#cellfactorysystems

Text

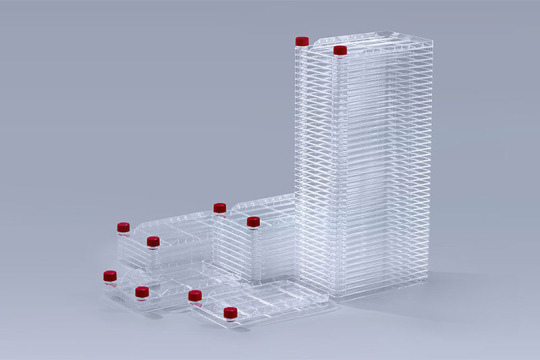

The Crucial Role of our Cell Factory in Biotechnology

In the dynamic landscape of biotechnology, our Cell Factory emerges as a transformative force, reshaping the boundaries of what's possible. Engineered with precision and innovation, this revolutionary product serves as the backbone of progress in diverse fields. Here's a glimpse into the pivotal role our Cell Factory plays:

Accelerated Bioproduction:

At the heart of biotechnology advancement lies the need for accelerated bioproduction. Our Cell Factory is a catalyst, driving efficiency and speed in the creation of biotechnological products. From pharmaceuticals to enzymes, its seamless integration expedites processes, meeting the demands of a rapidly evolving industry.

Unparalleled Precision:

Precision is not just a goal; it's our commitment. The Cell Factory ensures meticulous control over every stage of bioproduction, guaranteeing consistency and quality. Researchers and scientists can rely on the precision of our product to yield reliable and reproducible results, unlocking new frontiers in scientific discovery.

Cell Factory

Versatility Redefined:

Adaptability is the hallmark of our Cell Factory. Its versatile design accommodates a spectrum of applications, from gene therapy research to the development of novel vaccines. This flexibility empowers researchers and biotechnologists, offering them a single, comprehensive solution for a myriad of projects.

Elevated Sustainability:

In an era where sustainability is non-negotiable, our Cell Factory takes center stage. It champions eco-conscious practices, minimizing waste and energy consumption. By choosing our product, laboratories and biotech companies contribute to a greener future without compromising on scientific progress.

Innovation Unleashed:

Our Cell Factory is not just a product; it's a gateway to innovation. It empowers scientists and researchers to push the boundaries of what's possible in biotechnology. From CRISPR advancements to breakthroughs in personalized medicine, the Cell Factory stands as a testament to the endless possibilities that lie ahead.

Step into a future where the boundaries of biotechnological achievement are limitless. Our Cell Factory is not just a tool; it's a catalyst for progress, a key player in the transformative journey of biotechnology. Embrace the power of innovation, precision, and sustainability with our Cell Factory — the driving force behind a new era of scientific excellence.

0 notes

Text

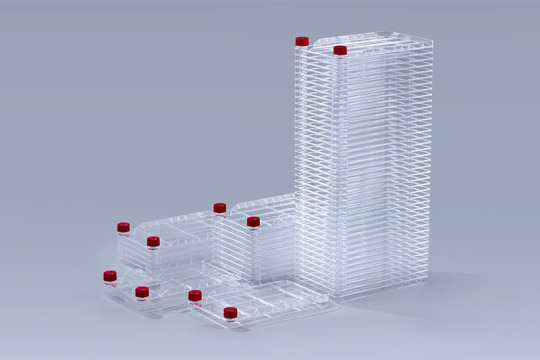

The Benefits of Cell Factory in Cell Cultivation

In the ever-evolving landscape of cell culture applications, the Cell Factory stands as a beacon of innovation, revolutionizing the way we approach cellular research and development. This cutting-edge system offers a myriad of advantages, positioning it as a cornerstone in the realm of cell cultivation.

Enhanced Productivity and Scalability:

One of the primary benefits of the Cell Factory lies in its ability to significantly enhance productivity and scalability. With multiple cell culture layers, it provides a larger surface area for cell attachment and growth, allowing for the cultivation of a higher cell density within a compact footprint. This scalability proves invaluable for industries requiring increased production yields.

Precise Control Over Culture Conditions:

The Cell Factory empowers researchers with precise control over crucial culture conditions. Each layer functions independently, enabling tailored optimization of variables such as media composition, pH, and oxygenation. This level of control ensures an ideal environment for diverse cell types, contributing to the reproducibility and reliability of experimental outcomes.

Cell Factory

Streamlined Workflow and Efficiency:

Designed with efficiency in mind, the Cell Factory streamlines the cell culture workflow. Its modular structure facilitates easy assembly, disassembly, and manipulation, reducing downtime between experiments. This efficiency not only saves valuable time but also enhances the overall productivity of the laboratory.

Minimized Contamination Risks:

Cell culture contamination is a persistent concern, often impacting experimental results. The closed system of the Cell Factory minimizes contamination risks by providing a controlled environment. This feature is particularly crucial in the production of biopharmaceuticals and other sensitive applications where maintaining a sterile culture is paramount.

Elevated Cost-Effectiveness:

By optimizing space, resources, and workflow, the Cell Factory contributes to elevated cost-effectiveness in cell culture applications. Its ability to accommodate larger culture volumes reduces the need for numerous smaller vessels, translating into lower consumable costs and increased overall operational efficiency.

In the realm of cell cultivation, the Benefits of Cell Factory are clear and compelling. From scalability to precise control, streamlined workflows, and minimized contamination risks, this innovative system represents a leap forward in optimizing cell culture applications. Embrace the future of cellular research with the unparalleled advantages offered by the Cell Factory.

0 notes

Text

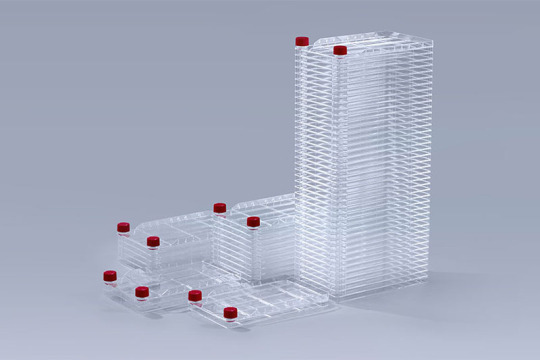

The Power of Cell Factory in Cell and Gene Therapy

In the fast-evolving realm of cell and gene therapy, innovation is the key to unlocking the full potential of groundbreaking treatments. At the forefront of this revolution is the transformative technology known as "Cell Factory." Catering specifically to enterprises in cell and gene therapy, Cell Factory stands as a cornerstone for progress, offering unparalleled applications in the field.

Precision in Production:

Cell Factory technology revolutionizes the production landscape, providing a precise and scalable platform tailored for the unique requirements of cell and gene therapy. Its advanced capabilities ensure the consistent and reliable manufacturing of therapeutic cells, a fundamental aspect for successful clinical outcomes.

Accelerating Advancements:

For companies pioneering the future of healthcare, the adoption of Cell Factory is a strategic leap towards accelerated advancements. The technology streamlines processes, reducing timelines from research to application, empowering enterprises to stay at the forefront of medical breakthroughs.

Cell Factory

Customization for Success:

One of the distinguishing features of Cell Factory is its adaptability. Companies can customize culture conditions, optimizing the growth and functionality of cells. This level of customization is instrumental in tailoring therapies to individual patient needs, marking a paradigm shift towards personalized medicine.

The Assurance of Quality:

In an industry where quality is non-negotiable, Cell Factory stands as a beacon of assurance. Its meticulous processes and stringent quality control measures ensure that every therapeutic cell produced meets the highest standards, building trust and confidence among practitioners and patients alike.

As we navigate the promising landscape of cell and gene therapy, Cell Factory emerges as a catalyst for progress. This technology not only meets the demands of the present but propels us into a future where the unimaginable becomes reality. Embrace Cell Factory, where innovation meets application, and together, let's redefine the boundaries of what's possible in the world of healthcare.

0 notes

Text

Diverse Applications of Cell Factory in Vaccine and Pharmaceutical Manufacturing

In the ever-evolving landscape of vaccine and pharmaceutical production, the applications of cell factory have emerged as a driving force behind innovation and efficiency. These dynamic facilities, utilizing living cells as bioengineered workhorses, showcase a myriad of applications that redefine the capabilities of the industry.

1.Biopharmaceutical Production: Cell factories serve as the epicenter for the large-scale production of biopharmaceuticals, including monoclonal antibodies, enzymes, and growth factors. Their ability to produce these complex molecules with precision has revolutionized therapeutic development.

2.Vaccine Manufacturing: The controlled environment of cell factories is particularly advantageous in vaccine production. From viral vectors to recombinant proteins, these facilities play a pivotal role in developing and scaling up vaccine production for a diverse range of infectious diseases.

3.Stem Cell Research and Therapy: Advancements in stem cell research find a robust platform in cell factories. These facilities provide a controlled environment for the cultivation and manipulation of stem cells, opening avenues for regenerative medicine and innovative therapeutic approaches.

Cell Factory

4.Gene Therapy: Cell factories play a crucial role in the production of viral vectors used in gene therapy. Their ability to consistently produce high-quality vectors is fundamental to the success of gene-based treatments for various genetic disorders.

5.Customized Protein Production: The flexibility of cell factories allows for the tailored production of proteins, meeting specific therapeutic needs. This customization is particularly valuable in addressing rare diseases or conditions with unique protein requirements.

6.Drug Screening and Testing: Cell factories facilitate the development of reliable cellular models for drug screening and testing. Their controlled environment ensures the reproducibility of results, enhancing the accuracy of pre-clinical trials.

In summary, the applications of cell factory span a wide spectrum, from the production of biopharmaceuticals and vaccines to groundbreaking advances in stem cell research and gene therapy. As the linchpin of innovation in the pharmaceutical and vaccine manufacturing realms, cell factories continue to redefine the possibilities and propel the industry towards new horizons.

0 notes

Text

Cell Factory Advantages: Elevating Efficiency in Pharmaceutical and Vaccine Production

In the dynamic landscape of pharmaceutical and vaccine production, the integration of cell factory has revolutionized the industry, offering a spectrum of advantages that streamline processes and elevate productivity.

Enhanced Production Efficiency: Cell factory, leveraging living cells as mini production units, amplify efficiency. These bioreactors enable the continuous generation of therapeutic proteins, vaccines, and various biopharmaceuticals at scale, optimizing manufacturing output.

Cost-Effectiveness: The controlled environment of cell factories allows for cost-effective large-scale production. Through optimized nutrient utilization and reduced waste, these facilities mitigate unnecessary expenses while ensuring maximal output.

Quality and Consistency: Cell factory ensure product uniformity and consistency, critical in pharmaceutical and vaccine manufacturing. The controlled conditions within these factories lead to highly reproducible results, minimizing batch-to-batch variations.

Flexibility and Innovation: Adaptability is a hallmark of cell factories. Their versatility in producing a wide array of therapeutic proteins and vaccines caters to the ever-evolving demands of the pharmaceutical industry. This flexibility encourages innovation in addressing new health challenges and emerging pathogens.

Cell Factory

Scalability: Cell factories seamlessly accommodate scaling, meeting the demands for increased production without compromising the quality or efficiency of the output. This scalability aligns with market fluctuations and growing demands in pharmaceutical and vaccine manufacturing.

Biological Safety and Regulatory Compliance: These facilities adhere to stringent regulatory standards, ensuring the safety and purity of the produced pharmaceuticals and vaccines. The controlled, sterile environment minimizes contamination risks, adhering to the highest industry standards.

In conclusion, the integration of cell factories in pharmaceutical and vaccine manufacturing stands as a transformative leap forward. Their benefits in terms of efficiency, cost-effectiveness, quality, flexibility, scalability, and regulatory compliance mark them as indispensable assets, driving the industry towards greater efficacy and innovation. As these advantages continue to unfold, cell factories remain the cornerstone of success in modern pharmaceutical and vaccine production.

0 notes

Text

Revolutionizing Pharmaceuticals with Cell Factory

In the ever-evolving landscape of pharmaceuticals, innovation is key to success. At FuDau Bio, our commitment to cutting-edge solutions has led us to develop our flagship product - the Cell Factory. This revolutionary product is at the forefront of advancing pharmaceutical research and manufacturing processes. In this article, we will delve into the vital role that Cell Factory play in the pharmaceutical industry.

1. Enhancing Drug Development Efficiency

Pharmaceutical companies worldwide are continually striving to bring new drugs and therapies to market efficiently. Cell Factory offer a game-changing solution. These state-of-the-art cell culture consumables provide a controlled environment for the cultivation of cells on a large scale. With Cell Factory, researchers can accelerate drug development processes, leading to quicker and more cost-effective results.

2. Ensuring Consistency and Quality

Consistency and quality are non-negotiable in pharmaceuticals. Cell Factory is designed to meet these demands head-on. Their precise control over environmental conditions, such as temperature, humidity, and nutrient supply, ensures that cell cultures remain stable and produce reliable results. This level of control is critical in maintaining the quality of pharmaceutical products.

Cell Factory

3. Versatility in Pharmaceutical Research

Pharmaceutical research is incredibly diverse, covering areas like vaccine development, biopharmaceuticals, and regenerative medicine. Cell Factories' versatility makes them a vital asset in this dynamic field. They can accommodate various cell types, allowing researchers to work on a wide range of projects. The adaptability of Cell Factories supports innovation and drives progress in pharmaceutical science.

In conclusion, Cell Factory is the cornerstone of progress in pharmaceutical research and development. Their ability to enhance efficiency, ensure quality, and adapt to diverse research needs is unparalleled. As the pharmaceutical industry continues to evolve, Cell Factory from FuDau Bio will remain a trusted partner, contributing to groundbreaking discoveries and the creation of life-saving medications. With Cell Factories, the future of pharmaceuticals is brighter than ever.

0 notes

Text

Leveraging Cell Factory for Vaccine Production

In today's ever-evolving world of biotechnology, the demand for efficient and reliable tools for vaccine production has never been greater. At FuDau Bio, we take pride in being at the forefront of innovation, providing cutting-edge solutions for cell culture needs. One such innovation is our Cell Factory, a product that is revolutionizing vaccine manufacturing.

The Cell Factory Advantage

Higher Yields and Efficiency: Cell Factory is designed to maximize cell culture productivity. With its multi-layered format, it provides a significantly larger surface area for cell growth compared to traditional cell culture vessels. This translates to higher cell yields, allowing for increased vaccine production capacity.

Precise Control: Cell Factory offers superior control over culture conditions, including nutrient supply, aeration, and waste removal. This ensures optimal growth conditions for your cells, leading to consistent and reliable vaccine production.

Cell Factory

Scalability: Whether you need a small-scale experiment or large-scale vaccine production, Cell Factory is adaptable to your needs. The modular design allows for easy scale-up, making it a versatile solution for a wide range of applications.

In summary, our Cell Factory is a game-changer in the field of vaccine production. Its capacity for higher yields, precise control, and scalability makes it the perfect solution for companies involved in vaccine development and manufacturing. With FuDau Bio, you can trust that you have a reliable partner in advancing vaccine production, helping meet global health challenges. Contact us to learn more about how Cell Factory can elevate your vaccine production processes and contribute to a healthier world.

0 notes

Text

How to clean up contamination in cell factory

Once the cells we culture in cell factory are contaminated, most of them are difficult to handle. If the contaminated cells are valuable and difficult to obtain again, the following methods can be used to remove them.

1. Use antibiotics

Antibiotics are more effective at killing bacteria in cell factories. Combination medication is more effective than medication alone. Preventive medication is more effective than medication after contamination. Preventive medication generally uses a double antibiotic (penicillin 100u/mL plus streptomycin 100μg/mL). After contamination, the cleaning method needs to be 5 to 10 times greater than the usual amount. The drug should be used for 24 to 48 hours after the addition, and then replaced with the usual routine. Culture fluid. This method may be effective in the early stages of contamination. In addition to penicillin and streptomycin, the antibiotics used can also include gentamicin, kanamycin, polymyxin, tetracycline, nystatin, etc. Commonly used are 400 to 800 μg/mL kanamycin or 200 μg/mL tetracycline. The medium is changed every 2 to 3 days and passed on for 1 to 2 generations for treatment. In recent years, it has been reported that 4-fluoro, 2-hydroxyquinoline (Ciprofloxacin, Cip), Pleu-romutilin derivative (Pleu-romutilin derivative, BM-Cyclin2: BM-1 and tetracycline derivative (BM-2)) Antibiotics are effective in killing mycoplasma when used alone or in combination. These three antibiotics are all prepared into 250X concentrated solutions in PBS and stored at -20°C for later use. The usage concentration Cip is 10 μg/mL, BM-1 is 10 μg/mL, and BM-2 is 5μg/mL. When using, first aspirate the contaminated culture medium, add RPMI1640 culture medium containing BM-1, then aspirate the culture medium after 3 days, add RPMI1640 culture medium containing BM-2, and culture for 4 days, and so on for 3 consecutive days. rounds, until it is proved by 33258 fluorescent staining microscopy that mycoplasma has been eliminated, then normal culture medium is added for culture and passage 3-4 times.

2. Heating treatment

Incubating contaminated tissue culture at 41°C for 18 hours can kill mycoplasma, but has adverse effects on cells. Therefore, a preliminary test should be conducted before treatment to explore the heating time that can kill mycoplasma to the maximum extent and have the least impact on cells. This method is sometimes unreliable. If treated with drugs first and then heated at 41°C, the effect will be better.

Cell Factory

3. Use mycoplasma-specific serum

Mycoplasma contamination can be removed with 5% rabbit mycoplasma immune serum (hemagglutination titer 1:320 or above). Because the specific antibody can inhibit the growth of mycoplasma, it turns negative 11 days after antiserum treatment and remains negative 5 months later. is negative. However, this method is more troublesome and not as convenient and economical as using antibiotics.

4. Other methods

In addition to the above-mentioned methods of removing contamination, there are also inoculation and sterilization methods in animals, macrophage phagocytosis methods, methods of adding bromouracil to contaminated culture bottles and then irradiating them with light, and filtration methods, etc., but they are all more troublesome and ineffective. Therefore, once mycoplasma contamination occurs, unless it is of particularly important value, it is generally discarded and re-cultured.

0 notes

Text

What are the impacts of cell factory systems on the vaccine industry?

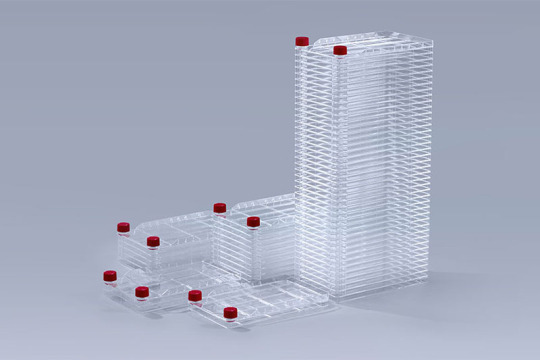

Cell factory systems are an ingeniously designed device for large-scale cell culture, mainly used in large-scale cell culture, such as the production of vaccines, monoclonal antibodies and the pharmaceutical industry.

In the vaccine industry, cell factory systems have been widely used to produce a variety of vaccines, such as Japanese encephalitis vaccines. The impact of cell factory on the vaccine industry is mainly reflected in the following aspects:

Improve production efficiency: The cell factory has the advantages of large culture area and small space occupation. It can provide the largest culture area in a limited space, thus improving the production efficiency of vaccines. For example, when producing hepatitis A vaccines, cell culture and virus amplification technologies in cell factories are already very mature and can greatly improve vaccine production efficiency.

Reduce production costs: The use of cell factories can reduce enterprises’ quality control costs and downstream purification costs. In addition, since the risk of contamination in cell factories is lower, losses in vaccine production can be reduced, thus reducing production costs.

Cell Factory Systems

Promote the automation of vaccine production: With the development of technology, cell factories are gradually replaced by automated production. Automated production can reduce errors caused by manual operations and improve the controllability and stability of the production process, thus improving the quality and reliability of vaccines.

Promote the integration of vaccine R&D and production: The use of cell factories can make vaccine R&D and production more closely integrated. During the vaccine development stage, cell factories can be used for vaccine production and testing to better understand the production characteristics and quality control requirements of the vaccine. This will also help speed up the development and launch of vaccines.

In summary, the use of cell factories can improve vaccine production efficiency, reduce production costs, promote vaccine production automation, and promote the integration of vaccine R&D and production. These effects are important for improving the quality and reliability of vaccines, reducing the price of vaccines, and promoting vaccine production.

0 notes

Text

Internal influencing factors when cultivating cells in cell factories

When we use cell factories to culture cells, the growth status of the cells is affected by various factors. These factors may seem inconspicuous, but if not paid attention to, they will cause heavy damage to the cells. So, how do small details when using cell factories affect cell growth, and how can we avoid pitfalls when using cell factories to culture cells?

1. Degree of contact between cells

Normal cells (diploids) have attachment contact inhibition, and cell growth stops after overgrowth. However, abnormal cells such as tumor cells have weak contact inhibition and can grow to higher cell densities, but some cells overgrow. The damage is difficult to reverse, so it is not recommended to have too high a cell density when culturing cells.

Important points: Generally, cells cultured in a cell factory can be passaged when the cell confluence reaches 70-80%. Do not overgrow the cells.

Cell Factory Systems

2. Cell growth attachments

Adherent cells will adhere to the wall under normal circumstances, but some cells themselves do not adhere firmly or have poor adhesion. At this time, coating attachments can promote cell adhesion. Therefore, when cultivating some special cells, the cell factory needs to be coated. Used after. Commonly used matrices include polylysine (D type, L type), gelatin, collagen, and extracellular matrix mixture, which can be selected according to needs during culture.

Key point: When the cell adhesion in the cell factory is poor, the matrix can be used to coat the cell factory.

3. pH value of culture medium

Most cell lines grow best when cultured in cell factories at around pH 7.4, and the indicator of conventional media is phenol red, so in most cases, the media we see are red, but different media There will be differences in color, for example DMEM is a little darker than 1640. When cultivating cells, you can also judge the cell status based on the color of the culture medium in the cell factory. For example, as the cells grow, the color of the culture medium will become lighter and yellower.

Key points: Pay attention to the color change of the culture medium when culturing cells, and deal with any abnormalities in a timely manner.

0 notes

Text

Four aspects to observe when cultivating cells in the cell factory

When we use cell culture consumables such as cell factories to culture cells, we need to perform routine inspections on the cells. Observe the cell morphology and growth, as well as the pH changes of the culture, the presence of pollution, etc. According to the dynamic changes of the cells, change the medium or pass the cells. If any abnormalities are found, timely measures should be taken. Generally, observations will be made from the following four aspects:

1.Cell morphology

Cells in good growth status can be seen under a general microscope. The cells are highly transparent, refractive, and have unclear outlines. When cells grow poorly, their outlines are enhanced, vacuoles, lipid droplets, and other granular objects often appear in the cytoplasm. The gaps between cells increase, and the cell shape can become irregular or even lose its original characteristics. Such as epithelial cells becoming epithelial-like cells, etc.

2. Cell growth

After the primary culture or passaged cell suspension is inoculated, it begins to proliferate after different incubation periods. Cell growth of passaged cell lines, embryonic tissue or larval tissue can usually be seen on the second day and can be connected into sheets within a week. After the inoculated cells have grown over the bottle wall, they should be cultured again in time. Otherwise, due to nutrient consumption and metabolic accumulation, the cells will enter the stasis or degeneration phase.

Cell Factory

3. Nutrient solution

Under normal circumstances, the culture medium is pink. If the cells are maintained at pH 6.5~6.6, the cells will fall off and die. When the culture fluid acidifies and turns yellow, it means that the metabolites in the culture fluid have accumulated to a certain amount and the culture fluid needs to be replaced with fresh culture fluid. If Hepes is added to the culture solution or cultured in a 5% CO2 incubator, the pH can be maintained relatively stable.

4. Microbial contamination

When microorganisms contaminate the cultured cell culture, the pH value will change and the culture solution will become turbid. After bacterial infection, due to the movement of bacteria, microscopic flashes can be seen under the light microscope; for fungal infection, many filamentous hyphae can be seen under the microscope, and sometimes there are dense clusters of spores; mycoplasma contamination requires some detection methods to detect .

These are the four observations that Fudau Bio shared with you when cultivating cells in the cell factory. I hope it will be helpful to everyone.

0 notes

Text

Quality standards to be followed by cell factories

Cell factories, which are used for large-scale production of cells or cellular products, must adhere to strict quality standards to ensure the safety, efficacy, and consistency of the final products. These standards are critical in various fields, including biopharmaceuticals, biotechnology, and regenerative medicine. Here are some of the key quality standards and guidelines that cell factories should follow:

1.Good Manufacturing Practices (GMP):

GMP is a set of regulations and guidelines that ensure the consistent quality and safety of pharmaceutical and biopharmaceutical products.

Cell factories involved in producing therapeutic cells or cellular products for human use must adhere to GMP standards, including cleanroom requirements, documentation, and quality control procedures.

2.ISO Standards:

International Organization for Standardization (ISO) has several standards relevant to cell factory operations, such as ISO 9001 (Quality Management System) and ISO 13485 (Quality Management System for Medical Devices).

ISO standards provide a framework for quality management, documentation, and process control.

Cell Factory

3.Cell Therapy Specific Guidelines:

Depending on the nature of the cell product, cell factories may need to adhere to specific guidelines or regulations. For example:

In the United States, the FDA provides guidelines for the development and manufacture of cellular therapies.

The European Medicines Agency (EMA) has similar guidelines for cell-based medicinal products.

The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) may also provide relevant guidelines.

4.Biological Safety:

Cell factories should implement measures to prevent contamination, maintain biological safety, and minimize the risk of adventitious agents.

This includes proper facility design, sterilization, and monitoring for microbial and viral contaminants.

Adhering to these quality standards is essential for the successful and ethical operation of cell factories, especially when producing cellular therapies or products for clinical use. Compliance with these standards helps ensure the safety, efficacy, and consistency of cell-based products and fosters trust among regulators, healthcare providers, and patients.

0 notes

Text

Welcome to come to our booth S1/851 at Arablab.

More: www.cellcultureflasks.com

#fudau#fdcell#cellfactory#cellfactorysystems#cellculturerollerbottles#petgmediabottles#cellcultureflasks#tflask#ARABLAB

0 notes

Text

Why do cell factory systems need surface TC treatment?

The purpose of surface TC treatment in cell factory systems is to improve conditions for cell attachment and growth and to increase the efficiency of cell processes. Here are some of the main reasons for surface TC treatment:

1. Improve cell attachment: Surface TC treatment can form a layer of coating or matrix on the surface of the matrix of the cell factory, providing a suitable environment for cell attachment. This coating is usually a highly biocompatible material, such as collagen, gelatin or polylactic acid, which can be used for surface treatment of cell culture media. Through surface TC treatment, cell adhesion factors, growth factors and extracellular matrix components required for cell adhesion can be provided, thereby enhancing the interaction between cells and the matrix, and facilitating the attachment and growth of cells in the factory.

2. Promote cell proliferation: Surface TC treatment can provide suitable surface properties required for cell division and proliferation. For example, some surface coatings have textures or microstructures that mimic the natural tissue environment to which cells are exposed, thereby promoting cell proliferation and expansion. In addition, appropriate surface TC treatment can also regulate the shape, size and division activity of cells by changing the physical and chemical properties around the cells.

Cell Factory Systems

3. Improve cell process efficiency: Through surface TC treatment, the efficiency and yield of cell process can be improved. Good cell attachment and growth environment can increase cell survival rate and cell product production. In addition, by controlling the conditions and methods of surface TC treatment, cell differentiation, maturation, and functional expression can also be regulated, thereby achieving better cell process effects.

4. Provide cell protection: Surface TC treatment can provide a layer of protection for cells to prevent harmful effects of the external environment. The coating can block the entry of harmful substances and reduce damage to cells by toxic substances or other adverse factors. This is particularly important for some cells or cell processes that are sensitive to environmental conditions.

In general, the purpose of surface TC treatment in cell factory systems is to improve the conditions for cell attachment and growth, promote cell proliferation, improve the efficiency of cell processes, and provide protection for cells. These measures can effectively improve the cell culture effect and production efficiency of the cell factory.

0 notes

Text

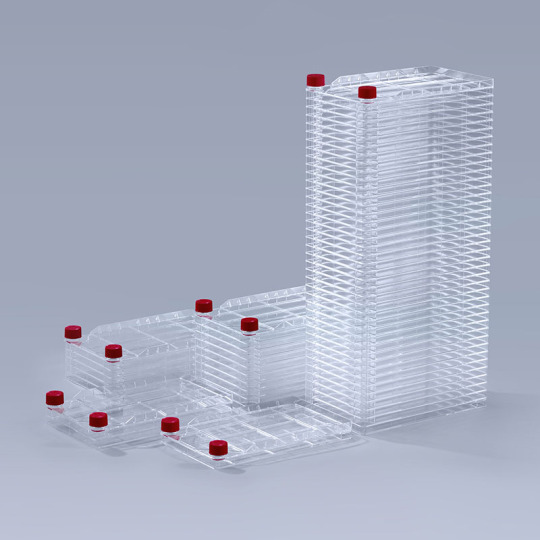

Application of Cell Factory Systems in Production of Inactivated Vaccine

Cell factory systems are a common cell culture tool during the preparation of inactivated vaccines. It adopts a multi-layer structure design, which not only takes up less space but has a large cultivation area, and can realize automatic operation with the help of special equipment. Do you know where this container is mainly used in vaccine preparation?

Inactivated vaccines are made by culturing viruses on a cell matrix, and then using physical or chemical methods to kill infectious viruses while maintaining the integrity of their antigenic particles, making them lose their pathogenicity but retain their antigenicity.

Inactivated vaccines can be composed of whole viruses or bacteria, or they can be composed of their split fragments as split vaccines. The inactivated vaccines currently used in China include inactivated polio vaccine, Japanese encephalitis inactivated vaccine, influenza vaccine, rabies vaccine, hepatitis A inactivated vaccine, EV71 hand, foot and mouth disease vaccine, new coronavirus inactivated vaccine, etc.

Cell Factory Systems

Cell factory systems are mainly used in cell culture or virus culture in vaccine preparation. In the early stage of small-scale culture, 1-layer, 2-layer, and 5-layer, 10-layer containers are mostly used. In the later stage of commercial production, 40-layer factories will be used, to harvest more cells and improve efficiency.

In general, the application of cell factory systems in vaccine production is very mature. In order to prevent external contamination during operation, it can also be equipped with corresponding pipeline systems to achieve sealed transfer of liquids, making the entire vaccine production process more efficient and stable.

0 notes

Text

Cell factory systems help the development of the biomedical industry

In recent years, the biomedical industry has ushered in unprecedented development opportunities. In this wave of rapid change, a revolutionary technology has attracted widespread attention, and that is the cell factory systems. As a representative of a new generation of biopharmaceutical production process, it opens a new situation for large-scale production of high-quality biopharmaceuticals.

Traditional biopharmaceutical production processes often rely on tedious cell culture techniques that are time- and resource-intensive. However, the emergence of cell factory systems has completely changed this phenomenon. It uses engineered cell lines and advanced automation technology, which greatly simplifies and speeds up the production process of drugs. By optimizing cell culture conditions, controlling culture parameters and implementing fixed-point detection, a large number of consistent biopharmaceuticals can be efficiently produced, providing strong support for the pharmaceutical industry.

The cell factory systems adopts a special multi-layer structure design, which can maximize the use of space, thereby saving a lot of factory space, manpower and material resources. It can be used in combination with automatic operation equipment to realize automatic cell culture, greatly reducing labor intensity and intensity. It can also use the supporting pipeline system to realize the closed transfer of liquid, reduce the risk of extracellular contamination of cells, and improve operational efficiency.

In short, the cell factory systems, as a common tool for large-scale cell culture, can save plant space and reduce the risk of exogenous contamination of cells. The emergence of this tool will help the better development of the biomedical industry.

0 notes