#boiler control system industry

Explore tagged Tumblr posts

Link

#market research future#boiler control market trends#boiler control system industry#boiler control technologies#boiler control market size

0 notes

Text

youtube

We have All Range of CIB Unigas, Siemens, Suntec, and Danfoss, Available Contact Us to Know more,

INDUSTRIAL GAS/OIL/ DUEL FUEL BURNERS & SPARES DISTRIBUTOR MORE EFFICIENT & ENVIRONMENTALLY FRIENDLY BURNERS & SPARES

Call us: +91 - 011 - 45755000 / +91 - 9910499471/72

Mail id: [email protected]

Visit: https://denovoindia.com

#Gas Burner Low Nox#Dual Fuel Burners Natural Gas#best gas burner in india#industrial gas burner suppliers#dual fuel burner supplier#industrial gas burner price#industrial gas burner dealers#industrial dual fuel burner installation#dual fuel burners for boilers#furnace oil burner#furnace oil fired burner#PNG and hsd fired burners#industrial gas burners#industrial LPG fired burners#siemens uv sensor#Siemens UV Flame Detectors#siemens burner management system#siemens controller#siemens servo motor#Siemens Gas Valve#siemens photocell#danfoss controller#nozzle#ingnition transformer#oil pump#Cofi ignition cable#ignition transformer#Suntec Fuel pump#suntec oil burner pump#suntec oil pump

0 notes

Text

“We are seeing a growing interest in cork as a sustainable material,” says Rui Novais, a materials expert at the University of Aveiro in Portugal. “Compared with materials like polyurethane foam [used for thermal insulation], products made with cork require less energy and produce less CO2 emissions.” The cork oak’s thick bark adapted to defend the tree from fire, making it a powerful insulating material that’s been used to shield fuel tanks on NASA spacecraft and electric car batteries. It’s also resistant to water and oil, and can withstand compression while retaining springiness. “It’s an extraordinary, renewable and biodegradable material,” says Novais. “It’s also very durable. It has been demonstrated that cork products remain virtually unchanged for more than 50 years.” Part of the carbon absorbed by cork oak trees is transferred to cork products, which can be used for long periods, repurposed and recycled. Several studies found that cork is carbon negative, meaning it can store more carbon than what is required to produce it. When cork planks are trimmed and punched to form natural cork stoppers, the leftovers are ground into granules and pressed together to form cork sheets or blocks. “Even cork dust is used to produce energy,” says João Rui Ferreira, secretary general of the Portuguese Cork Association. “It feeds the industry’s boilers and powers some of the production.”

[...]

Most of the cork produced in Portugal grows in the gently undulating hills and plains in the south of the country, in an ancient agroforestry system known as montado. This savannah-like ecosystem combines cork, holm oaks and olive trees with pastures, grazing livestock, crops and fallows. “The soil in southern Portugal is very poor, there is very little rain and temperatures are very high in the summer,” says Teresa Pinto-Correia, a professor at the University of Évora in Portugal specializing in rural landscapes and agricultural systems. “But this kind of system is productive even when resources are scarce and conditions are difficult.” For centuries, locals have preserved the montado because cork provided landowners with a source of income. This mosaic of habitats supports hundreds of species, including the Iberian lynx, the world’s most endangered wildcat, and the threatened Imperial eagle. One of the world’s oldest known cork oak trees, planted in 1783 in Águas de Moura, is known as “the whistler” because so many birds visit its large sprawling branches. Iberian pigs feed on acorns and goats graze the interwoven pastures. Interspersing cork oak trees with animals and crops can boost production and biodiversity, but also build soil, control erosion, retain water, combat desertification and sequester carbon, says Pinto-Correia.

138 notes

·

View notes

Text

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Text

Automatic Electric Boiler in Namakkal

Namakkal, a thriving industrial hub, is experiencing a significant transformation in energy utilization thanks to Energy Solution's innovative Automatic Electric Boilers. These eco-friendly, efficient, and automated solutions are designed to cater to various industrial applications, such as food processing, textile production, and pharmaceuticals. Unlike traditional boilers that rely on fossil fuels, these electric boilers operate on electricity, reducing carbon emissions and promoting a cleaner environment.

Energy solution's automatic control systems enable these boilers to operate autonomously, adjusting parameters in real-time, enhancing operational efficiency and reducing the need for constant human oversight. The electric design reduces wear and tear, resulting in lower maintenance requirements and longer equipment lifespan.

Energy solution's commitment to quality is evident in every aspect of their boilers, constructed from high-grade materials and featuring robust safety mechanisms. The company also provides exceptional after-sales support, ensuring clients receive the best service and maintenance, minimizing downtime and enhancing operational continuity.

In conclusion, Energy Solution's Automatic Electric Boilers are revolutionizing industrial operations in Namakkal, helping industries reduce their carbon footprint and improve operational efficiency.

Contact Us:

Energy Solutions

Location: Namakkal

Phone: +91 9994107694 | +91 9994107695

Mail: [email protected]

Website: www.energy-solutions.in

2 notes

·

View notes

Text

Boilers And Chillers Erection Services In India

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

2 notes

·

View notes

Text

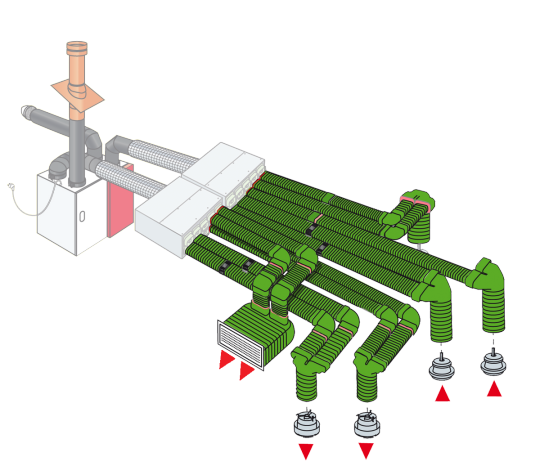

Understanding the Importance of HVAC Drawings and Blueprints: A Comprehensive Guide

Table of Contents: 1.Importance of HVAC Drawings 2.Purpose of HVAC Blueprints 3.Understanding HVAC Systems 4.Types of HVAC Drawings 5.Reading HVAC Drawings & Blueprints 6.Creating HVAC Drawings 7.Tips for Efficient HVAC Drawing Creation 8.Reading & Analyzing HVAC Blueprints 9.Importance of Blueprints in HVAC Installation 10.How HVAC Drawings Improve Maintenance and Troubleshooting 11.Future Trends in HVAC Drawing and Blueprint Technology 12.Conclusion

Importance of HVAC Drawings

HVAC (Heating, Ventilation, and Air Conditioning) drawings are fundamental blueprints essential for the design, installation, and maintenance of HVAC systems in buildings. These drawings provide a visual representation of the HVAC system's layout, including ductwork, piping, equipment placement, and electrical connections. They serve as a crucial communication tool between architects, engineers, contractors, and technicians, ensuring that the HVAC system functions effectively and efficiently.

Purpose of HVAC Blueprints HVAC blueprints serve multiple purposes throughout the lifecycle of a building. During the design phase, they help architects and engineers conceptualize the HVAC system's layout, ensuring optimal space utilization and compliance with building codes and regulations. During construction, blueprints guide contractors and technicians in the accurate installation of HVAC components, minimizing errors and rework. Additionally, these blueprints serve as reference documents for maintenance and troubleshooting tasks throughout the building's lifespan.

Understanding HVAC Systems Before delving into the specifics of HVAC drawings and blueprints, it's essential to understand the components and principles of HVAC systems. HVAC systems are designed to control indoor temperature, humidity, and air quality to create a comfortable and healthy indoor environment. They typically comprise heating units (such as furnaces or boilers), ventilation systems (including ductwork and fans), air conditioning units, and controls for regulation.

Types of HVAC Drawings HVAC drawings come in various types, each serving a specific purpose:

Floor Plans: Provide a bird's-eye view of the building layout, indicating the placement of HVAC equipment, vents, and ductwork.

Elevation Drawings: Offer vertical views of HVAC components, illustrating their height and position relative to other building features.

Sectional Drawings: Show cross-sectional views of HVAC systems, revealing internal details like ductwork and piping arrangements.

Schematics: Present simplified diagrams of HVAC systems, highlighting connections and flow paths for air and fluids.

Isometric Drawings: Provide 3D representations of HVAC components, offering a clearer understanding of spatial relationships and installation requirements.

Reading HVAC Drawings & Blueprints: Proficiently interpreting HVAC drawings and blueprints is essential for architects, engineers, contractors, and technicians. It requires a thorough understanding of symbols, annotations, scales, and industry standards. Symbols represent various HVAC components, such as fans, dampers, valves, and thermostats, while annotations provide critical information like dimensions, materials, and performance specifications. Additionally, familiarity with scales ensures accurate measurement and placement of components within the building layout.

Creating HVAC Drawings

Creating HVAC drawings involves a collaborative effort among architects, engineers, and designers. Modern CAD (Computer-Aided Design) software facilitates the drafting process, allowing for precise modeling and documentation of HVAC systems. Designers input architectural plans and specifications into CAD software, where they can manipulate components, generate layouts, and produce detailed drawings with ease. CAD software also enables revisions and updates to accommodate changes in project requirements or building codes.

Tips for Efficient HVAC Drawing Creation: To streamline the HVAC drawing creation process, consider the following tips:

Standardization: Establish standardized symbols, templates, and procedures to ensure consistency across drawings.

Clarity: Use clear and concise labeling, annotations, and legends to enhance readability and comprehension.

Accuracy: Double-check measurements, calculations, and specifications to minimize errors and discrepancies.

Collaboration: Foster open communication and collaboration among design team members to address potential conflicts or challenges early in the process.

Documentation: Maintain detailed records of revisions, approvals, and design decisions to track the evolution of HVAC drawings throughout the project lifecycle.

Reading & Analyzing HVAC Blueprints When reading HVAC blueprints, it's essential to pay attention to key elements such as:

Equipment Placement: Identify the location of HVAC units, vents, registers, and exhaust fans to ensure optimal airflow and distribution.

Ductwork Layout: Analyze the routing and sizing of ductwork to minimize pressure drops and airflow restrictions.

Piping Configuration: Review the layout of piping systems for heating, cooling, and fluid distribution, ensuring proper insulation and support.

Electrical Connections: Verify the placement and wiring of electrical components, such as motors, controllers, and sensors, to ensure safe and efficient operation.

Importance of Blueprints in HVAC Installation Accurate HVAC blueprints are critical for the successful installation of HVAC systems, as they provide precise instructions for contractors and technicians. By following the blueprints closely, installers can ensure that components are positioned correctly, connections are made accurately, and systems are commissioned properly. This adherence to the blueprint minimizes installation errors, reduces rework, and improves overall project efficiency and quality.

How HVAC Drawings Improve Maintenance and Troubleshooting Throughout the lifecycle of a building, HVAC drawings play a vital role in maintenance and troubleshooting activities. Maintenance technicians rely on blueprints to locate equipment, access service points, and perform routine inspections and repairs efficiently. When troubleshooting HVAC issues, technicians can refer to drawings to identify potential sources of problems, such as duct leaks, valve malfunctions, or electrical faults, enabling quicker diagnosis and resolution.

Future Trends in HVAC Drawing and Blueprint Technology The future of HVAC drawing and blueprint technology is marked by advancements in digitalization, automation, and integration. CAD software continues to evolve with features like 3D modeling, virtual reality (VR) simulation, and cloud collaboration, enhancing design visualization and communication. Building Information Modeling (BIM) platforms integrate HVAC drawings with other building systems, fostering greater coordination and efficiency throughout the construction process. Additionally, IoT (Internet of Things) sensors and AI (Artificial Intelligence) algorithms offer predictive maintenance capabilities, enabling proactive system monitoring and optimization.

Conclusion In conclusion, HVAC drawings and blueprints are indispensable tools for the design, installation, and maintenance of HVAC systems in buildings. By providing detailed visual representations of system layouts, components, and connections, these drawings facilitate effective communication and collaboration among project stakeholders. Whether creating drawings from scratch or interpreting existing blueprints, architects, engineers, contractors, and technicians must possess the necessary skills and knowledge to ensure the successful implementation and operation of HVAC systems. As technology continues to advance, embracing digital tools and techniques will further enhance the efficiency, accuracy, and sustainability of HVAC drawing and blueprint processes.

#gsourcetechnologies#architecturedesigns#engineeringdesigns#cad services#hvacdrawings#caddrafting#hvacservices#hvacsolutions#draftingservices

2 notes

·

View notes

Text

US Industrial Boilers Market Size, Share And Growth Analysis

Industrial boilers are critical components in various manufacturing processes, providing a reliable source of heat or steam for a wide range of industrial applications in the United States. These boilers are used in industries such as chemical processing, food and beverage production, pharmaceuticals, refineries, and power generation. They come in various types, including fire-tube boilers, water-tube boilers, and electric boilers, each designed to meet specific industrial needs. The primary function of industrial boilers is to efficiently generate heat or steam to facilitate various industrial processes, contributing to the overall productivity and energy efficiency of manufacturing operations.

𝐆𝐞𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐏𝐃𝐅: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=9131

The demand for industrial boilers in the United States is influenced by several factors, including economic growth, regulatory requirements, and technological advancements. As industries expand and modernize, the need for efficient and environmentally compliant boiler systems has increased. Stringent environmental regulations have prompted industries to replace older, less efficient boilers with newer, cleaner technologies. The adoption of advanced combustion and control systems in industrial boilers has become crucial in meeting emissions standards and optimizing energy utilization. Additionally, the U.S. government's focus on energy efficiency and sustainability is driving industries to invest in modern industrial boilers to reduce energy consumption and operational costs.

The demand for industrial boilers in the United States is also influenced by the growth of key end-user industries. Sectors such as chemical processing, food and beverage, and power generation have a substantial impact on the demand for industrial boilers. For instance, the chemical industry relies on industrial boilers for various processes such as chemical reactions and distillation. Similarly, the food and beverage industry utilizes boilers for cooking, pasteurization, and sterilization. The expansion of these industries, coupled with the need for reliable and efficient heating solutions, contributes to the ongoing demand for industrial boilers in the U.S. Technological advancements are playing a significant role in shaping the demand for industrial boilers. The integration of digital controls, sensors, and advanced monitoring systems enhances the efficiency and safety of industrial boiler operations. Smart boilers with features like remote monitoring, predictive maintenance, and real-time performance optimization are gaining traction in the market. This trend aligns with the broader industrial shift towards Industry 4.0 principles, where connectivity and data-driven insights play a pivotal role in optimizing manufacturing processes. As industries in the United States continue to prioritize efficiency, safety, and sustainability, the demand for technologically advanced industrial boilers is expected to persist, driving innovation in the sector.

2 notes

·

View notes

Text

The Ultimate Guide to Heating And Cooling: Everything You Need to Learn About Home Heating, Ventilation, and also Cooling

""

Introduction to A/c and Its Importance in Modern Living

Heating, ventilation, and cooling (COOLING AND HEATING) systems have become an essential part of our lives, ensuring comfort and also keeping ideal indoor air top quality. A/c technology incorporates a wide variety of systems as well as equipment designed to manage temperature, control humidity, and also supply fresh air flow. In this thorough overview, we will look into the globe of a/c, discovering its essential parts, benefits, and the most recent developments in the industry.In today's hectic globe, a/c systems are not just a deluxe yet a requirement. From household buildings to industrial facilities, cooling and heating systems play a vital role in preserving a comfy and healthy living or working environment. These systems not just provide temperature level control however additionally help in managing humidity degrees, filtering out toxins, and also making certain appropriate ventilation. By preserving an ideal indoor environment, a/c systems add to improved efficiency, boosted wellness, and reduced health risks for occupants.Understanding the Secret Elements of Cooling And Heating Solutions To fully realize the capability of heating and cooling systems, it is vital to understand their crucial elements. The primary components of a cooling and heating system include home heating devices(such as heating systems or boilers), ventilation systems (consisting of duct and fans), and also cooling devices(both main as well as private devices). These components function in consistency to supply efficient temperature control, proper air flow, as well as air flow throughout a building.Moreover, cooling and heating systems count on sophisticated controls and

thermostats to manage as well as maintain desired temperature level levels. These controls allow users to customize their indoor settings according to their preferences, ensuring optimal convenience in any way times. In addition, modern HVAC systems include energy-efficient innovations, assisting individuals decrease their carbon impact and save money on power costs.Stay tuned for our upcoming blog posts, where we will certainly dive deeper into each component of cooling and heating systems, discover typical troubleshooting tips, discuss best techniques for maintenance, and highlight the most recent fads forming the future of heating and cooling modern technology. Whether you are a homeowner, local business owner, or merely curious about discovering more concerning HVAC, this overview will outfit you with the expertise to make enlightened choices and also optimize your indoor setting.

Read more here morehartac.com

#hvac#emergency air conditioning repair near me#emergency air conditioning repair#emergency water heater repair

2 notes

·

View notes

Text

The Boiler Exchange

youtube

With over 25 years industry experience, The Boiler Exchange in Glasgow are the experts you can trust for all your central heating requirements. New boiler installations, replacement boilers, new combi boilers, and system upgrades. Our team of experts have the experience and knowledge to advise you correctly and keep you informed from quotation and design, all the way through to installation of your new boiler. combi boiler Scotland

We are aware that paying for a new boiler installation can be a costly and unexpected expense. This is why no matter the size of your budget, we are here to help find the perfect boiler for your home, and we provide fixed price boiler quotes for boilers to suit homes of all sizes.

boiler replacement Scotland

You can also choose from some optional extras, such as thermostats, smart controls, and upgrades. Flexible finance options are available to help spread the cost of your new boiler installation allowing you to pay monthly.

Contact us

The Boiler Exchange 272 Bath Street, Glasgow G2 4JR United Kingdom 0141 354 8885

Social Links: YouTube Facebook Twitter Instagram Pinterest

2 notes

·

View notes

Link

#market research future#boiler control market trends#boiler control system industry#boiler control technologies#boiler control market size

0 notes

Text

The Burner of An Asphalt Mixing Plant Determines its Success.

youtube

If you are well versed with the machine you will know how important the burner. The asphalt plant burner is the component which determines the success or failure of the product.

The coal and Oil dual purpose burners is a multi-fuel burner, which can use fuel oil alone, or coal alone. It is composed of the main burner, fuel valve group, pulverized coal supply system, and control system. The entire system has a one-key switching centralized control system, and there is no need to replace, add or remove any subsystems when switching the fuel types.

The coal and oil dual purpose burners is a newly designed multi-purpose burner, which is widely used in asphalt mixing plants, drying, boilers and other industries.

Find More Video On:

YouTube: https://www.youtube.com/@ZOOMLINEAsphaltPlants

TikTok: https://www.tiktok.com/@zoomlineasphaltplants

#coal burner#oil burner#gas burner#asphalt burner#fuel burner#asphalt mixing plant#asphalt plant#road construction#road machinery#road machines#heavy machines#heavy machinery#asphaltplant#concrete#bitumen#mobile asphalt drum mix plant#construction#heavy equipment#asphalt drum mix plant#heavy machinery transport#asphalt plant supplier#Youtube

2 notes

·

View notes

Text

What is HVAC and how it works?

HVAC, or heating, ventilation, and air conditioning, is a system that is designed to maintain indoor air quality and temperature within a particular building or space. The system comprises several components that work together to ensure optimal heating, cooling, and ventilation. This blog will discuss what HVAC is, its various components, and how it works.

What is HVAC?

HVAC is an acronym that stands for Heating, Ventilation, and Air Conditioning. The primary function of the system is to regulate the temperature and air quality within a building or space. HVAC systems are found in a wide range of settings, including residential, commercial, and industrial buildings.

HVAC Components

An HVAC system is made up of several components that work together to achieve its primary function. The main components of an HVAC system include:

1. Furnace or boiler: This is part of the system that provides heating. Furnaces use natural gas, propane, or electricity to generate heat, while boilers use water or steam.

2. Air Conditioner: This component of the system provides cooling. Air conditioners use refrigerant to absorb heat from the indoor air and transfer it outside.

3. Heat Pump: A heat pump is an all-in-one heating and cooling system that transfers heat from one location to another. In the summer, it removes heat from indoor air to cool the space, and in the winter, it pulls heat from outdoor air to warm the space.

4. Ducts: Ducts are channels that transport air throughout the building. They distribute heated or cooled air from the furnace, air conditioner, or heat pump to different rooms.

5. Thermostat: A thermostat is a device that controls the temperature of the HVAC system. It turns the system on and off and regulates the temperature based on the desired settings.

6. Air Handler: The air handler is a component of the HVAC system that regulates the circulation of air. It contains a blower that pushes air through the ducts and filters that remove contaminants from the air.

What is the HVAC Procedure?

HVAC systems work by using the laws of thermodynamics to regulate the temperature and air quality within a space. The laws of thermodynamics state that heat flows from warmer to cooler areas and that energy cannot be created or destroyed, only transferred. HVAC systems use this principle to transfer heat from one location to another and to maintain a constant temperature within the space.

The process of heating and cooling starts with the furnace or air conditioner. In the case of a furnace, natural gas or propane is burned to produce heat. This heat is then transferred to the air handler, where it is distributed through the ducts to the different rooms in the building. In the case of an air conditioner, the refrigerant absorbs heat from the indoor air and transfers it outside, leaving cool air to be distributed through the ducts.

The thermostat is the device that controls the temperature of the HVAC system. It is set to the desired temperature, and when the temperature falls below or rises above that setting, it sends a signal to the furnace, air conditioner, or heat pump to turn on or off. The thermostat also regulates the fan in the air handler, ensuring that the heated or cooled air is distributed evenly throughout the building.

Ducts are the channels that transport heated or cooled air throughout the building. They are usually made of metal or fibreglass and can be rectangular, round, or oval in shape. The ducts are connected to the air handler and distribute air to the different rooms in the building.

The air handler is the component of the HVAC system that regulates the circulation of air. It contains a blower that pushes air through the ducts and filters that remove contaminants from the air. The air handler also contains a heat exchanger, which helps transfer heat from the furnace to the air handler.

Conclusion: The HVAC system is an essential component of modern buildings and homes. It provides comfortable indoor air quality and thermal comfort.

For more information or services contact https://www.appliedenergy.ca/.

#Energy Management#Greenhouse Gas#GHG#Net Zero#Climate Change#Carbon#Carbon Neutral#Paris Climate Change#Energy Audits#Measurement & Verification#Energy Financing#HVAC#LEED#Energy Modelling#GREENHOUSE DESIGN

2 notes

·

View notes

Text

Achieving Optimal Performance with High-Quality IBR Fitting and Flanges What You Need to Know

In the complex world of industrial operations, achieving optimal performance is paramount. When it comes to steam and power generation systems, the choice of components plays a crucial role. IBR (Indian Boiler Regulations) Fittings and Flanges are integral parts of these systems, ensuring efficiency and safety. As a leading IBR Fitting and Flanges distributor in Vadodara and a trusted IBR Fitting and Flanges dealer in Gujarat, Tube Trading Co. recognizes the importance of these components. In this blog post, we will delve into the key aspects of IBR fittings and flanges, shedding light on how the right choice can contribute to achieving peak performance in industrial settings.

Understanding IBR Fittings and Flanges

What is IBR?

The Indian Boiler Regulations (IBR) are a set of regulations governing the design, fabrication, and inspection of boilers and related components in India. IBR compliance is mandatory for manufacturers and users of boilers and associated equipment to ensure safety and quality standards.

IBR Fittings

IBR fittings are components designed to connect and control the flow of fluids within a steam or power generation system. These fittings must adhere to IBR standards to guarantee their reliability and safety in high-pressure environments. Examples of IBR fittings include bends, elbows, tees, reducers, and valves.

IBR Flanges

Flanges are essential components that connect pipes, valves, and other equipment in a steam or power system. IBR flanges, compliant with IBR regulations, are designed to withstand high pressure and temperature conditions. They provide a secure and leak-proof connection between different sections of a piping system.

Importance of High-Quality IBR Fittings and Flanges

Safety Compliance

In industries where steam and power generation are critical processes, safety is non-negotiable. IBR regulations are in place to ensure that the components used in these systems meet stringent safety standards. Choosing high-quality IBR fittings and flanges from a reputable distributor in Gujarat is essential for compliance and to mitigate the risk of accidents.

Reliability and Durability

The harsh conditions of industrial operations demand components that can withstand high temperatures, pressures, and corrosive environments. High-quality IBR fittings and flanges are constructed from materials that offer exceptional durability, ensuring a longer lifespan and minimal downtime for maintenance.

Efficient Performance

The efficiency of a steam or power generation system depends on the seamless operation of its components. Inferior fittings and flanges can lead to inefficiencies, including leaks and pressure drops, resulting in decreased system performance. By choosing top-notch IBR fittings and flanges from a reliable distributor in Vadodara, industrial operators can optimize the performance of their systems.

Applications of IBR Fittings and Flanges

Power Plants

In power plants, where steam is a primary component in electricity generation, IBR fittings and flanges are extensively used. These components help regulate the flow of steam and ensure the integrity of the entire system.

Chemical and Petrochemical Industries

Industries dealing with chemicals and petrochemicals operate in demanding environments. IBR fittings and flanges play a crucial role in maintaining the integrity of piping systems that transport hazardous substances.

Refineries

Refineries, involved in processing crude oil into various products, rely on high-pressure steam for many processes. IBR fittings and flanges are vital in ensuring the safe and efficient operation of these steam systems.

Textile and Food Processing Units

In textile and food processing, where steam is used for various purposes, IBR fittings and flanges are employed to guarantee the reliability and safety of steam transport.

Choosing the Right IBR Fitting and Flanges Distributor

Selecting the right distributor is as crucial as choosing the right components for your industrial applications. As a reputable IBR Fitting and Flanges distributor in Vadodara, Tube Trading Co. stands out for several reasons:

Extensive Product Range

We offer an extensive range of IBR fittings and flanges, catering to diverse industrial needs. Our products are sourced from trusted manufacturers, ensuring quality and reliability.

Compliance with Standards

All our IBR fittings and flanges comply with Indian Boiler Regulations and other relevant industry standards. We prioritize safety and performance in every product we offer.

Technical Expertise

Our team of experts possesses in-depth technical knowledge about IBR fittings and flanges. We provide valuable insights and guidance to help our clients make informed decisions.

Timely Delivery

At Tube Trading Co., we understand the importance of timely delivery in industrial settings. We ensure that our clients receive their orders promptly, minimizing downtime and disruptions.

Conclusion

In the intricate tapestry of industrial operations, the choice of IBR fittings and flanges can significantly impact the efficiency, safety, and reliability of steam and power systems. Tube Trading Co., as a trusted IBR Fitting and Flanges distributor in Vadodara and a reputable IBR Fitting and Flanges dealer in Gujarat, takes pride in being a reliable partner for industries across the region. Our commitment to quality, safety, and customer satisfaction sets us apart in the competitive landscape.

If you are in search of high-quality IBR fittings and flanges to enhance the performance of your industrial processes, look no further than Tube Trading Co. Contact us today for all your IBR fitting and flange requirements, and let us contribute to the success and efficiency of your operations.

#IBR Fitting and Flanges distributor in Gujarat#IBR Fitting and Flanges distributor in Vadodara#IBR Fitting and Flanges dealer in Gujarat#Steel Companies#Steel Industry#Construction Material#Stainless Steel#business#India#Gujarat#Vadodara

6 notes

·

View notes

Text

Going to rant in this post because I don't care about being "low-key" anymore and no one will read this anyway but to preamble I agree with all the points in this post but I also feel like the underlying unasked question in this post is "why aren't we using nuclear energy" and. It's a good question. But I don't like the reply that just seems to be "because capitalism and no other reason."

Because, honestly, nuclear is maybe our best nonrenewable option. But there are a lot of cons to that option that have already been Explored and no I'm not talking about "but what if it goes boom?!?!?!"

Nuclear energy facilities take a lot of money to build. Specifically a lot of tax dollars. "I'd rather my tax dollars go toward nuclear energy than fossil fuels" yes I'm with you. But consider just how much nuclear energy it would take to power modern grid systems and suddenly we're looking at a lot of facilities and a lot of tax dollars.

But okay, budgets are reallocated and we start building nuclear power facilities. Yay! We are providing as many construction jobs for blue collar and white collar civil engineering as coal plants! Yay!

The lifespan of a nuclear power plant is roughly 30 years. 20-40 specifically. This is a greater lifespan of a coal mine (30 avg. maximum) and shorter than a coal power plant (avg. 50), for comparison. So now we have to get into decommission and reclamation the same way we do in mining. Once the site is decommissioned, everyone packs up and moves onto some other area, or rebuilds something somewhere else, right?

Well... sure. But it's a bit more complicated with uranium than it is with tailings. See, mine tailings (the byproduct/waste of mineral processing) can almost always go through their own environmental rehabilitation process. Sulfur oxidizes, lead and arsenic leach over time into water in non-toxic amounts... it's all just of the earth after all, and to the earth it all returns. A mine, over time, can be reclaimed by the land surrounding it.

Uranium cannot, at least not over a reasonable amount of time. Look at the Marshall Islands, Yucca Mountain, and the uranium mine tailings issues studied in Kazakhstan. Even small amounts of radioactive leaching has turned these places to ecological no-go zones, especially the Marshall Islands where radiation has been leaching into the ocean since the waste facility's inception. It's no Chernobyl, but it's still bad news bears.

"But 1 cylinder of uranium produces as much electricity as 1 ton of coal!" True!! Coal plants also burn ~9000 tonnes of coal per day. So say we replaced all fossil fuel energy with nuclear energy with a thanos-snap today. We would have to use 9000 uranium cylinders per day. Where do we then store the depleted, but still harmfully radioactive, uranium? Our track record isn't great. There isn't a good answer and there isn't a good option. It will bring the same tragic ecological disasters as coal does, the only difference is that we won't see it, because some poor exploited nation's shores will be the ones to suffer and not our ozone layer.

"Nuclear energy is safer for workers!" Is it? If nuclear energy produced as much capital gain as fossil fuel industries, would that not make the industry more dangerous due to worker exploitation? Statistics never tell the full story.

I've gotten to know miners. Coal and copper and gold, specifically. And those who work oil fields and pipelines, boiler builders and surveyors. From one province to another, death rates are vastly different. Drive 10 hours east and work there and suddenly your life expectancy is cut in half.

And I guess my TL;DR is that energy will always cost us, because that is the nature of things. What and how much it costs isn't determined by the industry, it's determined by those who control it. The nuclear energy fear-mongering is stupid, but so is believing it costs us less than fossil fuels and the belief that there is an objective "less" to begin with.

And we should not lose sight of renewable energy. RENEWABLE ENERGY. Of which nuclear energy is NOT.

I wish all environmentalists a very suck cocks in hell

25K notes

·

View notes

Text

Choosing the Right Oxygen Scavenger Chemical for Your Application

Introduction:

In the ever-evolving landscape of industrial processes, the management of oxygen levels is a critical consideration. The presence of oxygen can lead to corrosion, bacterial growth, and a range of other issues that compromise the integrity of systems and infrastructure. Enter oxygen scavenger chemicals - essential components in safeguarding against these challenges. This comprehensive guide explores the importance of selecting the right oxygen scavenger chemical for your specific application, with a focus on key players in the industry, such as Oxygen Scavenger Chemical Supplier in Gujarat and Oxygen Scavenger Chemical Manufacturer in India.

Understanding the Role of Oxygen Scavenger Chemicals:

Oxygen scavenger chemicals, as the name suggests, are substances designed to remove or reduce oxygen content in various environments. They play a vital role in industries such as water treatment, oil and gas, and food preservation. By mitigating the presence of oxygen, these chemicals contribute to corrosion prevention, microbial control, and the overall preservation of product quality.

Key Players in India: Oxygen Scavenger Chemical Manufacturer in India and Supplier in Gujarat

India has emerged as a significant player in the production and supply of oxygen scavenger chemicals. Among the noteworthy contributors, Oxygen Scavenger Chemical Manufacturers in India and Oxygen Scavenger Chemical Supplier in Gujarat stand out for their commitment to quality, innovation, and reliability. These entities play a crucial role in meeting the diverse needs of industries relying on oxygen scavenger solutions.

Oxygen Scavenger Chemical Supplier in Gujarat: A Hub of Expertise

Gujarat has positioned itself as a hub for industrial solutions, and oxygen scavenger chemicals are no exception. Suppliers in Gujarat provide a range of options, tailored to meet the unique requirements of different applications. Their expertise extends to understanding the regional and global demands, making them key players in the supply chain of oxygen scavenger chemicals.

Choosing the Right Oxygen Scavenger for Your Application:

Application-Specific Formulations:

Oxygen scavenger requirements vary across industries. Manufacturers in India offer a range of formulations designed for specific applications, whether it's water treatment, boiler systems, or food packaging. Understanding the unique needs of your application is the first step in making an informed choice.

1. Effectiveness in Low Oxygen Conditions:

The efficiency of an oxygen scavenger is paramount. Suppliers in Gujarat, known for their quality products, ensure that their offerings are effective even in low oxygen conditions. This is crucial for applications where maintaining extremely low oxygen levels is essential.

2. Compatibility with Other Chemicals:

In complex industrial processes, chemicals often interact. Choosing an oxygen scavenger that is compatible with other chemicals in your system is crucial for maintaining the overall integrity and effectiveness of your processes.

3. Environmental Impact:

Responsible manufacturing is a hallmark of Oxygen Scavenger Chemical Manufacturers in India. Considering the environmental impact of the chosen oxygen scavenger is increasingly important in today's landscape. Opting for environmentally friendly options aligns with sustainable business practices.

4. Regulatory Compliance:

Adherence to regulatory standards is non-negotiable in industrial applications. Suppliers in Gujarat are well-versed in navigating the intricate web of regulations governing the production and distribution of oxygen scavenger chemicals, ensuring that their products meet and exceed industry standards.

Case Studies: Realizing the Benefits of the Right Oxygen Scavenger

To illustrate the tangible benefits of choosing the right oxygen scavenger, we explore real-world case studies. These examples highlight how the implementation of effective oxygen scavenger solutions has not only prevented corrosion but also improved operational efficiency and extended the lifespan of critical infrastructure.

Conclusion: Securing the Future with the Right Oxygen Scavenger

As industries continue to evolve, the role of oxygen scavenger chemicals becomes increasingly crucial. The choice of the right oxygen scavenger can spell the difference between seamless operations and costly setbacks. Manufacturers and suppliers in Gujarat and India at large are instrumental in providing solutions that go beyond mere chemical reactions – they contribute to the longevity, efficiency, and sustainability of industrial processes.

In the intricate dance of industrial chemistry, selecting the ideal oxygen scavenger is not just a choice; it's a strategic decision that reverberates across systems and processes. As we navigate the complexities of modern industry, the expertise of Oxygen Scavenger Chemical Suppliers in Gujarat and Oxygen Scavenger Chemical Manufacturers in India serves as a guiding light, ensuring that your application is equipped with the best possible defense against the challenges posed by oxygen.

#Oxygen Scavenger Chemical Supplier in Gujarat#Oxygen Scavenger Chemical Manufacture India#Oxygen Scavenger Chemical Exporter in Gujarat#Oxygen Scavenger Chemical Manufacturer#petrochemical companies#oil and gas industry#chemical companies#oil companies#manufacturer

6 notes

·

View notes