#chemical installation in water waste treatment plant in india

Text

Chemical Product for Water Treatment | Aquarius projects | Vadodara | Gujarat | India

Aquarius Projects offers a full chemical portfolio for anti-scalants, anti-foam and any other chemical product required for the operation of water treatment and desalination plants. We offer chemical installation in water waste treatment plant in Vadodara, Gujarat, India.

#chemicals service in vadodara#chemical product for water waste treatment plant in gujarat#chemical installation in water waste treatment plant in india

0 notes

Text

Chemical Product for Water Waste Treatment | Aquarius projects | Vadodara | Gujarat | India

Aquarius Projects offers a full chemical portfolio for anti-scalants, anti-foam and any other chemical product required for the operation of water treatment and desalination plants. We offer chemical installation in water waste treatment plant in Vadodara, Gujarat, India.

#chemicals service in vadodara#chemical product for water waste treatment plant in gujarat#chemical installation in water waste treatment plant in india

0 notes

Text

Chemical Product for Water Waste Treatment | Aquarius projects | Vadodara | Gujarat | India

Aquarius Projects offers a full chemical portfolio for anti-scalants, anti-foam and any other chemical product required for the operation of water treatment and desalination plants. We offer chemical installation in water waste treatment plant in Vadodara, Gujarat, India.

#chemicals service in vadodara#chemical product for water waste treatment plant in gujarat#chemical installation in water waste treatment plant in india

0 notes

Text

In today's fast-paced industrial world, efficiency and precision are key to successful operations. The automation of systems, particularly in industries where water management is crucial, has seen significant advancements over the years. One such innovation is the PLC Based Pump Controller, a technology that is redefining how industries manage water resources. At Adhunik Automation India, we are at the forefront of this revolution, providing cutting-edge solutions that ensure optimal performance and reliability.

Understanding PLC Based Pump Controllers

A Programmable Logic Controller (PLC) is an industrial computer used to control machinery and processes. When integrated into pump systems, a PLC becomes the brain behind the operation, managing the flow, pressure, and distribution of water or other fluids with unmatched precision. Unlike traditional pump controllers, which rely on mechanical switches and relays, PLC based systems offer superior flexibility, scalability, and ease of integration with other industrial systems.

Why Choose PLC Based Pump Controllers?

Enhanced Efficiency PLC based pump controllers significantly improve the efficiency of water management systems. By monitoring real-time data and making instantaneous adjustments, these controllers reduce energy consumption, minimize waste, and optimize the overall performance of the pump system. This leads to considerable cost savings over time, making it a smart investment for any industry.

Increased Reliability One of the primary advantages of using a PLC based pump controller is its reliability. These systems are designed to operate in harsh industrial environments, withstanding extreme temperatures, vibrations, and electrical noise. Moreover, PLCs are known for their long operational life and low maintenance requirements, reducing downtime and ensuring continuous operation.

Flexible and Scalable PLC based pump controllers offer unparalleled flexibility. They can be easily programmed to meet the specific needs of different industries, whether it's water treatment, chemical processing, or agricultural irrigation. Additionally, as your operations grow, the system can be scaled up by adding more modules or upgrading the software, without the need for major hardware changes.

Real-Time Monitoring and Control With PLC based systems, operators can monitor the performance of pumps in real-time. This allows for immediate detection of any anomalies, such as leaks or blockages, enabling quick corrective action. The ability to control the system remotely through SCADA (Supervisory Control and Data Acquisition) further enhances operational efficiency, especially in large or geographically dispersed installations.

Environmental Benefits Efficient water management is crucial not only for reducing operational costs but also for minimizing environmental impact. By optimizing pump operations, PLC based controllers help reduce water wastage and energy consumption, contributing to sustainability goals. This is particularly important in industries that are heavily regulated in terms of water usage and environmental compliance.

Applications of PLC Based Pump Controllers

The versatility of PLC based pump controllers makes them suitable for a wide range of applications. Some of the key industries that benefit from this technology include:

Water Treatment Plants: Ensuring the precise control of water flow and pressure, crucial for maintaining water quality and meeting regulatory standards.

Agriculture: Automating irrigation systems to ensure optimal water usage, improving crop yields and reducing resource wastage.

Chemical Processing: Managing the flow of liquids in complex chemical processes, where accuracy and reliability are paramount.

Oil and Gas: Controlling the extraction and transportation of fluids in challenging environments, where safety and efficiency are critical.

Why Adhunik Automation India?

At Adhunik Automation India, we understand the unique challenges faced by different industries in managing water resources. Our PLC based pump controllers are designed with these challenges in mind, offering a solution that is not only technologically advanced but also tailored to your specific needs. We take pride in delivering high-quality, reliable, and cost-effective automation solutions that empower our clients to achieve their operational goals.

Conclusion

The future of water management lies in automation, and PLC based pump controllers are at the heart of this transformation. With their ability to enhance efficiency, reliability, and sustainability, these systems are becoming an indispensable tool for industries worldwide. At Adhunik Automation India, we are committed to providing innovative solutions that drive your success. Contact us today to learn how our PLC based pump controllers can revolutionize your operations.

0 notes

Text

Advanced Wastewater Storage Tanks in Pune: Reliable Solutions from Prefab Tanks

Effective wastewater management is a critical aspect of industrial and municipal operations. With the growing focus on environmental sustainability and regulatory compliance, industries in Pune and across India are seeking reliable and efficient solutions for wastewater storage and processing. Prefab Tanks offers state-of-the-art wastewater storage tanks that are designed to meet the diverse needs of industries and municipalities, ensuring safe and efficient wastewater management.

The Importance of Wastewater Storage Tanks

Wastewater storage tanks play a vital role in collecting, storing, and processing wastewater before it is treated or safely disposed of. These tanks are essential for managing the byproducts of industrial processes, sewage systems, and other waste-generating activities. Proper wastewater storage is crucial to prevent environmental contamination, ensure compliance with regulations, and protect public health.

In Pune, a rapidly growing industrial hub, the need for reliable wastewater storage tanks is paramount. Industries across sectors such as manufacturing, chemical processing, pharmaceuticals, and more require robust solutions for managing their wastewater effectively.

Features of Prefab Tanks' Wastewater Storage Tanks

Prefab Tanks provides high-quality wastewater storage tanks in Pune and throughout India. Our tanks are designed with the latest technology and materials to offer superior performance and durability. Here are some key features of our wastewater storage tanks:

1. Durable Construction

Our tanks are made from corrosion-resistant materials, ensuring long-lasting durability even in harsh environments. Whether dealing with acidic or alkaline wastewater, our tanks are built to withstand the toughest conditions.

2. Customizable Designs

We understand that different industries have unique requirements. That’s why we offer customizable waste water tank designs to meet the specific needs of your facility. From capacity to configuration, our tanks can be tailored to fit your exact specifications.

3. Leak-Proof Design

Leakage of wastewater can lead to severe environmental damage and costly fines. Our wastewater storage tanks are engineered with a leak-proof design to ensure that all wastewater is securely contained until it can be treated or disposed of properly.

4. Easy Installation and Maintenance

Our tanks are designed for easy installation and minimal maintenance, reducing downtime and operational costs. We provide full support during the installation process and offer maintenance services to keep your tanks in optimal condition.

5. Compliance with Regulations

Prefab Tanks’ wastewater storage tanks are designed to comply with local and international environmental regulations. We ensure that our tanks meet all necessary standards for wastewater storage, helping your facility stay compliant with industry norms.

Applications of Wastewater Storage Tanks in Pune

The demand for wastewater storage tanks in Pune is driven by the city’s diverse industrial landscape. Here are some of the key applications of our tanks:

Industrial Wastewater Management: Industries such as manufacturing, chemical processing, and pharmaceuticals generate significant amounts of wastewater that need to be stored and treated before disposal. Our tanks provide a safe and efficient solution for managing this wastewater.

Municipal Sewage Systems: Municipalities in Pune use our wastewater storage tanks to store sewage and other waste materials before they are processed in treatment plants.

Agriculture: Agricultural operations in and around Pune use our tanks to store runoff and wastewater from irrigation and livestock management, ensuring that contaminants do not reach water sources.

Why Choose Prefab Tanks for Wastewater Storage in India?

When selecting a wastewater storage tank for your operations, Prefab Tanks offers several advantages:

Expertise in Wastewater Solutions

With extensive experience in the industry, we understand the unique challenges of wastewater management and provide solutions that are both effective and reliable.

High-Quality Materials

We use only the best materials in the construction of our tanks, ensuring that they are resistant to corrosion, wear, and other forms of degradation that can occur with prolonged exposure to wastewater.

Comprehensive Support

From initial consultation and design to installation and maintenance, we offer full support to ensure that your wastewater storage system operates efficiently.

Competitive Pricing

We provide high-quality wastewater storage tanks at competitive prices, offering exceptional value for your investment.

Timely Delivery

We understand the importance of time in industrial operations, and we ensure that your tanks are delivered and installed according to your schedule.

Conclusion

Investing in high-quality wastewater storage tanks is essential for any industry or municipality looking to manage wastewater effectively and responsibly. Prefab Tanks offers reliable, durable, and customizable wastewater storage tanks in Pune and across India. Our tanks are designed to meet the stringent requirements of modern wastewater management, ensuring that your operations remain compliant and environmentally responsible.

#Waste water storage tanks#Wastewater storage tanks in Pune#Wastewater storage tanks in India#Prefab tanks storage tank#waste water tank design#waste water tank

0 notes

Text

Understanding the Manufacturing Process of FRP Grating

Introduction to FRP Grating

D Chel Oil & Gas is one of the leading FRP Grating Manufacturers in India. FRP grating is a versatile material widely used in industrial settings for its durability and corrosion resistance. It combines fiberglass reinforcement with a resin matrix to create a composite material that surpasses traditional options like steel or wood in many applications.

Key Steps in FRP Grating Manufacturing

Resin Selection for FRP Grating

The manufacturing process of FRP grating begins with selecting the appropriate resin. Resin types such as polyester, vinyl ester, or phenolic are chosen based on the desired mechanical properties and environmental conditions. Polyester resins are cost-effective and offer good corrosion resistance, while vinyl ester resins provide superior chemical resistance and fire retardancy. Phenolic resins are known for their high-temperature performance.

Molding Process vs. Pultrusion Process

Two primary methods are used by FRP grating manufacturers: molding and pultrusion. Molded grating involves layering resin and fiberglass in a mold and curing it under controlled conditions. This method allows for intricate designs and varied thicknesses. In contrast, pultruded grating is formed by pulling continuous fibreglass strands through a resin bath and then through a heated mould. Pultruded grating offers high strength and stiffness with excellent corrosion resistance.

Role of Manufacturers in FRP Grating Production

Quality Assurance by FRP Grating Suppliers:

Manufacturers play a crucial role in ensuring the quality of FRP grating through rigorous quality control measures. This includes raw material inspection, process monitoring, and testing of finished products to meet industry standards and customer specifications. Consistent quality assurance enhances product performance and durability.

Customization Options for FRP Grating

Manufacturers offer customization options to tailor FRP grating solutions to specific project requirements. This includes various panel sizes, mesh patterns, surface textures, and colors. Customized FRP grating finds applications in industrial flooring, platforms, walkways, and chemical processing plants, where specific design and performance criteria must be met.

Challenges and Tradeoffs in FRP Grating Manufacturing

Cost Considerations and Performance Tradeoffs

While FRP grating offers significant long-term cost savings through reduced maintenance and extended service life, initial costs can be higher than traditional materials. Balancing cost considerations with performance attributes such as strength, durability, and corrosion resistance is crucial for optimizing investment in FRP grating solutions. We are also GRP Pipe Manufacturers in India.

Environmental Impact of FRP Production

The environmental impact of FRP grating production includes energy consumption during manufacturing, waste generation, and considerations for end-of-life disposal. Manufacturers are increasingly adopting sustainable practices, such as recycling fiberglass waste and using eco-friendly resins, to minimize environmental footprint and support green building initiatives.

Related Types:

FRP Pipe Manufacturers in India

FRP Sheet Manufacturers in India

FRP Flange Manufacturers in India

FRP Fitting Manufacturers in India

FRP Valve Manufacturers in India

High-grade FRP grating manufacturers in India

FRP grating suppliers in India are well-known for creating high-quality, long-lasting, and corrosion-resistant gratings constructed of fibre reinforced plastic (FRP). These gratings are commonly used in industries such as chemical processing, water treatment, maritime, and oil and gas, where their non-corrosive qualities ensure long-term performance even in hostile situations. FRP gratings are lightweight but sturdy, making them simple to install and maintain. They are a cost-effective alternative for industrial flooring, walkways, and platforms.

FRP grating manufacturers in India are well-known for creating high-quality, long-lasting, and corrosion-resistant gratings constructed of fibre reinforced plastic (FRP). These gratings are commonly used in industries such as chemical processing, water treatment, maritime, and oil and gas, where their non-corrosive qualities ensure long-term performance even in adverse conditions. FRP gratings are lightweight but sturdy, making them simple to install and maintain. They are a cost-effective alternative for industrial flooring, walkways, and platforms.

0 notes

Text

Waste Water Treatment Plant in Pune

Water treatment service in Pune

Wastewater management is a critical aspect of urban infrastructure, essential for protecting water resources and ensuring public health. In Pune, a rapidly growing city in India, the need for effective wastewater treatment has become increasingly important. Prakrriti Enterprises has emerged as a leading provider of comprehensive wastewater treatment solutions, addressing the city’s needs with innovative technologies and sustainable practices.

The Importance of Wastewater Treatment

Effective wastewater treatment is crucial for several reasons:

Environmental Protection: Untreated wastewater can pollute rivers, lakes, and groundwater, leading to severe environmental degradation. Effective treatment ensures that harmful pollutants are removed, protecting aquatic ecosystems and biodiversity.

Public Health: Contaminated water is a breeding ground for pathogens that can cause diseases. Treating wastewater reduces the risk of waterborne illnesses, safeguarding public health.

Resource Conservation: Treated wastewater can be reused for various purposes, such as irrigation, industrial processes, and even as a potable water source after advanced treatment. This conserves precious freshwater resources.

Regulatory Compliance: Governments and environmental agencies have stringent regulations regarding wastewater discharge. Proper treatment ensures compliance with these laws, avoiding legal penalties and fostering sustainable development.

Pune’s Wastewater Challenges

Pune faces several challenges in managing its wastewater:

Rapid Urbanization: The city’s population growth has led to increased wastewater generation, putting pressure on existing treatment infrastructure.

Aging Infrastructure: Much of Pune’s wastewater treatment infrastructure is outdated and in need of modernization to handle the current and future load.

Industrial Pollution: The presence of numerous industries in and around Pune contributes to the complexity of wastewater treatment, as industrial effluents often contain hazardous chemicals that require specialized treatment.

Water Scarcity: Pune experiences periodic water shortages, making the reuse of treated wastewater an attractive option to supplement the city’s water supply.

Prakrriti Enterprises: Leading the Way in Wastewater Treatment

Prakrriti Enterprises has established itself as a pioneer in providing cutting-edge wastewater treatment solutions in Pune. With a focus on sustainability, innovation, and customer satisfaction, the company offers a range of services tailored to meet the city’s unique needs.

Advanced Treatment Technologies

Prakrriti Enterprises employs state-of-the-art technologies to ensure efficient and effective wastewater treatment:

Biological Treatment: Utilizing advanced biological processes, such as activated sludge and membrane bioreactors (MBR), the company effectively removes organic matter and nutrients from wastewater, producing high-quality effluent.

Chemical Treatment: For industrial effluents containing hazardous chemicals, Prakrriti Enterprises uses advanced chemical treatment processes, including coagulation, flocculation, and advanced oxidation, to neutralize pollutants and ensure safe discharge.

Physical Treatment: The company employs physical treatment methods like sedimentation, filtration, and flotation to remove suspended solids and other contaminants from wastewater.

Tertiary Treatment: To produce water suitable for reuse, Prakrriti Enterprises offers tertiary treatment options, such as ultrafiltration, reverse osmosis, and UV disinfection, ensuring that treated water meets the highest quality standards.

Customized Solutions

Understanding that each client has unique requirements, Prakrriti Enterprises provides customized wastewater treatment solutions:

Residential Complexes: The company designs and installs compact, efficient treatment plants for residential complexes, ensuring that domestic wastewater is treated and recycled for non-potable uses like gardening and flushing.

Industrial Units: Prakrriti Enterprises offers tailor-made treatment solutions for various industries, addressing specific effluent characteristics and regulatory requirements.

Municipal Corporations: Collaborating with municipal authorities, the company helps upgrade and expand existing treatment infrastructure, ensuring that the city’s growing population is served effectively.

Commercial Establishments: From hotels to shopping malls, Prakrriti Enterprises provides comprehensive treatment solutions that help commercial establishments manage their wastewater responsibly.

Solutions Offered by Prakrriti Enterprises

Prakrriti Enterprises offers a range of solutions to address Pune’s wastewater treatment challenges:

Decentralized Treatment Systems: To alleviate the burden on central treatment facilities, Prakrriti Enterprises designs and implements decentralized treatment systems for residential and commercial complexes. These systems treat wastewater onsite, reducing the load on municipal infrastructure and enabling water reuse.

Upgrading Existing Infrastructure: The company specializes in upgrading and retrofitting existing treatment plants with modern technologies. This not only improves the efficiency and capacity of the plants but also ensures compliance with current environmental regulations.

Zero Liquid Discharge (ZLD) Systems: For industries with stringent discharge requirements, Prakrriti Enterprises offers ZLD systems that treat and recycle all wastewater, leaving no discharge. This is particularly beneficial in areas facing water scarcity, as it maximizes water reuse.

Advanced Monitoring and Control Systems: To ensure optimal performance, Prakrriti Enterprises integrates advanced monitoring and control systems into their treatment plants. These systems use real-time data to monitor treatment processes and make necessary adjustments, ensuring consistent water quality.

Commitment to Sustainability

Sustainability is at the core of Prakrriti Enterprises’ operations:

Energy Efficiency: The company designs energy-efficient treatment plants that minimize operational costs and carbon footprint.

Resource Recovery: By promoting the reuse of treated wastewater and recovery of valuable resources like biogas and nutrients, Prakrriti Enterprises contributes to a circular economy.

Environmental Stewardship: The company actively engages in community outreach and education programs, raising awareness about the importance of wastewater treatment and environmental conservation.

Success Stories

Prakrriti Enterprises has an impressive track record of successful projects in Pune:

Residential Complexes: The company has installed several decentralized wastewater treatment plants in residential complexes across Pune, enabling communities to recycle and reuse water, reducing their dependence on municipal supply.

Industrial Projects: Prakrriti Enterprises has partnered with various industries to develop customized treatment solutions, ensuring compliance with environmental regulations and promoting sustainable practices.

Municipal Collaborations: Working with Pune’s municipal authorities, the company has helped upgrade several treatment plants, enhancing their capacity and efficiency to serve the city’s growing population.

The Future of Wastewater Treatment in Pune

As Pune continues to grow, the demand for effective wastewater treatment solutions will only increase. Prakrriti Enterprises is committed to staying at the forefront of this vital industry, continually innovating and improving its services to meet the city’s evolving needs.

The company’s future plans include:

Research and Development: Investing in R&D to develop new technologies and processes that enhance treatment efficiency and sustainability.

Expanding Services: Extending its reach to more residential, commercial, and industrial clients, providing them with top-notch wastewater treatment solutions.

Community Engagement: Strengthening its community engagement efforts to raise awareness about the importance of wastewater treatment and promote sustainable practices.

#Water Treatment Pune#Water Solutions In Punjab#Ro Plant Manufacturers#Ro Plant Supplier#Ro Plant Installation

0 notes

Text

Impure Water a Big Issue in India - How to Manage This Situation?

Contaminated water is a prominent issue in India. This water has a bad impact on the health of physical well-being. This issue makes one feel that something ought to be done now. Here is how one should handle it.

Importance of Clean Water

Clean water is critical for human health. It helps prevent diseases and allows one to live a healthy life. Water is a basic necessity. Hence people have the right to get safe water. Contaminated water affects health. Without clean water, communities may suffer from water-borne diseases such as cholera and dysentery.

Causes of Water Contamination

The sources of water contamination in India are numerous. Awareness of all these causes aids in discovering the right ways to deal with them.

Industrial Waste:

Companies emit pollutants into the water systems.

The release of chemicals or toxins into the water sources usually contaminates the water.

The use of SS water tanks in this case is the safest way to store clean water.

Agricultural Runoff:

Some classified pollutants such as pesticides and fertilizers pollute surface and underground water.

They enter into the water systems in forms like contaminated run-offs.

For water storage, use a custom water tank. This will help in storing raw water for agricultural purposes.

Household Waste:

Sewage disposal in the wrong manner.

Employment of dangerous cleaning materials.

Contaminated water with pollutants is entering the nearby streams or rivers.

Solutions for Clean Water

Protection and management of water sources reduce water pollution. Therefore, the provision of sustained solutions can prevent water pollution. The necessary measures that one should take include:

Water Treatment Plants:

The expansion of existing treatment facilities is necessary.

Another important recommendation is frequent maintenance of existing plants.

Check whether the treated water is safe for use.

Use of Stainless Steel Water Tanks:

The stainless steel water tanks are long-lasting and do not get affected by rusting.

SS water tanks help to preserve water in a manner that the water does not come into contact with contaminants.

They are good for keeping clean water for drinking.

Public Awareness:

Inform the public on the aspects of water precautions.

Advocate for the use of treated water in everyday requirements.

Advocate for a custom water tank as many homeowners do not know the advantages that come with having the water tanks customized.

Rainwater Harvesting:

Store rainwater in specially designed stainless steel water tanks.

Use the stored rainwater for other purposes except drinking.

Minimize reliance on dirty water sources.

Government Initiatives

The government greatly influences the availability of clean water. They have to stress high standards and proper consumption of water resources in addition to proper investments in the infrastructure of the water.

Regulations and Enforcement:

Keep monitoring industrial waste disposal.

It is necessary to take some specific measures like fining the violators to discourage pollution.

Use water quality testing in the villages.

Infrastructure Development:

Construct more water treatment plants.

Enhance rural water supply infrastructure.

Fund developments promoting the installation of SS water tanks.

Support for Research:

Finance projects on the development of new methods and technologies in water purification.

Promote ideas that relate to the conservation of water resources and the use of water sparingly.

Support the global organizations to apply the best practices.

Community Involvement

People in communities can make a difference in the world. Local approaches support governmental actions. It is recommended to participate in the following activities for improved results.

Water Conservation:

Fix leaks promptly.

Use water-saving fixtures.

Store rainwater in a custom water tank.

Clean-Up Drives:

Pave way for river and lake cleaning exercises.

Discharge wastes and pollutants.

Educate people on the need to use clean water not only for drinking but also for cooking.

Community Education:

Perform seminars and trainings regarding water.

Explain proper ways to dispose of waste.

Encourage the utilization of SS water tanks for safe storage.

Conclusion: Water pollution is one of the pressing problems of India. The use of stainless steel water tanks is excellent for the safe storage of water from any potential and existing contaminants.

Purever provides genuine SS water tanks. Their tanks are very useful in the provision of safe and clean water storage. Purever provides the best water for your family. Select Purever for a carefree and long healthy life ahead.

#stainless steel water tanks#SS water tanks#custom water tank#customized steel water tanks#commercial SS water tanks#purever water storage tanks

1 note

·

View note

Text

STP plant for hospitals

In the heart of India’s industrial growth, hospitals generate a significant amount of wastewater containing harmful pathogens, chemicals, and pharmaceuticals that pose a threat to public health and the environment. Proper management of this wastewater is crucial to prevent contamination of water bodies, soil, and air, which can lead to severe ecological and health issues. Sewage Treatment Plants (STPs) designed specifically for hospitals are essential for ensuring that wastewater is treated properly before being released or reused. Thermodynamic Services, a leader in environmental and industrial solutions, offers advanced STP plants for hospitals, tailored to meet the highest standards of safety and efficiency. These STP plants incorporate multi-stage filtration and biological treatment processes to remove a wide range of contaminants, ensuring that discharged water meets safety standards. This helps hospitals comply with strict environmental regulations, avoid penalties, and promote sustainable waste management practices, reducing their environmental footprint and protecting public health.

Thermodynamic Services provides end-to-end support for STP plants, from initial consultation and design to installation, commissioning, and maintenance. Their STP plants are designed for continuous operation, ensuring consistent and efficient treatment of hospital wastewater. With expertise in addressing the unique challenges faced by hospitals, Thermodynamic Services offers customizable solutions that can be tailored to the specific requirements of different hospitals. Their advanced treatment processes ensure pathogen removal, chemical treatment, and safe discharge of treated water, contributing to improved hygiene and safety in hospital operations. Investing in an STP plant from Thermodynamic Services not only ensures compliance with environmental regulations but also demonstrates a hospital’s commitment to public health and safety, enhancing its reputation and building trust with the community. Contact Thermodynamic Services today to learn more about their advanced STP plant solutions and how they can help your hospital manage wastewater effectively.

0 notes

Text

Water Quality Sensor Market - Forecast(2024 - 2030)

Water Quality Sensor Market Overview

The Water Quality Sensor Market size is estimated to reach $2,690.4 Million by 2027, growing at a CAGR of 7.5% during the forecast period 2022-2027, attributed to growing demands for contaminant free water as well as increasing prevalence of water-borne diseases like cholera, typhoid and so on. Government stringency on laws or policies related to industrial waste treatment, rise of aquaculture activities, along with surge in research studies on water quality monitoring processes, have been aiding its market growth. Adoption of water quality sensors help in identification or measurement of concentration levels for chemical oxygen demand, total organic carbon, chlorine, and many more. Additionally, widespread utilization of fluorescence spectroscopic technique to characterize river water pollution as well as significant construction projects related to environment testing labs, can propel the market growth overtime. Government regulations or initiatives for drinking water quality monitoring, testing and surveillance as well as rising water pollution due to rapid industrialization, presence of toxic metal effluents and related hazardous substances are some of the major factors set to transform the Water Quality Sensor industry outlook in the coming time.

Water Quality Sensor Report Coverage

The “Water Quality Sensor Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Water Quality Sensor Market.

By Type: Residual Chlorine Sensor, Conductivity Sensor, Total Organic Carbon (TOC) Sensor, pH Sensor, Oxidation-reduction Potential (ORP) Sensor, Chemical Oxygen Demand (COD) Sensor, Turbidity Sensor, Others

By Pollutants: Physical, Chemical, Biological

By Installation: Fixed, Portable

By Body Material: Metallic, Plastic, Glass

By Display: Analog, Digital

By Application: Wastewater Treatment, Marine Quality Assessment, Drinking Water Quality Control, Industrial, Environmental Testing, Aquaculture, Municipal Water Quality Monitoring, Others

By Geography: North America (U.S, Canada, Mexico), Europe (U.K, Germany, France, Italy, Spain, Others), APAC (China, Japan India, South Korea, Australia, Others), South America (Brazil, Argentina, Others), RoW (Middle East, Africa)

Request Sample

Key Takeaways

pH water quality sensor market held the largest share in 2021, owing to factors like to rising demand for wastewater treatment within industrial plants and growing need across aquaculture environments.

Water Quality Sensors for Drinking Water Quality Control application is analyzed to witness the fastest growth during 2022-2027, attributing to government initiatives or guidelines regarding drinking water monitoring or testing, rising prevalence of waterborne diseases and so on.

APAC dominated the Water Quality Sensor market in 2021, owing to surge in wastewater treatment facilities, growing industrialization and so on.

Government regulations or initiatives towards drinking water quality monitoring, testing and surveillance alongside rise in water pollution due to rapid industrialization, presence of toxic metal effluents and related hazardous substances is analyzed to significantly drive the market growth of Water Quality Sensor market during the forecast period 2022-2027.

Water Quality Sensor Market Segment Analysis- By Type

Based on type, pH sensor segment dominated the Water Quality Sensor market with a share of 33% in 2021, attributed to factors including growing demand for wastewater treatment across industrial plants, rising need within aquaculture environments, and so on. With governmental regulations or stringency on industrial pollution control laws, monitoring industrial wastewater with its treatment have emerged a key factor for industrial plant functioning. Since pH value act as an important indicator for monitoring hydrogen concentration in industrial sewage, domestic sewage, and many other weak alkali environments, there is significant impact on the market growth of pH water quality sensors. Additionally, increasing agricultural activities, expansion projects related to utility sectors, rapid rise in industrial wastage, and so on, have been catering to the need for water quality testing through pH measurement. Moreover, significant number of R&D activities, and growing demand towards water acidity measurement from aquaculture sector, have been also aiding its market growth. In August 2020, ANB Sensors had revealed about its plans on the launch of S series ocean pH sensor, capable of providing calibration-free pH monitoring of the world’s ocean as well as waterways. With variable size availability, these mechanically robust sensors offered wet or dry storage, alongside easy adaptability to fit any type of housing or end use applications, with minimal user intervention. These factors have eventually helped in influencing the market growth of pH Water Quality Sensor industry overtime.

Inquiry Before Buying

Water Quality Sensor Market Segment Analysis- By Application

Water Quality Sensor for Drinking Water Quality Control applications are analyzed to grow with the highest CAGR of 8.3% during 2022-2027, owing to rising prevalence of waterborne diseases, governmental initiatives or guidelines regarding drinking water monitoring or testing and so on. With massive amounts of industrial wastes or effluents being exposed to the waterbodies, the need for efficient treatment of drinking water becomes highly essential. According to the Brihanmumbai Municipal Corporation’s (BMC) annual Environment Status Report (ESR) 2020-2021, areas namely Dadar, Dharavi, Parel, Byculla, Goregaon as well as Mulund have reported an increase in contamination of drinking water over the last one year. This report highlighted that out of the total 29,051 water samples which were checked by the civic body, 275 (i.e. 0.94 per cent) of the total samples were found contaminated. This showed potential demand for water quality sensors for testing, measurement and surveillance, to eliminate high contamination levels of drinking water, driving adoption of varied spectroscopic techniques. In June 2022, Kerala Water Authority had revealed about launching a special drive under which drinking water quality will be assessed of each schools within the state. For this, water authority’s 86 labs and lab facility of the ground water department will be utilized for chemical as well as microbiological testing of water samples. This initiative was taken in regards with a series of food poisoning cases being reported in schools over the last week. Such factors will help in expanding the Water Quality Sensor market size for drinking water quality control applications in the coming time.

Water Quality Sensor Market Segment Analysis- By Geography

APAC dominated the Water Quality Sensor market with a share of 38% in 2021, and is analyzed to have a significant market growth during the forecast period 2022-2027. Factors including growing industrialization, surge in wastewater treatment facilities, and government policies or initiatives to minimize water pollution hazards have attributed to its market growth. Additionally, stringent government rules on waste and sewage disposal procedures, growing demand for portable or safe drinking water, and increasing establishment of environmental testing laboratories, have been also aiding the demand for water quality sensors in the region. In March 2021, Housing Infrastructure Development Corporation (Hidco), headquartered in Kolkata, India had started installation of smart sensors in nine water tanks within New Town, Kolkata. This will help in generating reports every 24 hours through random checking as well as monitoring of the water quality. These factors are set to transform the APAC Water Quality Sensor industry outlook in the long run.

Schedule a Call

Water Quality Sensor Market Drivers

Government Regulations or Initiatives towards Drinking Water Quality Monitoring, Testing and Surveillance is Driving the Demand for Water Quality Sensors:

Government regulations or initiatives towards drinking water quality monitoring, testing, and surveillance act as one of the major drivers boosting the market growth of water quality sensor. This growth is attributed to factors like rising industrial wastes disposal in waterbodies, surging cases of drinking water contamination levels, significant industrial pollution hazards and high dependency of rural households on contaminated water sources. In order to address such issues, various government organizations or authorities have started implementing stringent laws, guidelines or regulations for regular monitoring, testing as well as surveillance of drinking water quality, industrial wastewater treatment, utilization of spectroscopic techniques and so on, thus driving the need for water quality sensors. In March 2021, an Indian Government Ministry, named Jal Shakti Ministry had launched guidelines, the framework related to monitoring, testing, and surveillance of drinking water quality. These guidelines specified work to be done in terms of monitoring and surveillance of water quality within the state, block/tehsil, as well as village levels, which have been prepared under consultation from Indian Council of Medical Research. Under this guideline, total dissolved solids, total alkalinity, chloride, turbidity, pH value, chloride, total hardness, iron, total coliform bacteria, e.coil, fluoride, sulphate and nitrate were the prescribed water quality parameters, catering to the market growth of water quality sensors. In November 2021, the Union Minister, Ministry of Jal Shakti, Government of India announced about its establishment of 2000 water testing laboratories already, as a move towards completely transforming the drinking water sector. The government further stated about making water-quality testing infrastructure available to every village for improving services in terms of quantity, quality, and regularity, with targeting about 6000 laboratories by the year 2022. Such factors can be considered vital in propelling the growth of Water Quality Sensor industry in the long run.

Rise in Water Pollution due to Rapid Industrialization, Presence of Toxic Metal Effluents and Related Hazardous Substances is Accelerating the Market Growth of Water Quality Sensors:

Rising water pollution due to rapid industrialization, presence of toxic metal effluents as well as many other hazardous substances can be considered a major driver impacting the growth of Water Quality Sensor market. With rising establishment of varied industrial facilities, there is generation of massive amounts of toxic and hazardous amounts of wastes, which are being dispersed in the nearby waterbodies, without proper chemical treatment. This in turn, creates an adverse impact on the waterbodies including rivers, oceans and so on, causing pollution, hampering the aquatic habitat as well as humans. Regular and controlled monitoring of water bodies through utilization of water quality sensors for measuring content of total organic carbon, chlorine, arsenic and so on, help in minimizing hazards like water-borne diseases, skin diseases and many others. According to the State of Environment Report 2022, from the Centre for Science and Environment (CSE), out of the 33 monitoring stations in Ganga, about 10 had high levels of contaminants. The river being the focus of the Centre’s Namami Gange mission had reported high levels of toxic metals like lead, nickel, iron, arsenic and cadmium. Additionally, the Central Water Commission had tested water samples from 688 stations for heavy metals between August 2018 and December 2020, which showed that pollution, total coliform as well as bio chemical oxygen demand was high in 239 and 88 stations across 21 states. This findings highlighted an indication of poor wastewater treatment from industry, agricultural as well as domestic households. In January 2022, the National Green Tribunal (NGT) had ordered around hundred industrial units in the Tarapur MIDC area, Maharashtra's Palghar district to collectively pay around Rs 186 crore. This was a part of environmental compensation to be paid by the industries, for polluting water bodies in the region through releasing untreated effluents into them. These factors are set to help in expansion of the Water Quality Sensor market size in the coming time.

Water Quality Sensor Market Challenges

High Manufacturing Costs coupled with Integration of Advanced Technologies is Hampering the Market Growth of Water Quality Sensors:

High manufacturing costs coupled with integration of advanced technologies act as one of the major constraints impeding the growth of Water Quality Sensor industry. Due to integration of varied electronic components, as well as the need to balance out parameters like precision, robustness, accuracy and so on, the costs associated with manufacturing tends to become expensive. According to Fondriest Environmental Inc., the average price of water quality sensor ranges between approximately $345 to $12884. With shift towards advanced technologies like IoT in water quality testing and monitoring applications, varied companies have started working on production of such advanced sensors, which requires costly components, skilled labour and time. This in turn, creates an adverse impact on the adoptability of water quality sensors majorly across small scale enterprises, rural households, and so on. Apart from this, incapability of certain water quality sensors to provide higher resolution, less reliability, continuous monitoring and others have been also limiting its adoption overtime.

Buy Now

Water Quality Sensor Industry Outlook

Product launches, acquisitions and R&D activities are key strategies adopted by players in the Water Quality Sensor Market. The top 10 companies in the Water Quality Sensor market are:

Endress+Hauser

ANB Sensors

Yokogawa Electric Corporation

Hach Company

Hanna Instruments

Xylem Inc.

Libelium

Schneider Electric

Hunan Rika Electronic Tech Co., Ltd (Rika Sensor)

Honeywell Inc.

Recent Developments

In February 2021, Yokogawa Electric Corporation announced about the launch of TB820D right angle scattered light turbidity detector, FC800D non-reagent type free available chlorine sensor unit, RC800D reagent type residual chlorine sensor unit, FLXA402T liquid analyzer for turbidity and chlorine, as well as PG400 pulse generator for clean unit, as an addition to its OpreX Analyzers lineup for water treatment facilities. These was meant to extend its availability in Southeast Asia, the Middle East, South Korea, Australia, and Taiwan, ensuring high-quality drinking water.

In November 2019, Hach launched a colorimetric chlorine analyzer, CLI7sc which was designed to help water professionals manage disinfection processes effectively. This also helped in accurate data collection to meet compliance reporting regulations.

In June 2019, Endress+Hauser launched the Memosens CCS51D amperometric sensors for free chlorine measurement in process water, drinking water, water and wastewater treatment, cooling water as well as all utilities and processes requiring clean treated water. With a special membrane design, these sensors provided an extremely fast response time, intended to help plant operators run disinfection processes on tight limits and save chemicals.

#Water Quality Sensor Market#Water Quality Sensor Market Share#Water Quality Sensor Market Size#Water Quality Sensor Market Forecast#Water Quality Sensor Market Report#Water Quality Sensor Market Growth

0 notes

Text

Chemical Product for Water Treatment | Aquarius projects | Vadodara | Gujarat | India

Aquarius Projects offers a full chemical portfolio for anti-scalants, anti-foam and any other chemical product required for the operation of water treatment and desalination plants. We offer chemical installation in water waste treatment plant in Vadodara, Gujarat, India.

#chemicals service in vadodara#chemical product for water waste treatment plant in gujarat#chemical installation in water waste treatment plant in india

0 notes

Text

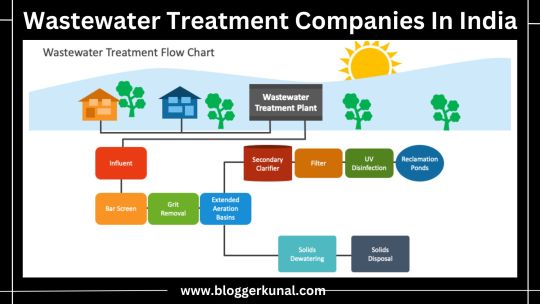

10 Top Wastewater Treatment Companies in India — Blogger Kunal

VA Tech Wabag

With 98 years of expertise, VA Tech Wabag, headquartered in Vienna, offers cutting-edge wastewater solutions globally, focusing on industrial water treatment, seawater desalination, and sludge treatment.

Read More: Top 20 Solar Power Plants In India

Thermax India

Established in 1980 in Pune, Maharashtra, Thermax provides rapid wastewater solutions to municipal corporations and industries, offering chemicals, water management, heating, and cooling solutions.

Read More: Various Types of Sewage Treatment Plants Used in India

General Electric

A global leader in wastewater treatment, GE Water, headquartered in Bengaluru, Karnataka, delivers innovative technologies like reverse osmosis and filters for efficient wastewater treatment.

Read More: Top 10 Real Estate Developers In Faridabad

Siemens India Water Technologies

With a presence in Mumbai since 1969, Siemens specializes in drinking water treatment, industrial and municipal wastewater treatment, and water treatment plants.

Read More: Top 10 Real Estate Developers In Bangalore

Aqua Innovative Solutions

Known for its agricultural wastewater solutions, Aqua Innovative Solutions utilizes the NuWay method to produce pure water while addressing environmental concerns.

Read More: Top 10 Real Estate Developers In Goa

Voltas Limited

A division of TATA, Voltas Water and Treatment focuses on industrial and sewage wastewater treatment, offering a range of products like Moving Bed Biofilm Reactors and technologies like reverse osmosis.

Read More: Top 10 Real Estate Developers In Ghaziabad

Hindustan Dorr-Oliver Limited

Providing wastewater treatment services to both public and private sectors, Hindustan Dorr-Oliver offers solutions including sewage treatment plants and water recycling.

UEM India Private Limited

Based in Noida, UEM India specializes in wastewater treatment, collaborating with Toshiba Water Solutions to plan, build, and install wastewater treatment systems.

Read More: Best Real Estate Developers In Pune

SFC Environment Technologies Private Limited

With a focus on solid waste and municipal sewage treatment, SFC Environment Technologies offers a wide range of products, including solar-dried sludge and disc filters.

Read More: Most Famous Real Estate Companies In Noida

ION Exchange

Originally from the UK, Ion Exchange is a prominent wastewater treatment company in India, offering solutions for commercial, institutional, industrial, and home wastewater needs.

These companies play a crucial role in addressing India’s wastewater challenges, promoting environmental sustainability, and ensuring access to clean water for all.

Read More: Top Real Estate Developers In Haryana

0 notes

Text

Top Supplier of HDPE Spiral Tanks in Maharashtra

Sunfiber is a leading solution provider for industrial customizations, specializing in the manufacturing and supply of various industrial products.

Products include HDPE/PP/FRP Spiral Tanks, Reactors, Blowers, Scrubbers, Hoppers, Vacuum Receiver Tanks, Nutches, Headers, Stirrers/Agitators, and Fabricated Fittings like Bends, Tees, and Reducing Tees.

Specialization:

Sunfiber is proud to be a manufacturer and supplier of HDPE Spiral Tanks in Maharashtra, India.

HDPE Spiral Tanks are constructed from high-density polyethylene (HDPE), offering strength, durability, and resistance to corrosion, chemicals, and UV rays.

The manufacturing process involves winding HDPE sheeting into a spiral shape, resulting in a robust and lightweight tank that is easy to install and maintain.

Applications:

These products find diverse applications across industries such as:

Bulk Drugs and Pharmaceuticals

Chemical Industries / Pollution Control

Water & Waste Water Treatment Plants

Textile Industries

Food Processing Units

Pulp & Paper Mills

Fertilizer Plants

Oil & Gas / Petrochemicals Plants

Chemical Storage Tanks

Transport Vessels

Water Treatment Tanks

Specifications:

Storage Material: Water, Chemicals/Oils

Capacity: 50000 L

Brand: Sempra

Color: Black

Orientation Type: Vertical

Shape: Round

Country of Origin: Made in India

Service Areas:

Sunfiber serves as the Top Supplier of HDPE Spiral Tanks in Maharashtra, covering key locations such as Mumbai, Pune, Nagpur, Nashik, Vasai-Virar, Solapur, Bhiwandi, Amravati, Kolhapur, Akola, Latur, Jalna, Panvel, Navi Mumbai, Parbhani, Dhule, Nanded, Jalgaon, Ahmadnagar, Chandrapur.

Read the full article

#Ahmadnagar#Akola#Amravati#Bhiwandi#Chandrapur#Dhule#HDPESpiralTanks#India#Jalgaon#Jalna#Kolhapur#Latur#Maharashtra#Manufacturer#Mumbai#Nagpur#Nanded#Nashik#NaviMumbai#Panvel#Parbhani#Pune#Solapur#Supplier#Vasai-Virar

0 notes

Text

Find The Top Commercial RO Plant Manufacturer In Sonipat ?

Netsol Water is aware that Sonipat's inadequate water supply necessitates constructing or installing a high-grade commercial RO plant to comply with the city's permits relating to commercial businesses.

Knowing that certain areas of our city's water distribution system may have established concentrations of hazardous chemicals such as arsenic, lead, & mercury, or biological or organic contamination, could be more exciting. Installing commercial RO plants therefore becomes essential. Commercial RO Plant is the best commercial ro plant manufacturer in sonipat at best affordable price.

Our company organization, Netsol Water, is a Noida-based producer of commercial RO plants with branches around Sonipat. One of the largest exporters of several RO water treatment system types is Netsol Water.

Characteristic Features checked prior to putting up & installation of a Commercial RO plant can be mentioned below:

Minimize the amount of water or liquid waste that is produced during filtering; Reduce the amount of maintenance that is required.

It should generate excellent quality drinking water & water-dependent machinery or gadgets for utilization by businesses as well as infrastructure projects.

It is intended to support as well as benefit from cutting-edge, popular membrane-based technologies.

A commercial RO system should eliminate hazardous contaminants, undesirable salts, or heavy metals along with purifying water.

Conditions & Factors to think about prior to setting-up while mounting or installing a Commercial RO plant

Before purchasing, mounting, or installing a commercial reverse osmosis system, you must evaluate the quality of your supply water to determine the types of pollutants present. By getting a thorough report on this, you may add the appropriate Commercial RO Plants to your commercial permits. For example, if biological pollutants such as viruses are present in the source water, an RO facility equipped with a UV system is required; conversely, an Activated Carbon Filter is required if the examination produces a disagreeable odor as well as an unappealing color.

In this circumstance, financial budgeting is the most crucial consideration. The kind of RO installed at your manufacturing facility's commercial factory will also be determined by the funding you have access to for setting up a commercial RO. As Accordingly, it necessitates to lay out an economical expense early to choose to buy & install.

The crucial part of handling investments or fundings related to budgeting is selecting while choosing a reliable brand or firm that satisfies your needs & desires while residing within your means.

Since Netsol Water is not only a reputable firm or company in Sonipat, but also has hundreds of satisfied customers, we advise acquiring a Commercial RO water treatment plant from them. Also, quality will be of the top-class received at the most unexpected low cost. Along with commercial ro plant there is netsol water who is best commercial ro plant manufacturer in all over the india at best affordable price and quality.

The expenditure or the outflow cost of its upkeep maintenance

Commercial RO Plant systems are susceptible to wear & strain on their pumps, membranes, & other parts. As subsequently a given extent of deployment & utilization, they have to be substituted or replaced. Our professionals employ cost-effective, cutting-edge trending technology to maintain your Commercial RO to the highest standard.

Conclusion

When making it crucial in the water treatment plant system, the elimination or removal of salt & minerals is crucial. Given this, the only way to completely remove all of these contaminants & make it safe to drink is with a top-notch Commercial RO Plant from Netsol Water as well as its subsidiary Commercial RO Plant. We are the best option if you're looking for a durable & trustworthy Commercial RO Plant in Sonipat. Netsol Water & Commercial RO Plants are out of the most loyal, reputable firms or companies, offering & providing a variety of RO ultra-purification systems for several business as well as commercial utilizations or applications.

0 notes

Text

Who Is The Best ETP And STP Plant Manufacturer In Singrauli?

Because of the large concentration of power plants, Singrauli, which is situated in the Vindhya area of Madhya Pradesh, is also known as India's energy capital. It is a growing industrial hub. In Singrauli, the production of sewage & industrial effluents has increased due to rapid urbanization & industrialization.

To responsibly manage its water assets/resources & assistance industrial expansion while respecting the environment, Singrauli must effectively treat these wastewater streams. Whereas STPs(Sewage Treatment Plants) manages, handles municipal, community, & residential sewage, ETPs(Effluent Treatment Plants)handle industrial effluents.

Singrauli's approach to clean industrial production relies heavily on well-designed ETP & STP Plants.

Singrauli's ETP(Effluent Treatment Plant)-STP(Sewage Treatment Plants) Plant Requirements

Numerous cement, chemical, & other related industries, as well as coal-based thermal power facilities, can be found in Singrauli. These units' effluent includes residues, acids, alkalis, suspended particles, hazardous metals, oil & grease, & chemical oxygen demand.

The region's groundwater supplies, aquatic ecosystem, & public health are all at risk when untreated industrial effluents are directly dumped into rivers & lakes.

To treat this wastewater employing/utilizing various physico-chemical & biological processes to remove contaminants before final disposal in accordance with discharge rules, ETP plants are necessary. ETPs stop additional industrial pollutants from reaching Singrauli water bodies. Netsol Water is the best etp & stp plant manufacturer in singrauli at best affordable price.

In addition to industrial effluents, Singrauli's increasing urbanization & population growth have led to a rise in the amount of sewage produced by homes & businesses. Residential or Domestic level sewage consisting of nutrients, organic waste, pathogens & chemicals.

The release of raw sewage into water sources increases the need for biochemical oxygen & spreads illness by contaminating surface & groundwater. STPs effectively treat sewage by removing contaminants or rendering it safe for the environment through the utilization of screens, sedimentation tanks, the activated sludge process, clarifiers, filters, & chlorine dosing.

Given the degree of urbanization & industry, Singrauli urgently needs an ETP-STP plant with enough capacity to treat sewage & effluents to approved levels before disposal. This will make it possible for Singrauli to sustainably expand its industrial base without endangering the public's health or its water supplies.

The Experience of Netsol Water as a Manufacturer of STP & ETP Plants

Leading provider of end-to-end solutions for the design, engineering, supply, installation, testing, commissioning, & operation of sewage treatment & effluent treatment facilities is Netsol Water.

With more than ten years of extensive industry expertise, we provide specialized ETP-STP Plants utilizing cutting-edge technology to meet the treatment requirements of various Madhya Pradeshi companies and municipalities.

Based on effluent characteristics & specified discharge requirements, we design and build complete ETP facilities for industries in Singrauli, comprising collection, equalization, primary, secondary, and tertiary treatment units.

Our specialty is the cost-effective treatment of complicated industrial effluents using appropriate technologies such as activated carbon, clarifiers, bioreactors, filters, diffused aeration, and stripping towers.

Our offering covers tertiary, advanced, and traditional municipal sewage treatment. From conception to completion, we carry out STP projects, handling all aspects of design, hydraulic analysis, equipment size, procurement, installation, testing, and operator training. SBR, MBBR, MBR, SBIOX, ASP, and ultrafiltration technologies are used in our STP Plant and are customized to meet the demands of individual projects.

Being a sustainability-focused business, we include technologies like automation, solar energy, and remote monitoring into our designs to minimize carbon emissions and enhance plant performance.

Through effective process control, preventative maintenance, and regular performance monitoring, our treatment systems reliably satisfy the CPCB/MPPCB specified discharge criteria. We help customers get regulatory consent orders in a timely manner.

In summary

Singrauli's industrial boom cannot be sustained without an efficient and dependable sewage and wastewater treatment plant that meets strict regulations. Leading producer of STP and ETP plants, Netsol Water uses cutting-edge treatment technology to offer specialized end-to-end solutions from idea to commissioning.

By providing solutions, Netsol Water enables Singrauli companies to comply with effluent discharge rules and maintain pollution-free water bodies.

0 notes

Text

ETP STP WTP WWTP Manufacturer, Supplier, Design Consultants, India

ETP STP WTP WWTP Manufacturer, Supplier, Design, Engineering, Process Consultancy, Installation, Commissioning Services, Consultants, Pune, Maharashtra, India.

Effluent Treatment Plants, ETP, Waste Water Treatment Plants, WWTP, Water Treatment Plants, WTP, Sewage Treatment Plants, STP, Demineralization Plants, Demineralization Plants, DM Plants, Water Ultrafiltration Plants, Water Recycling Plants, Water Treatment Plants Operation & Maintenance, Water Treatment Plants Operation & Process Maintenance, Water Treatment Plants O&M, Waste Water Treatment Plants Operation & Maintenance, Waste Water Treatment Plants Operation & Process Maintenance, Waste Water Treatment Plants O&M, Industrial Water Softeners, Reverse Osmosis Plants, Industrial Reverse Osmosis Plants, RO Plants, Industrial RO Plants, Water Filtration Plants, Industrial Water Filtration Plants, Environmental Legal Services, Bioculture, WTP Design Services, WTP Engineering And Process Consultancy Services, WTP Consultants, WTP Consultancy Services, WTP Engineering Consultants, WTP Process Consultants, Water Treatment Components, Water Treatment Chemicals, Analytical Laboratory Services, Environmental Audits, Safety Engineering Consultancy, Environmental Safety Audits, ETP Training Programs, STP Training Programs, EMS Consultancy Services, OSHAS Consultancy Services, Manufacturer, Supplier, Exporter, Installation Services, Commissioning Services, Consultants, Consultancy Services, Pune, Maharashtra, India, Sri Lanka, Bangladesh, Asia, Africa, Middle East, UAE United Arab Emirates, Gulf, South America, North America, Europe, Kasarani, Roysambu, Nairobi, Kenya, Qatar.

0 notes