before-buy

The Automotive Tapes Marketsize was valued at USD 5.17 Million Square Meters in 2023 and is projected to reach USD 7.32 Million Square Meters by 2032, exhibiting a CAGR of 5.1 % during the forecast period.

The Global Automotive Tapes Market segments and Market Data Break Down are illuminated below:

Type: Specialty, Double-sided, Masking, Others,Function: Bonding, Masking, Noise, vibration, and harshness {NVH}, Others,Application: Interior, Exterior, Wire Harnessing, Others}

Data Sources & Methodology

The primary sources involves the industry experts from the Global Automotive Tapes Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects.

In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age.

Enquire for customization in Report @: https://marketresearchforecast.com/report/automotive-tapes-market-1644/checkout?type=corporate

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact US:

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

0 notes

Text

Unleash the power of precision and protection with our high-quality masking tape, specially designed for all your automotive needs.

Call 9822619307 OR Get it here- https://www.pioneertapes.com/contact-us

#MaskingTape#Automotive#easy#tears#silverresistant#resistant#Adhesives#adhesivetape#AdhesiveInnovation#easily#automotiverepair#PrecisionAndProtection#ProfessionalTools#Package#cardboardcrafts#PackingPerfection#PackagingInnovation#PioneerTapes

0 notes

Text

Glass Cloth Tape is the Best Heat Resistant Adhesive Tape!

A tape plays a crucial role in everyday’s life and in various applications it is used. The tapes are known for their durability and strength. Tapes come in a variety of range that is tailored to meet specific tasks. Some varieties such as electrical tape, masking tape, foam tape and cloth tape, each serves distinct purposes. Some tapes are water resistant which make them a suitable tool for outdoor use and the adhesive grips firmly serves to most surfaces. The adhesive can hold firmly to surfaces and making it a popular choice among different sectors. Electrical tapes, the stretchy nature allows for snug wrapping around wires and safeguarding the wire against shocks and shorts.

Glass Cloth Tape

It’s a very good heat resistant tape

Glass cloth tape is durable and is the best heat resistant adhesive tape that is used in widespread of industries such as electrical and automotive sector. Due to the exceptional strength, resistance to heat and flexibility these tapes are reliable solution for a wide range of applications. The flexibility of it makes it suitable for sealing and wrapping applications where a tight, conformable seal is required. This tape can be easily torn by hand and conforms well to irregular surfaces, allowing for quick and hassle free application. Beyond its strength and heat resistance, the tape also provides a good chemical resistance.

Known for its durability

Poron foam tape is renowned for its exceptional cushioning, durability and sealing properties. Whether protecting medical equipment, providing best cushioning for electronic devices or even sealing automotive components the tapes offers reliable performance. These tapes can be easily die cut, laminated, or fabricated to meet specific requirements. The pressure sensitive adhesive backing ensures that a secure bond for various substrates. It remains reliable and stable even when exposed to extreme temperatures, where as other materials fails. Poron foam tapes offer impressive durability and longevity.

#Glass Cloth Tape#Poron foam tape#Pvc Foam Tape Single Sided#PTFE Teflon Adhesive Tape#Double Sided Acrylic Adhesive Tape

0 notes

Text

Essential Automotive Body Shop Supplies

1. Body Fillers and Putty

Body fillers, also known as Bondo, are used to fill in dents, scratches, and other imperfections on a vehicle's surface. These fillers are typically two-part compounds that harden to create a smooth, paintable surface. Putty is used for finer applications and minor imperfections. automotive body shop supplies

2. Primers

Primers are essential for preparing surfaces before painting. They provide a good bonding surface for paint, prevent rust, and help create a smooth finish. There are various types of primers, including epoxy primers, urethane primers, and etching primers, each suited for different applications.

3. Paint and Clear Coats

Automotive paints and clear coats are crucial for restoring the vehicle's exterior. These include:

Base Coats: The color layer applied to the vehicle.

Clear Coats: A protective, transparent layer that gives the paint a glossy finish and protects against UV rays and environmental damage.

4. Sanding and Abrasive Materials

Sanding materials are used to smooth surfaces before painting and to shape body filler. These materials range from coarse to fine grits, including sandpaper, sanding discs, and sanding blocks.

5. Adhesives and Sealants

High-quality adhesives and sealants are used for bonding various materials and sealing joints to prevent water and air leaks. These include urethane adhesives for windshields, panel bonding adhesives, and seam sealers.

6. Masking Supplies

Masking supplies protect areas that should not be painted. They include masking tape, masking paper, plastic sheeting, and specialized masking films. Proper masking ensures clean paint lines and prevents overspray.

7. Cleaning and Degreasing Agents

Before any repair or painting work, surfaces must be thoroughly cleaned and degreased. Cleaning agents and degreasers remove contaminants like grease, oil, wax, and road grime, ensuring proper adhesion of fillers and paints.

8. Protective Equipment

Personal protective equipment (PPE) is essential for the safety of body shop technicians. This includes:

Respirators and Masks: To protect against fumes, dust, and airborne particles.

Gloves: To protect hands from chemicals and sharp objects.

Eye Protection: Safety glasses and face shields to protect against debris and chemical splashes.

9. Welding Supplies

Welding is a critical part of many body repairs, requiring various supplies such as welding wire, electrodes, and shielding gases. These supplies are necessary for joining metal panels and ensuring structural integrity.

10. Detailing Supplies

Detailing supplies help achieve a flawless finish and include polishing compounds, waxes, microfiber cloths, and buffers. These are used to remove minor imperfections, polish painted surfaces, and protect the vehicle's finish.

11. Body Panels and Replacement Parts

Body shops often need replacement parts such as fenders, bumpers, hoods, and doors. These parts must match the original specifications of the vehicle to ensure a proper fit and finish.

The Importance of Quality Supplies

Using high-quality supplies is crucial for several reasons:

Durability: Quality supplies ensure that repairs are long-lasting and can withstand environmental stress.

Finish: High-grade paints, primers, and detailing products contribute to a professional and aesthetically pleasing finish.

Safety: Proper adhesives, sealants, and welding supplies ensure the structural integrity and safety of the vehicle.

Efficiency: Good supplies make the repair process smoother and faster, increasing productivity and reducing downtime.

Conclusion

Automotive body shop supplies are fundamental to the repair and restoration process. From fillers and primers to paints and protective equipment, each supply plays a vital role in achieving high-quality, durable, and safe repairs. Investing in the best supplies not only enhances the quality of the work but also ensures customer satisfaction and safety.

article on car body repair tools

0 notes

Text

There are several different types of SLAA crepe paper tape available, each with its own unique characteristics and recommended uses.

Here are some of the common types:

General Purpose Masking Tape, for Marking and Labeling, house hold repair.

UV-Resistant Masking Tape, for exterior painting projects.

Multi-Surface Painter's Tape, for walls, windows, ceiling.

High-temperature Masking Tape, automotive masking tape for curves.

High-Adhesion Painter's Tape, for stucco, for concrete, for brick, rough surfaces.

0 notes

Text

What are the classifications and uses of adhesive tape?

Adhesive Tape comes in a variety of types, each designed for specific applications. Here is a classification of different tapes along with their common uses:

1. Packaging and Sealing Tapes

Packing Tape: Used for sealing boxes and packages for shipping. It typically comes in clear or brown.

Common Uses: Shipping, storage, and moving boxes.

Water-Activated Tape (Gummed Tape): Activated by water and bonds strongly with cardboard.

Common Uses: Sealing heavy or high-value packages, providing tamper-evident security.

2. Adhesive Tapes

Cellophane Tape : A clear, thin tape used for light-duty sealing.

Common Uses: Wrapping gifts, sealing envelopes, light repairs.

Double-Sided Tape: Adhesive on both sides, used for bonding surfaces together.

Common Uses: Mounting photos, attaching posters, crafting.

Duct Tape: Cloth or scrim-backed tape with a strong adhesive, water-resistant.

Common Uses: Heavy-duty repairs, sealing, and waterproofing.

Masking Tape: Easy-to-tear paper tape, used mainly in painting.

Common Uses: Masking off areas during painting, labeling, and bundling.

3. Electrical and Electronic Tapes

Electrical Tape: Made from vinyl, used for insulating electrical wires.

Common Uses: Insulating wires, color-coding cables, minor electrical repairs.

Kapton Tape: Polyimide tape used for high-temperature and electrical insulation.

Common Uses: Electronics manufacturing, aerospace applications.

Copper Tape: Conductive tape used for electrical connections and shielding.

Common Uses: EMI shielding, circuit repairs, and antennae manufacturing.

4. Specialty Tapes

Gaffer Tape: Cloth tape with a matte finish, easily removable without residue.

Common Uses: Securing cables, stage and film production, temporary repairs.

Teflon Tape (PTFE Tape): Used in plumbing to seal pipe threads.

Common Uses: Plumbing, preventing leaks in threaded connections.

Anti-Slip Tape: Textured tape that provides traction on slippery surfaces.

Common Uses: Stairs, walkways, ramps, and industrial equipment.

VHB Tape (Very High Bond Tape): High-strength bonding tape used in place of mechanical fasteners.

Common Uses: Automotive assembly, construction, electronics.

5. Medical Tapes

Surgical Tape: Used to secure dressings and bandages.

Common Uses: Medical dressings, securing IV lines, wound care.

Micropore Tape: Breathable tape used for delicate skin.

Common Uses: Wound care, securing lightweight dressings, skin protection.

6. Decorative and Craft Tapes

Washi Tape: Decorative paper tape used for arts and crafts.

Common Uses: Scrapbooking, card making, decorating.

Fabric Tape: Adhesive tape made from fabric.

Common Uses: Hemming, temporary fabric repairs, crafting.

7. Industrial and Construction Tapes

Foil Tape: Aluminum or copper foil backing with an adhesive, used for sealing and insulation.

Common Uses: HVAC duct sealing, insulation, reflective shielding.

Strapping Tape: High tensile strength tape used for bundling and reinforcing.

Common Uses: Securing heavy loads, palletizing, and reinforcing packages.

Conclusion

Different tapes are designed to meet specific needs, whether for everyday household use, industrial applications, or specialized tasks. Understanding the classifications and uses can help in selecting the right tape for the job, ensuring optimal performance and efficiency.

These tapes are integral to many industries and applications, providing essential solutions for a wide range of tasks and challenges.

0 notes

Text

Get heat and UV-resistant Automotive Masking Tape from Shengli Abrasive & Adhesive

Automotive masking tape is a specialized type of adhesive tape specifically designed for use in the automotive industry during painting, detailing, and other surface treatment processes. Shengli Abrasive & Adhesive presents an impressive collection of high-quality, UV, and heat resistant Automotive Masking Tape which has excellent edge tear and is ideal for car paint masking. It is engineered to withstand the harsh conditions of automotive refinishing, providing clean lines and preventing paint bleed-through while being easily removable without leaving residue behind. Our automotive masking tape plays a crucial role in achieving high-quality paint finishes and detailing in the automotive industry.

0 notes

Text

What are the benefits of using automotive masking tape?

Automotive masking tape is specifically designed for use in automotive painting. It is made with a strong adhesive that can withstand high temperatures and is resistant to solvents and chemicals commonly used in automotive painting. This tape is also flexible and can conform to curved surfaces, making it ideal for masking off intricate areas on a car.

How to choose the right automotive masking tape for your needs

When choosing automotive masking tape, there are a few things to keep in mind:

The type of surface you will be masking. Some masking tapes are designed specifically for use on certain surfaces, such as paint, metal, or plastic.

The width and thickness of the tape. The width of the tape should be sufficient to cover the area you are masking, and the thickness of the tape should be appropriate for the level of protection you need.

The temperature range in which the tape will be used. Some masking tapes are not designed for use in extreme temperatures.

How to prepare your car for masking

Before applying automotive masking tape to your car, it is important to prepare the surface. This includes cleaning the area thoroughly to remove any dirt, dust, or grease. It is also important to dry the area completely before applying the tape.

How to apply automotive masking tape to your car

To apply automotive masking tape to your car, follow these steps:

Cut a piece of tape that is long enough to cover the area you are masking.

Starting at one end, apply the tape to the surface, pressing it down firmly to ensure a good bond.

Overlap the tape slightly to prevent any overspray from seeping through.

Continue applying the tape until the entire area is covered.

How to remove automotive masking tape without damaging your paint

To remove automotive masking tape without damaging your paint, follow these steps:

Gently peel the tape back at an angle.

If the tape is difficult to remove, use a heat gun or hair dryer to warm it up.

Be careful not to overheat the paint, as this can damage it.

If there is any adhesive residue remaining, use a mild solvent to remove it.

Tips and Tricks

Here are a few tips and tricks for using automotive masking tape:

Overlap the masking tape slightly to prevent any overspray from seeping through.

Use masking paper or film for extra protection in areas that are difficult to mask, such as headlights and taillights.

Be careful not to tear the paint when removing the masking tape and paper.

If you are unsure about how to apply or remove automotive masking tape, consult a professional.

Conclusion

Automotive masking tape is a versatile and easy-to-use tool that can help to protect your car from the elements during winter weather. By following the tips above, you can ensure that your car is well-protected and looks its best all winter long.

For more info: https://www.tubetape.works/what-it-is

#automotive masking tape#carpainting#large tube tape#maskingtape#carmaskingtape#automotivemaskingtape#cars

0 notes

Text

0 notes

Text

Guide to Unveil the Versatility of Pre-taped Masking Film

In the realm of painting and renovation projects, achieving clean lines and protecting surfaces is paramount. This is where pre-taped masking film steps in as a versatile tool, offering convenience and efficiency in various applications. Let’s delve into the world of pre-taped masking film and explore its wide-ranging uses.

Ensuring Precise Edges in Painting Projects

One of the primary uses of Pre taped masking film is in painting projects. Whether you’re painting walls, trim, or furniture, this film provides a barrier that ensures crisp lines and prevents paint bleed. The integrated tape makes it easy to secure the film in place, saving time and effort compared to traditional masking methods.

Surface Protection to Guard Against Damage

During construction or renovation projects, surfaces like floors, countertops, and windows are susceptible to damage from spills, scratches, or debris. Pre-taped masking film acts as a protective shield, safeguarding these surfaces from potential harm. It’s particularly useful in high-traffic areas or environments where multiple trades are working simultaneously.

Dust Containment: Minimizing Cleanup Efforts

In environments where dust control is crucial, such as renovation sites or workshops, pre-taped masking films serves as a barrier to contain dust and debris. By sealing off openings or covering surfaces, it helps minimize the spread of dust, reducing cleanup efforts and ensuring a cleaner working environment.

Surface Preparation to Streamline the Process

Before painting or applying finishes, proper surface preparation is essential for achieving optimal results. Pre-taped masking film simplifies this process by providing a quick and effective way to mask off areas that don’t require treatment. Whether you’re priming, sanding, or applying texture, this film allows you to work with precision and efficiency.

Weatherproofing and Protection

When working on outdoor projects, exposure to the elements can pose challenges. Pre taped masking films offers weatherproofing capabilities, protecting surfaces from rain, wind, and UV exposure. Whether you’re painting exterior walls, staining a deck, or applying sealant to windows, this film ensures that your work withstands outdoor conditions.

Automotive Applications to Enhance Efficiency

In the automotive industry, pre-taped masking film is a valuable asset for various tasks, from detailing to painting. Whether you’re masking off sections of a vehicle for touch-up paint or protecting interiors during repairs, this film streamlines processes and helps maintain a professional finish.

Artistic Endeavors to Supporting Creativity

Beyond traditional construction and renovation projects, pre-taped masking film finds its place in the realm of art and creative endeavors. Artists and crafters utilize this versatile material for masking off sections of canvas, creating intricate designs, or protecting surfaces during mixed-media projects. Its ease of use and flexibility make it a valuable tool in unleashing artistic expression.

Unlocking the Potential

Pre taped masking film is a jack-of-all-trades in the world of painting, construction, and creative endeavors. Its versatility, ease of use, and ability to streamline processes make it an indispensable tool for professionals and DIY enthusiasts alike. Whether you’re striving for precision in painting, safeguarding surfaces from damage, or exploring artistic possibilities, pre-taped masking films unlocks a world of potential, one project at a time.

1 note

·

View note

Text

Automotive Paint Flash Time Explained

So, you have read or been told the flash time between coats is so many minutes. Just what exactly does that mean and how important is it? There are many so called experts that have their own ideas but are they right? In this article; automotive paint flash time explained...

What is flash time between coats, is it something really crucial or just a suggestion? Well, it is both, and I know that is a vague answer but I will explain.

What Does Flash Time Mean When Painting a Car?

Here is the technical definition of what paint flash time is. Flash time in car painting refers to the waiting period between applying coats of paint.

It's essentially the time it takes for the solvents in the first coat to evaporate enough for a second coat to adhere properly.

This definition has everything you really need to know about flash times. Unfortunately, many car painters think they know better, or stick to exactly what the back of the paint can says.

Who is right? The seasoned old painter that says you wait to the next day to spray clear over a base coat? Or, is the directions on the can the best method to follow?

Paints have changed over the years and they keep changing. So, the season old painter is way off, you do not want to wait 24 hours. However, the instructions on the can could also be wrong but for different reasons.

How Do You Know the Proper Flash Time?

I understand that you may be confused on flash times, due to all the conflicting information out there. As the definition for paint flash time explained. You are waiting for the paint solvents to evaporate before applying the next coat.

This applies to primers, base coats, clear coats, single stages and sealers. Now, there are some products that tell you, no flash times. That you keep spraying until the desired coverage is achieved, but that is another topic.

If you kept spraying clear coat and not giving each coat time to tack up, it will run and sag. It is like building a house. You can’t lay several layers of block, and start building the main structure on it before the mortar cures.

Painting basically follows the same methodology. If you apply a layer of paint and then another on top of the first layer before it firms up. The first layer isn’t going to hold the second layer of paint, it will give way.

Due to humidity, temperatures and general moisture in the air, flash times vary from specs. The back of the can may say to flash your coats 10 to 15 minutes.

However, if you are painting in a super dry and hot environment. The solvents in your paint will dry far faster. This goes the extreme the other direction as well. If your environment is cool and damp, your solvents may not evaporate for 20 to 30 minutes.

That’s right, the specs on the back of the can are a guide, a general suggestion. They kind of leave it up to the painter to make the best decision based on their painting conditions. So then, how can you know the correct paint flash time?

The Tape Test

What is the flash time between coats and what does tape have to do with it? Well, you do not stick the tape into the paint. But you are going to use some, green, yellow or blue tape is the best.

The tape test is really simple. You take some tape, peel it or rip it off, doesn’t matter. Put your finger to the sticky side. Notice how your finger sticks to it when you pull it away?

This is what you want your coats to feel like. This will apply more to the clear or single stages paints than base coats or sealers. Base coats, sealers and primers dry a bit different but you can still use this method if you are unsure.

If you are applying a clear coat, touch an area that doesn’t matter. Possibly the masking tape or paper or even up in a wheel well.

If you touch the freshly painted surface. Your finger should stick ever so lightly but not pull off with any clear on your finger. If no paint comes off on your finger, your coat is what is called tacky and ready for the next coat. This is paint flash time or often called paint flash-off.

When the specifications indicate a flash time of 10 minutes, you can perform a touch test after that period. If paint still transfers onto your finger, wait an additional 5 minutes and test again. Once the paint feels sticky or dry to the touch, it's time to apply the next coat.

Why Is Paint Flash Time Important

As mentioned, there are painters that claim to wait 24 hours before spraying the clear coat. Why would they think this is correct if specs call for minutes instead of hours?

If you remember the definition of paint flash time, it refers to the solvents evaporating. By spraying the clear over a base coat too soon, you can trap the solvent trying to evaporate. What does that mean?

Trapping the vapors coming off the base coat, can cause tiny white spots, sometimes bubbles in the clear. On the other hand, if you wait too long to apply the clear coat, it will not bond to the base coat. This can also cause lifting and bubbles.

So, you can see that flash times can make or break your paint job. You may not see vapor spots in a light color but for darks and or blacks, it looks horrible.

However, if your clear coat doesn’t bond to the base coat, you can get paint lifting and bubbles like this.

The ideal method is for each coat you apply, allow the solvents to evaporate but the material to not totally dry or cure.

Base coat flash time can be manipulated by heat and cold. If you are spraying a panel that is hot. Either from a heated paint booth to sitting out in the sun. This can deliver bad vapor trapping.

The base coat applied to a hot surface can immediately appear dry. However, this is just the surface, the solvent can be trapped under the surface of the base coat. When you apply the clear, the solvents in it will release the solvents in the base coat and cause vapor spots.

Choosing the Correct Paint Reducers by Temps

Most production clear coats do not normally use reducers. However, the activators you mix in them do commonly come in temperature selections.

Single stage paints, base coats, primers and sealers often require reducers and or basemaker. Ideally, you want to paint in temperatures between 70° and 72°F with the humidity around 50%.

When you have these conditions, it is far easier to experiment with fast to medium reducers or activators. You can decide which is best based on the brand and type of paint or primer you are using.

You may find with the temps between 70° and 72°F. Shooting a base coat with a fast reducer or basemaker, works best. Especially when the need for several coats is required to get the achieved look.

As with clear coats, a medium or even slow drying may work best for how you want to the surface to flow out. Of course, the slower the dry time is for clear, the longer your flash times need to be.

So, the slower your reducer, activator or basemaker, the longer your flash times will need to be. Even with primers. Most people don’t think too much about flashing their primers. But to build good filling coats, flash times for primers help.

If your environment it around 75°F but your humidity is high, like between 75% and 90%. You would want to use a fast-drying reducer, activator or basemaker.

On the reverse side, if the temps are around 75°F, and the humidity is between 10% and 30%. You then would want to use a slower drying reducer, activator or basemaker.

Most paint manufacturers only list temperature ranges. You also need to pay attention to the humidity as well.

What If Your Paint Flash Time Is Too Long

If you wait too long before applying any coat on top of the other, then the coats won’t bond. By the coats not bonding, separation, lifting, bubbling or discolorations can occur.

When spraying a sealer before top coating. Be sure to read the paint flash time on the can. Some sealers can flash up to a few hours. However, no matter the flash time, if you wait too long, you will need to scuffy the surface and clean before applying another layer.

This applies to primers, sealers, base coats and clear coats. For the best outcome, you never want to allow a coat to dry that long to where it would require to be scuffed.

If you have to scuff a surface before applying the next, do not wipe it down with a solvent type cleaner. If you can wipe it off with a mid-coat tack cloth would be best. However, if it is heavy in debris, you can use a cloth dampened with water, then the tack cloth.

Primers are more forgiving and you can just sand them. Sealers and top-coats need to be super clean before spraying them.

Conclusion

From the things I have gone over, you can see that paint flash times are really critical. You may not believe this, but all those clear coat issues Honda’s had between 2003 to 2011, were due to the clear not bonding.

Cars are painted far different at the factory than what a body shop would. They are electrostatically sprayed. However, they still have flash times and the base coats were too cured before the clear was applied. Not to mention they didn’t apply a thick enough coating of clear.

Remember, do not spray a coat on anther too soon, as you can get vapor trap. Also, do not wait too long, as the layers will not bond.

If ever in doubt, just touch the paint somewhere it won’t hurt the looks, to see if it is tacky. Remember to adjust your temps in reducers based on your temperature and humidity.

I have an article on Creating Your Own Paint Booth at Home. Having some form of paint booth can immensely help on the look and quality of your paint job.

Read your paint specifications on the cans, but remember, they are general guides. However, they are close to what the flash times need to be. You just adjust due to your environment.

Do not listen to the people that claim you wait days to apply coats. Read your paint specs or ask your paint store. If you need help, reach out and Contact Me.

Read the full article

0 notes

Text

Essential Toolkit: A Guide to Body Shop Paint Equipment in Saudi Arabia

The Kingdom of Saudi Arabia boasts a thriving automotive industry, and keeping vehicles looking their best requires skilled technicians and the right equipment. Body shops play a crucial role in maintaining and restoring car exteriors, and having access to the proper Body Shop Paint Equipments is paramount. This article delves into the essential equipment needed for a well-equipped Saudi Arabian body shop, catering to various repair and refinishing needs.

The Foundation: Spray Guns and Essential Gear

The cornerstone of any body shop paint operation is the Spray Gun. These tools allow for controlled application of paint, primer, and clear coat, ensuring a smooth, professional finish. Here are some key considerations when choosing spray guns in Saudi Arabia:

Technology: Options range from traditional High-Volume, Low-Pressure (HVLP) guns to more advanced Reduced Pressure (RP) models. HVLP guns offer a good balance of efficiency and affordability, while RP guns provide even greater control and material transfer efficiency.

Gravity Feed vs. Pressure Feed: Gravity feed guns offer superior control and a lighter weight, but require a pressurized paint container. Pressure feed guns are more versatile for handling thicker materials but can be heavier and require constant paint flow.

Nozzle Size: The nozzle size determines the spray pattern and material flow rate. Smaller nozzles are ideal for detail work, while larger ones are suited for base coats and larger areas.

Beyond spray guns, a well-equipped body shop will require additional tools:

Air Compressors: Provide a reliable source of compressed air for spray guns and other pneumatic tools.

Paint Mixers: Ensure thorough and consistent mixing of paint components for optimal results.

Personal Protective Equipment (PPE): Respirators, gloves, and safety glasses are essential to protect technicians from paint fumes and overspray.

The Preparation Stage: Tools for a Flawless Foundation

Before applying paint, proper surface preparation is key. Here's where essential equipment comes into play:

Sanding Equipment: Orbital sanders and random orbital sanders allow for efficient removal of old paint, rust, and imperfections. A variety of sanding discs with different grits cater to various stages of surface preparation.

Abrasives: Sandpaper in different grits (coarse to fine) is used for sanding and smoothing body panels.

Masking Materials: High-quality masking paper and masking tape are crucial for protecting areas not intended for paint.

Cleaning Supplies: Degreasers, wax removers, and tack cloths ensure a clean surface free of contaminants that could affect paint adhesion.

The Finishing Touches: Achieving a Showroom Shine

Once the paintwork is complete, the final stage involves achieving a flawless finish. Here's the equipment needed:

Buffing Machines: Rotary polishers and dual-action polishers help remove minor imperfections and buff the paint to a high gloss.

Polishing Compounds and Pads: A variety of polishing compounds and pads with different cutting powers cater to different stages of the polishing process, from removing swirls to achieving a final shine.

The Saudi Arabian Advantage: Considering Local Factors

When selecting Body Shop Paint Equipment in Saudi Arabia, consider these factors:

Climate: The hot and dry climate can impact paint drying times and equipment performance. Opt for equipment designed for high-temperature environments.

Availability of Parts and Service: Ensure easy access to replacement parts and reliable service providers for your chosen equipment brands.

Safety Regulations: Body shops in Saudi Arabia must adhere to specific safety regulations. Choose equipment that complies with local safety standards.

Beyond the Essentials: Specialized Equipment

For body shops catering to specific repair needs, additional equipment might be necessary:

Spot Welders: For repairing small dents and punctures in metal body panels.

Frame Machines and Pullers: For straightening bent frames and restoring a vehicle's structural integrity.

Paint Booths: Enclosed booths with ventilation systems provide a controlled environment for paint application, minimizing dust and ensuring a clean finish. These are especially crucial for high-end paint jobs.

Investing in Quality for Long-Term Success

While the initial cost of high-quality Body Shop Paint Equipment might seem high, it's an investment in the long run. Durable, reliable equipment ensures efficient operations, minimizes rework, and ultimately leads to higher customer satisfaction. Additionally, investing in efficient spray guns and proper ventilation systems can contribute to significant paint material savings.

Conclusion

Having the right Body Shop Paint Equipment is fundamental for any body shop in Saudi Arabia to thrive. From essential spray guns and surface preparation tools to equipment for achieving a flawless finish, investing in the right gear empowers technicians to deliver high-quality repairs and restorations. By considering factors like climate, local regulations, and the types of repairs undertaken, Saudi Arabian body shops can create a well-equipped workspace optimized for efficiency, safety, and long-term success. With the proper equipment and skilled technicians, body shops can keep the Kingdom's vehicles looking their best for years to come.

0 notes